Patents

Literature

55results about How to "Homogenization guaranteed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

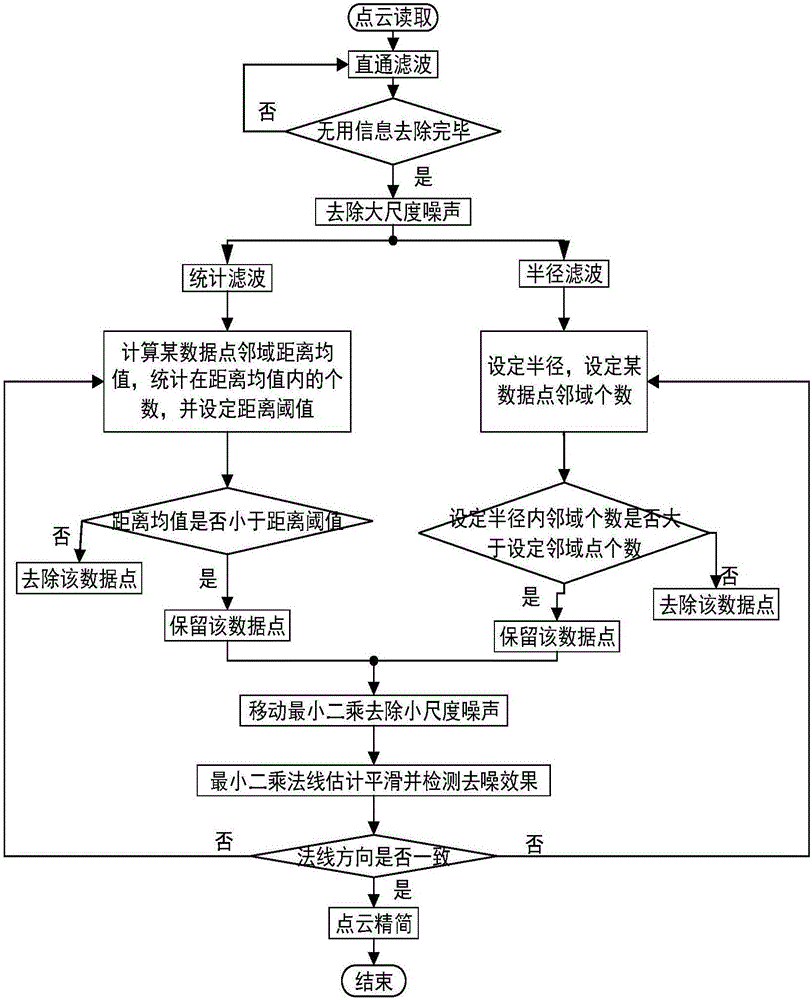

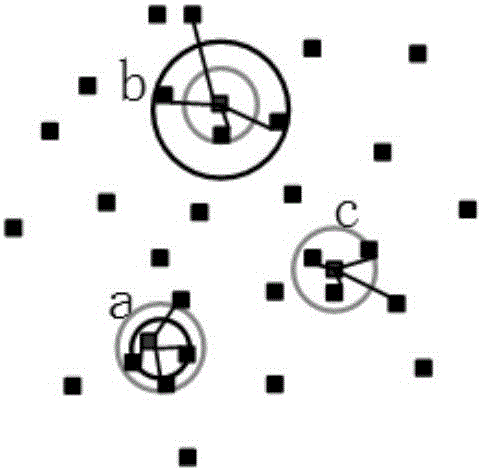

Denoising and simplifying method of point cloud model

InactiveCN106846272AHomogenization guaranteedReduce time complexityImage enhancementImage analysisPoint cloudVoxel

The invention discloses a denoising and simplifying method of a point cloud model. The method specifically comprises the first step of collecting an image and preprocessing the image; the second step of conducting removal of large-scale noise on a three-dimensional point cloud model obtained in the first step; the third step of adopting moving least square to remove small-scale noise; the fourth step of conducting grid downsampling based on voxel on point cloud data which is denoised in the third step to obtain a simplified point cloud model. The problem in the prior art that the occupied memory is large, and the operation of a computer is influenced due to long processing time is solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

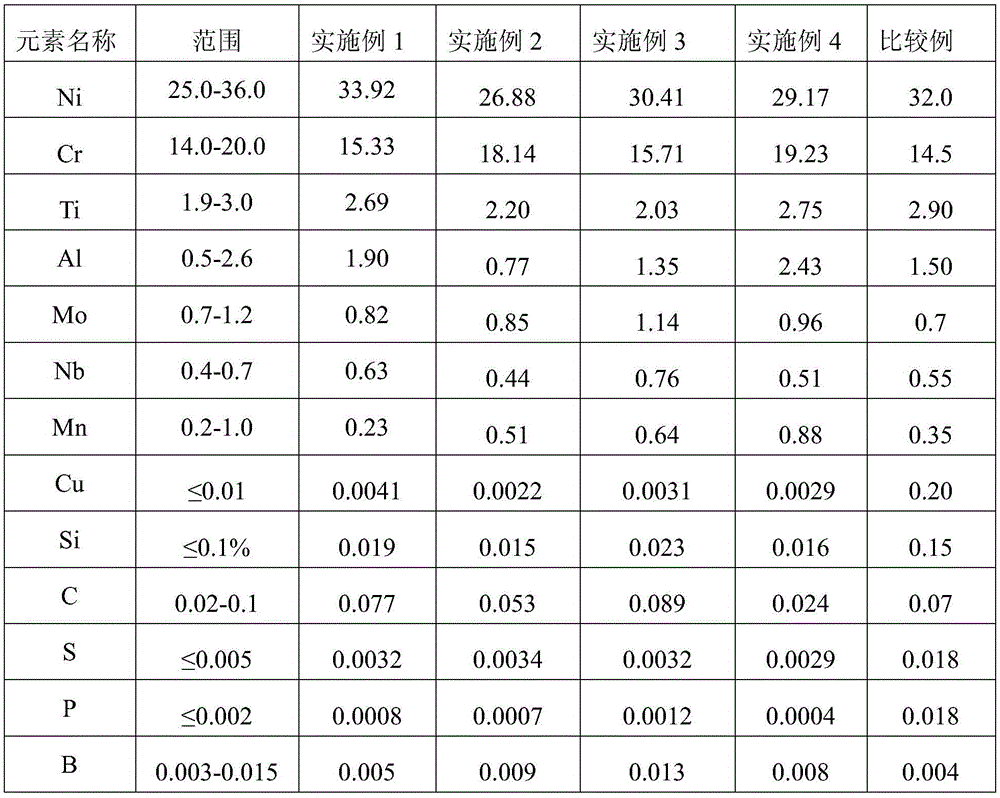

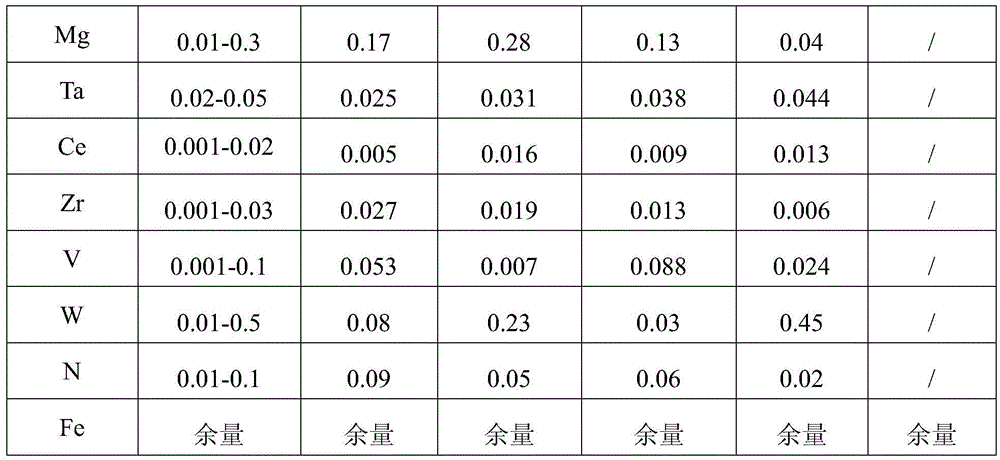

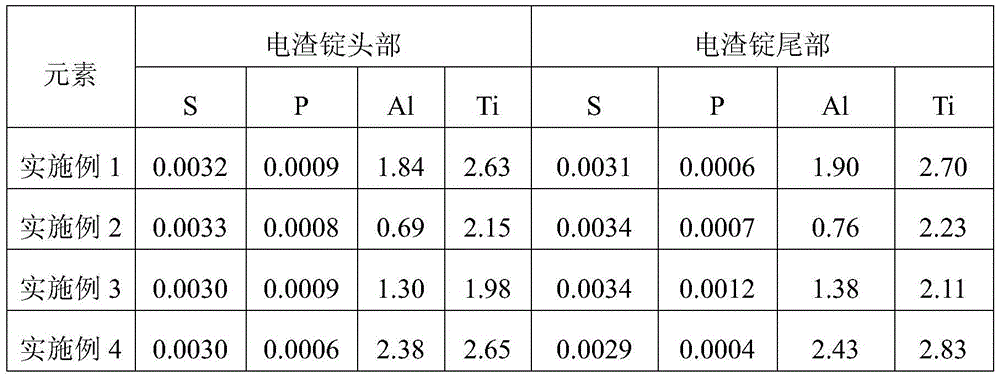

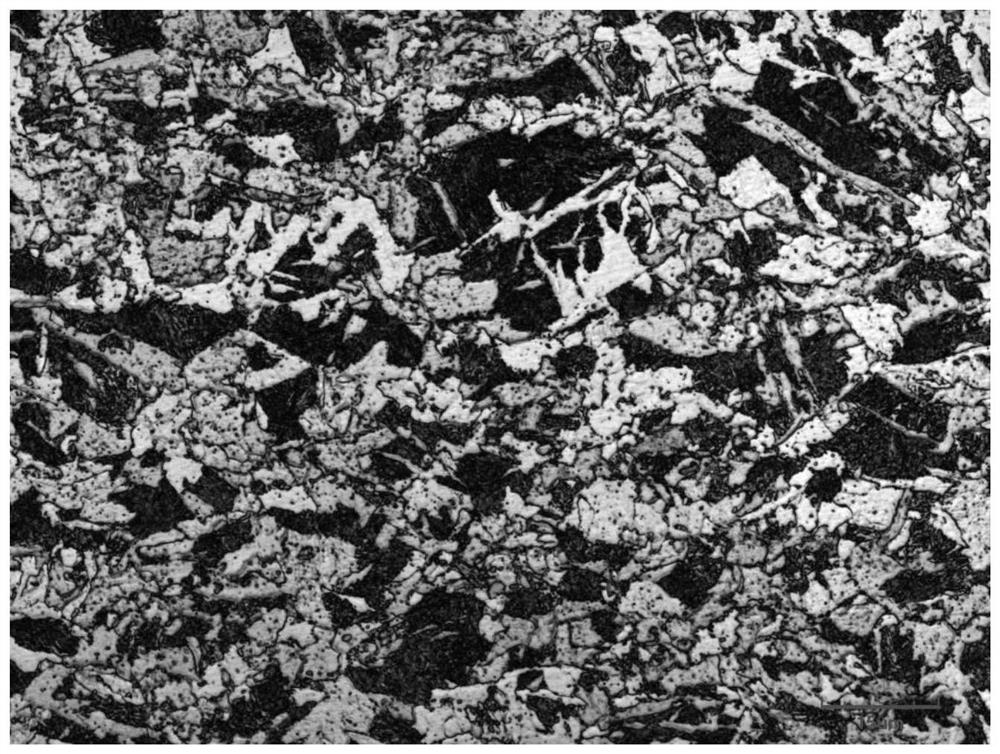

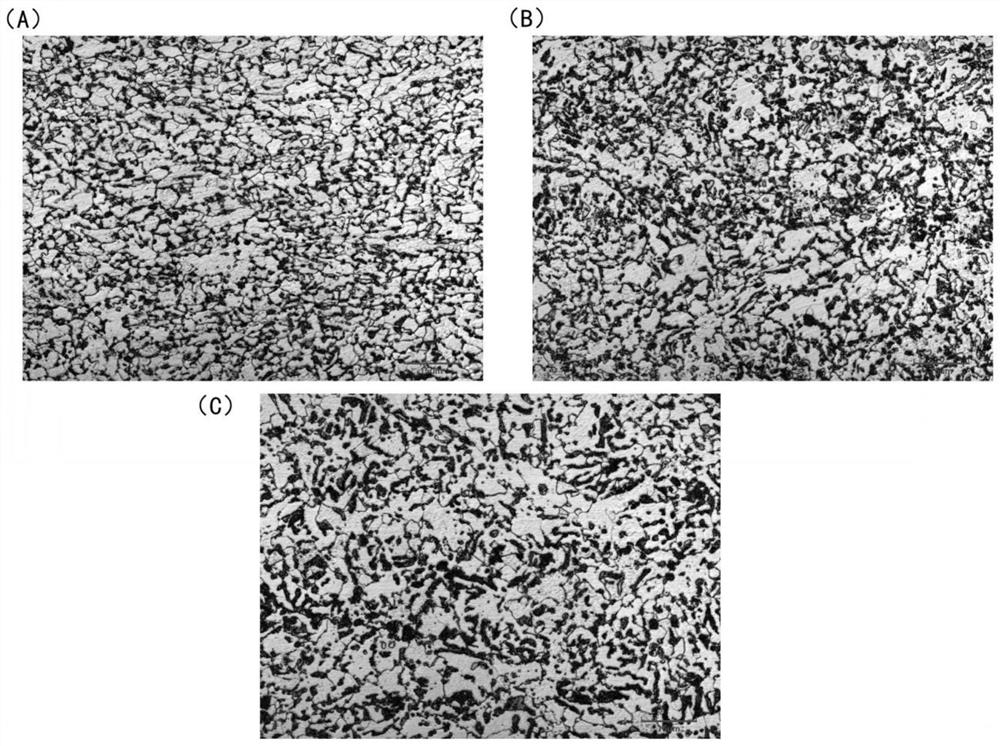

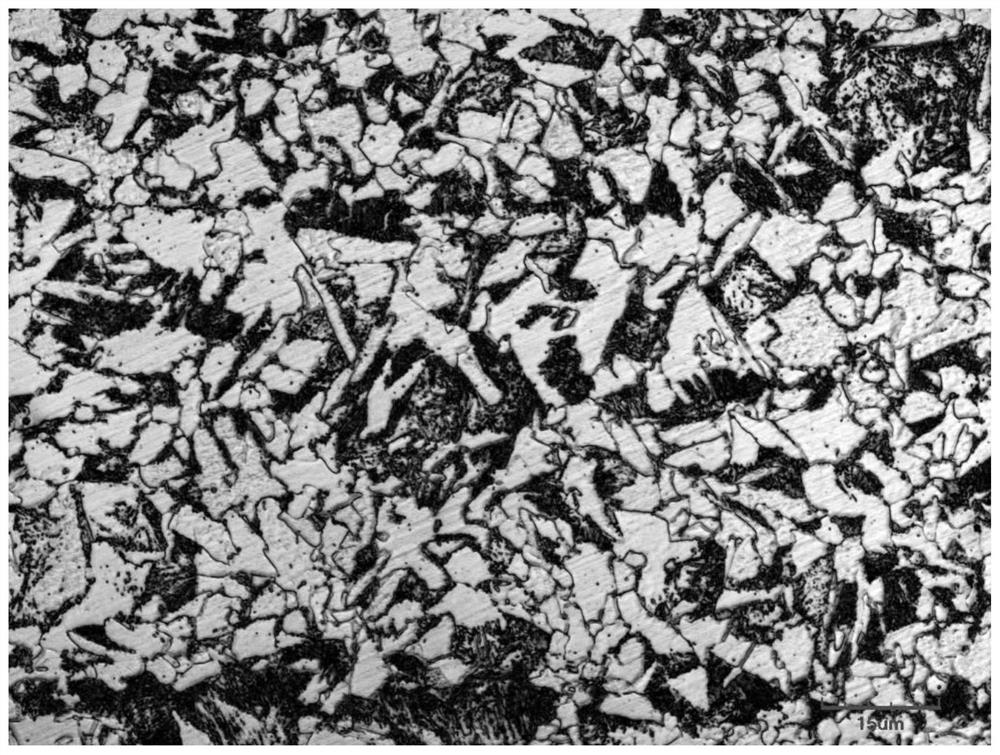

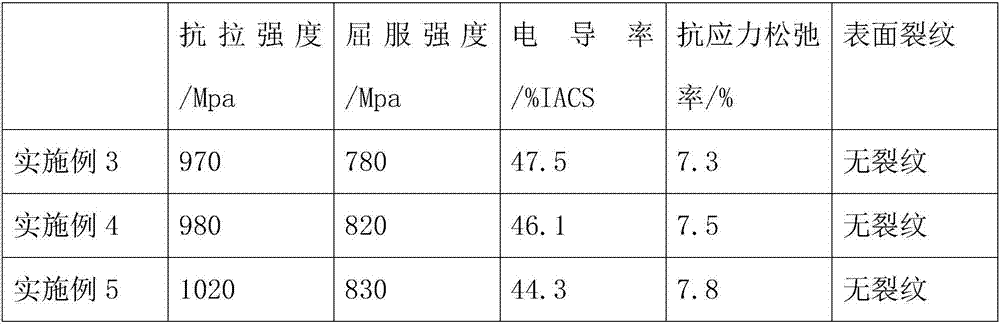

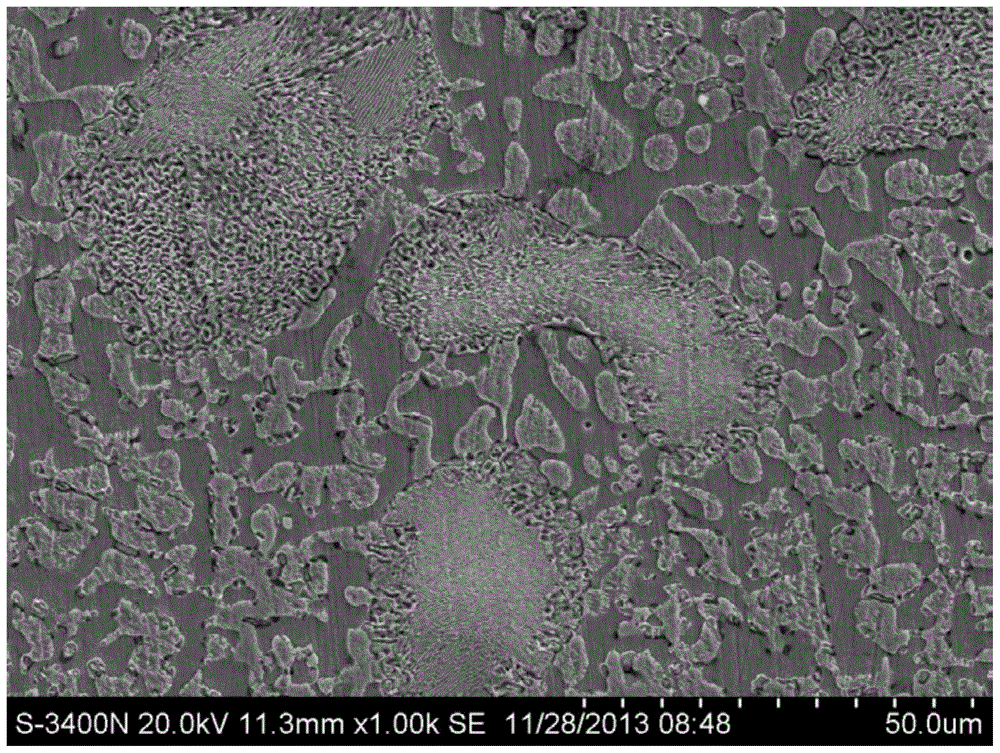

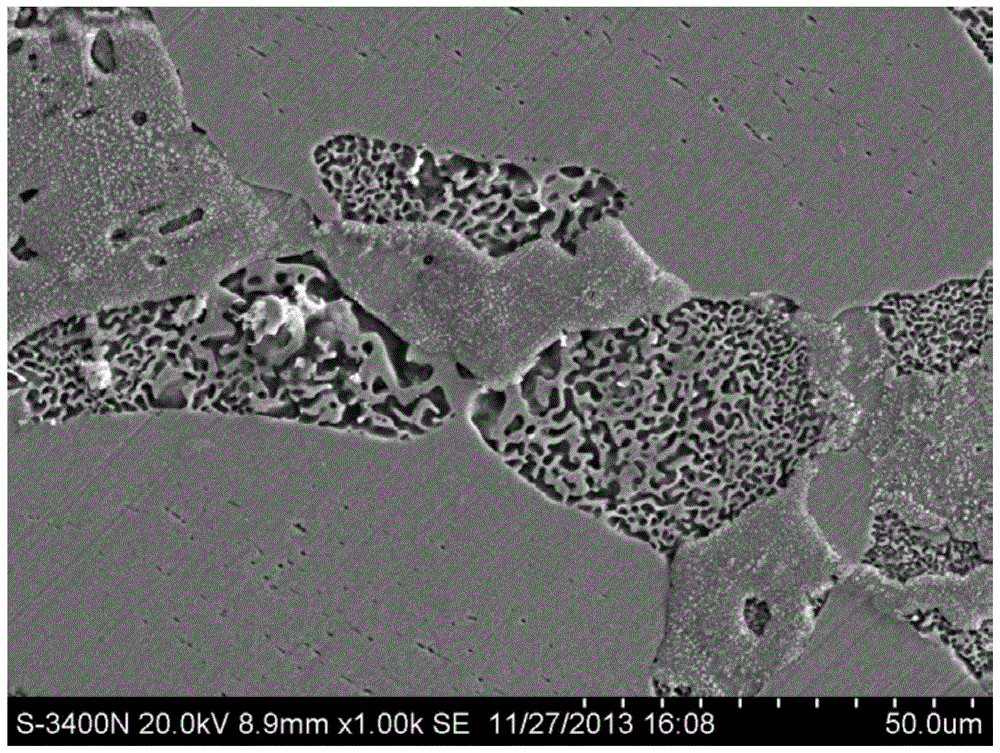

Micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and preparation method

The invention relates to a micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and a preparation method. The material comprises elements such as Ni, Cr, Ti, Al, Mo, Nb, Mn, C, B, Mg, Ta, Ce, Zr, V, W, N, Fe and the like. The material can be used in a working environment with a high temperature, high load, strong oxidization and strong corrosion, is low in nickel content, has good tensile strength, good endurance strength, good fatigue strength and excellent oxidization resistance, good corrosion resistance and good resistance to fuel gas, and can be used for preparing a gas inlet valve and a gas outlet valve of a medium-high-load engine.

