Patents

Literature

80results about How to "Large deformation space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

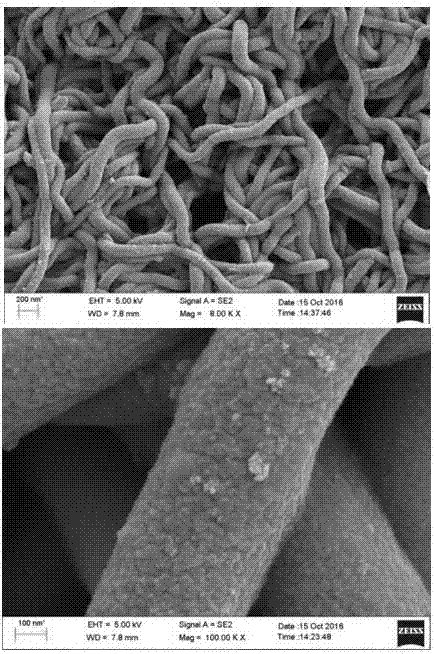

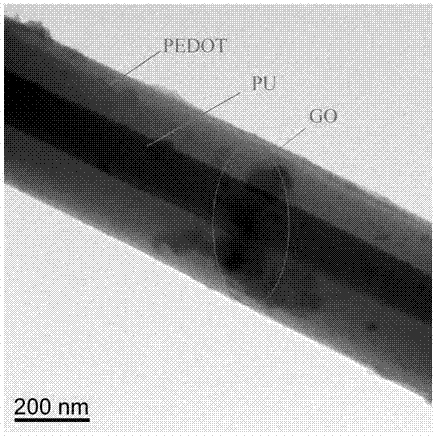

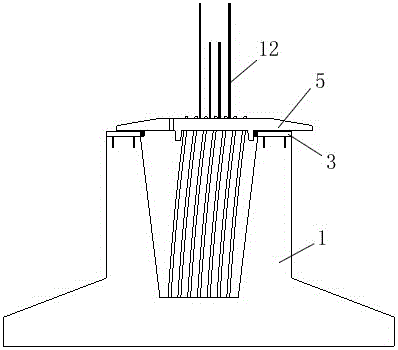

Flexible and extensible multifunctional nanofiber sensor and preparation method thereof

InactiveCN107192485ASmall finenessIncrease deposition polymerization rateFibre typesNanosensorsCopper wireIn situ polymerization

The invention discloses a flexible and extensible multifunctional nanofiber sensor and a preparation method thereof. An electrostatic spinned polyurethane nanofiber membrane doped with graphene oxide is used as a flexible matrix. An in-situ polymerization method is used to in-situ polymerize conductive polymer polythiophene on the surface of the polyurethane nanofiber doped with graphene oxide, and the polyurethane / polythiophene nanofiber membrane which is doped with graphene oxide and is provided with a skin-core structure is prepared. The surface of the nanofiber membrane is compounded with a gel membrane with a conductive copper wire to prepare the flexible and extensible multifunctional nanofiber sensor. The sensor can be used for detecting multi-mechanical stimulation environments with pressure, stretching, bending and the like, and has the advantages of high sensitivity and wide sensing range. In a human body monitoring system, the sensor can monitor pulse, heartbeat, muscle group vibration and other human health physiological indicators in real time, and can detect the full-range movement of a human body, including the movement of facial expressions and large and small joints.

Owner:ZHONGYUAN ENGINEERING COLLEGE

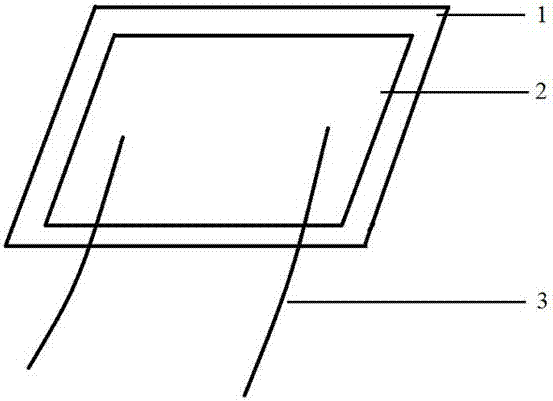

Stretchable multi-mode sensor based on nanofiber core spun yarn and preparation method thereof

ActiveCN109355715AAchieve integrationAvoid separate preparationElectro-spinningUltrasonic/sonic fibre treatmentFiberYarn

The invention discloses a flexible stretchable multi-mode sensor based on a nanofiber core spun yarn and a preparation method thereof. The flexible stretchable multi-mode sensor comprises an elastic conductive core yarn and a carbon nano tube / polymer compounded nanofiber, wherein the surface of the elastic conductive core yarn is coated with the carbon nano tube / polymer compounded nanofiber through an electrospinning technique to prepare a continuous nanofiber core spun yarn, the nanofiber core spun yarn is woven into a fabric according to a weaving principle, and the flexible stretchable multi-mode sensor based on the nanofiber core spun yarn is obtained by utilizing a flexible polymer packaging mode for the fabric; the elastic conductive core yarn is prepared by coating a carbon nano tube / polymer conductive solution to the surface of the elastic conductive core. By adopting the weaving mode and the like, an intelligent sensing unit weaves the fabric, then a novel intelligent wearableclothing is assembled, and development of a flexible intelligent wearable product is effectively promoted.

Owner:ZHONGYUAN ENGINEERING COLLEGE

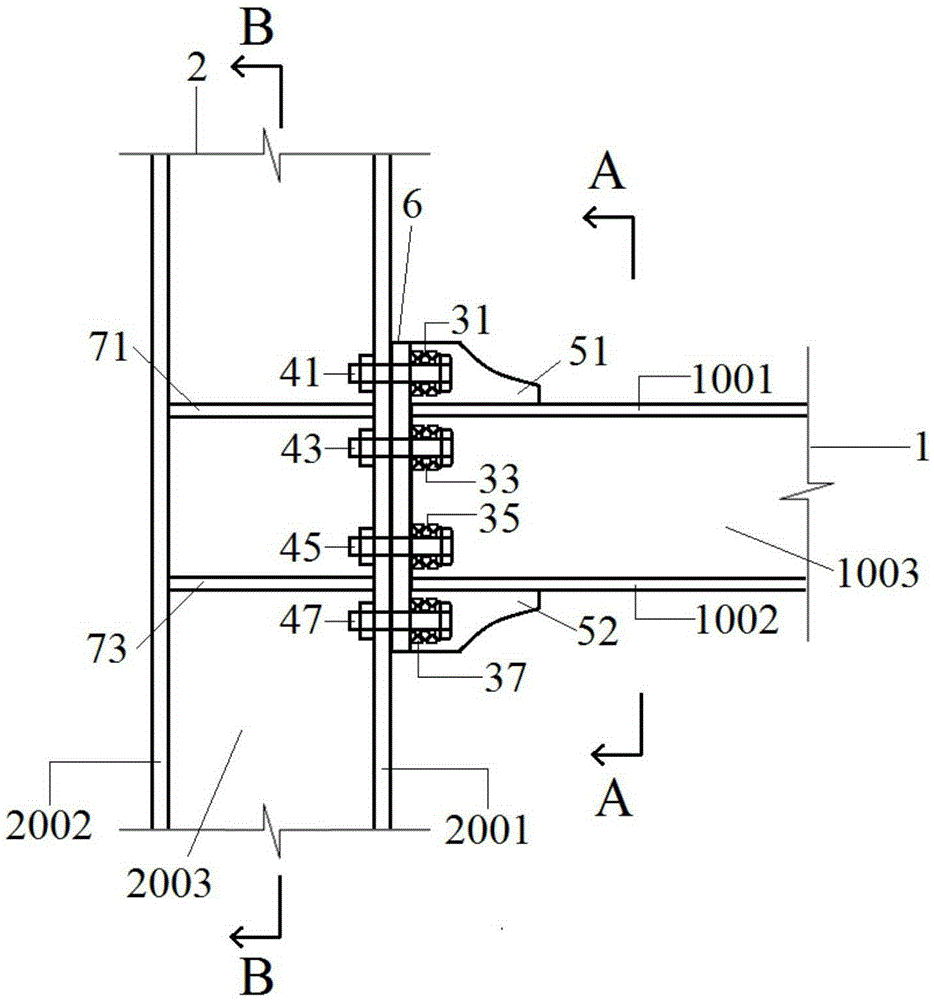

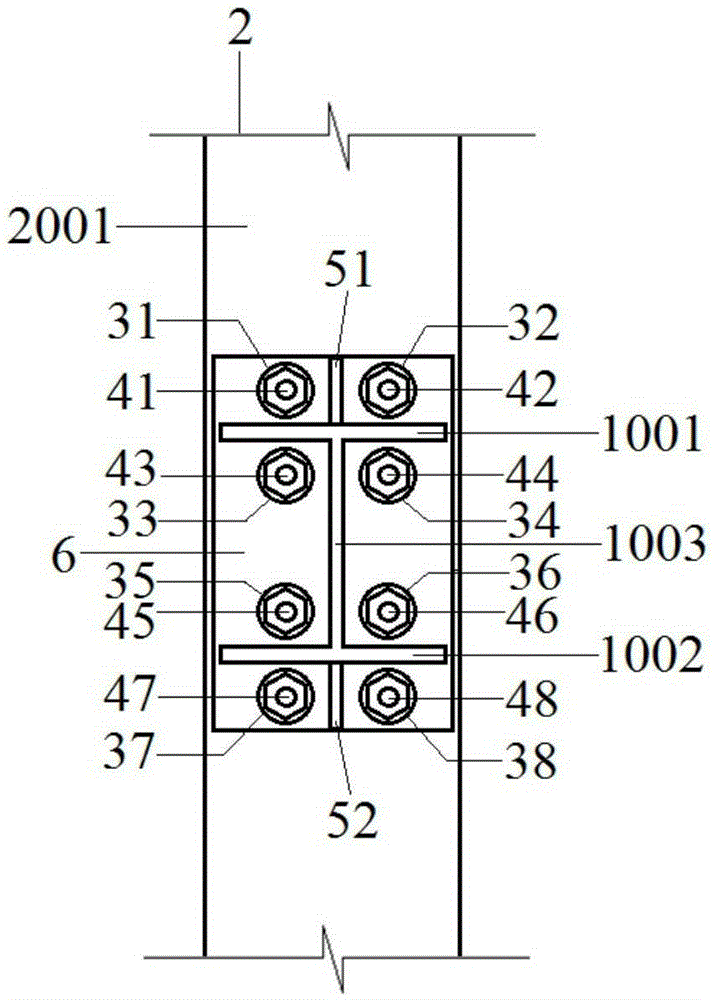

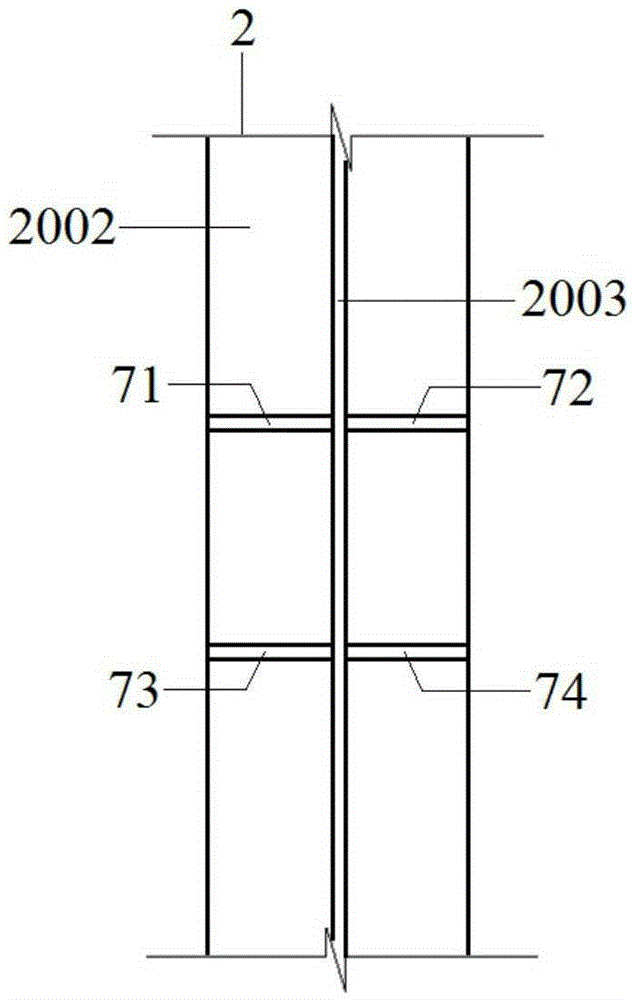

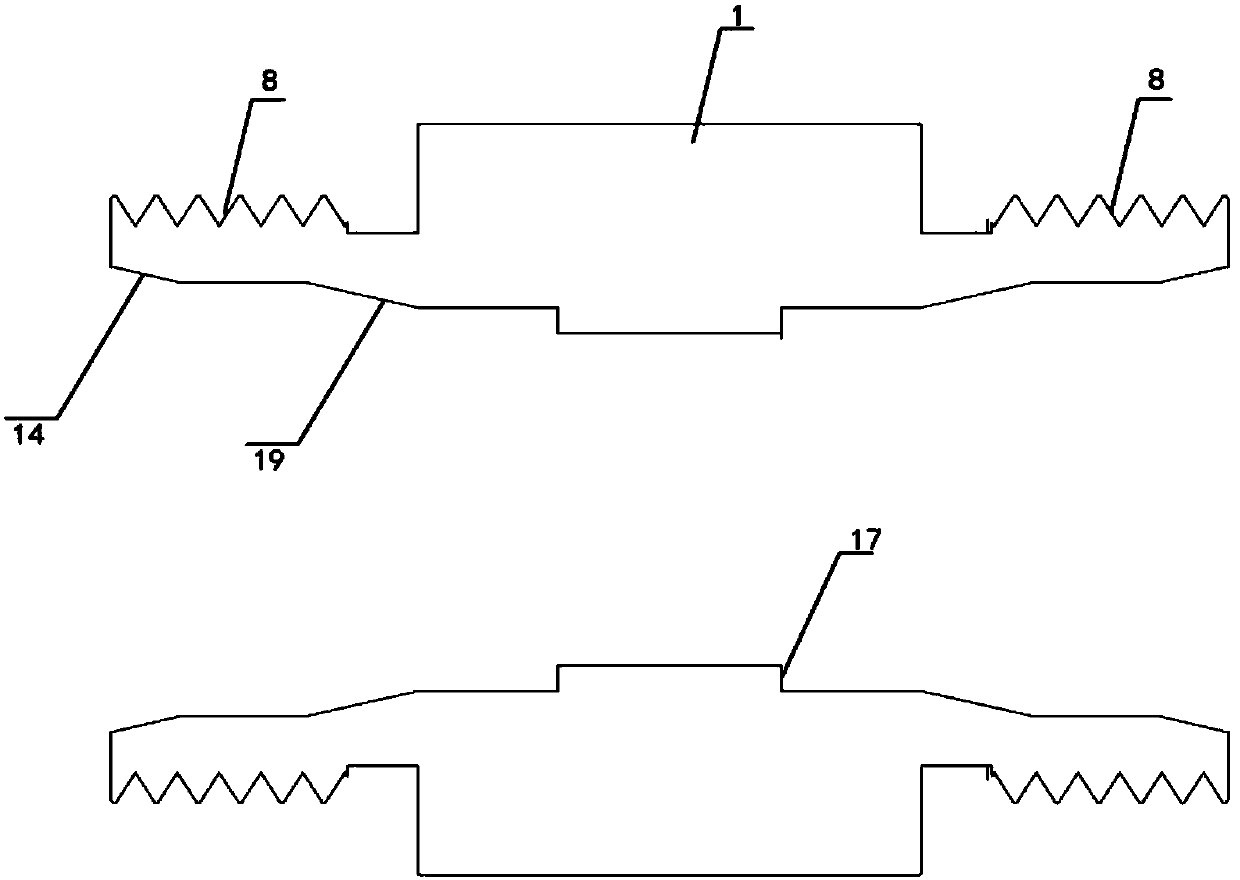

Self-resetting steel structure beam-column aseismatic joint based on shape memory alloy ring spring set

The invention discloses a self-resetting steel structure beam-column aseismatic joint based on a shape memory alloy ring spring set. The self-resetting steel structure beam-column aseismatic joint comprises H-shaped steel beam-columns and a joint region used for connecting the H-shaped steel beam-columns, each H-shaped steel beam-column comprises an H-shaped steel beam and an H-shaped steel column, and the beam end of each H-shaped steel beam sticks close to a front flange of the corresponding H-shaped steel column through an end plate, so that the H-shaped steel beams and the H-shaped steel columns are placed in a mutually perpendicular manner. The joint region comprises a first ring spring set, a second ring spring set, a third ring spring set, a fourth ring spring set, a fifth ring spring set, a sixth ring spring set, a seventh ring spring set, an eighth ring spring set, a first high-strength bolt, a second high-strength bolt, a third high-strength bolt, a fourth high-strength bolt, a fifth high-strength bolt, a sixth high-strength bolt, a seventh high-strength bolt, an eighth high-strength bolt, an upper-side end plate reinforcing rib, a lower-side end plate reinforcing rib, the end plate, an upper-side first column reinforcing rib, an upper-side second column reinforcing rib, a lower-side first column reinforcing rib and a lower-side second column reinforcing rib. The self-resetting steel structure beam-column aseismatic joint is simple in form and is stressed reasonably.

Owner:TONGJI UNIV

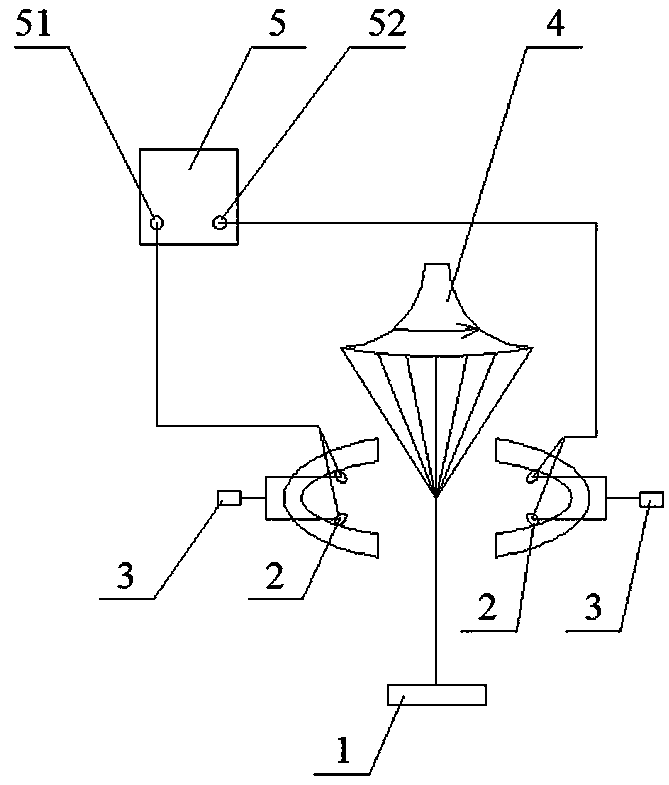

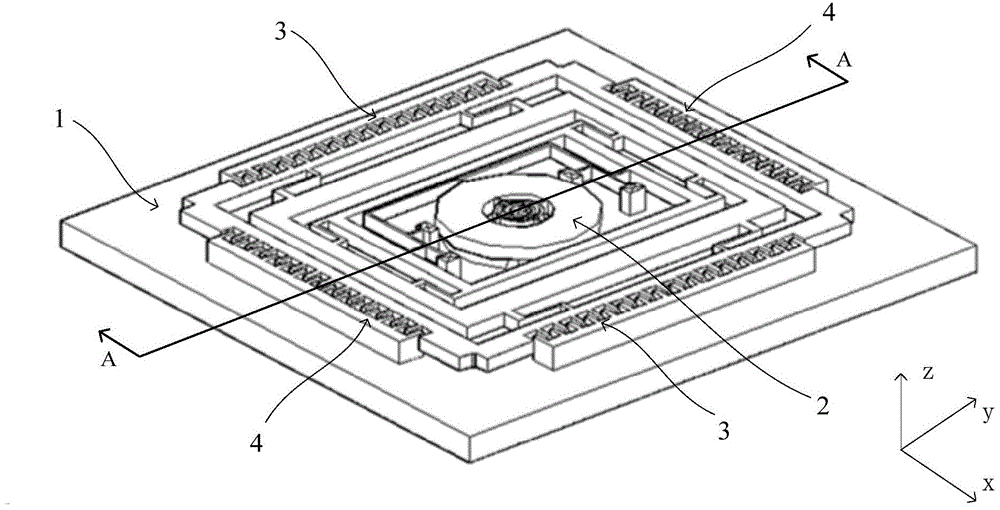

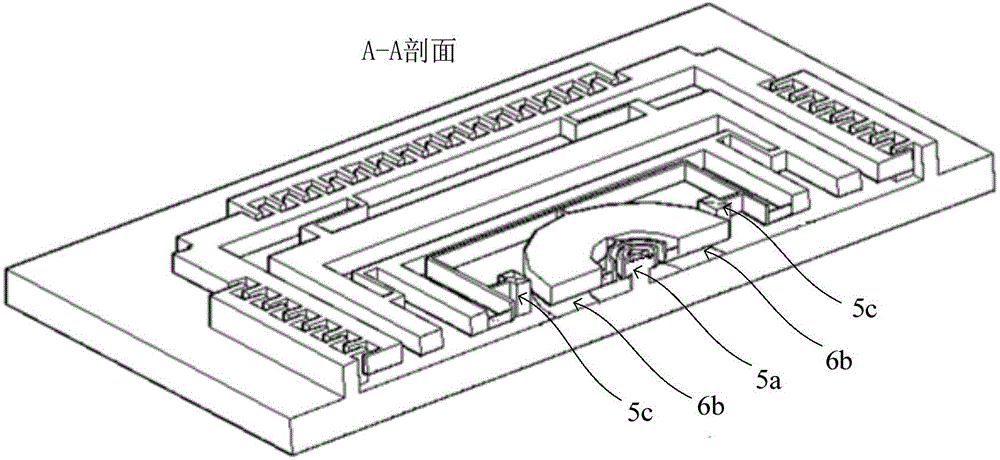

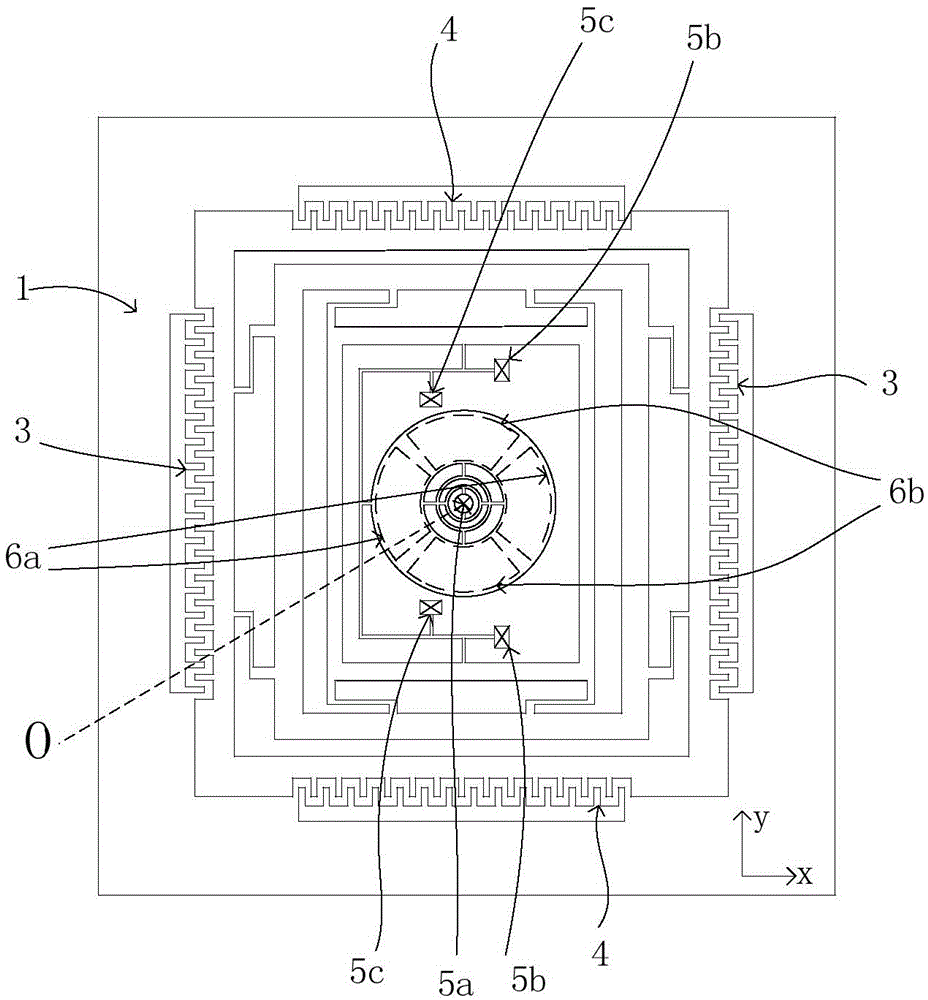

Micro-electromechanical deformable structure and triaxial multi-degree of freedom micro-electromechanical gyroscope

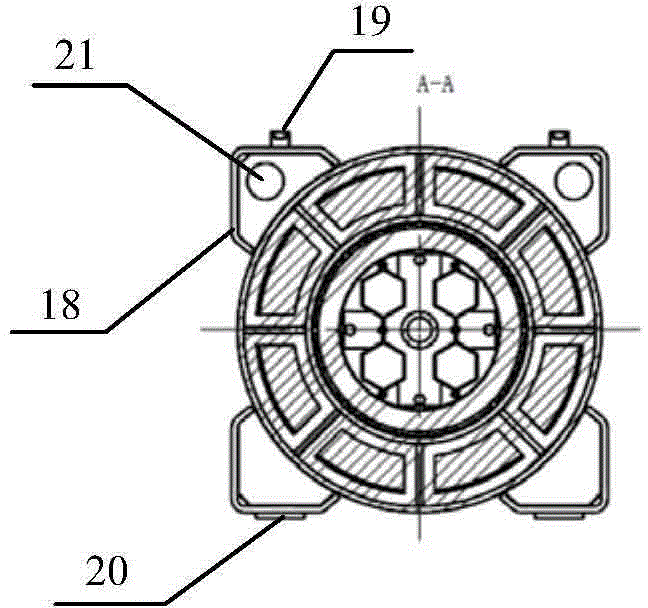

ActiveCN104406579ASmall resistance to deformationLarge deformation spaceSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesDifferential capacitanceCapacitance

