Patents

Literature

78results about How to "Small resistance to deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

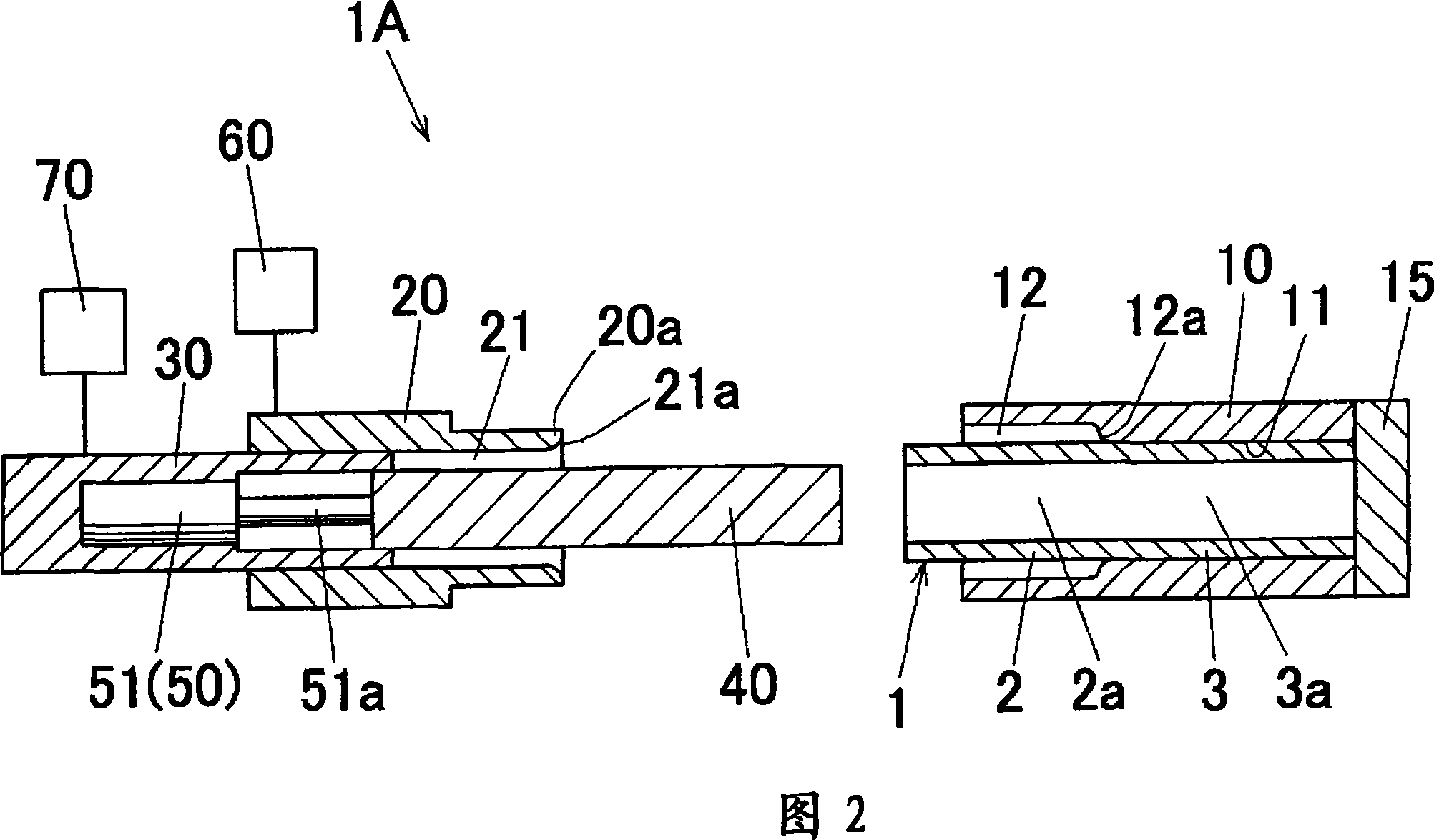

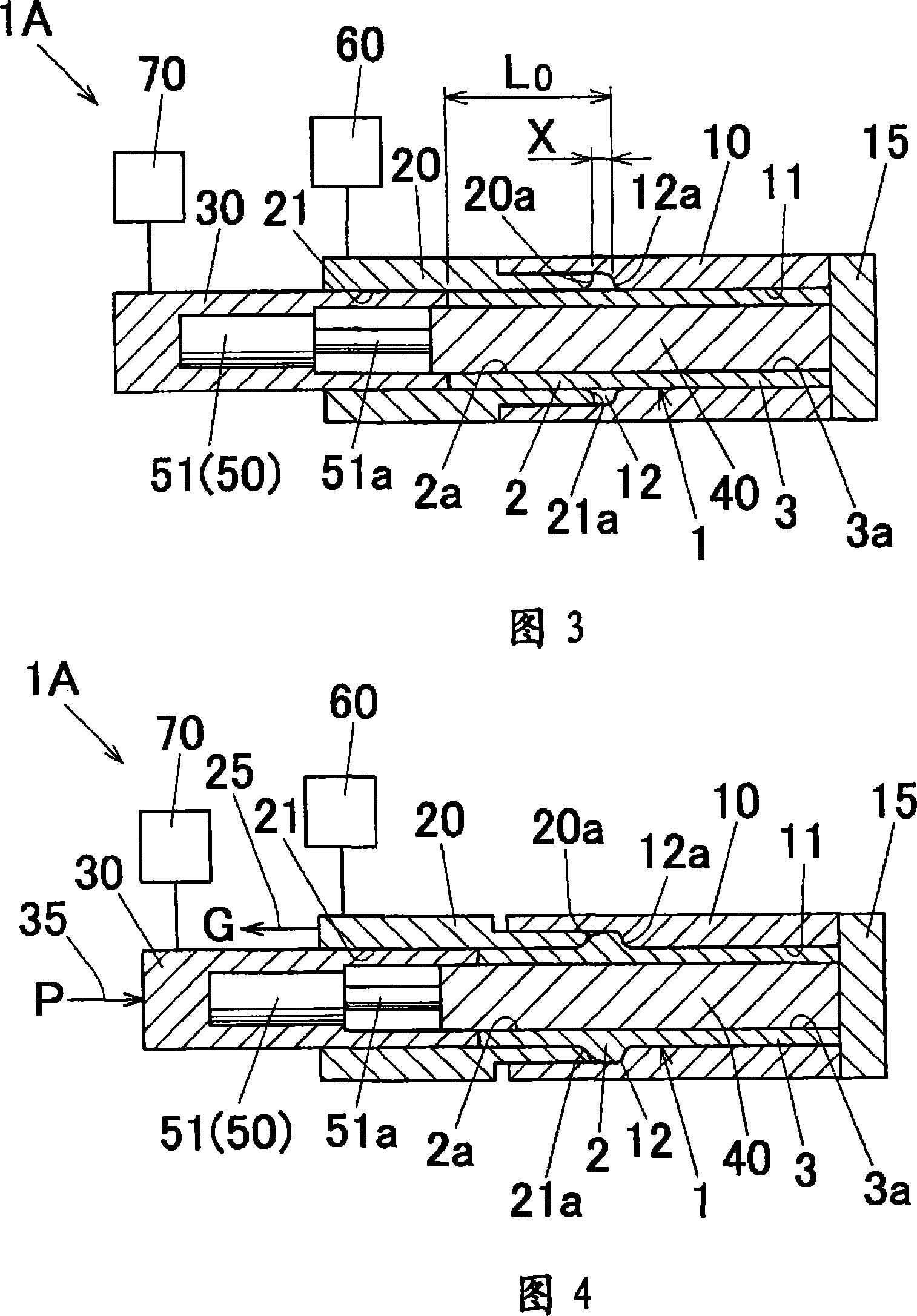

Upsetting method and upsetting apparatus

InactiveCN101111329AEfficient preparationReliable shapeMetal-working apparatusEngine componentsDistal portionBiomedical engineering

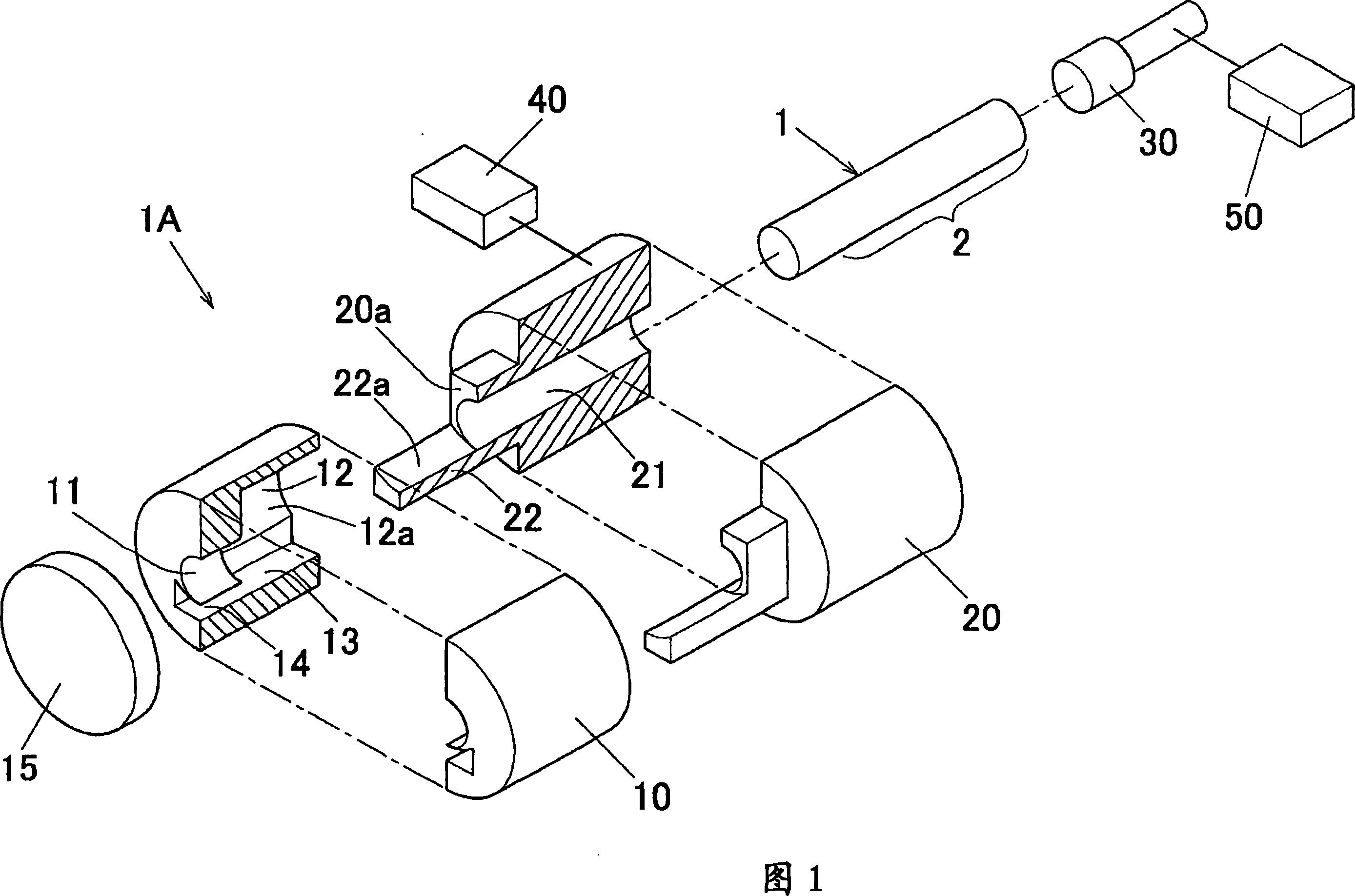

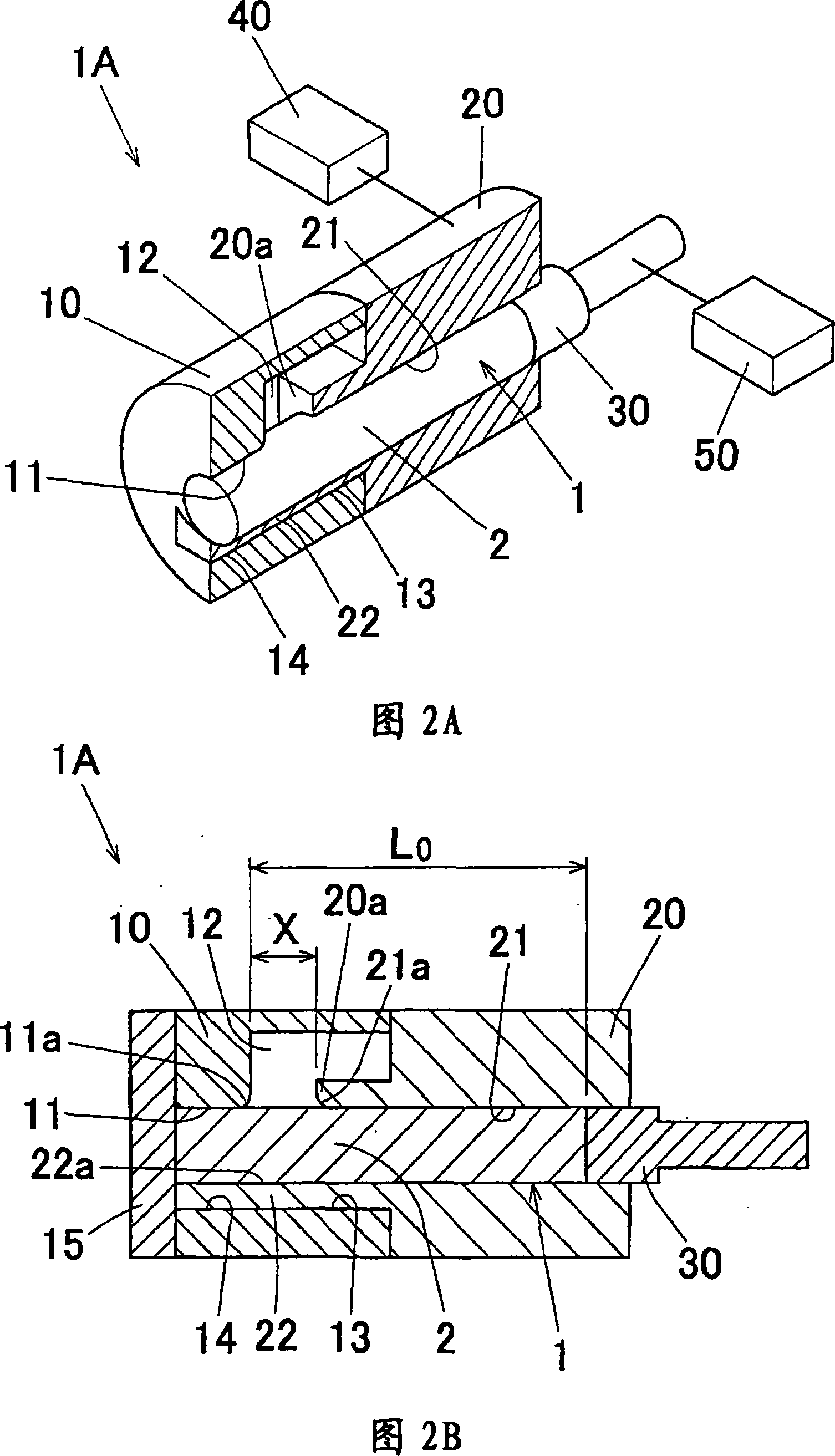

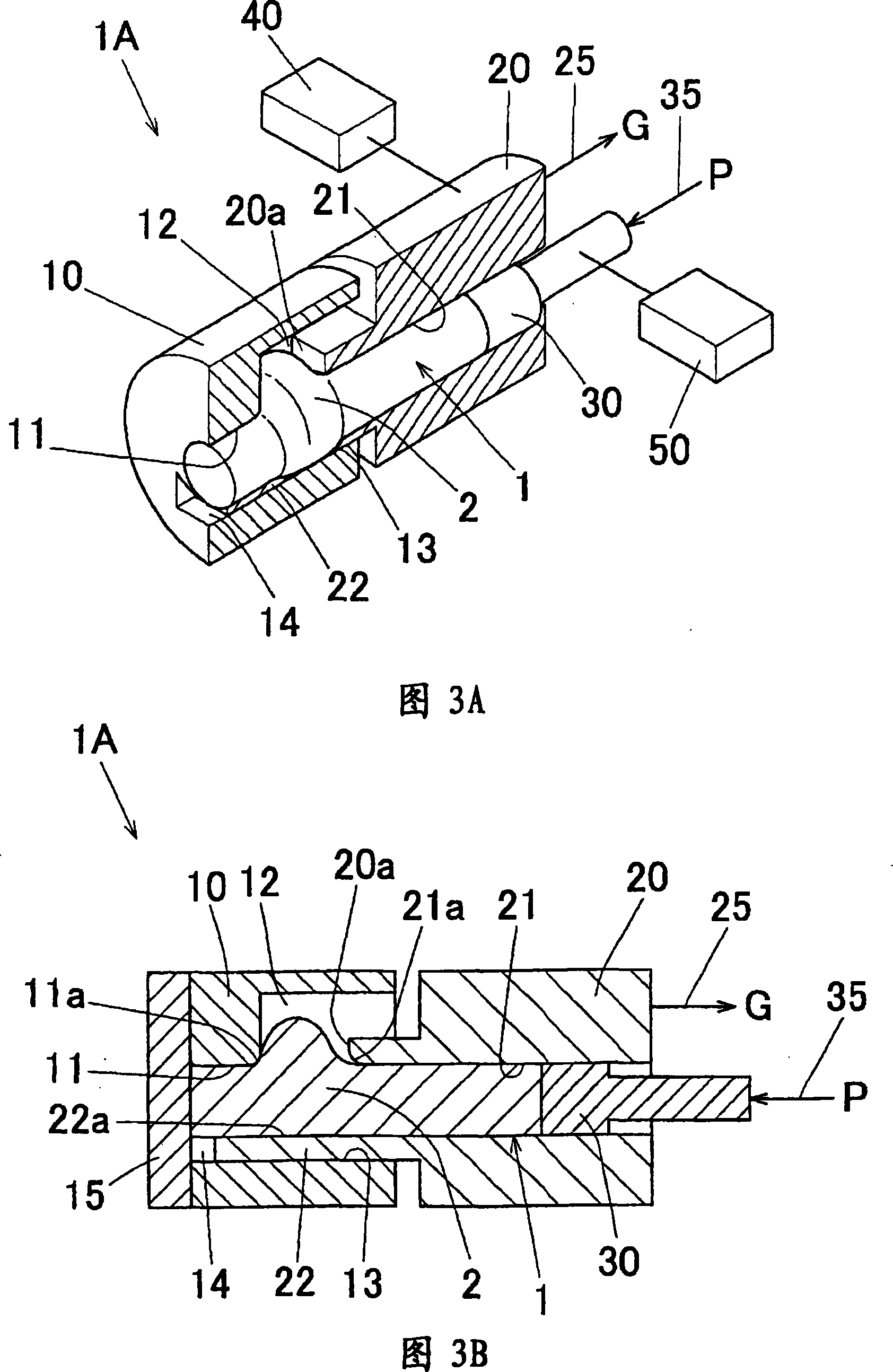

The present invention provides an upsetting method capable of unevenly expanding the diameter of a portion to be expanded in the circumferential direction of a blank. A guide body (20) having an insertion hole (21) through which the planned diameter expansion portion (2) of the holding blank (1) is inserted in a vertical bending preventing state is prepared. A protruding piece portion (22) for suppressing diameter expansion that protrudes in the axial direction of the guide body (20) is integrally provided on a part of the front end portion (20a) of the guide body (20). The predetermined diameter expansion portion (2) of the blank (1) fixed in the stationary mold (10) is inserted and held in the insertion hole (21) of the guide body (20). Next, while moving the punch (30) and pressing the portion (2) of the blank (1) to be enlarged by the punch (30) in the axial direction, the guide body (20) is directed toward the punch (30) is moved in the opposite direction of the moving direction, whereby the planned diameter expansion portion (2) of the blank (1) exposed between the front end portion (20a) of the guide body (20) and the fixed mold (10), The diameter expansion is performed in a state where the diameter expansion is suppressed for the contact portion of the planned diameter expansion portion (2) with the protruding piece portion (22).

Owner:SHOWA DENKO KK

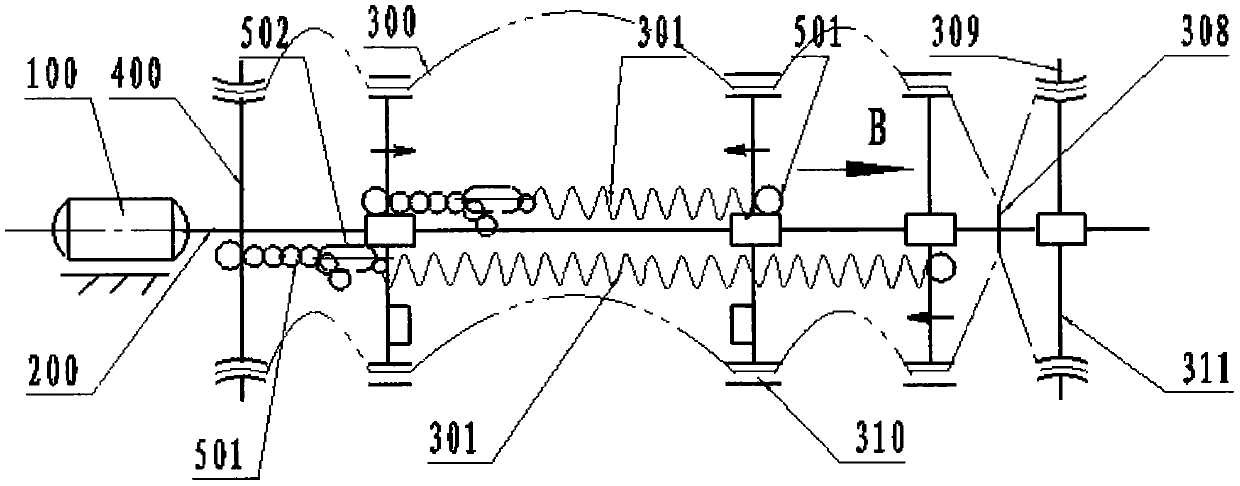

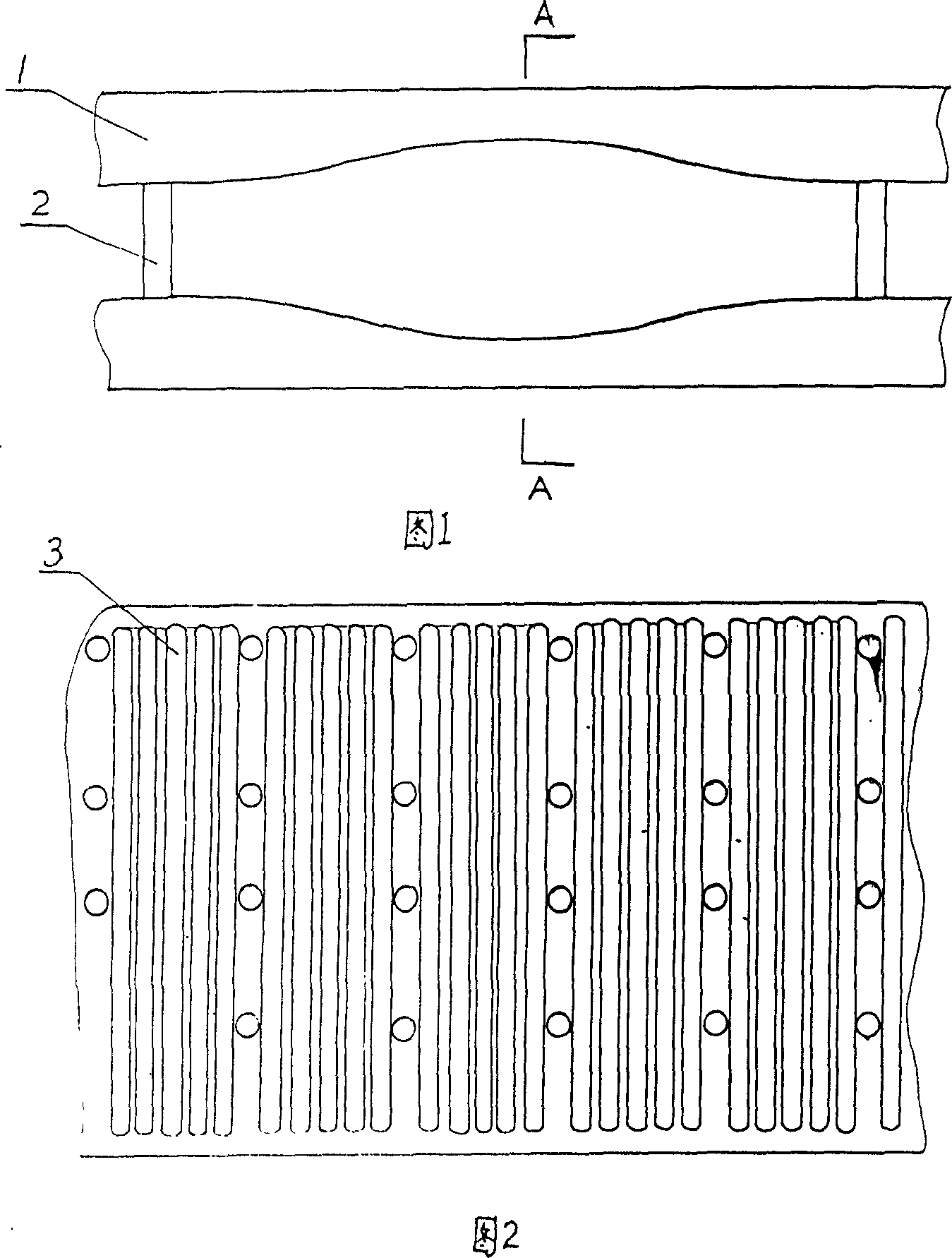

Hot impact extrusion process and device for large annular barrel type forged piece

ActiveCN101537438ASolve process problemsImprove uniformityExtrusion containersRams/plungersImpact extrusionLubricant

The invention relates to a hot impact extrusion process and a device for a large annular barrel type forged piece, which belongs to the technical field of hot forming of a large hollow forged piece. The process comprises the following steps: firstly, an extrusion cushion is placed on a press platform; secondly, the blanks to be heated are put on the extrusion cushion; thirdly, an extrusion cylinder is sleeved on the extrusion cushion; fourthly, a profiling punch is applied with force so that a mold cavity is filled with the blanks; fifthly, the lubricant is added; sixthly, a solid punch is applied with force so that the blanks are extruded to the set position of the process; seventhly, a hollow punch is sleeved on the solid punch and applied with pressure, so that the blanks are extruded to the set positioned of the process; eighthly, the extrusion cushion is taken out and a bottom flushing drain cap is replaced; and ninthly, the core material at the bottom is flushed out through the hollow punch. The devices required for finishing the process comprise an extrusion cylinder, an extrusion cushion, a profiling punch, a solid punch, a hollow punch, a solid extension rod, a hollow extension rod and a bottom flushing drain cap. The invention solves the difficult problems existing in the large annular barrel forged piece of long process flow of free forging, more forging times and large reverse extrusion molding for die forging and improves the utilization ratio of the material and the molding quality of the forged piece.

