Patents

Literature

32results about How to "Does not affect scaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

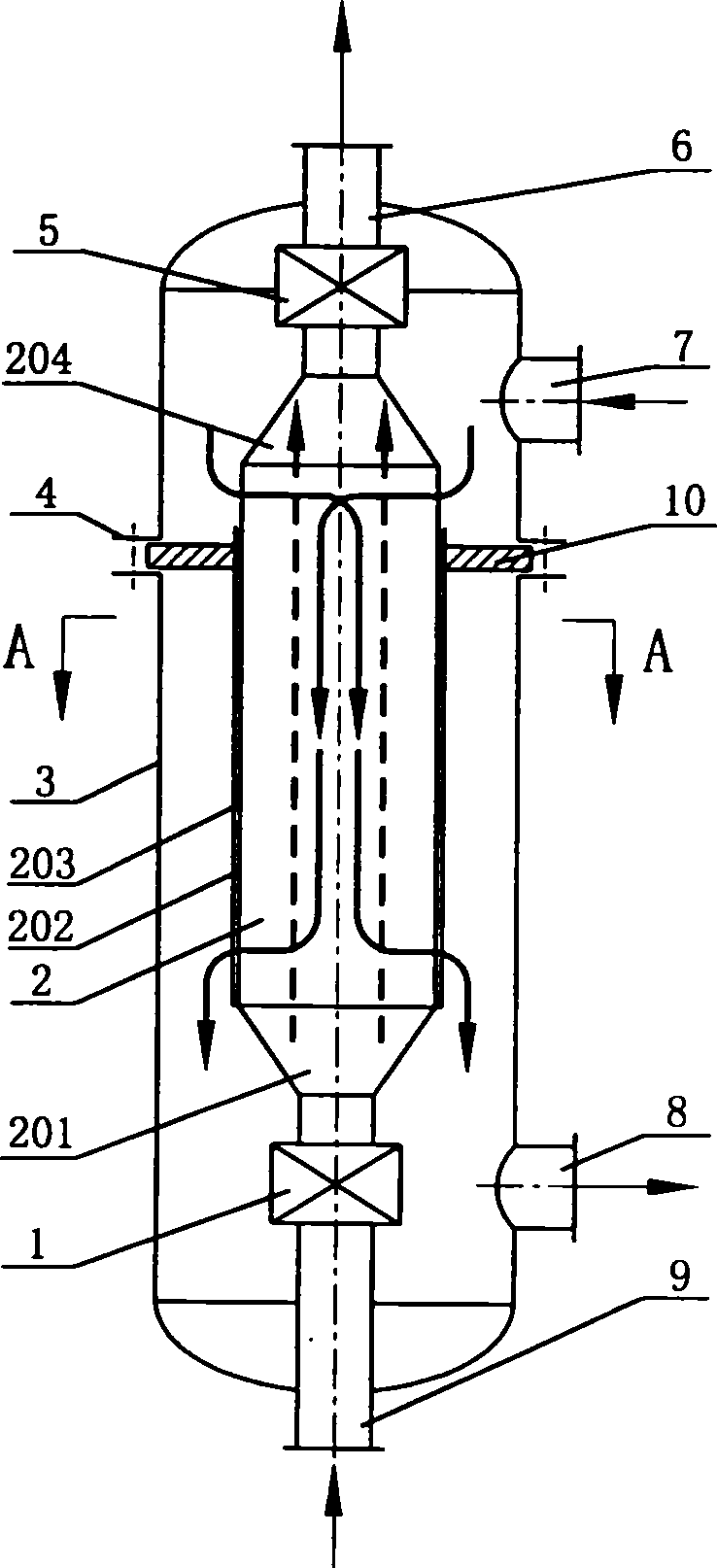

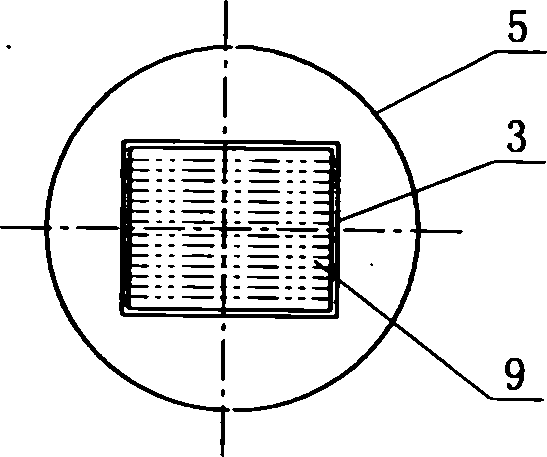

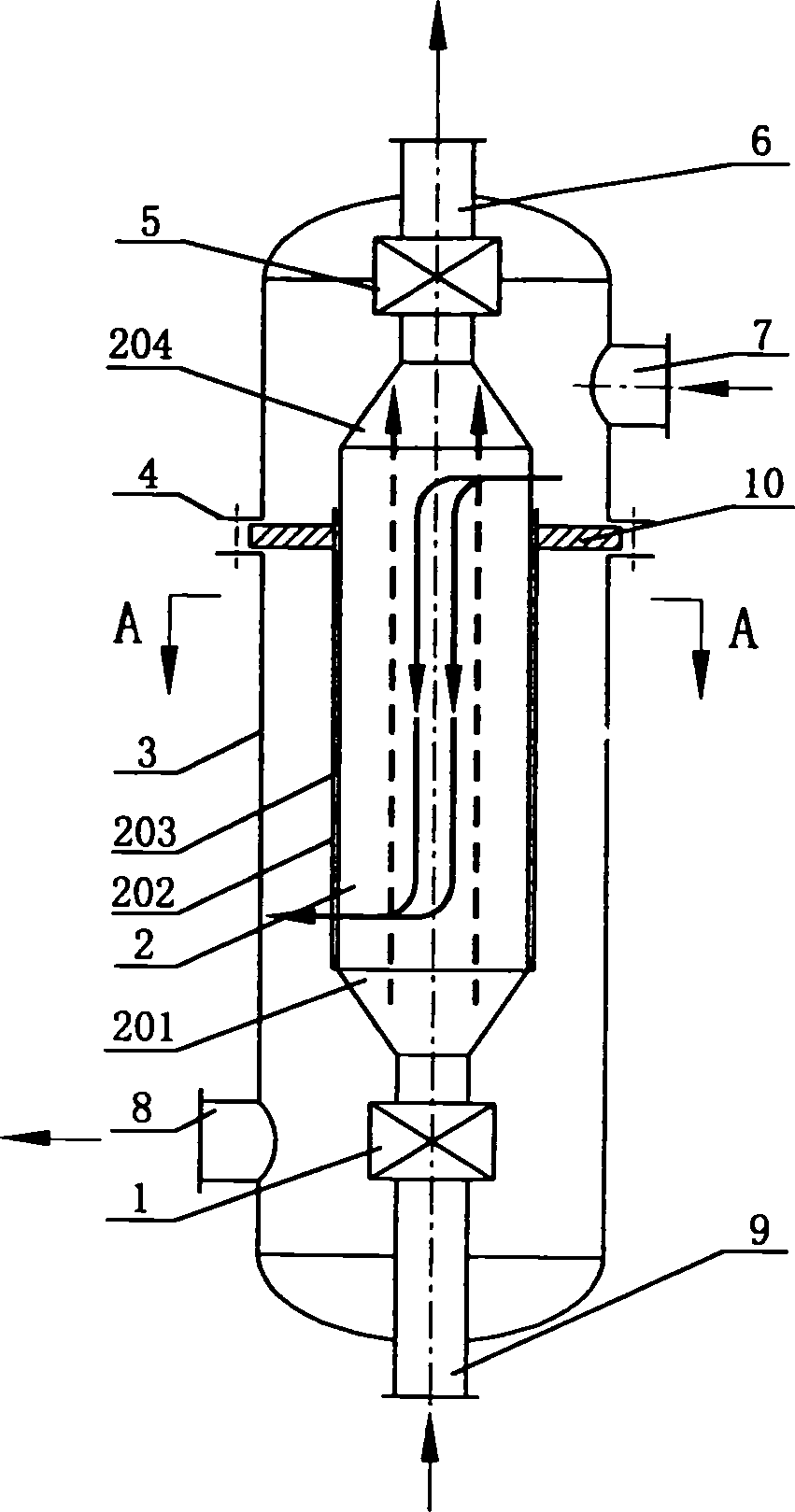

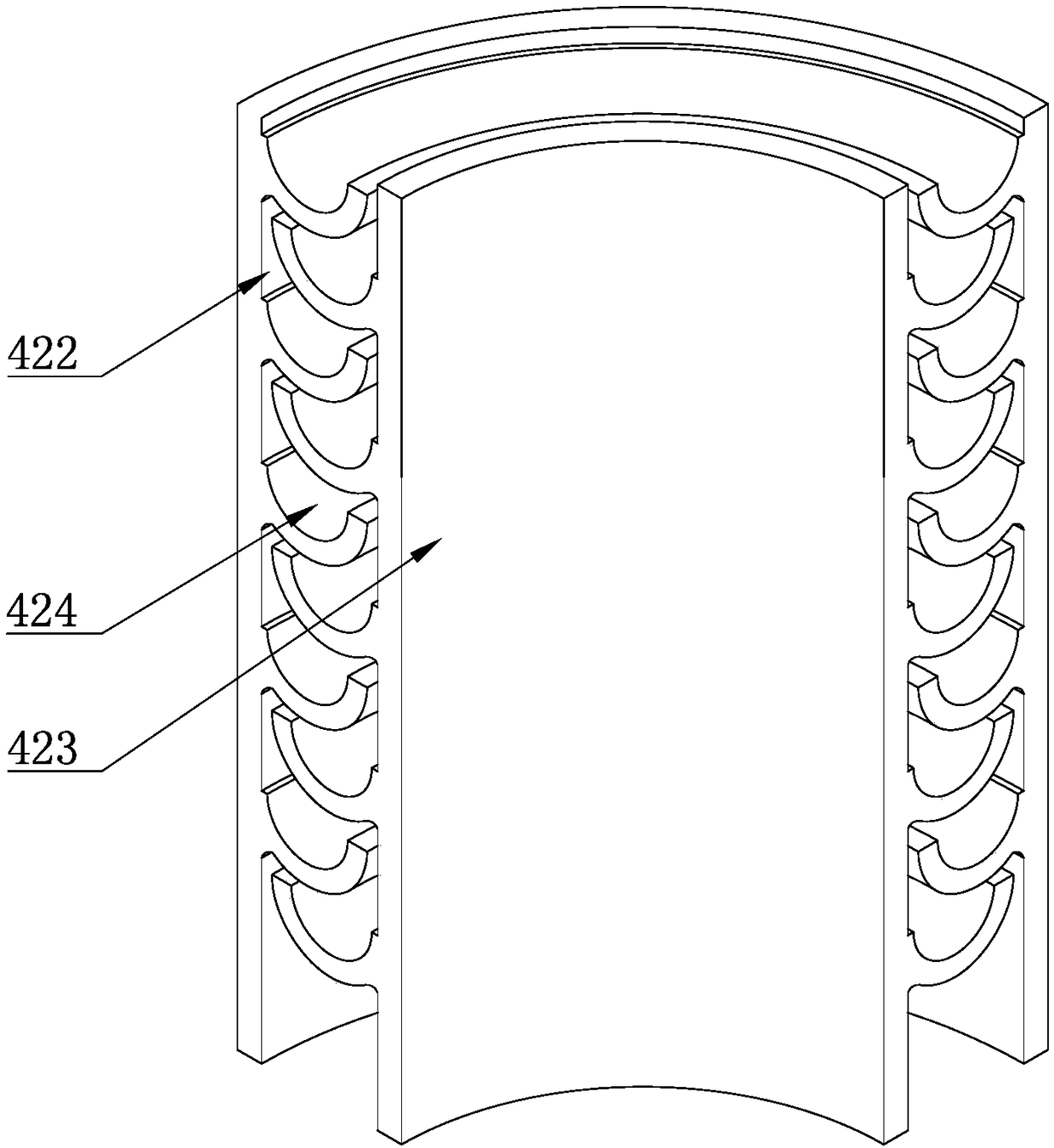

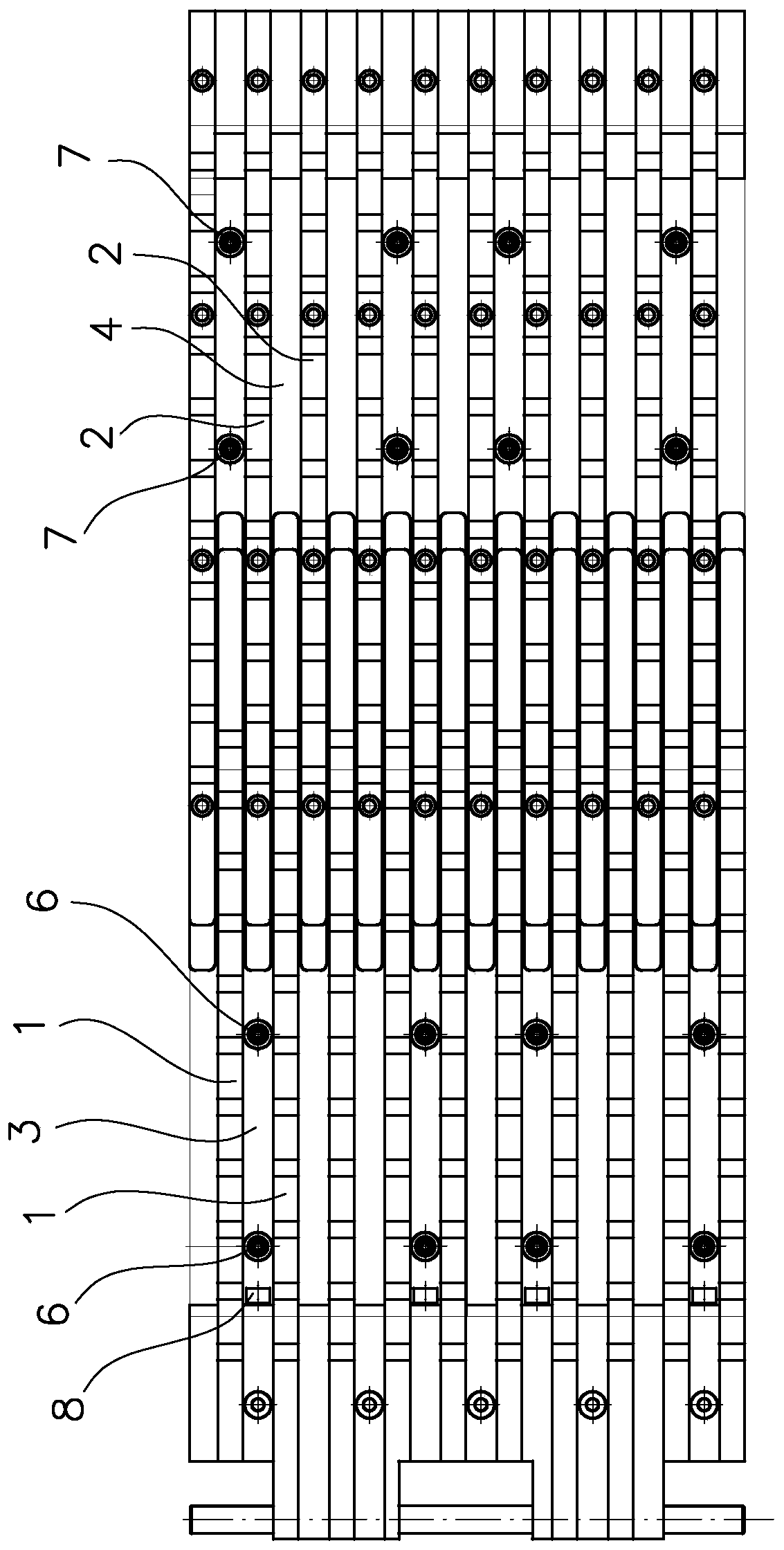

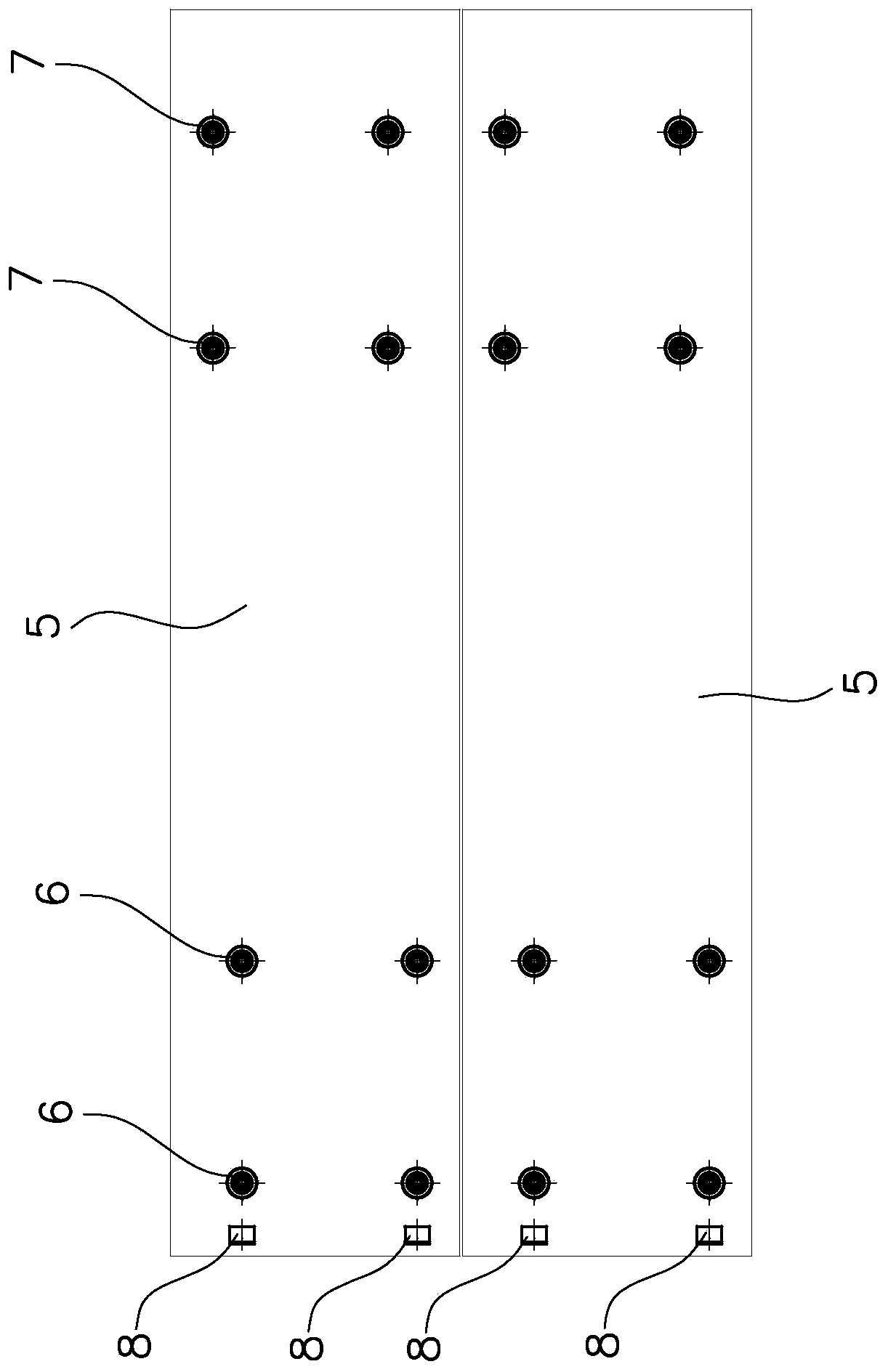

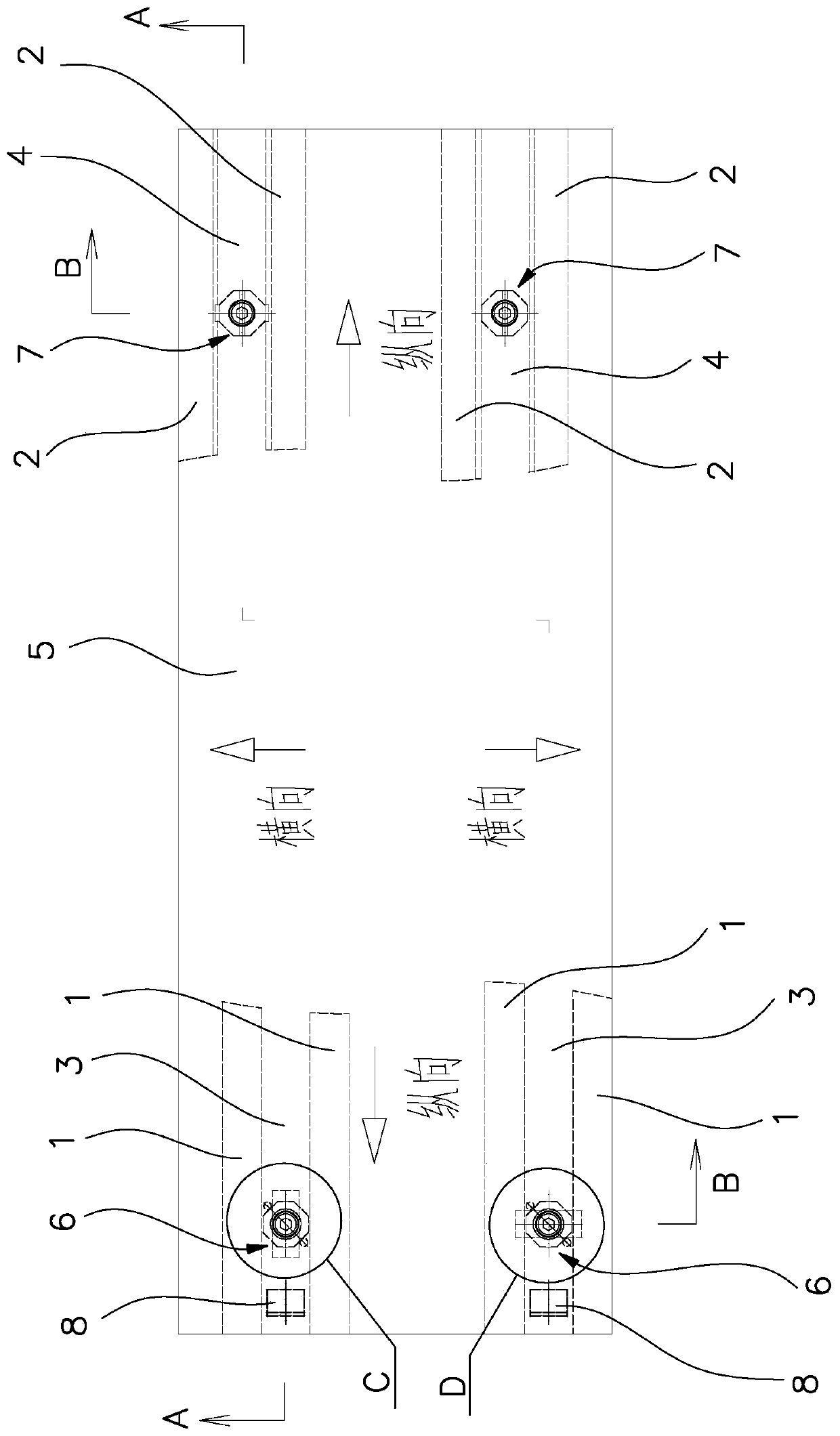

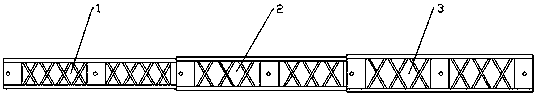

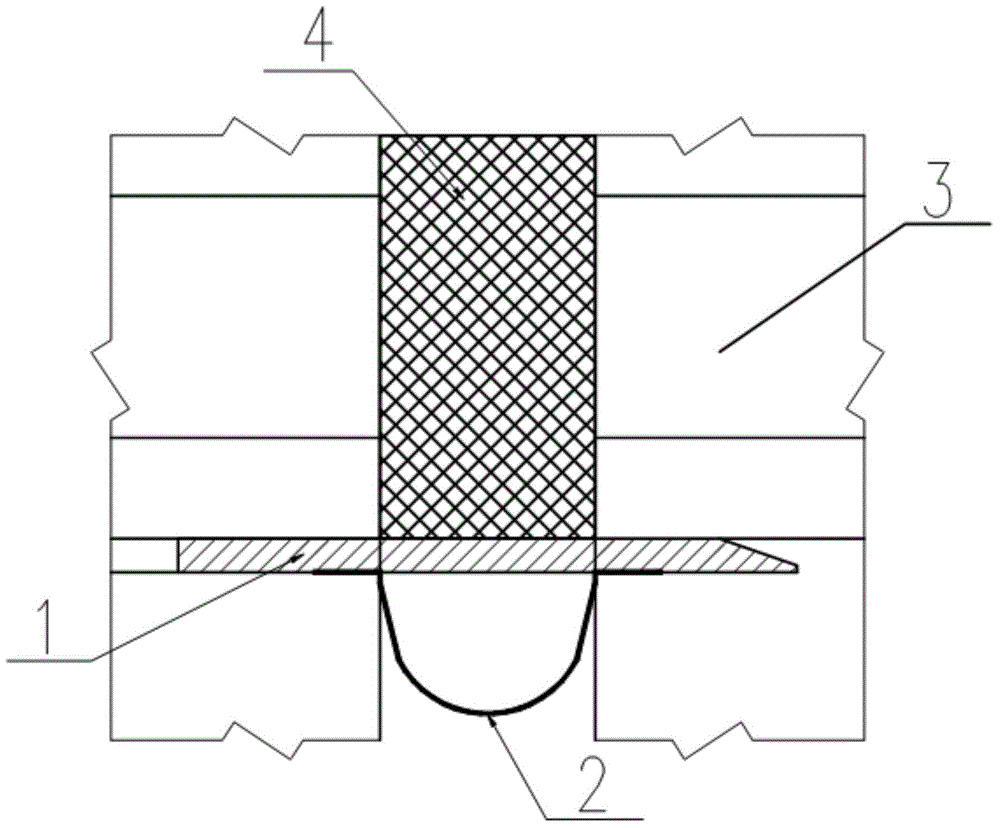

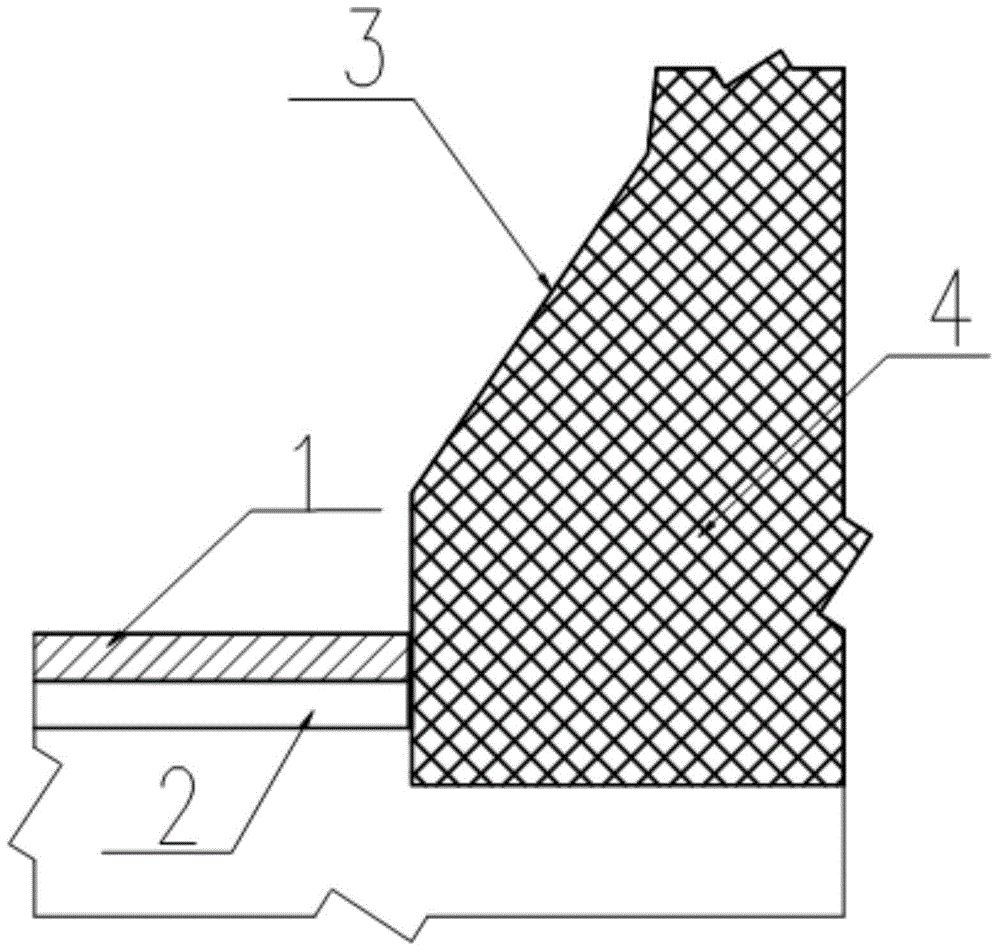