The invention relates to a triaxial multi-degree of freedom micro-electromechanical gyroscope. The triaxial multi-degree of freedom micro-electromechanical gyroscope comprises an inner framework, a middle framework, an outer framework, a linkage part positioned in the inner framework, an annular detection capacitor positioned in the center, an annular polar plate of which outer edge of the annular polar plate is connected with the linkage part, two groups of driving capacitors and two groups of second detection capacitors, wherein the two groups of driving capacitors are symmetrically distributed on the two sides, parallel to an x axis, of the outer framework; the two groups of second detection capacitors are symmetrically distributed on the two sides, parallel to a y axis, of the outer framework. The triaxial multi-degree of freedom micro-electromechanical gyroscope adopts a single structure design, capacitance type electrostatic driving and differential capacitance detection; the driving mode is simple; as the structure is compact, the gyroscope size is reduced; the gyroscope is suitable for massive production, small errors are produced under the influence of temperatures and the processing technology, and great measurement precision and sensitivity can be realized.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

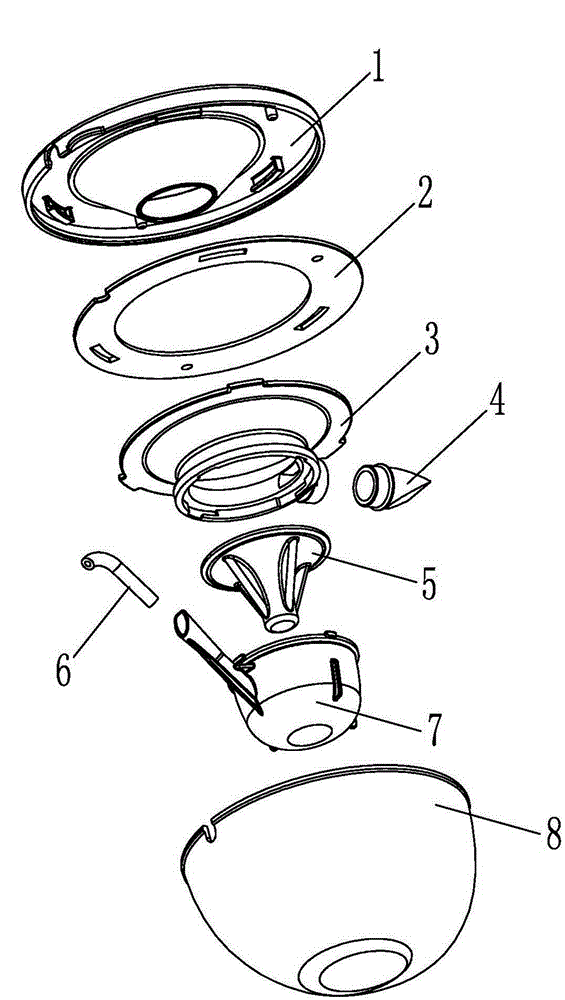

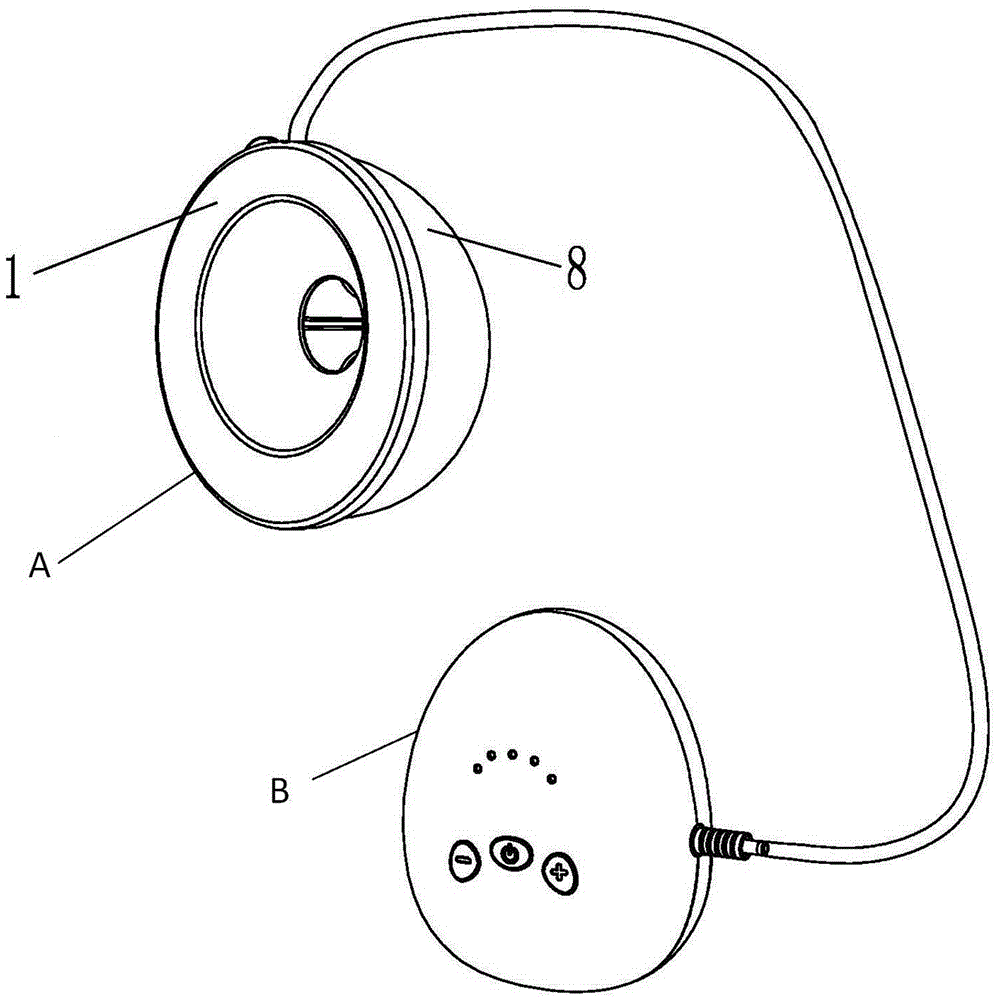

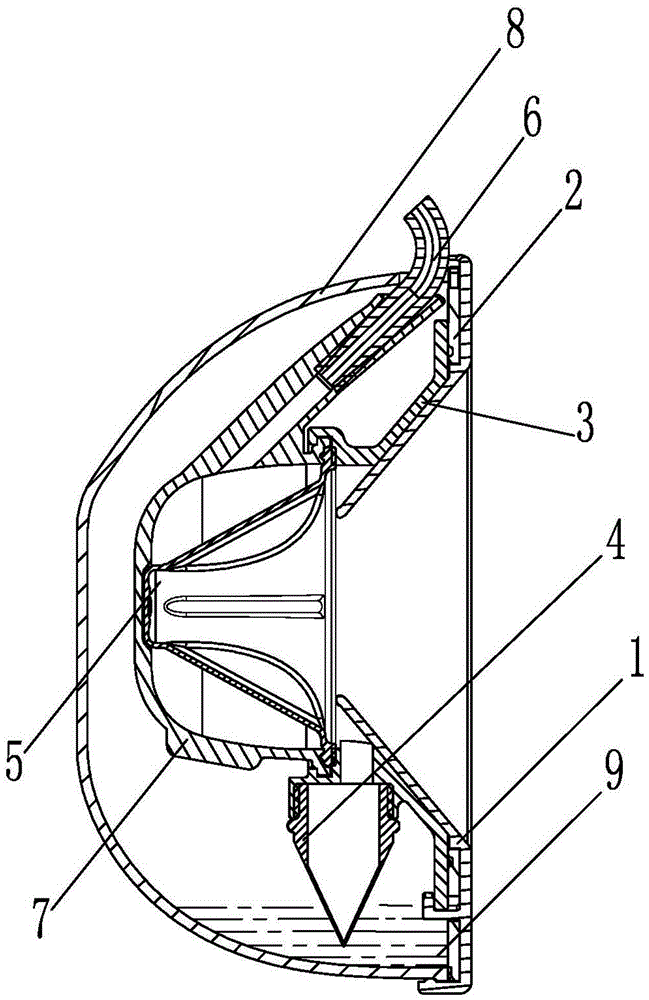

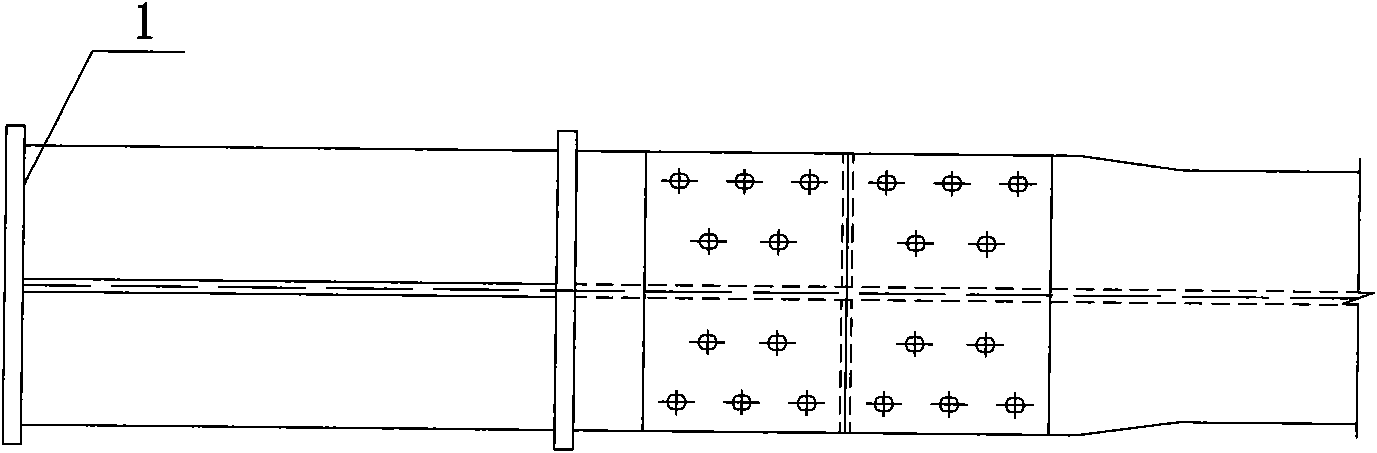

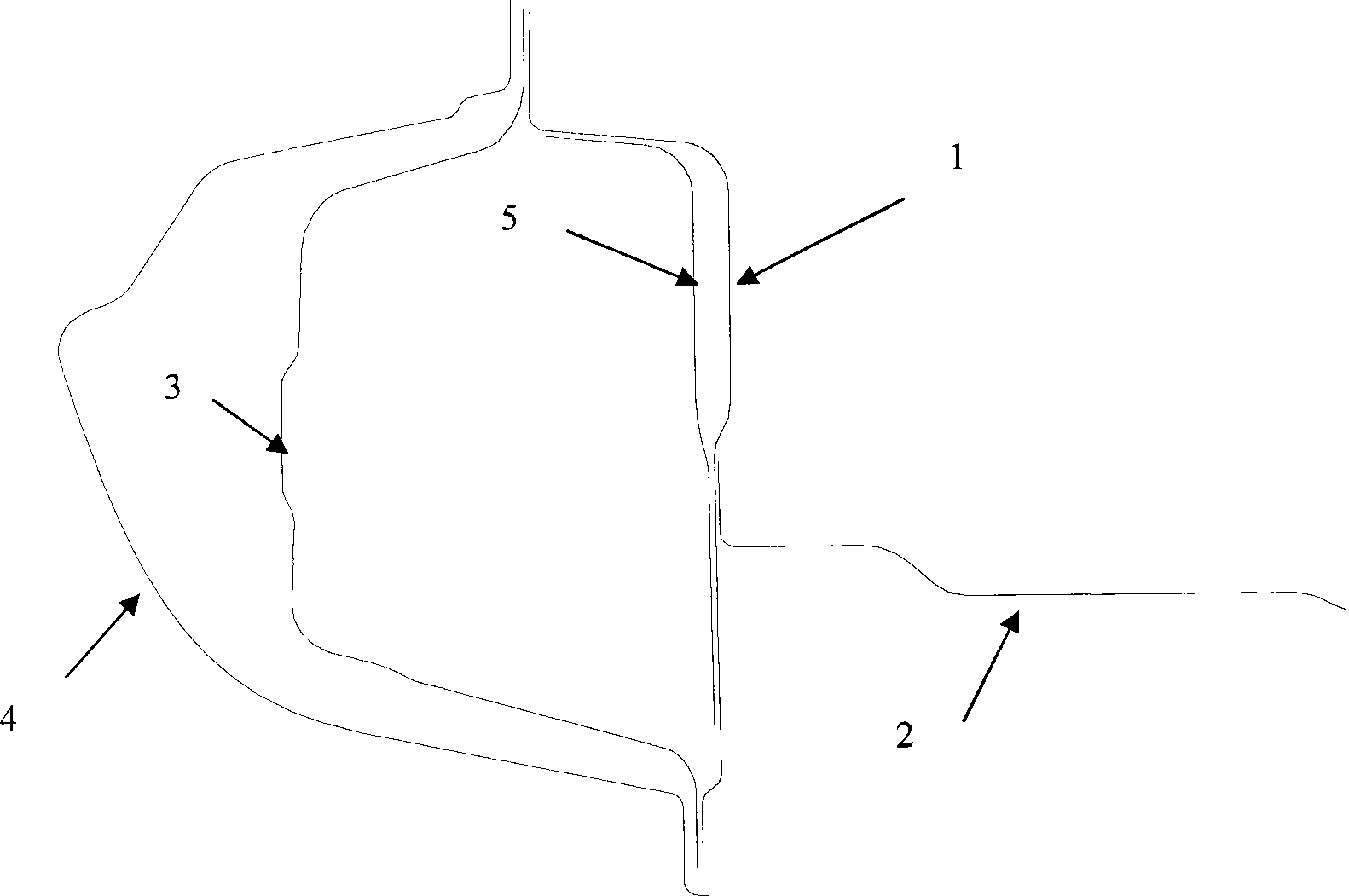

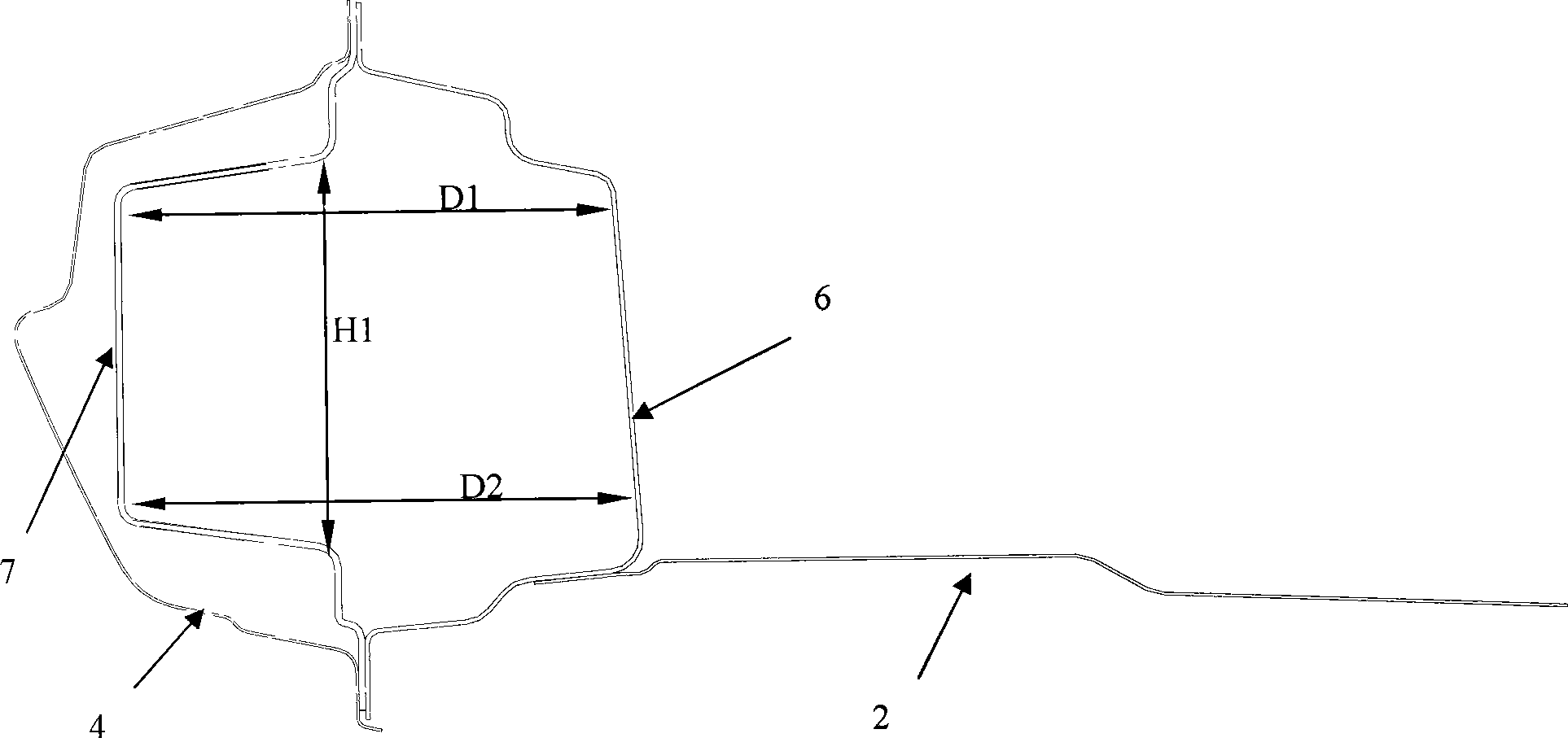

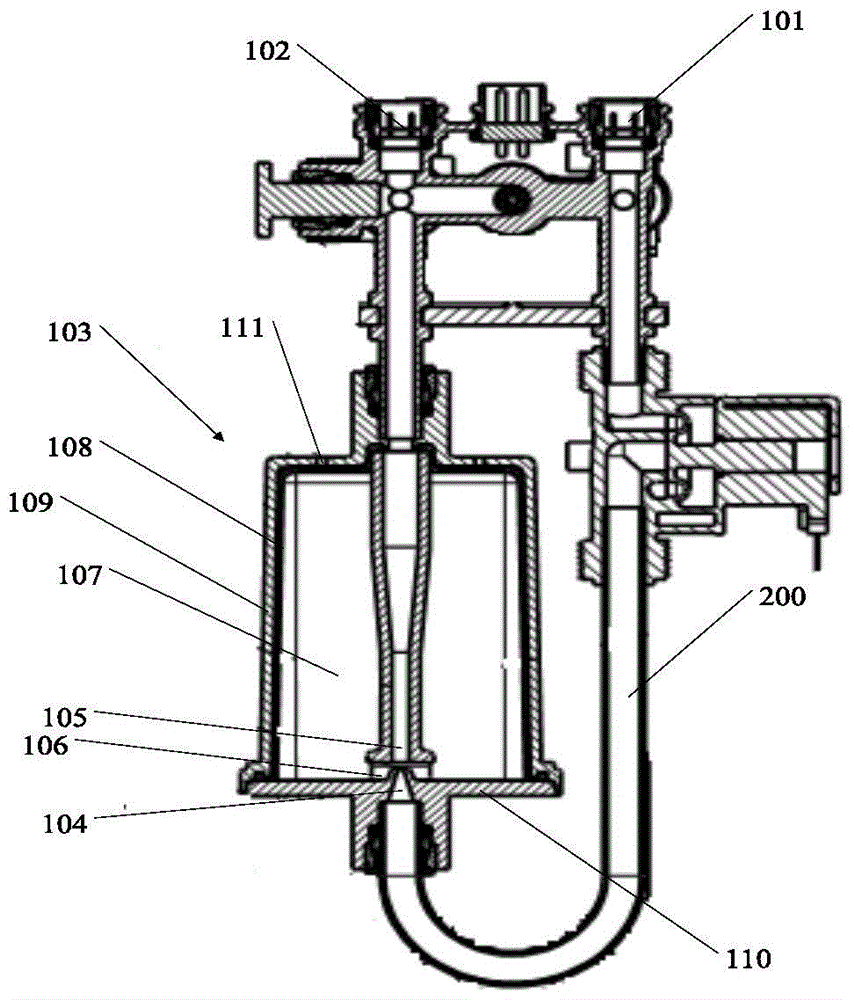

Breast pump capable of being used while user lies down without holding

The invention relates to a breast pump capable of being used while a user lies down without holding, and belongs to the field of maternal and child appliances. The breast pump comprises a negative pressure source and a milk sucking device. Different from other milk sucking devices, the milk sucking device comprises a hemispheric cup and a bottom cover; a tapered breast holder fitting breasts of human bodies is arranged in the middle of the bottom cover; a central connection piece and a waterproof ring are embedded in the bottom cover; a connector of the central connection piece is connected with a one-way valve seat, the bottom cover, an air bag and a shell in an embedded manner, wherein the shell provides space needed by airbag deformation; the bottom cover and the central connection piece can be integrated. During use, the one-way valve seat is soaked in milk; the air bag is provided with a plurality of symmetrical grooves at least. The breast bump can be used when the user lies down without holding and is particularly suitable for weak puerperae.

Owner:陈俊波

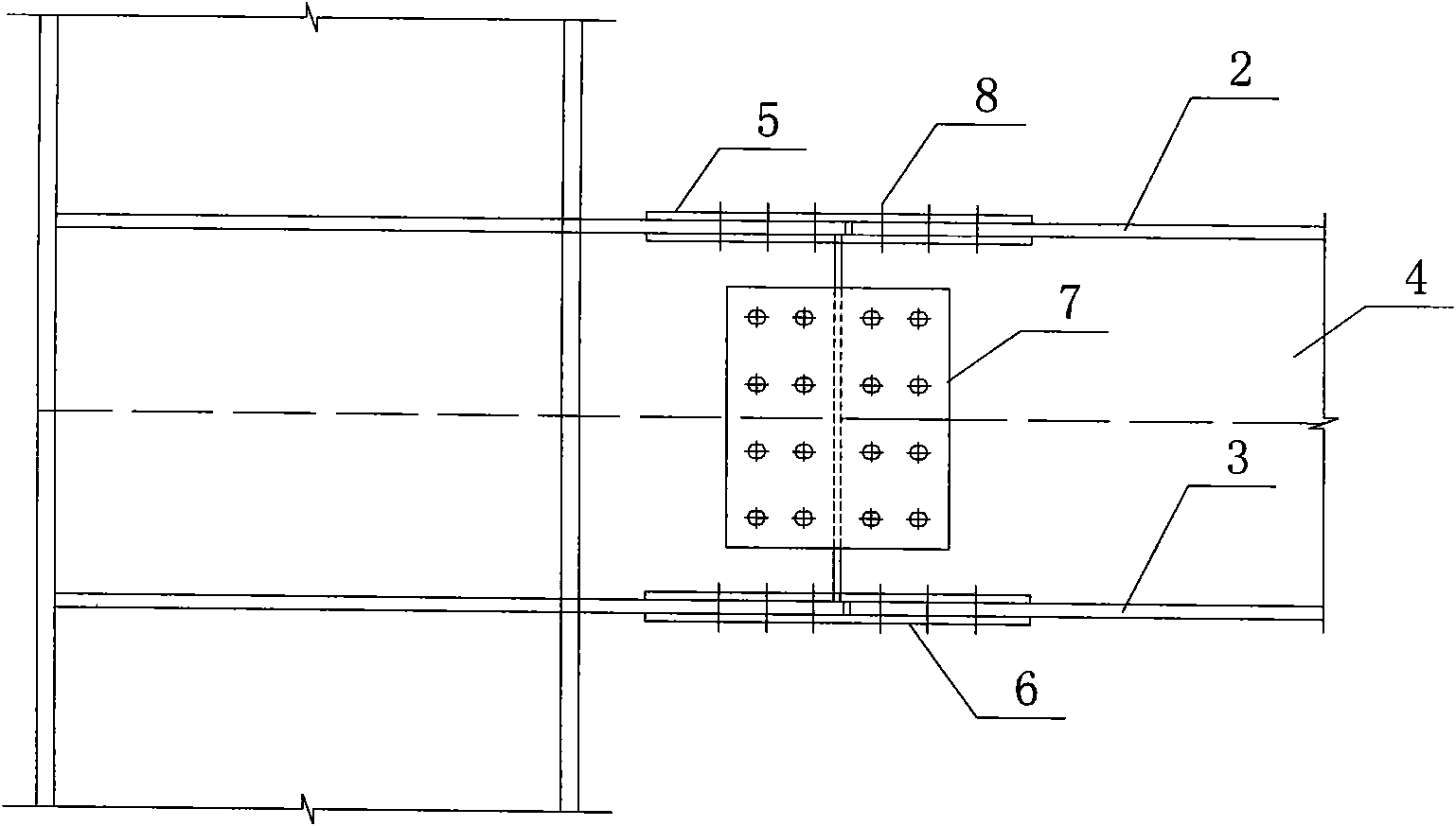

Steel structure beam-column slotted hole rotating type high-strength bolt connection ductility joint

InactiveCN101624845AImprove ultimate carrying capacityLarge deformation spaceBuilding constructionsEngineeringDistortion

The invention relates to a steel structure beam column, in particular to a high-strength bolt connection joint for the steel structure beam column. The invention provides a slotted hole rotating type high-strength bolt connection ductility joint for the steel structure beam column, which comprises a column, a top flange plate of a beam, a bottom flange plate of the beam, a web of the beam, a top flange splicing plate of the beam, a bottom flange splicing plate of the beam, a web splicing plate and a plurality of web friction type high-strength bolts, wherein the top flange plate and the bottom flange plate are connected through the high-strength bolt in a butted mode. The bolt hole of the high-strength bolt is a slotted hole along the shearing direction of the bolt hole, and the high-strength bolt is positioned in the middle in the length direction of the slotted hole. The high-strength bolt connection ductility joint can provide larger distortion space, improve the energy consumption and the internal force redistribution capability of the structure, and cannot cause brittle failure during the earthquake; therefore, the shock-proof performance of the structure is enhanced.