Owner:NANJING DEV ADVANCED MFG

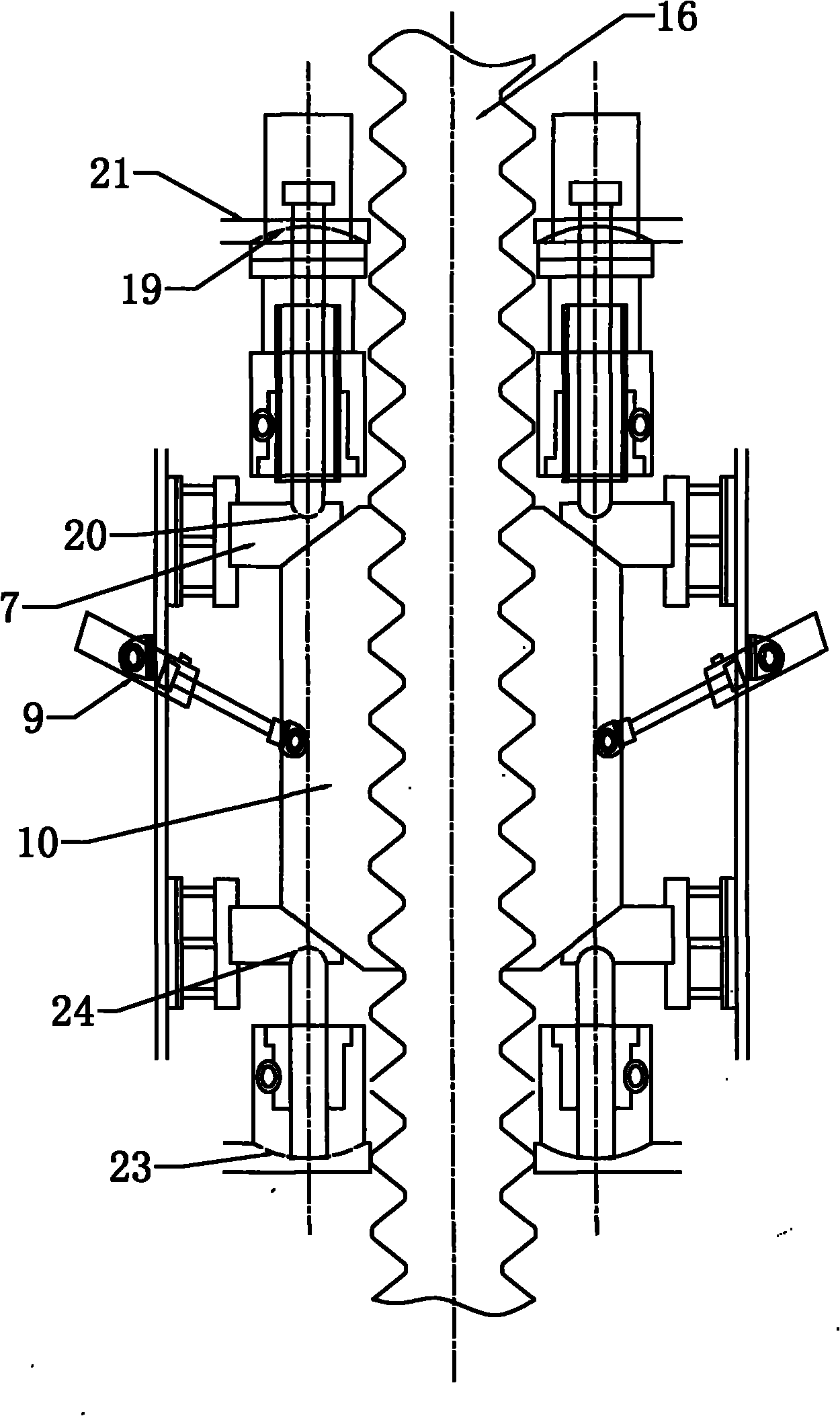

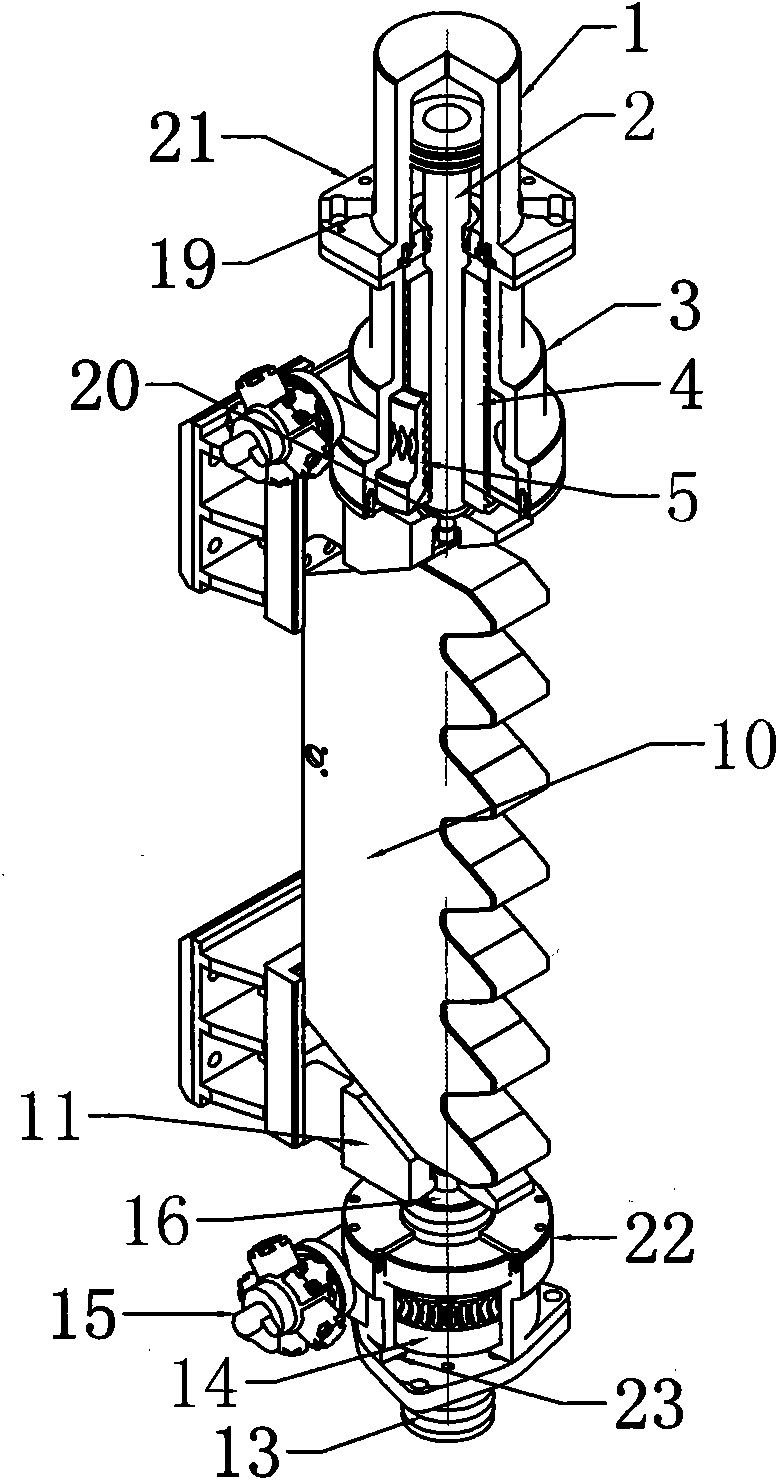

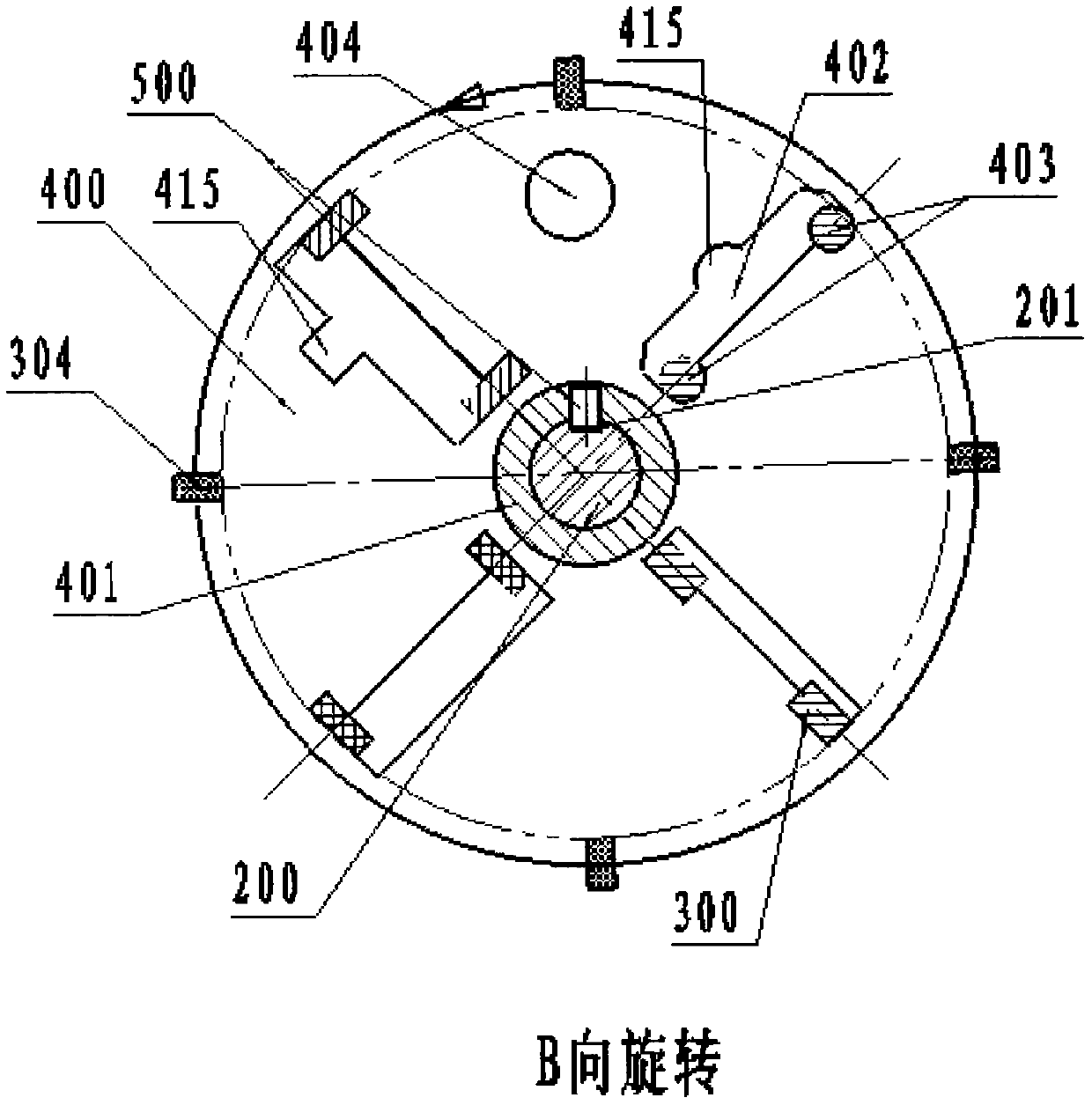

Locking device with double spherical hinge bearing structure for pile legs of self-elevating drilling platform

ActiveCN101871208AEliminate bad effectsEliminate binding forceArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention provides a locking device with hinge with a double spherical hinge bearing structure for pile legs of a self-elevating drilling platform, which comprises a top locking assembly, a bottom locking assembly and a locking block, wherein the locking block is tabled on a pile leg rack through a cog, and the top locking assembly and the bottom locking assembly are respectively assembled on bearing platforms at the upper side and the lower side of the locking block and are respectively contacted with the locking block through a top wedge block and a bottom wedge block; and a top upper spherical hinge, a top lower spherical hinge, a bottom upper spherical hinge and a bottom lower spherical hinge are respectively arranged at the contact places of the top locking assembly and the bottom locking assembly as well as the bearing platform, the top wedge block and the bottom wedge block. With the scheme, the invention not only ensures the effective locking of the platform, but also solves the problem that the locking device is difficult to unlock; and each locking device is uniformly loaded after locking, and the load smoothly transfer between a lifting device and the locking device, thereby greatly saving the operating time of the staff.

Owner:KEEN OFFSHORE ENG CO LTD +1

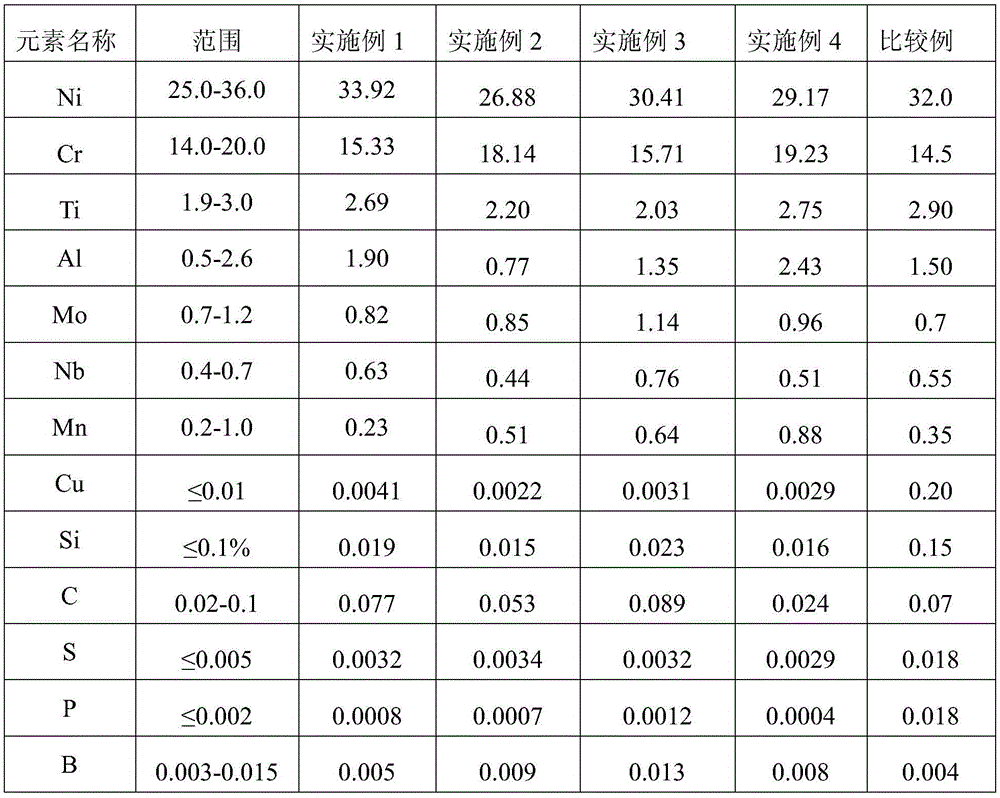

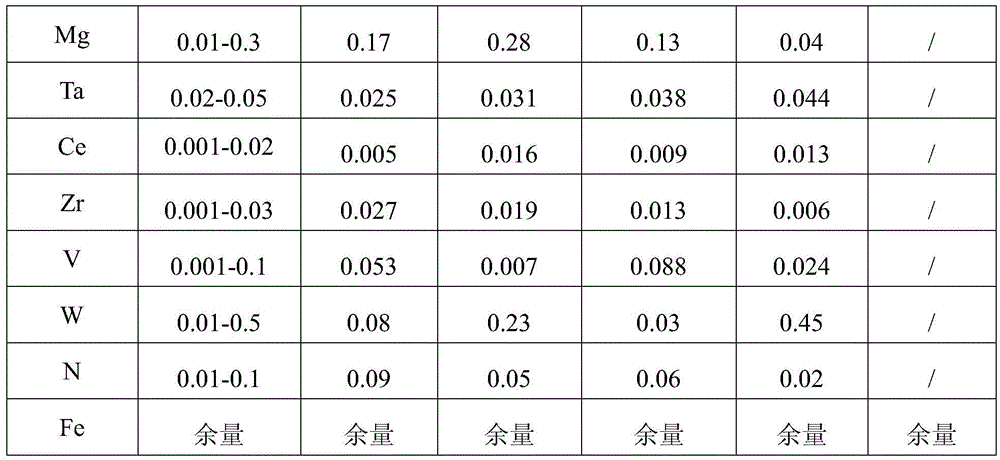

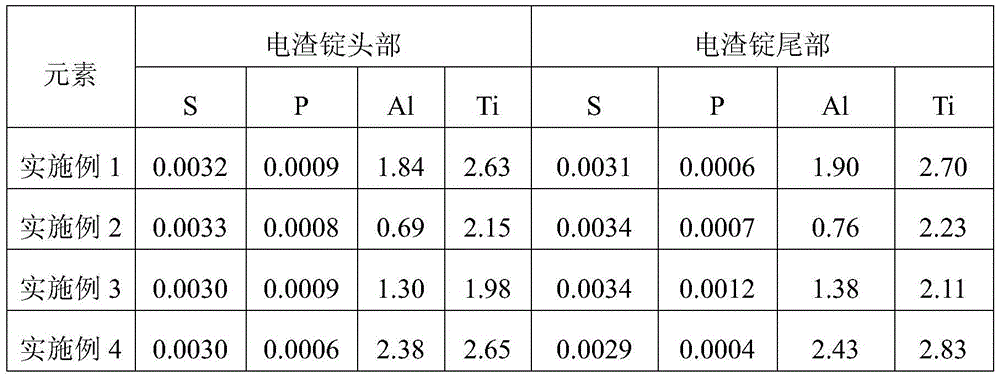

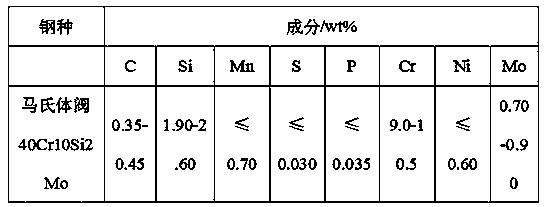

Micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and preparation method

The invention relates to a micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and a preparation method. The material comprises elements such as Ni, Cr, Ti, Al, Mo, Nb, Mn, C, B, Mg, Ta, Ce, Zr, V, W, N, Fe and the like. The material can be used in a working environment with a high temperature, high load, strong oxidization and strong corrosion, is low in nickel content, has good tensile strength, good endurance strength, good fatigue strength and excellent oxidization resistance, good corrosion resistance and good resistance to fuel gas, and can be used for preparing a gas inlet valve and a gas outlet valve of a medium-high-load engine.

Owner:CHONGQING MATERIALS RES INST

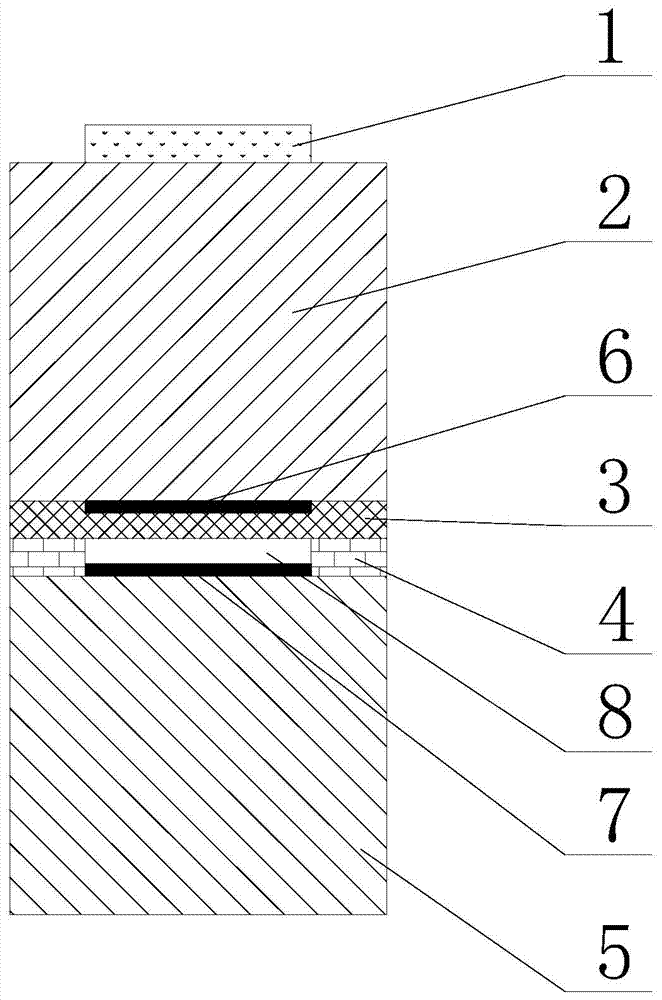

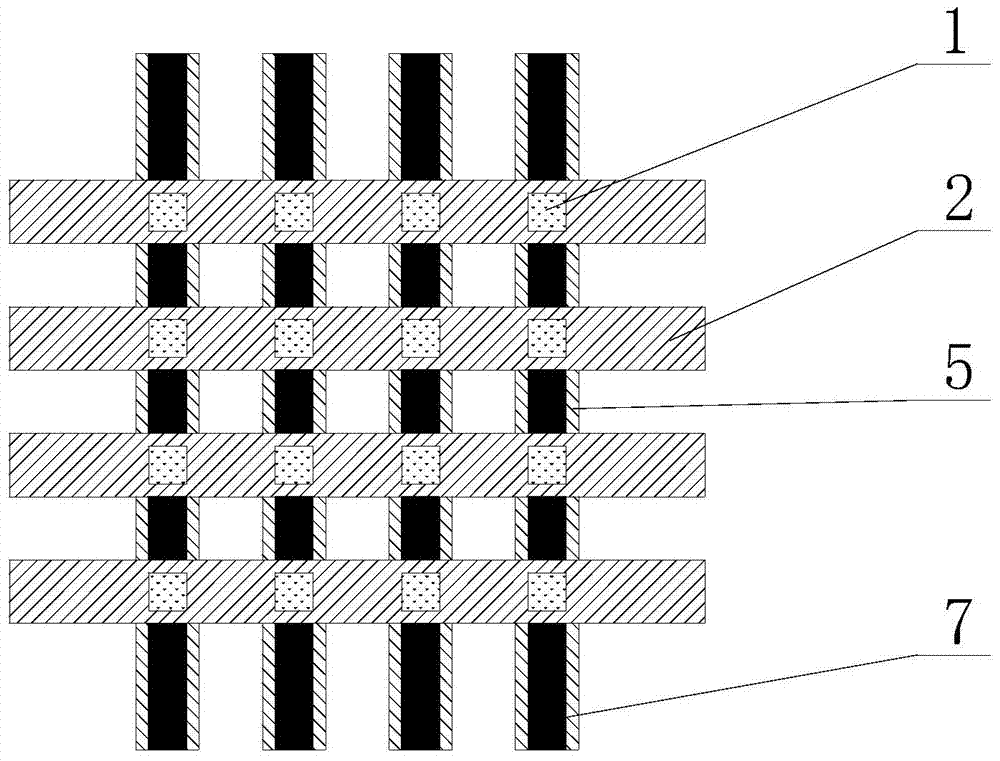

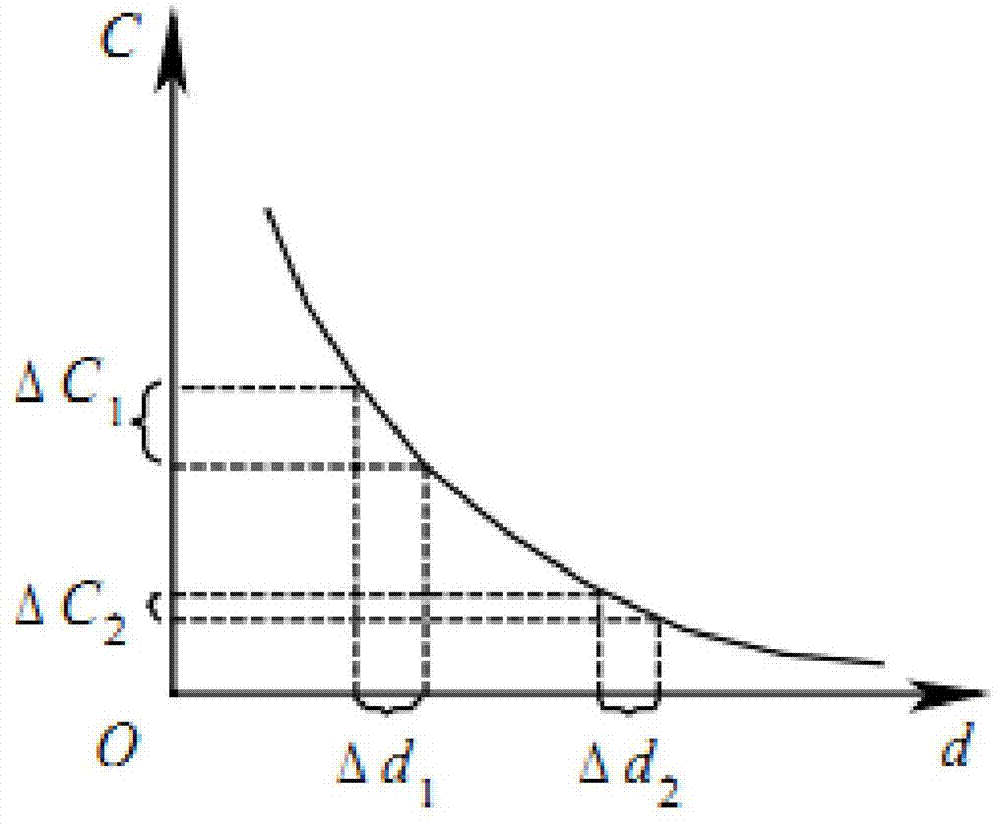

Flexible capacitive pressure sensing device

InactiveCN104266788AImprove conductivityImprove flexibilityForce measurementFluid pressure measurement using capacitance variationPressure senseEngineering

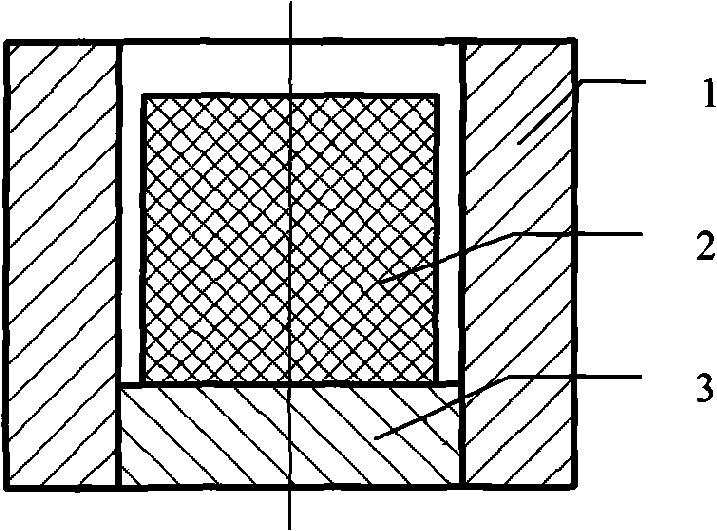

The invention relates to a flexible capacitive pressure sensing device. A plurality of strip-shaped lower counter electrodes are arranged in the horizontally longitudinal direction below a plurality of strip-shaped upper counter electrodes arranged in the horizontally transverse direction, and corresponding to all the cross areas of the upper counter electrodes and the lower counter electrodes, pressure acting areas are connected to the centers of the upper surfaces of the upper counter electrodes in a pasted mode; the center areas of the lower surfaces of the upper counter electrodes are plated with a silver coating serving as an upper electrode; an insulating protection layer corresponding to cross areas in size is arranged below the upper electrode; the center areas of the upper surfaces of the lower counter electrodes are plated with a sliver coating serving as a lower electrode; two pad strips are arranged on the two sides of the lower electrode. Each cross area forms a capacitive sensor, the multiple capacitive sensors form a capacitive sensing array, and the multiple capacitive sensing arrays form the large-area flexible capacitive pressure sensing device. The capacitive sensors are good in elasticity and can be fully attached to non-planar objects, and therefore the sensory sensitivity and the compression resilience of the capacitive sensors can be guaranteed; besides, the flexible capacitive pressure sensing device can perform large-area measurement on various stress surfaces.