Owner:CHONGQING MATERIALS RES INST

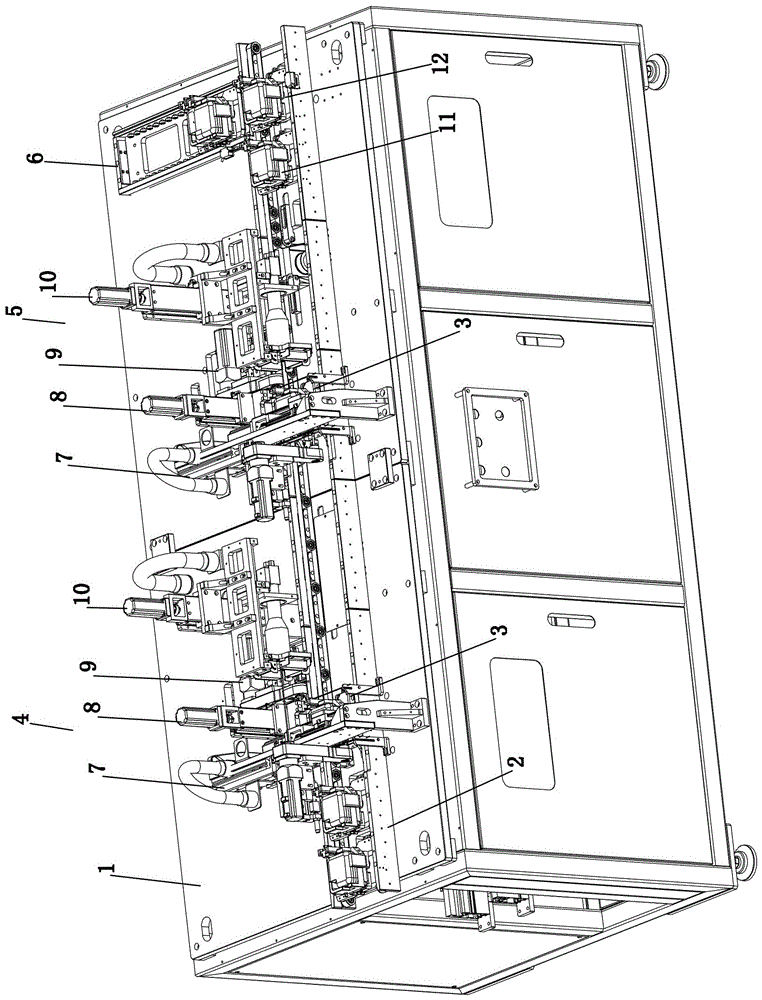

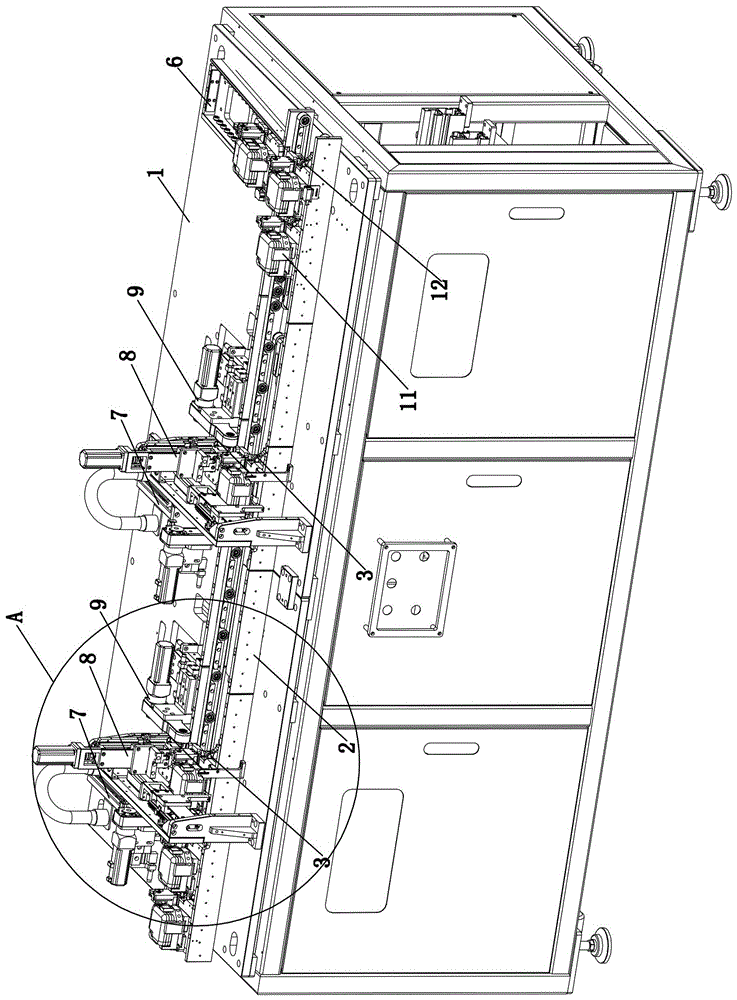

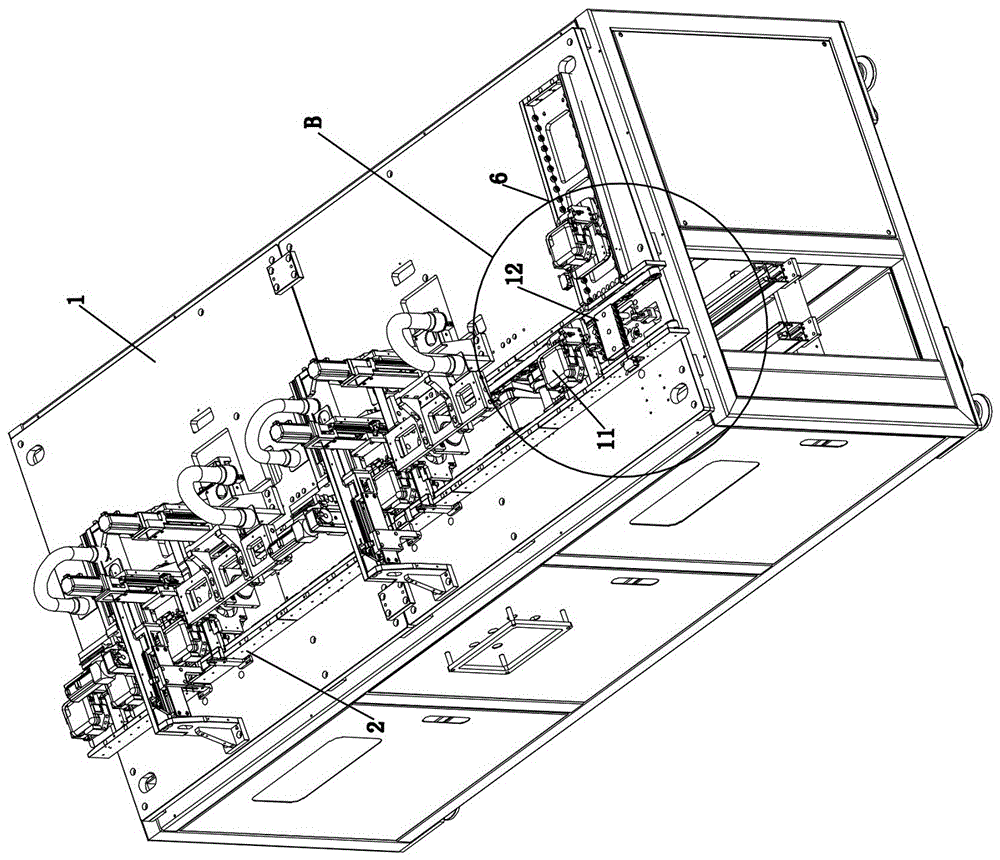

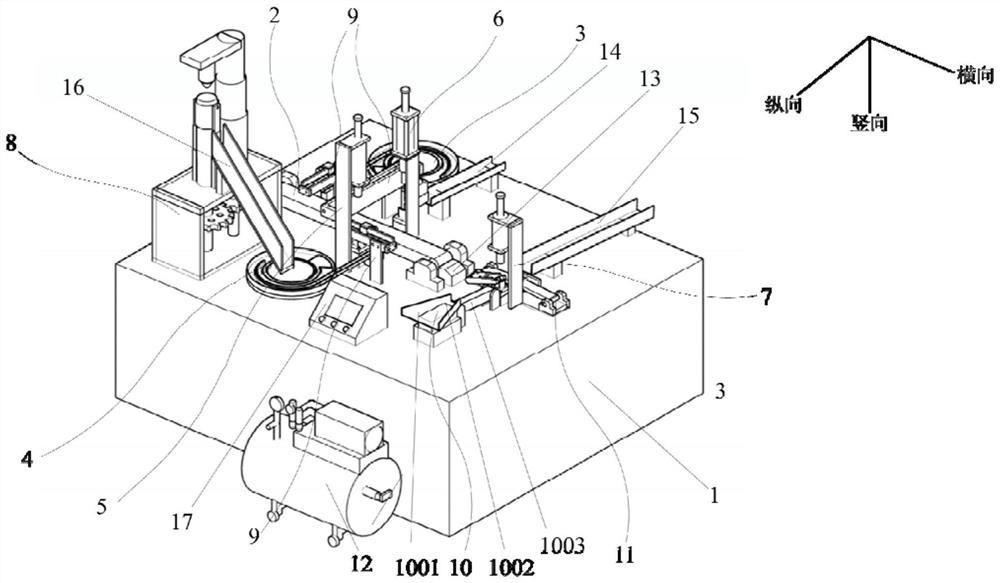

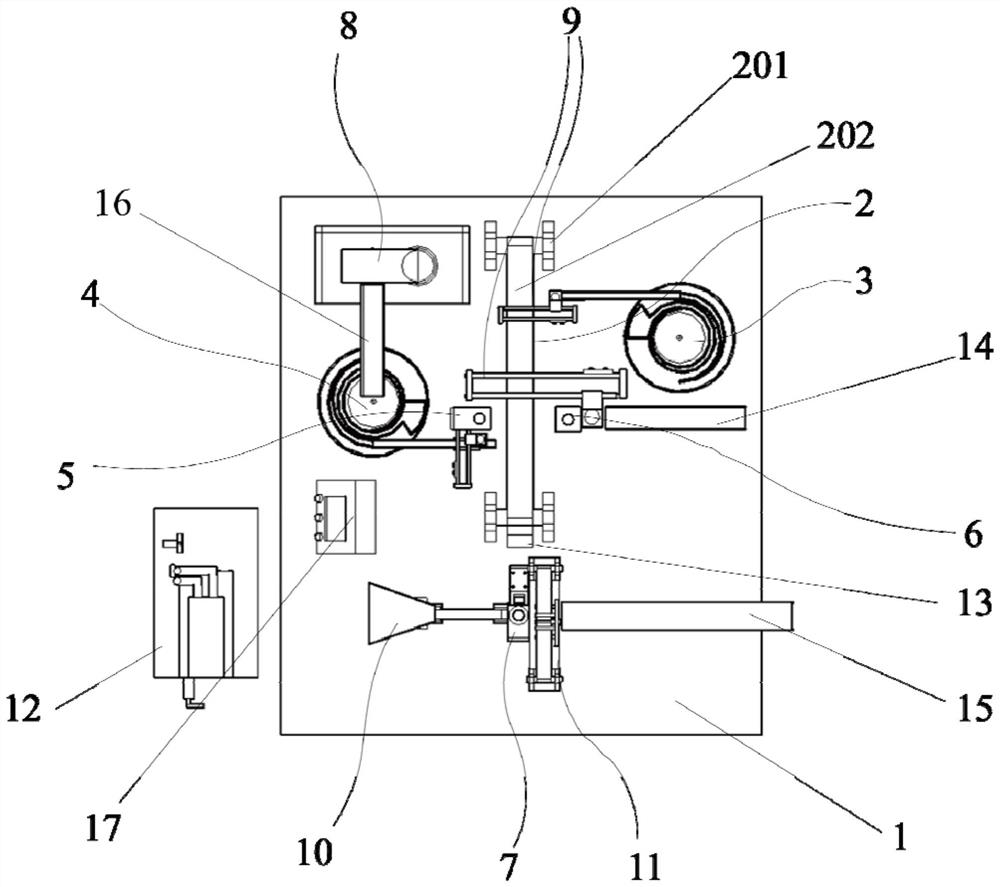

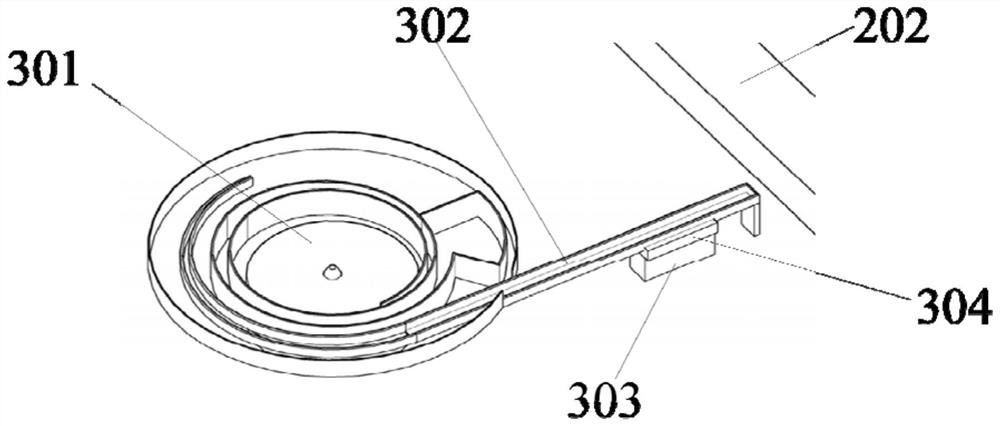

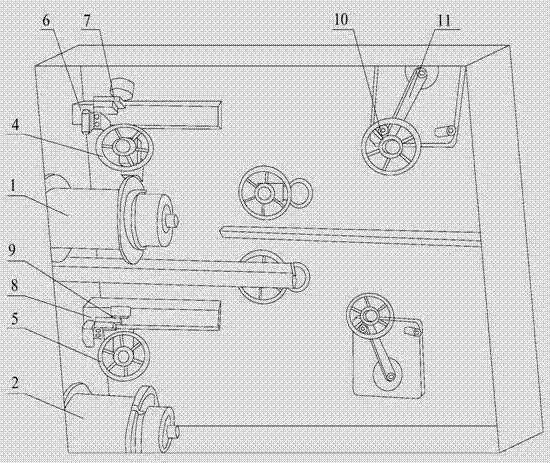

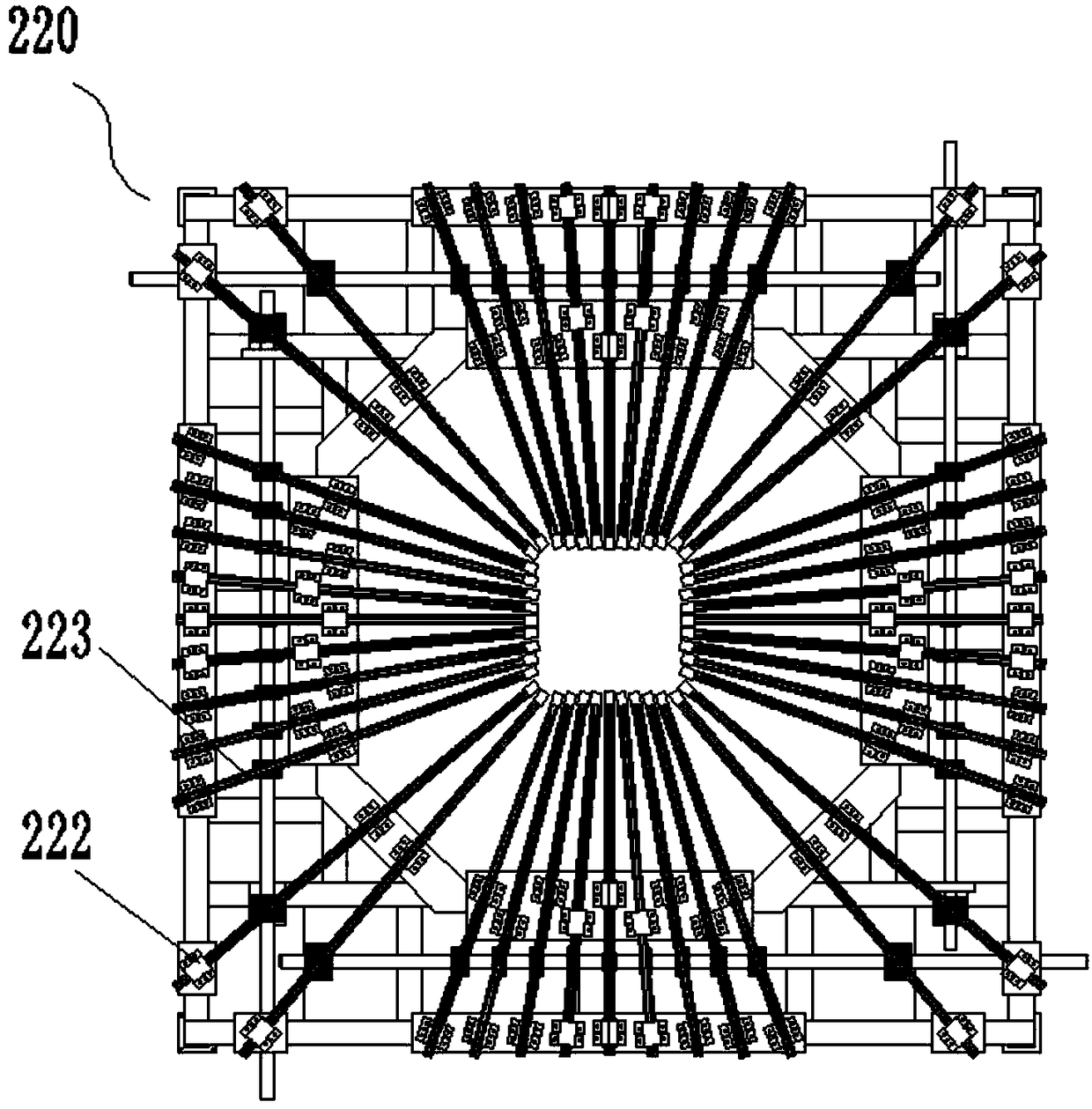

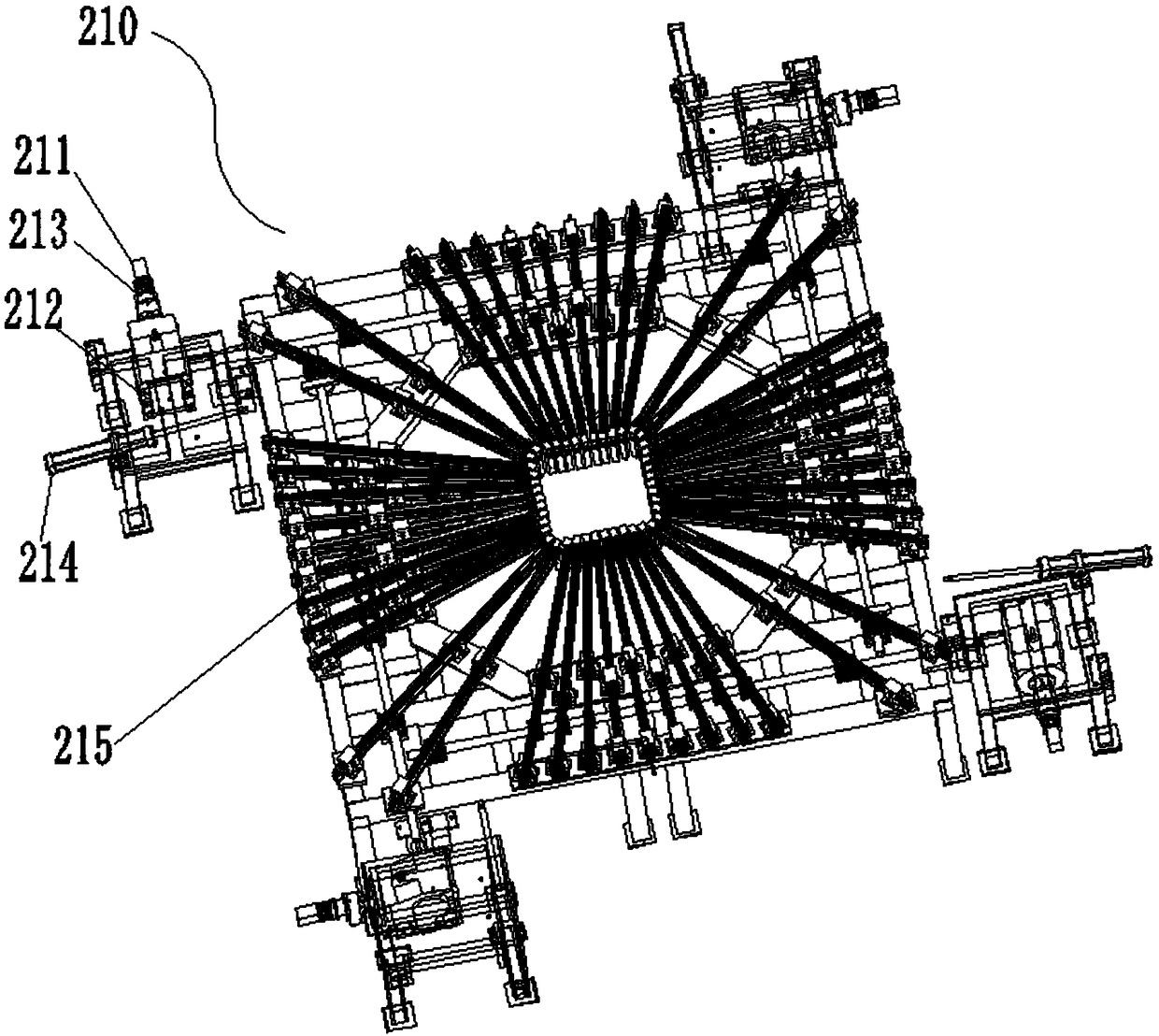

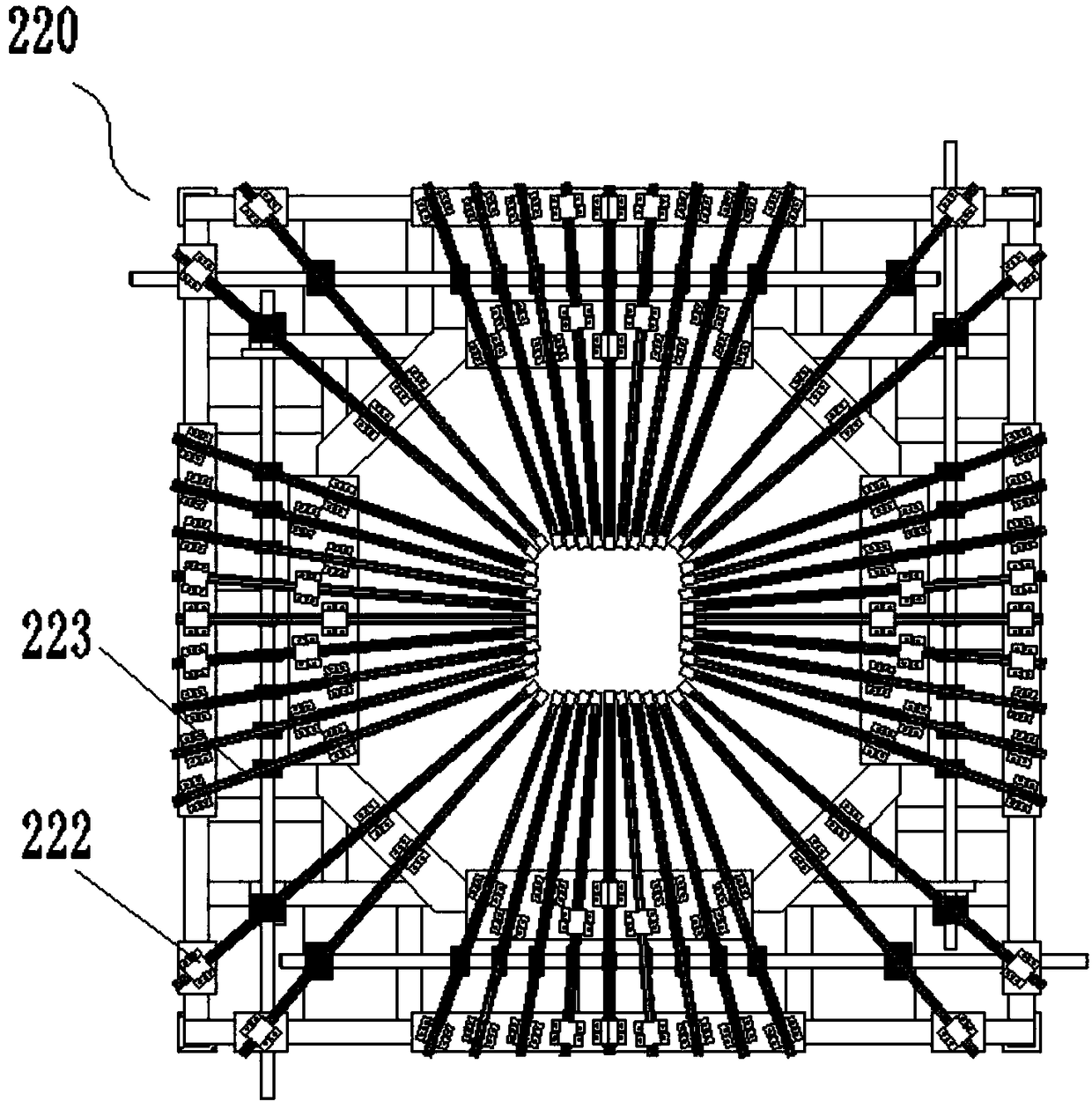

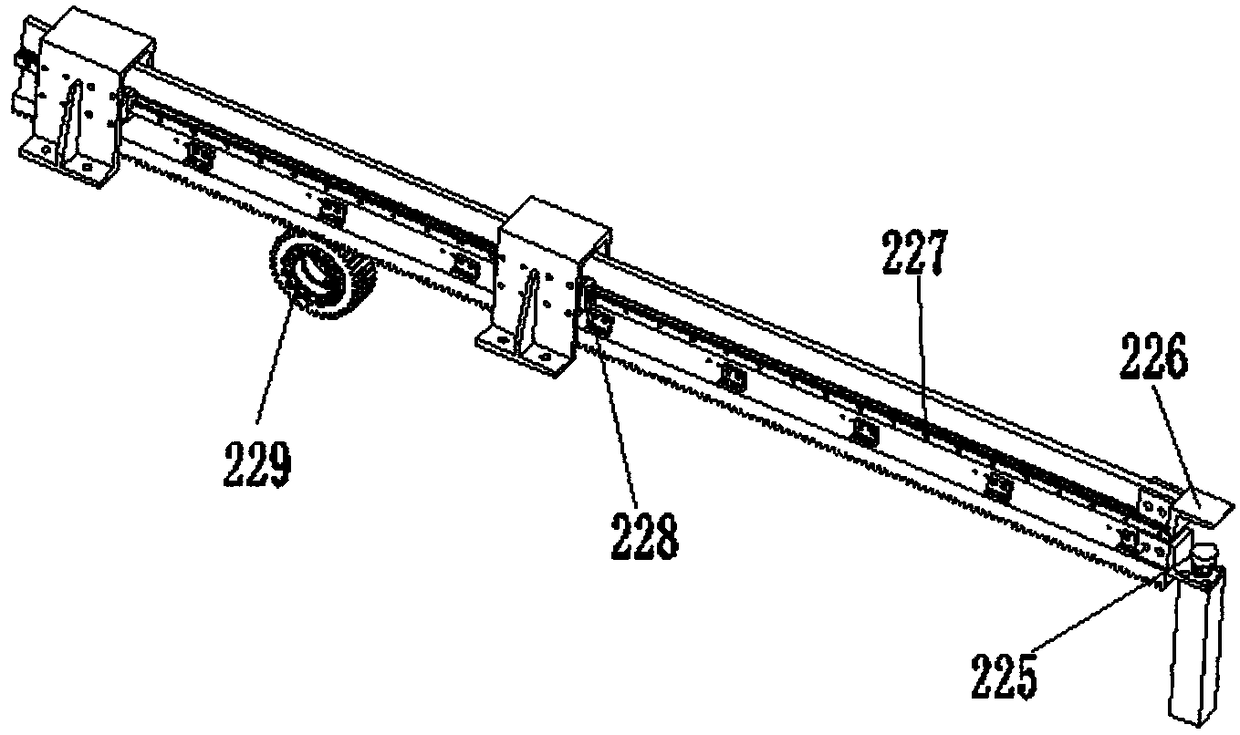

Connecting base self-centering locking production line and connecting base self-centering locking technology

ActiveCN106002207AHomogenization guaranteedImprove quality and efficiencyMaterial gluingMetal working apparatusEngineeringProduction line

The invention discloses a connecting base self-centering locking production line and a connecting base self-centering locking technology. The connecting base self-centering locking production line comprises a working table, a material belt, a positioning mechanism, a first centering mechanism, a second centering mechanism, a product fixing mechanism, a defective product ejecting mechanism and a defective product material belt; the connecting base self-centering locking technology comprises the following processing steps: S1, positioning a product; S2, clamping the position in the Y-axis direction; S3, clamping the position in the Z-axis direction; S4, scanning and shooting a plug and a connecting base center by a CCD; S5, inserting the plug in the connecting base; S6, scanning and shooting the gap between the connecting base and a mounting hole by the CCD; S7, fine tuning the gap; S8, locking a jig; and S9, discharging a non-defective project and ejecting the defective product. The connecting base self-centering locking production line is used for automatically adjusting and locking the mounting clearance of the connecting base, ensures uniform product assembling, improves production quality and production efficiency of the product, and is suitable for modern high-speed automatic production.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Clamping device for acrylic sheets

The invention discloses a clamping device for acrylic sheets. The clamping device comprises a driving unit and multiple clamping modules; the multiple clamping modules are different in angle and gap, and are used for fixing the sheets; and the driving unit is used for driving the clamping modules. The clamping device automatically sets different pressing forces according to the thickness change of the sheets, prevents the slip falling or pressure blasting phenomenon in the sheet clamping process, relieves the workload of workers, is convenient for installation and disassembly of the sheets, improves the working efficiency, is provided with an auxiliary heating device capable of realizing the temperature adjustment from normal temperature to 450 DEG C, is wide in adjusting range, and can effectively guarantee the heating uniformity of stretched sheets.