Owner:SHANGHAI BAOYE GRP CORP +1

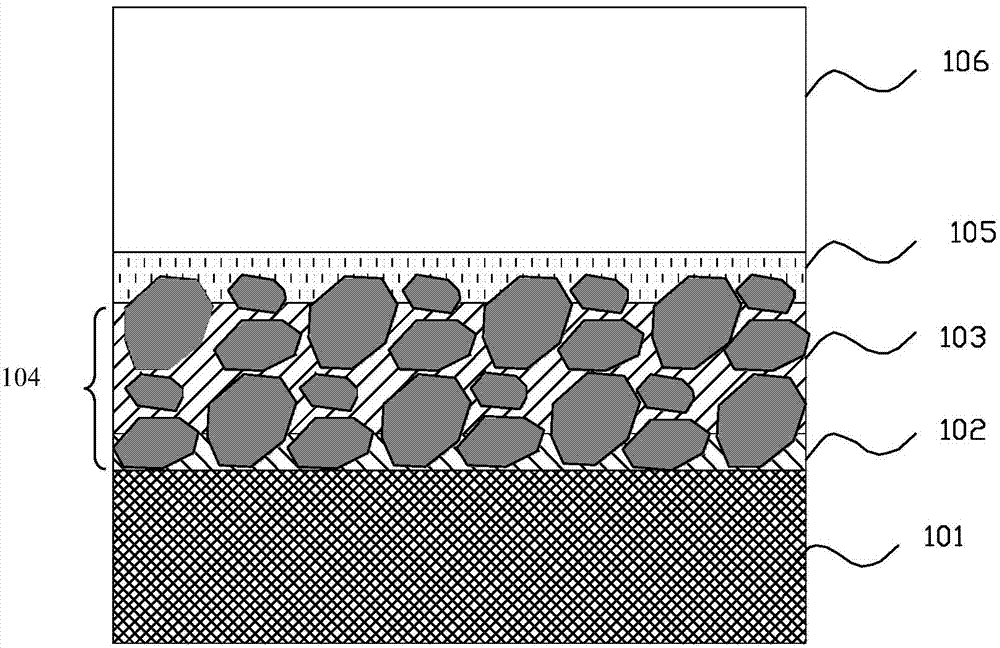

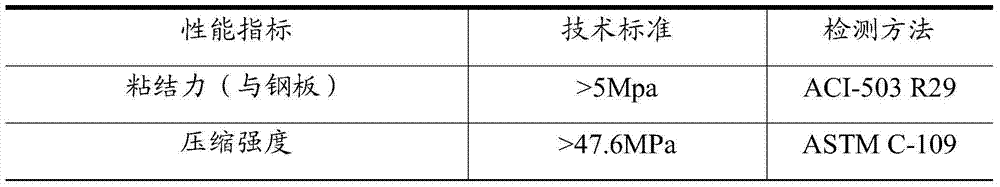

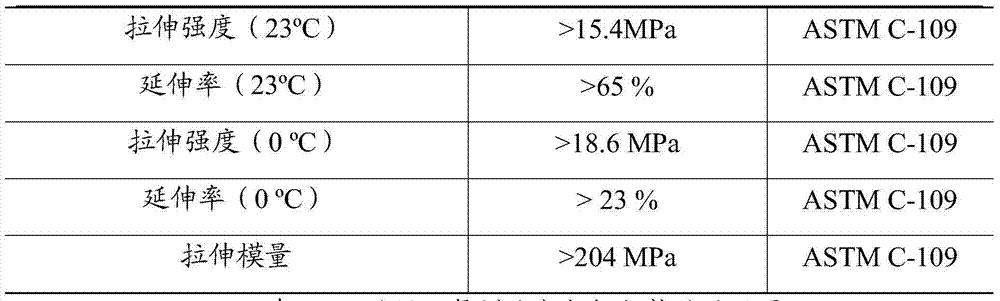

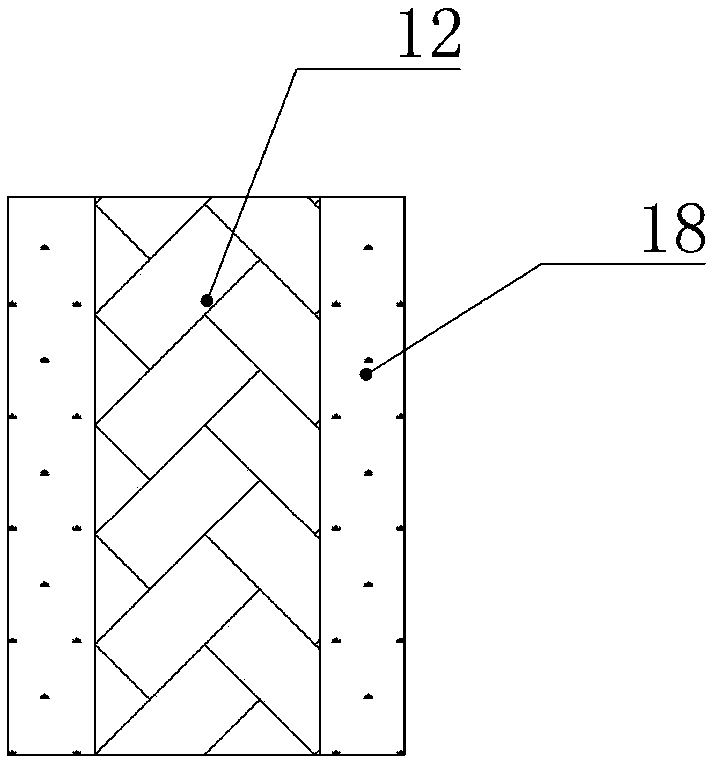

Steel bridge deck paving structure and construction method thereof

InactiveCN103774553AImprove adhesionStrong resistance to deformationBridge structural detailsBridge erection/assemblyEpoxyAsphalt mastic

The invention discloses a steel bridge deck paving structure and a construction method thereof. A combined type connecting layer and an ultrahigh-viscosity modified asphalt mastic rubble layer are laid on a bridge deck steel plate of a steel bridge deck in sequence, wherein the combined type connecting layer comprises a first modified epoxy resin and rubble layer and a second modified epoxy resin and rubble layer, a bonding material layer is further arranged between the combined type connecting layer and the ultrahigh-viscosity modified asphalt mastic rubble layer, and the bonding material layer is made of active epoxy resin materials. Compared with a traditional epoxy resin asphalt concrete bridge deck paving layer, the steel bridge deck paving structure and the construction method are low in construction cost, needless for dedicated equipment, beneficial to construction organization and high in construction speed, and have clear advantages on road sections with high traffic pressure.

Owner:广州新粤交通技术有限公司 +1

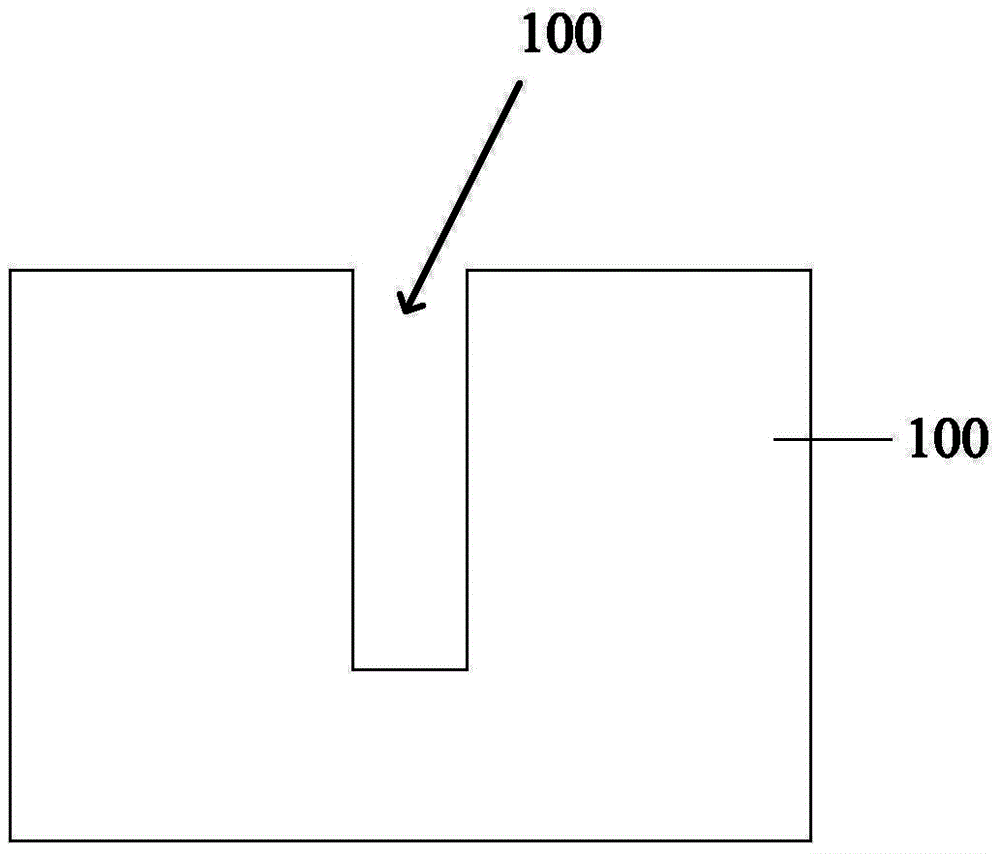

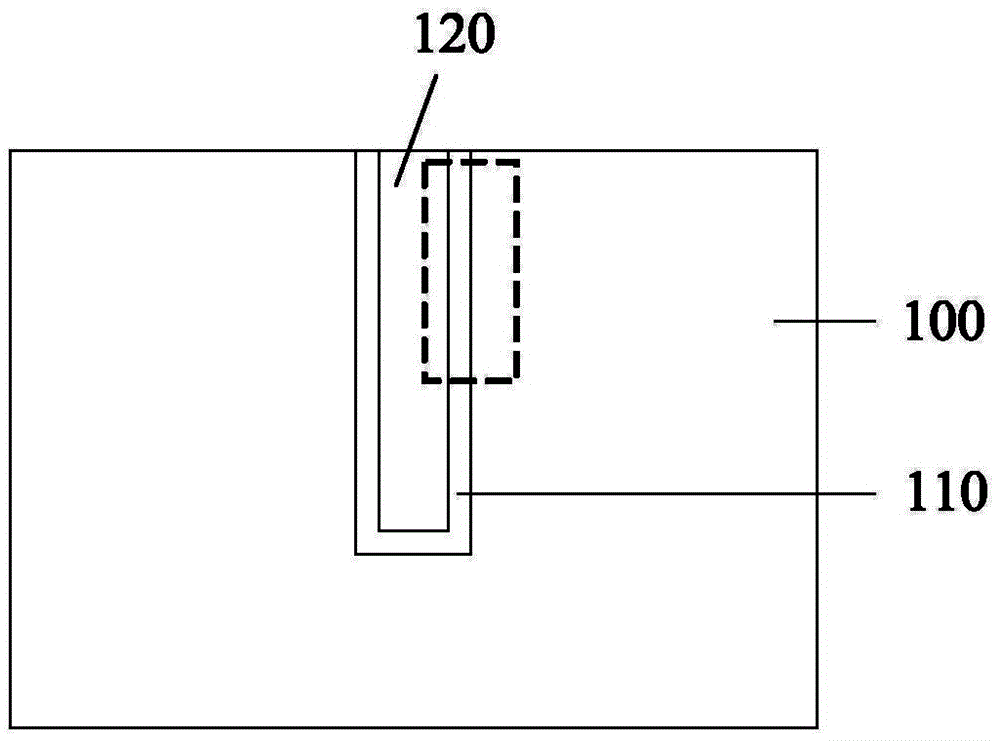

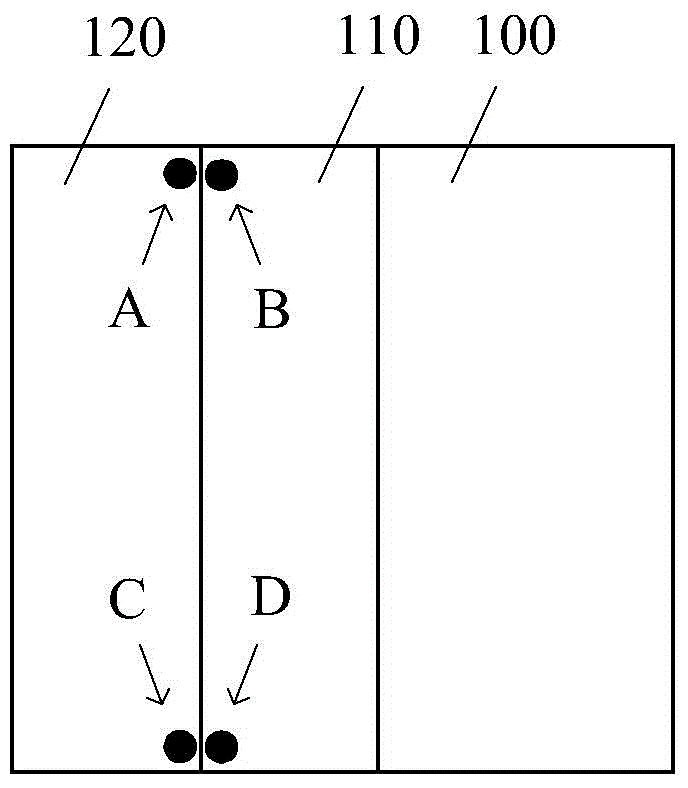

Forming method of silicon through hole

ActiveCN104576508AReduce layeringReduce crackingSemiconductor/solid-state device manufacturingLarge deformationDiffusion barrier

The invention relates to a forming method of a silicon through hole. The forming method comprises the following steps: providing a semiconductor substrate; forming a ring-shaped through hole in the semiconductor substrate, wherein the semiconductor substrate inside the ring-shaped through hole is an isolated semiconductor pillar; forming diffusion barrier layers on the side wall and at the bottom of the ring-shaped through hole; full filling the ring-shaped through hole with a conductive layer; removing all the semiconductor pillar or removing part of the semiconductor pillar to reserve part of a thickness until an opening with a depth-to-width ratio of greater than or equal to 20 is formed; and sealing the opening to form an air gap. According to the method, firstly the ring-shaped through hole is formed, the ring-shaped through hole is full filled with the conductive layer, then the semiconductor pillar formed inside the ring-shaped through hole in a surrounding manner is removed to form the opening and the opening is sealed to form the air gap; the air gap provides a large deformation space for plastic deformation of the conductive layer and is beneficial for releasing stresses in the conductive layer and an insulating layer; the possibility that a silicon through hole generates the layering and cracking phenomena is reduced; and reliability of the silicon through hole is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Preparation method of ultralow-temperature TA7ELI titanium alloy plate

ActiveCN109013738AImprove ultra-low temperature deformation performancePromote homogenizationMetal rolling arrangementsAcid washingRoom temperature

The invention discloses a preparation method of an ultralow-temperature TA7ELI titanium alloy plate. The method comprises the following steps: (1) a TA7ELI titanium alloy plate blank is heated for thefirst time; (2) the TA7ELI titanium alloy plate blank is rolled as a first semi-finished plate blank after primary heating; (3) the first semi-finished plate blank is formed to a second semi-finishedplate blank through polishing, acid washing and cutting in sequence; (4) the second semi-finished plate blank is heated for the second time; (5) the second semi-finished plate blank is rolled as a second semi-finished plate blank after secondary heating; and (6) the second semi-finished plate blank is straightened after insulation, and is cooled in air to reach the room temperature to obtain theTA7ELI titanium alloy plate. The high-temperature heating treatment and the reversing rolling method are adopted to provide larger deformation space for twin deformation, in the leading deformation role, of the plate under ultralow temperature; and the plate blank structure uniformity is promoted to obtain the ultralow-temperature TA7ELI titanium alloy plate.

Owner:WESTERN TITANIUM TECH

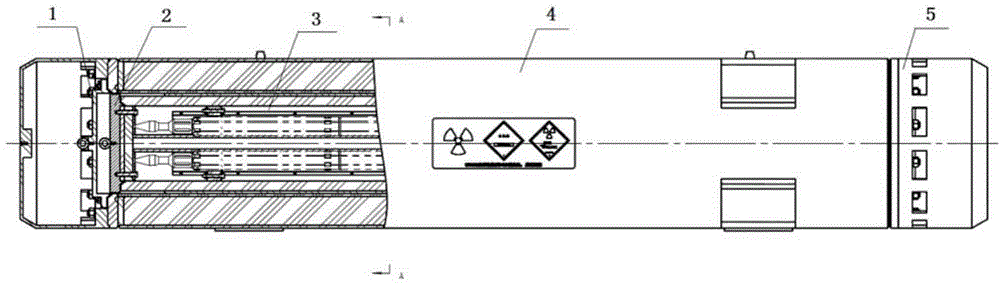

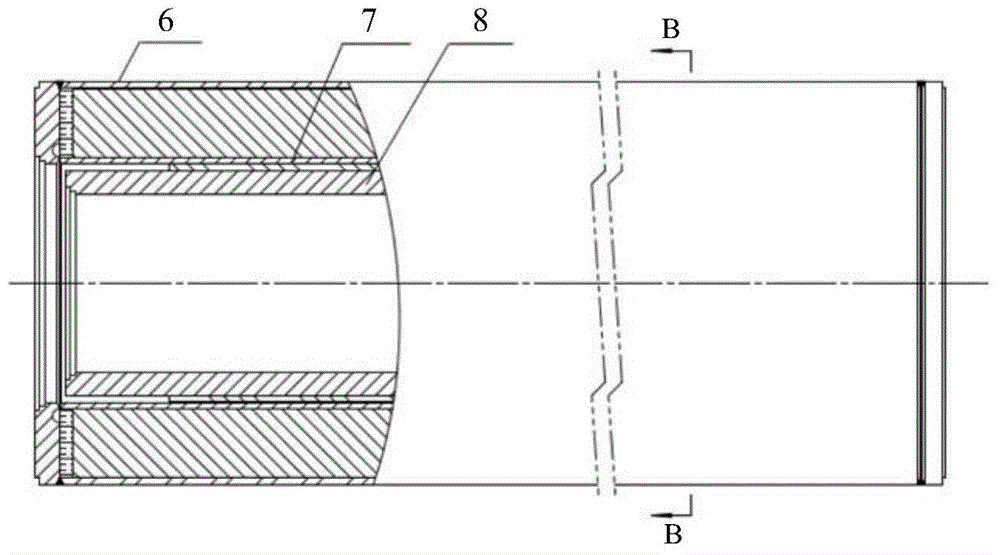

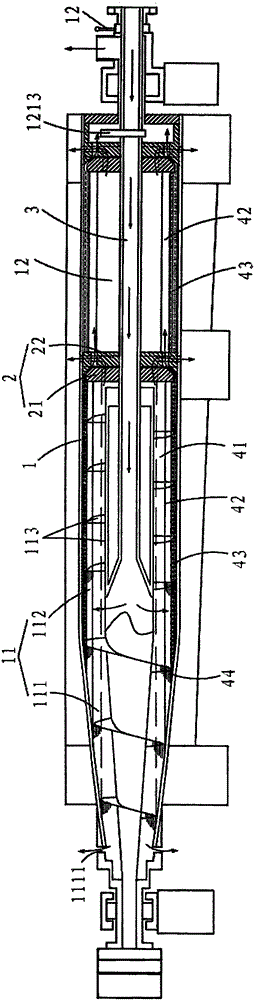

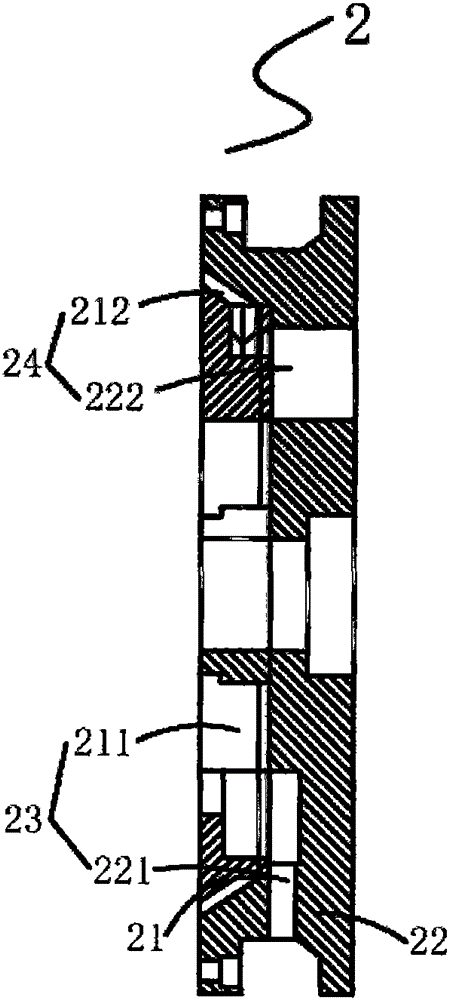

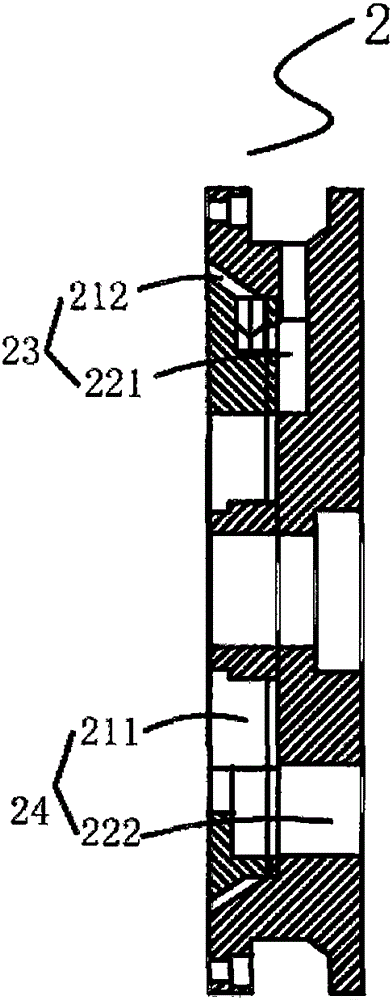

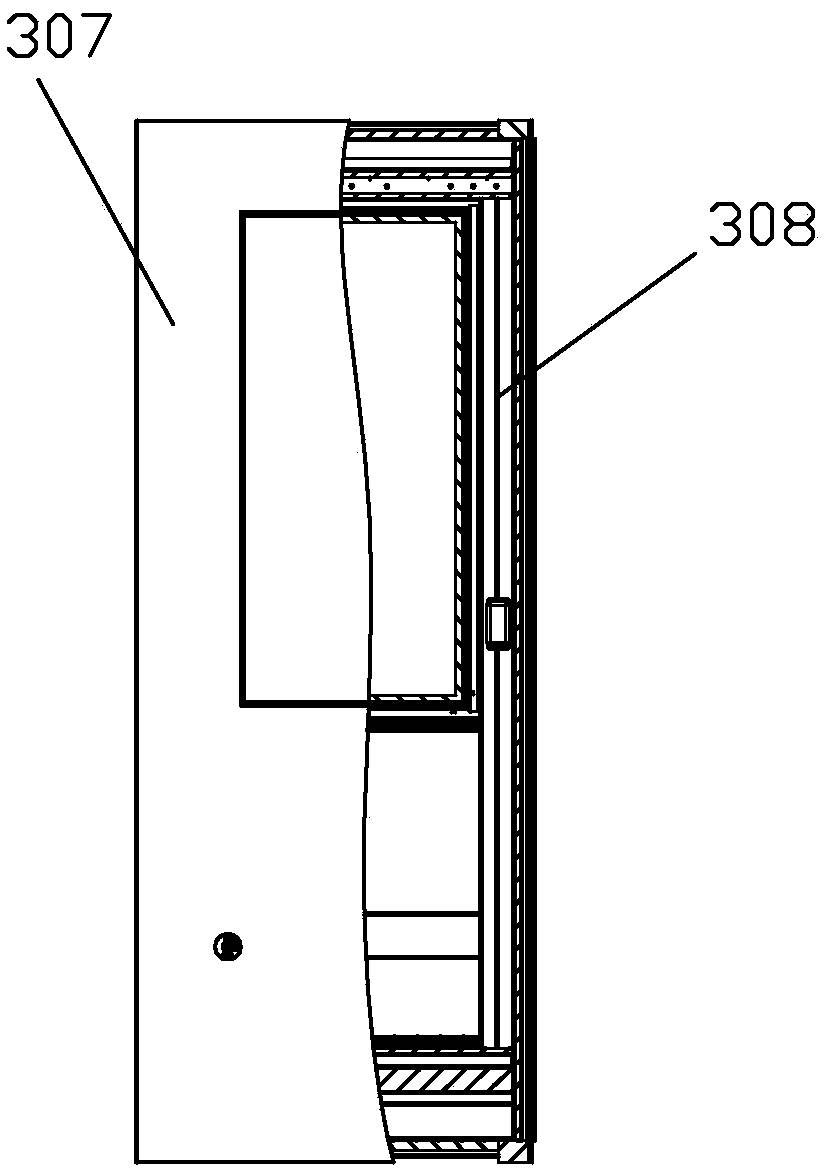

Conveying container for fast reactor MOX fuel component

ActiveCN104575648AImprove stress statusImprove shielding effectPortable shielded containersRadioactive agentEngineering

