Telescopic device of highway bridge

A telescopic device, highway bridge technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of accelerating the aging degree of rubber belts, easy to stick rubber belts, inconvenient to replace rubber belts, etc., to avoid sticking and replacement. The effect of the rubber belt is convenient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

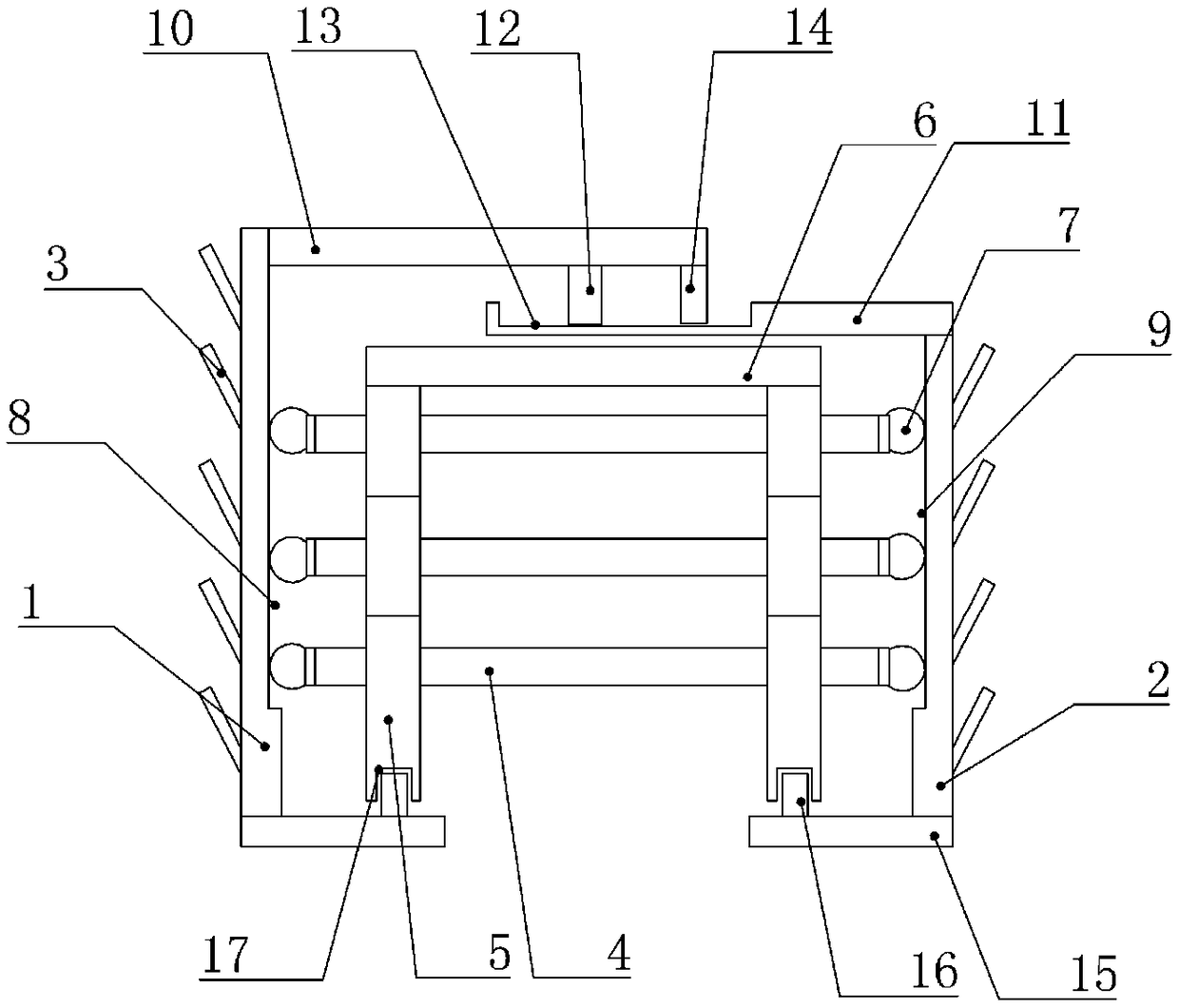

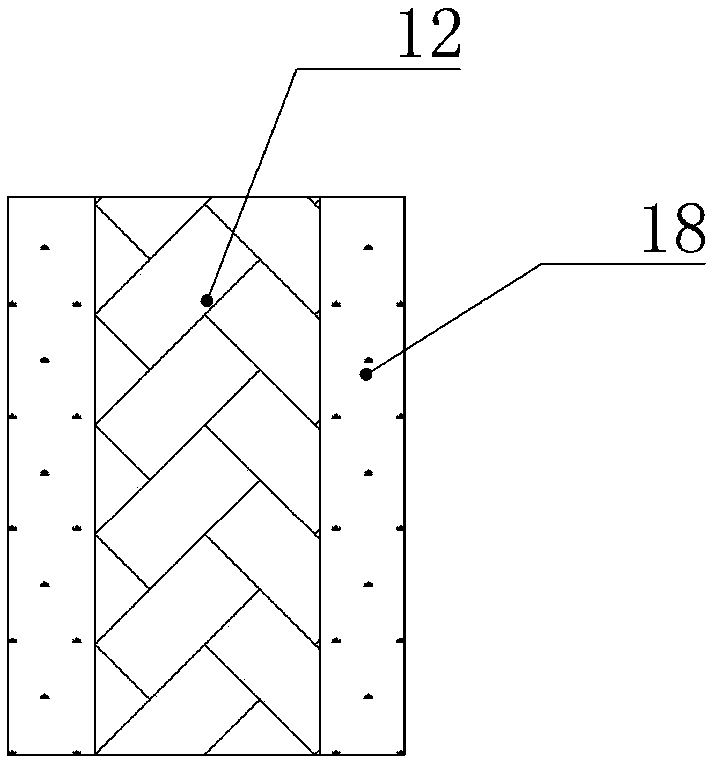

[0017] The reference signs in the accompanying drawings of the description include: first fixed plate 1, second fixed plate 2, metal sheet 3, rubber belt 4, vertical rod 5, elastic strip 6, roller 7, first chute 8, second The chute 9 , the first extension plate 10 , the second extension plate 11 , the slider 12 , the third chute 13 , the sealing block 14 , the support plate 15 , the first bump 16 , the first groove 17 , and the deformation layer 18 .

[0018] Example figure 1 and figure 2 Shown: a telescopic device for a highway bridge, including a telescopic mechanism, a first fixed plate 1 and a second fixed plate 2, the first fixed plate 1 and the second fixed plate 2 are vertically arranged, and the telescopic mechanism is located on the first fixed plate Between 1 and the second fixed plate 2, the first fixed plate 1 and the second fixed plate 2 are made of steel, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com