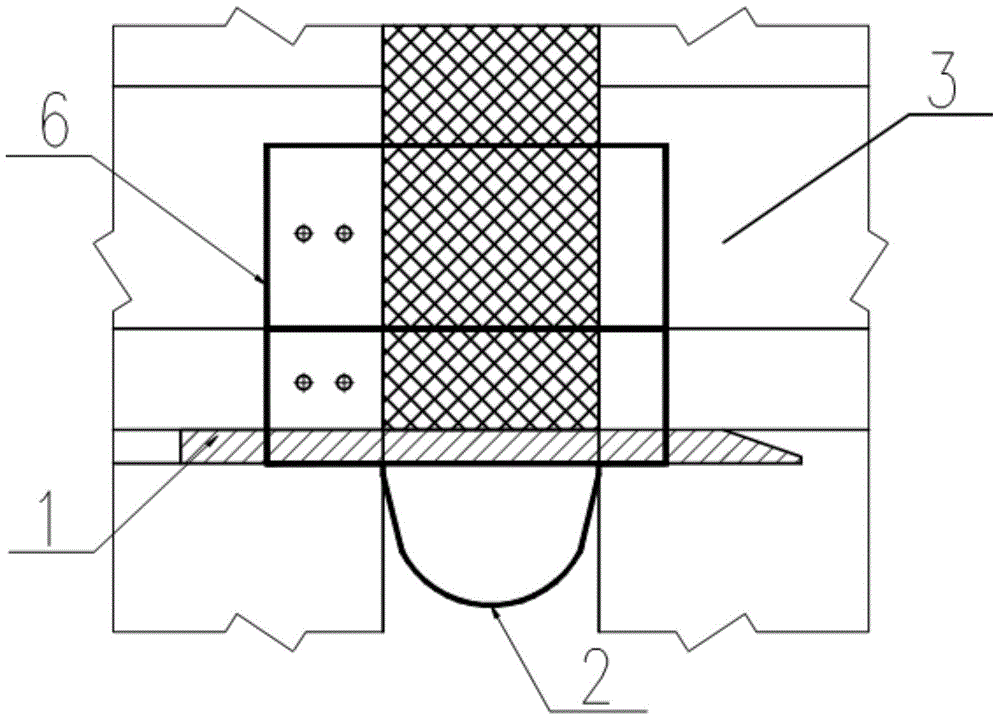

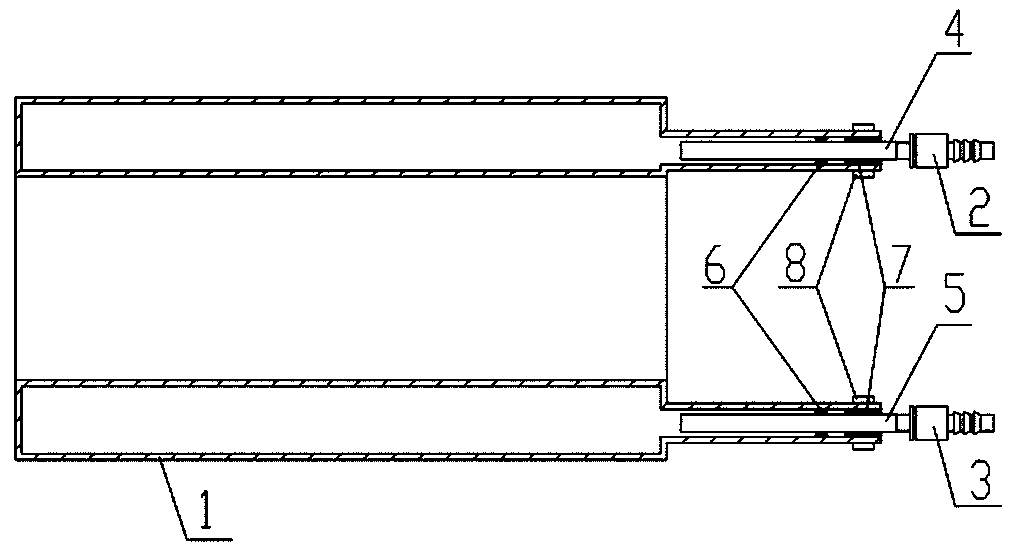

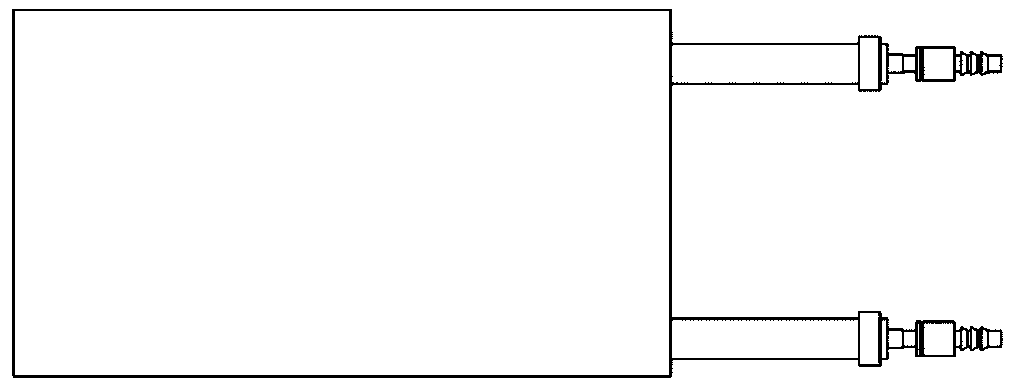

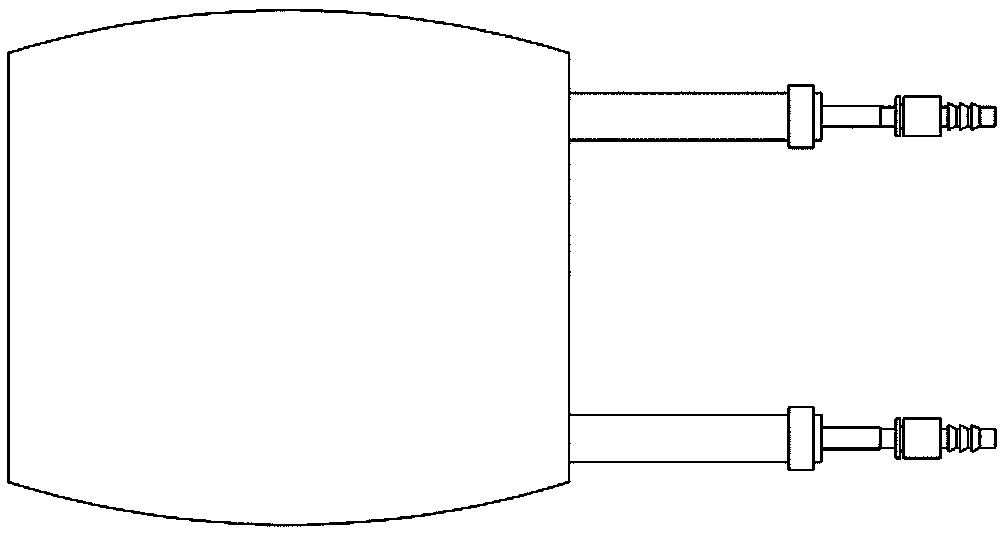

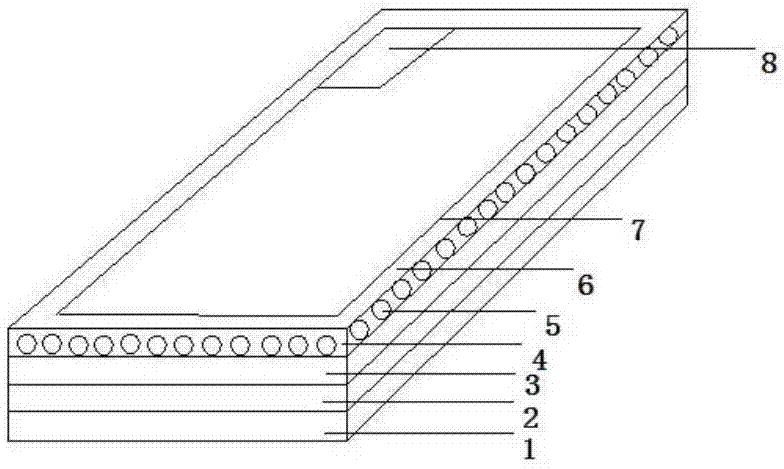

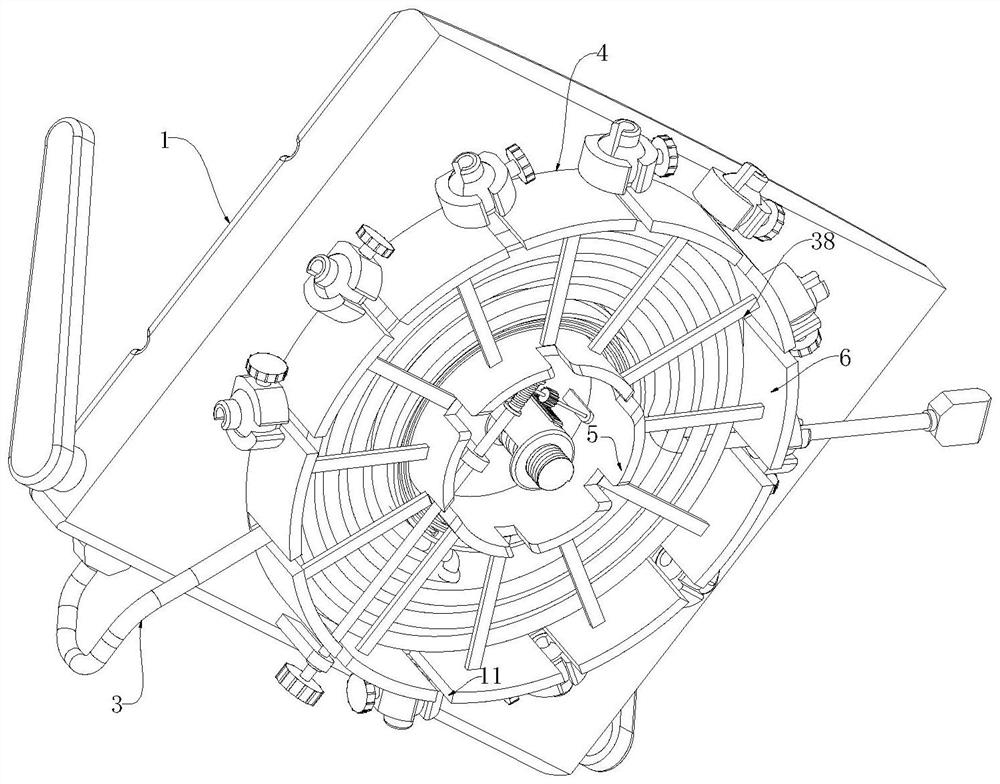

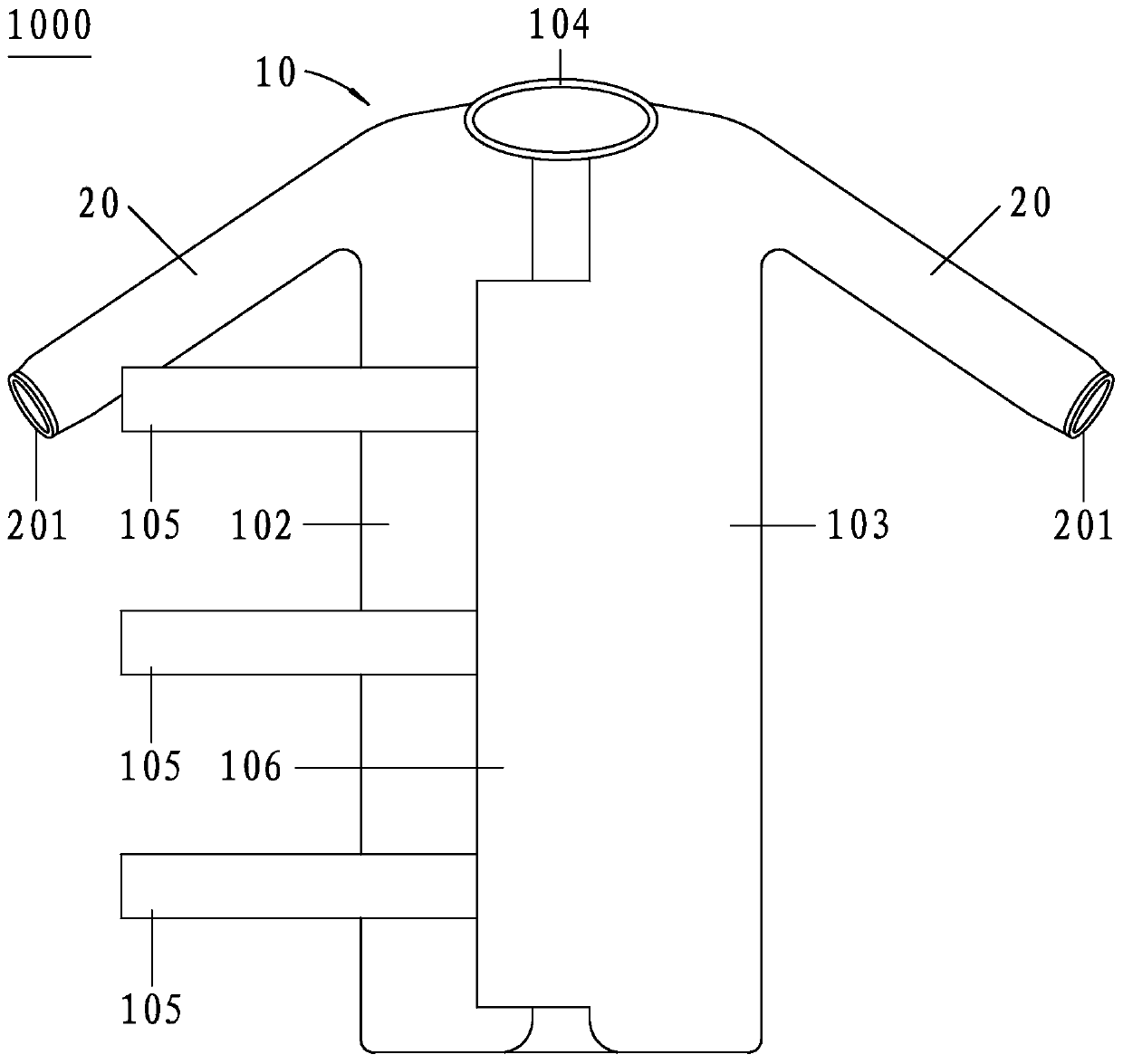

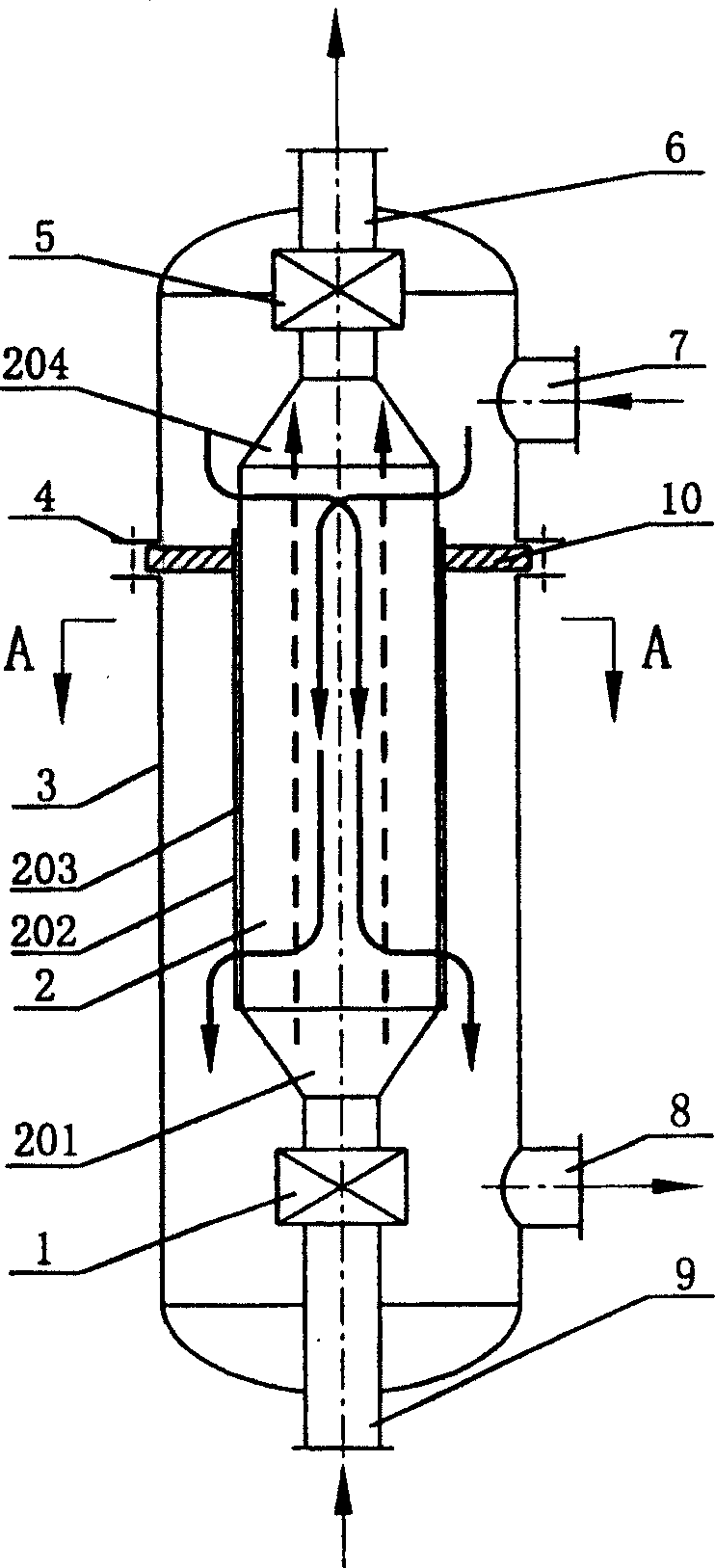

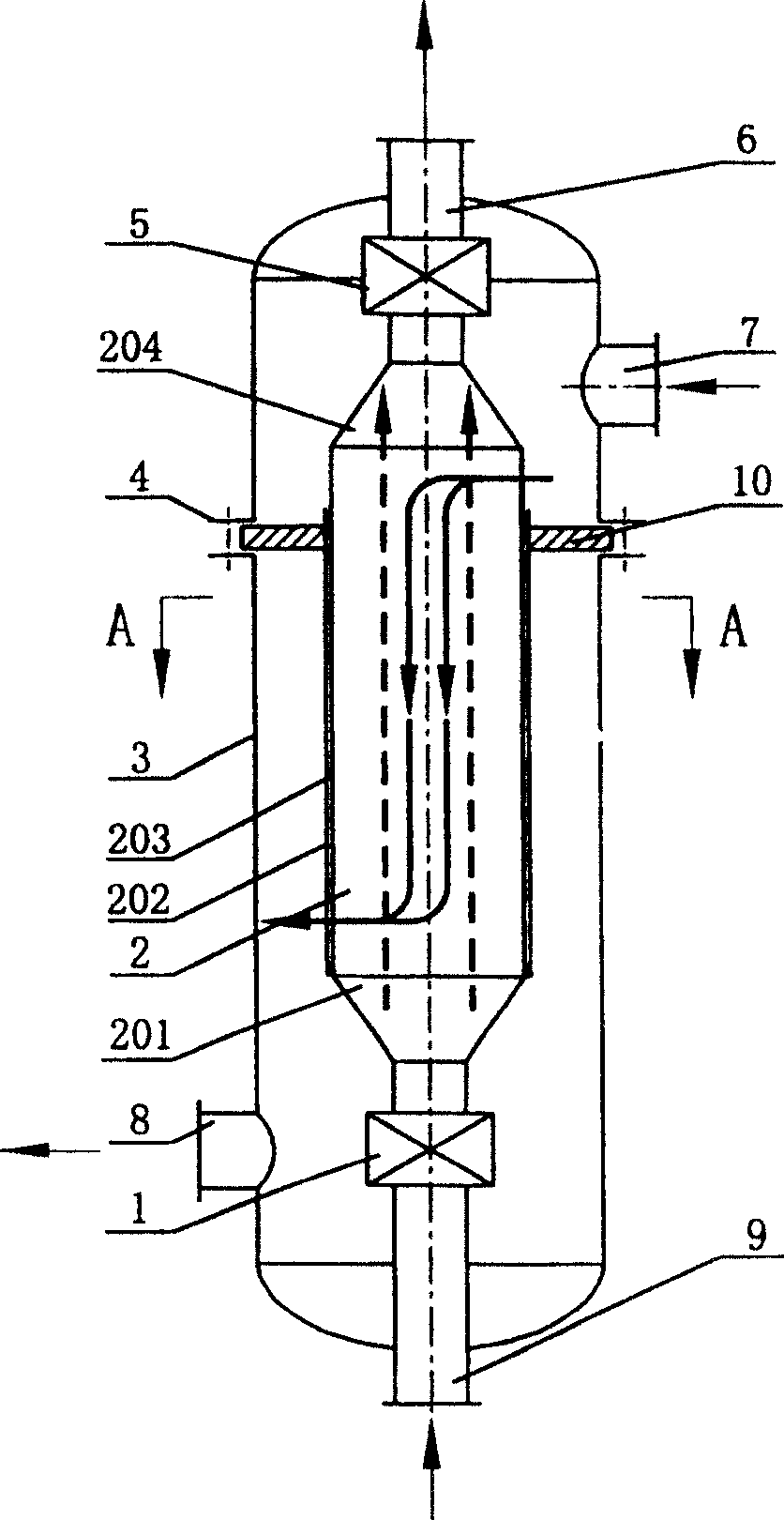

Plate-shell type heat exchanger

ActiveCN1884951AImprove reliabilityDoes not affect scalingStationary conduit assembliesStationary plate conduit assembliesPlate heat exchangerHeat transmission

The invention relates to a board heat exchanger, which uses ripple sheet as heat transmission element, wherein the invention comprises a frame, a board medium entrance connecting tube, and a board medium entrance tube; said frame is arranged with sheet beam, whose lower end via board medium entrance connecting tube is connected to the fixing expanding valve, and upper end via board medium outlet connecting tube is connected to the free expanding valve; two expanding valves absorb the thermal expansion displacements between sheet and frame, sheet beam frame and cylinder frame, without bearing the weight of sheet beam, to improve the reliability of board heat exchanger; the sheet beam frame compresses the layered sheet to bear the pressure difference between mediums, without affecting the flexibility; and the outer frame is cylinder, to bear higher medium pressure; one or two ends of sheet beam frame are arranged with side open; the invention can improve the application of board heat exchanger.