Owner:AI CAN SEIK MACHINERY EQUIP JIANGSU CO LTD

Aluminum alloy sheet for wine cover material and production method of aluminum alloy sheet

InactiveCN104561668AReduce chemical composition segregationHomogenization guaranteedMagnesiumThin sheet

The invention discloses an aluminum alloy sheet for a wine cover material and a production method of the aluminum alloy sheet. The aluminum alloy sheet for the wine cover material comprises the following components in percentage by weight: 0.63-0.68 percent of silicon, 0.72-0.77 percent of iron, 0.005-0.04 percent of copper, 0.01-0.04 percent of manganese, 0.015-0.05 percent of magnesium, 0.005-0.05 percent of chromium, 0.005-0.05 percent of zinc, 0.025-0.035 percent of titanium and the balance of aluminum. The production method comprises the following steps: smelting, casting, milling, soaking, performing hot rough rolling, performing hot finish rolling, and performing cold rolling, thereby obtaining the aluminum alloy sheet for the wine cover material which is uniform and fine in grains, balanced in deformation texture and recrystallization texture, good in deep drawability and stable in performance and has high mechanical processability. The earing ratio is greatly reduced, the yield of the wine cover during punch forming is improved, the production cost is reduced, and the aluminum alloy sheet has obvious economic benefits.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

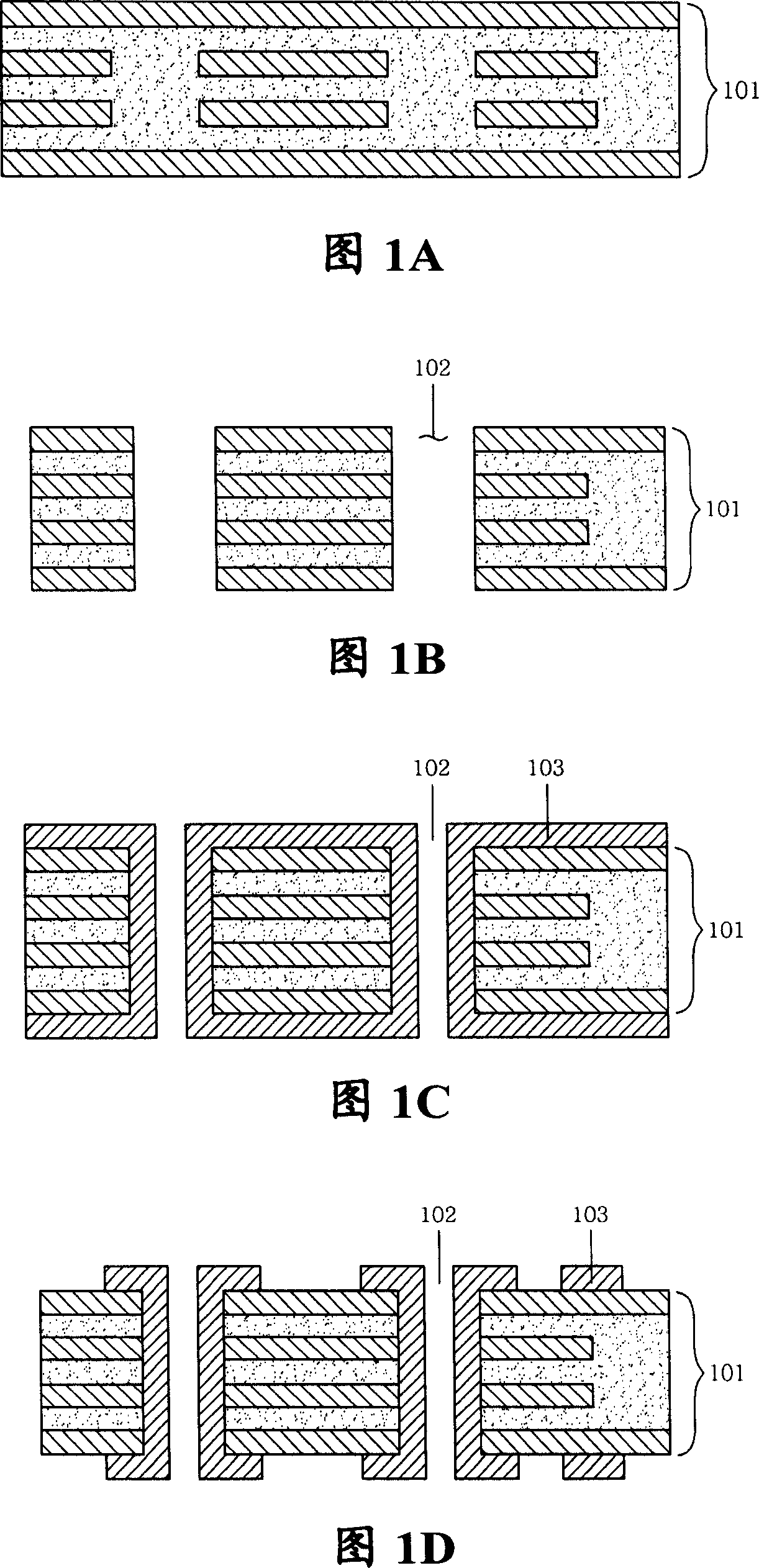

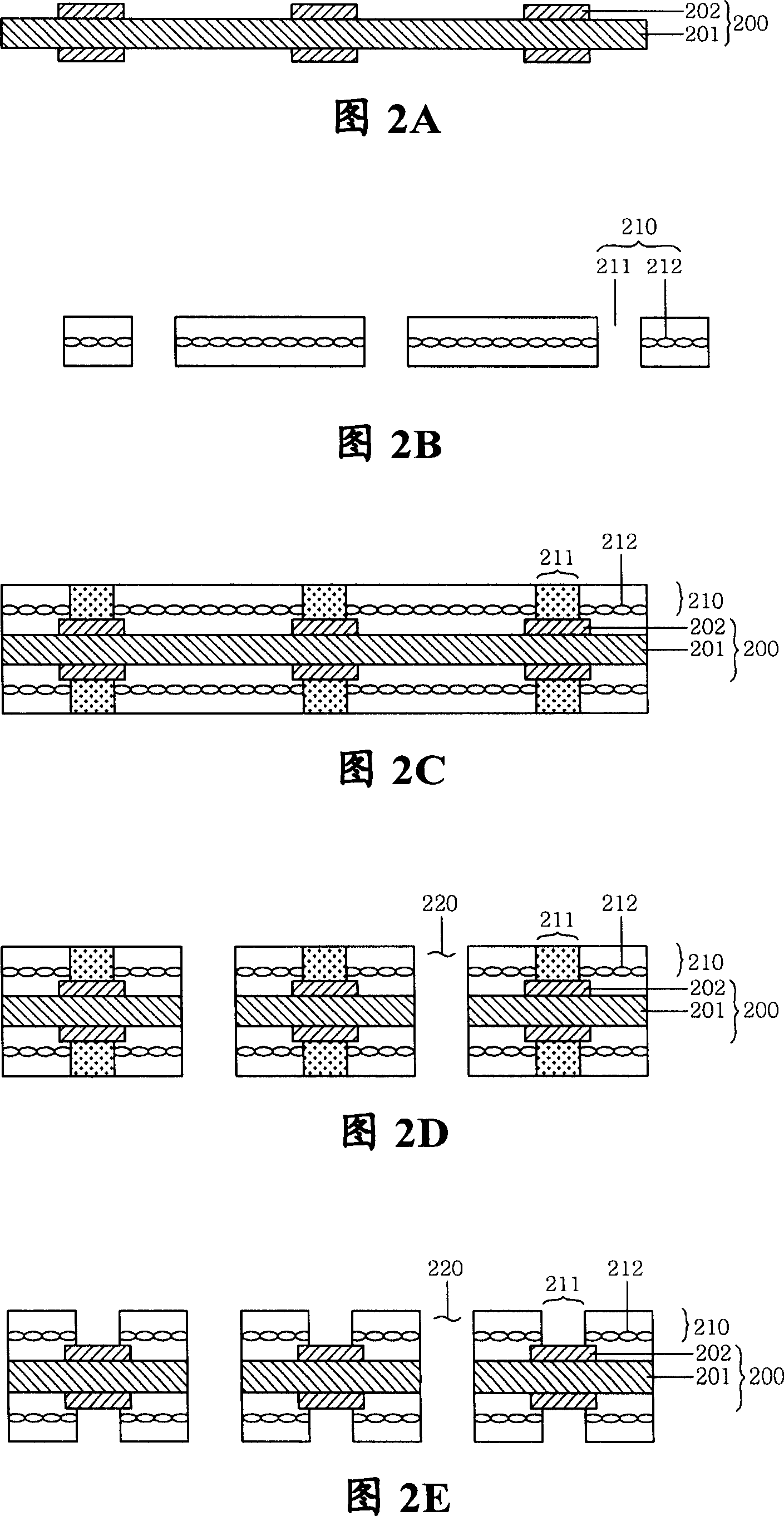

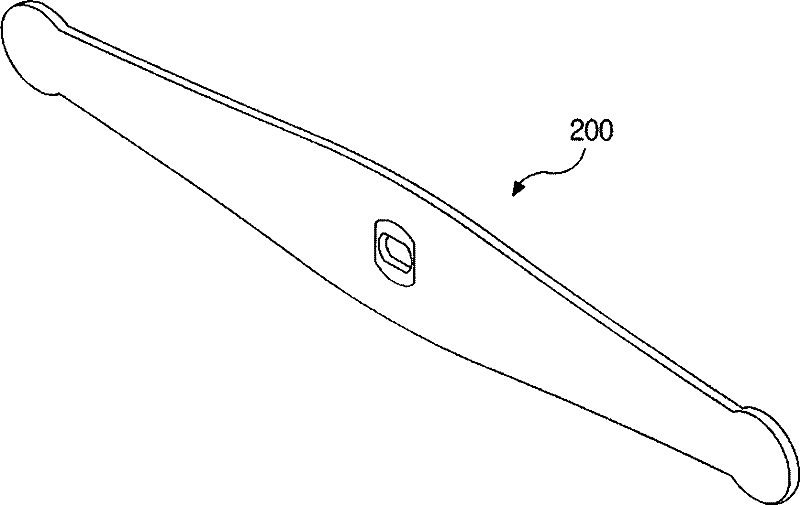

Method forming via hole that utilizes lazer drill

InactiveCN1972564AReduce processing timeHomogenization guaranteedInsulating layers/substrates workingConductive material chemical/electrolytical removalDrillLaser drilling

The invention provides a method for forming via holes by using a laser driller, the method comprises: (a) preparing to form a first circuit substrate having circuits on two sides of an insulative layer; (b) preparing to drill a plurality of prepregs having holes by automatically drilling on positions at which via holes are to be formed; (c) cumulating the prepregs on the two sides on which the first circuit substrate is formed; and (d) machining the via hole postions filled with resins flowed out from the prepregs in the step (c) by the laser driller so as to form the via holes.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