Owner:SHANGHAI UNIV OF ENG SCI

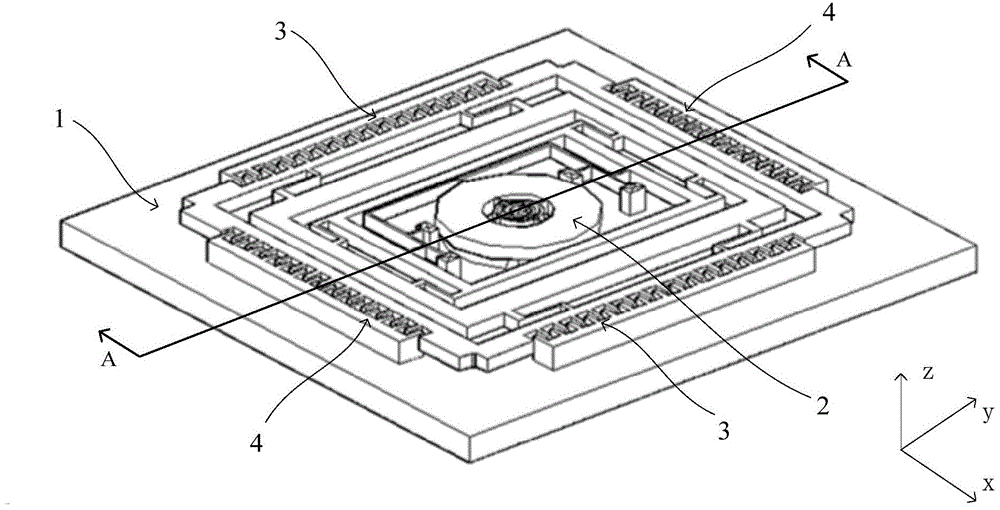

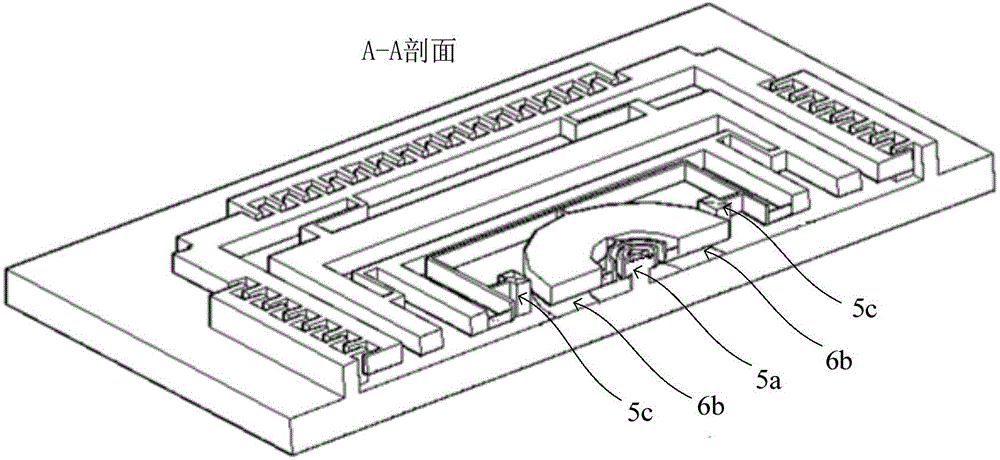

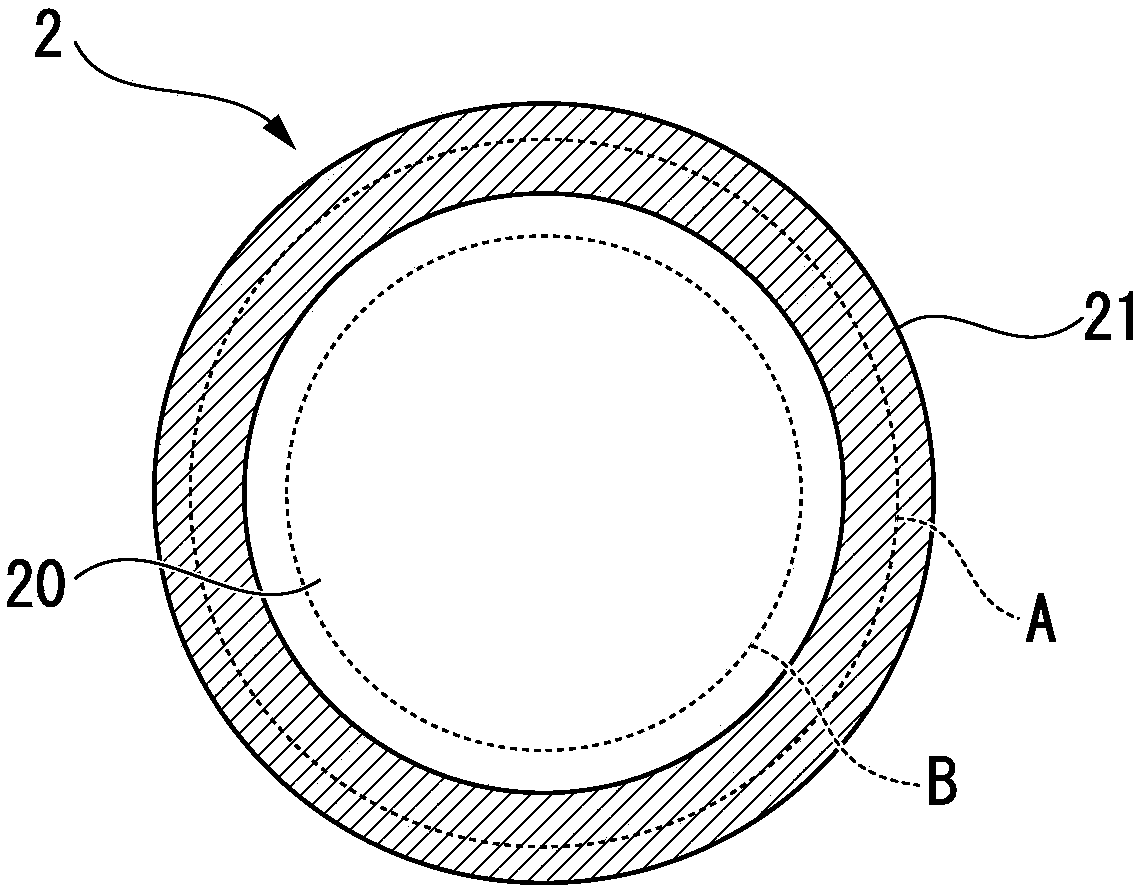

Micro-electromechanical deformable structure and triaxial multi-degree of freedom micro-electromechanical gyroscope

ActiveCN104406579ASmall resistance to deformationLarge deformation spaceSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesDifferential capacitanceCapacitance

The invention relates to a triaxial multi-degree of freedom micro-electromechanical gyroscope. The triaxial multi-degree of freedom micro-electromechanical gyroscope comprises an inner framework, a middle framework, an outer framework, a linkage part positioned in the inner framework, an annular detection capacitor positioned in the center, an annular polar plate of which outer edge of the annular polar plate is connected with the linkage part, two groups of driving capacitors and two groups of second detection capacitors, wherein the two groups of driving capacitors are symmetrically distributed on the two sides, parallel to an x axis, of the outer framework; the two groups of second detection capacitors are symmetrically distributed on the two sides, parallel to a y axis, of the outer framework. The triaxial multi-degree of freedom micro-electromechanical gyroscope adopts a single structure design, capacitance type electrostatic driving and differential capacitance detection; the driving mode is simple; as the structure is compact, the gyroscope size is reduced; the gyroscope is suitable for massive production, small errors are produced under the influence of temperatures and the processing technology, and great measurement precision and sensitivity can be realized.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

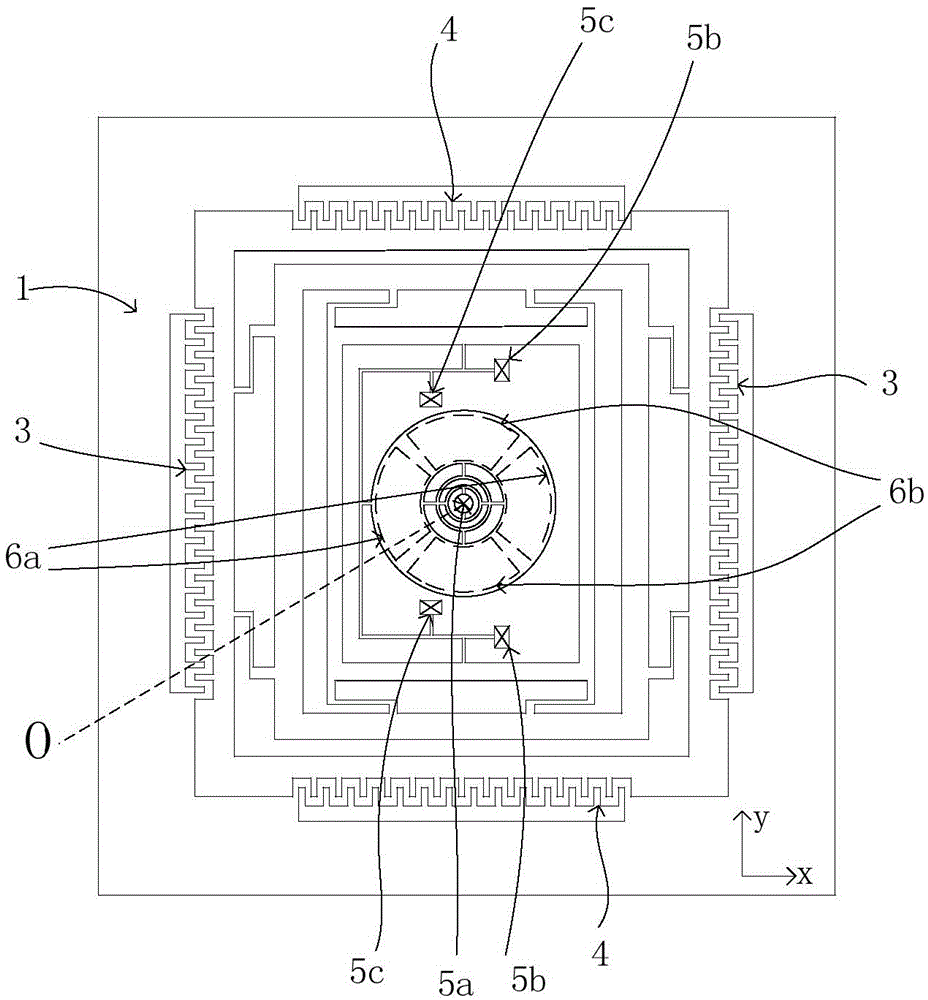

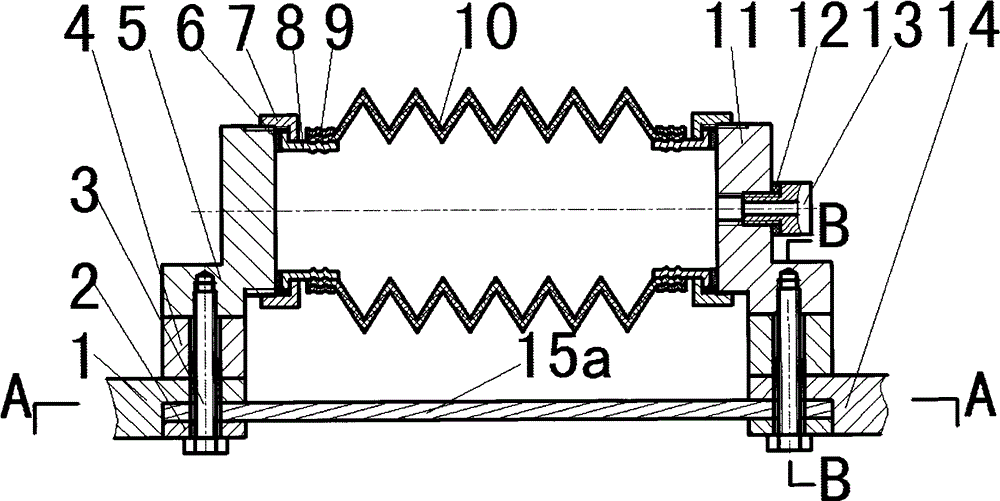

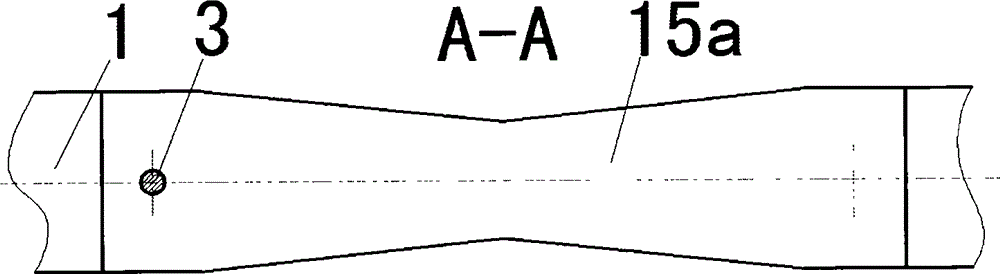

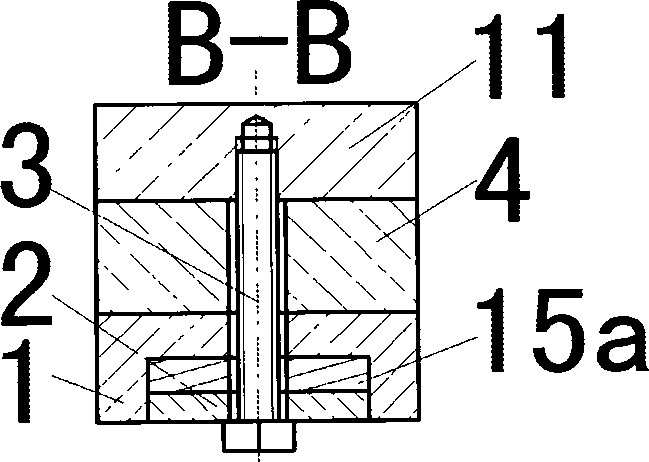

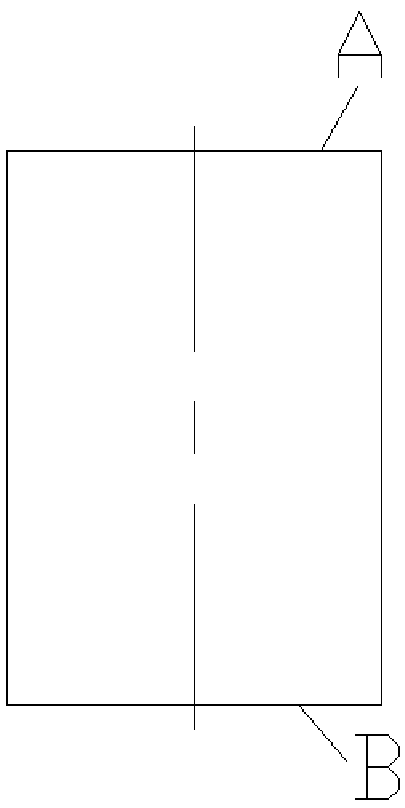

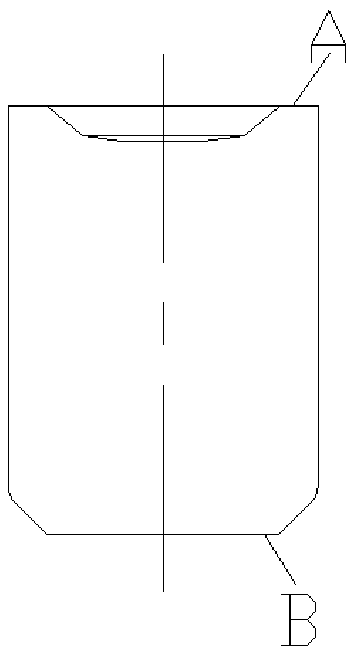

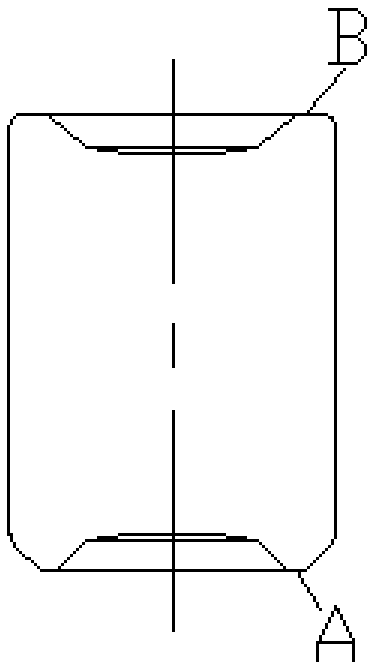

Square cell case forming method

ActiveCN104942117ASmall resistance to deformationGood formabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsAlloyMetallurgy

The invention provides a square cell case forming method capable of efficiently forming an aluminum alloy plate into a high flatness square cell case with high precision; the method comprises the following steps: drawing the aluminum alloy plate so as to form a first square cylinder (2), wherein a part of the periphery of a side wall portion (2a) of the first square cylinder forms an oblique surface (2f); the bottom (2d) of the first square cylinder (2) serves as the bottom of the cell case; continuously drawing or fine processing so as to form the final square cell case, wherein the plate thickness of the side wall becomes under 60% of that of the aluminum alloy plate.

Owner:KOBE STEEL LTD

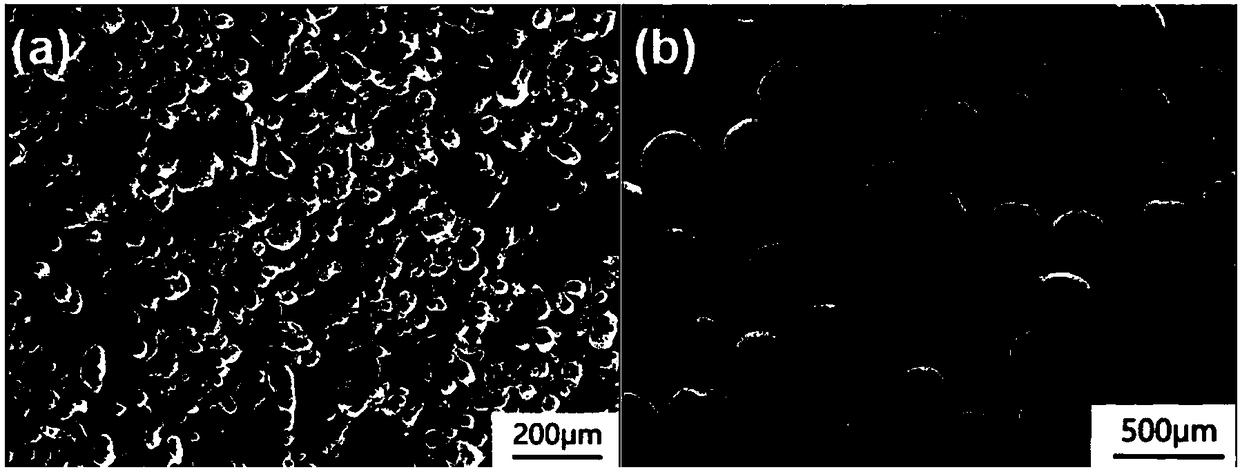

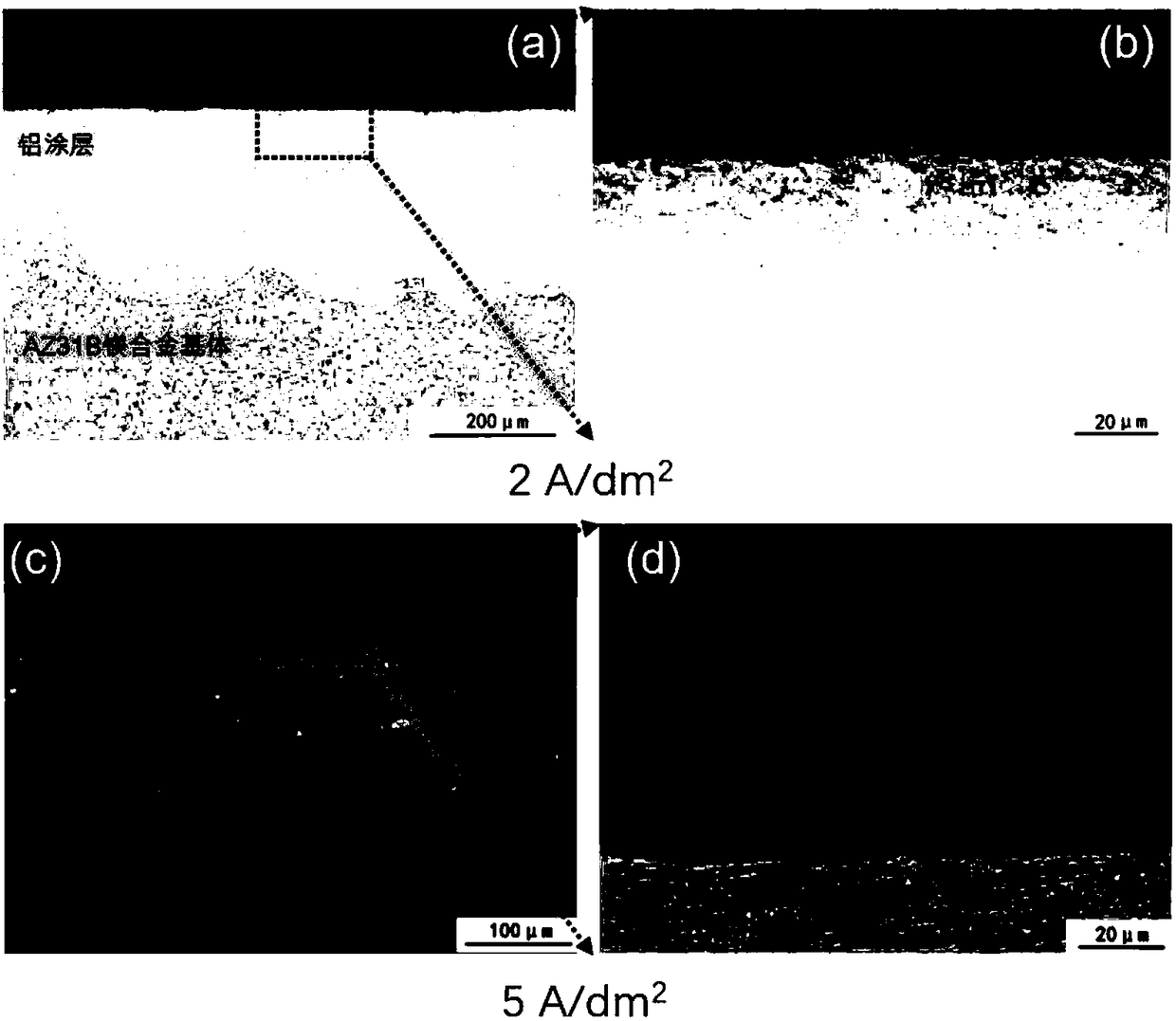

Anticorrosive and wear-resistant low density composite structure coating on surface of magnesium alloy, and production method thereof

PendingCN108559987AAchieve corrosiveAchieve protectionAnodisationSuperimposed coating processIsolation effectWear resistant

The invention discloses an anticorrosive and wear-resistant low density composite structure coating on the surface of a magnesium alloy, and a production method thereof. The composite structure coating comprises an anticorrosive bottom layer and a wear-resistant top layer which are sequentially arranged on the surface of the magnesium alloy from bottom to top, the anticorrosive bottom layer is a high-density aluminum layer or aluminum alloy layer, and the wear-resistant top layer is a high-hardness alumina ceramic layer. The high wear resistance of the surface of the magnesium alloy is realized by means of the high-hardness alumina top layer, and the great improvement of the corrosion resistance of the magnesium alloy substrate is realized by the physical isolation effect of the high-density aluminum or aluminum alloy coating and the top alumina layer to a corrosion medium in order to finally achieve the corrosion and wearing dual protection effects of the magnesium alloy substrate. The production method makes the low-cost production of a magnesium alloy protection layer with anticorrosion and wear resistance dual characteristics become possible, and the residual compressive stressin the aluminum and aluminum alloy coating can delay the generation and cracking of cracks under a periodical load condition and improve the fatigue life of the magnesium alloy, so the application field of the magnesium alloy is significantly expanded.