Owner:GANSU LANPEC TECH +2

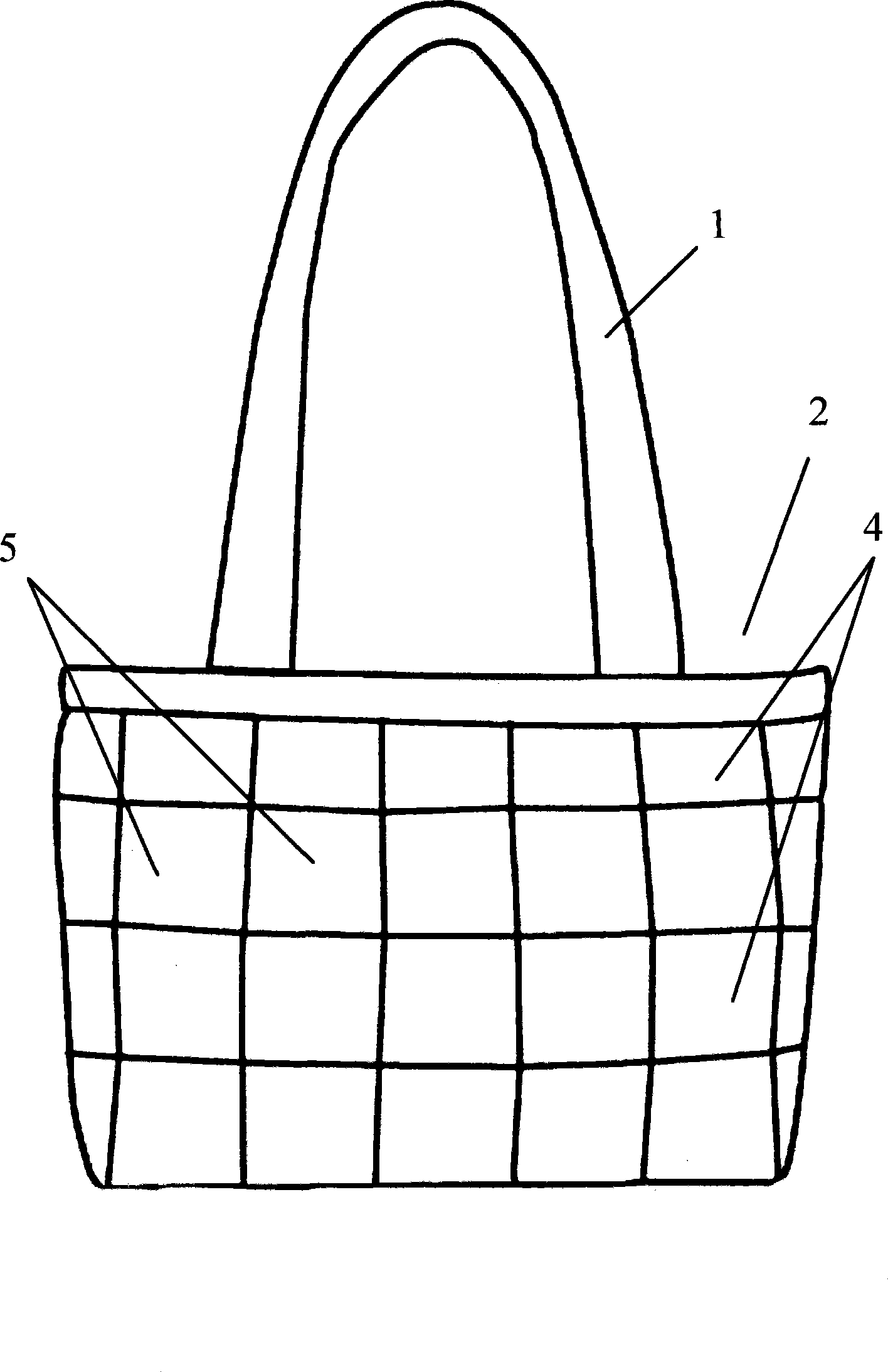

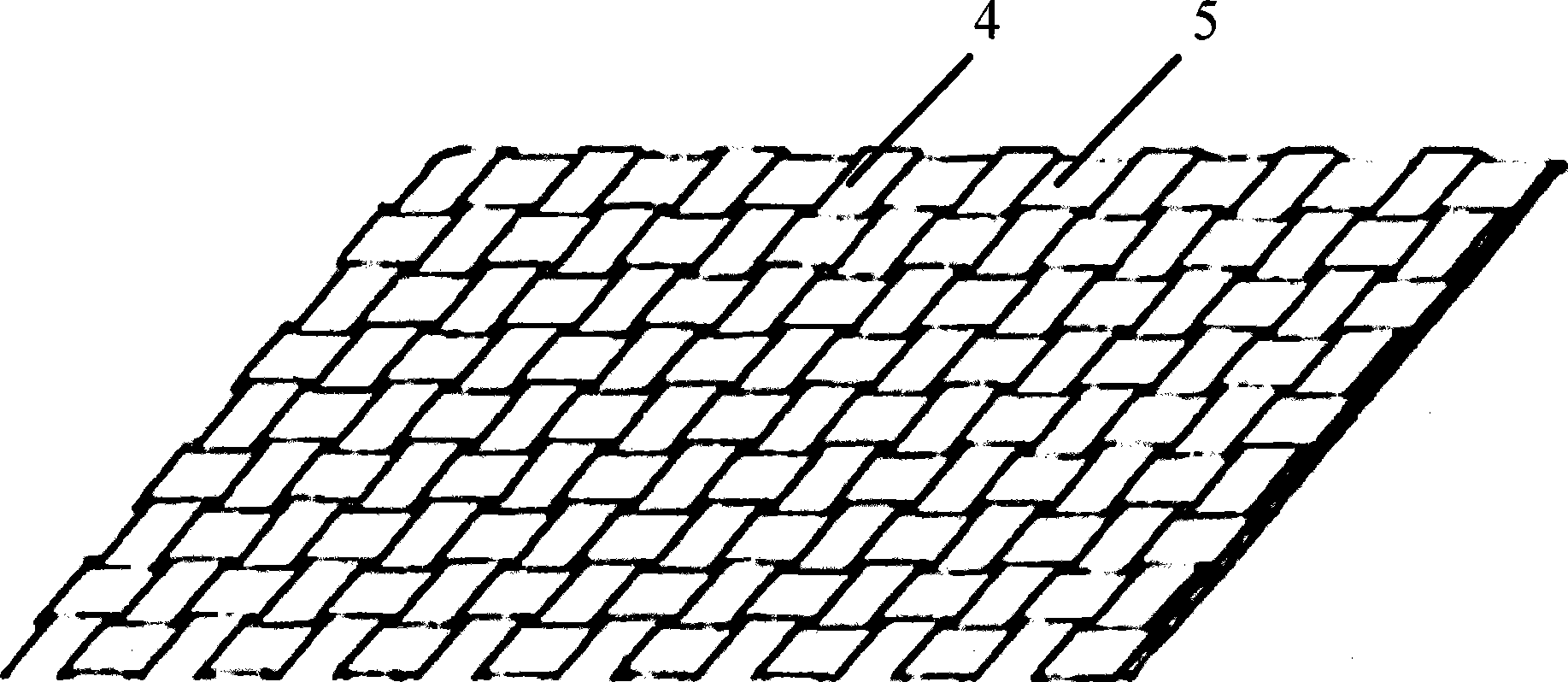

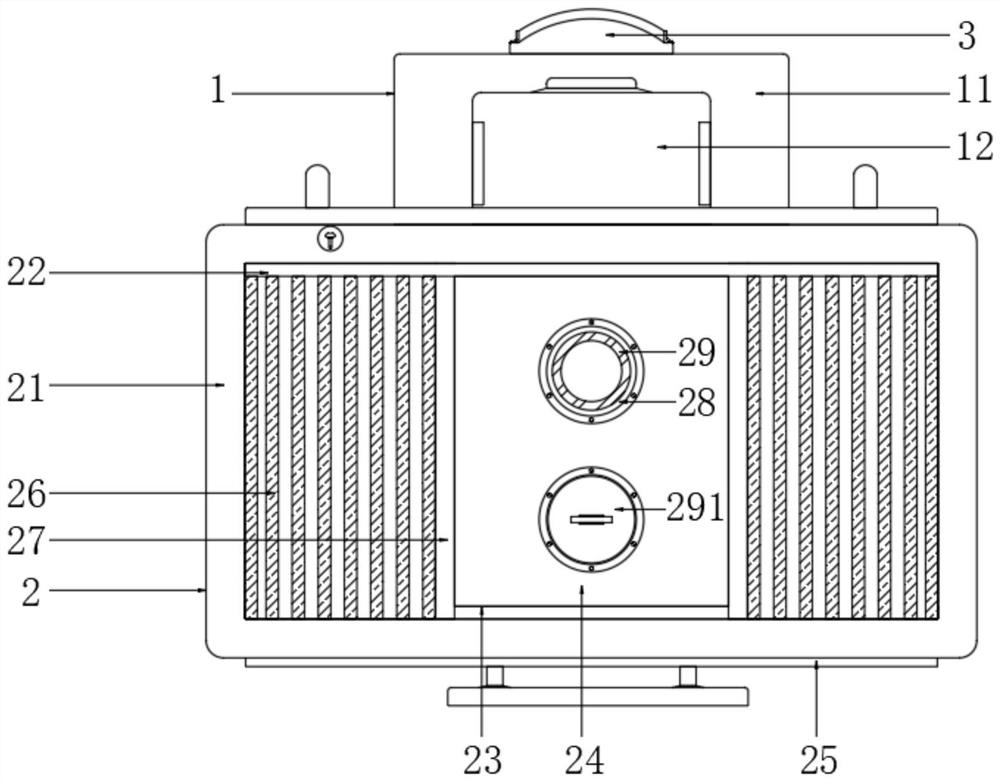

Safety band type luggage and weaving method thereof

InactiveCN101390678AHigh tensile strengthHigh strengthHandbagsLuggageEngineeringUltimate tensile strength

The invention relates to a safety belt-type bag and a weaving method thereof. The external bag body is mainly weaved from at least one longitude belt and one latitude belt. The whole fixed longitude belts present a ring structure, with the two ends respectively arranged at the edges of the external upper part of the internal bag body; and the latitude belts are respectively arranged at the inside parts or the surfaces of the longitude belts. The weaving method includes the following steps: cutting a plurality of longitude belts and latitude belts out into suitable length, arranging the longitude belts in order, and arranging the latitude belts on the bottoms and the surfaces of the longitude belts in order from top to bottom through interpenetration or superposition so as to form a desirable shape. The weaving method is simple and practical, not only avoids the problem that the splicing joints and the stitched parts are easy to break and craze, but also improves the overall tensile-strength of the bag, thus improving the overall fastness and the durability of the bag.

