Automobile brake pad processing device

A technology for processing devices and brake pads, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of difficult adjustment, low processing efficiency, inconvenient operation, etc., to ensure position adjustment accuracy and improve locking efficiency. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

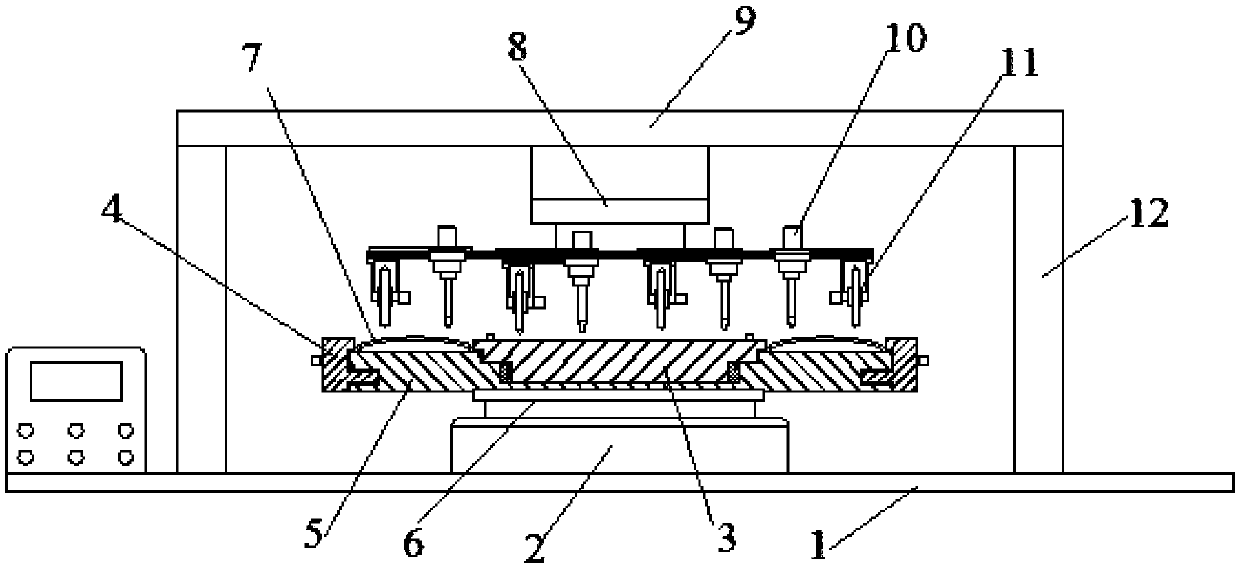

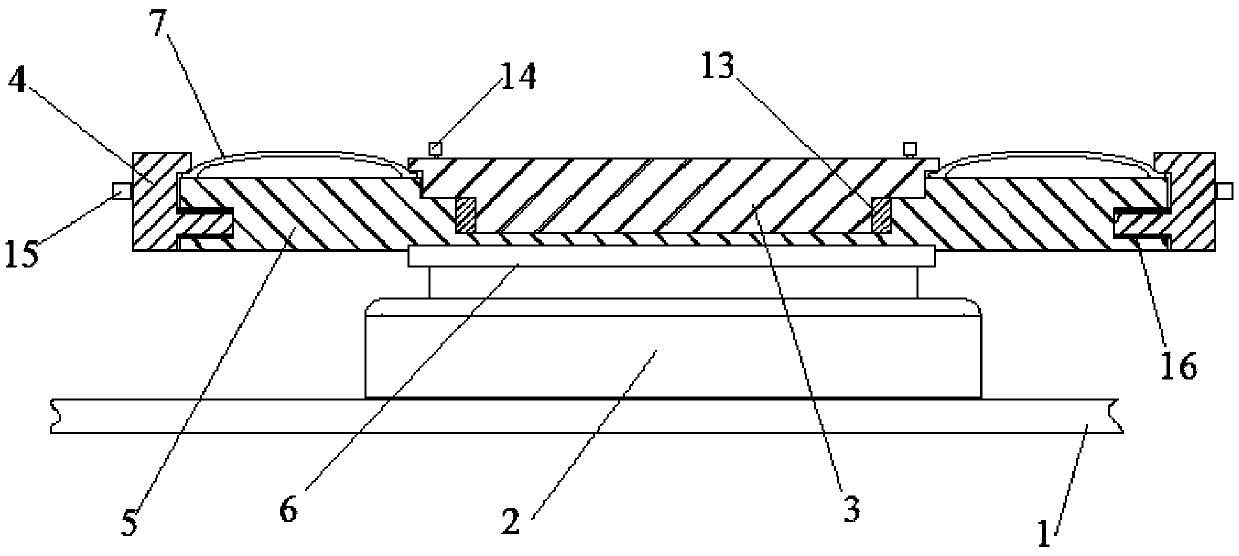

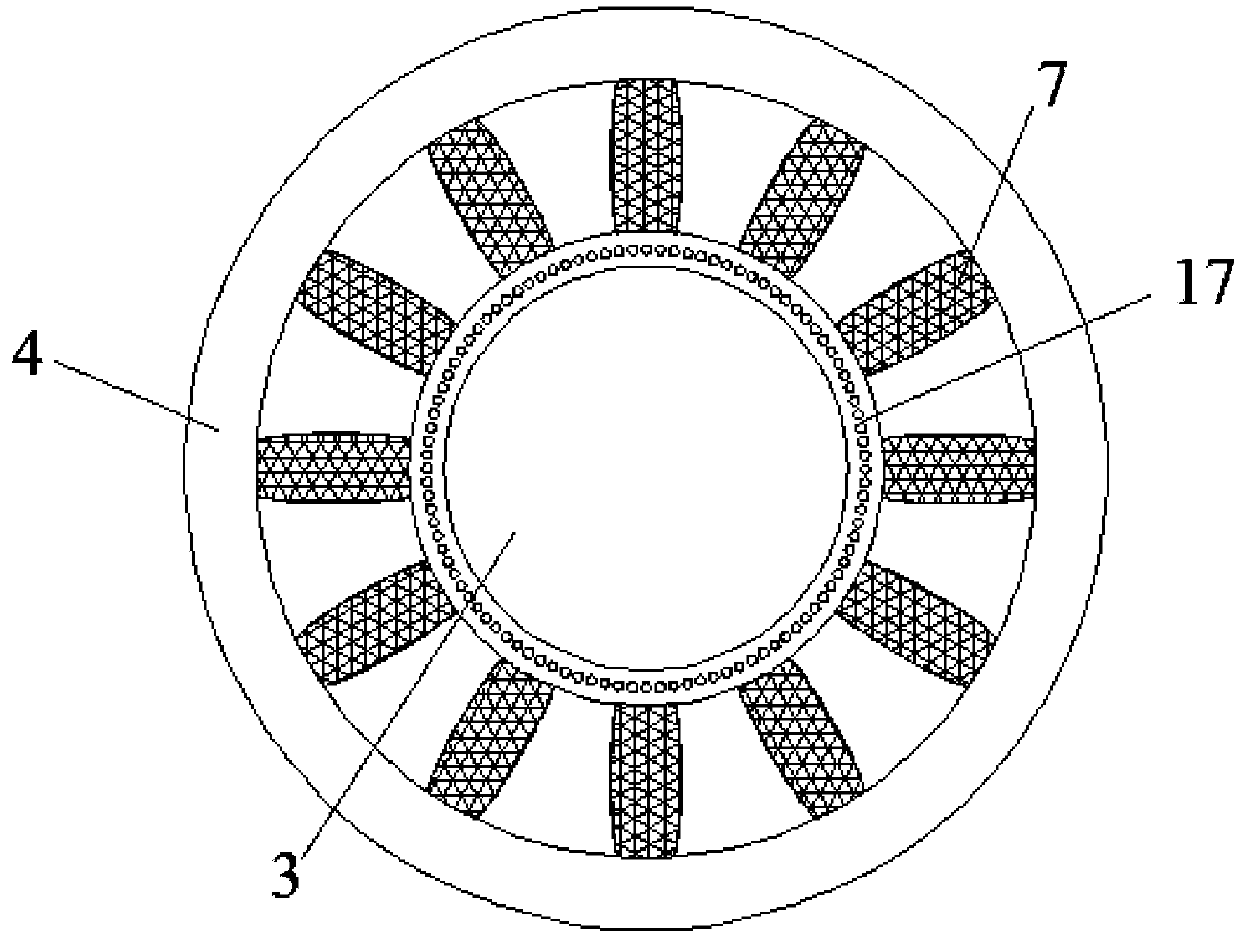

[0033] see Figure 1-5 , in an embodiment of the present invention, the automobile brake pad processing device includes a base 1, a vertical frame 12, a beam 9, a rotating disc 8, a processing tool disc, a workpiece processing table 5, an inner locking disc 3, an outer locking disc 4 and The lifting support 2, wherein, the two sides of the base 1 are provided with a vertical frame 12, and the top of the vertical frame 12 is provided with the crossbeam 9, which is characterized in that,

[0034] The center of the beam 9 is provided with a rotating disk 8 extending downward, and the output end of the rotating disk 8 can rotate around its own vertical axis;

[0035] The lower end surface of the output end of the rotating disk 8 is fixedly connected with a processing tool disk, and the processing tool disk is driven to rotate through the rotating disk;

[0036] Multiple groups of processing tools are arranged on the processing tool disc along its circumference array, and each gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com