Oil tube packer capable of conveniently replacing rubber sleeve

A convenient packer technology, applied in the direction of sealing/packing, drilling pipe, casing, etc., can solve the problem that the tubing packer cannot quickly lock the position of the seat key, it is inconvenient to disassemble and recycle the rubber cartridge, and it cannot be conveniently installed Replacing rubber cartridges and other issues to achieve the effect of increasing anti-off performance, reducing maintenance difficulty and cost, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

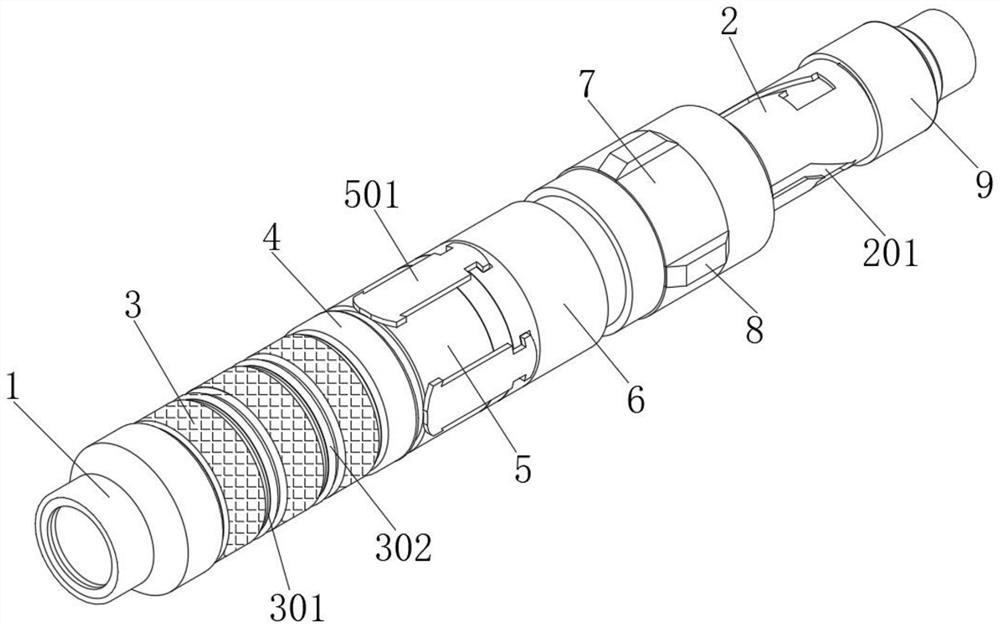

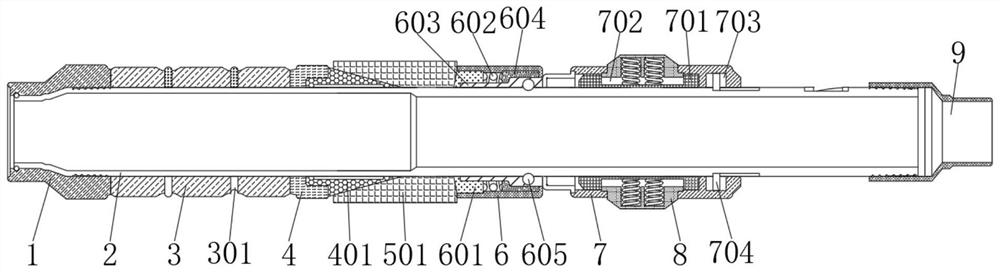

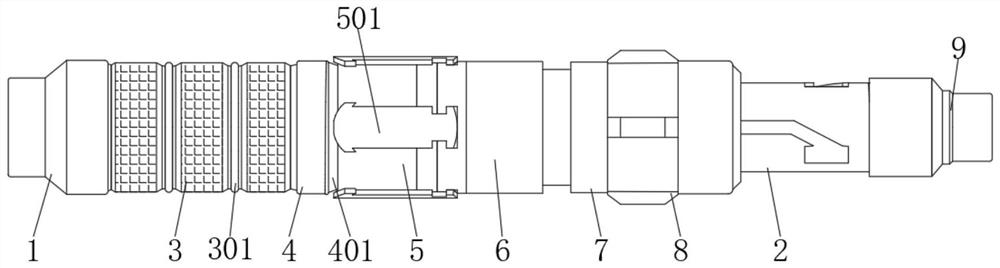

[0035] see Figure 1-8, A convenient oil pipe packer for replacing rubber cylinders proposed by the present invention includes a central pipe 2, a slip seat 6 and a centralizing block sheath 7. The outer side of the central pipe 2 is provided with a chute 201. The end is provided with a threaded pipe 202, and the outer side of the central pipe 2 is provided with a ball groove. One end of the outer side of the central pipe 2 is respectively installed with an upper joint 1 and a lower joint 9 through the threaded pipe 202. The outer side of the central pipe 2 is close to one end of the upper joint 1. A rubber tube 3 is installed, a limit sleeve 4 is installed on the outer side of the central tube 2 close to the end of the rubber tube 3, a slip sleeve 5 is installed on the outer side of the central tube 2, and slips are installed on the outside of the slip sleeve 5 at equal distances. 501, one end of the central tube 2 close to the slip sleeve 5 is installed with a protective pie...

Embodiment 2

[0038] see Figure 2-8 , compared with the first embodiment, the present embodiment further includes: the inner side of the upper joint 1 is provided with an inner thread 101, and the upper joint 1 passes through the inner thread The cooperation of 101 and threaded pipe 202 can facilitate the quick disassembly and assembly of the upper joint 1, improve the assembly efficiency of the upper joint 1, and also facilitate the local replacement of the upper joint 1, and the upper joint 1 can limit the position of the rubber cylinder 3, It is convenient for the rubber cylinder 3 to be compressed and expanded to form an annular space to seal the oil pipe. A conical groove 102 is provided on one side of the inner thread 101, and the conical groove 102 can cooperate with the conical pipe 203 to improve the connection stability. , to prevent the connection between the upper joint 1 and the central pipe 2 from shaking, to ensure the sealing stability of the rubber cylinder 3 to the oil pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com