Owner:GUOXIN MINGTIAN BEIJING TECH

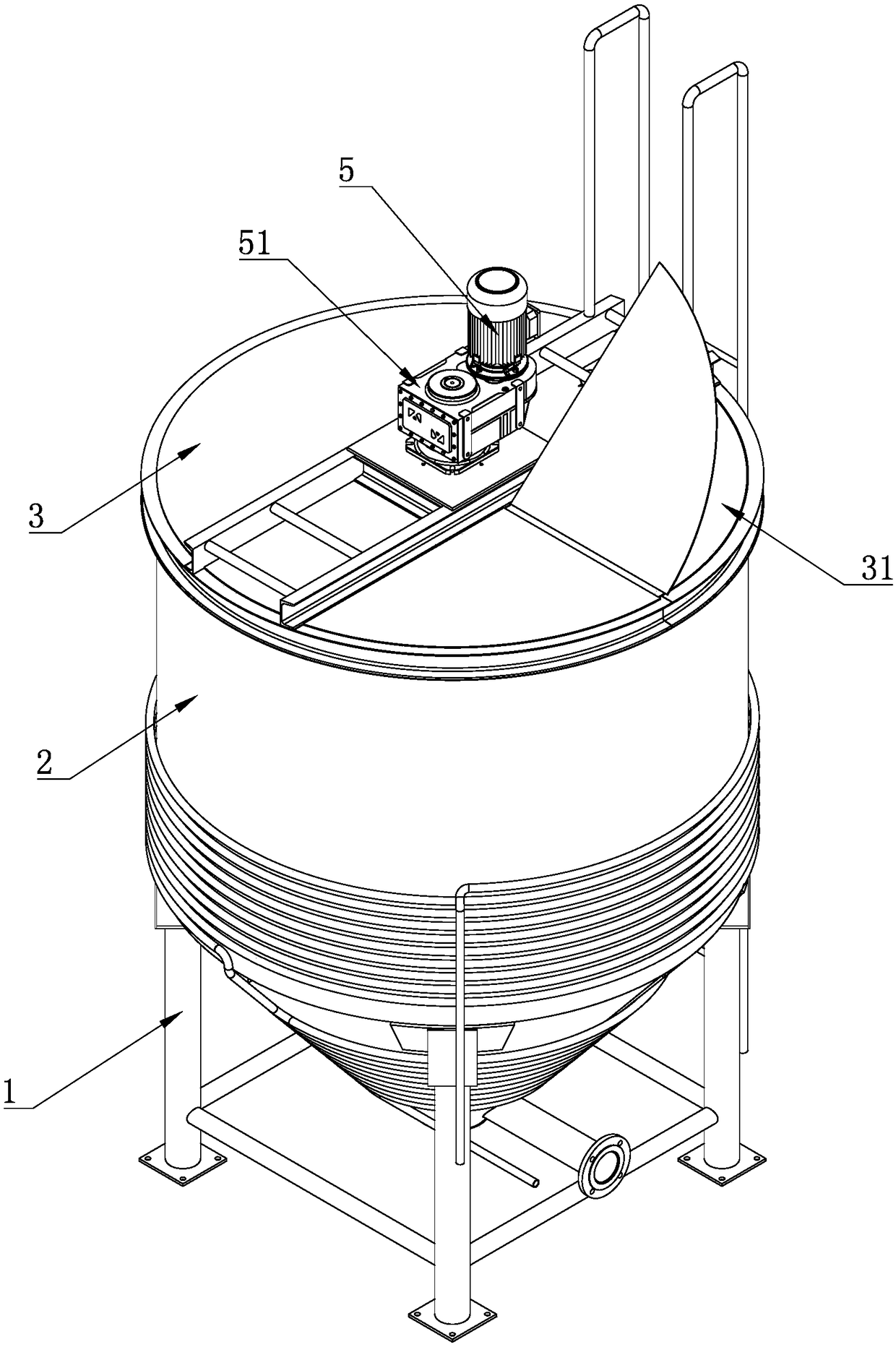

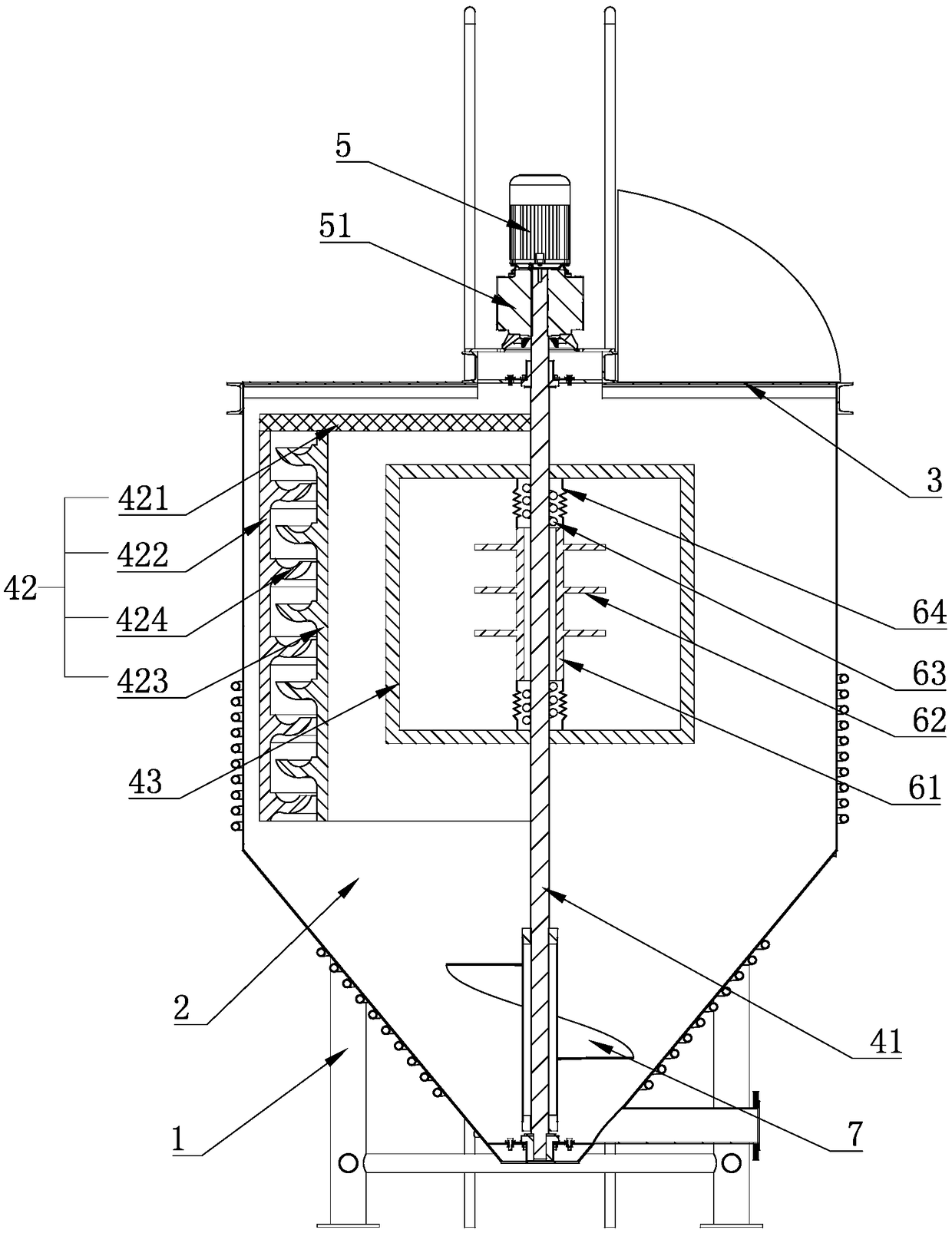

Mortar stirring machine

PendingCN108890891AEven mortarGood mixing effectCement mixing apparatusSolid waste managementEngineering

The invention discloses a mortar stirring machine. The machine comprises a supporting frame, a barrel body, a barrel cover, a stirring assembly and a driving device used for driving the stirring assembly, the barrel body is located on the supporting frame, the barrel cover is connected with the barrel body and is provided with a feeding port, the stirring assembly is connected with the barrel cover and extends into the barrel body, the stirring assembly comprises a rotary shaft which is connected with the driving device, a grounding member which is connected with the rotary shaft and a stirring rod which is located on the inner side of the grounding member, the stirring rod is U-shaped, the two ends of the stirring rod are connected with the rotary shaft, the grounding member is arranged close to the inner wall of the barrel body, the grounding member comprises a sector connecting plate, a first arc-shaped plate and a second arc-shaped plate which are connected below the connecting plate, and stirring blades are arranged on the opposite side walls of the first and second arc-shaped plates. By the combination of the grounding member and the stirring rod, the failure of stirring mortars close to the inner wall of the barrel body is prevented, mortars everywhere in the barrel body can be uniformly stirred and grounded by the stirring assembly, and the obtained mortars are more uniform.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

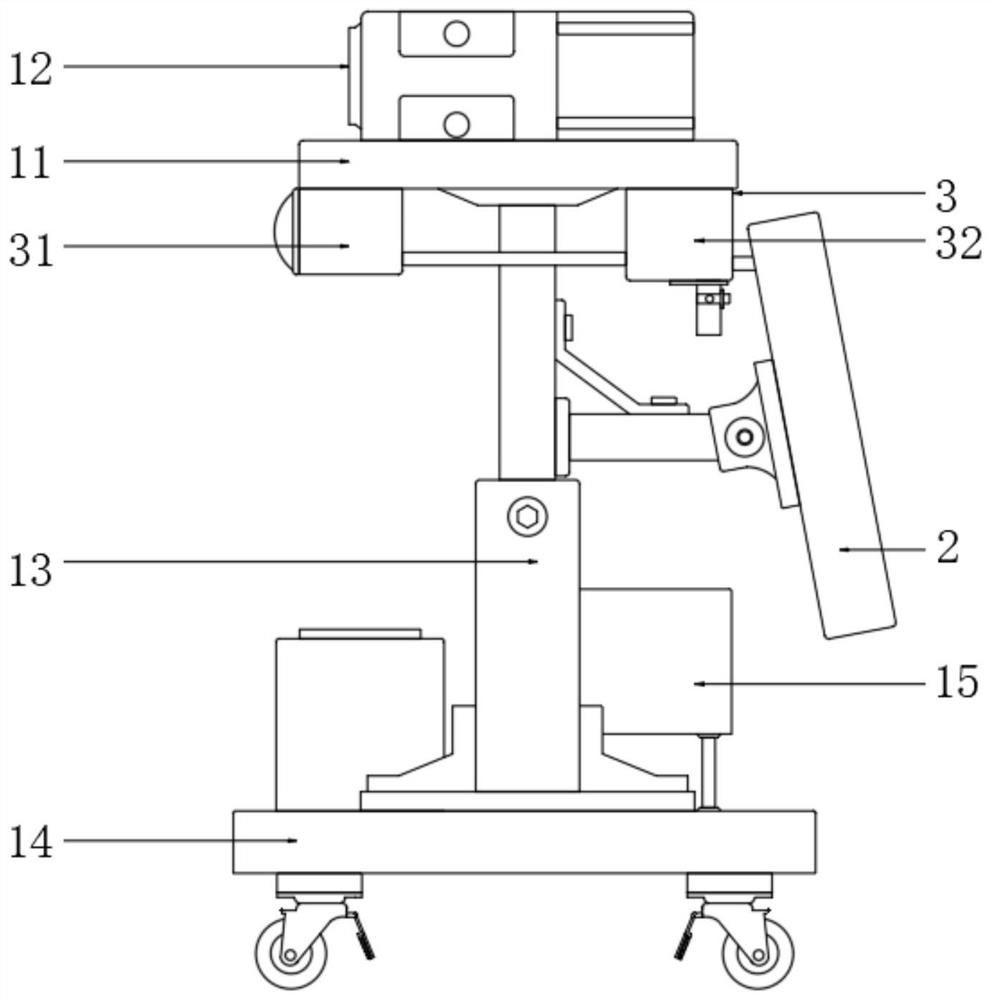

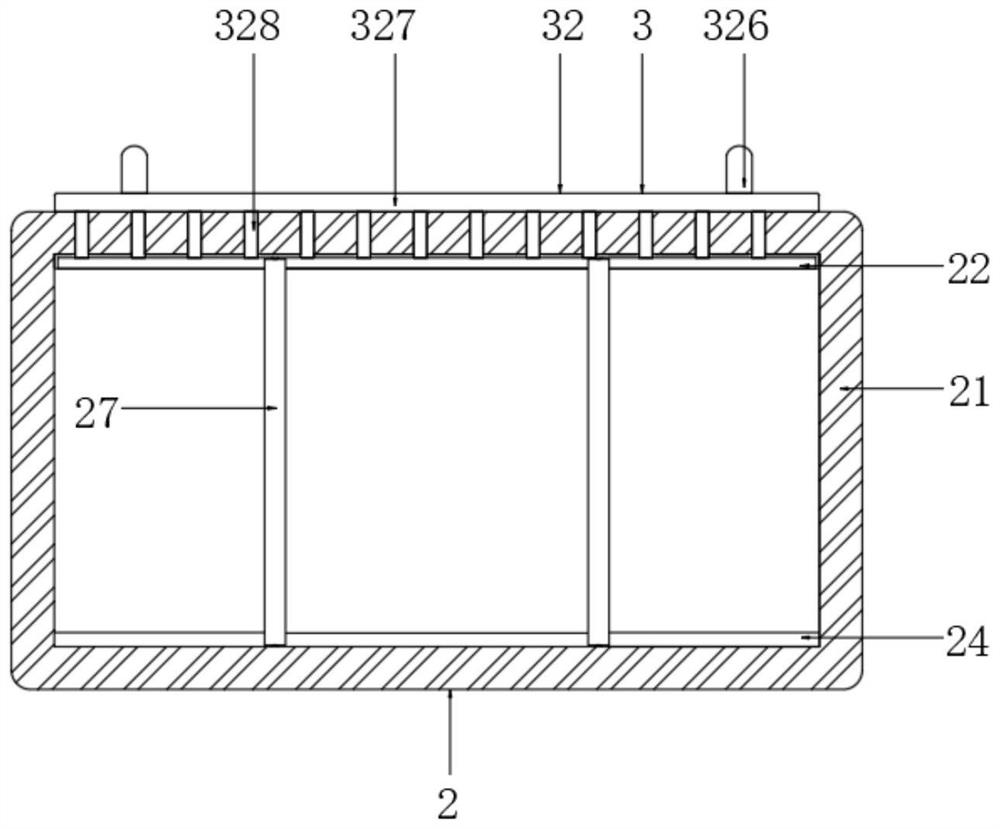

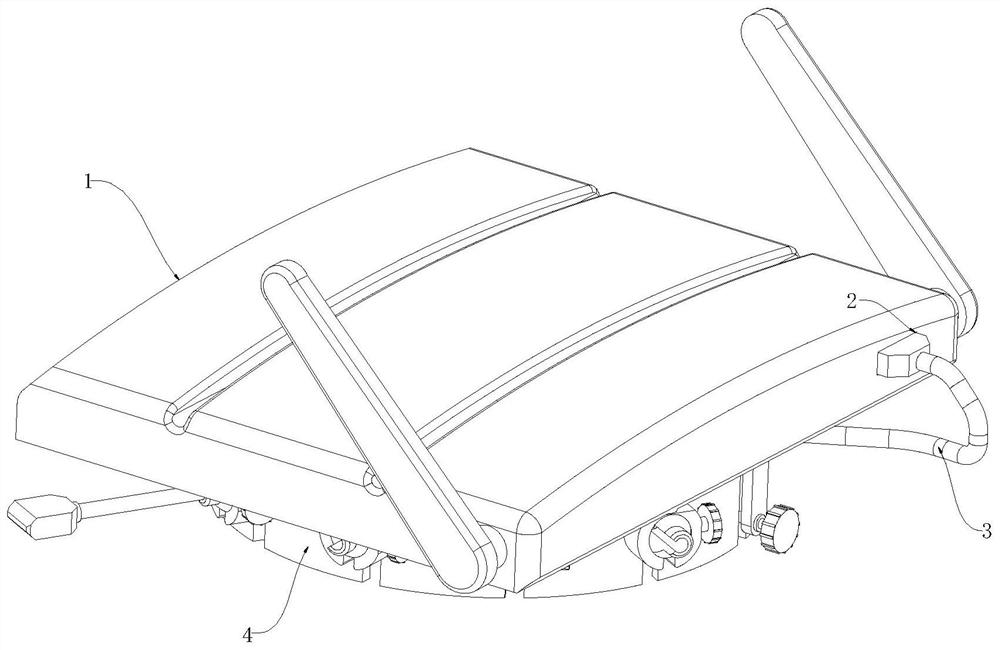

Drawing measurement device suitable for highway design in windy and dusty area

ActiveCN112706543AQuality improvementEasy reference drawingMeasurement apparatus componentsBathroom accessoriesMeasurement deviceStructural engineering