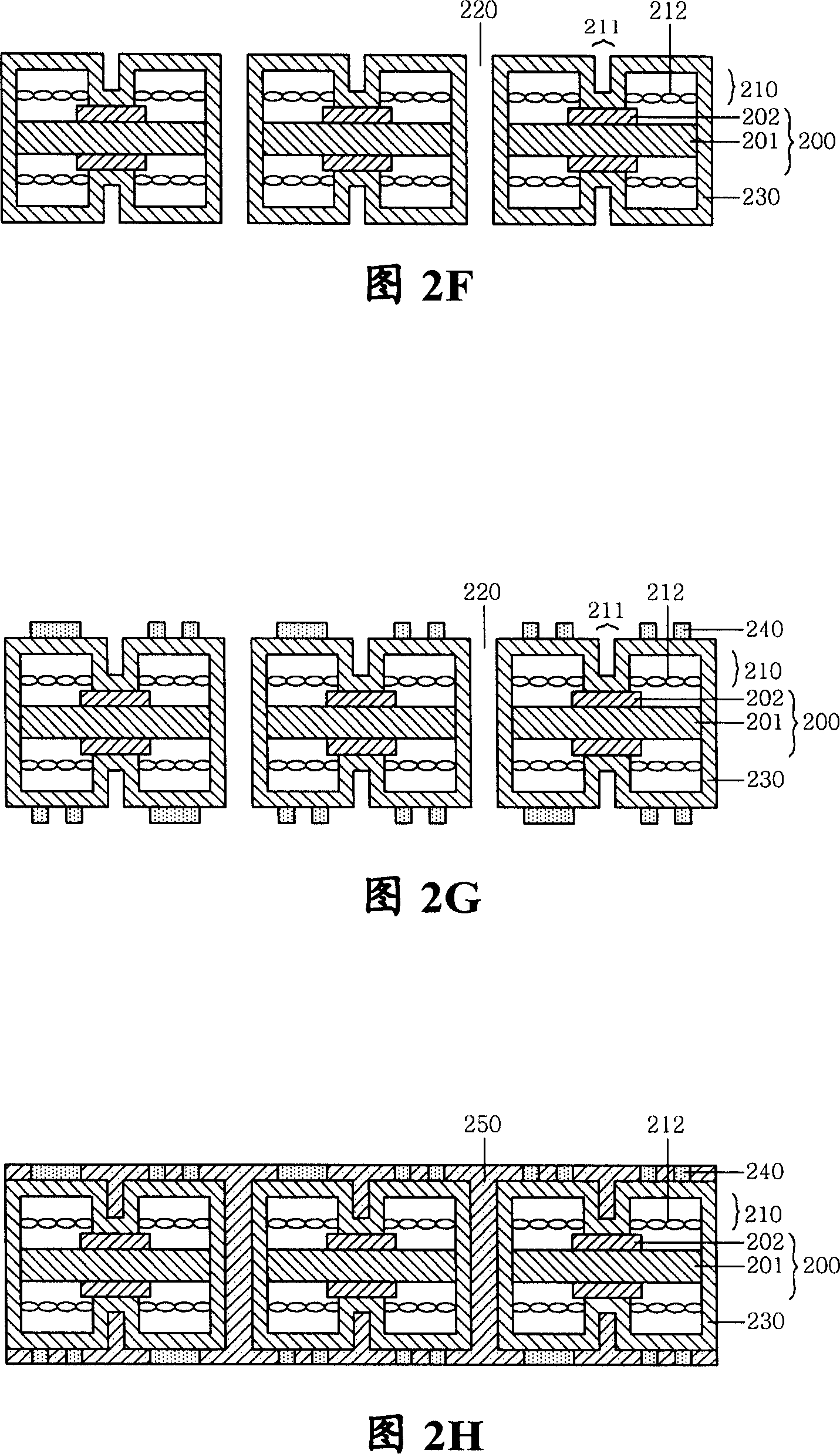

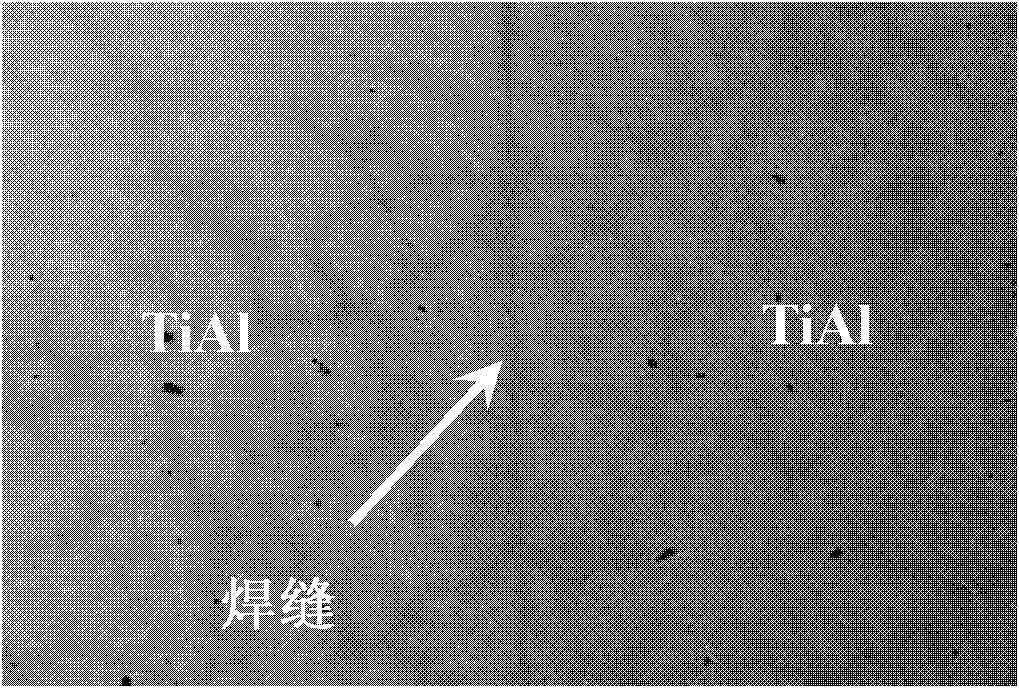

Method for realizing TiAl-based alloy connection by adopting Al foil as intermediate layer

InactiveCN102151981AHomogenization guaranteedStable performanceNon-electric welding apparatusCorrosionHeating furnace

The invention provides a method for realizing TiAl-based alloy connection by adopting an Al foil as an intermediate layer and relates to a TiAl-based alloy connection method. The method solves the problems that the existing TiAl alloy joint obtained through soldering has low high-temperature strength, and impurity elements which do not exist in TiAl alloy base materials are led in the connection process to cause that the corrosion resistance, the oxidation resistance and other properties of the joint are deteriorative. The method comprises the following steps: firstly, machining TiAl-based alloy into the required dimension; secondly, polishing after TiAl-based alloy connection surfaces are polished by sand paper and placing into acetone for ultrasonic cleaning; thirdly, placing the Al foil among the connection surfaces, applying the pressure, placing into a vacuum heating furnace for welding, heating and heat preservation and cooling to the room temperature, namely finishing the TiAl-based alloy connection. A welded joint or a joint of the TiAl-based alloy connected by the method can be used at the high temperature of 600-800 DEG C so as to avoid the leading-in of other impurities in the welding process. The method is applied to the technical field of TiAl-based alloy connection.

Owner:HARBIN INST OF TECH

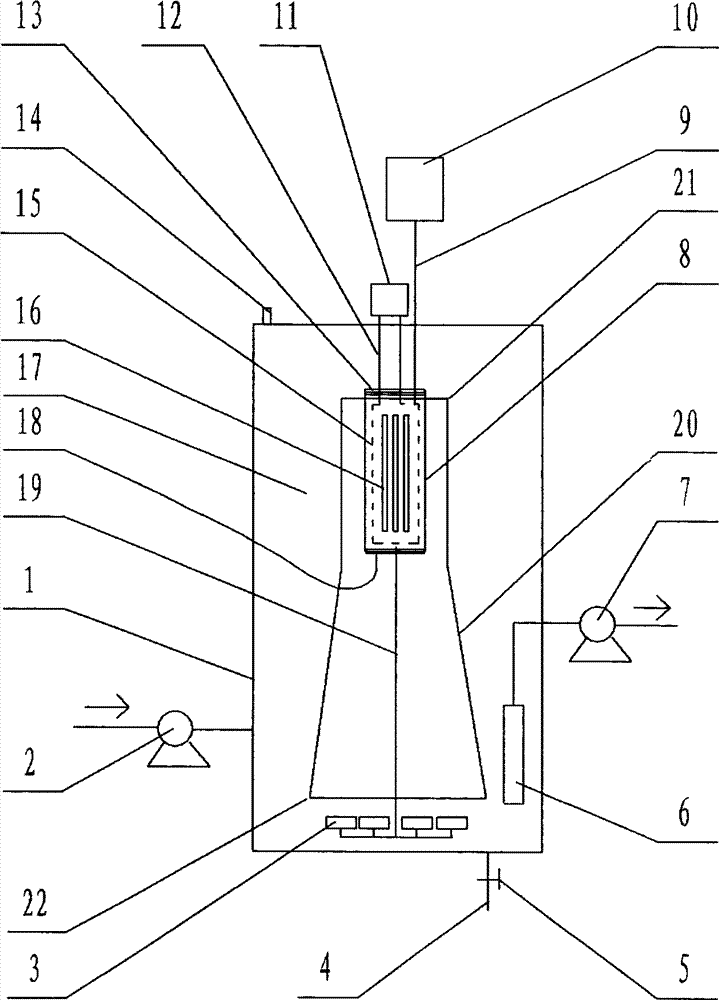

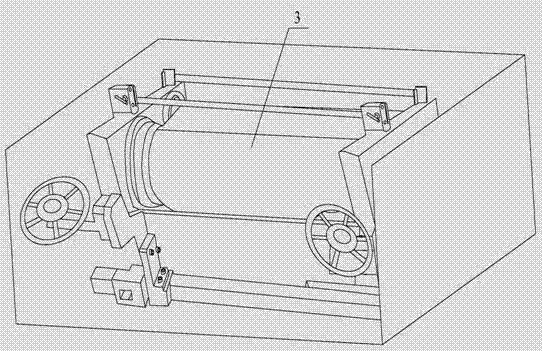

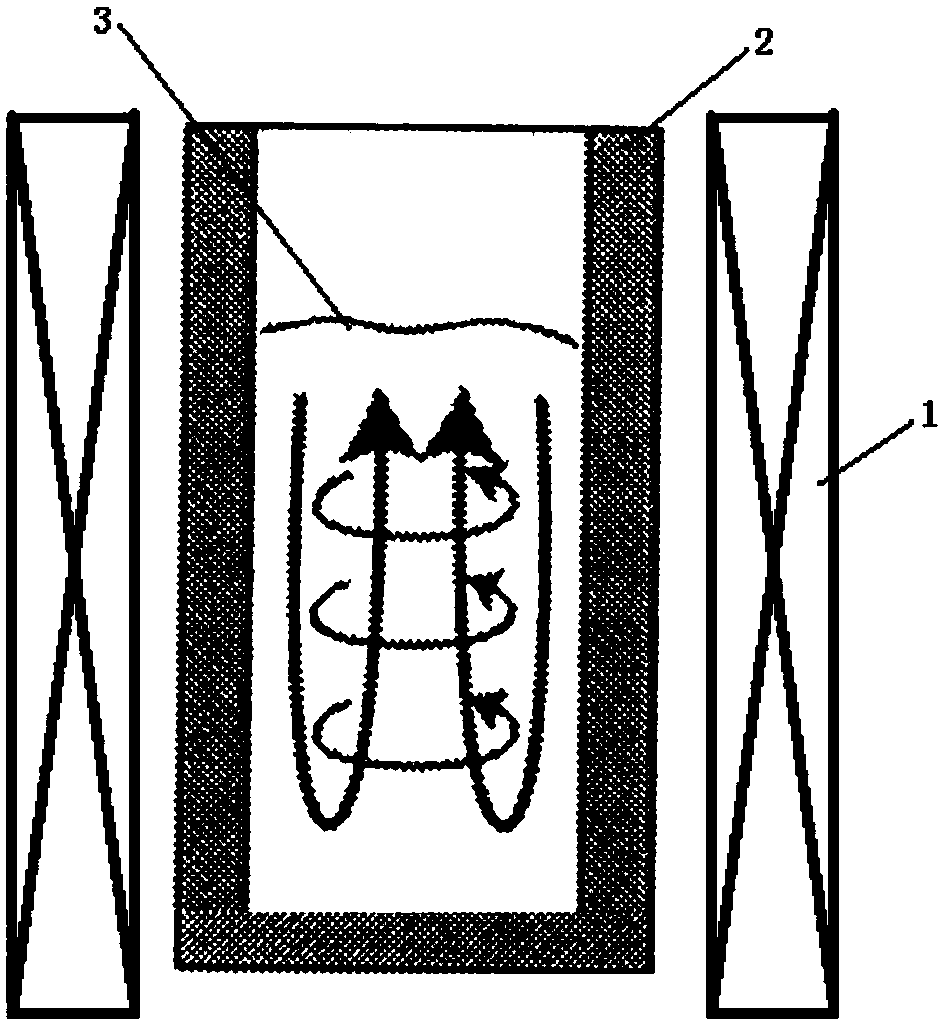

Large-throughput ultraviolet photocatalytic wastewater degradation reactor adopting microwave excitation light source

InactiveCN103086462ANo need to worry about temperature rise effectExpansion design volumeWater/sewage treatment by irradiationMicrowaveUltraviolet

The invention relates to a large-throughput ultraviolet photocatalytic wastewater degradation reactor adopting a microwave excitation light source, and belongs to the technical field of wastewater treatment. A scheme adopted in the invention aims at the problems comprising useless energy dissipation caused by a case that a quantity of microwave energy is absorbed by wastewater, small wastewater throughput of a single tank of a reactor, insufficient internal liquid cycle intensity and the like in present electrodeless ultraviolet photocatalytic degradation technologies against industrial wastewater containing organic pollutants. In the scheme, electrodeless ultraviolet lamps are placed in a caged non-opaque metal microwave restraint to restrain microwaves and repress the useless dissipation of the microwaves, an ultraviolet-transmitting quartz tube used for gas-liquid isolation is arranged between the microwave restraint and the wastewater, and the quartz tube is arranged in the upper portion of the chamber tube of the suspending and vertical cylindrical member of the inner cavity of the reactor. The scheme solves all the problems.

Owner:NINGBO UNIV

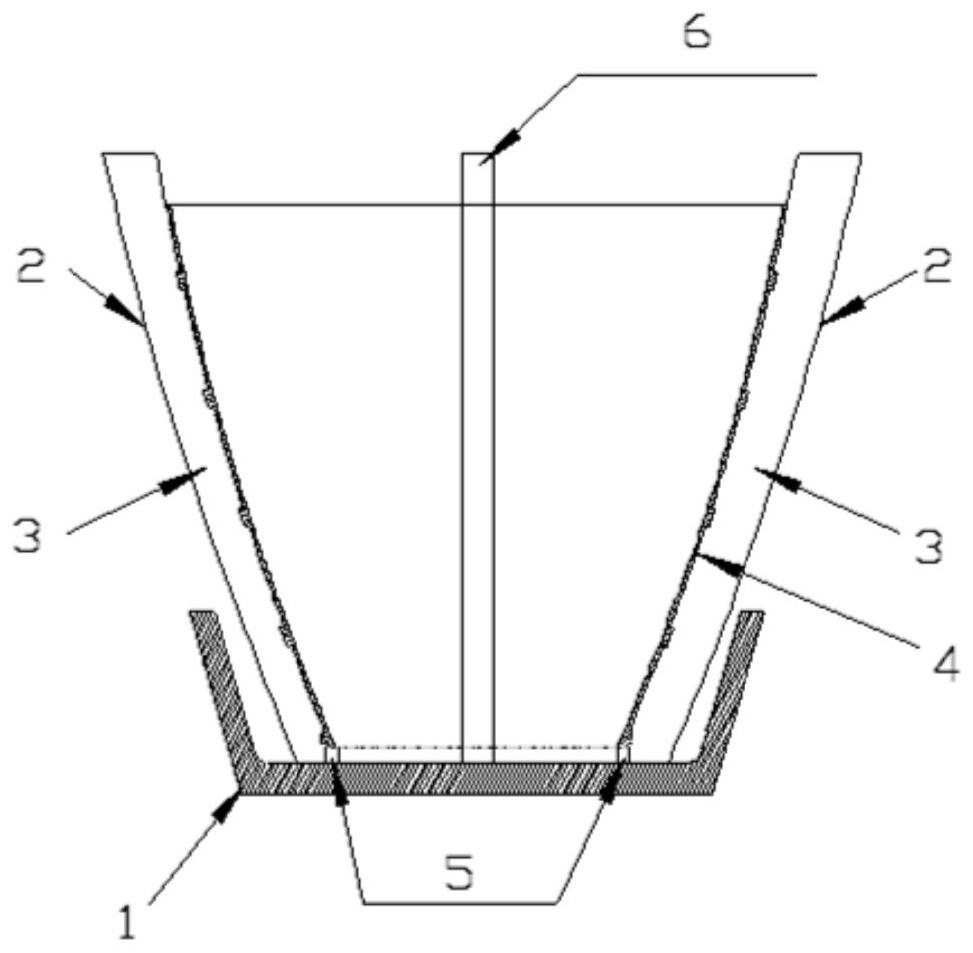

Melt siliconizing method for small-size circular-section ceramic-based composite material component

ActiveCN112341213AImprove the uniformity of modificationAvoid deformationCrucible furnacesCrucibleLiquid silicon

The invention relates to a melt siliconizing method for a small-size circular-section ceramic-based composite material component. The invention aims to solve problems that in the LSI process preparation process of a small-size circular-section ceramic matrix composite zero component, the internal and external density gradient difference is likely to be generated, the component density uniformity is poor, deformation is liable to happen, and bottom liquid silicon is liable to be accumulated and bonded. The method mainly comprises the steps of preparing a fused siliconizing tool, machining a small-size circular-section ceramic-based composite material component semi-finished product and preparing the small-size circular-section ceramic-based composite material component; wherein specifically, an inner mold of the small-size circular-section ceramic-based composite material component semi-finished product is filled with SiC sand; meanwhile, powder is packed into a gap, namely a powder filling area, formed between the outer wall of the small-size circular-section ceramic matrix composite component semi-finished product and the inner wall of the first crucible unit. Due to internal andexternal double-sided melt infiltration, the process effectively improves the modification uniformity.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

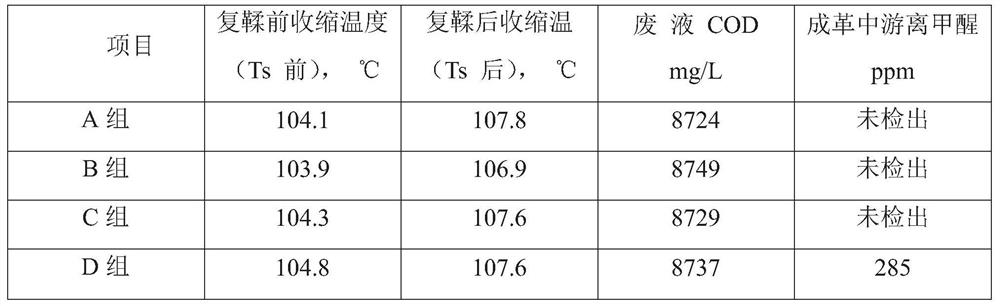

Preparation method of amino resin retanning agent, retanning agent and application of retanning agent

ActiveCN111961173AGood water solubilityThere will be no precipitation of salt crystalsTanning treatmentTextile/flexible product manufacturePolymer scienceEther

The invention discloses a preparation method of an amino resin retanning agent. The preparation method comprises the following steps: firstly, modifying a dialdehyde monomer by using amino-terminatedpolyoxyethylene ether to obtain a dialdehyde modifier, then carrying out nucleophilic addition reaction with an amino monomer to generate a non-ionic amino resin prepolymer, finally adding an etherifying agent to seal free aldehyde groups, and adjusting the pH value to be neutral so that the amino resin retanning agent is obtained, wherein the molar ratio of primary amino in the amino monomer to aldehyde groups in the dialdehyde monomer is 1: 1.3-1: 3, and the proportion of unreacted aldehyde groups in the dialdehyde modifier is 40%-90%. The invention further discloses the retanning agent andan application thereof. According to the amino resin retanning agent provided by the invention, salt reactants are not involved in the whole process, the product quality is good, the comprehensive performance is high, the retanning performance can be comparable with that of a traditional amino resin retanning agent, formaldehyde is not used as a raw material in the preparation process, and the risk of residual formaldehyde brought by the retanning agent in finished leather processing is fundamentally eliminated.