Owner:XI AN JIAOTONG UNIV

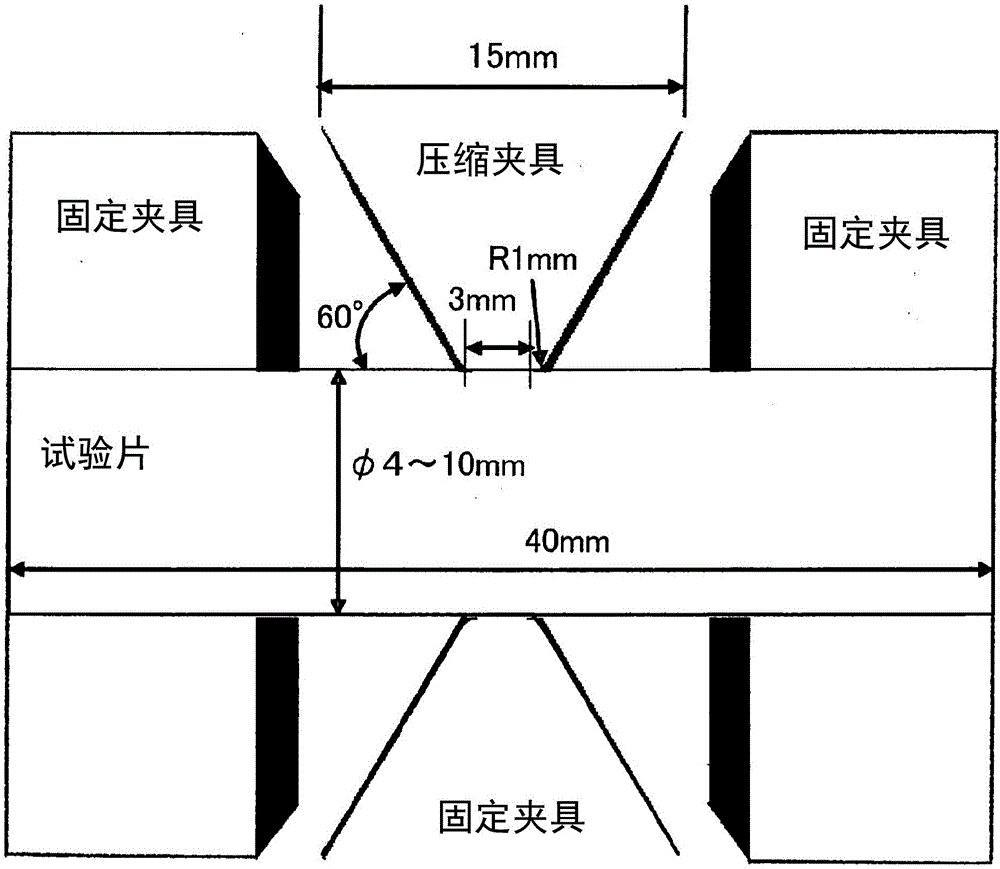

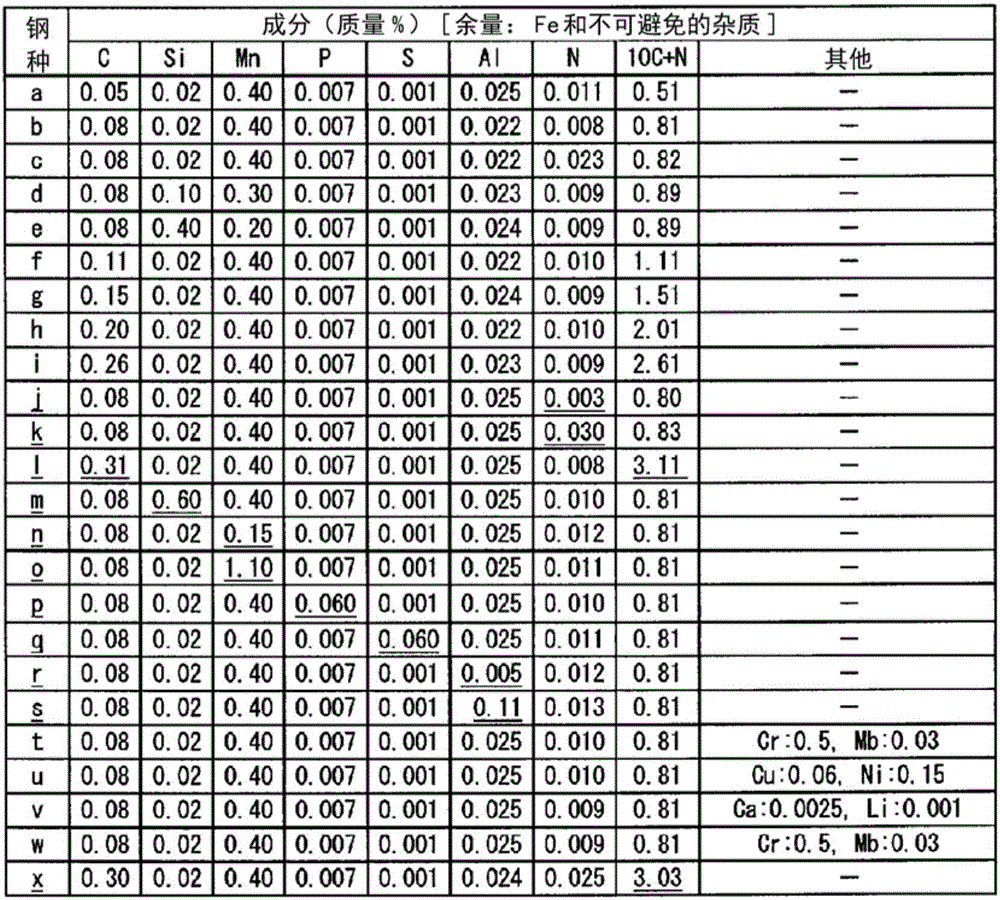

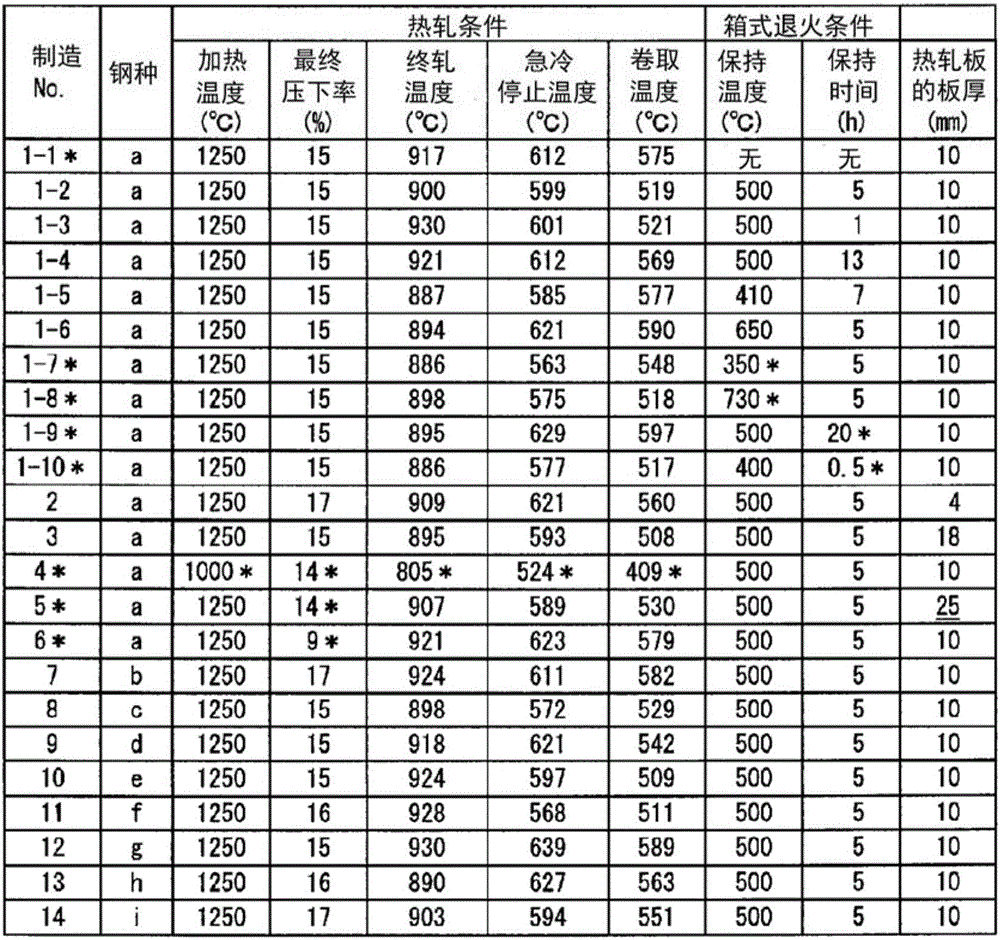

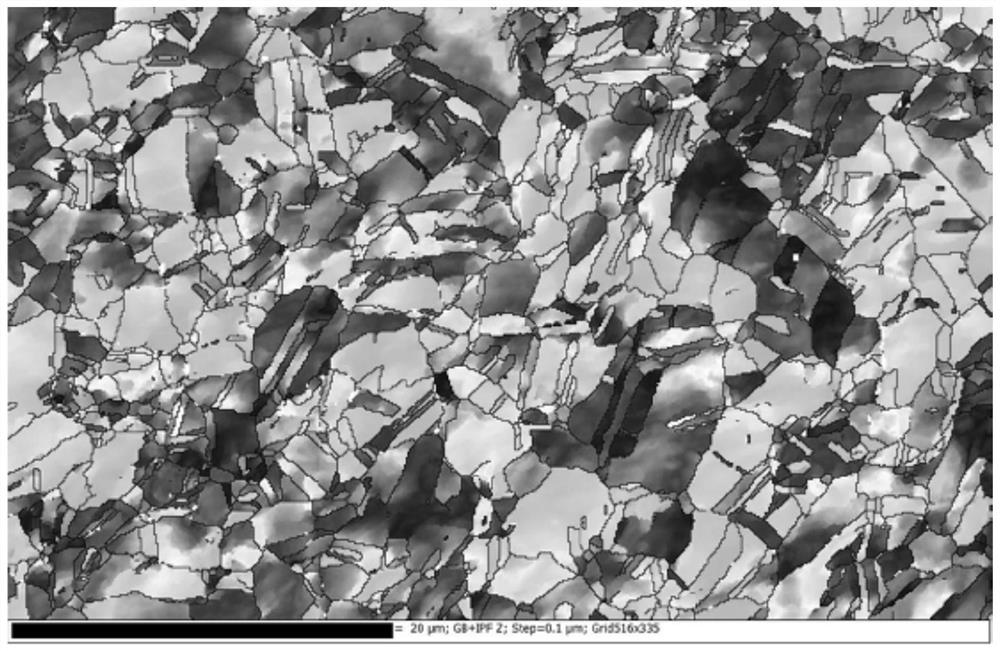

Hot-rolled steel plate exhibiting excellent cold workability and excellent surface hardness after working

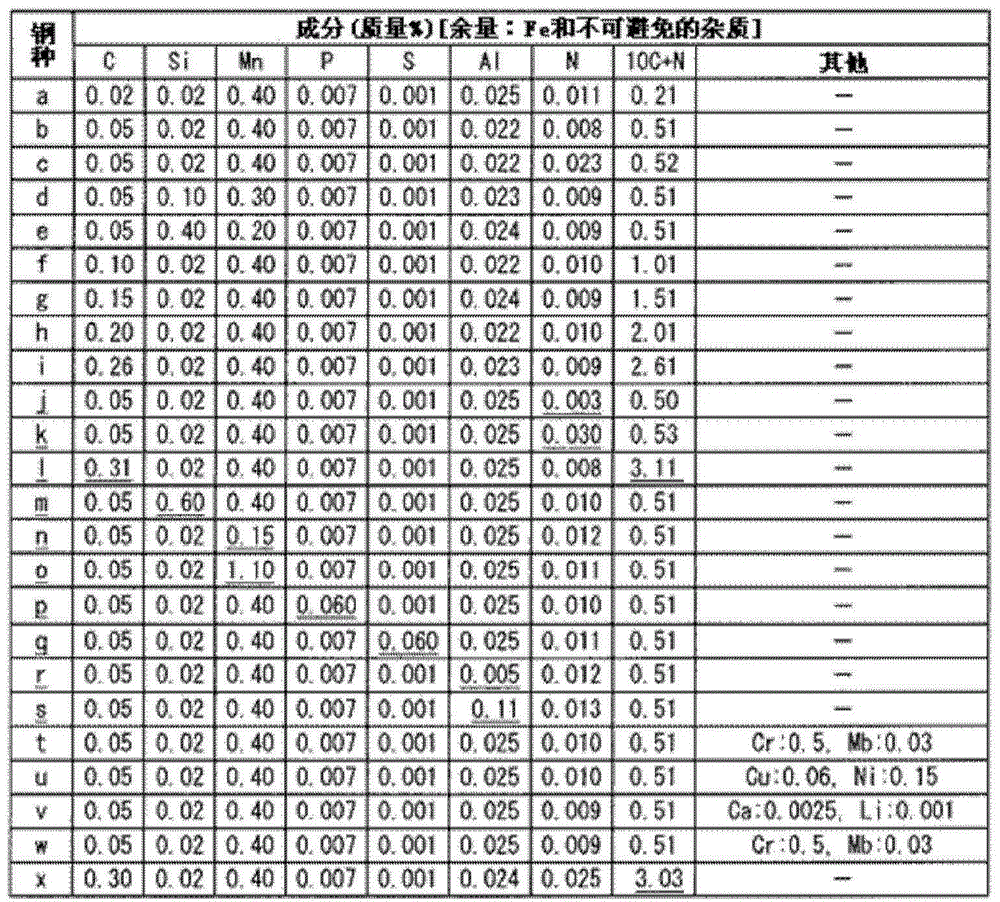

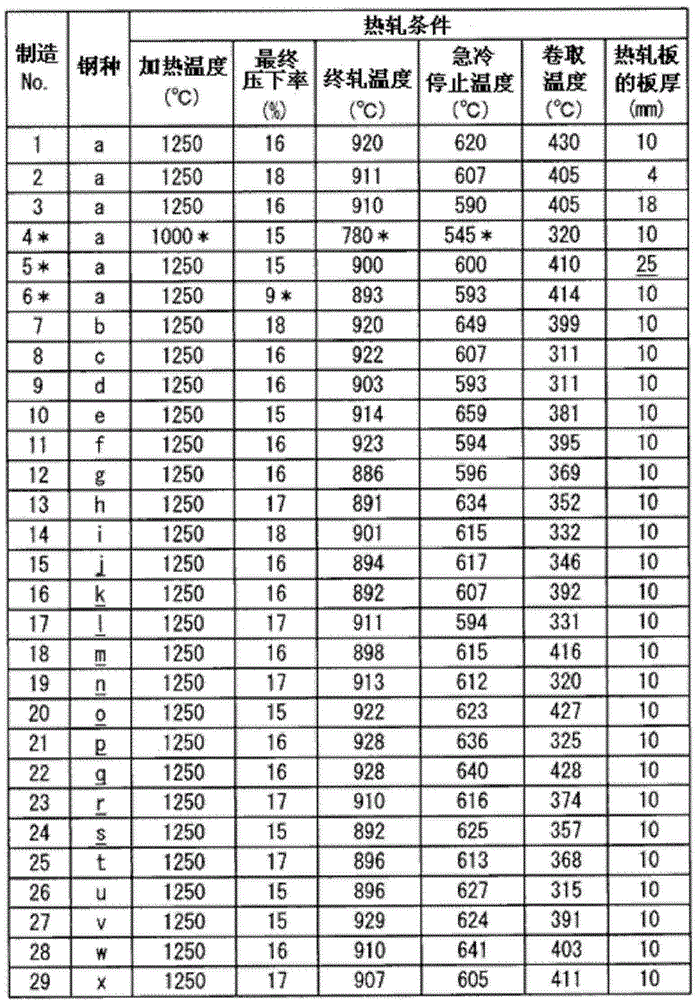

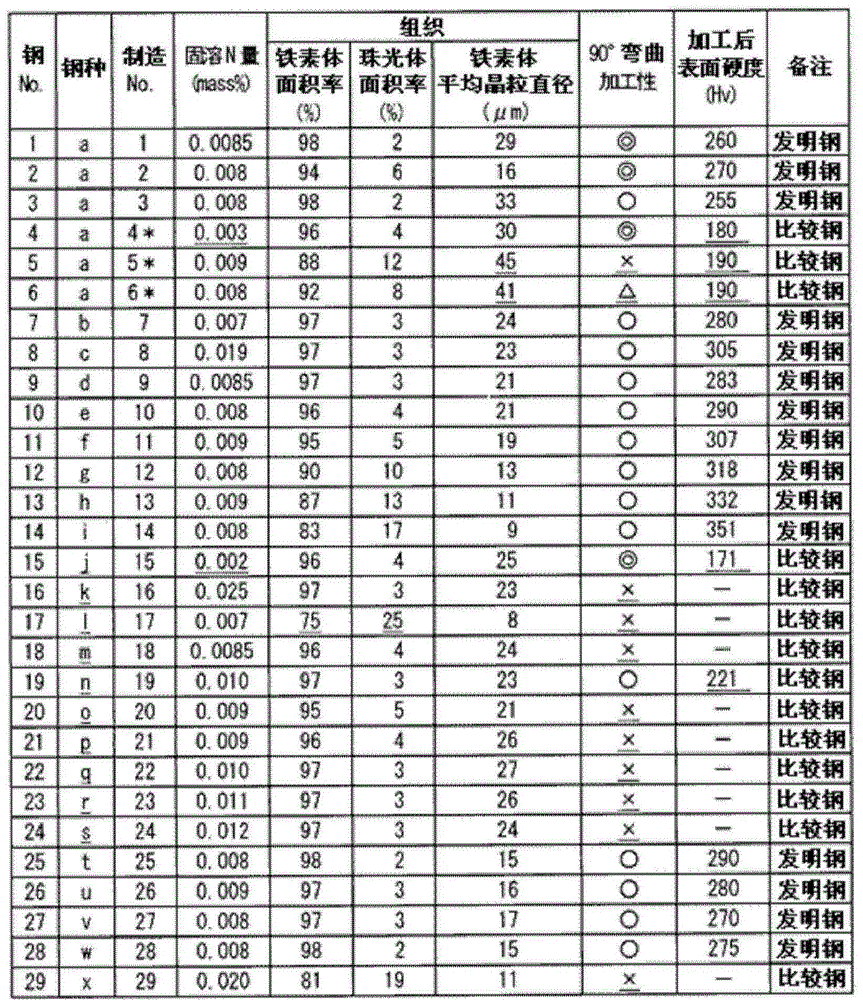

InactiveCN104903484AGuaranteed surface hardnessExtend your lifeFurnace typesHeat treatment furnacesPearliteImpurity

This hot-rolled steel plate has: a plate thickness of 3 to 20mm; a composition which contains, in mass%, up to 0.3% (exclusive of 0%) of C, up to 0.5% (exclusive of 0%) of Si, 0.2 to 1% of Mn, up to 0.05% (exclusive of 0%) of P, up to 0.05% (exclusive of 0%) of S, 0.01 to 0.1% of Al and 0.008 to 0.025% of N with the balance consisting of iron and unavoidable impurities and which satisfies two relationships, namely, the content of solid-soluted N ≥ 0.007% and 10C+N≤3.0 (wherein C and N represent the contents of C and N respectively); and a structure which contains, in area fraction with respect to the whole structure, less than 20% of pearlite with the balance being ferrite and in which the mean grain diameter of the ferrite is 3 to 35μm. The hot-rolled steel plate exhibits good cold workability during cold working, and exhibits a prescribed surface hardness after the working.

Owner:KOBE STEEL LTD

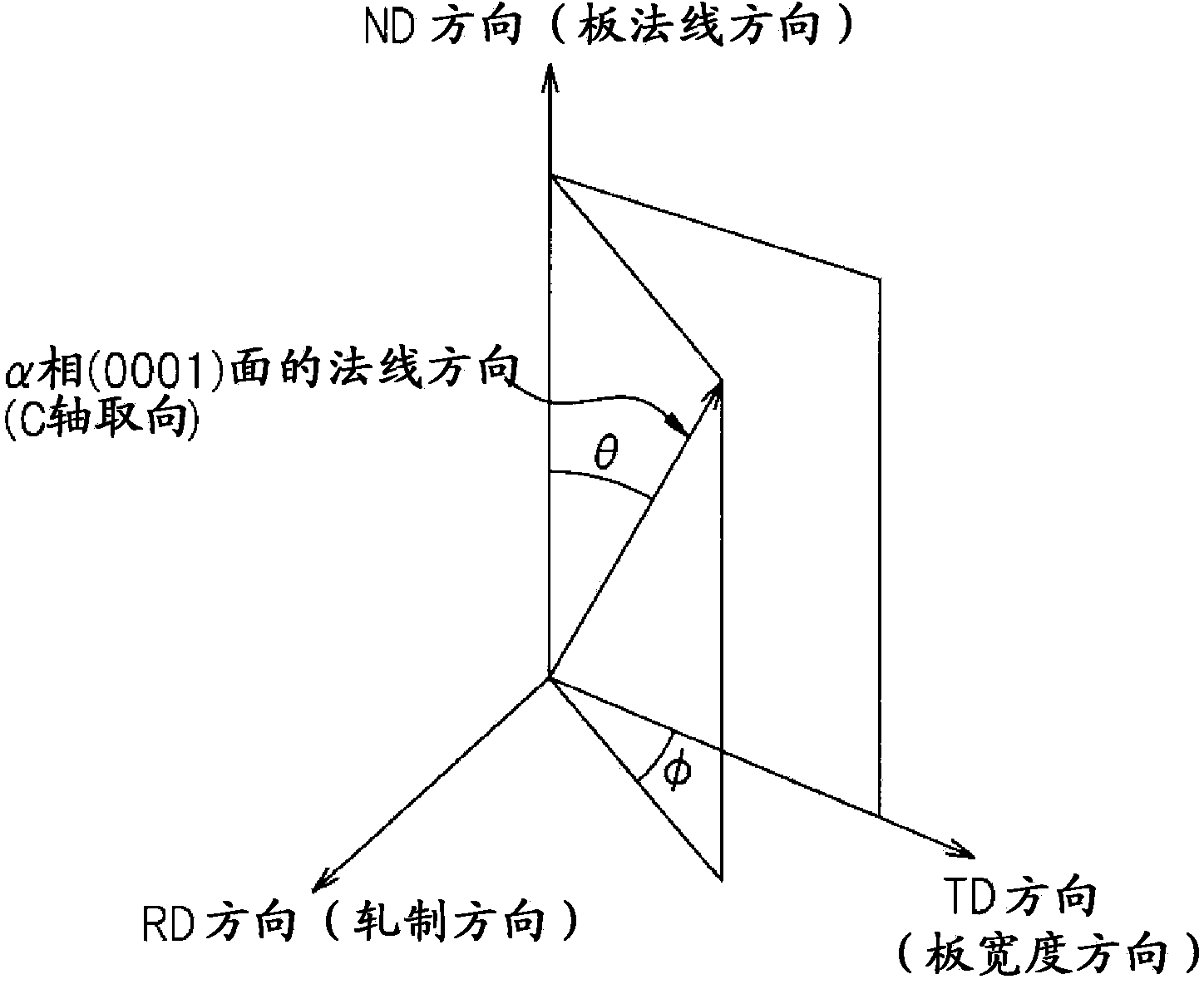

Alfa and Beta type titanium alloy sheet with excellent cold rolling properties and cold handling properties, and production method therefor

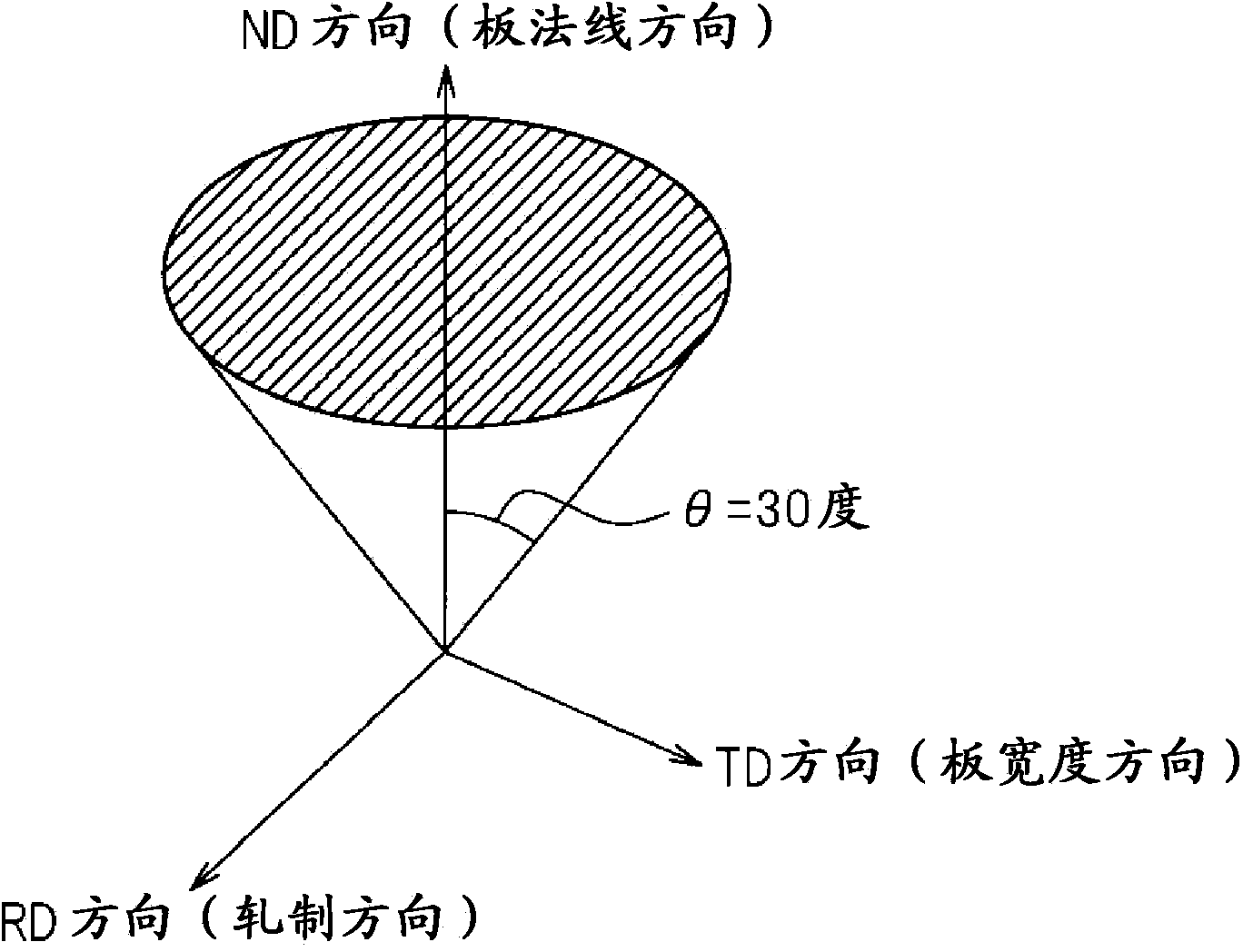

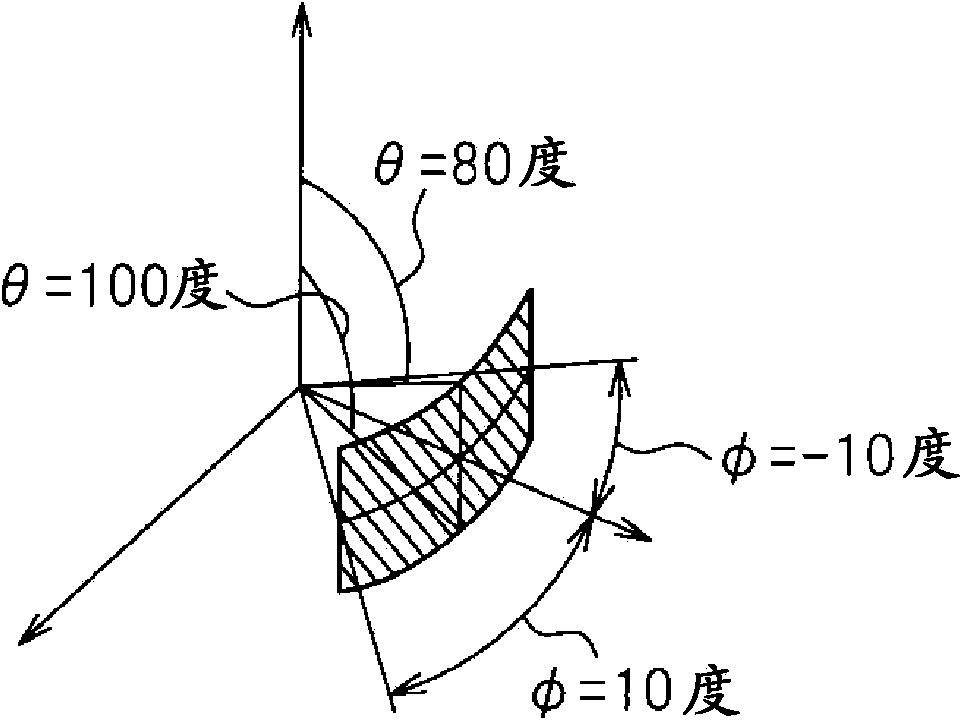

ActiveCN103392019ASmall resistance to deformationHigh plate thickness reduction rateMetal rolling arrangementsRelative intensityX-ray