The invention relates to a conveying container of a fuel component, in particular to a conveying container for a fast reactor MOX fuel component. The conveying container structurally comprises a cylinder body component, wherein a middle penetrating component used for accommodating the fuel component is arranged in the cylinder body component; a compression end cover is arranged on the end part of the cylinder body component; the cylinder body component comprises an inner cylinder, a middle cylinder and an outer cylinder; the compression end cover is divided into two layers; the first layer of compression end cover is fixedly connected with the inner cylinder of the cylinder body component to form a first layer of containing boundary of radioactive substances; the second layer of compression end cover is fixedly connected with the middle cylinder of the cylinder body component to form a second layer of containing boundary of the radioactive substances; a shielding body and a heat isolating layer are arranged between the middle cylinder and the outer cylinder. The conveying container has better shielding property, containing property, buffering property and heat isolating property; the requirement on transportation of the radioactive substances by regulations can be met; in the whole transportation process, the MOX fuel component can be kept in a subcritical state.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

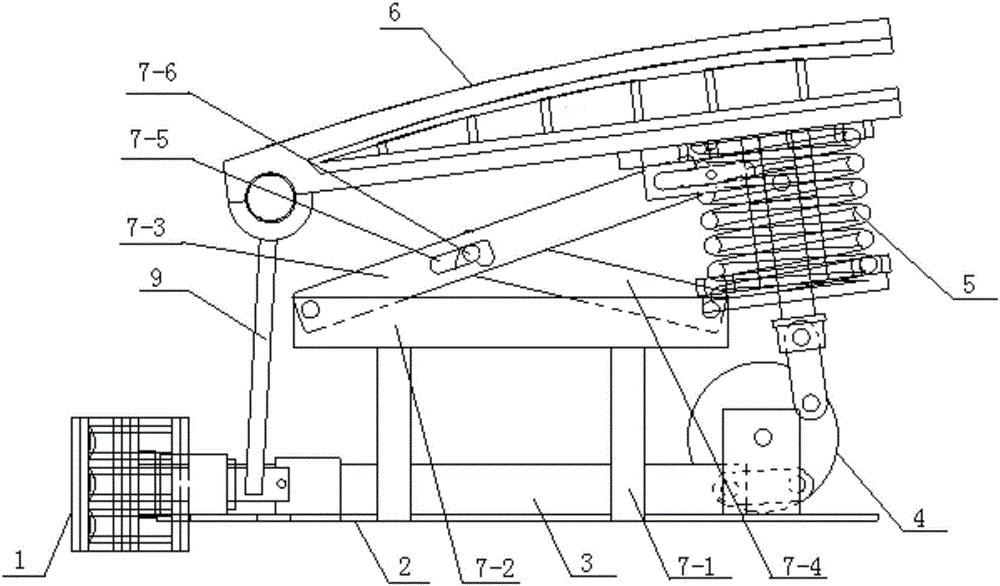

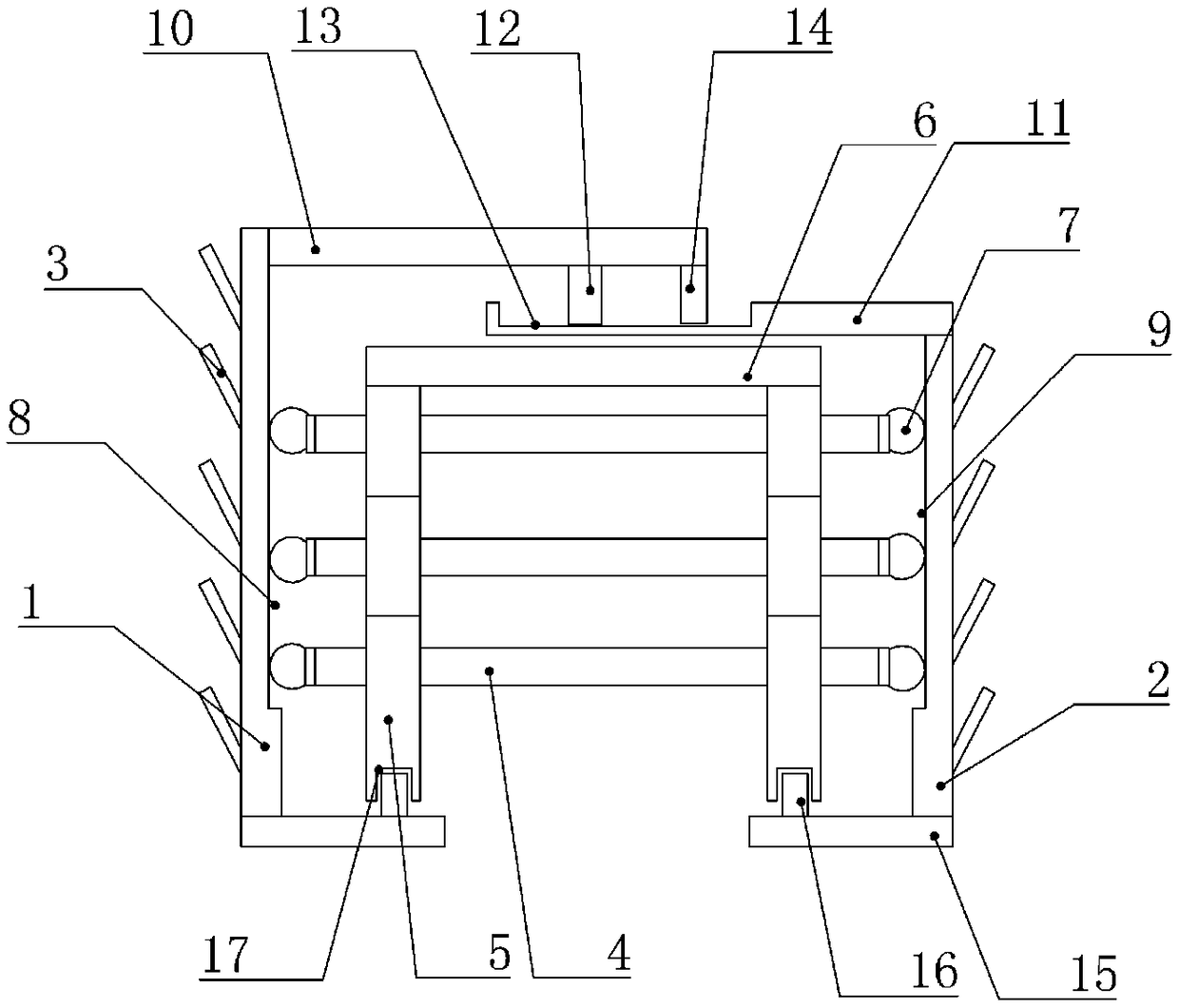

Drum-type shock absorption suspension device

InactiveCN102829113ALarge deformation spaceMeet the needs of matching different rigidities in different directionsRubber-like material springsEngineeringShock absorber

The invention relates to a drum-type shock absorption suspension device. Aiming at the defect that the shock absorption performance of the traditional drum-type shock absorption suspension device is not adapted to the shock characteristic of a cab, the invention constructs the drum-type shock absorption suspension device comprising an inner steel cylinder and an outer steel cylinder which are sleeved coaxially, wherein rubber is filled between the inner steel cylinder and the outer steel cylinder; the inner surface of the outer steel cylinder has two opposite partial inner surfaces, and gaps exist between the partial inner surfaces and the rubber and axially pass through two ends of the outer steel cylinder. Due to the existence of the gaps, the vertical rigidity and the longitudinal rigidity of a shock absorber are different; and the sizes of the gaps are determined according to the shock characteristics of various different devices, and thus, the shock absorption property of the shock absorber can be consistent with that of the cab.

Owner:GUANGXI LIUGONG MASCH CO LTD

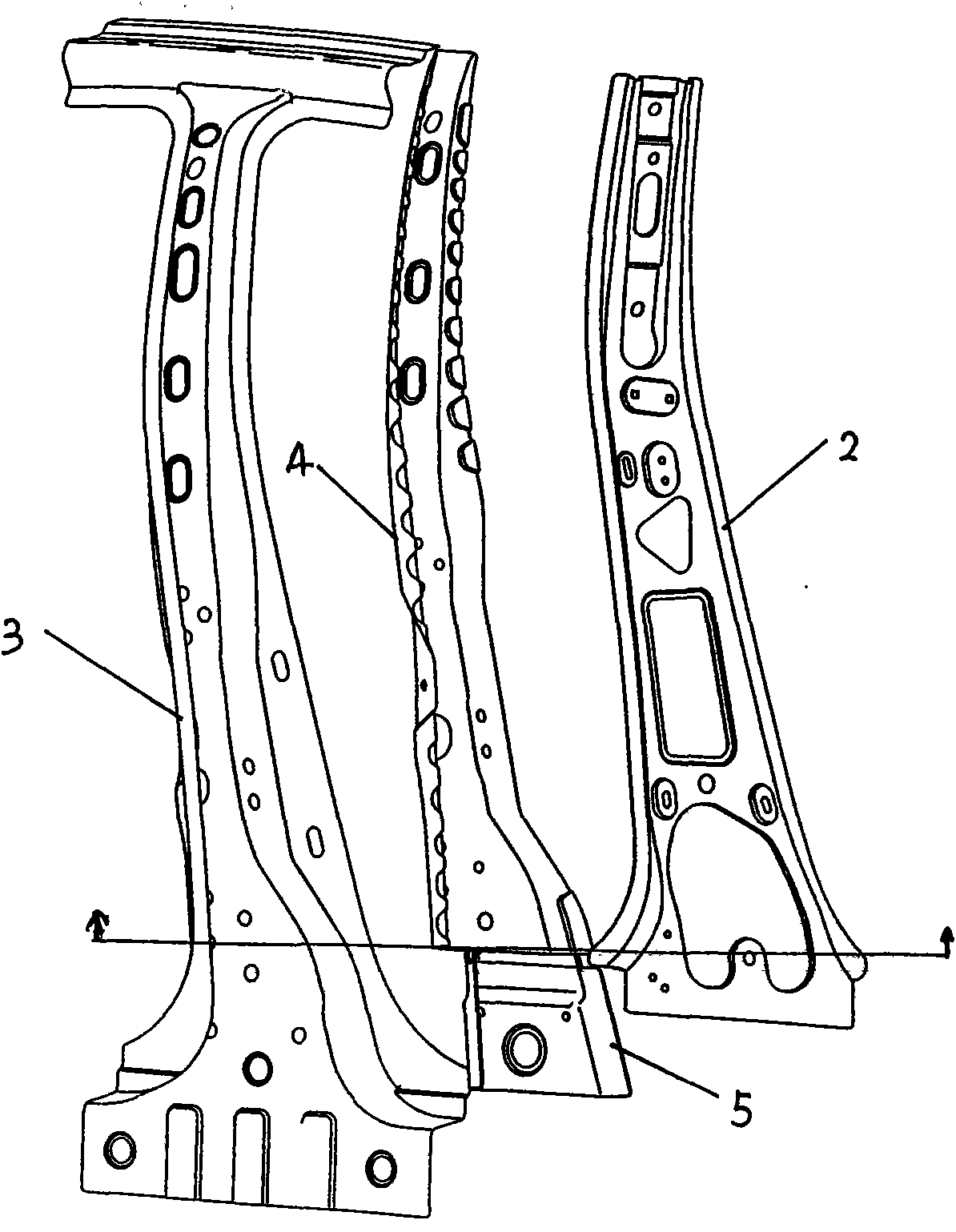

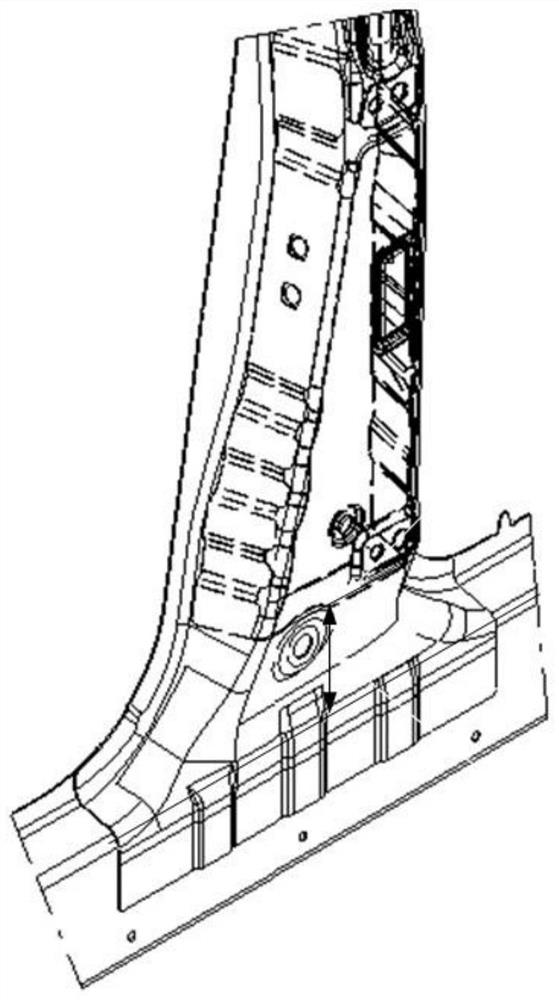

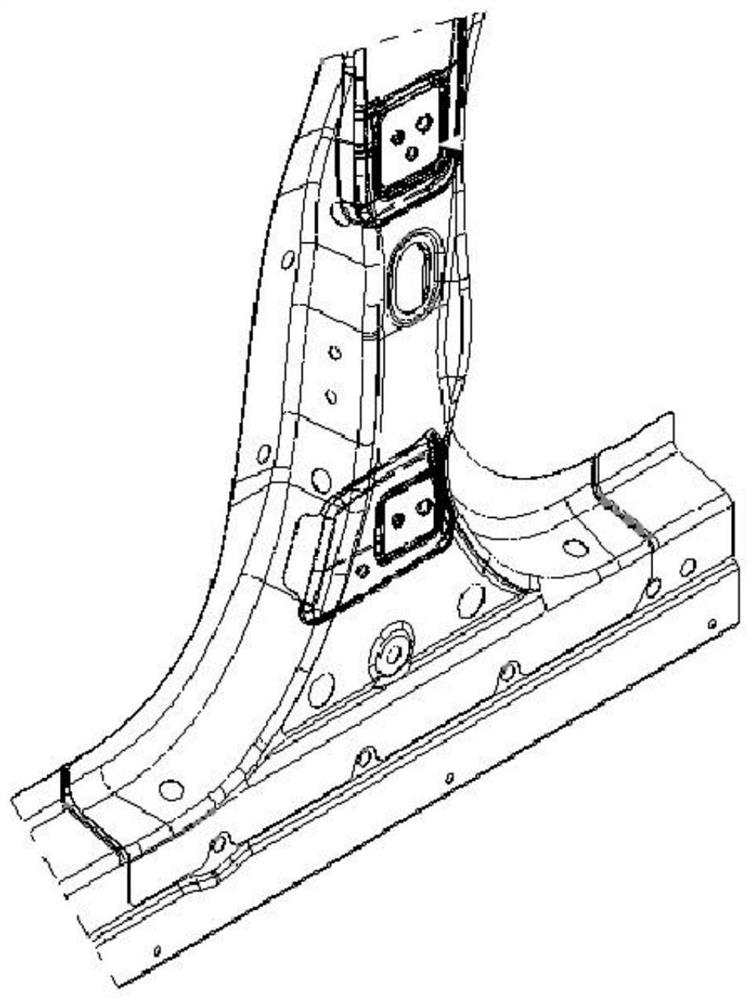

Center pillar assembly of sedan

The invention relates to a center pillar assembly of a sedan, which comprises a lateral outer skin, a center pillar inner skin, a center pillar reinforcer, a center pillar hinge installing reinforcerand a center pillar lower reinforcer, wherein the cross sections of the lateral outer skin and the center pillar reinforcer have U-shaped structure in the same direction; the lateral outer skin is coated outside the center pillar reinforcer; the lateral outer skin and the center pillar reinforcer are in butt welding with the center pillar inner skin; a center pillar cavity is formed between the center pillar reinforcer and the center pillar inner skin to provide larger deforming space, thus being capable of better absorbing energy during the lateral collision process, reducing invasion amountof the center pillar and reducing damage of passengers; the inner lateral surface of the center pillar reinforcer is also welded with the hinge installing reinforcer; the center lower reinforcer is welded at the lower part of the center pillar and the inner lateral surface of the hinge installing reinforcer to reinforce the integral structure of the center pillar, so that the energy during the lateral collision process is easy to be transmitted onto a doorsill beam and a roof crossrail by the center pillar, thus forming a complete energy transmission passage and guaranteeing the safety of thepassengers.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Solid-liquid four-phase horizontal spiral centrifuge

InactiveCN106540819AAchieve four-phase separationIncrease diversityRotary centrifugesEngineeringCentrifuge

The invention discloses a solid-liquid four-phase horizontal spiral centrifuge, which belongs to the field of centrifugal separation equipment. The solid-liquid four-phase horizontal spiral centrifuge comprises a rotary drum, wherein the rotary drum comprises a first separation chamber, a second separation chamber and a separation plate, the first separation chamber comprises a conic section and a straight section, a spiral conveyor is arranged in the first separation chamber, an end cover is fixedly connected to the end of the second separation chamber, and liquid holes at different distances from the axis are radially formed in the end cover; the separation plate is arranged between the first separation chamber and the second separation chamber, an overflowing hole which is used for communicating the first separation chamber with the outer wall of the rotary drum and a communicating hole which is used for communicating the first separation chamber with the second separation chamber are formed in the separation plate, and the distances between one end, which is located in the first separation chamber, of the overflowing hole and the axis as well as between one end, which is located in the first separation chamber, of the communicating hole and the axis are different; and the end cover comprises the separation plate and an outer cover which is fixedly connected to the separation plate, and a cavity is formed between the separation plate and the outer cover. Compared with the prior art, the solid-liquid four-phase horizontal spiral centrifuge has the beneficial effects that solid-liquid-liquid-liquid four-phase separation is realized, the separation diversity is increased, the product quality and the production efficiency are increased, and the cost is reduced.