Owner:科凯精细化工(上海)有限公司

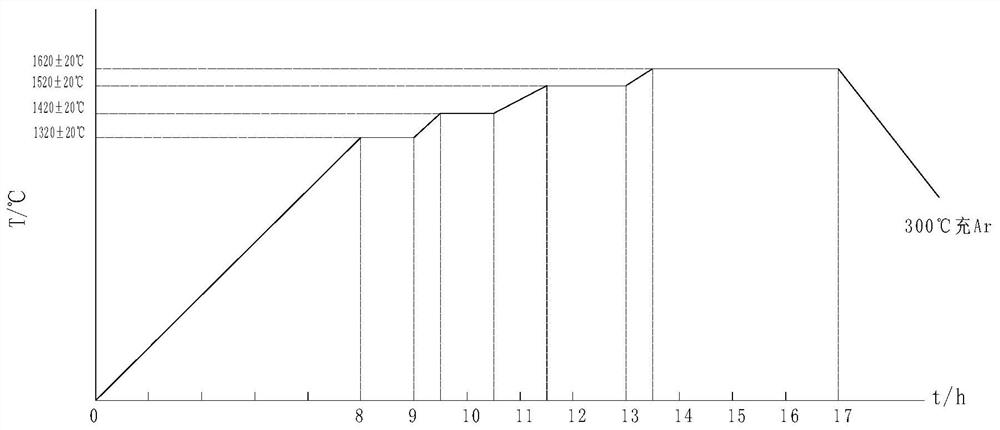

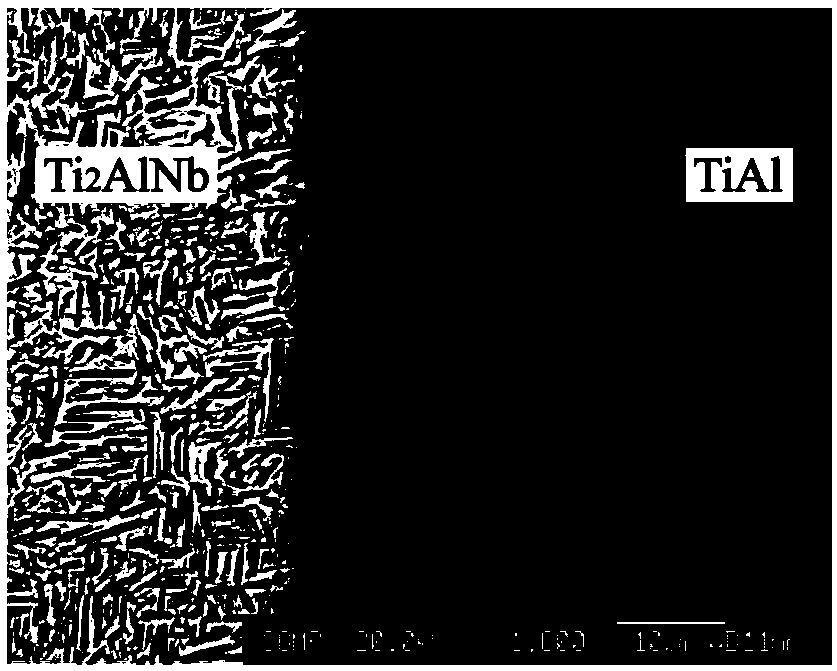

Diffusion welding bonding method using Ti foil as intermediate layer

InactiveCN108772622AGuaranteed performanceGuaranteed stabilityWelding/soldering/cutting articlesNon-electric welding apparatusRoom temperatureAlloy

The invention provides a diffusion welding bonding method using Ti foil as the intermediate layer. The connection in the method refers to the connection of TiAl alloy to Ti2AlNb alloy or Ti3Al-based alloy. The method is to process a TiAl alloy and a Ti2AlNb alloy or a Ti3Al based alloy into a desired size. The welded base material is polished and polished; the soldered base material and Ti foil are ultrasonically cleaned in acetone; the Ti foil is placed between the welded base materials, placed in a vacuum heating furnace, pressure is applied, and the welding is completed after heating, heatpreservation, and cooling. The invention can avoid the introduction of impurity elements in the welding process, and can obtain the connection interface without continuous brittle phase, the tensile strength of the joint at room temperature reaches 380-410 MPa, and the tensile strength at 650 DEG C can reach 350 MPa to 370 MPa.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

700MPa-grade thermal forming axle housing steel and preparation method thereof

ActiveCN112195403AImprove impact toughnessAvoid formingRolling resistance optimizationChemical compositionMaterials science

The invention discloses 700MPa-grade thermal forming axle housing steel. The 700MPa-grade thermal forming axle housing steel is prepared from the following chemical components in percentage by mass: 0.17%-0.27% of C, 0.30%-0.50% of Si, 1.2%-1.8% of Mn, less than or equal to 0.02% of P, less than or equal to 0.009% of S, less than or equal to 0.1% of Ti, less than or equal to 0.2% of Cr and the balance of Fe and inevitable impurities, wherein the mass fraction of Si and Mn meets the condition that Si / Mn is more than or equal to 0.23 and less than or equal to 0.27. The invention further discloses a preparation method. The preparation method comprises the steps of adopting the chemical components for smelting, continuous casting, heating, rough rolling, finish rolling, curling and machining treatment with the heating temperature of 1180 DEG C-1220 DEG C and the heating time of 150 min-200 min to obtain the 700MPa-grade thermal forming axle housing steel. The mechanical properties before and after heat treatment are excellent, and a plate obtained after heat treatment is free of obvious microscopic banded structures and has excellent impact toughness.

Owner:SHOUGANG CORPORATION +1

Preparation method capable of remarkably overcoming surface defect of copper alloy material for lead frame

ActiveCN107447121AImprove surface propertiesImprove performanceSemiconductor/solid-state device detailsSolid-state devicesRare earthZinc alloys

The invention discloses a preparation method capable of remarkably overcoming the surface defect of a copper alloy material for a lead frame. The preparation method comprises the following steps that S1, a copper-iron alloy with the iron content being 7% is refined; S2, high-purity copper and wood coal are added into a high-frequency induction smelting furnace, heating is conducted until the high-purity copper is completely melted to obtain copper liquid, heating continues to be conducted, the copper-iron alloy with the iron content being 7%, a copper-zinc alloy, a copper-phosphorus alloy, a copper-tin alloy, a copper-titanium alloy and mixture rare earths are added, and stirring and smelting are conducted to obtain a copper-alloy solution; S3, the components of the copper-alloy solution are detected, and casting is conducted to obtain strips; S4, the strips are subjected to uniform annealing, the annealing temperature is 650-730 DEG C, repeated hot rolling is conducted, then the strips are transferred to be subjected to intermediate annealing finish rolling, the intermediate annealing temperature is 690-710 DEG C, and then a finish rolling product is obtained; and S5, the finish rolling product is subjected to ageing treatment and cooled with a furnace to obtain the copper alloy material, with the surface defect remarkably overcome, for the lead frame. According to the preparation method capable of remarkably overcoming the surface defect of the copper alloy material for the lead frame, uniformization of the copper alloy material for the lead frame is promoted, the surface performance of the alloy material is improved, and the comprehensive performance of the copper alloy material is improved.

Owner:安徽晋源铜业有限公司

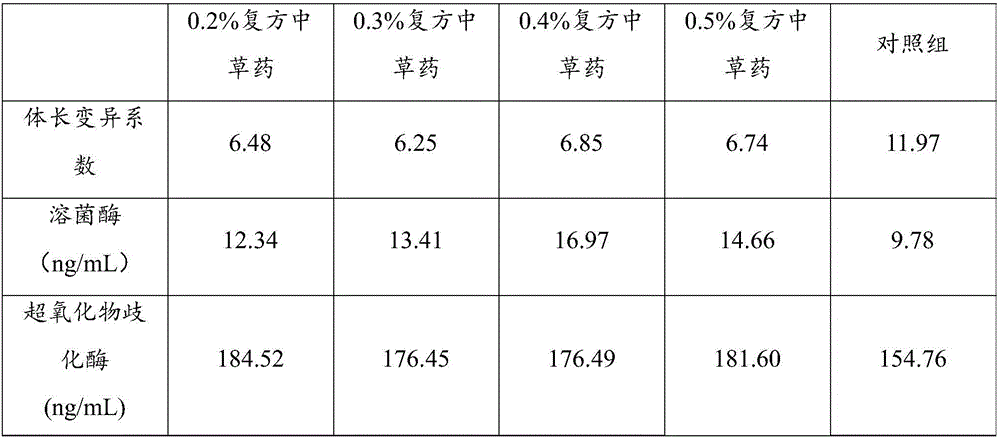

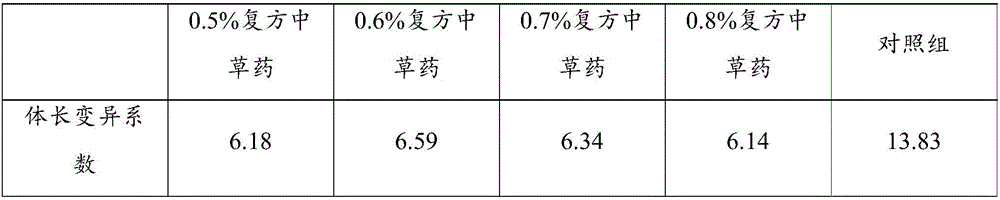

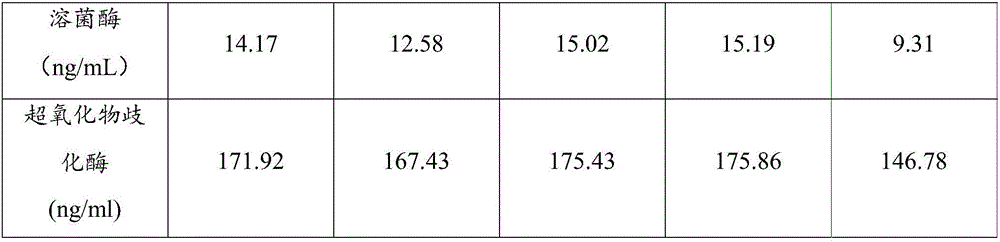

Method for prompting balanced growth and immune fortification of oreochromis niloticus fries

ActiveCN106172144APromotes balanced growthHomogenization guaranteedFood processingClimate change adaptationBiologyTraditional Chinese medicine

The invention discloses a method for prompting balanced growth and immune fortification of oreochromis niloticus fries. The method comprises following steps of seedling culture, basic diary food preparation, composite traditional Chinese medicine preparations and seedlings feeding. Compared with the prior art, the method for prompting balanced growth and immune fortification of oreochromis niloticus fries has following advantages: (1) the method is capable of effectively prompting balanced growth of oreochromis niloticus fries so that uniformization of fries; (2) basic diary food in the method is prepared through proper proteins, fat ratio and traditional Chinese medicine ratio such that immunity stress response capabilities of oreochromis niloticus fries are improved; (3) basic diary food and traditional Chinese medicine belong to green feeds and satisfy the safety standard and cause no pollution on fish and water so that the healthy breeding requirement is satisfied.

Owner:姜银兰 +1

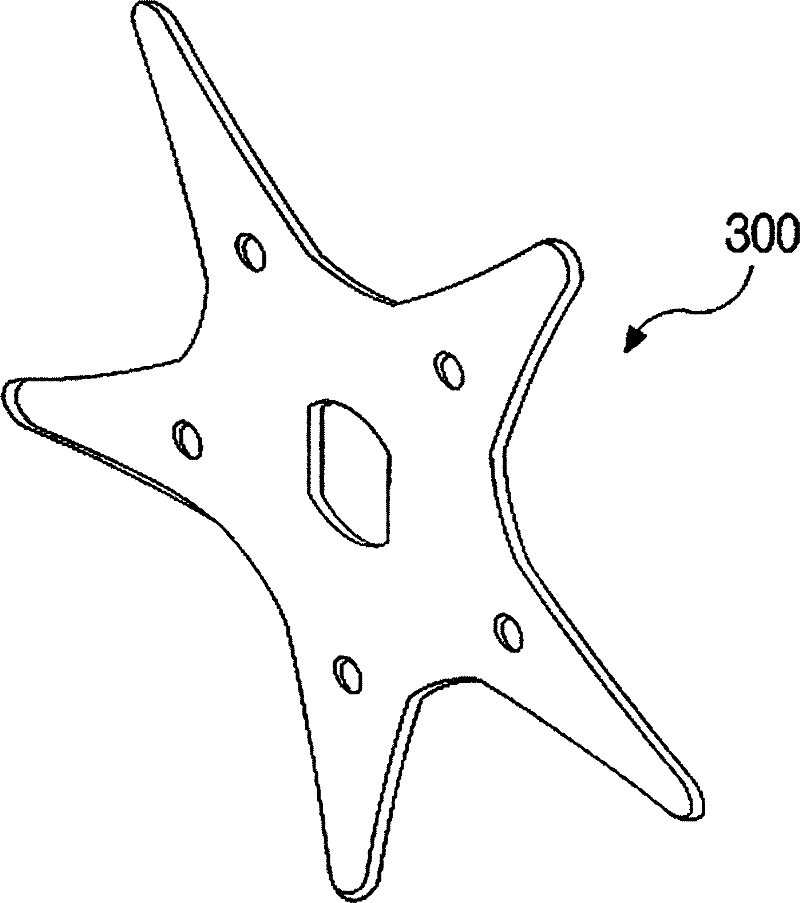

Aluminum pressing out board of unnecessary shearing process and use for method of production fish reel parts thereof

InactiveCN102476133AImprove workabilityAchieve homogenizationExtrusion diesReelsMethods of productionMechanical engineering

An extruded rectangular aluminum panel without the need of shearing process and a fish reel part manufacturing thereof using the same are provided to improve the efficiency of manufacturing fish reel parts, such as a handle arm or a drag, from the extruded rectangular aluminum panel. CONSTITUTION: A method for manufacturing a fish reel part using an extruded rectangular aluminum panel (100) is as follows. A 7075 aluminum rod is put into an extruder. The melt of the7075 aluminum rod is extruded into a rectangular plate with a width of 55 to 150mm, a length of 1000 to 2000mm, and a thickness of 2.5 to 3.9mm. The extruded aluminum rectangular panel is pressed and cut by a press machine to obtain a handle arm or a drag.

Owner:朴顺花

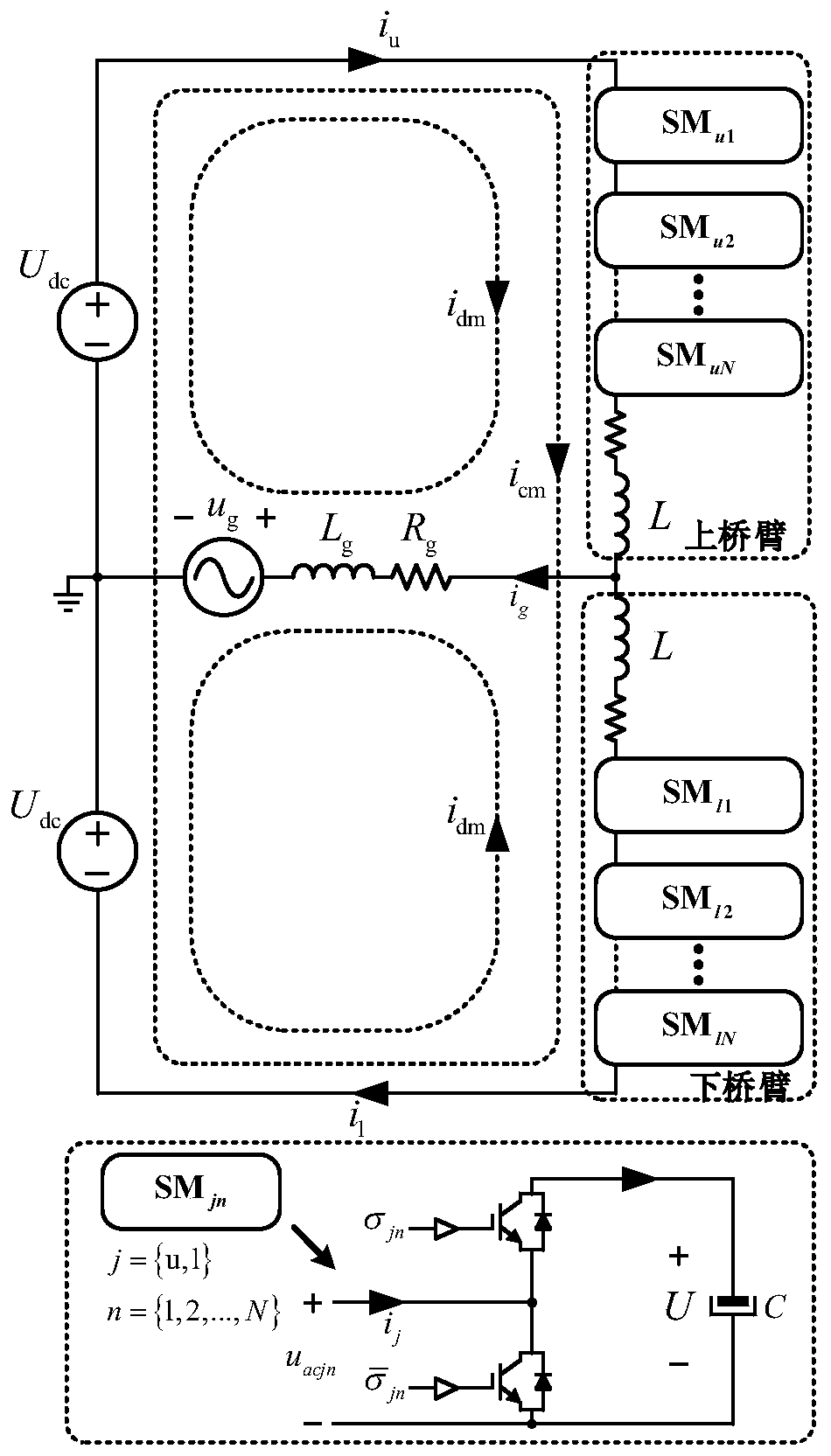

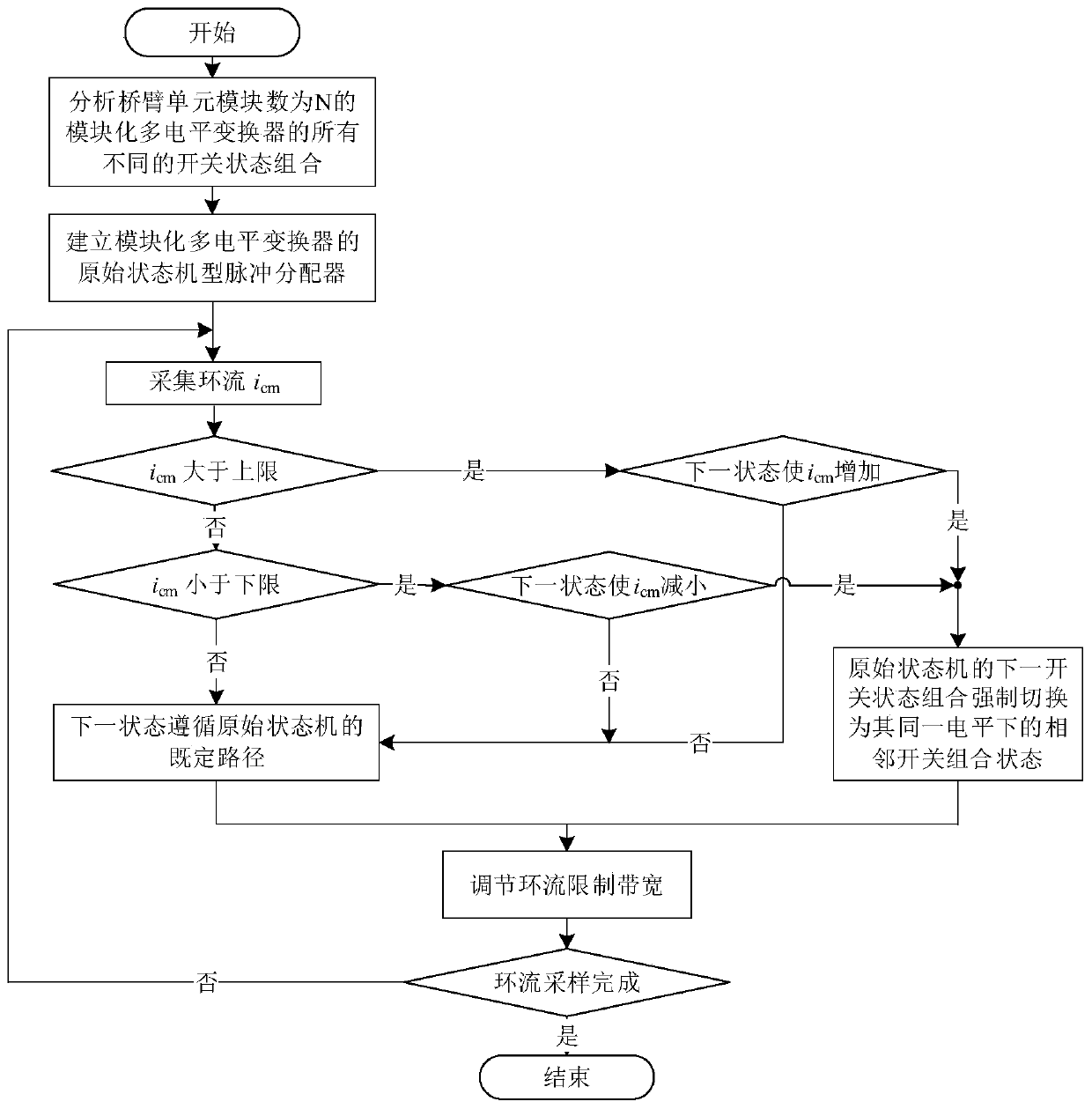

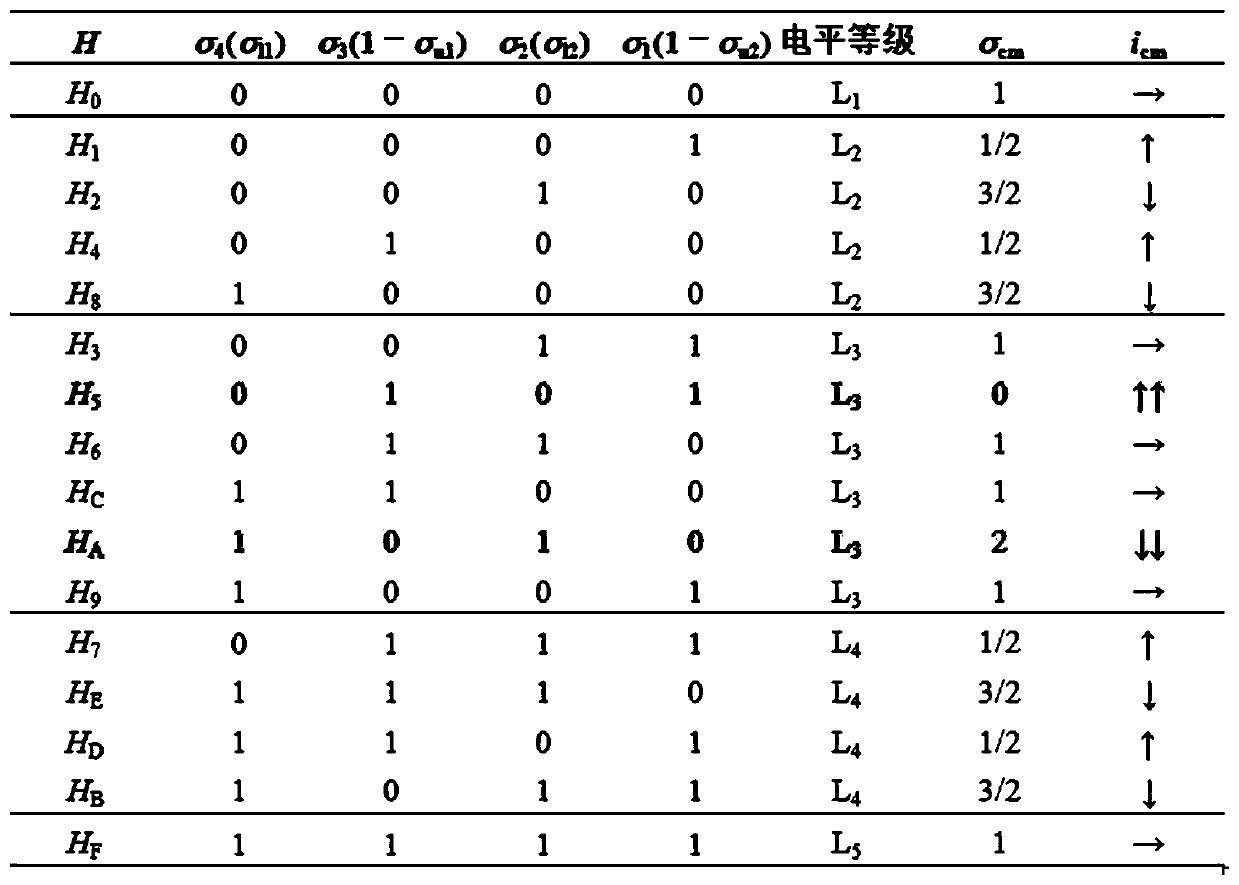

Low frequency ring current suppression method of modularized multilevel converter under carrier stacked pulse width modulation

ActiveCN109861570AReduce switching frequencySimple designAc-dc conversionSwitched currentCapacitor voltage

The invention relates to a low frequency ring current suppression method of a modularized multilevel converter under carrier stacked pulse width modulation. According to the low frequency ring currentsuppression method, on the premise that the output voltage level of a phase bridge arm is strictly equal to the level of a target waveform, a pulse distribution mode of a fixed route of an original state machine is improved reasonably, an appropriate redundant state is used adequately at a level moment affecting a ring current, changes of the ring current are always limited within the reasonablerange, the magnitude of low frequency ring current caused by capacitor voltage fluctuation of unit modules is suppressed effectively, and switch current stress of the unit modules is lowered. Meanwhile, according to the low frequency ring current suppression method, on the premise of not generating narrow pulses, uniformity and minimality of switching motions of the unit modules are maintained tothe maximum extent, and balance of capacitor voltage of the unit modules is not affected. In addition, according to the low frequency ring current suppression method, limiting frequency bands are appropriate to make sure that loss increasing of the unit modules is not caused by the frequent switching motions of the unit modules.