Owner:NIPPON STEEL CORP

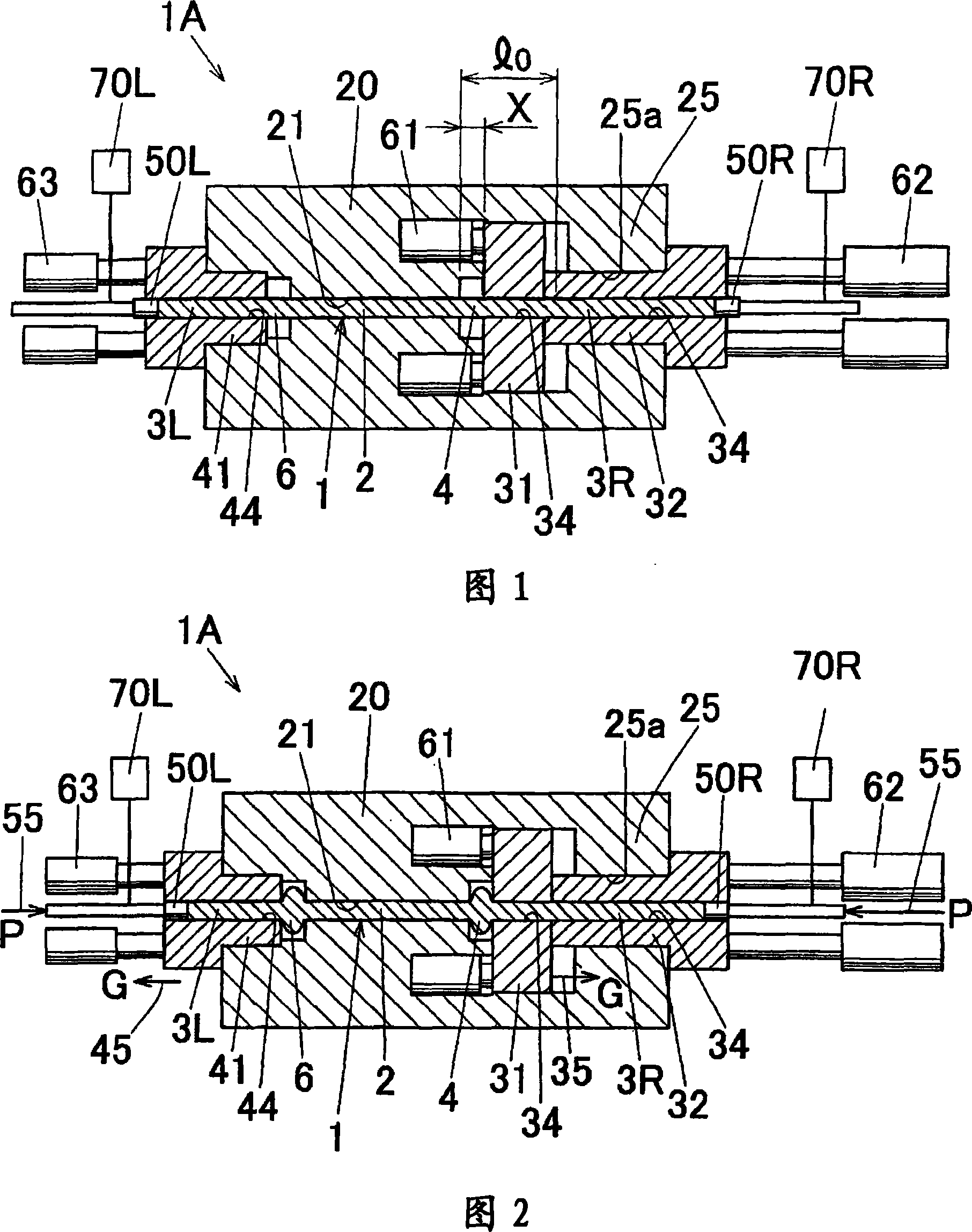

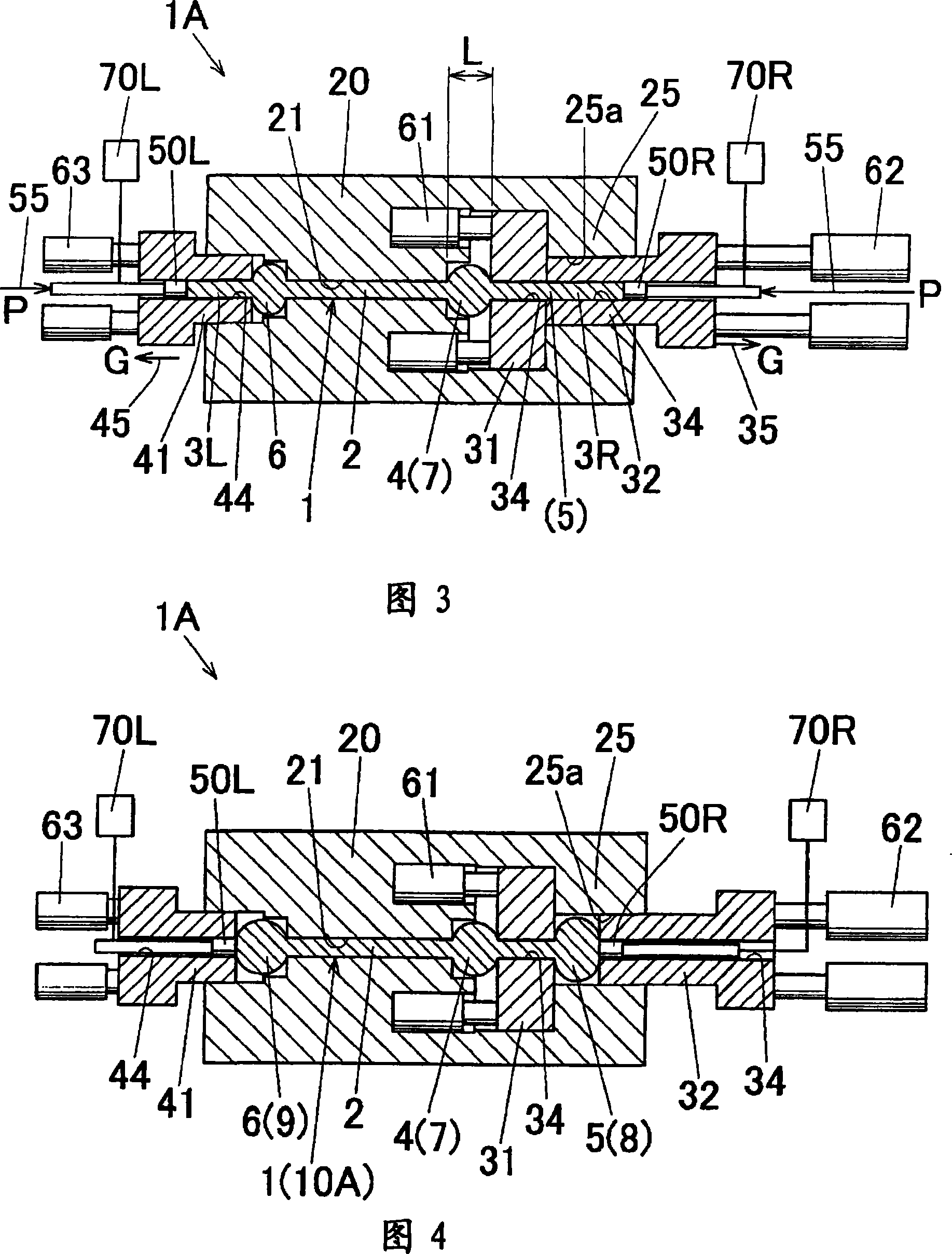

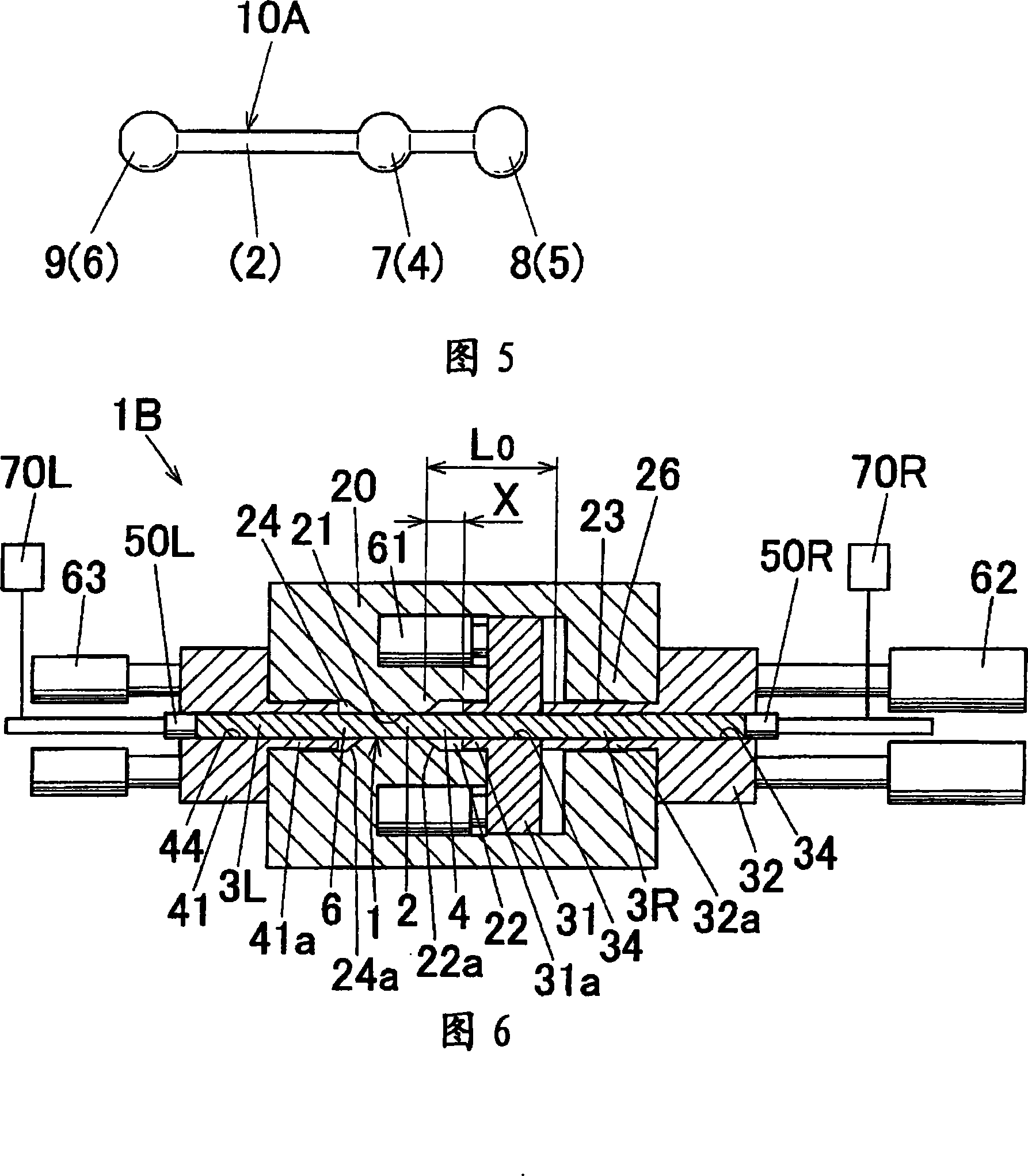

Upsetting method and upsetting apparatus

InactiveCN101111327AReduce processing costsGet cheapMetal-working apparatusEngine componentsEngineeringMechanical engineering

A upsetting method and an upsetting device capable of efficiently increasing the diameter of a bar-like material at at least two positions. In the method, a plurality of guides (31) and (32) having insertion holes (34) are prepared, and the bar-like material (1) fixed to a fixed die (20) is inserted into the insertion holes (34) of the plurality of guides (31) and (32) in order and held therein. Next, while the material (1) is axially pressed by a punch (50R), the plurality of guides (31) and (32) are integrally moved in a direction opposite to the moving direction of the punch (50R) in a mutually fitted state to increase the diameter of the first exposed part (4) of the material (1) exposed between the first guide (31) disposed on the forefront among the plurality of guides (31) and (32) and the fixed die (20). After the first guide (31) is moved, the second guide (32) disposed on the rear side of the first guide (31) among the plurality of guides (31) and (32) is moved in the direction opposite to the moving direction of the punch (50R) to increase the diameter of the second exposed part of the material (1) exposed between the both guides (31) and (32).