Owner:JINAN HANRUIMI MECHANICAL EQUIP MFG CO LTD

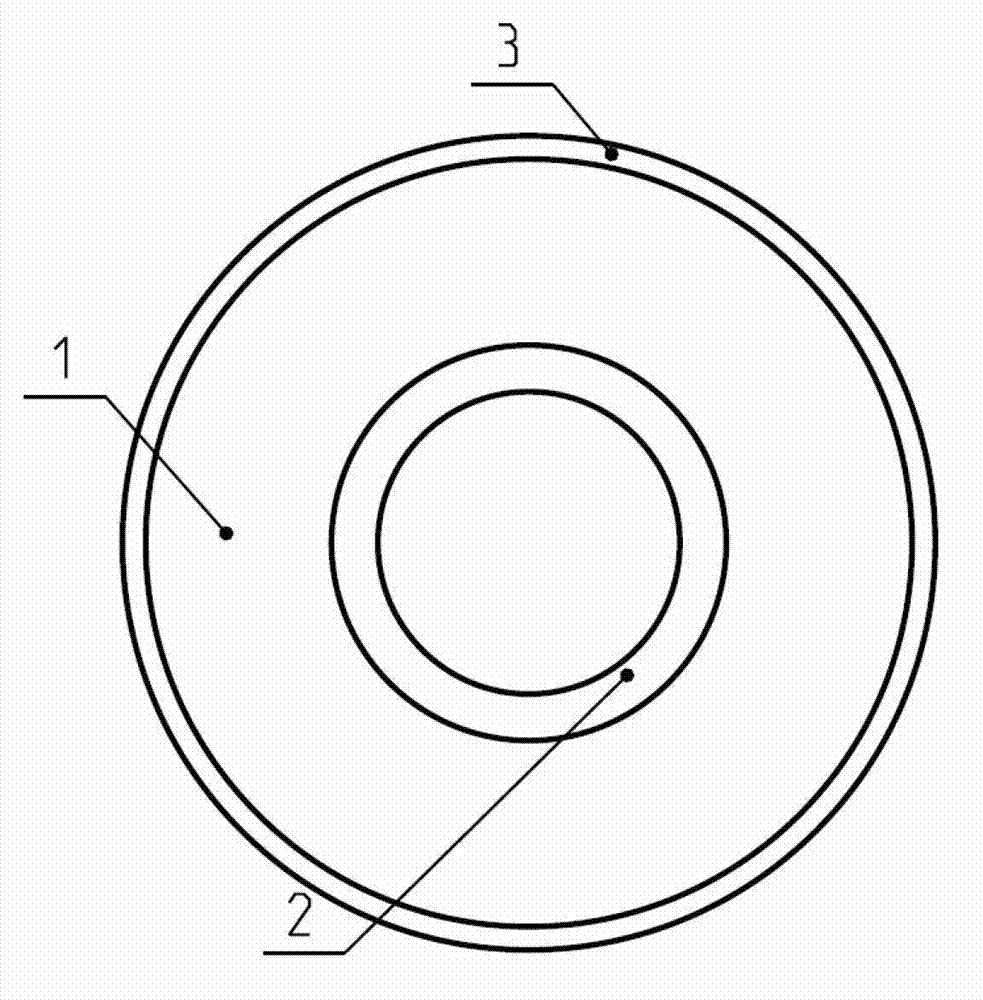

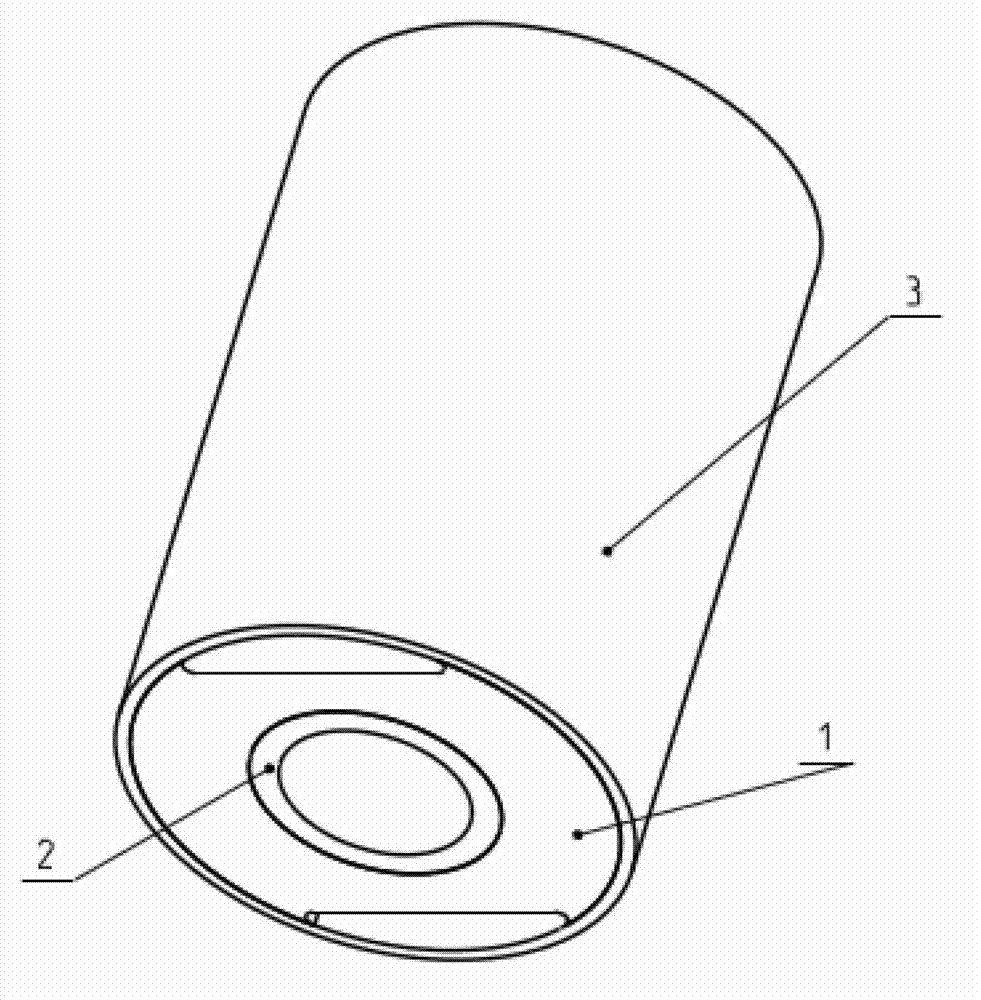

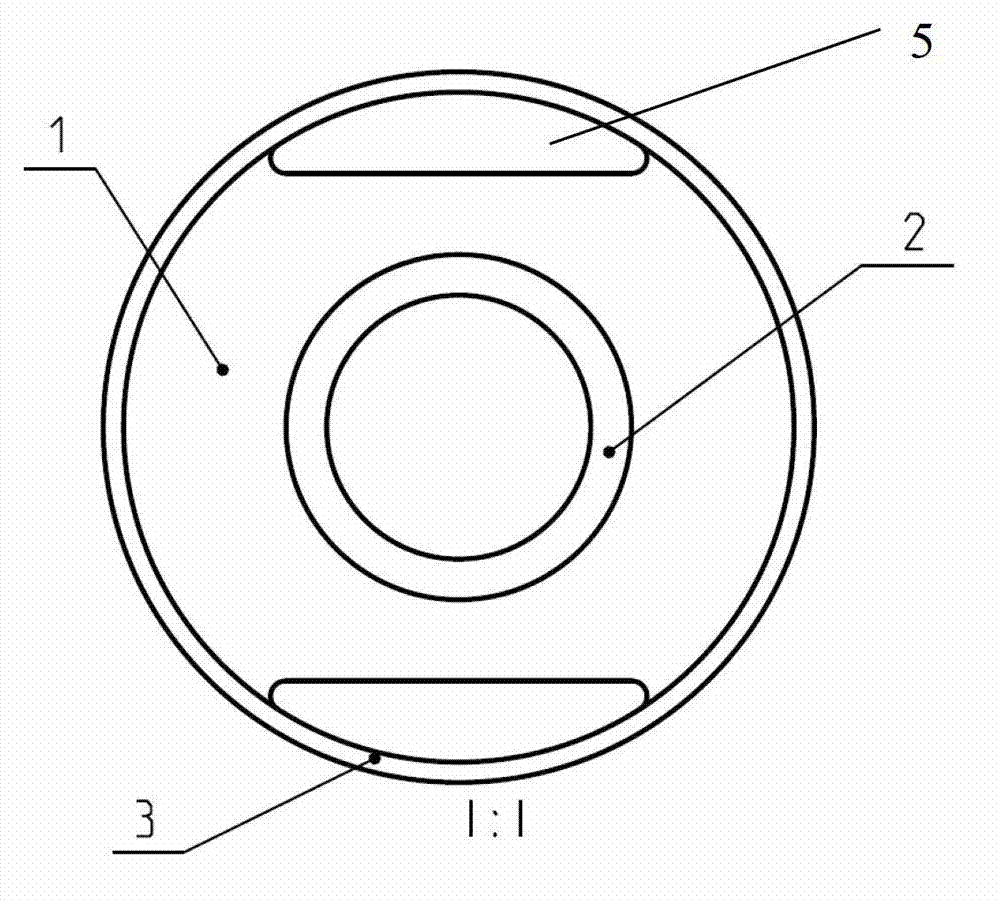

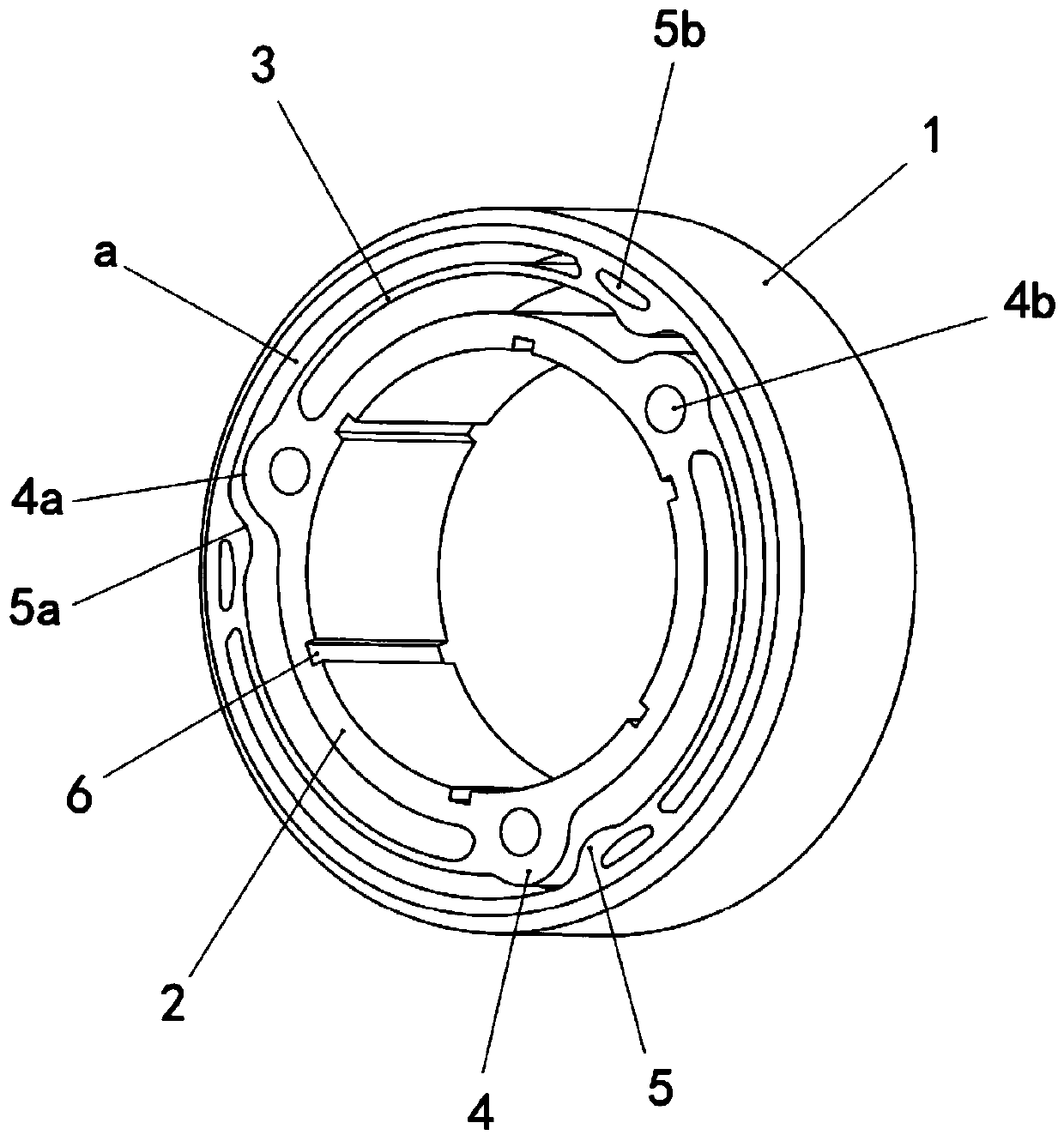

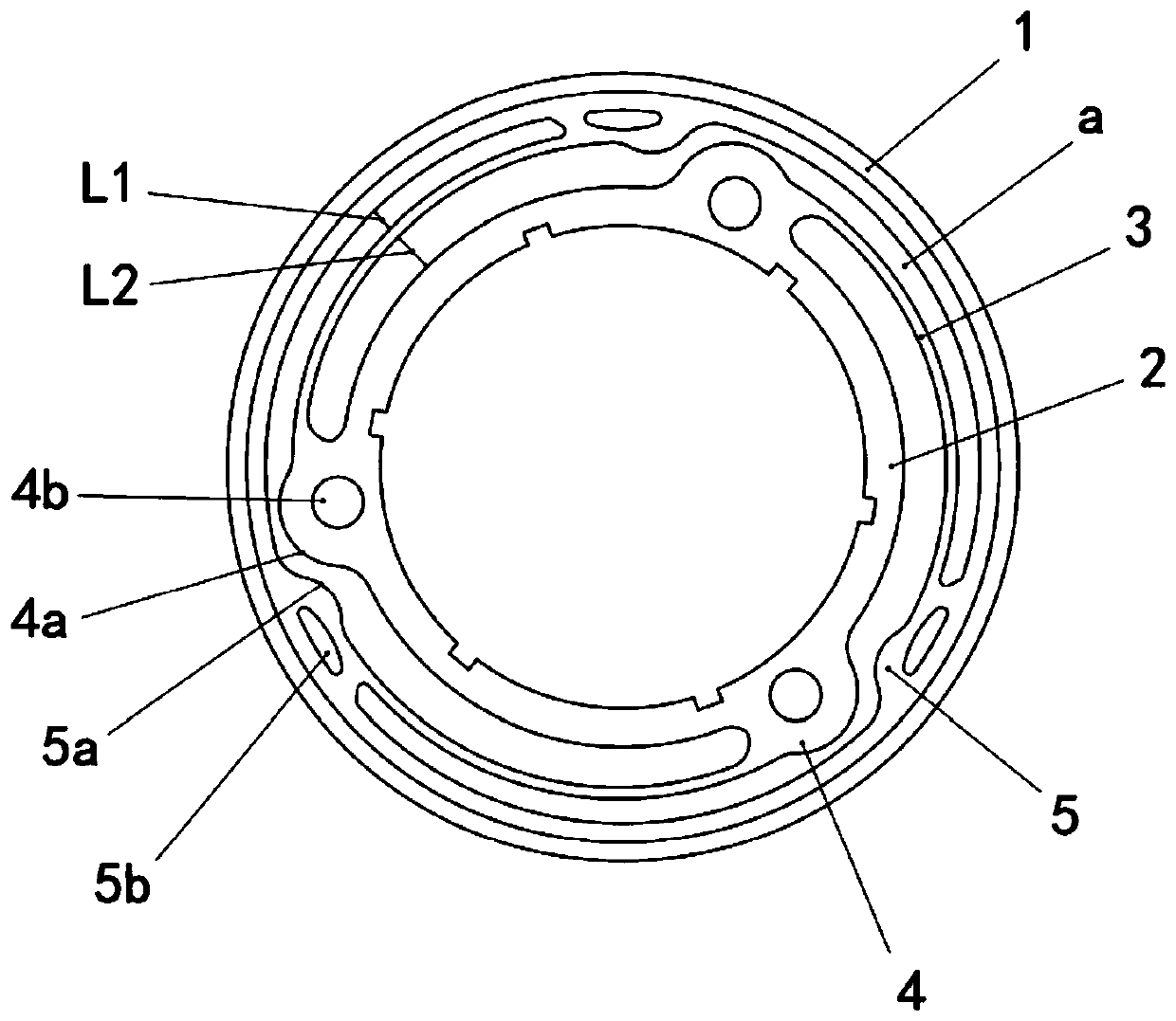

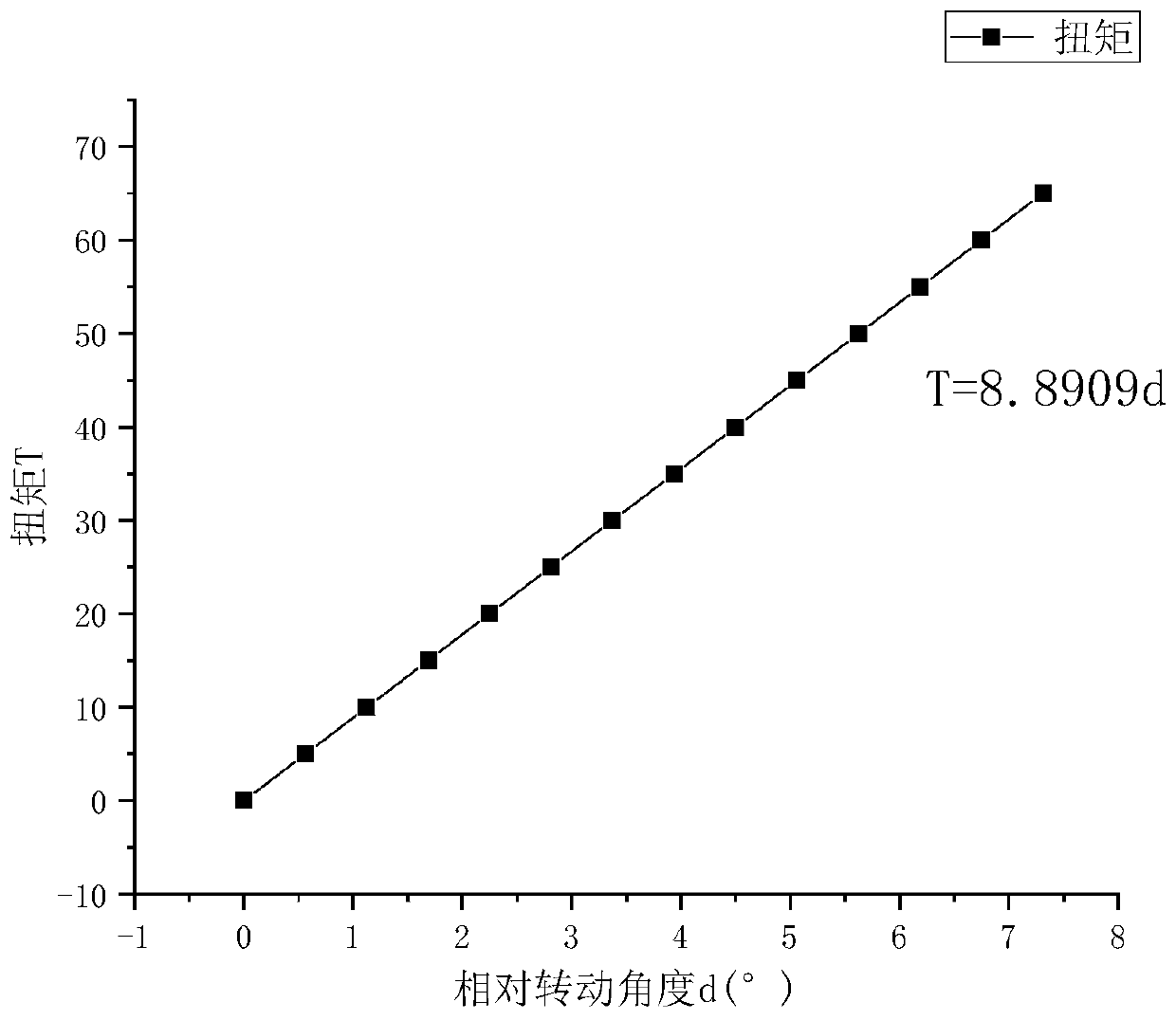

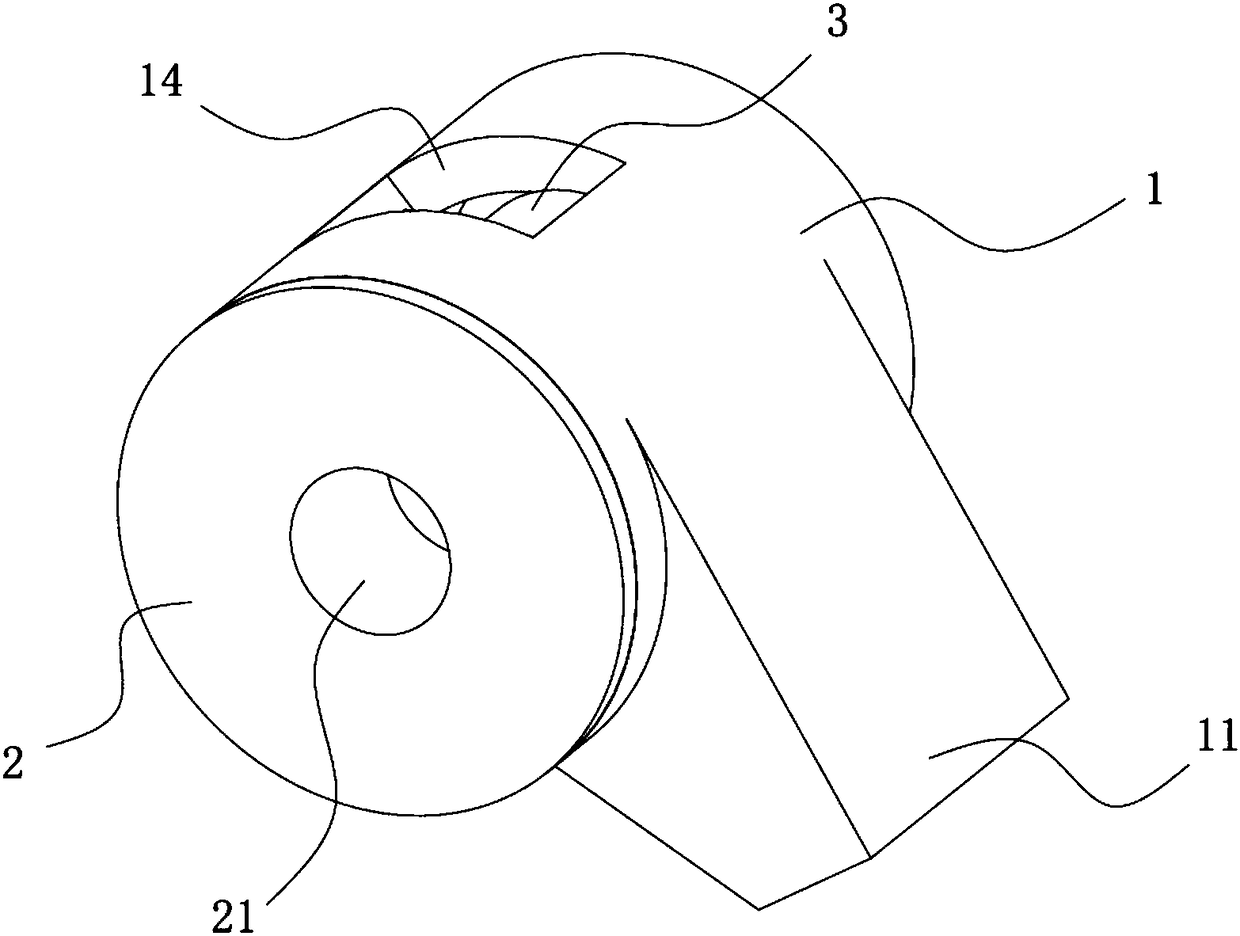

One-way plane torsional spring

ActiveCN110566614AImprove performance parametersConvenient parametric designJointsLow internal friction springsEngineeringMechanical engineering

The invention provides a one-way plane torsional spring. The one-way plane torsional spring comprises a torsional spring outer ring, a torsional spring inner ring and multiple torsional spring elasticbodies. The torsional spring inner ring is located on the inner side of the torsional spring outer ring, a gap exists between the torsional spring outer ring and the torsional spring inner ring, andthe multiple torsional spring elastic bodies are distributed in the gap between the torsional spring outer ring and the torsional spring inner ring, wherein the torsional spring elastic bodies are ledout of the inner peripheral surface of the torsional spring outer ring and are in stretching connection to the outer peripheral surface of the torsional spring inner ring in the outer peripheral direction of the torsional spring inner ring with a surrounding curve as the stretching reference, an abutting portion is arranged on the outer peripheral surface of the torsional spring inner ring, a stopping portion cooperating with the abutting portion is arranged on the inner peripheral surface of the torsional spring outer ring, and the stopping portion is located in front of the forward direction of the tangential directions of the torsional spring elastic bodies. According to the one-way plane torsional spring, on one hand, the one-way relative rotation angle of the torsional spring inner ring and the torsional spring outer ring in the plane torsional spring is increased, on the other hand, the overall rigidity when the torsional spring inner ring and the torsional spring outer ring inthe plane torsional spring rotate relatively is basically unchanged, and the one-way plane torsional spring has the beneficial effects of being simple in structure and high in practicality.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

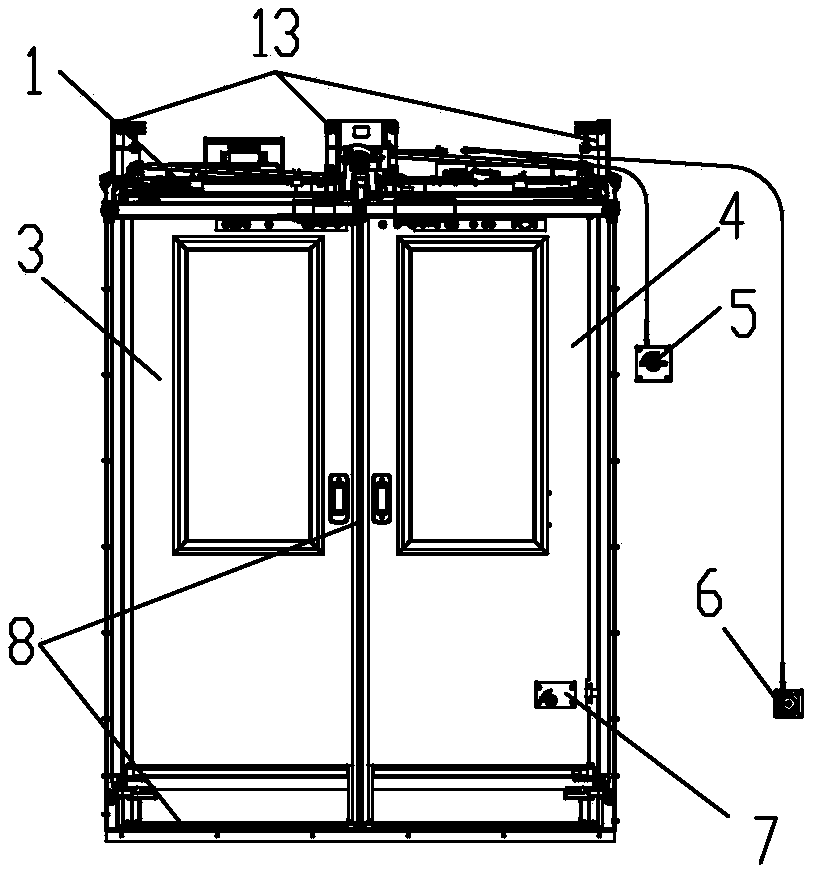

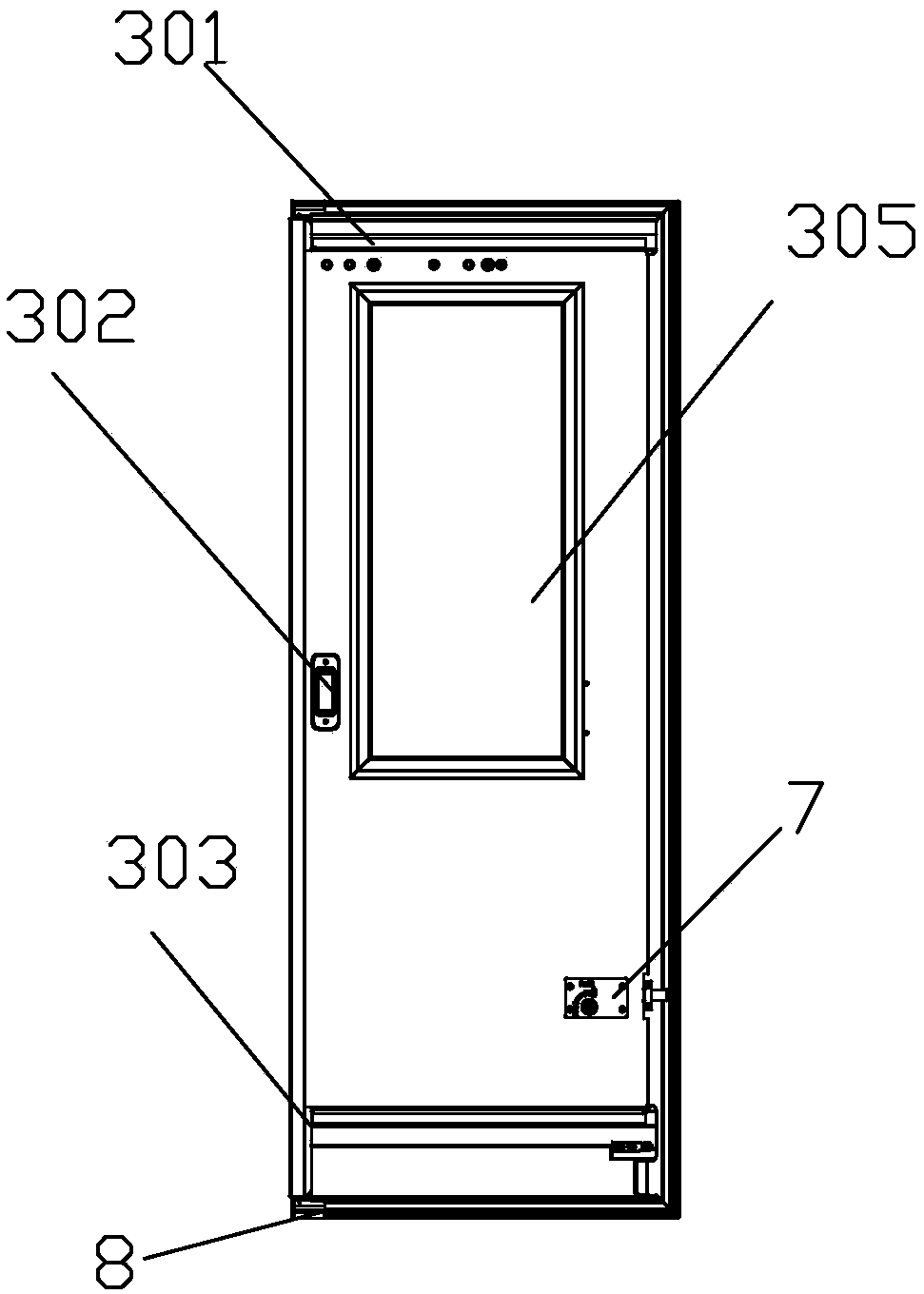

Sliding-plug door

PendingCN110552592AOvercome the defect of uneven forceImprove coordinationWing operation mechanismsSealing arrangementsEngineeringElectrical and Electronics engineering

Owner:北京天乐泰力科技发展有限公司

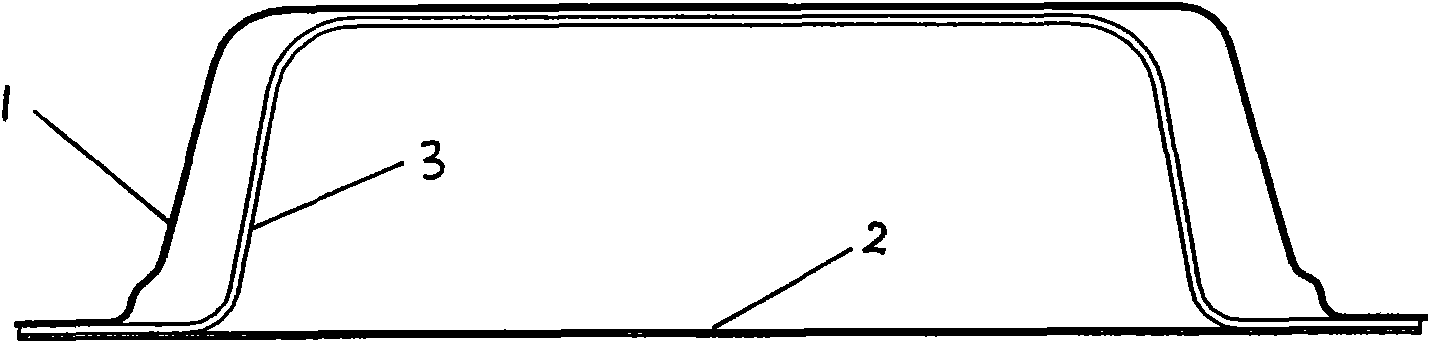

Section structure for car side sill

InactiveCN101445129ALarge deformation spaceSmall amount of deformationSuperstructure subunitsEngineeringCavity size

The invention relates to a section structure for a car side sill, which comprises a side sill reinforcing element welded with a side panel outer skin and a side sill internal plate welded with a front footplate. Both the side sill reinforcing element and the side sill internal plate have a U-shaped section, and are butt welded to form the hollow cavity of the side sill. The structure can maximize the hollow cavity size of the section of the side sill, so as to provide larger deformation space. An impact force generated due to collision on the side panel can be absorbed through the deformation of the side sill hollow cavity, transmitted to a crossbeam of the footplate via the side sill hollow cavity structure and then transmitted to different components of a car body, so as to reduce deformation of a passenger compartment and reduce intrusion of local collision, thereby achieving the purpose of protecting passengers.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Automobile front device based on pedestrian protection

InactiveCN106184107AReduce impact forceReduce harmPedestrian/occupant safety arrangementEngineeringCam

The invention provides an automobile front device based on pedestrian protection and relates to an automobile front device. When a pedestrian collides with an automobile, due to the arrangement of the positions of a front bumper, an engine cover and a windshield of the automobile, the pedestrian is likely to be seriously harmed, and serious losses of both an automobile driver and the pedestrian are caused. The automobile front device comprises a front elasticity adjusting assembly, a bottom board, a trigger rod, a cam mechanism and a lifting mechanism. The front bumper of the automobile is fixedly installed on the bottom board through the front elasticity adjusting assembly. The trigger rod is located on the bottom board, the front end of the trigger rod is fixedly connected with the front bumper, the rear end of the trigger rod is hinged to the cam mechanism, the lifting mechanism is arranged above the cam mechanism, the cam mechanism is connected with the engine cover of the automobile through the lifting mechanism, and the engine cover of the automobile inclines towards the front bumper under the adjustment effect of the lifting mechanism. The automobile front device is used at the front portion of the automobile.