Owner:扬州永茂电力建设有限公司 +1

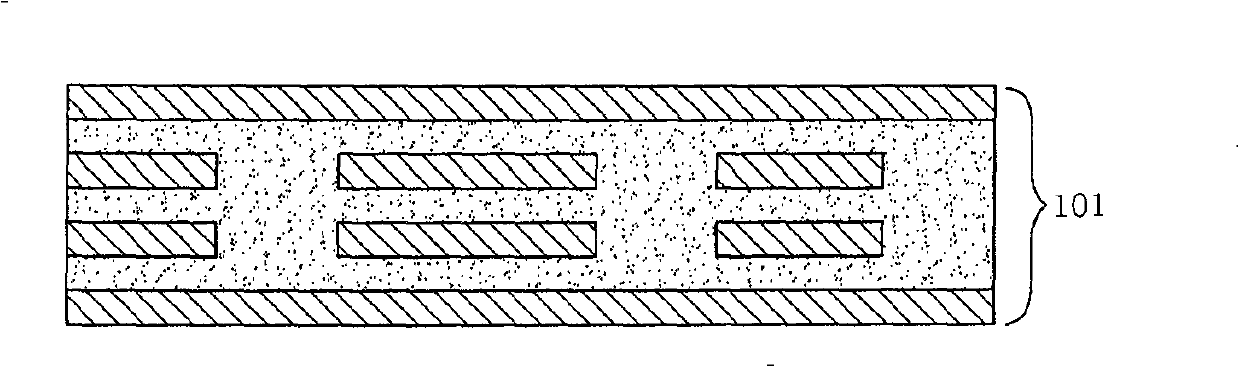

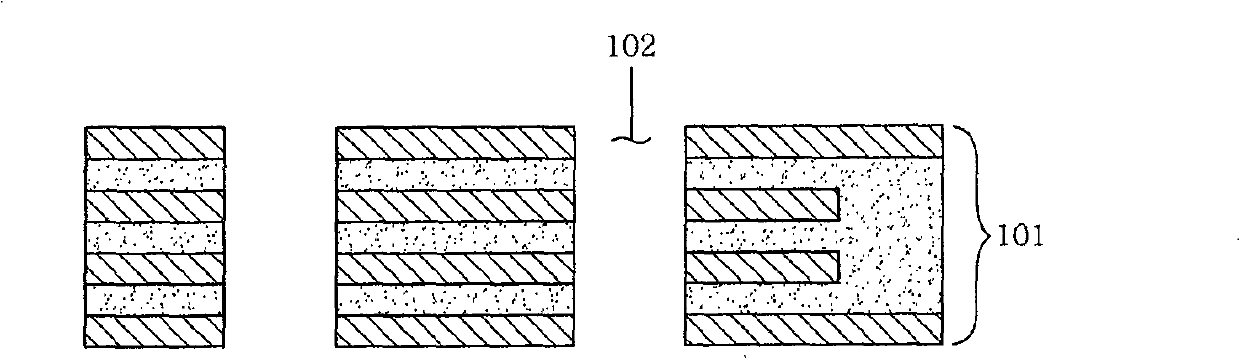

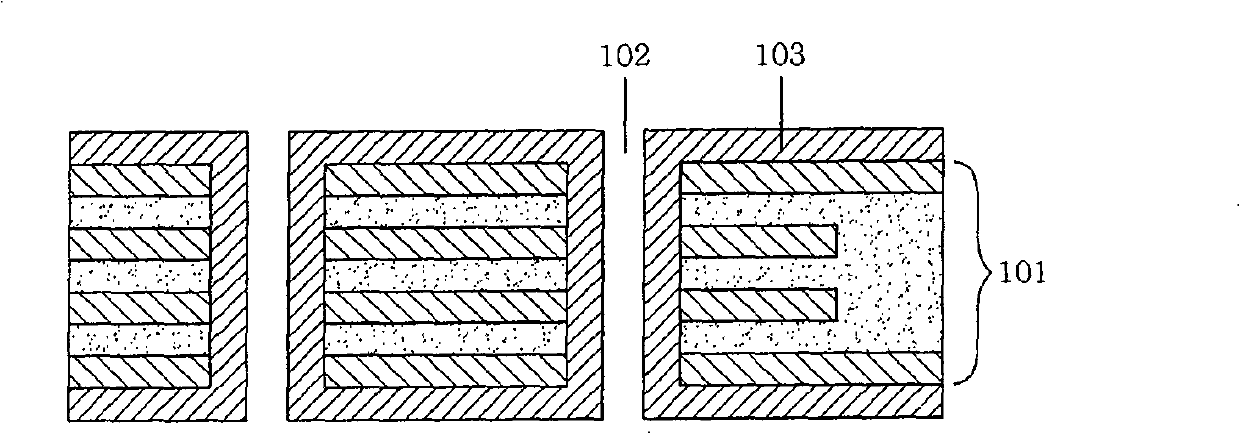

Method for forming through-hole that utilizes lazer drill

InactiveCN100518444CReduce processing timeHomogenization guaranteedInsulating layers/substrates workingConductive material chemical/electrolytical removalGlass fiberInsulation layer

A method for forming a via hole using a laser drill is provided to reduce plating defects through uniformization of the shape of hole by previously removing a glass fiber of prepreg with a mechanical drill and forming the via hole in a resin filled in a part where the glass fiber is removed by the laser drill. A method for forming a via hole using a laser drill includes the steps of: preparing a first circuit substrate(200) having circuits(202) on both surfaces of an insulation layer(201); preparing a plurality of prepregs(210) having via hole points punched through mechanical drilling; stacking the prepregs(210) on both surfaces where the circuits(202) of the first substrate(200) are formed; and fabricating the via hole with a laser drill at the via hole points filled with resin by flowing down the resin of the prepregs(210) at the above step.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Production method for titanium-lead alloy

The invention relates to a production method for a titanium-lead alloy, which comprises the steps of material mixing, material feeding, vacuumizing and ignition, after a reaction of 60 seconds, the reaction product is naturally cooled for 6 hours to normal temperature and then taken out. Based on the basic principle of a self-propagation in-situ reaction method, that is, raw materials are fully homogenized before being alloyed, and by making full use of the principle of in-situ reduction, the invention uses a quick smelting furnace under the protection of special argon to complete an alloying process in a short time, thereby solving the problems that titanium and lead are difficult to alloy, the solid solubility is low and the components of the alloy are not homogenized and guaranteeing the homogenization of the components of the produced product, in addition, the lead content can be controlled to be 25% at most.

Owner:莱芜市金石粉末冶金有限公司 +1

Method for expanding capacity of microwave photo-catalytic coupling wastewater degradation device, and improving internal circulation

InactiveCN103112921AIncrease throughputExpansion design volumeWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisPhoto catalyticMicrowave

The invention relates to a method for expanding the capacity of a microwave photo-catalytic coupling wastewater degradation device, and improving the internal circulation, and belongs to the technical field of wastewater treatment. On the premise of taking the microwave and photo-chemical catalytic coupling effect into consideration, the reactor aims at solving the problems of small wastewater treatment amount of a single tank of a reactor, high repeated operation frequency, insufficient internal liquid circulating strength and the like, which exist in the existing technology of microwave photo-catalytic degradation to organic pollutant industrial wastewater. The method comprises the following steps of forcibly separating and distributing the microwave radiation area inside the reactor by adopting a metal cage to lead a coupling catalytic degradation effect to perform in the metal cage; maintaining a space without microwave radiation between the outer wall of the metal cage and the inner wall of the reactor; and erecting a flared component which is used for guiding and intensifying liquid circulation right below the metal cage. According to the method, the designed capacity of the reactor is permitted to be greatly expanded, and formation of a powerful internal liquid circulation can be facilitated.

Owner:NINGBO UNIV

High-strength ceramic binder

The invention relates to a high-strength ceramic binder, and belongs to the technical field of machining. According to the present invention, a high-frequency energy-absorption component foamed nickelis adopted and is subjected to mixed grinding with a co-permeation agent and the like, and low-temperature gas discharge and high-temperature solid phase diffusion are sequentially performed to forma three-dimensional network compact alloy structure so as to enhance the impact energy; the alloy structure as a substrate layer is added with nanometer iron powder, such that the lasting bonding performance can be maintained under high temperature and strong impact force, the fatigue resistance is good, the impact force can be resolved and absorbed, and a firm maintaining effect can be formed between the alloy structure and a grinding tool so as to improve the application effect; by using multi-component mixed ball milling and pressing, hard components are formed through multiple layers and are evenly dispersed, such that the filling with the hard impact-resistant component and the soft viscous material can improve the impact resistance and the fatigue resistance; and the prepared high-strength ceramic binder can solve the problem of poor improvement in the impact resistance and the fatigue resistance during the application of the commonly used ceramic binder in grinding tools.