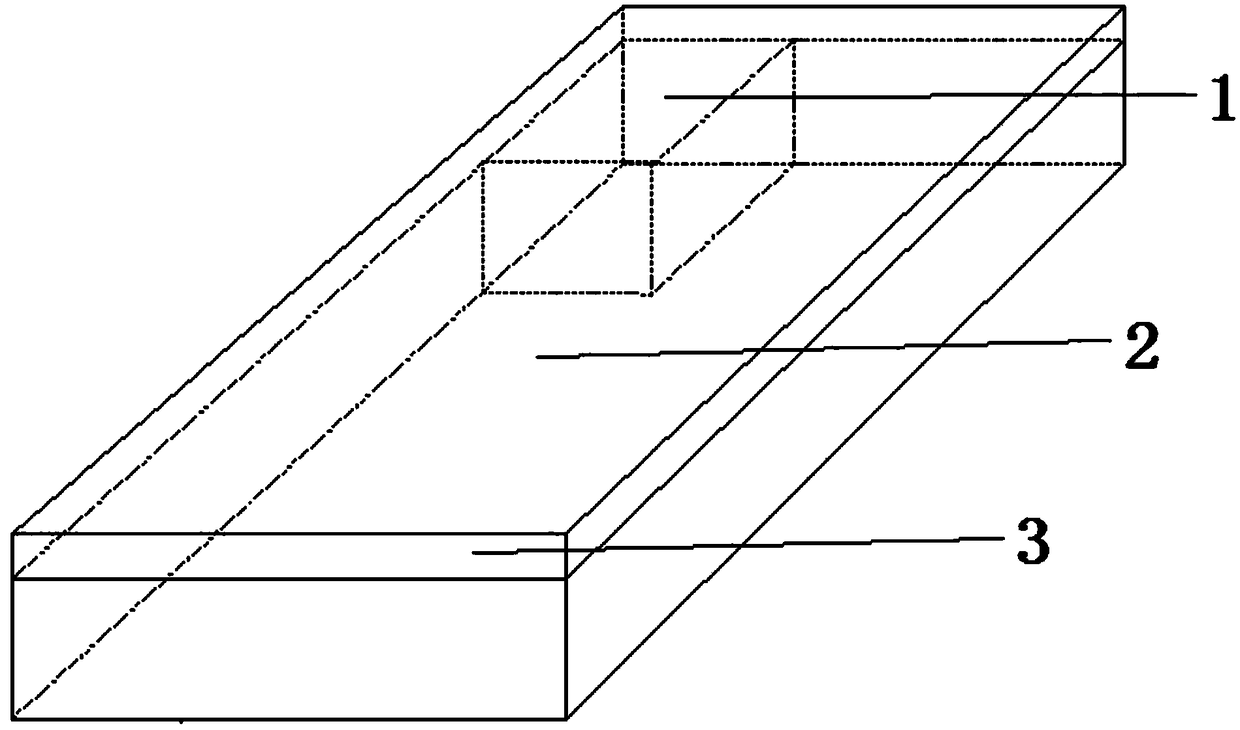

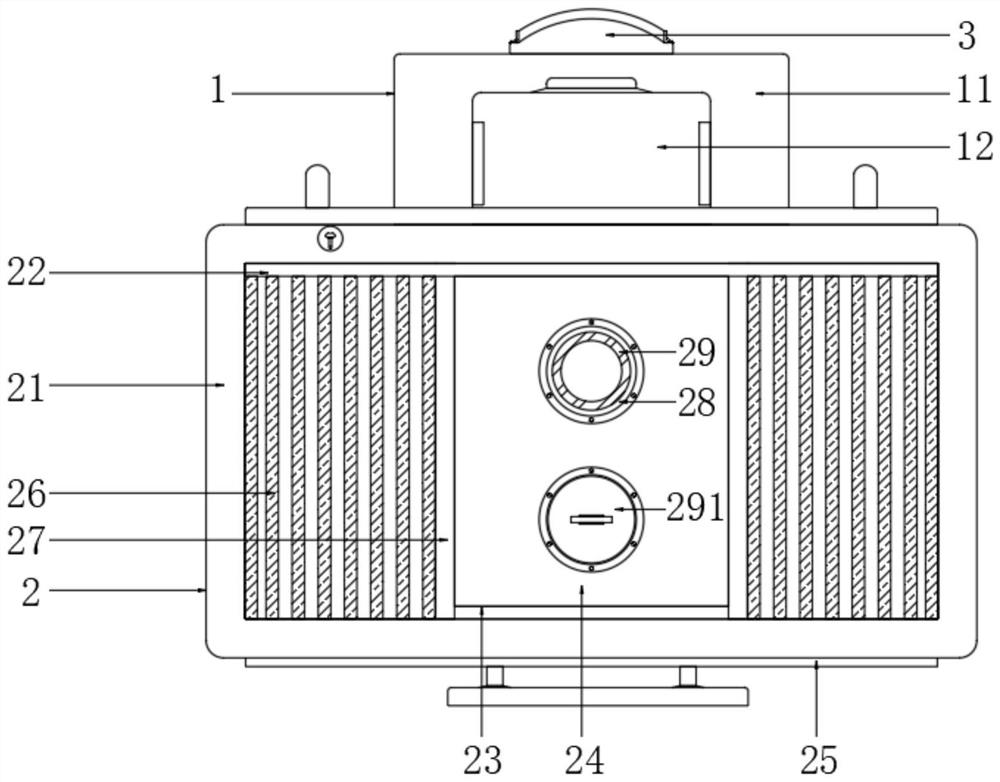

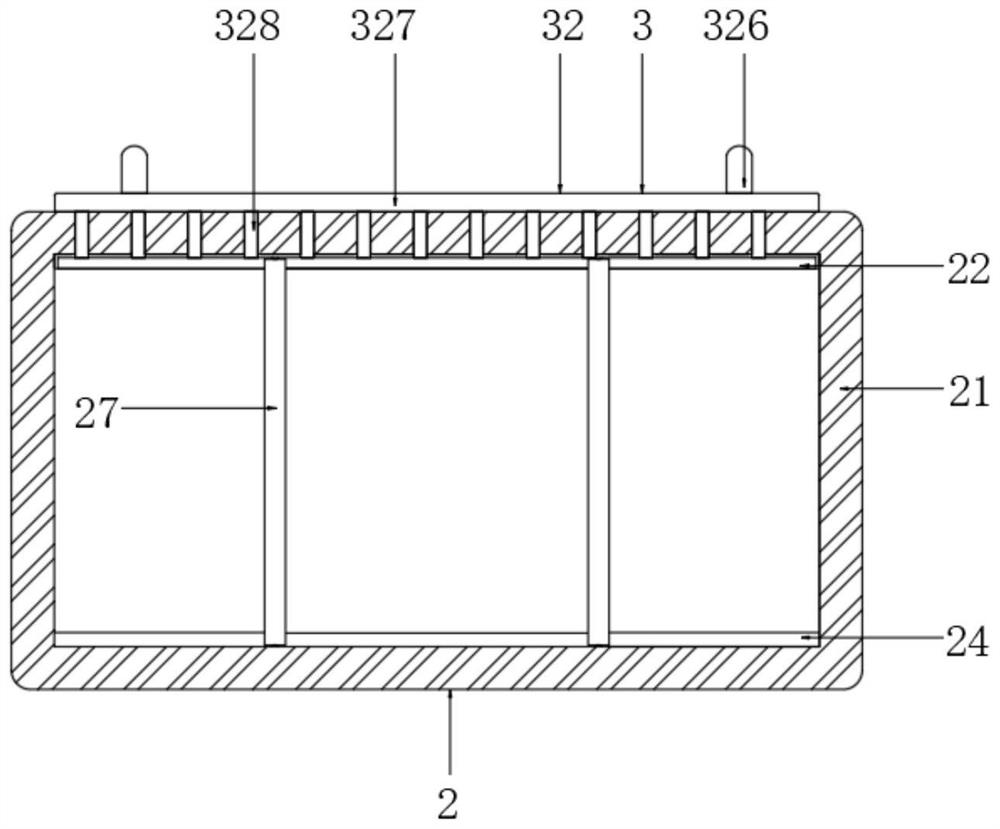

The invention discloses a drawing measurement device suitable for highway design in windy and dusty area in the technical field of highway design. The drawing measurement device comprises a supporting component, a drawing component and an automatic cleaning component, wherein the supporting component comprises a supporting plate, and a measurement instrument body is fixed to the top of the supporting plate; he drawing component comprises a sand prevention shell hinged to a connecting frame, two sets of connecting guide plates are slidably connected to the middle in a first U-shaped base, a transparent plate is fixedly arranged between the two sets of connecting guide plates, and the top end of organ type dust-proof folded cloth is located in the first U-shaped base; and the automatic cleaning component is arranged at the left side of the bottom of the supporting plate. According to the drawing measurement device, the drawing component is arranged, a handheld drawing pen penetrates through a sleeve to draw paper located in the sand prevention shell, and due to the arrangement of the organ type dust-proof folded cloth, a user can conveniently hold the drawing pen with the hand to enable the transparent plate to move leftwards or rightwards for drawing, and the paper in the sand prevention shell is not influenced by outside wind and sand, so that the paper is prevented from being stained or damaged, and the drawing quality of the user is improved.

Owner:广东瑾诚城市规划勘测设计有限公司

Household high-altitude internal and external window cleaning device

The invention relates to a household high-altitude internal and external window cleaning device. The device is suitable for cleaning the glass of high-altitude internal and external windows at home. The device comprises a wiping head, a guide rail and a base. A sliding block is arranged in a sliding groove of the guide rail. The wiping head is arranged on the left side of the sliding block. A rubber scraping strip is arranged on the front side of the wiping head. A hole is formed in the right side of the main body of the wiping head. A pull rope is arranged. A reel is arranged at the top end of the guide rail and is connected with the wiping head. Compared with the prior art, the direction of the wiping head is controlled through the guide rail instead of manpower. The wiping head can automatically rebound through a coil spring, so that the device is more labor-saving. The device is simple in structure and low in cost. The device is convenient and labor-saving in cleaning operation, and the participation degree of people is low.

Owner:SHANGHAI UNIV OF ENG SCI

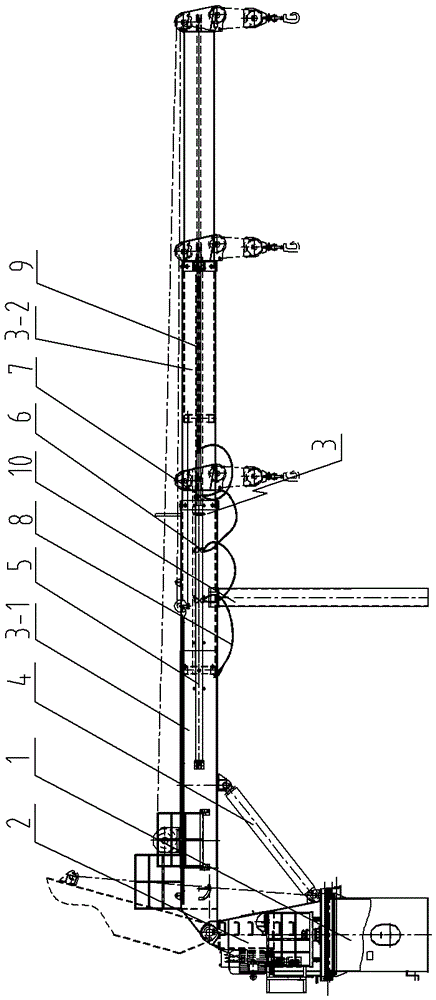

Angle-adjustable and transverse-adjustable movable trestle

ActiveCN111663430ADoes not affect scalingEasy to usePortable bridgeUnderground chambersClassical mechanicsStructural engineering