Owner:JIAMUSI UNIVERSITY

Linear vibrating motor

PendingCN106787584AIncrease vibration amplitudeReduce volumeDynamo-electric machinesElastic componentEnergy consumption

The invention discloses a linear vibrating motor. The linear vibrating motor comprises a casing, a vibration assembly, a stator assembly and elastic components, wherein the vibration assembly comprises a mass block and magnets symmetrically embedded in the mass block; a first through hole is formed between two magnets in the mass block; the stator assembly comprises a coil located in the first through hole and a magnetism increasing component arranged in the coil; second gaps are reserved between two ends of the coil and two side wall surfaces of the first through hole; first gaps are formed between two ends of the mass block and the inner wall surface of the casing, and the two elastic components are arranged in the two first gaps. The magnetism increasing component increases a magnetic field produced by the coil to replace magnetic field driving force produced by multiple coils and magnets, and the required energy consumption is reduced by increasing the amplitude of the mass block; the second gaps serve as vibration space for linear movement of the mass block, so that the length of the casing is only required to be the sum of the length of the mass block and the length of the two first gaps, and the overall size of the motor is reduced.

Owner:WENZHOU FUERTE ELECTRONICS TECH CO LTD

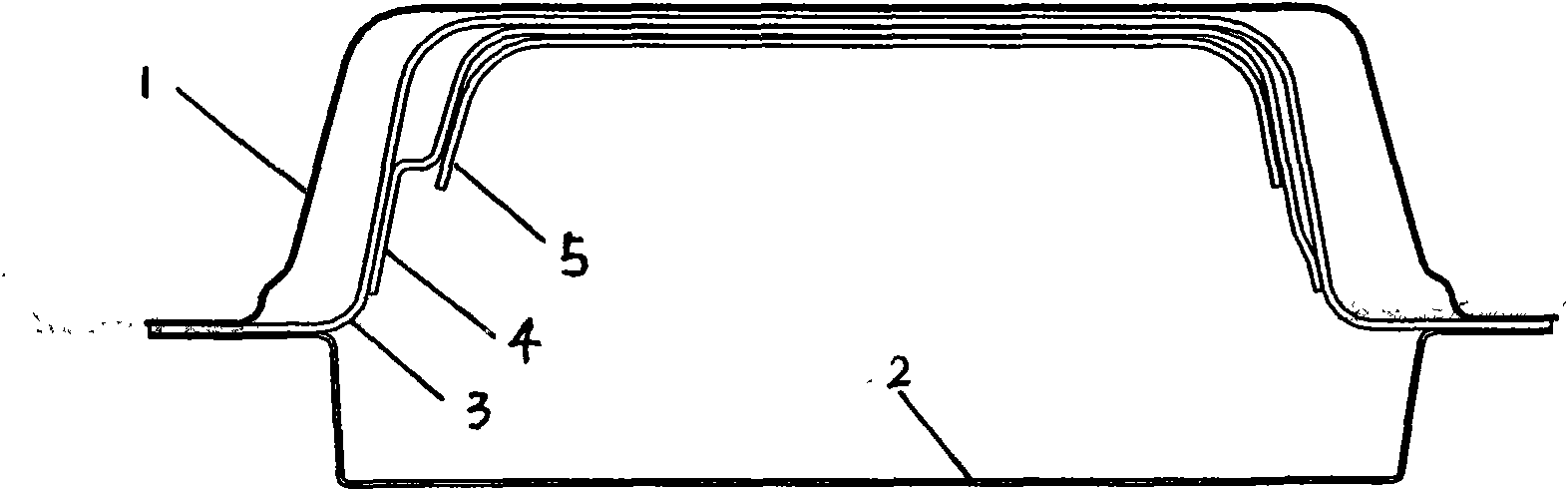

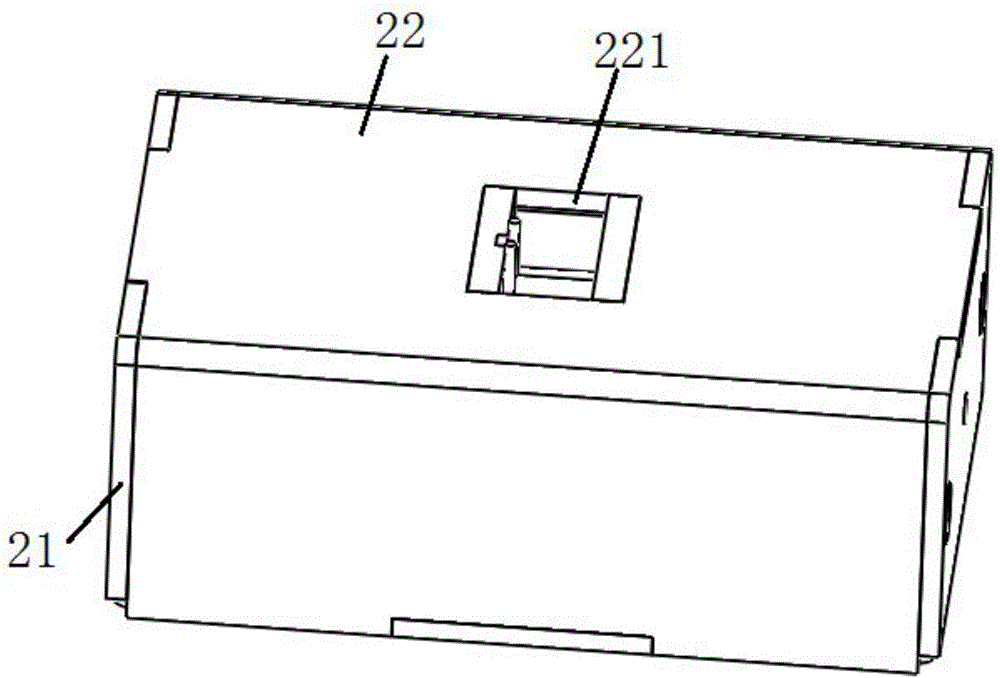

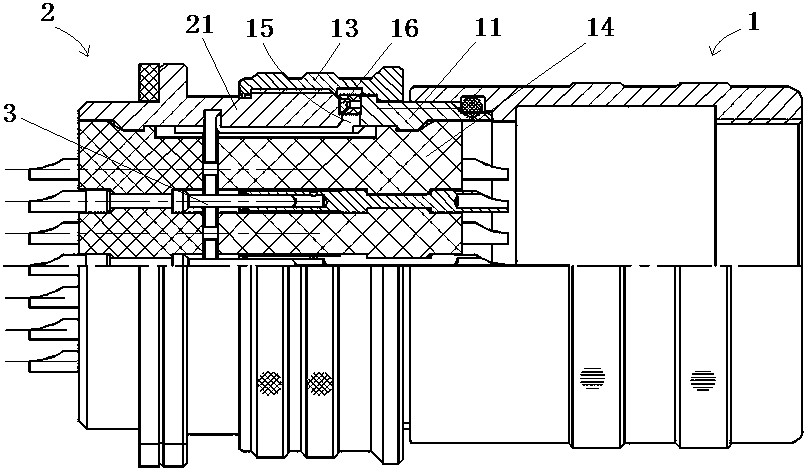

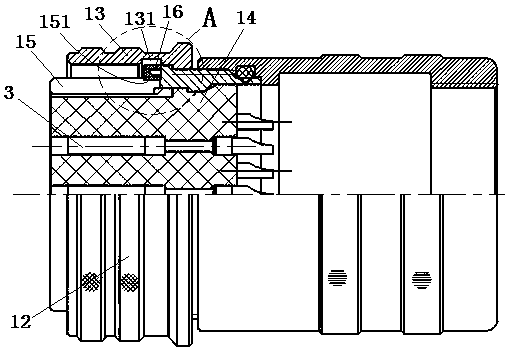

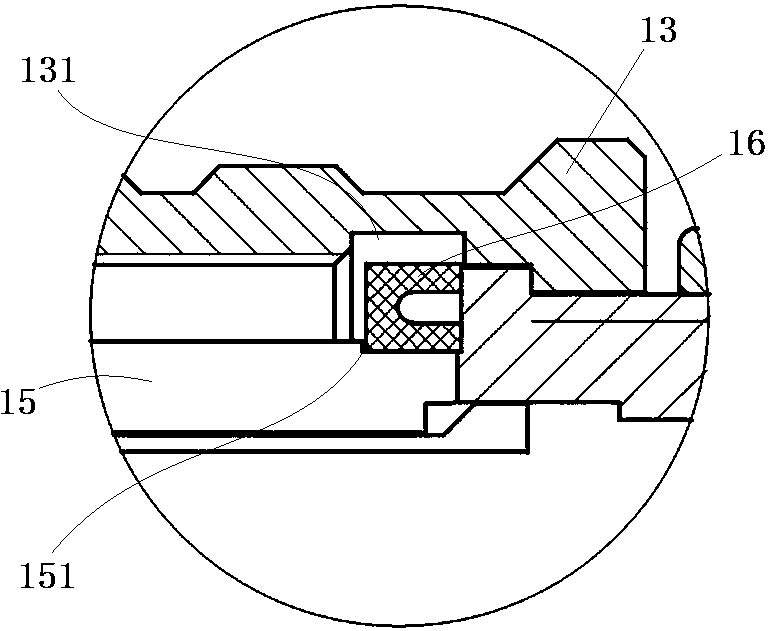

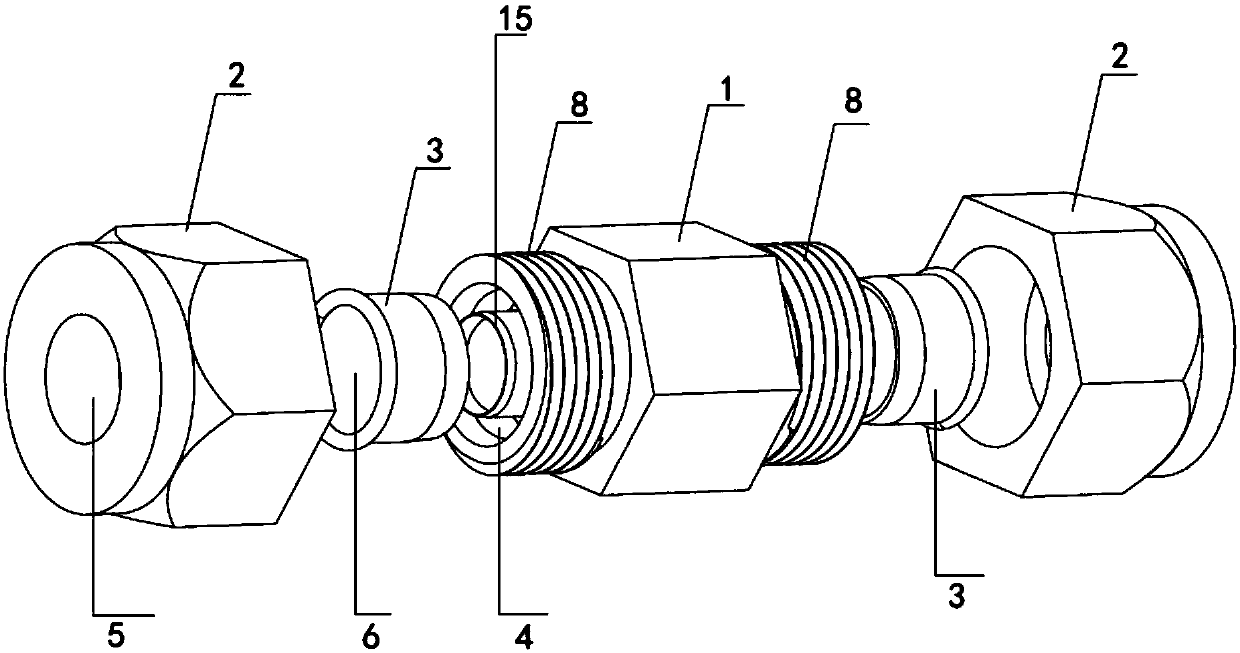

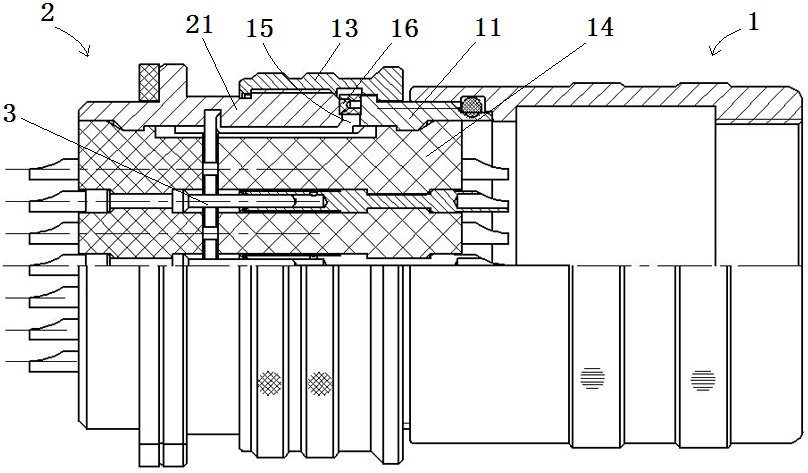

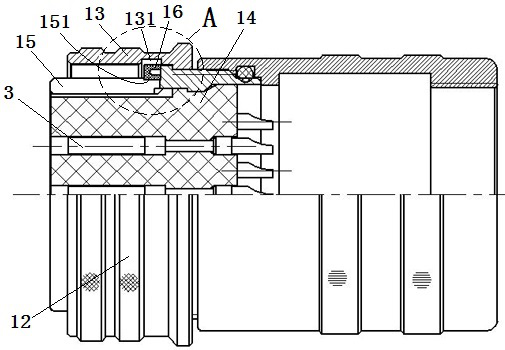

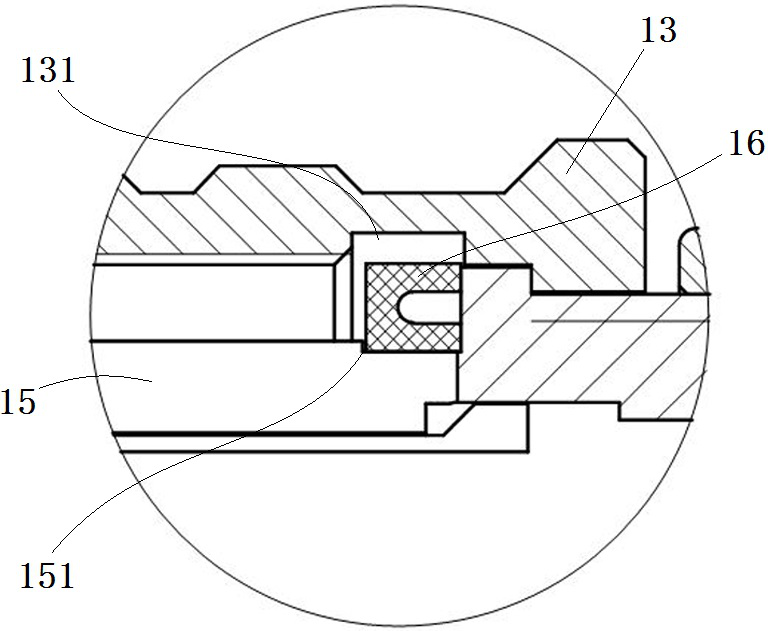

Circular connector and connector assembly

ActiveCN109119818AExtended service lifeLarge deformation spaceCouplings bases/casesEngineeringLarge deformation

The invention relates to a circular connector and a connector assembly. The connector assembly comprises a plug connector and a socket connector, wherein the plug connector comprises a plug shell, theperiphery of the plug shell is rotatably assembled with a connecting sleeve, the plug connector further comprises a plugging end which is mutually plugged with the socket connector, the inner circumferential surface of the plugging end is provided with a rotation-stopping spline, the periphery of the rotation-stopping spline is provided with a sealing ring, and the inner circumferential surface of the connecting sleeve is provided with an annular groove used for providing a radial deformation space for the sealing ring when the sealing ring is axially extruded by the front end face of the plugging end of the socket connector at the position corresponding to the sealing ring. The annular groove enables the sealing ring to have an enough large deformation space when being subjected to the axial extrusion and radial deformation of a socket shell. Meanwhile, the sealing ring in the gap will not be damaged because the gap between the inner wall of the connecting sleeve and the spline is too small when the connecting sleeve is screwed, and the service life of the sealing ring is prolonged. The resistance of the screwing is enabled to be reduced, and the screwing is more labor-saving.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

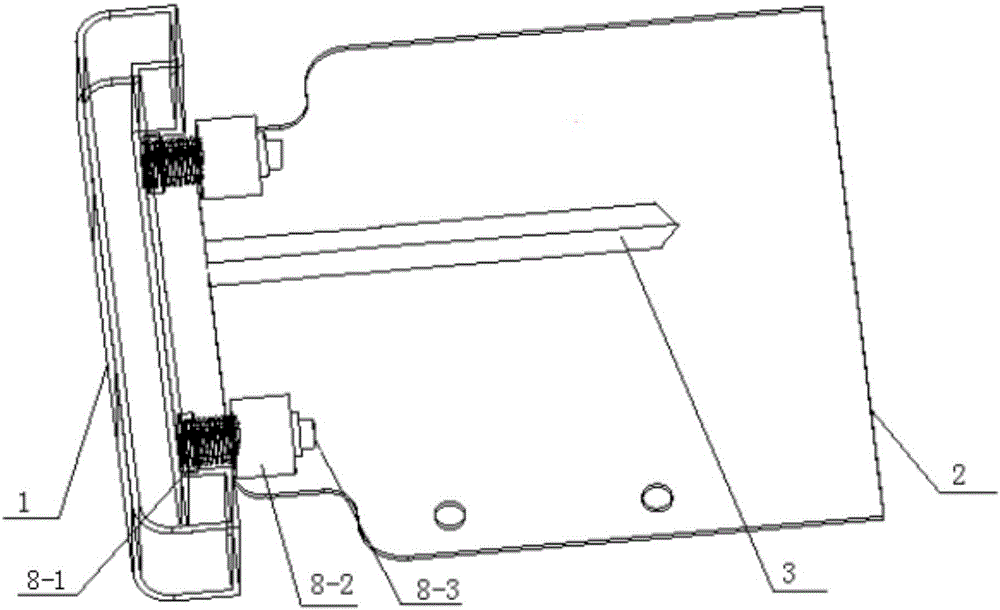

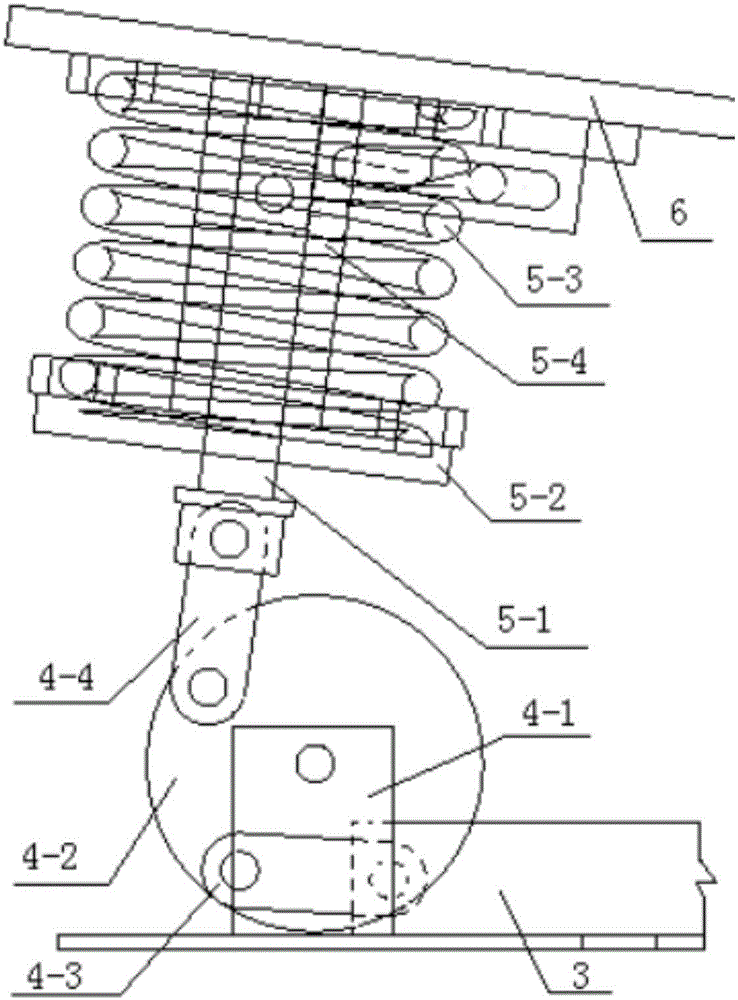

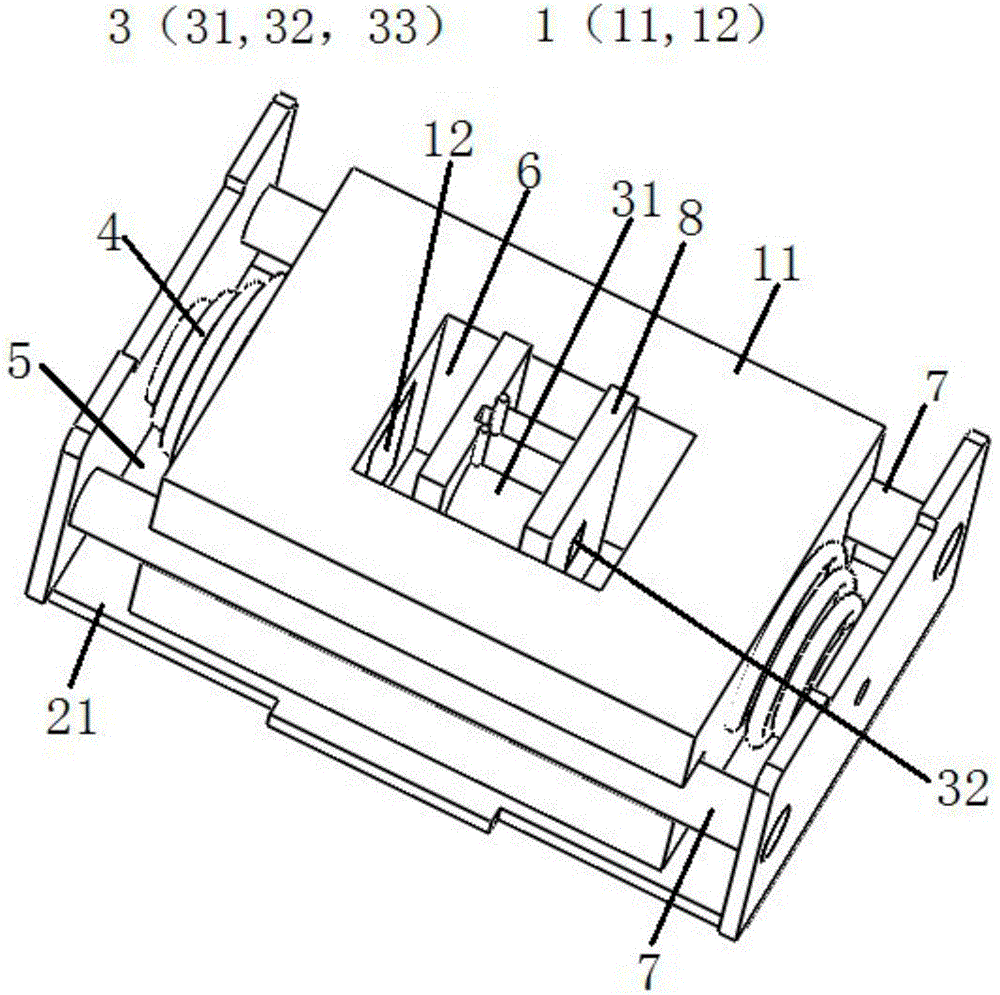

Vehicle engine cover bruising hinge structure

InactiveCN106988634AReasonable structural designLarge deformation spacePedestrian/occupant safety arrangementHingesFixed hingeAerospace engineering

The invention discloses a vehicle engine cover bruising hinge structure. The structure comprises a movable hinge plate and a fixed hinge plate; the fixed hinge plate comprises a fixed hinge plate body and a transition hinge plate; the movable hinge plate is hinged with the transition hinge plate through a pin shaft module; and the transition hinge plate is hinged with the fixed hinge plate body through a shearing pin. The vehicle engine cover bruising hinge structure is reasonable in design, and is liable to collapse when a vehicle and a pedestrian head are collided to increase the engine cover deformation space so as to achieve the purpose of improving the protecting effect of the pedestrian head; the movable hinge plate is deformed and collapsed without separating from the fixed hinge plate, and the energy is fully absorbed to achieve reliability and safety; and the structure is simple in structure and low in cost.