Owner:陈小强

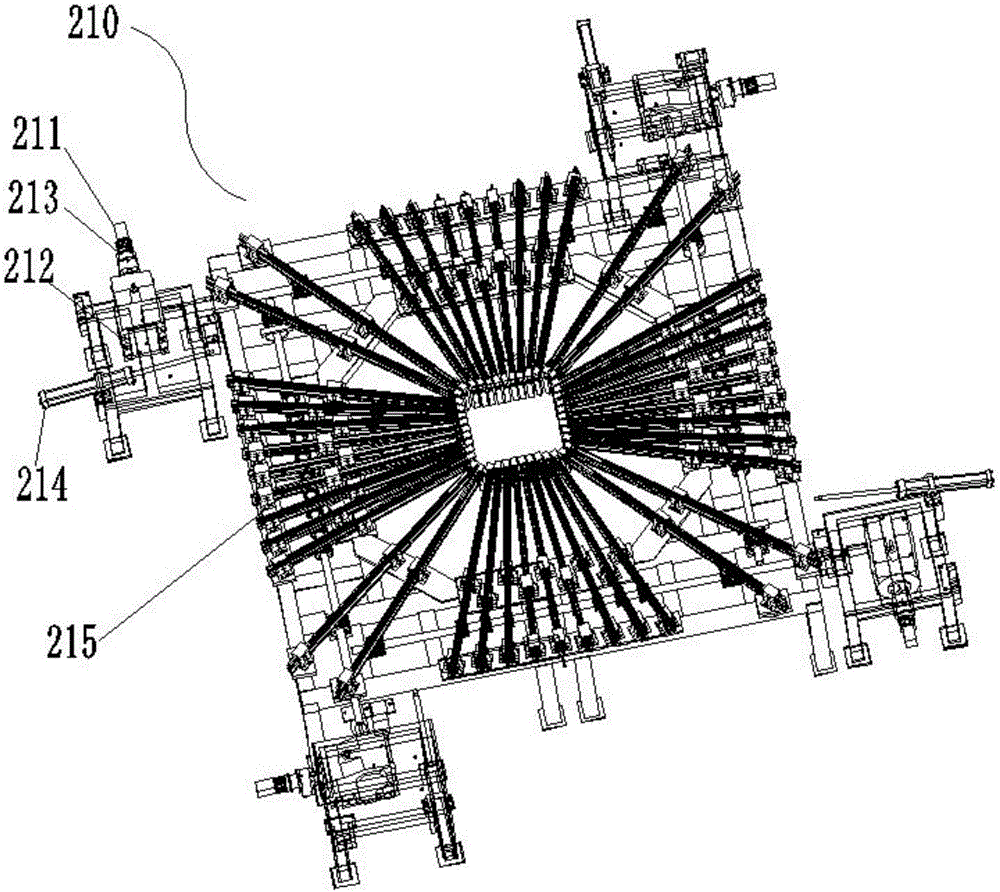

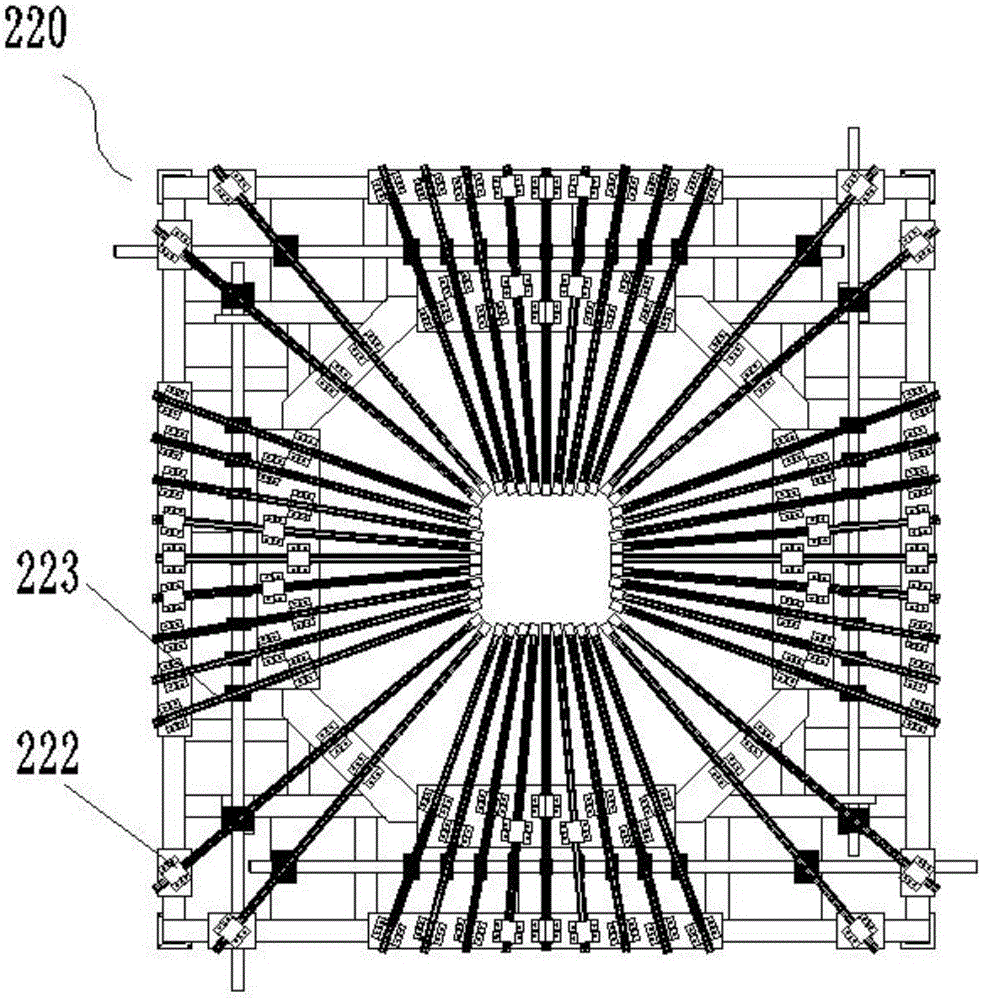

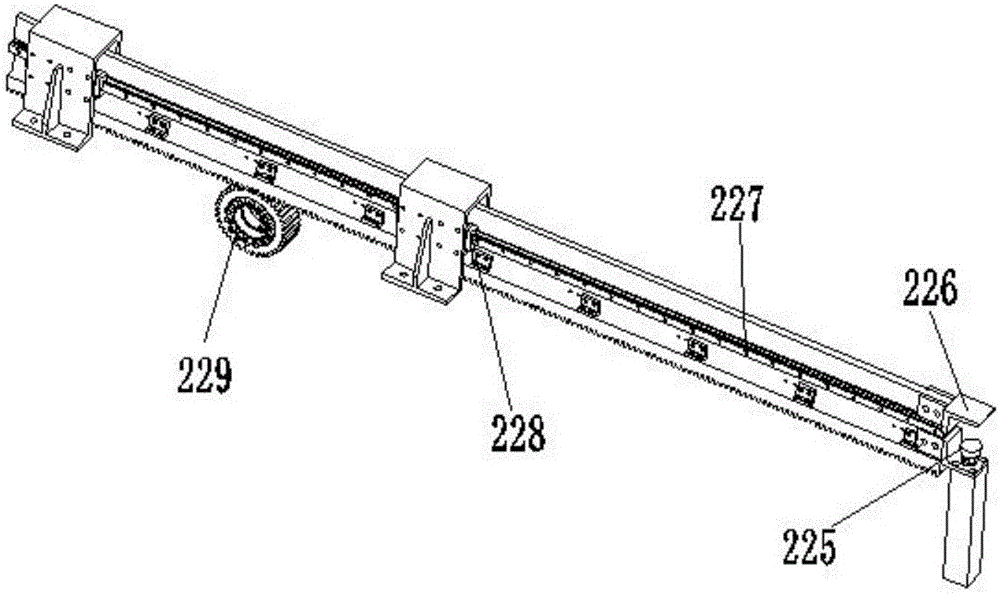

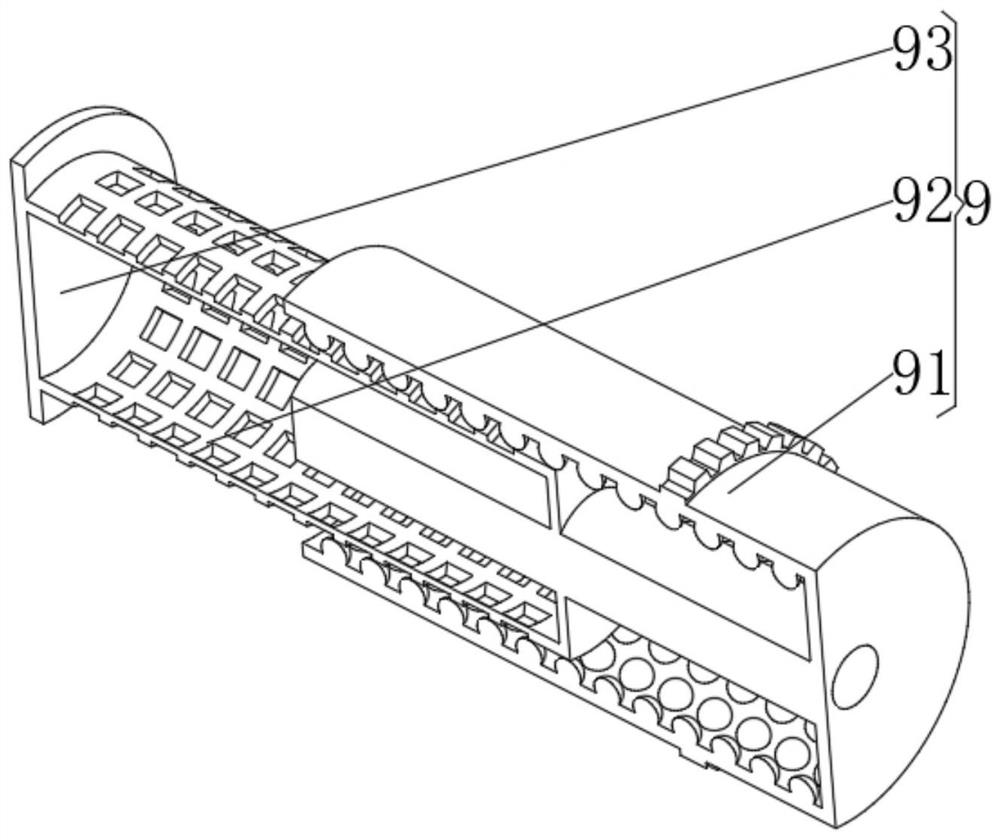

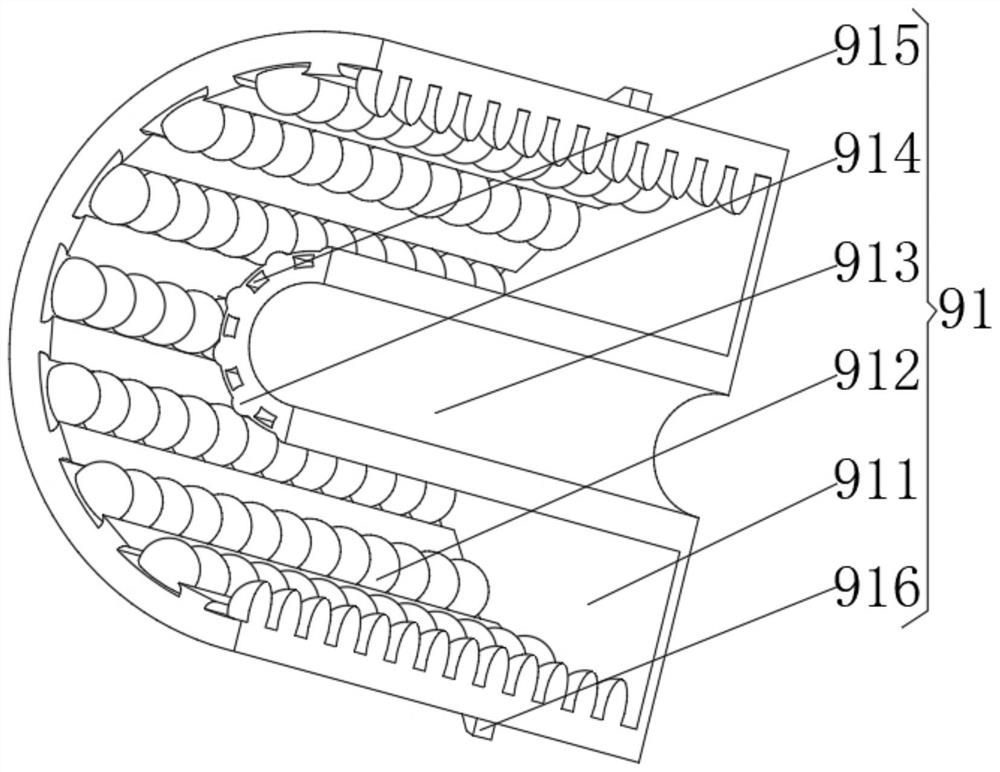

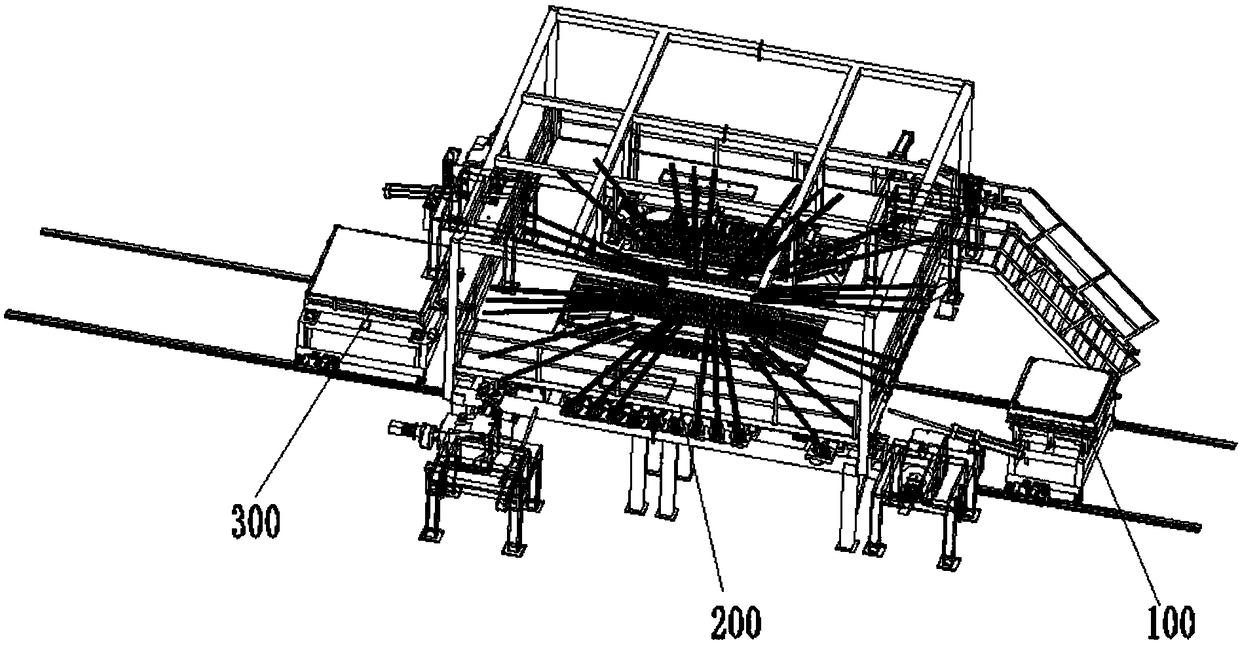

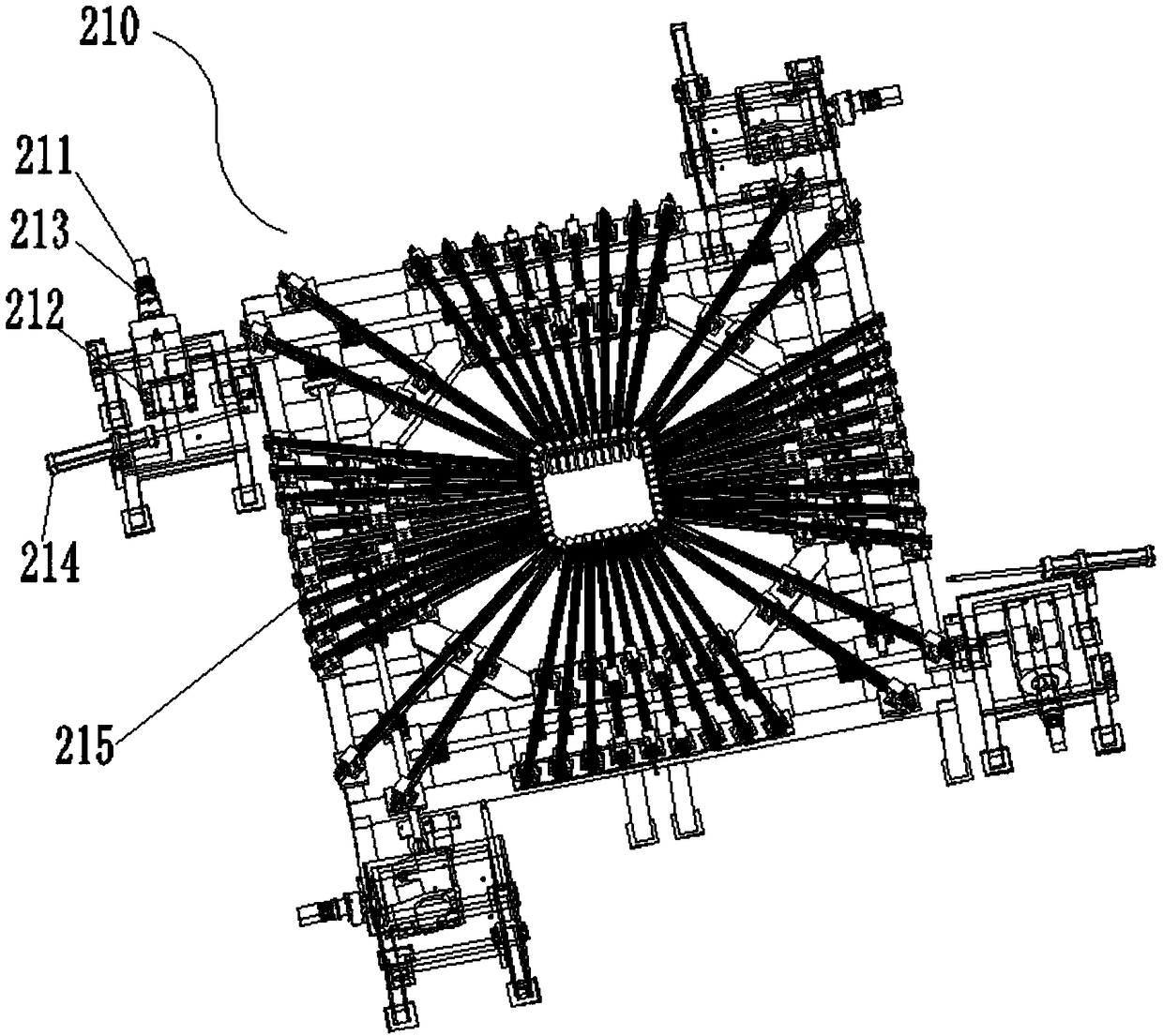

Ceramic plastic patch type underground drip irrigation tape assembly line

ActiveCN114453883ARealize automated assemblySave manpower and material resourcesClimate change adaptationAssembly machinesDrip tapeAgricultural science

The invention provides a ceramic plastic patch type underground drip irrigation tape assembly line which comprises a workbench, a conveying mechanism is arranged on the workbench, and a ceramic water seepage piece feeding mechanism, a plastic patch feeding mechanism, an irrigation emitter assembly mechanism, an irrigation emitter airtightness checking mechanism and an irrigation emitter-drip irrigation pipe assembly mechanism are arranged on the portion, around the conveying mechanism, of the workbench. A plastic patch manufacturing mechanism is arranged above the ceramic water seepage sheet feeding mechanism; part grabbing and conveying manipulators are arranged on the working table around the ceramic water seepage sheet feeding mechanism, the plastic patch feeding mechanism and the emitter air tightness inspection mechanism; a drip irrigation pipe feeding mechanism and a drip irrigation belt finished product conveying mechanism are arranged on the portions, on the two longitudinal sides of the irrigation emitter-drip irrigation pipe assembling mechanism, of the workbench correspondingly. According to the assembly line for the ceramic plastic patch type underground drip irrigation tape, automatic assembly of the ceramic plastic patch type underground drip irrigation tape can be achieved, manpower and material resources are saved, and uniformity of products can be guaranteed.

Owner:NORTHWEST A & F UNIV

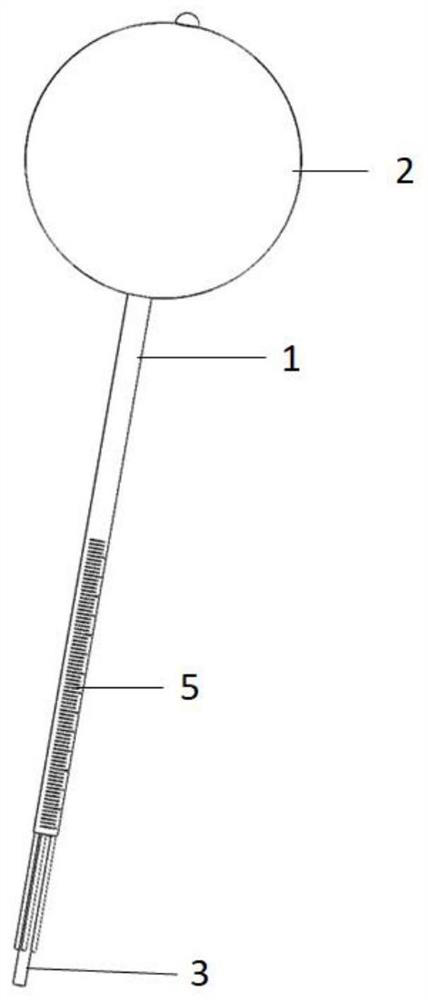

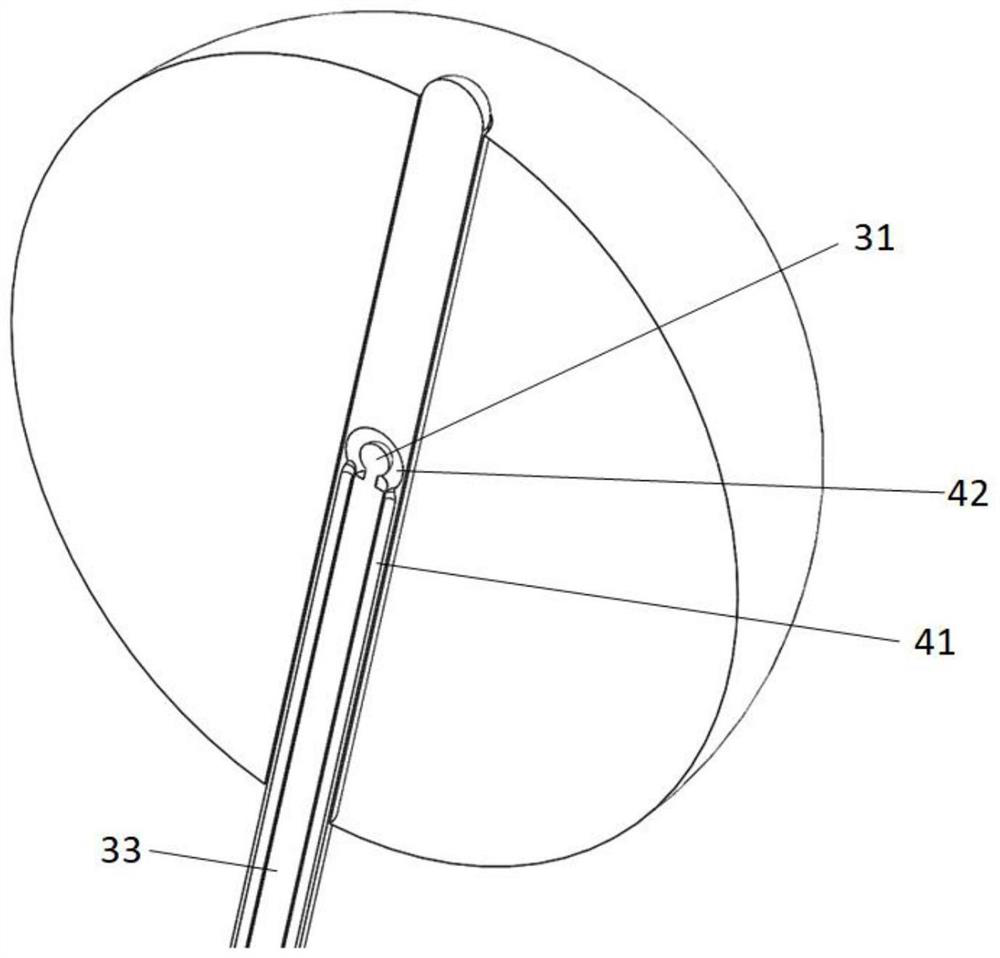

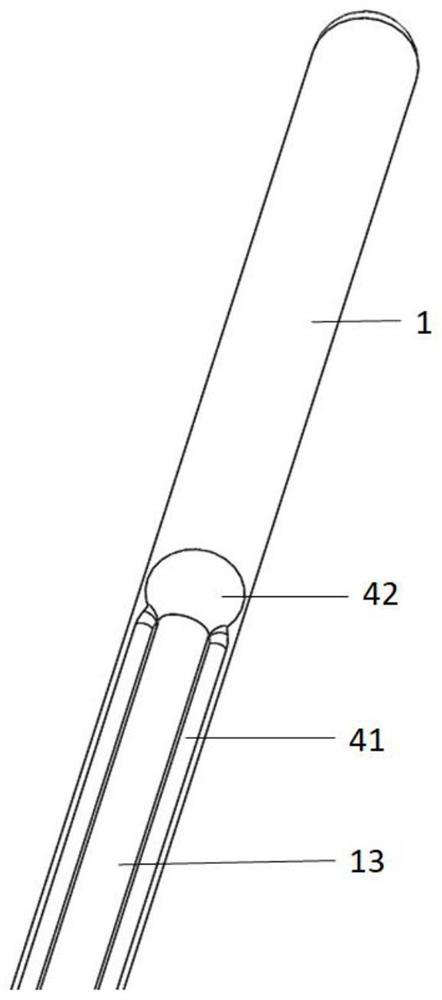

Photodynamic therapy instrument used in human body cavity and cavity organ

ActiveCN112402807AHomogenization guaranteedIncrease output powerLight therapyPhysicsBiomedical engineering

Owner:GENERAL HOSPITAL OF PLA

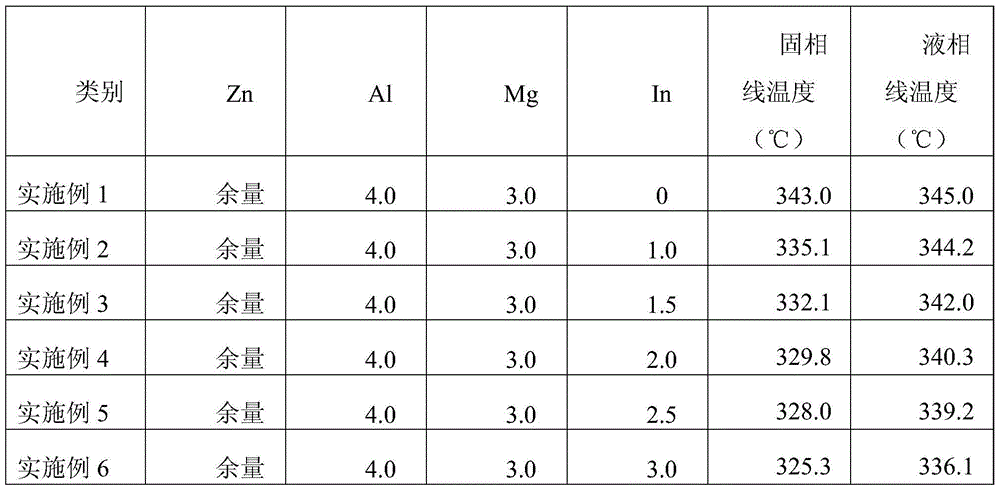

A kind of znalmgin high temperature lead-free solder

InactiveCN103934590BPrevent oxidationHomogenization guaranteedWelding/cutting media/materialsSoldering mediaMolten saltOxidation resistant

The invention relates to ZnAlMgIn high temperature lead-free solder, and belongs to the technical field of manufacturing lead-free solder for electronic first-grade encapsulation in the micro-electronic industry. The ZnAlMgIn high temperature lead-free solder comprises (by mass) 3.9 to 4.1 percent of Al, 2.4 to 3.1 percent of Mg, 0.5 to 3.0 percent of In, or 0.05 to 1.0 percent of P, and the balancing Zn. The ZnAlMgIn high temperature lead-free solder is smelted with a fused salt protection method, alloy burning losses are small, and texture is even. According to the ZnAlMgIn high temperature lead-free solder, on the basis of Zn4Al3Mg near-eutectic alloy, the elements of In and P are proposed to be added in a micro amount to lower the melting point of the alloy and improve the oxidation resistance and wettability of the alloy. The ZnAlMgIn high temperature lead-free solder is low in cost, free from toxic elements such as Pb, good in wettability, good in mechanical property and capable of meeting the requirement for replacing traditional high-lead solder.