Owner:SHOWA DENKO KK

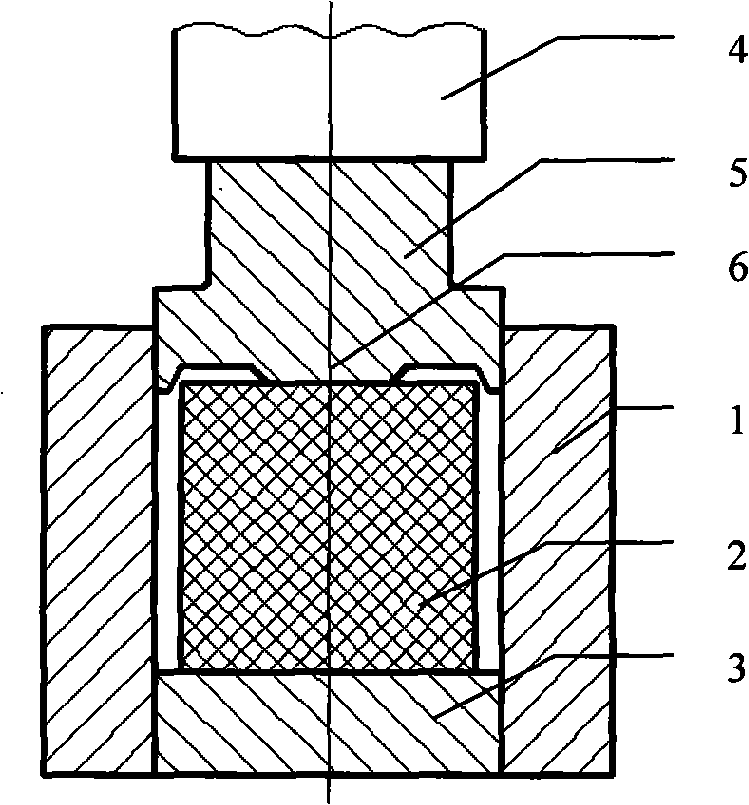

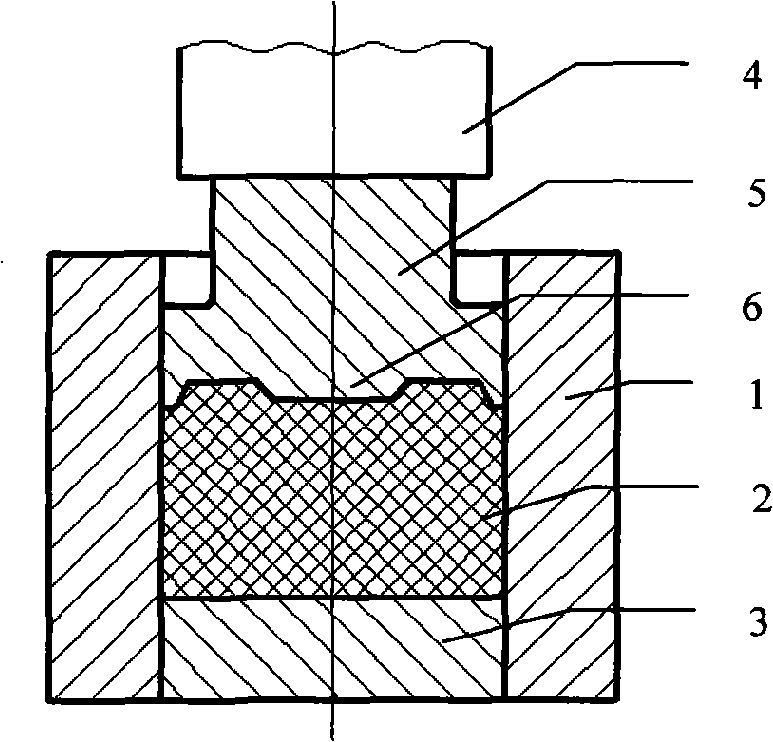

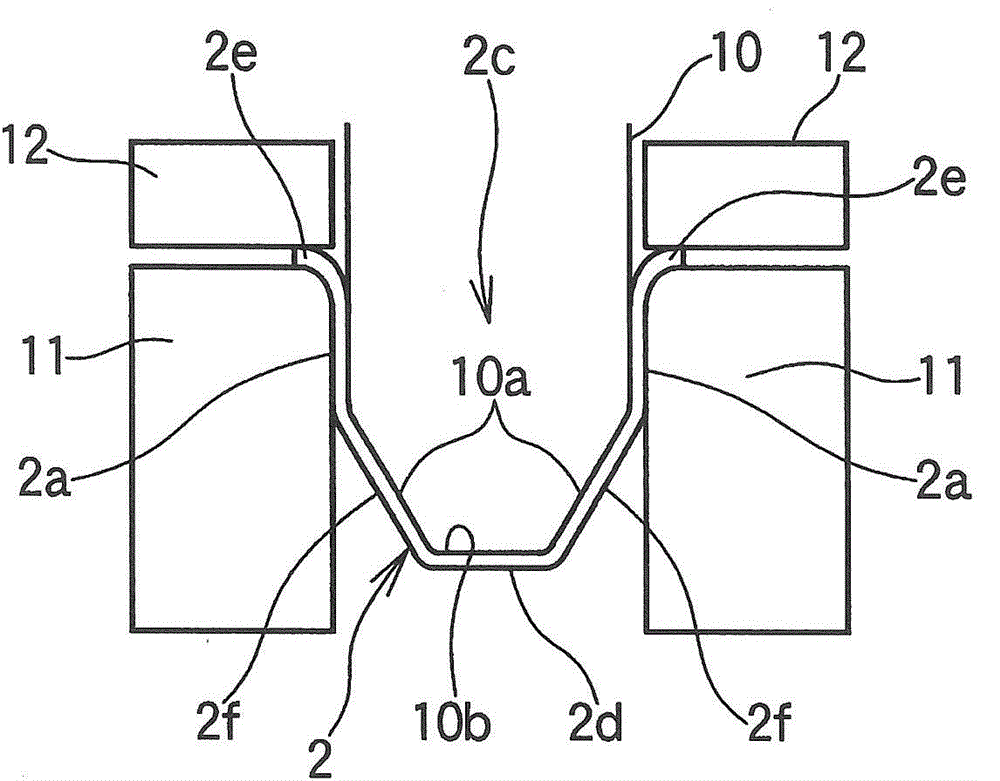

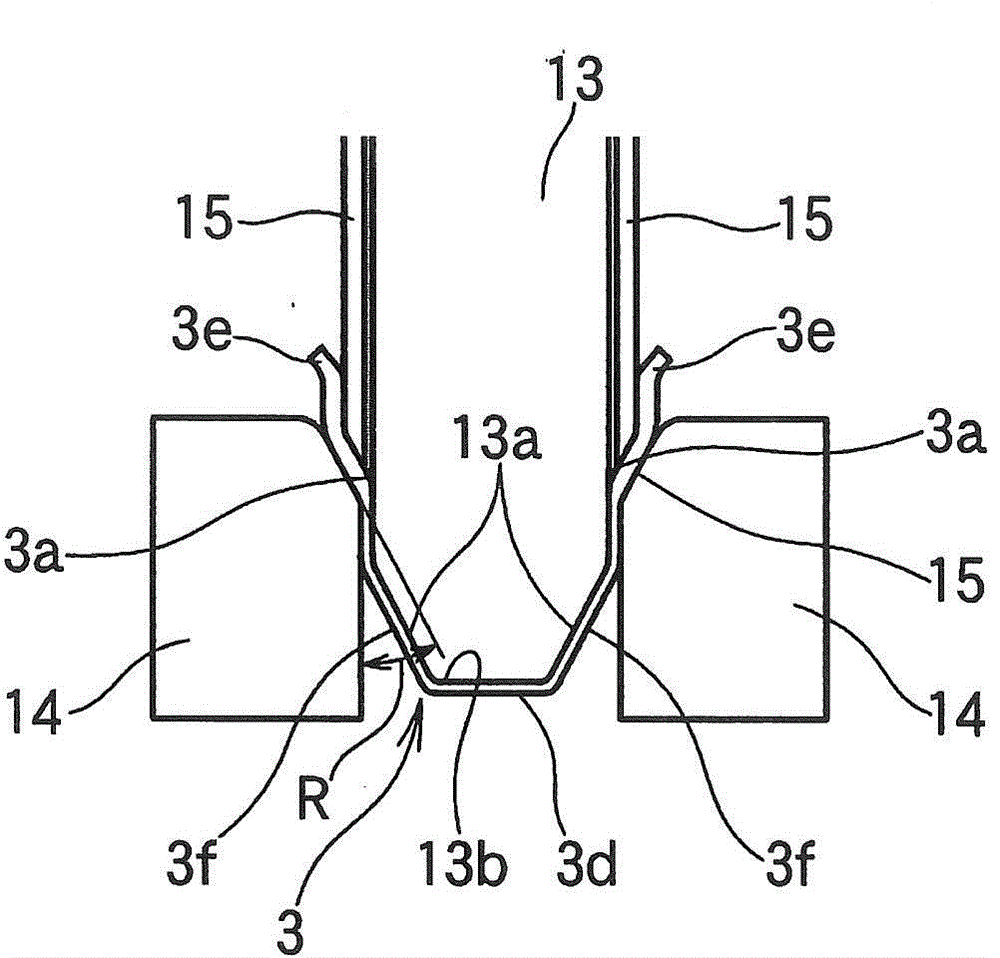

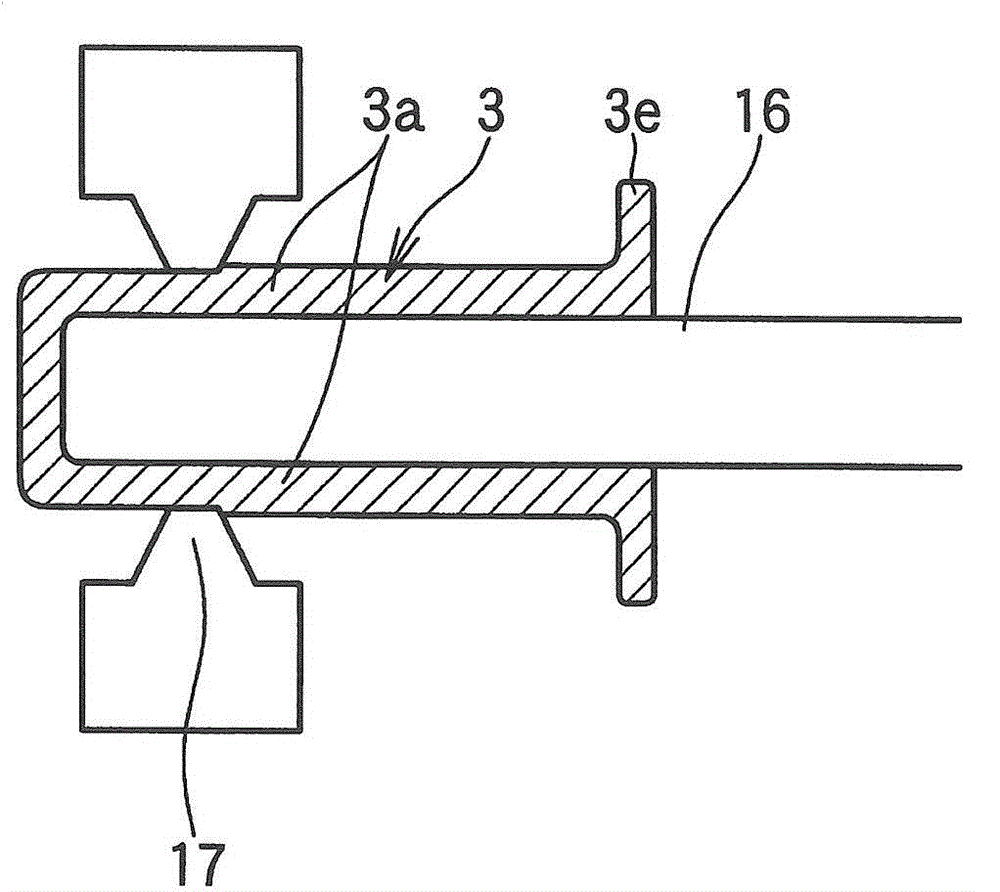

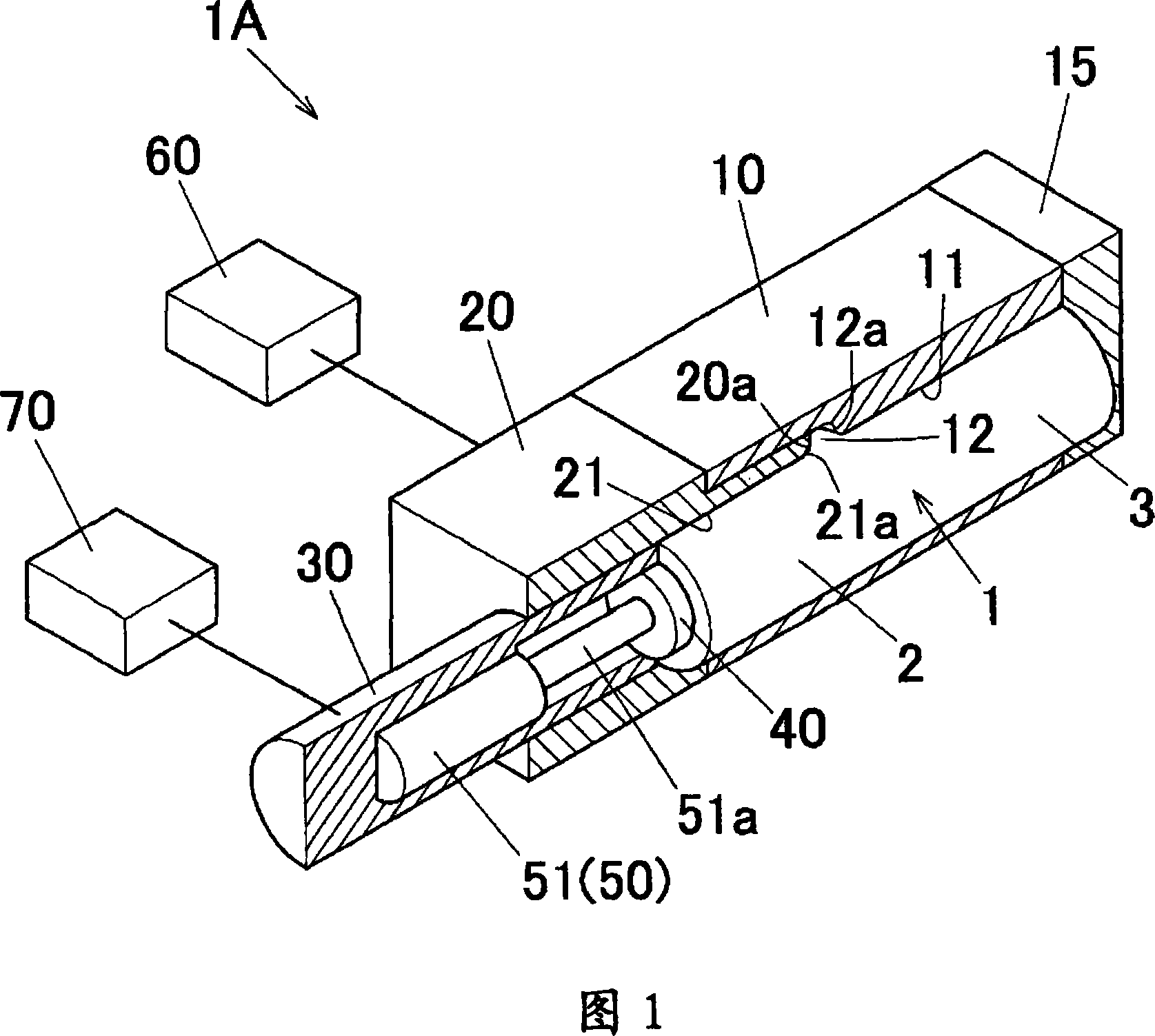

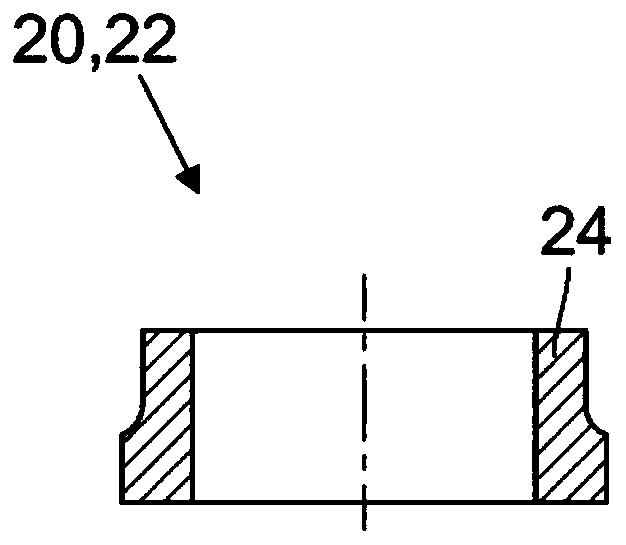

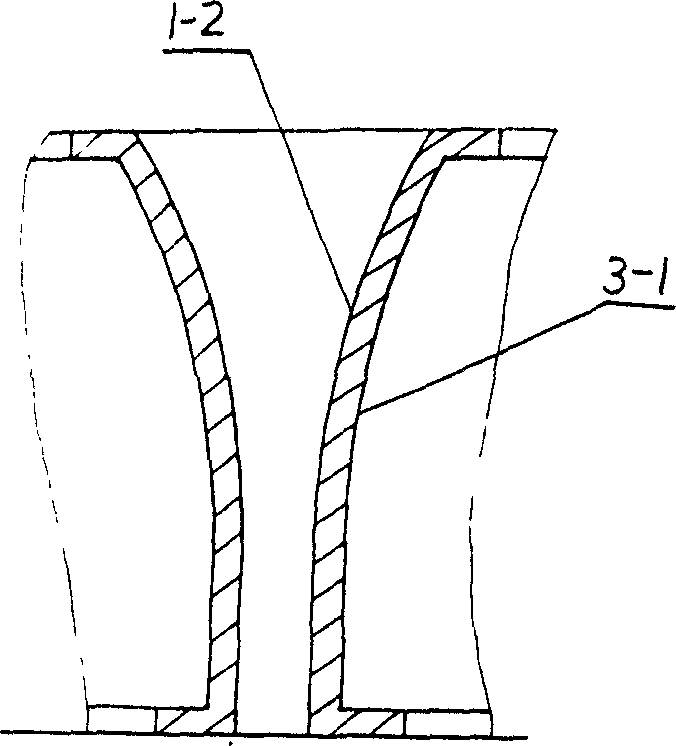

Method and apparatus for upsetting cylindrical material

InactiveCN101111328AQuality improvementAvoid bendingMetal-working apparatusEngine componentsEngineeringMechanical engineering

A method and a device for upsetting a cylindrical material capable of securely swelling the intended part of the cylindrical material to the inside or outside so that its wall thickness can be increased. A core (40) is disposed in the hollow parts (2a) and (3a) of the intended part (2) and the unintended part (3) of the cylindrical material (1). The unintended part (3) of the material (1) is disposed in the arresting hole (11) of an arresting die (10). The intended part (2) of the material (1) is disposed in a molding recessed part (12). The intended part (2) of the material (1) is disposed in the insertion hole (21) of a guide (20). Next, while the intended part (2) of the material (1) is pressurized in the axial direction with a punch (30), the guide (20) is moved in an opposite direction (25) to the moving direction (35) of the punch to swell the work predicted part (2) of the material (1) to the outside so that its wall thickness is increased in the molding recessed part (12).

Owner:SHOWA DENKO KK

Preparation method for mortar and carbonized wood composite floor

InactiveCN107178195AEasy to viewHigh resilienceDischarging arrangementWood treatment detailsSolid woodUnderfloor heating

A preparation method of mortar carbonized wood composite floor. The preparation of carbonized wood needs to put the billet into the superheated steam box for multiple infiltration treatment, then carry out the phenolic resin modification treatment, and finally carry out the carbonization treatment twice, and put it into the Carbonized wood can be obtained after modification in a vacuum heating container filled with phenolic resin; after the mortar is prepared, it is poured into a special floor molding mold and smoothed, and the mold is used to form a floor heating positioning groove on the lower surface of the mortar layer , the distribution groove of carbonized wood is formed on the upper surface; then the prepared carbonized wood is placed in the distribution groove, after demoulding, curing and drying, the upper surface is polished, and then sprayed with a layer of coating containing SiO2 nano-reinforced material for protection. Mortar carbonized wood composite flooring can be obtained. The invention can solve the problems of non-solid wood flooring such as hardness, poor foot feeling, low comfort, and slow heat conduction, and the problems of easy syneresis, deformation and cracking of solid wood flooring applied to floor heating.

Owner:孔晓静

Hot-rolled steel sheet having good cold workability and excellent hardness after working

InactiveCN106232847AExtend your lifeGuaranteed hardnessFurnace typesMetal rolling arrangementsSheet steelPearlite

This hot-rolled steel sheet has a thickness of 3-20 mm and contains specific amounts of C, Si, Mn, P, S, Al and N with the balance made up of iron and unavoidable impurities. The contents of solid-solved N, C and N are within specific ranges, and bainitic ferrite having a specific average crystal grain size and pearlite have specific area occupancies in the structure, with the balance occupied by polygonal ferrite. This hot-rolled steel sheet has a specific hardness distribution in the thickness direction.

Owner:KOBE STEEL LTD

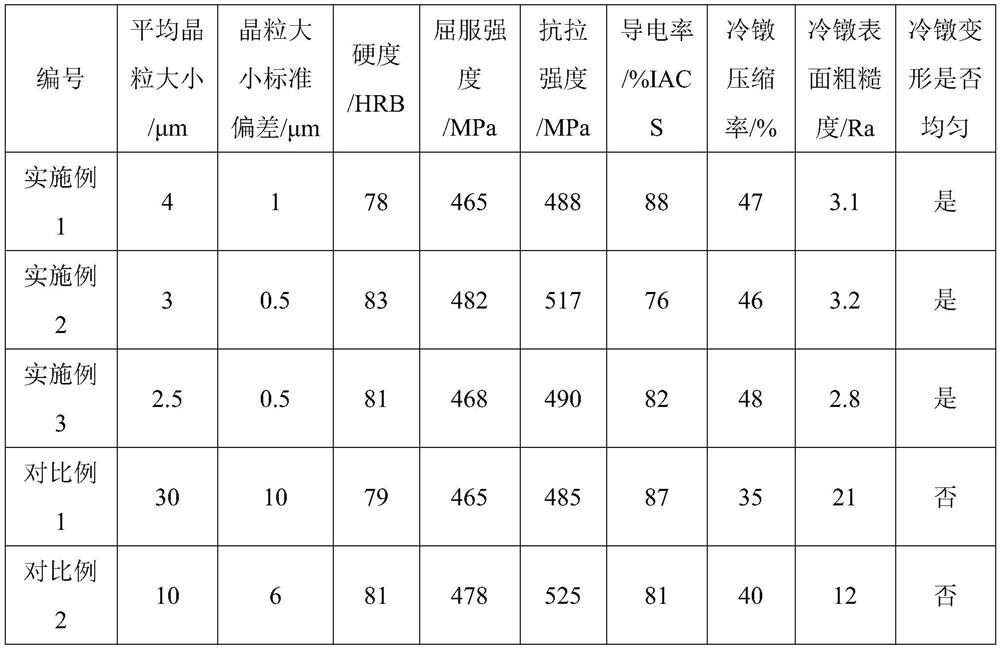

Chromium-zirconium-copper alloy for cold heading and preparation method of chromium-zirconium-copper alloy

The invention discloses a chromium-zirconium-copper alloy for cold heading. The chromium-zirconium-copper alloy is characterized in that the average grain size of the chromium-zirconium-copper alloy is smaller than or equal to 4 [mu] m, and the standard deviation of the grain size is smaller than or equal to 1 / 2 of the average grain size. According to the chromium-zirconium-copper alloy, the average grain size of the chromium-zirconium-copper alloy is controlled to be smaller than or equal to 4 [mu] m, the standard deviation of the grain size is smaller than or equal to 1 / 2 of the average grain size, and the fine grain size means that the higher grain boundary volume fraction is achieved; due to the fact that the grain boundary structure is relatively loose, movement of grains during cold heading is facilitated, and the cold heading performance is improved; and in addition, the fine grain size and the more uniform grain size are beneficial to improving the smoothness of a cold heading product, and the cellulite phenomenon is avoided.

Owner:JINTIAN COPPER GROUP CORP NINGBO

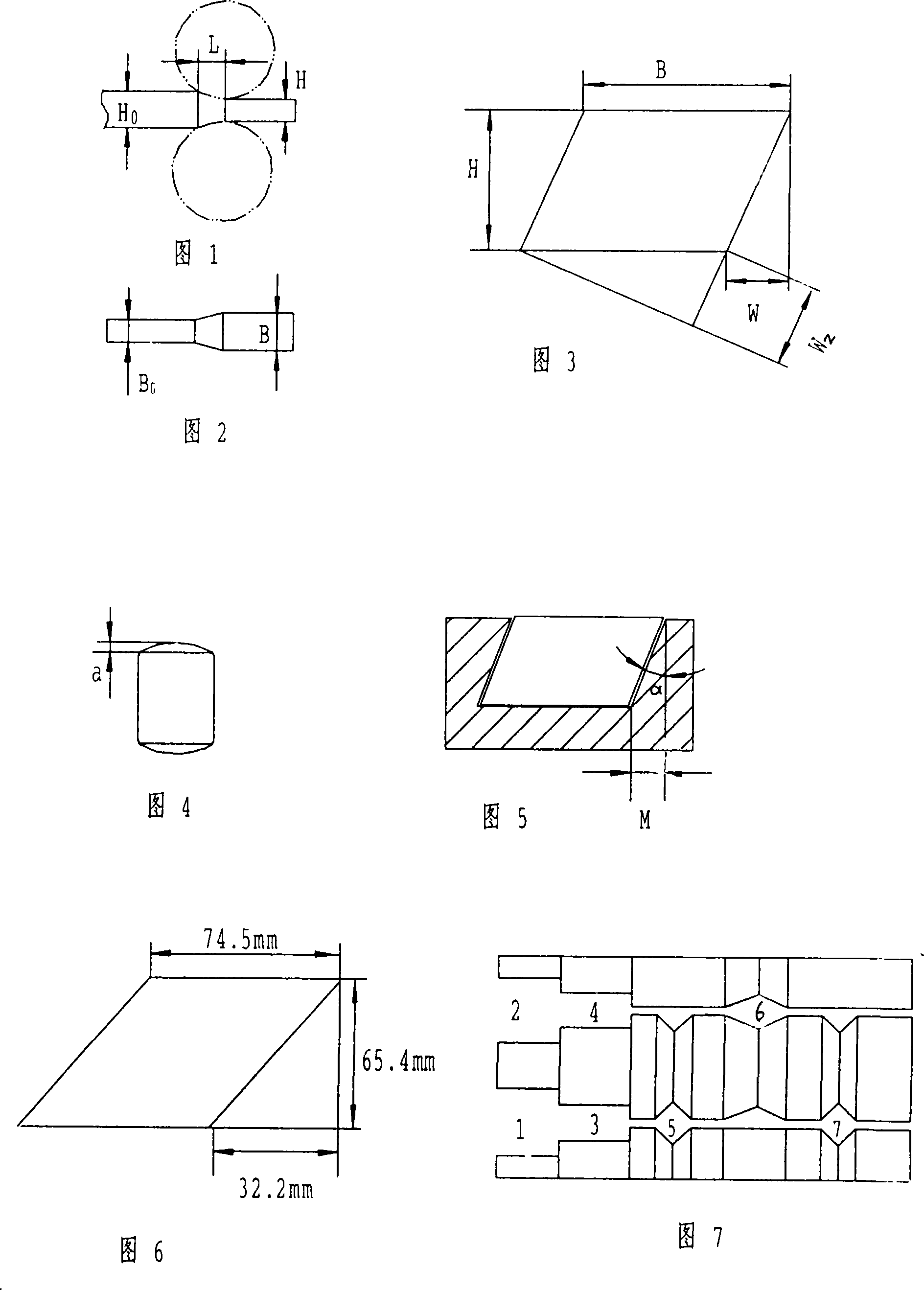

Plain-barreled roll rhomboidity rolling method

InactiveCN101176881AEasy to processEasy to manageGuiding/positioning/aligning arrangementsRoll mill control devicesSquare cross sectionDistortion

The invention relates to a plain-barreled roller skew rolling method, belonging to the steel rolling technical field, which aims to solve the molding rolling problem by adopting an unpunched plain-barreled roller rolling a workpiece. The invention uses continuous casting blank of square cross section as raw materials in two steps: a plain-barreled roller skew rolling step and a diamond-square hole rolling step. The invention adopts unpunched plain-barreled rolling in the step of the plain-barreled rolling; the skew degree of the workpiece is produced by controlling press distance and using inclined guide device through 4 to 8 pass rolling; the workpiece obtains a diamond-shaped cross section as the incremental skew degree. Then the diamond-square hole rolling step adopts diagonal square hole, diamond-shaped hole and diagonal square hole in sequence through three pass rolling, obtaining a workpiece of regular square cross section. The invention has the advantages that: the designing idea is quite the reverse of the present plain-barreled roller rolling method, skillfully utilizes the skew degree of the workpiece produced by the plain-barreled rolling and enables the workpiece to form a diamond-shaped cross section; then go to the diamond-square hole rolling step to produce the square steel. The invention resolves the difficult problem of the workpiece distortion and turnover in prior plain roller forming process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

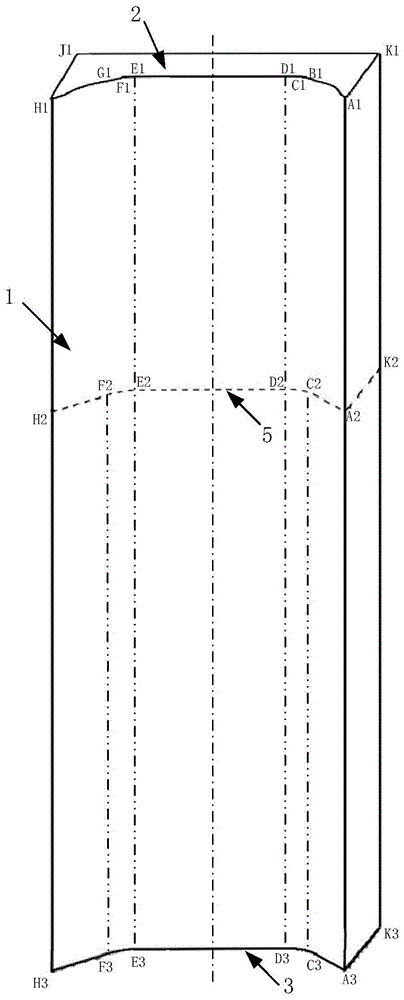

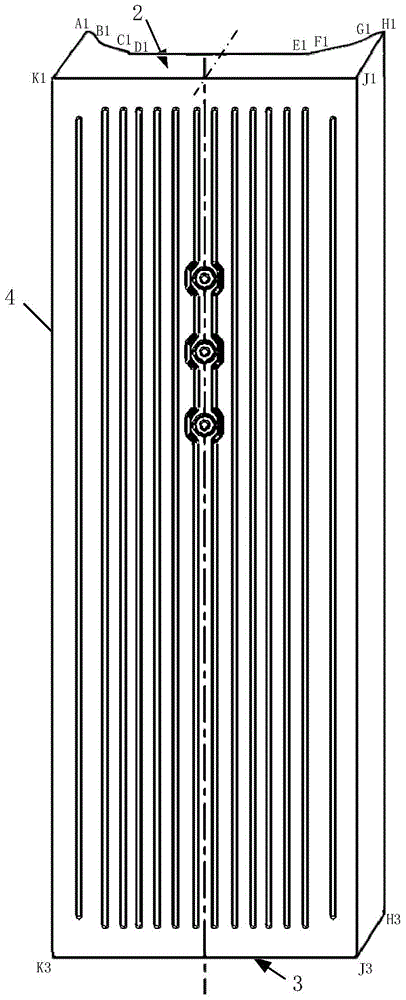

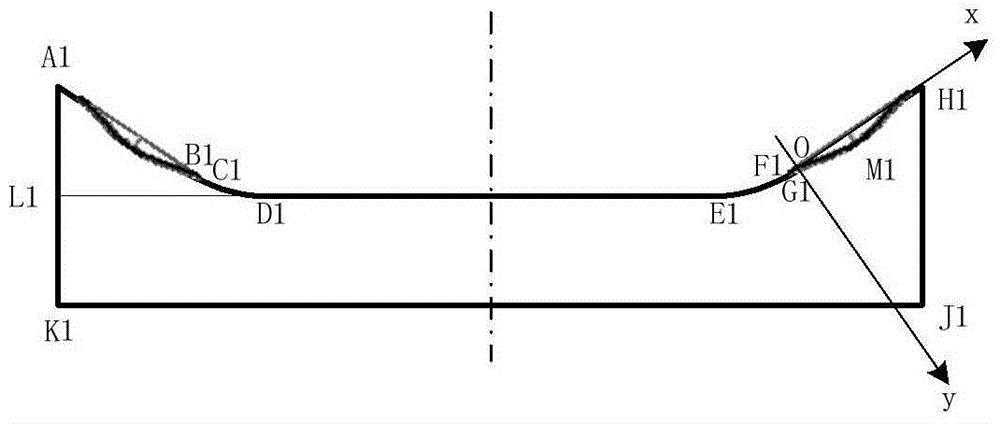

Narrow-edge copper plate for slab mold with continuous variable taper at corner

InactiveCN105983665AIncrease the scope of application of steel typesSmall resistance to deformationShrinkage coefficientCopper

The invention discloses a narrow-edge copper plate for a slab mold with a continuous variable taper at the corner, relates to machinery or equipment in metal continuous casting and in particular to a manufacturing or casting mold plate for a bottom opening mold for metal continuous casting. An upper mouth profile curve of the narrow-edge copper plate is formed by connection of an upper mouth straight line, a funnel curve, an upper mouth oblique line and an upper mouth arc; the funnel curve is continuous with an oblique line curvature; the two ends of the upper mouth arc are tangent to the upper mouth oblique line and the upper mouth straight line respectively; the taper of a chamber part of the narrow-edge copper plate of the slab mold is continuously decreased in the height direction of the slab mold progressively; the progressive decrease speed of the taper is gradually slow; and the length of the profile of the horizontal cross section of the narrow-edge copper plate of the slab mold continuously varies downwards in the height direction of an upper mouth of the slab mold so as to form a corner funnel region with a funnel-shaped curve with the taper to be decreased progressively and shrink. According to the narrow-edge copper plate, local stress concentration generated in the movement deformation and shrinkage process of a billet shell can be prevented, the narrow-edge copper plate is suitable for differences of solidification shrinkage coefficients of different kinds of steel, and the application range of the kind of the steel is enlarged.

Owner:BAOSHAN IRON & STEEL CO LTD

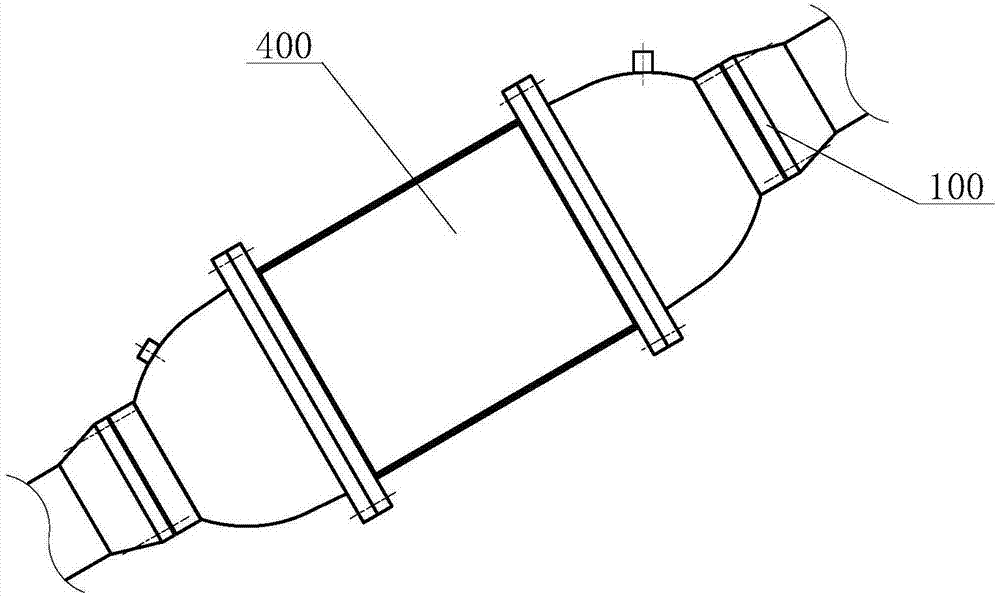

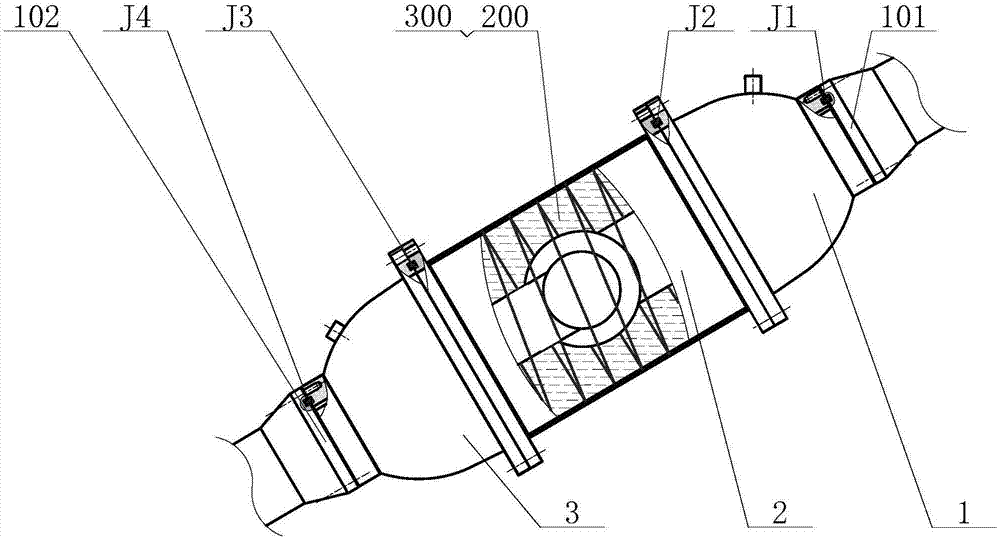

Flexible parabola-shaped abnormal plate spring framework joint

InactiveCN104608143AAccording to the distribution of stressEasy to transformJointsEngineeringAbnormal shaped

The invention relates to a flexible parabola-shaped abnormal plate spring framework joint, and belongs to the technical field of application of robots and mechanical arms. According to the joint, an abnormal plate spring is used as a framework, the joint is bent through the drive of fluid, and the joint can be used as various joints of a robot. When an elastic corrugated pipe is inflated, the elastic corrugated pipe extends and is restrained by the plate spring to be bent towards one side of the plate spring. When gas in the elastic corrugated pipe is released, the joint is restored to be in an extension state under the effect of the plate spring. The pressure in the elastic corrugated pipe is controlled to enable the joint to be bent and to be kept at a certain angle. The elastic corrugated pipe has good flexibility, the plate spring has good elasticity, and therefore the joint has good flexibility. Through the improvement of the cross section of the plate spring, the bending space can be increased, the strength demand can be met, the flexibility is improved, and plate spring materials are saved. The flexible parabola-shaped abnormal plate spring framework joint is flexible in bending action, small in energy consumption, convenient to control and has a good flexible adaptability effect.