Owner:CHERY COMML VEHICLE ANHUI

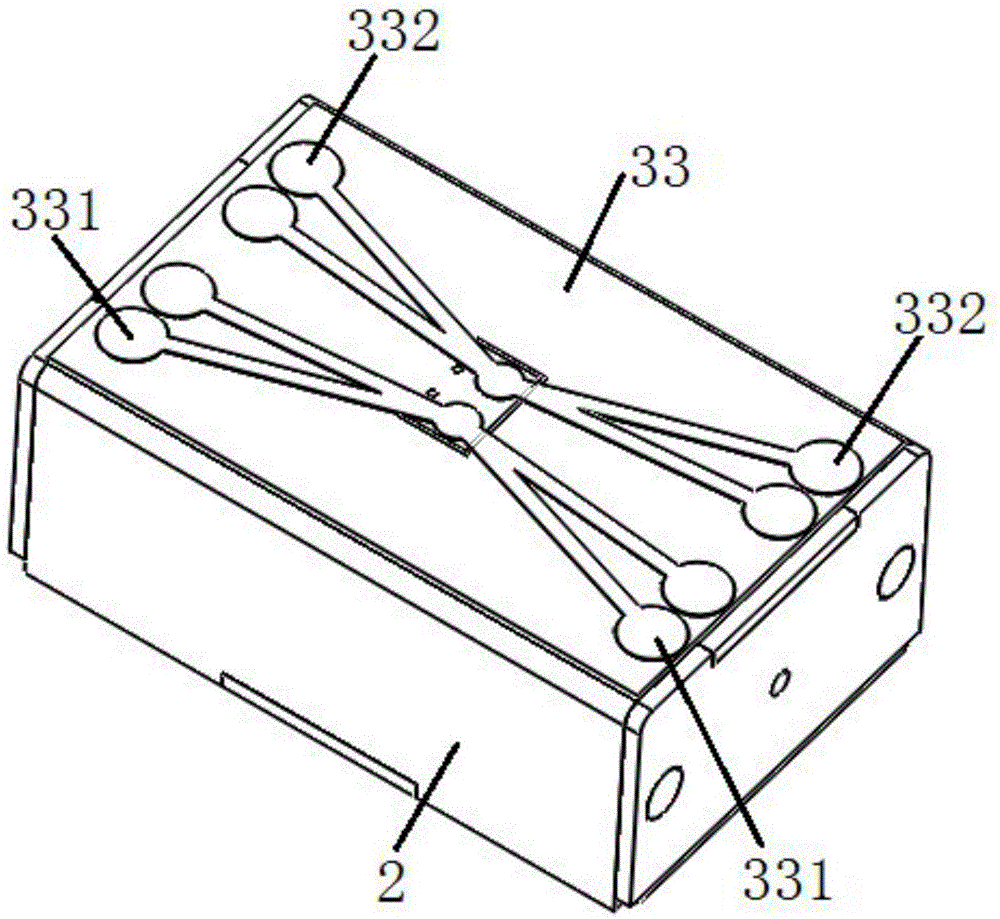

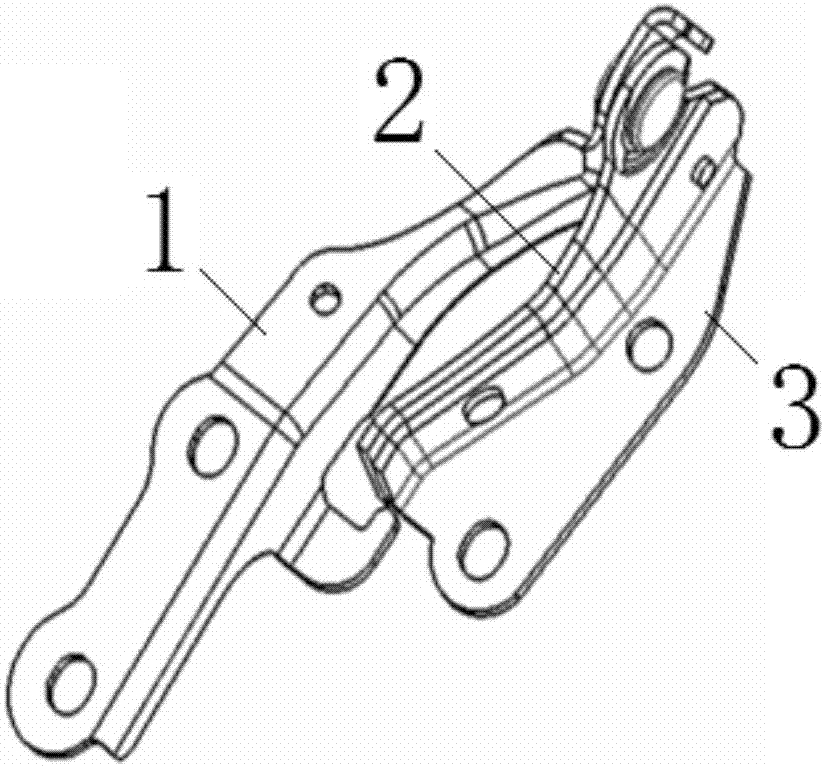

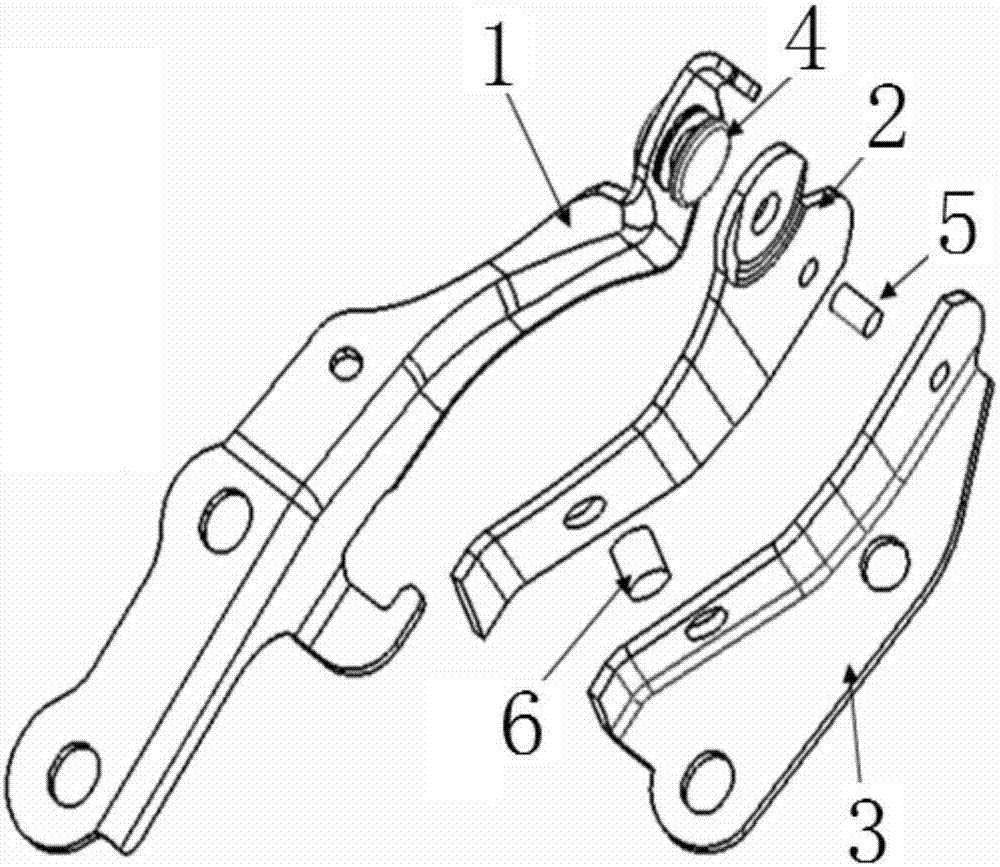

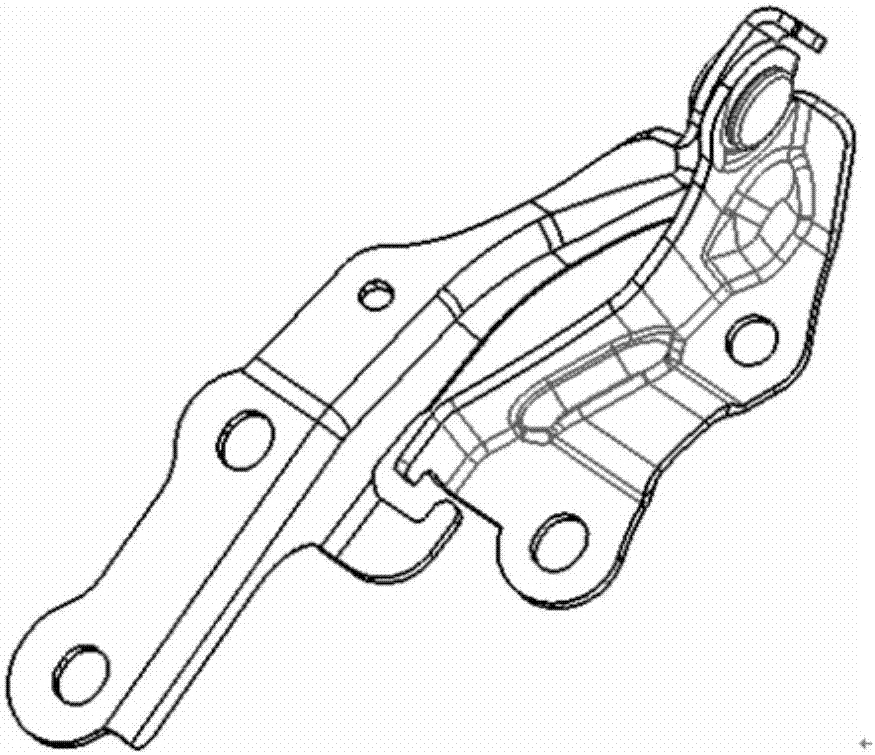

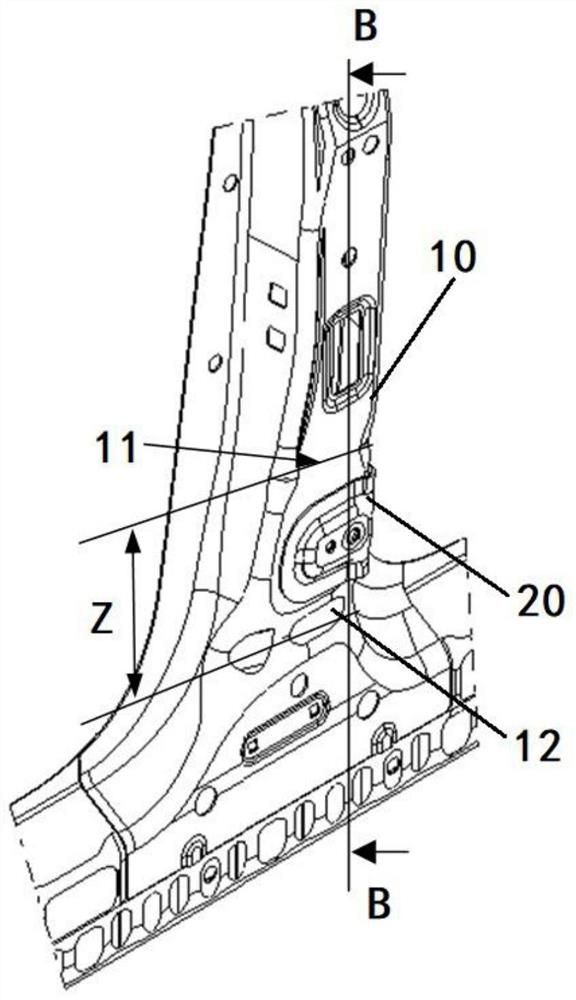

B-pillar lower hinge reinforcing plate assembly

PendingCN112249166ALarge deformation spaceImprove deformationWing accessoriesSuperstructure subunitsEnergy absorptionAutomobile design

The invention relates to a B-pillar lower hinge reinforcing plate assembly, and belongs to the technical field of automobile design and manufacturing. The B-pillar lower hinge reinforcing plate structure comprises a B-pillar reinforcing plate and a lower hinge reinforcing plate, an energy absorption area is arranged on the B-pillar reinforcing plate, and the area between the horizontal connectingline of triangular ribs on the two sides and the horizontal line passing through through columnar ribs is defined as the energy absorption area; the projection welding nut is welded on the lower hingereinforcing plate to form a lower hinge reinforcing plate assembly for mounting a vehicle door hinge; the lower hinge reinforcing plate assembly is fixed to the outer side of the B-pillar reinforcingplate, and the welding face of the periphery of the lower hinge reinforcing plate is welded to the B-pillar reinforcing plate so that a closed box body structure can be formed between the lower hingereinforcing plate and the B-pillar reinforcing plate. According to the B-pillar lower hinge reinforcing plate assembly, the structure for inducing deformation of the B column is ingeniously arranged,so that deformation of the B column meets the design expectation during side collision, and the side collision safety of a whole vehicle is effectively improved.

Owner:IAT AUTOMOBILE TECH

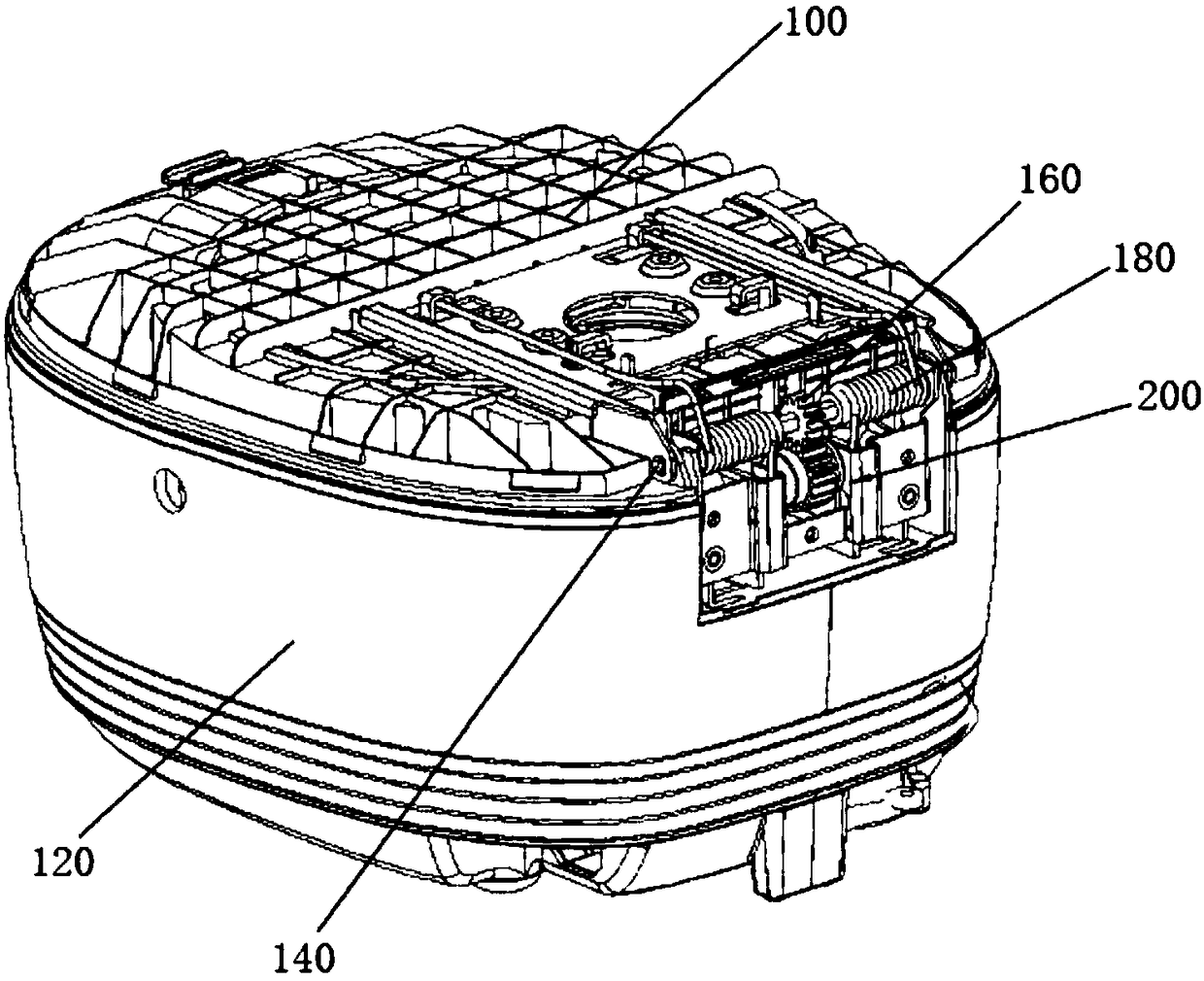

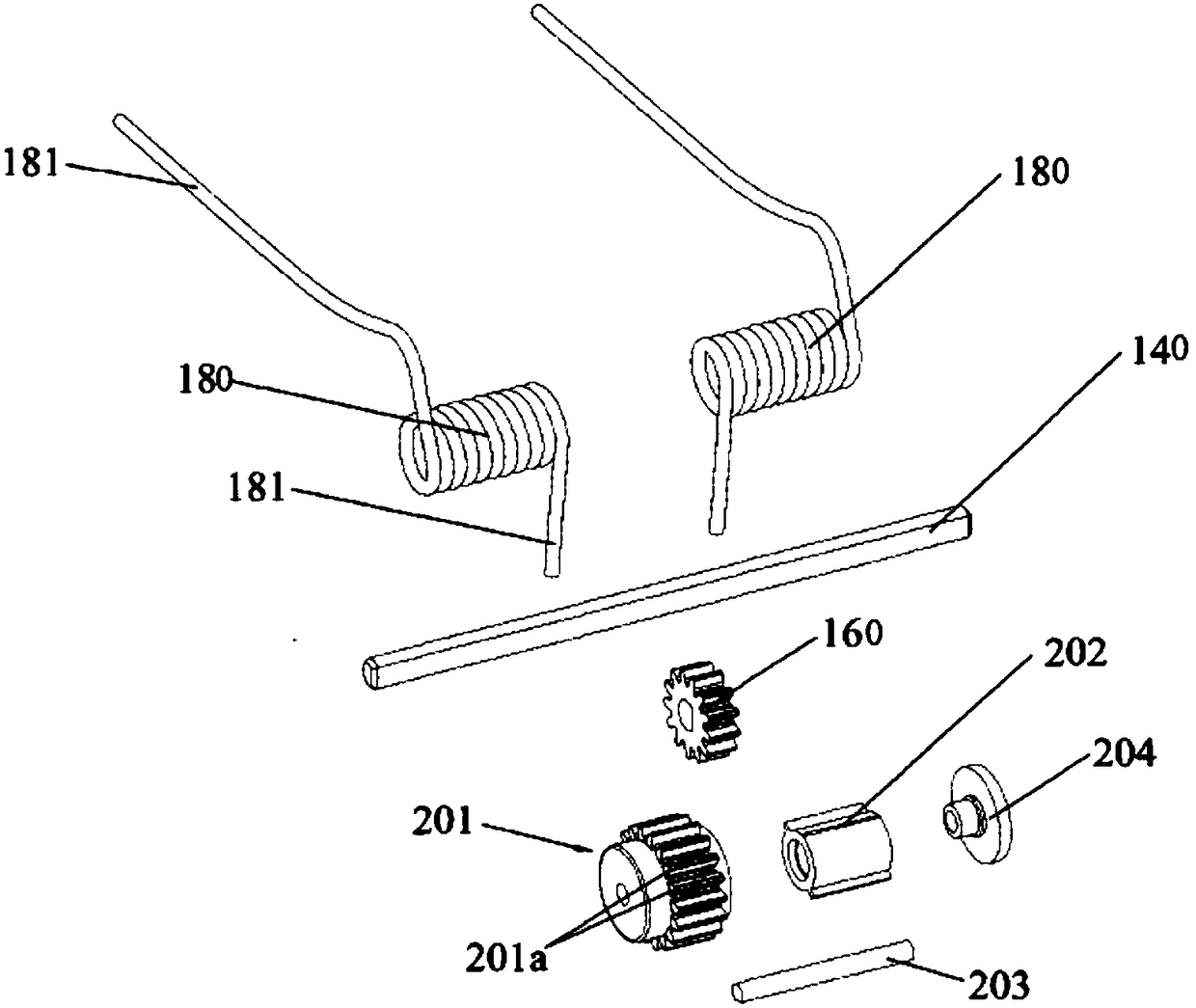

Damping device and device with same

ActiveCN108143293APass directlyTimely deliveryCooking-vessel lids/coversEngineeringStructural engineering

The invention discloses a damping device and a device with the same, and belongs to the technical field of kitchen appliances and components of the kitchen appliances. By the aid of the damping deviceand the device, the problems of complicated structures, low resistance and the like of existing damping devices can be solved. The damping device comprises a mounting fixing shell cover, a seal cover, clips and an inner core. The shell cover and the seal cover can be closed up to form a closed space, the clips are arranged in the shell cover, and rotating force can be transmitted by hinge shaftsand the inner core; the clips comprise elastic force portions and blocking portions, inner core lugs are arranged on the outer wall of the inner core and are butted onto the blocking portions when theinner core rotates to reach set locations, and elastic force can be provided by the elastic force portions to the blocking portions, so that the rotational speeds of the inner core can be reduced. The damping device and the device with the damping device have the advantages that integral structures can be simplified, only few components are required, accordingly, the cost can be lowered, and thevolume of the device can be diminished; resistance can be provided by the clips, and accordingly the damping device and the device have large deformation spaces and the high elastic force.

Owner:GREE ELECTRIC APPLIANCES INC

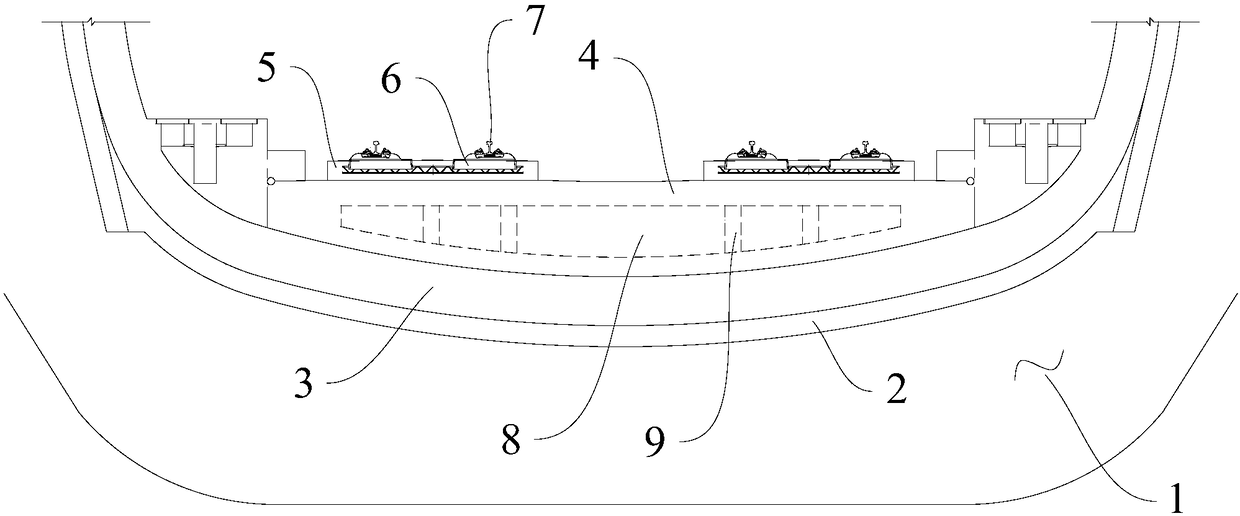

Cavity type prevention device for tunnel bottom deformation of ballastless track, and construction method

ActiveCN108331593AImprove structural strengthMeet changing needsUnderground chambersTunnel liningEngineeringLarge deformation

The invention discloses a cavity type prevention device for tunnel bottom deformation of a ballastless track, and a construction method of the cavity type prevention device. The cavity type preventiondevice comprises cavity chambers formed in an inverted arch filling layer, and a plurality of vertical columns are further arranged inside the cavity chambers. The construction method comprises the steps that reinforcement cages of the inverted arch filling layer are bound; a plurality of inner formworks are arranged in the inverted arch filling layer in the longitudinal direction of a tunnel, sothat all the inner formworks form the required cavity chambers of a plurality of closed areas; and the inverted arch filling layer is poured, so that the inverted arch filling layer with the cavity chambers is formed. Through forming of the cavity chambers, a sufficiently large deformation space can be provided for tunnel bottom surrounding rock, the surrounding rock volume increment caused by surrounding rock stress adjusting can be counteracted by utilizing the cavity structures, and the situation that the surrounding rock volume increment directly affects a top plate of the inverted arch filling layer, and consequently the tunnel bottom arches upwards and is not smooth is avoided; and the cavity chambers play the roles of stress releasing and reducing of damage of the tunnel base loadto a tunnel inverted arch in the operation period simultaneously.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

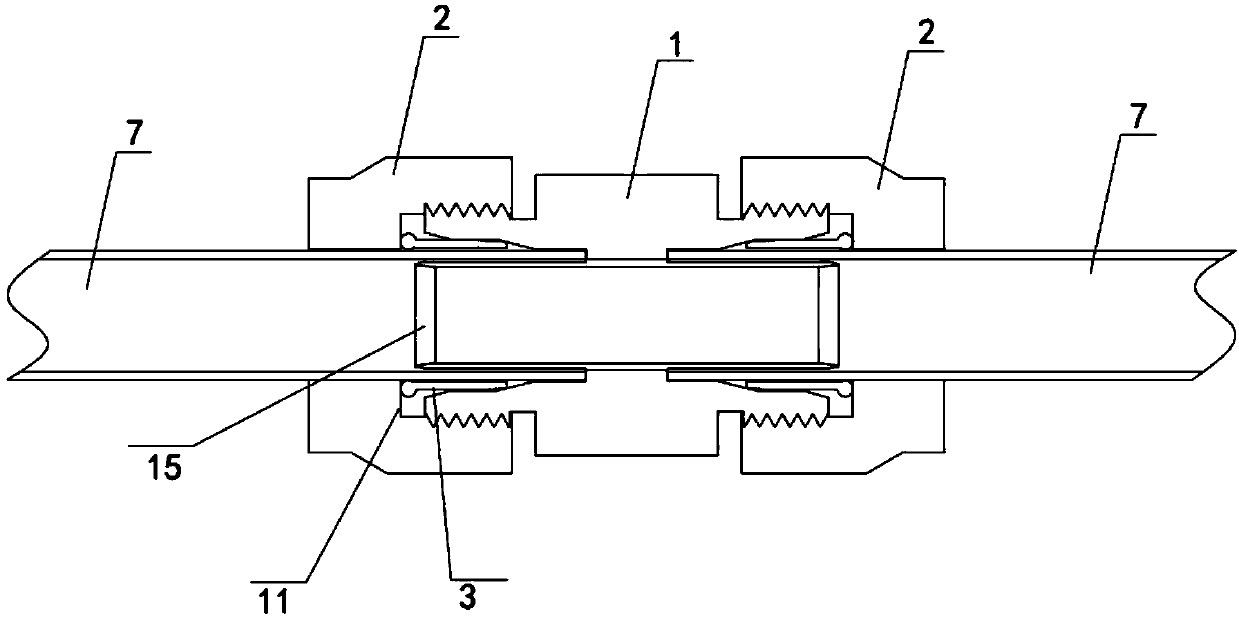

Tube connection device

PendingCN107906278APrevent pulling outEnable connectivityJoints with sealing surfacesCouplingEngineering

The invention discloses a tube connection device which comprises a ring body, caps and outer bushes. Each outer bush comprises a first bush body and a convex bag portion. When the caps are screwed onto the ring body, the outer bushes can be driven to move towards the interior of the ring body; and when the outer bushes move inwards, the inner side wall of the ring body generates radial inward extrusion force to the convex bag portions. The tube connection device has the advantages that when tube connection is needed, to-be-connected tubes sequentially penetrate the caps and the outer bushes tobe inserted into the ring body, then the caps are unceasingly screwed, and in the process of screwing the caps, the caps unceasingly get close to the ring body; and in the process, step portions on the inner sides of the caps can unceasingly extrude the outer bushes, the convex bag portions generate extrusion to the side walls of the to-be-connected tubes, the to-be-connected tubes generate deformation, and therefore the connection effect is achieved.