Owner:BEIJING UNIV OF TECH

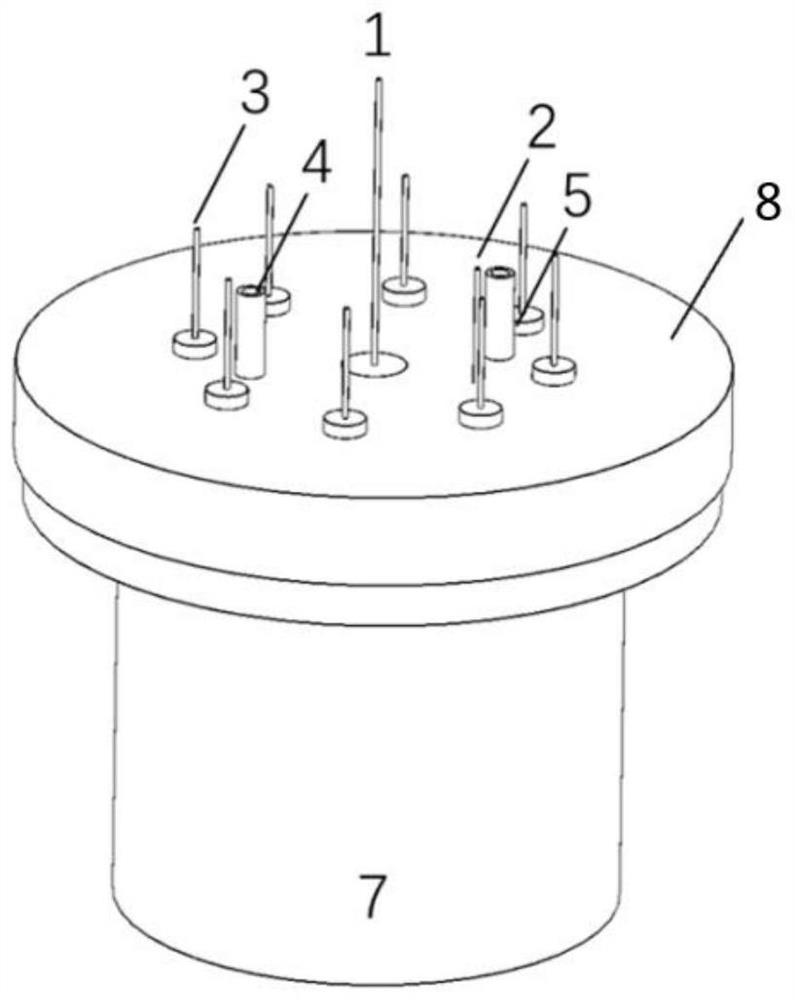

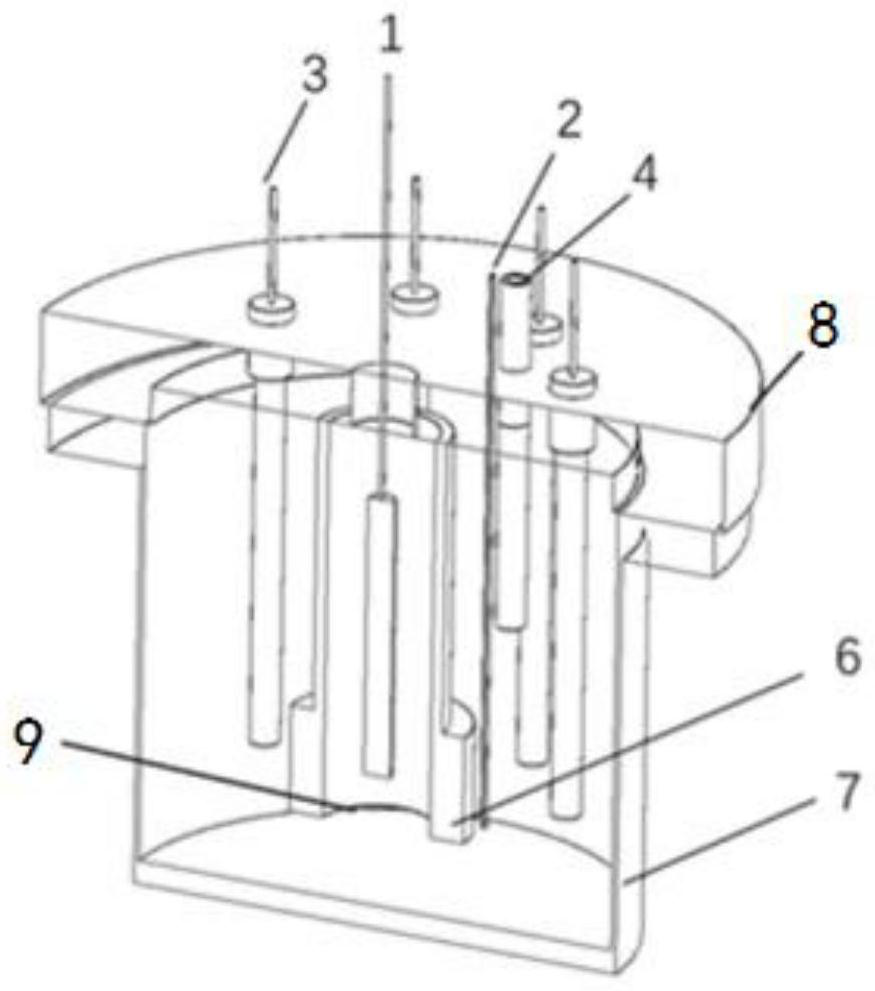

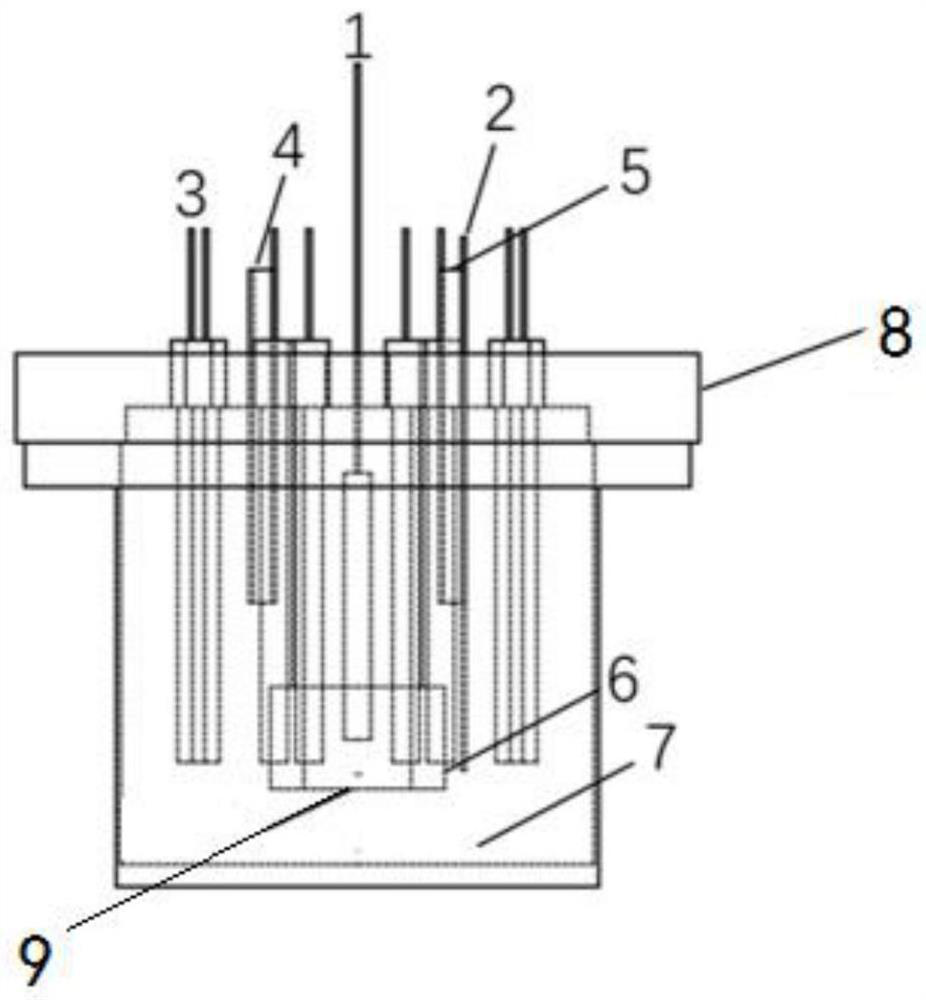

Multi-working-electrode sleeve double-chamber bioelectrochemical sewage treatment device

PendingCN114573092AImprove processing efficiencyImprove stabilityTreatment by combined electrochemical biological processesSustainable biological treatmentMechanical engineeringBioelectrochemistry

The invention discloses a multi-working-electrode sleeve double-chamber bioelectrochemical sewage treatment device which comprises a tank body and a sealing cover, a sleeve used for placing a counter electrode is arranged in the tank body, the sleeve is located at the center of the tank body, the upper end of the sleeve is connected with the sealing cover, an ion exchange membrane is arranged at the lower end of the sleeve, and a counter electrode chamber is arranged in the sleeve. A working electrode chamber is formed between the sleeve and the cell body; a liquid changing pipe and an air outlet pipe are arranged on the sealing cover and are respectively communicated with the working electrode chamber; working electrodes, a counter electrode and a reference electrode are arranged on the sealing cover in a penetrating manner, the counter electrode penetrates into the counter electrode chamber, and the multiple working electrodes are annularly distributed on the periphery of the counter electrode; the reference electrode is arranged close to the counter electrode, and the working electrode and the reference electrode both extend into the working electrode chamber; and the plurality of working electrodes are connected with the multi-channel potentiostat. The device can directionally enrich electrochemical active microorganisms, has the functions of efficiently growing a biological membrane and ensuring the uniformity of a microorganism growth environment, and improves the sewage treatment efficiency.

Owner:BEIJING UNIV OF TECH

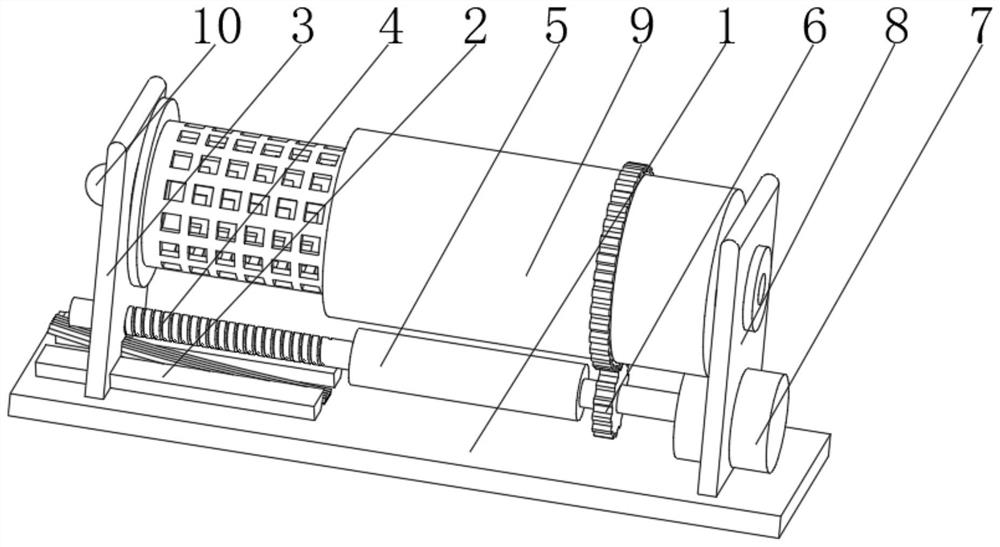

Diamond wire cutting machine and diamond wire replacing method thereof

The invention discloses a diamond wire cutting machine and a diamond wire replacing method thereof. The diamond wire cutting machine belongs to the technical field of wire cutting technology and solves the problems that in the prior art, a diamond wire cutting machine is poor in cutting continuity, uneven in wire mesh tension and poor in product quality. The diamond wire cutting machine comprises a paying-off wheel, a take-up wheel and main rollers; the input ends of the main rollers are sequentially connected to the paying-off wheel, a first winding displacement wheel and a plurality of guide wheels through diamond wires; the output ends of the main rollers are sequentially connected to the multiple guide wheels, a second winding displacement wheel and the take-up wheel through diamond wires; a plurality of groups of parallel diamond wires are wound around the surfaces of the main rollers; and the paying-off length of the paying-off wheel is at least 100m longer than the sum of the total length of the diamond wires wound around the lower surfaces of the main rollers in a cutting process state and the length of the maximum advancing wire amount. According to the diamond wire cutting machine and the diamond wire replacing method thereof, the connecting wire end is always located at the take-up wheel, and therefore the phenomenon that breakage occurs again can be avoided, the cutting continuity can be guaranteed, and the wire mesh cutting force can be homogenized by adopting a complex-wire cutting method.

Owner:江苏金晖光伏有限公司

Oil stir-frying equipment for oil expression

The invention relates to oil stir-frying equipment for oil expression. The equipment comprises a base, a limiting mechanism is fixedly connected to the left side of the top of the base, a reciprocating push plate is movably connected to the outer surface of the limiting mechanism, a threaded rod is in threaded connection with the portion, located above the limiting mechanism, of the reciprocating push plate, and a magnetic column is fixedly connected to the end, away from the reciprocating push plate, of the threaded rod, a driving gear is movably connected to the end, away from the threaded rod, of the magnetic column, a driving motor is rotatably connected to the side, away from the magnetic column, of the driving gear, a frying mechanism is rotatably connected to the top of the side, close to the reciprocating push plate, of a positioning mounting plate, and an indicator lamp is movably connected to the side, away from the frying mechanism, of the reciprocating push plate. The invention relates to the technical field of machinery. The electromagnetic effect is used for charging the indicator lamp, surrounding operators are prompted, the safety of the operators is ensured; the wind power intensity is increased and reduced through displacement changes, seed coats and oil plants are separated, and the subsequent processing quality of the oil plants is protected.

Owner:李和金

A Stretch Forming System for Acrylic Sheets

The invention discloses a stretching forming system for an acrylic sheet. The stretching forming system comprises a sheet feeding device, a clamping device and a sheet discharging device. The clamping device is located in a stretching forming area of the system. The sheet feeding device and the sheet discharging device are located on the two sides of the stretching forming area. The sheet feeding device is used for moving the sheet to the clamping device. The sheet discharging device is used for moving the treated sheet out of the clamping device. The clamping device comprises a drive unit and a plurality of clamping die sets. The angles and distances between the clamping die sets are different. The clamping die sets are used for fixing the sheet. The drive unit is used for driving the clamping die sets. Automatic control operation is adopted in the stretching forming system, time and labor are saved, the workload of workers is relieved, and the work efficiency is improved; a heating device is arranged, and it can be guaranteed that in the conveying process, the temperature of the sheet is not excessively consumed; and heating uniformity of the stretched sheet can be effectively guaranteed.

Owner:AI CAN SEIK MACHINERY EQUIP JIANGSU CO LTD

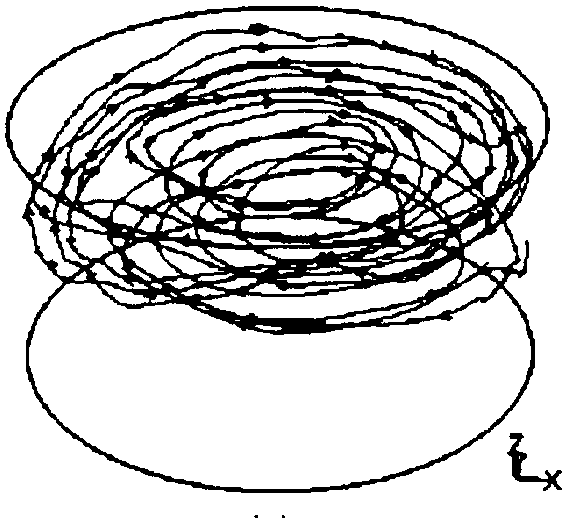

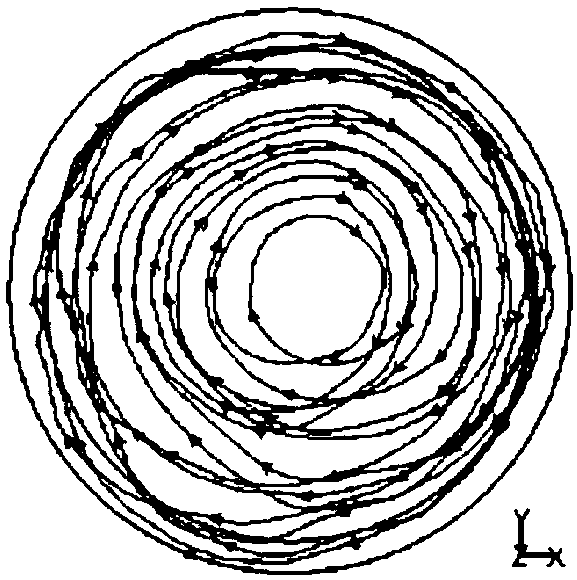

Aluminum system deoxidizing and carburizing alloy for converters, and manufacturing method thereof

The invention discloses an aluminum system deoxidizing and carburizing alloy for converters, and a manufacturing method thereof. The components of the alloy include, by weight percentage, 40-50% of aluminum, 18-22% of carbon, and 28-48% of iron; and the particle size of the alloy is 30-50 mm. During manufacturing, raw materials use aluminum ingots, a carburant, and industrial pure iron with particle sizes of 5-12 mm; the aluminum ingots can be melted in an induction furnace crucible, the carburant and the industrial pure iron can be added according to the ratio of finished alloy content, spiral electromagnetic stirring can be simultaneously applied, the current of the spiral electromagnetic stirring is 150-250 A, the frequency is 2.5-4 Hz, and the spiral electromagnetic stirring can be stopped after the alloy is completely solidified; and a crusher can be utilized to crush the alloy into small pieces with the particle sizes of 30-50 mm, and packaging can be performed. A deoxidizer andthe carburant can be combined; and the uniformization of the alloy can be guaranteed through the spiral electromagnetic stirring, so that the disadvantages of floating and uneasy melting of the carburant after addition during steel-making can be avoided, rapid recarburization of molten steel can be achieved, and needs of carbon steel straight up temperatures in a converter can be met.

Owner:ANGANG STEEL CO LTD

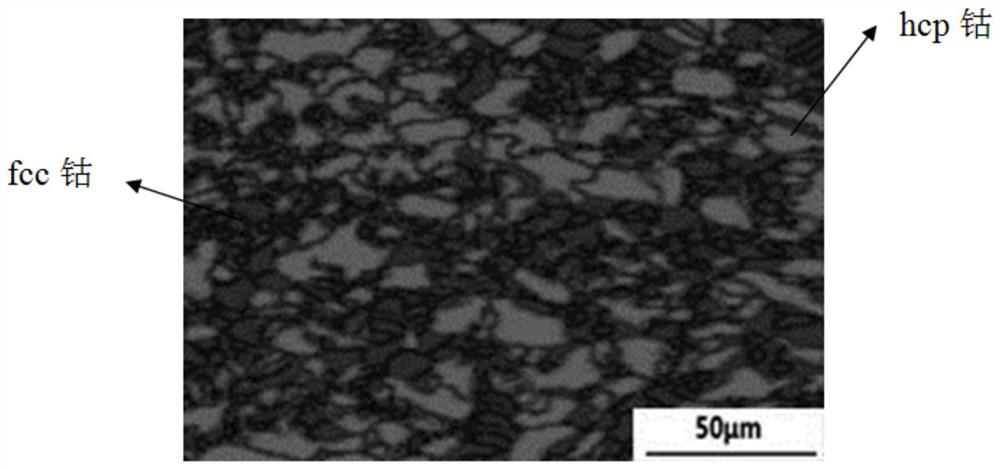

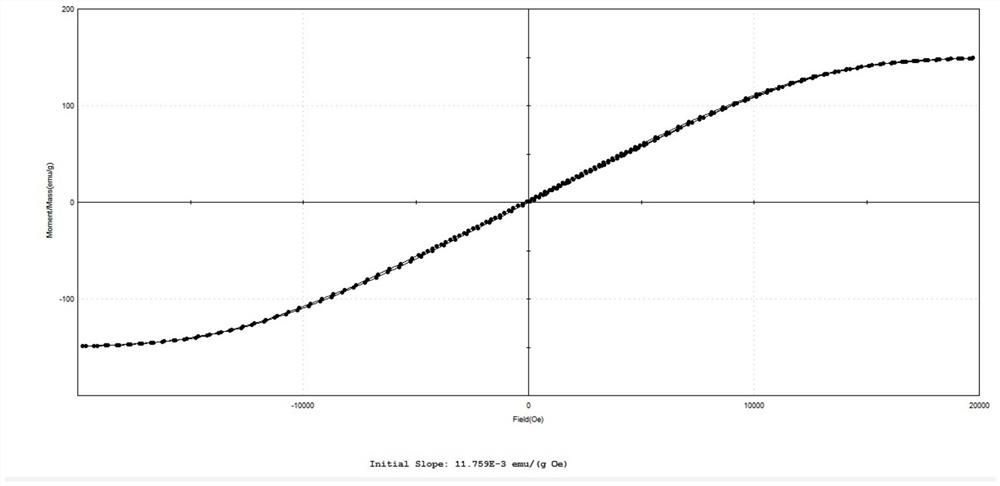

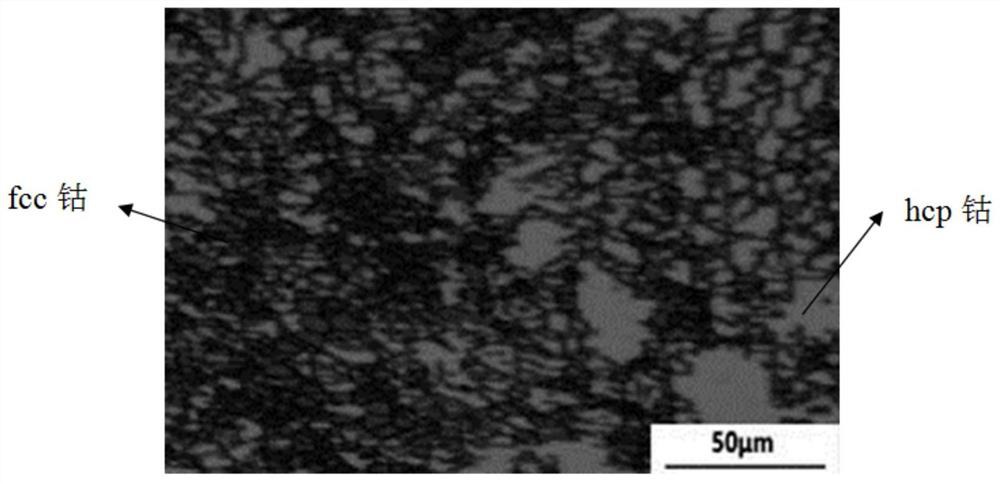

A preparation method and application of ultra-high-purity cobalt plate with controllable structure

ActiveCN110923645BEliminate defects such as shrinkage and porosityHomogenization guaranteedVacuum evaporation coatingSputtering coatingManufactured materialCobalt

The invention discloses a preparation method and application of ultra-high-purity cobalt plate with controllable structure. The preparation method includes: cold press forming, high vacuum vertical melting, high vacuum electron beam melting furnace, and stainless steel sheath in argon chamber Three-dimensional high-speed isothermal hot forging with coordinated control of pass, forging deformation and total deformation, variable angle cross-controlled rolling and heat treatment, turning processing, packaging and other steps, the purity of the prepared ultra-high-purity cobalt is ≥99.995%, the average The grain size is 10-40 μm, the content of β-Co with fcc structure in the plate exceeds 50%, the magnetic permeability is greater than 70%, and the non-uniformity of magnetic permeability is less than 1%. The preparation method designed in the present invention can effectively control the grain size and grain size distribution of the finished product, and regulate the tissue distribution of the finished product, which provides raw material guarantee for its use as a high-quality target.

Owner:CENT SOUTH UNIV

A clamping device for acrylic sheet

The invention discloses a clamping device for acrylic sheets. The clamping device comprises a driving unit and multiple clamping modules; the multiple clamping modules are different in angle and gap, and are used for fixing the sheets; and the driving unit is used for driving the clamping modules. The clamping device automatically sets different pressing forces according to the thickness change of the sheets, prevents the slip falling or pressure blasting phenomenon in the sheet clamping process, relieves the workload of workers, is convenient for installation and disassembly of the sheets, improves the working efficiency, is provided with an auxiliary heating device capable of realizing the temperature adjustment from normal temperature to 450 DEG C, is wide in adjusting range, and can effectively guarantee the heating uniformity of stretched sheets.

Owner:AI CAN SEIK MACHINERY EQUIP JIANGSU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com