Owner:JIANGNAN UNIV

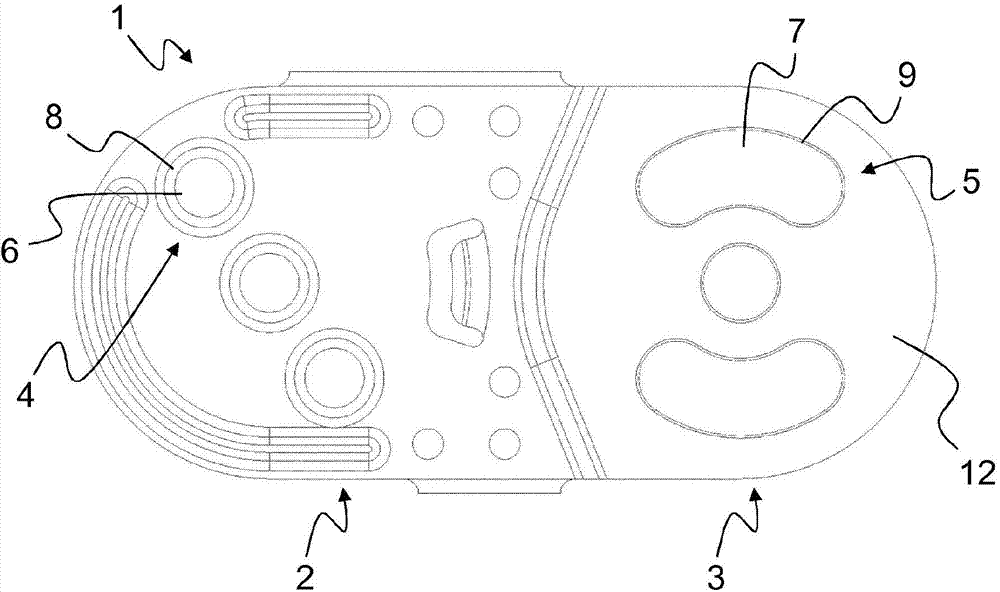

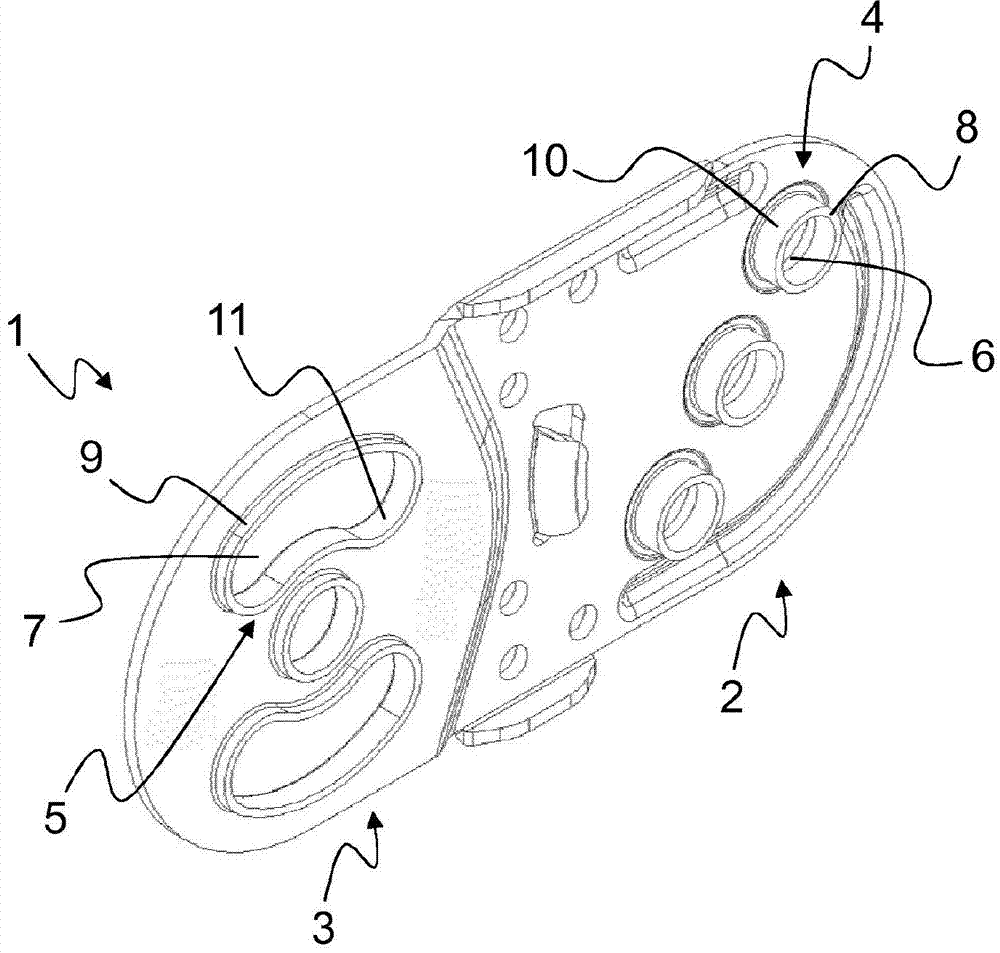

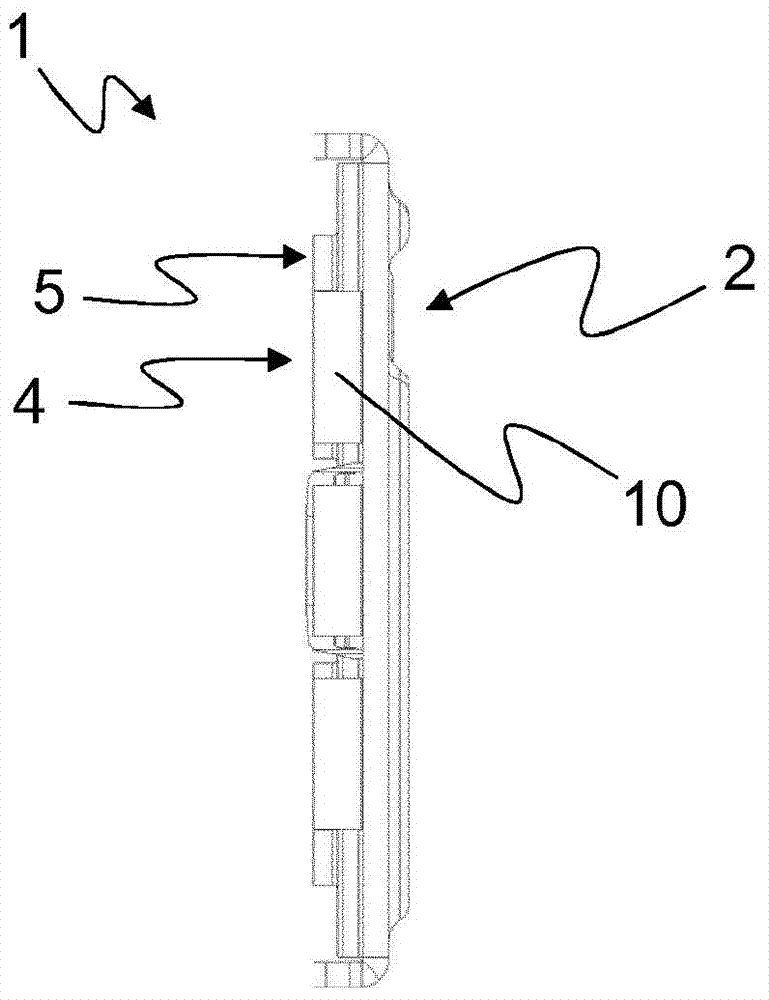

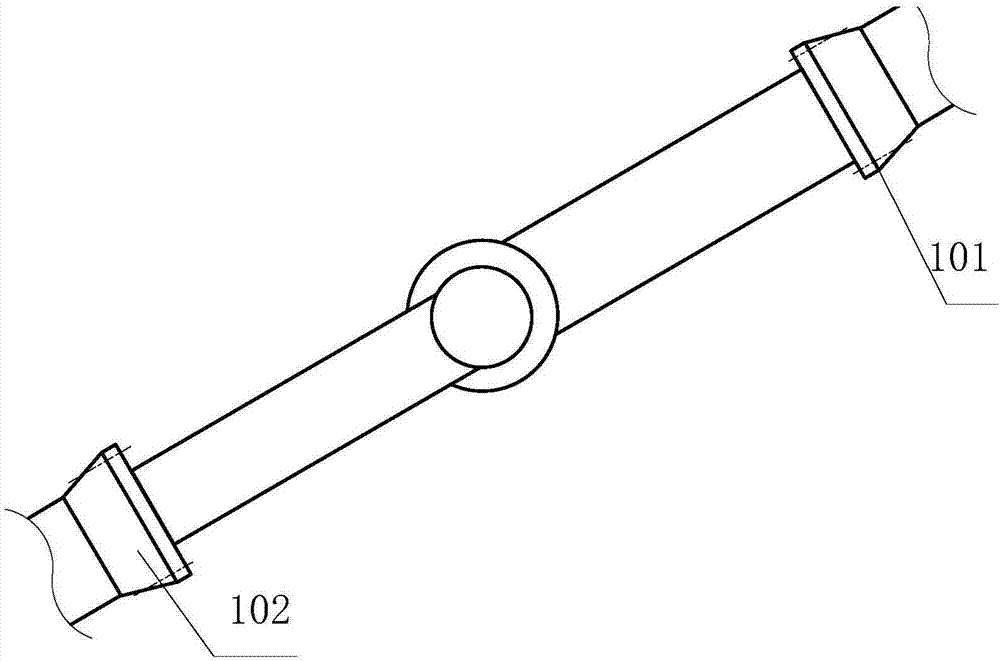

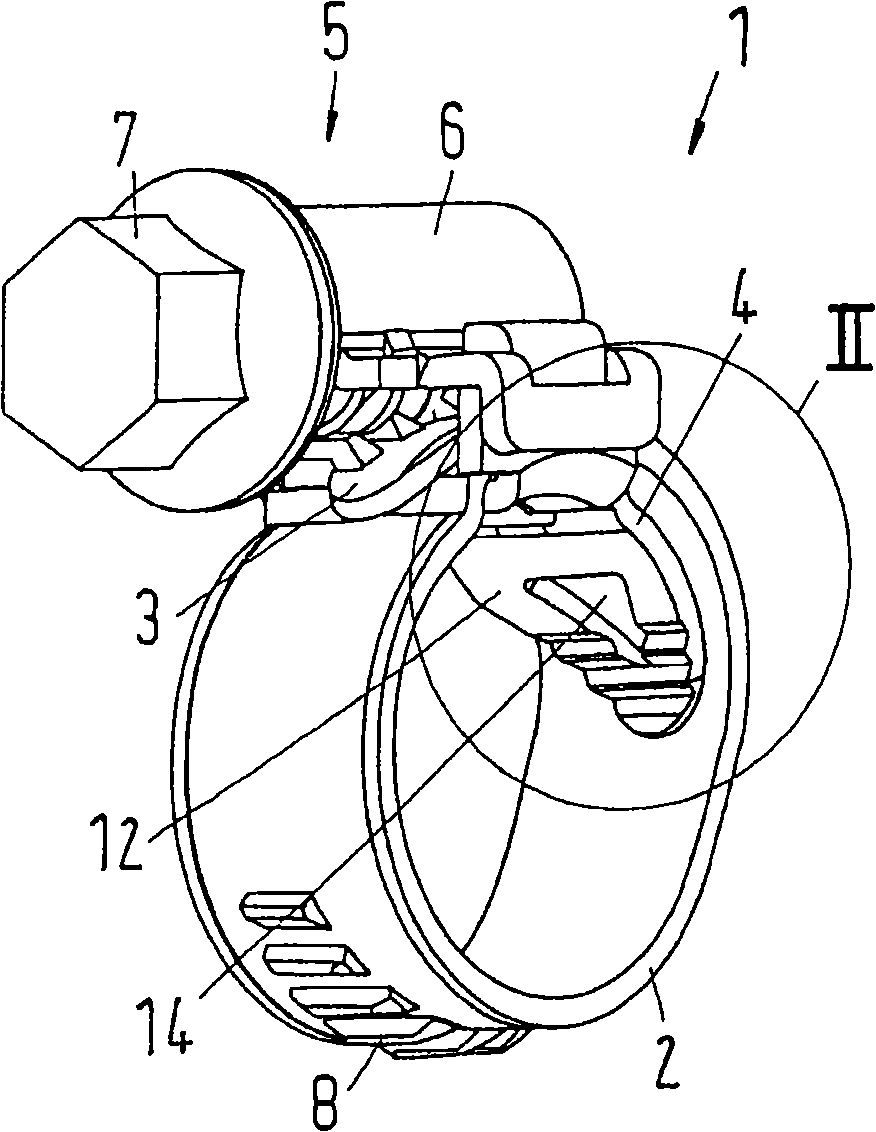

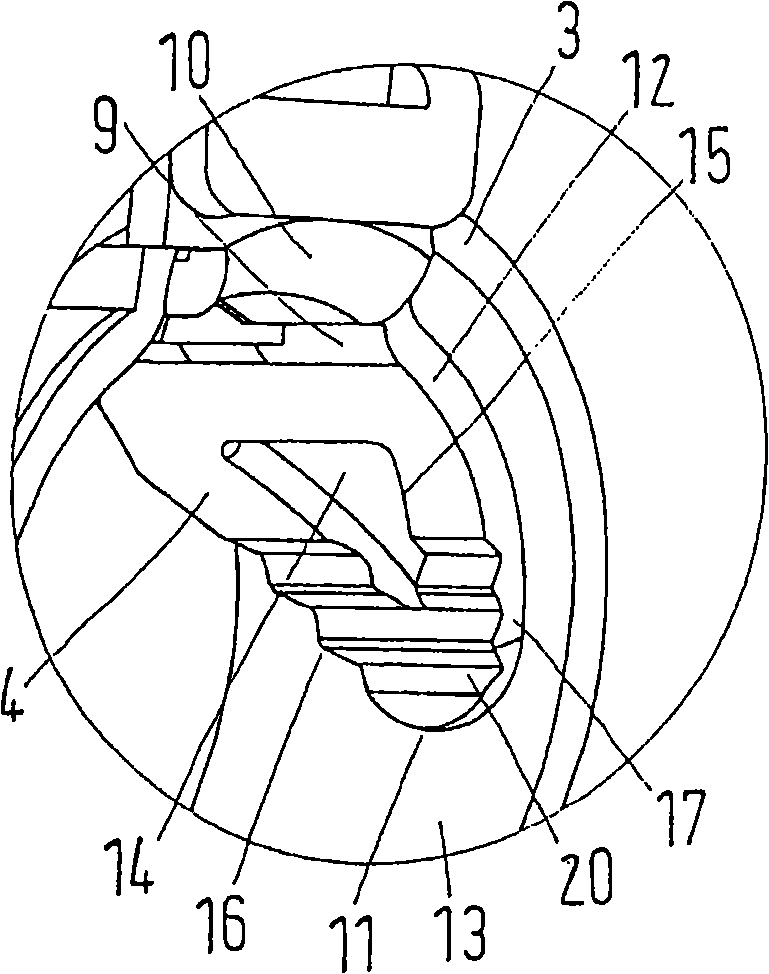

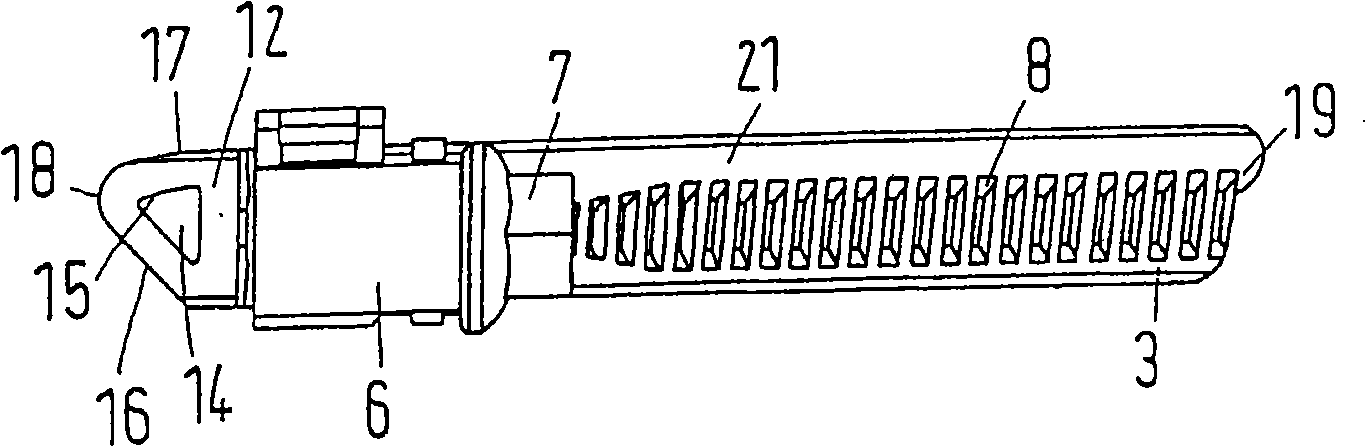

Metal connecting plate of a chain link of an energy chain

ActiveCN104204607AIncrease contact surfaceIncrease the intensity valueHauling chainsHoisting chainsEngineeringChain link

The invention relates to a metal connecting plate (1) of a chain link of an energy chain, which metal connecting plate has two ends (2, 3), wherein one end (2) has first elements (4) and the other end (3) has second elements (5), wherein the first elements (4) can be inserted into the second elements (5) of a further connecting plate (1) in such a way that the connecting plates (1) are rotatably connected to each other. The first and second elements (4, 5) are each formed by a hole (6, 7) having a border (8, 9). The borders (8, 9) form stop surfaces (10, 11) corresponding to each other, which stop surfaces protrude substantially perpendicularly to an extent of the connecting plate (1).

Owner:椿本缆线牵引有限公司

Thermal-insulation adhesive for die-forging of forge pieces and preparation method thereof

The invention discloses a thermal-insulation adhesive for die-forging of forge pieces, which is used for forming die forging pieces and especially suitable for thermal-insulation forming of high-temperature alloy, titanium alloy and aluminum alloy die-forging pieces. The adhesive for thermal-insulation materials can form a continuous, uniform and compact film for thermal insulation and lubrication on the surface of a forge piece. The adhesive disclosed by the invention is prepared from the following components in percentage by weight: 20-40% of organosilicon heat-resistant resin or organic titanium epoxy resin, 20-40% of glass powder, 0-5% of trisodium phosphate, 2-6% of anhydrous borax, 0-5% of graphite, 1-3% of leafing aluminum paste, 1-5% of magnesium aluminum silicate suspending agent and 10-40% of xylene. The invention can accurately control the forging temperature, reduce the number of times of blank returning, prolong the forgeable time each time, lower the cost of the used coating materials, widen the optional range of the thermal-insulation coating materials, and the like. Meanwhile, the invention also provides a preparation method of the thermal-insulation adhesive.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND +1

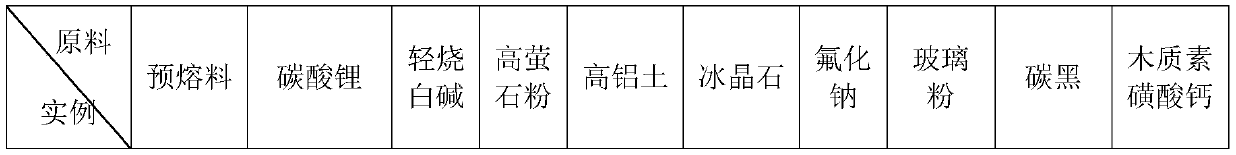

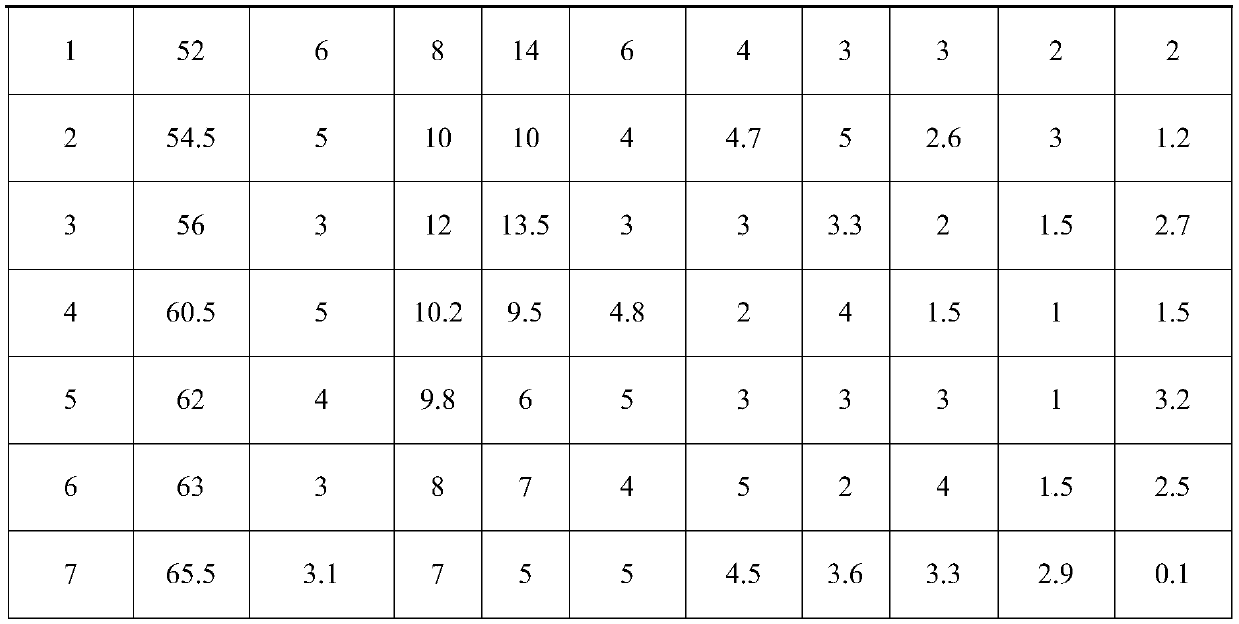

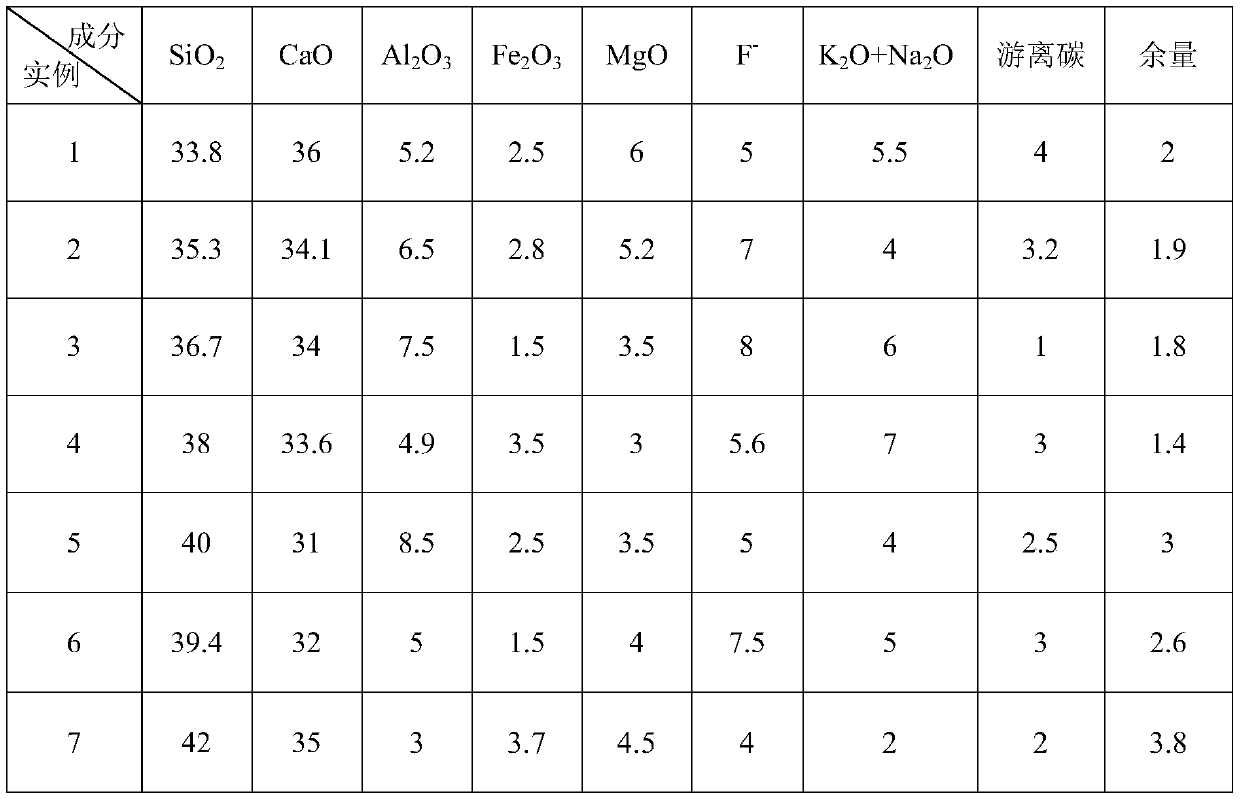

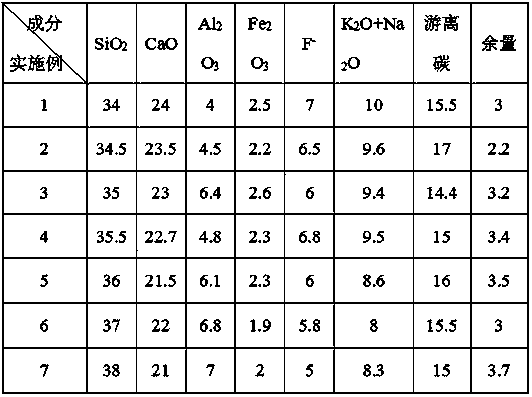

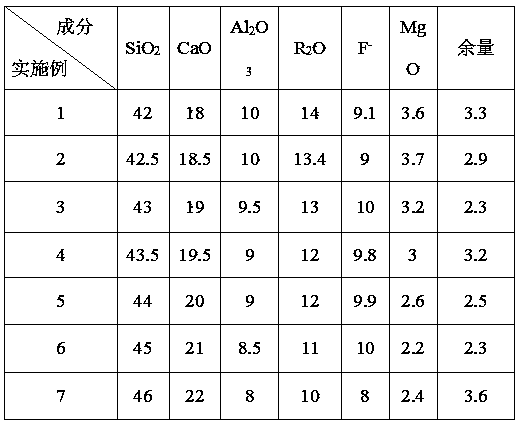

Continuous casting crystallizer functional protection material for ultra-low carbon IF steel

The invention discloses a continuous casting crystallizer functional protection material for ultra-low carbon IF steel. The functional protection material is prepared from the following raw materialsincluding, by weight, 52%-65.5% of a pre-melting material, 3%-6% of lithium carbonate, 7%-12% of light roasting white alkali, 5%-14% of high fluorite powder, 3%-6% of high alumina, 2%-5% of cryolite,2%-5% of sodium fluoride, 1.5%-4% of glass powder, 1%-3% of carbon black and 0.1%-3.2% of calcium lignosulphonate. Protective slag ensures the heat preservation effect and the melting effect, molten steel recarburization and casting blank slag inclusion are effectively prevented, and the obtained IF steel casting blank subcutaneous and internal quality is good.