Owner:HANGZHOU WENGER SCI & TECH CO LTD

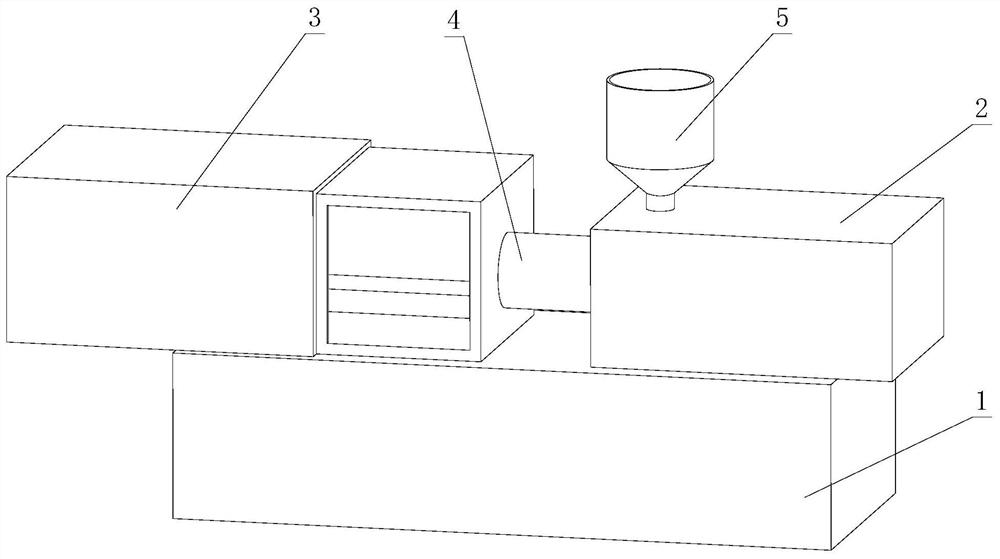

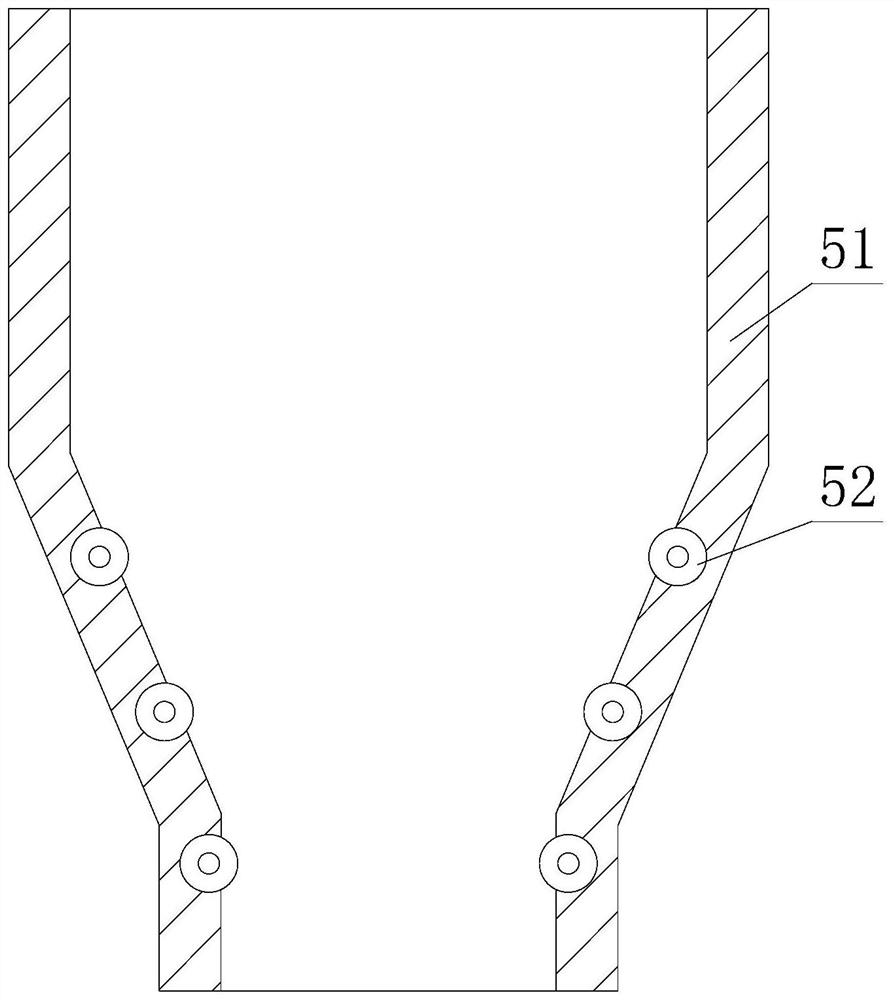

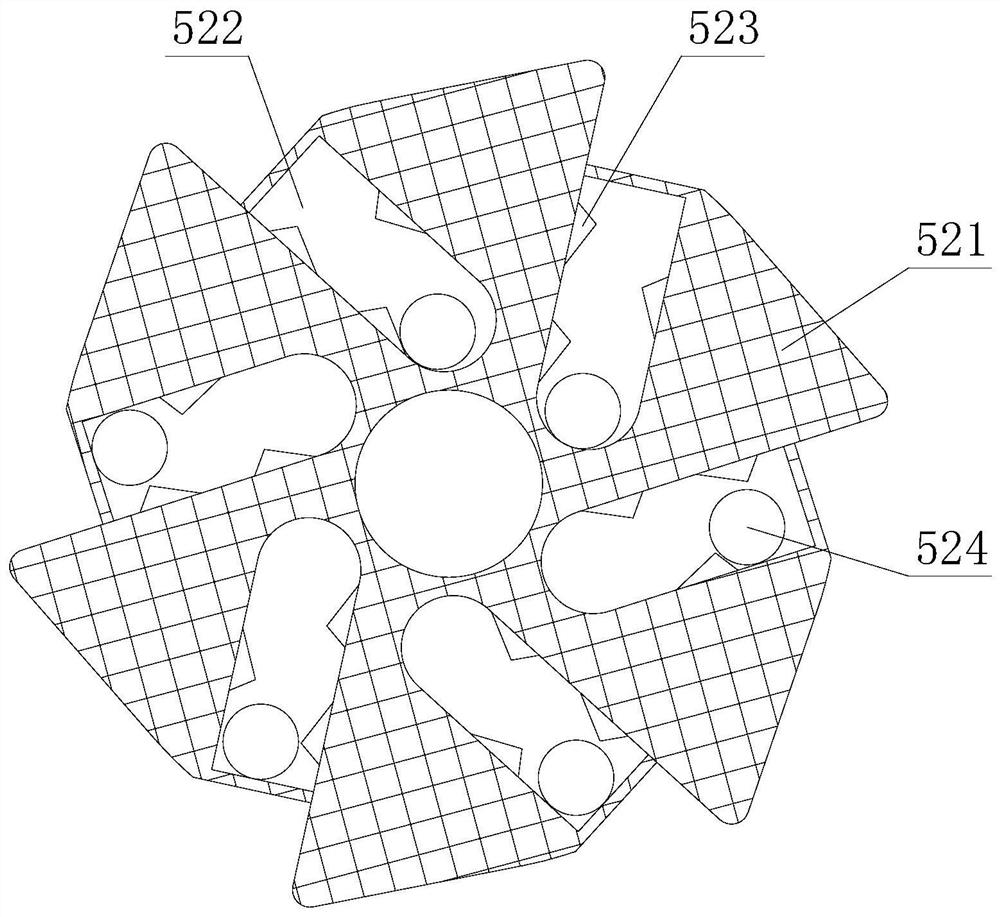

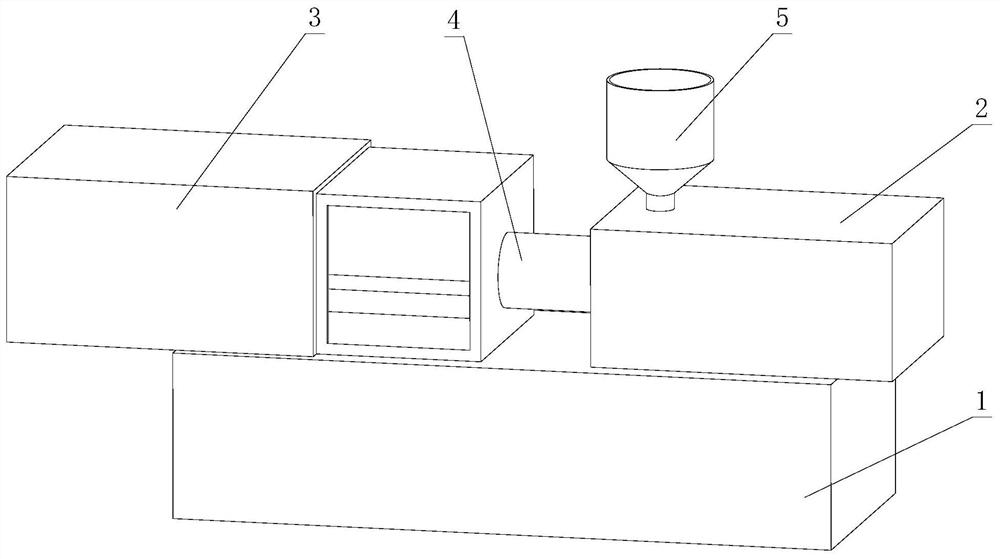

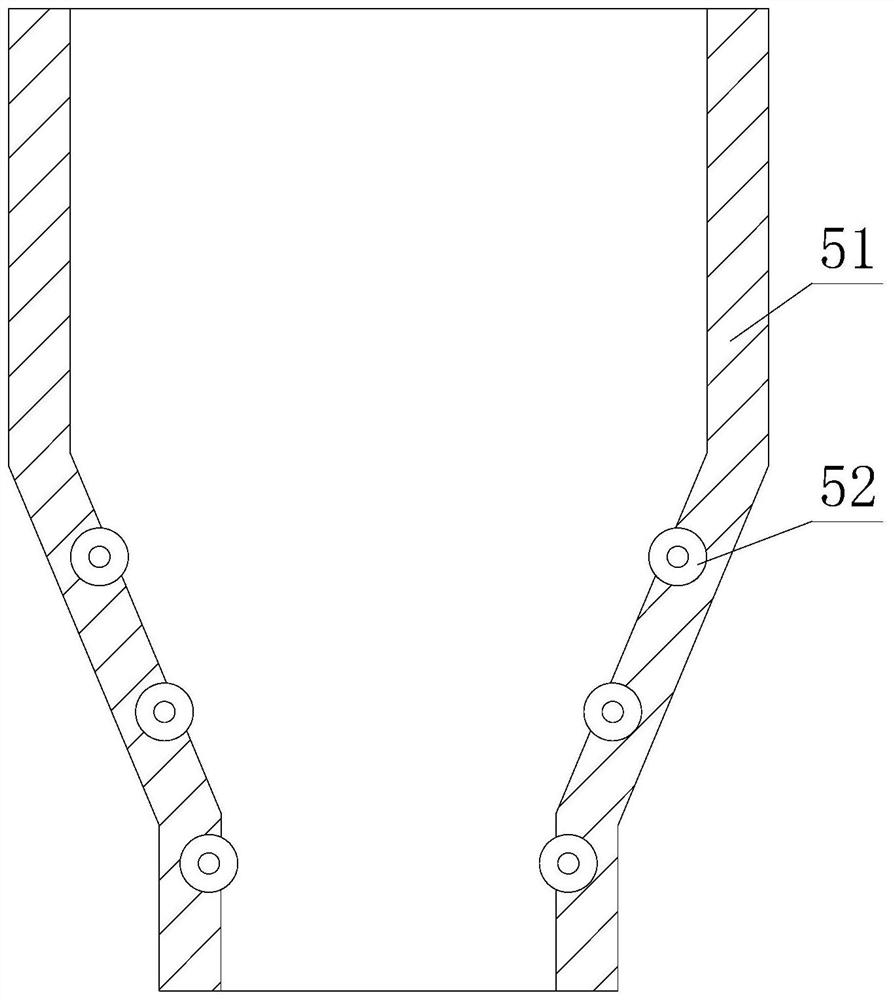

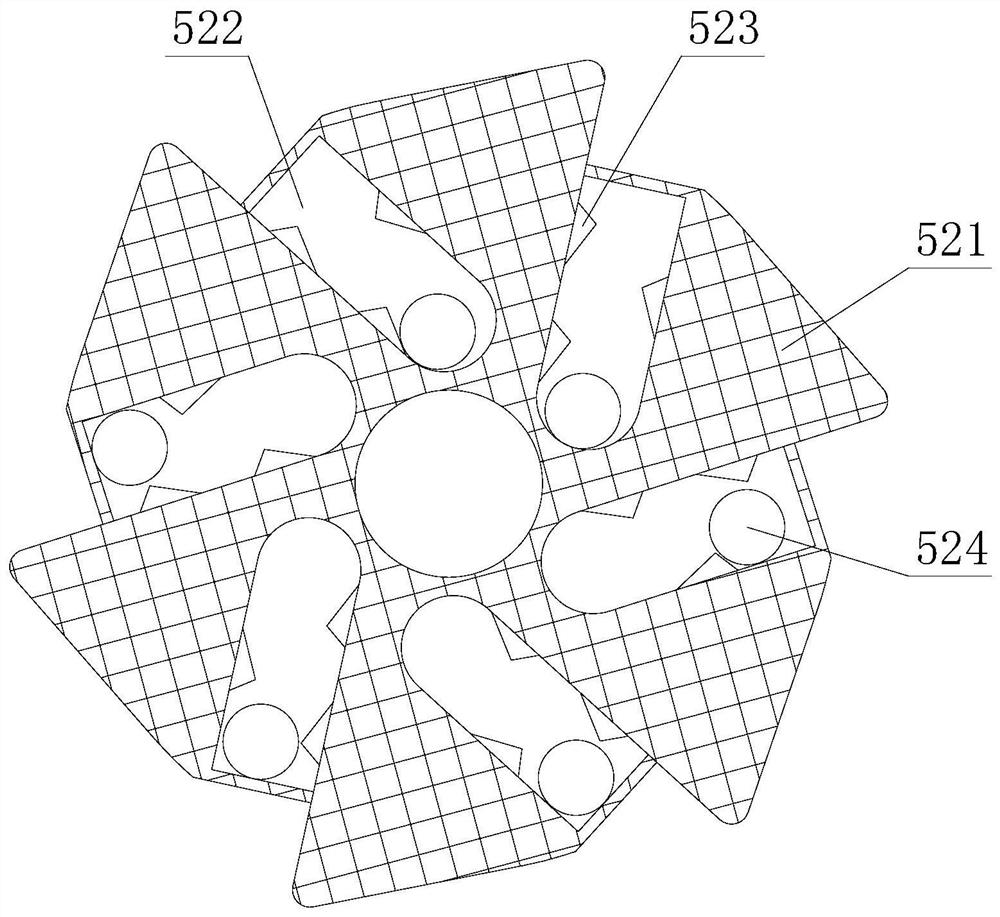

Mold injection molding device special for new energy automobile interiors

The invention discloses a mold injection molding device special for new energy automobile interiors, and relates to the technical field of mold injection molding. The mold injection molding device comprises a base, a mold combining structure and a feeding structure are arranged on the left side and the right side of the upper end of the base correspondingly, a heating structure is arranged betweenthe mold combining structure and the feeding structure, a hopper is arranged on the side, close to the heating structure, of the upper end of the feeding structure, and a material bin is arranged inthe hopper. Through the design of inner vibration grooves and guide blocks, when a windmill wheel rotates, vibration balls can move in the inner vibration grooves, and when the vibration balls move tothe surfaces of the guide blocks, the vibration balls move in the inclined direction, so that the vibration balls impact the side wall of the windmill wheel so as to generate vibration; and through the different rotating positions of the inner vibration grooves, the moving speeds of the vibration balls are different, the vibration balls impact the windmill wheel after moving so as to generate vibration, injection molding raw materials adhering to the windmill wheel are separated from the surface of the windmill wheel, blockage is avoided, and the injection molding raw materials circulate smoothly.

Owner:辽宁信兴汽车零部件有限公司

Telescopic device of highway bridge

InactiveCN109356024APlay a protective effectExtended service lifeBridge structural detailsArchitectural engineeringMetal sheet

The invention relates to the technical field of highway bridges, and discloses a telescopic device of a highway bridge. The telescopic device comprises a telescopic mechanism and two vertically arranged fixed plates. The telescopic mechanism is located between the two fixed plates, a plurality of metal sheets are arranged on the outer sides of the fixed plates at equal intervals, and the metal sheets are arranged upwards obliquely. The telescopic mechanism comprises a plurality of rubber belts and a plurality of vertical rods, the rubber belts are perpendicular to the fixed plates, the rubberbelts are arranged in parallel and connected through the vertical rods, extending plates are hinged to the upper ends of the two fixed plates, the extending plates are overlapped and are in sliding connection, the lower ends of the two fixed plates are horizontally connected with supporting plates, and a clearance is arranged between the two supporting plates. The vertical rods are divided into aplurality of branch rods, and the branch rods are detachably connected. According to the telescopic device, the rubber belts are protected, and the rubber belts can be replaced conveniently.

Owner:CHONGQING VOCATIONAL INST OF ENG

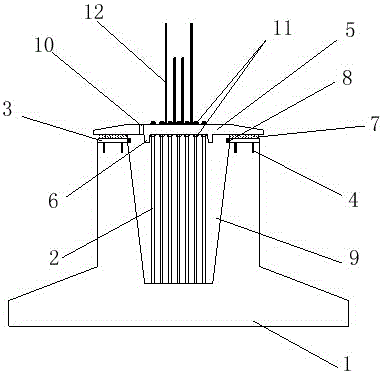

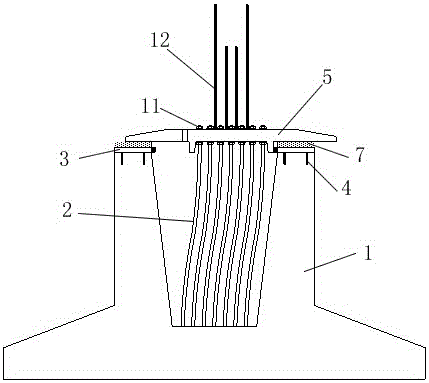

Reinforced concrete vibration-isolated foundation

ActiveCN105649101AExtend the natural vibration periodStrong deformationFoundation engineeringReinforced concreteFilling materials

The invention relates to a reinforced concrete vibration-isolated foundation. The reinforced concrete vibration-isolated foundation comprises a ring-shaped foundation, high-elasticity reinforcing steel bars, a cup-mouth steel plate, anchoring pins, a steel cover plate, a limiting baffle bar, sealing grease, buffer cushions, a damping filling material, positioning holes, nuts, injection holes and column joint bars, wherein the ring-shaped cavity of the foundation is filled with the damping filling material to achieve the energy-dissipating damping effect. According to the reinforced concrete vibration-isolated foundation, the foundation in the conventional vibration-isolated foundation and a vibration-isolated supporting base are integrated to achieve the dual functions of foundation stress and vibration isolation, so that relatively great uplift force can be borne; the reinforced concrete vibration-isolated foundation has capacity of damping energy dissipation, can be limited and automatically returned, can obtain required horizontal stiffness by adopting different working modes, and can realize the vibration-isolating effect without mounting the vibration-isolated supporting base, so that the engineering cost can be reduced, and the building space can be saved.

Owner:福建省中禹水利水电工程有限公司

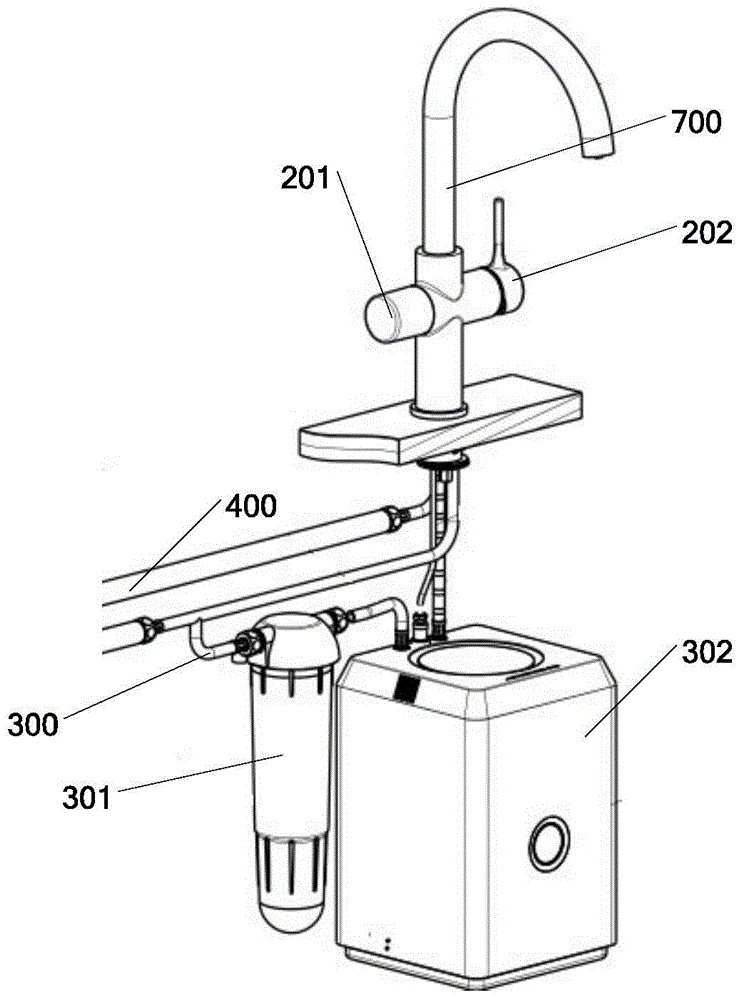

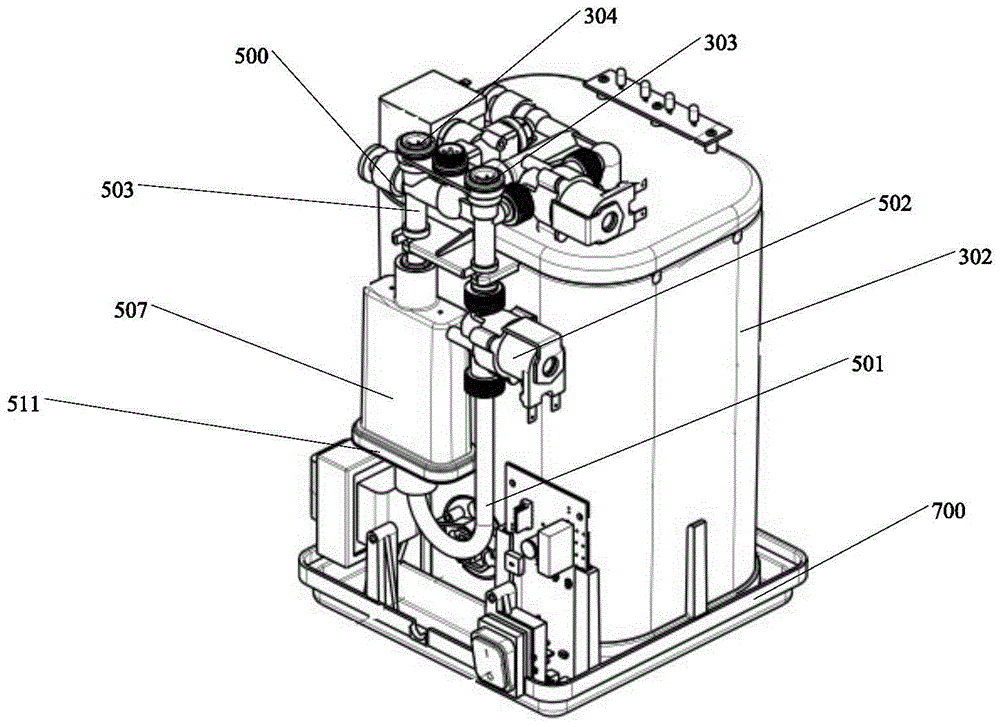

A faucet assembly

ActiveCN104888522BNo waterNo drip problemMultiple way valvesFiltration separationWater flowEngineering

Owner:GUANGZHOU SEAGULL KITCHEN & BATH PROD

A special mold injection device for new energy vehicle interior

Owner:辽宁信兴汽车零部件有限公司

A circular connector and connector assembly

ActiveCN109119818BExtended service lifeLarge deformation spaceCouplings bases/casesClassical mechanicsStructural engineering

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com