Owner:西峡县西保冶金材料有限公司

Processing method of solid wood floor for underfloor heating

InactiveCN107042569ASolve easy syneresisSolve cracking and deformationWood treatment detailsThermal wood treatmentHazardous substanceUnderfloor heating

A processing method for solid wood flooring for floor heating. First, the blank is placed in a superheated steam box for soaking treatment, and then the blank is placed in a vacuum heating container filled with phenolic resin for modification, and then sent into a high-temperature atmosphere furnace. The blank is subjected to two carbonization treatments: after the first carbonization treatment is completed, the blank is first placed in a saturated steam box for humidity control and moisture recovery treatment, and then a silicon carbide coating is sprayed on its lower surface, and then the second carbonization treatment is performed; finally Put it into a vacuum heating container equipped with phenolic resin and modify it again, and after sealing the paint on each surface of the blank, you can get a solid wood floor for floor heating; the solid wood floor prepared by the invention can be used for floor heating, and has anti-corrosion Insect-proof performance, does not contain any harmful substances, and has no negative impact on human body and environment.

Owner:孔晓静

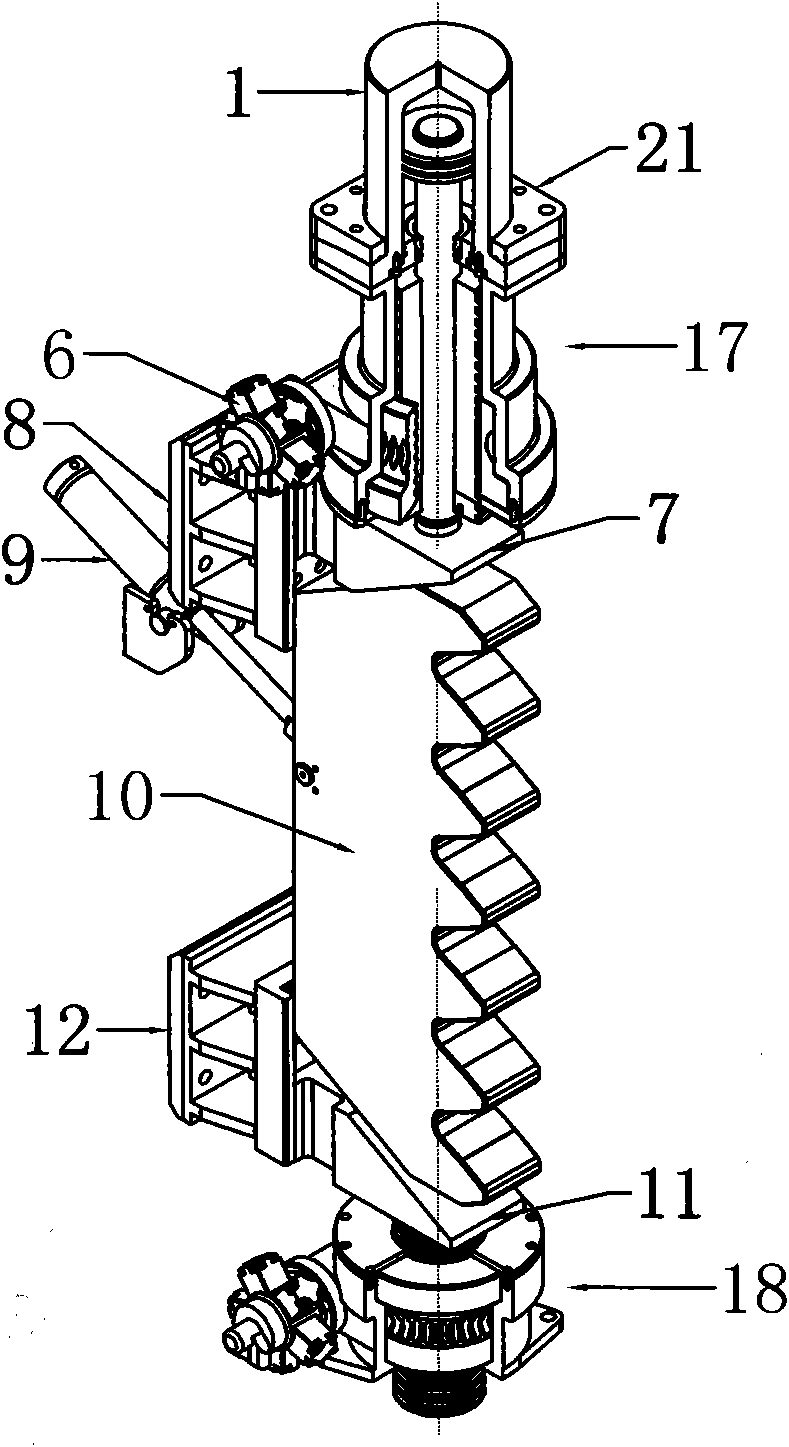

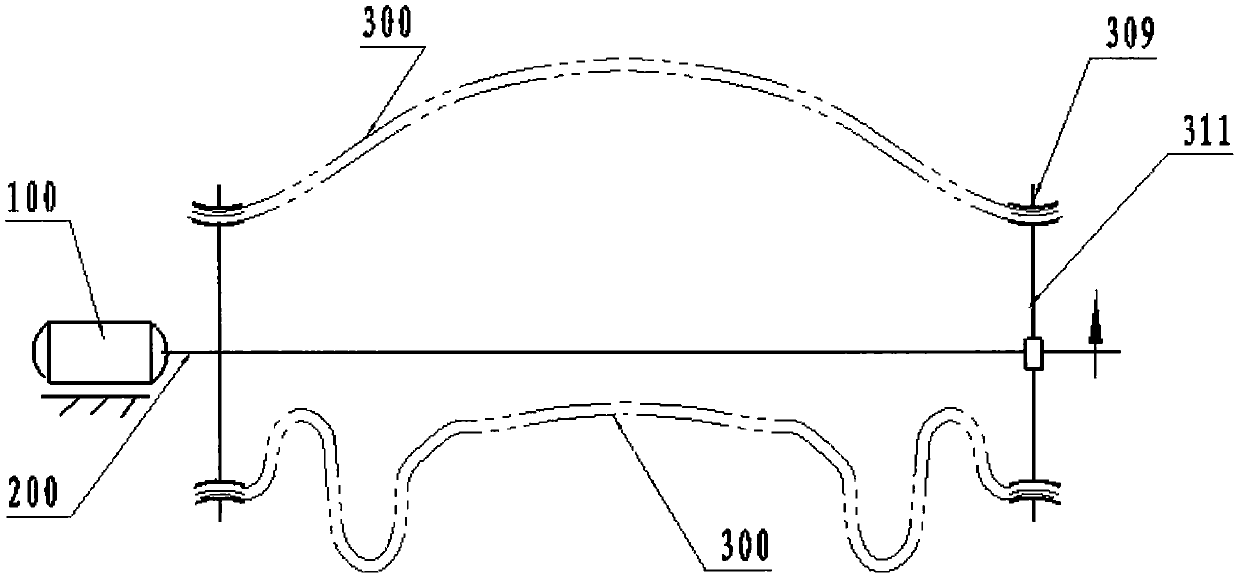

Mechanical leg and arm joint with full-sea-depth self-balancing type high-pressure sealing device

ActiveCN107166041AAdapt to sealing requirementsAchieving tightnessEngine sealsManipulatorExhaust valveUpper limb

The invention belongs to the technical field of deep sea sealing, and particularly relates to a mechanical leg and arm joint with a full-sea-depth self-balancing type high-pressure sealing device. The mechanical leg and arm joint comprises a mechanical leg and arm joint body and the full-sea-depth self-balancing type high-pressure sealing device, wherein the mechanical leg and arm joint body is composed of an upper limb and a lower limb which are hinged, and the full-sea-depth self-balancing type high-pressure sealing device is composed of an upper adapter bowl, an elastic leather bag pipe and a lower adapter bowl. The elastic leather bag pipe is connected with the upper adapter bowl and the lower adapter bowl through end face static sealing structures. The upper adapter bowl and the upper limb are connected through an end face static sealing structure, and the lower adapter bowl and the lower limb are connected through an end face static sealing structure. The upper adapter bowl, the elastic leather bag pipe and the lower adapter bowl are combined to form a cavity. Transformer oil is injected into the cavity through an oil charge valve opening, and air inside the cavity is emitted through a vent valve opening. The mechanical leg and arm joint can correspondingly extend or retract according to the joint movement angle change, and it is guaranteed that the mechanical leg and arm joint is not corroded or polluted by seawater.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

Machining method for slotted slit toothed tube for automobile damping

InactiveCN109226654AIncrease productivityLow manufacturing costRailway componentsVehicle componentsEngineeringDeep hole

The invention provides a machining method for a slotted slit toothed tube for automobile damping. According to the method, machining is performed through a cold header. The method comprises the following steps that S1, a cropping mold is used for cutting off wire rods into the needed length, and a product with a first end face and a second end face is obtained; S2, a deep hole is pressed at the first end face, and a shallow hole is pressed at the second end face; S3, the deep hole is punched to form a through hole; S4, teeth are pressed at the two end faces; S5, key grooves are pressed at thefirst end face and the second end face. The straight tube with the teeth at the two end faces and the key grooves in the two ends of an inner hole is obtained through cold heading one-time forming, machining procedures are simplified, the product efficiency is improved, the manufacturing cost is lowered, and the market competitiveness of enterprises is improved.

Owner:GUANGZHOU KOIDE KOKAN

Worm drive hose clip

ActiveCN101493167ALow bending stiffnessReduce the risk of injuryHose connectionsHaberdasheryEngineeringScrew thread

Owner:NORMA GERMANY GMBH

Multifunctional scrubbing operation head

InactiveCN111588293ASmall resistance to deformationThe mechanical model is simpleBathroom accessoriesElectric machineryEngineering

The invention belongs to the technical field of bathing or fitness, and relates to a multifunctional scrubbing operation head. The operation head comprises an operation head motor and further comprises a transversely-arranged rotating shaft connected with the motor and a flexible body operation part connected with at least two positions of the rotating shaft body in the axial direction directly orthrough a radial support, wherein the flexible body operation part body is distributed on the periphery or the outer side of the rotating shaft body in a suspended mode. The operation head is small in deformation resistance to human body curve fitting, a mechanical model is simple, the operation force is uniform, and the fitting precision of the operation head to a human body curve is far superior to that of a solid roller. Materials of the flexible body operation part are wide, flexible and convenient to obtain. The operation head has multiple functions and strong practicability, and can bewidely applied to places such as families, schools, hotels, senile apartments, public bathrooms, gymnasiums and the like.

Owner:宋大勇

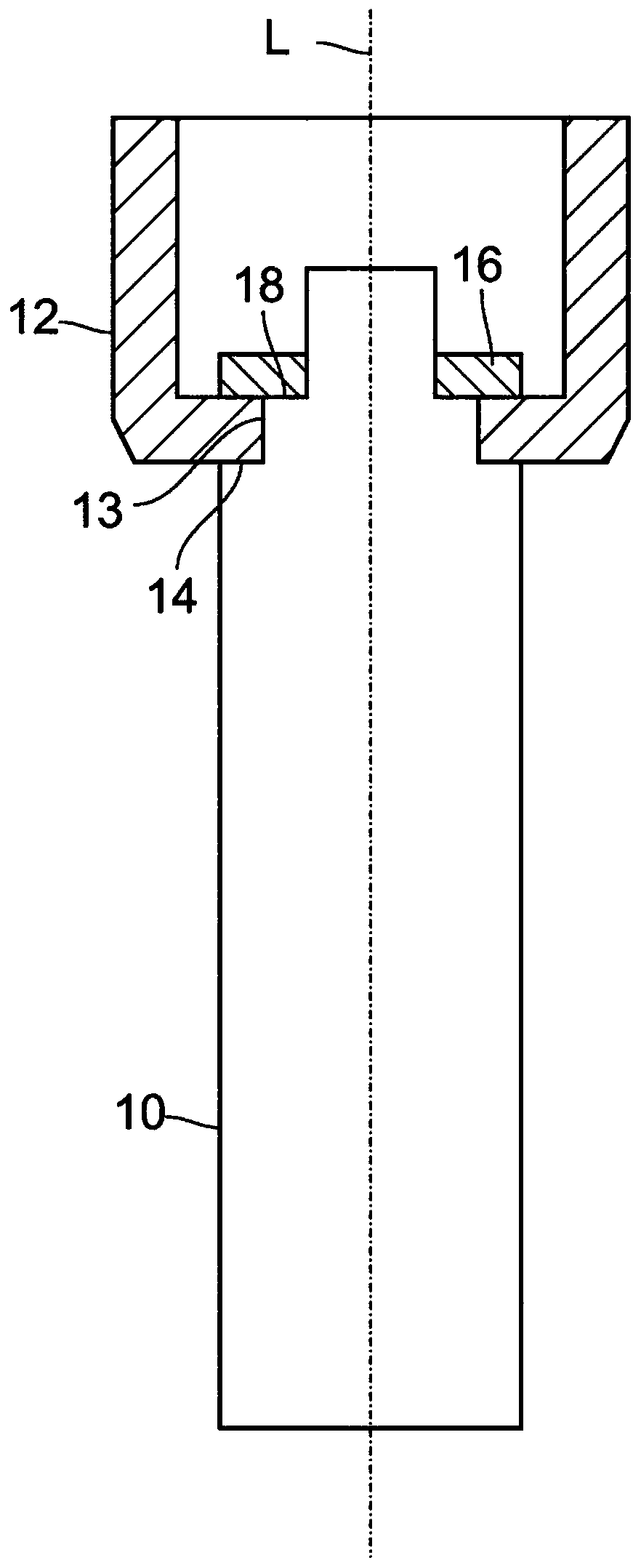

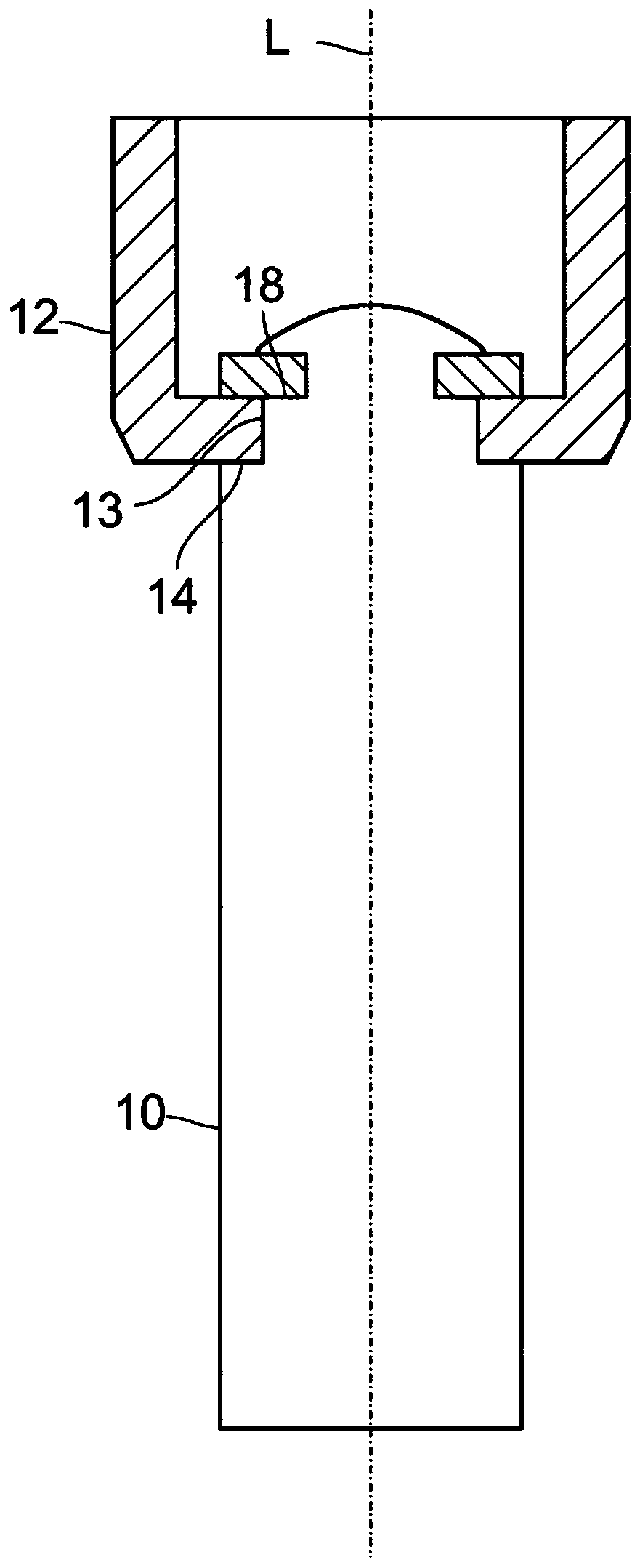

Electromagnetic control device, in particular for adjusting camshafts of an internal combustion engine

InactiveCN110475950ASimplify the manufacturing processGuaranteed costValve arrangementsMachines/enginesEngineeringInternal combustion engine

The present invention relates to an electromagnetic control device, in particular for adjusting camshafts or a camshaft section of an internal combustion engine, comprising an energisable coil unit (44), by means of which an armature (12) mounted for movement along a longitudinal axis (L) can be moved relative to a pole core between a retracted position and an extended position; a tappet (26), which is mounted for movement along the longitudinal axis (L) with a free end portion (28) with which, in the extended position, the tappet (26) interacts with a camshaft in order to adjust the camshaft,and with an inner end portion (30), with which the tappet (26) is attached to the armature (12), wherein the tappet (26) is attached in a form-fitting manner to the armature (12) by means of a deformable connection element. The invention also relates to a method for the form-fitting attachment of a tappet (26) to an armature (12) of an electromagnetic control device (42) of this kind.

Owner:KENDRION VILLINGEN GMBH

Low-stress sheet metal blank crystallizer

The low pressure metal sheet blank crystallizer consists of two opposite wide water cooled copper plates and two narrow copper plates defining the width of the sheet blank. The wide copper plates have top sprue in continuous curve shape and form cavity with arced work surface and large smooth work chamber. The wide copper plates are provided with circulating water cooling channels in the outer surfaces and have homogeneous cooling and high heat conducting of the crystallizer for continuous operation. Using the crystallizer can eliminate concentrated stress in the steel blank knee point, avoid crack, and reach high production efficiency, high product quality and long service life of the crystallizer.

Owner:西峡龙城冶材集团有限公司

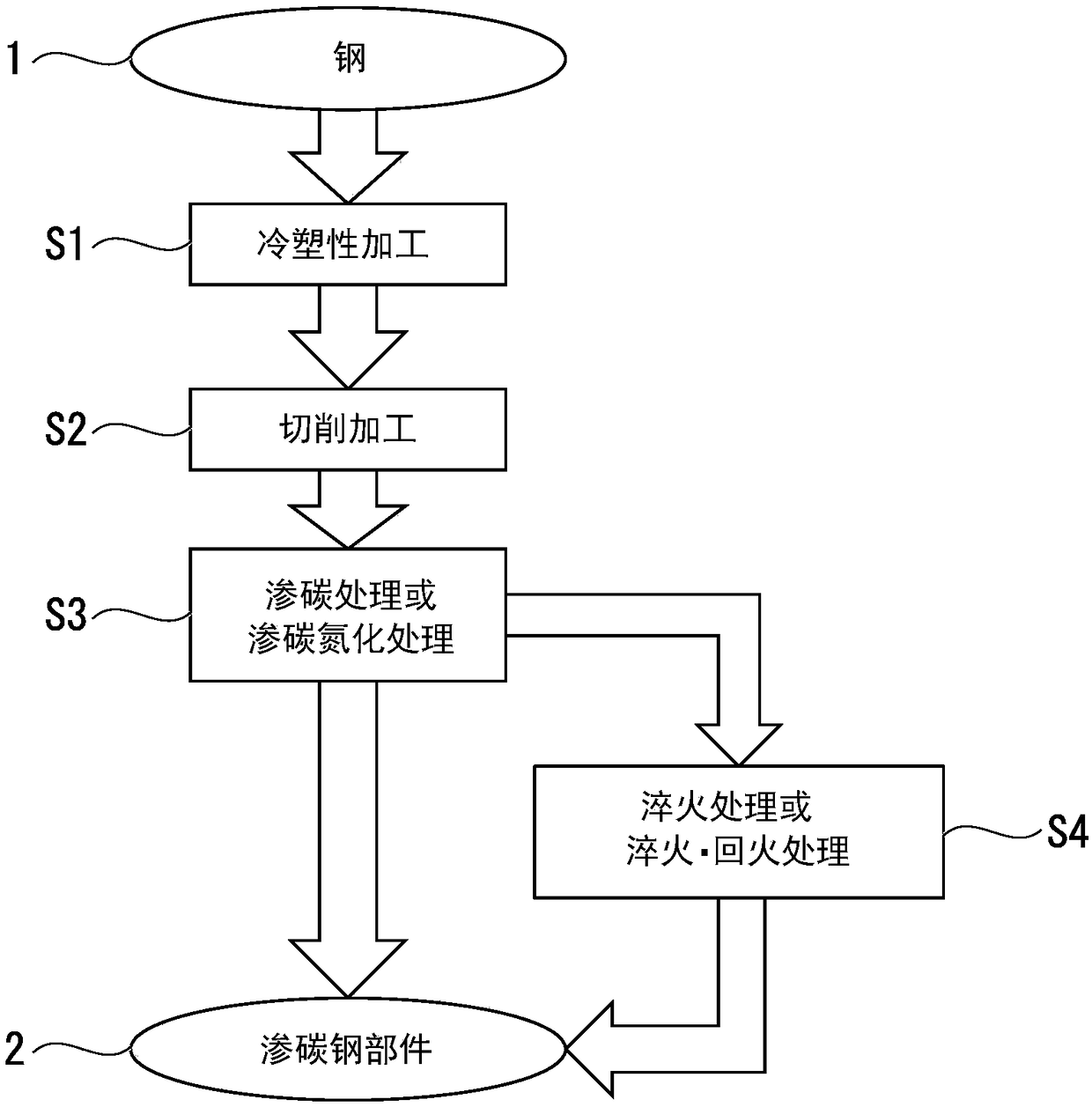

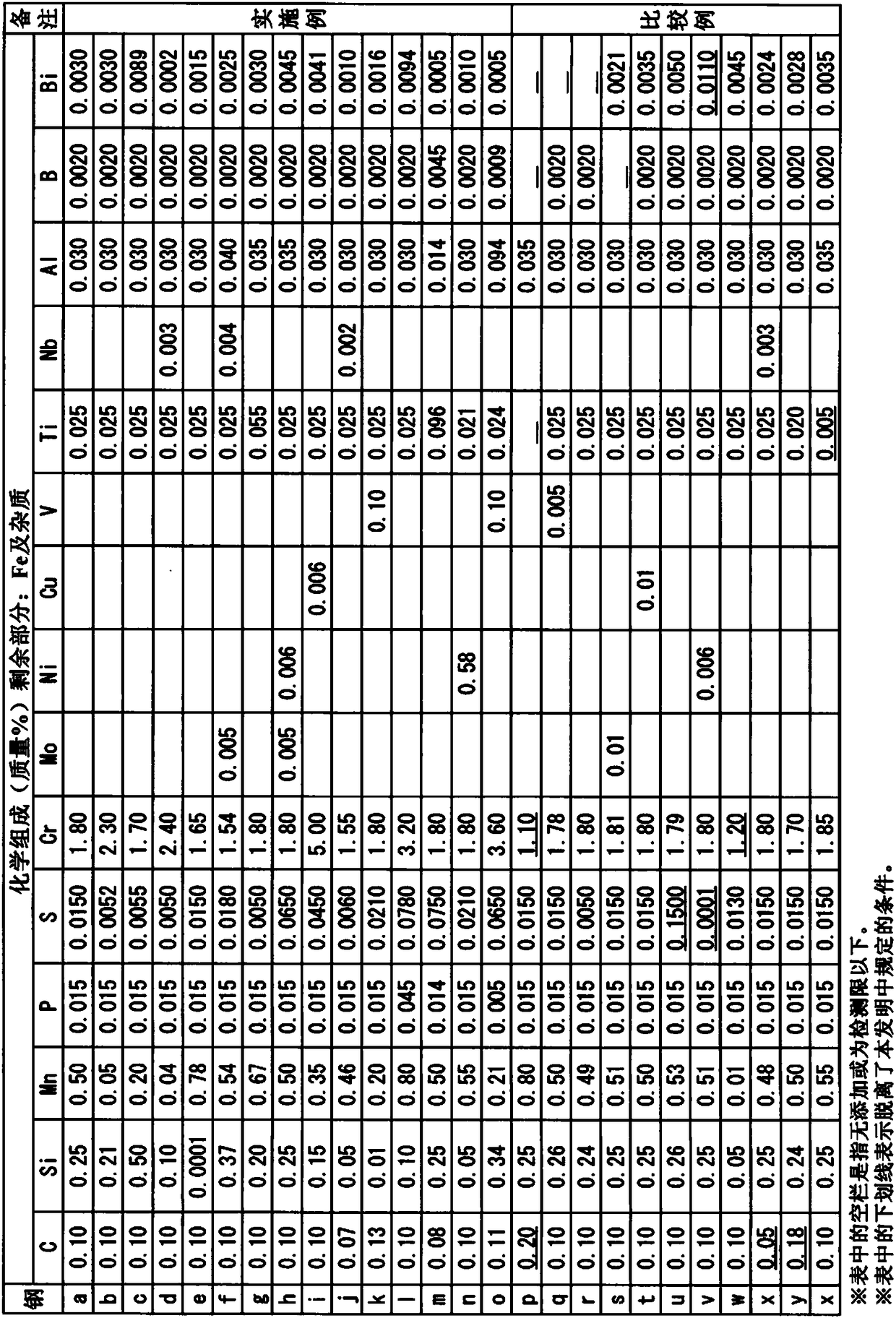

Steel, carburized steel component, and carburized steel component production method

InactiveCN108291285ACheap manufacturingHigh strengthSolid state diffusion coatingFurnace typesChemical compositionSulfide

Steel according to one embodiment of the present invention includes prescribed ranges of chemical components, has a quenching index Ceq of more than 7.5 but less than 44.0, and has a metal structure that includes 85-100 area% of ferrite. The average distance between sulfides that have an equivalent circular diameter of at least 1 [mu]m but less than 2 [mu]m that are observed in a cross-section that is parallel to the rolling direction of the steel is less than 30.0 [mu]m. The density of the sulfides that have an equivalent circular diameter of at least 1 [mu]m but less than 2 [mu]m that are observed in the cross-section that is parallel to the rolling direction of the steel is 300 / mm<2> or higher.

Owner:NIPPON STEEL CORP

Valve steel continuous casting crystallizer functional protection material

The invention discloses a valve steel continuous casting crystallizer functional protection material. The material comprises the following raw material components including, by weight, 36.0-42.0% of pre-melt materials, 14.0-17.0% of wollastonite, 9.0-11.0% of fine glass powder, 3.0-5.0% of lithium carbonate, 7.0-9.0% of fluorite, 2.0-4.0% of sodium fluoride, 3.0-5.0% of cryolite, 10.0-12.0% of graphite carbon, 2.0-3.5% of carbon black and 2.0-3.5% of a binder. According to the valve steel continuous casting crystallizer functional protection material, the thermal insulation effect and the melting effect are guaranteed, furthermore, pulling break, slag inclusion and depression of casting blanks are effectively prevented, and the non-cleaning rate of the surfaces of the obtained casting blanks reaches up above 98%.

Owner:西峡县西保冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com