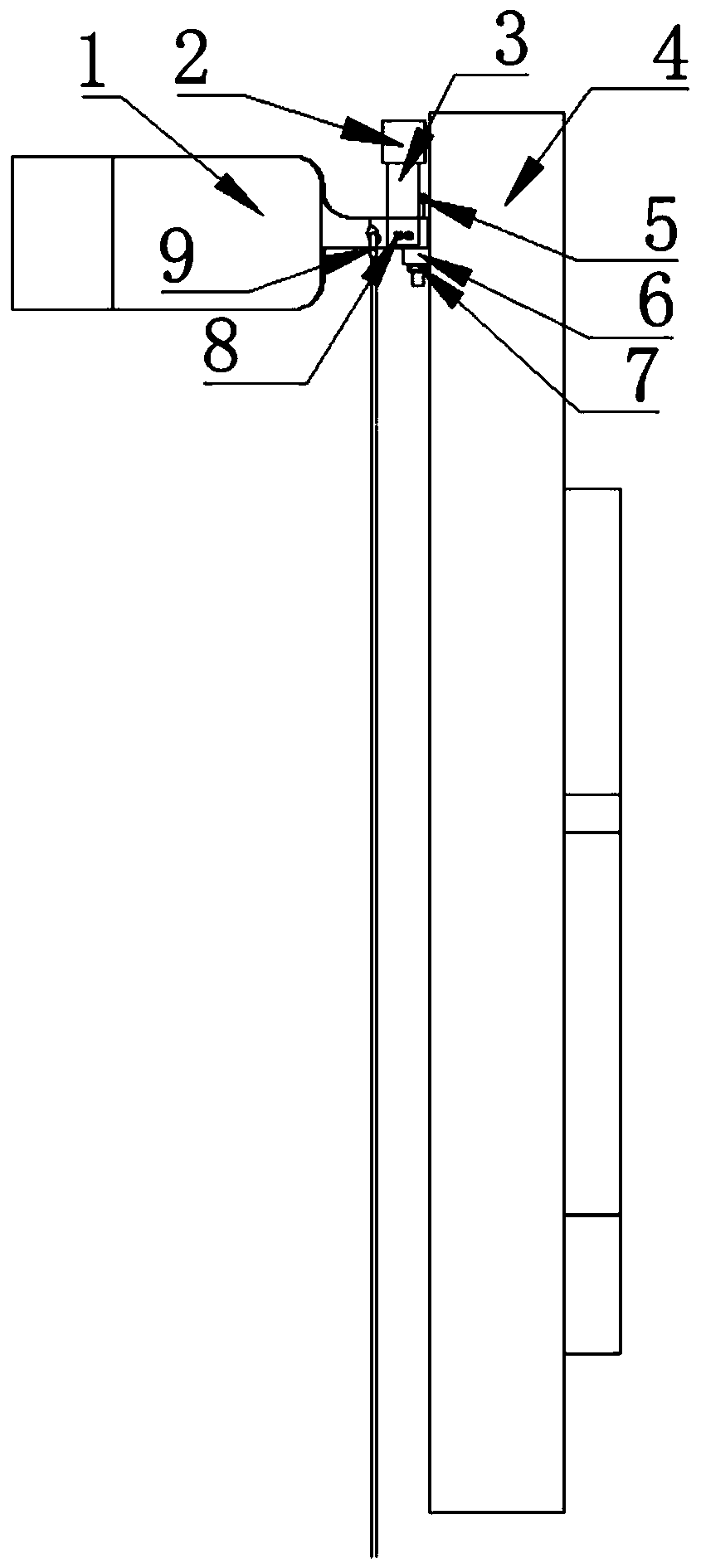

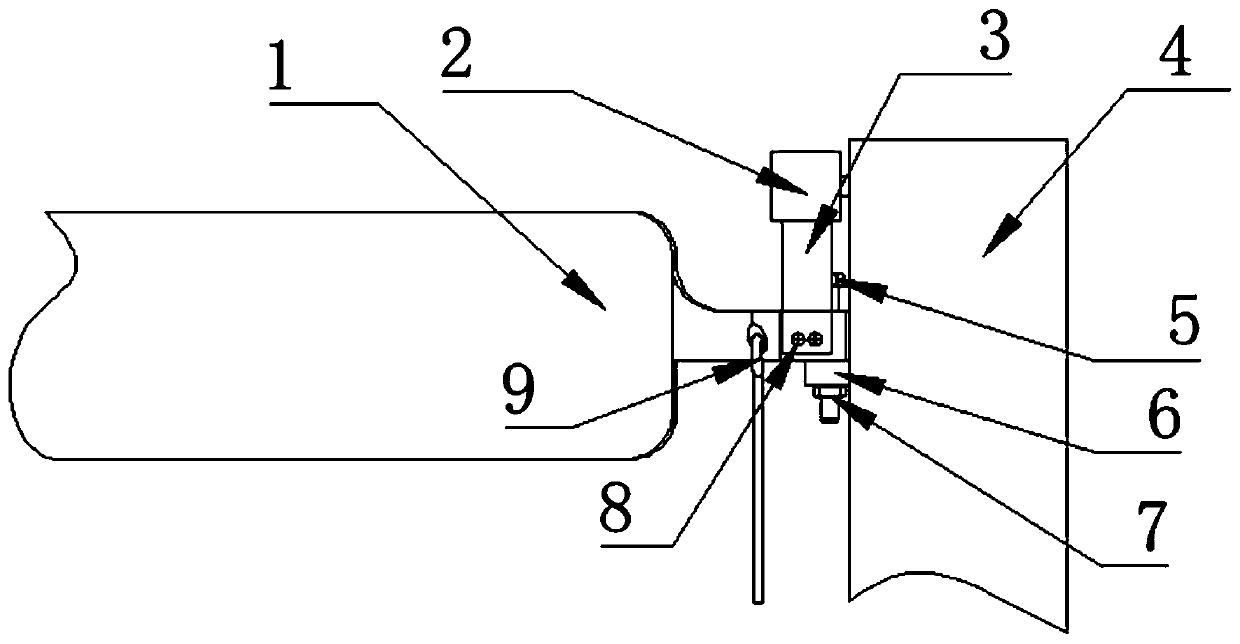

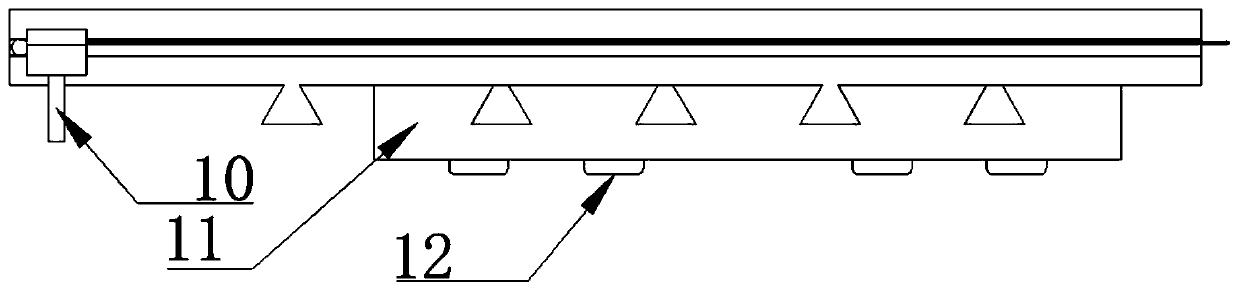

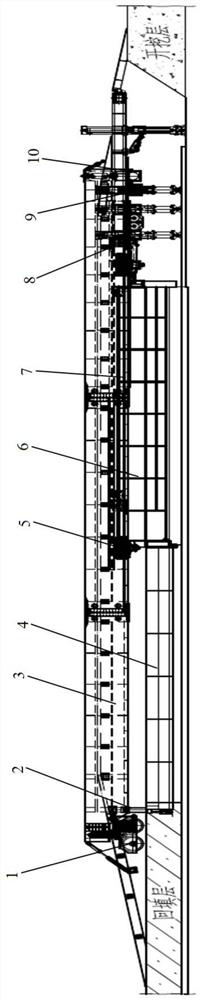

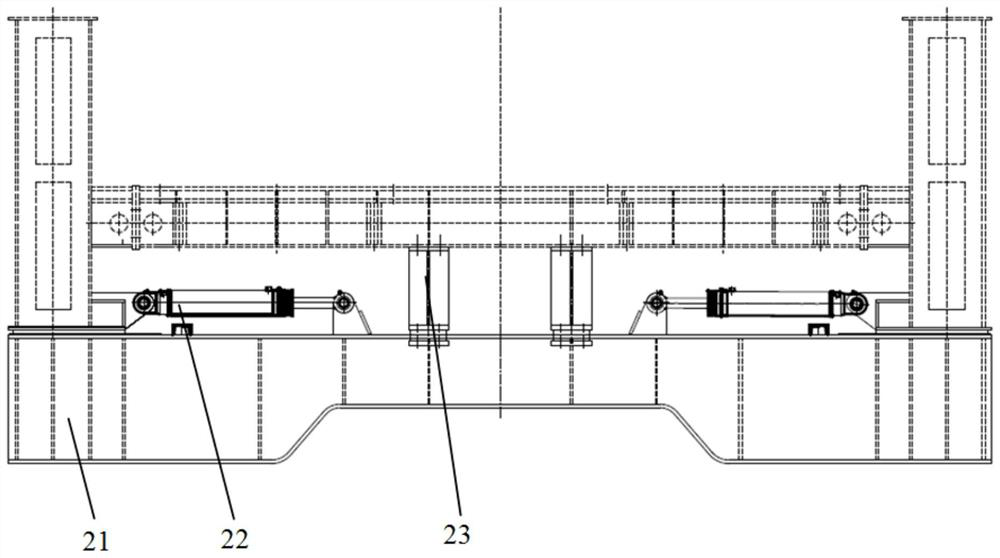

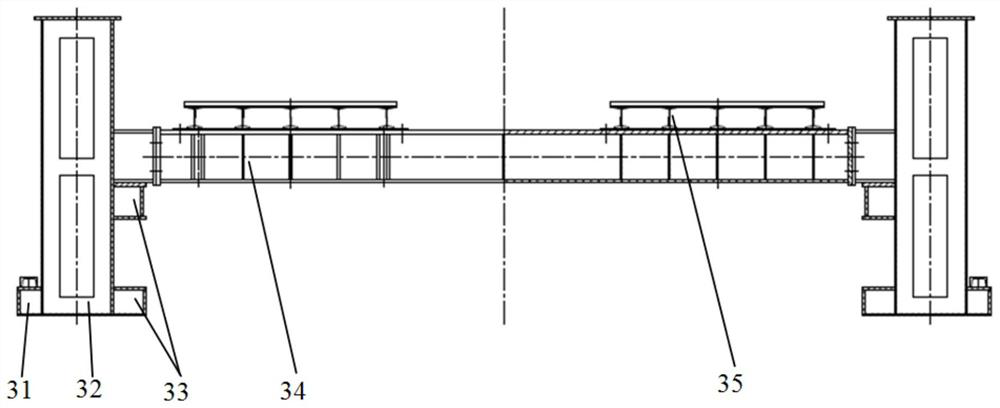

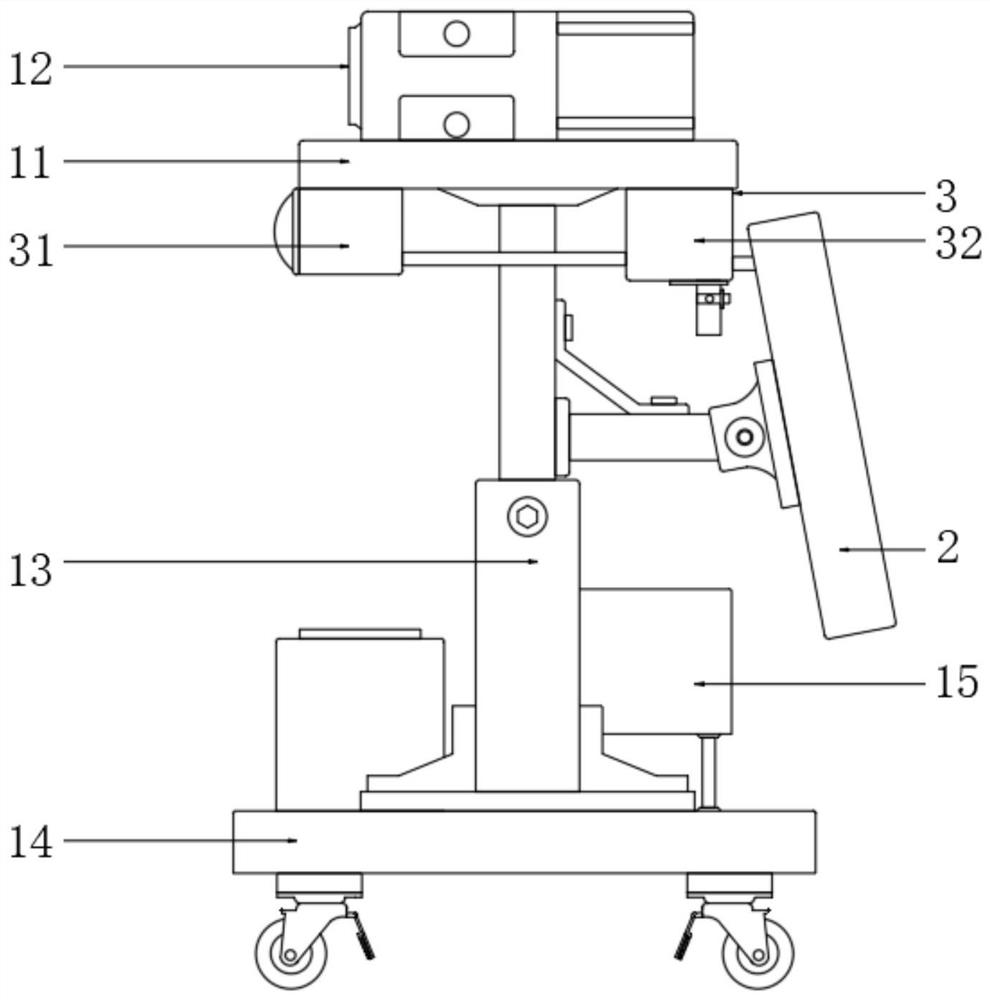

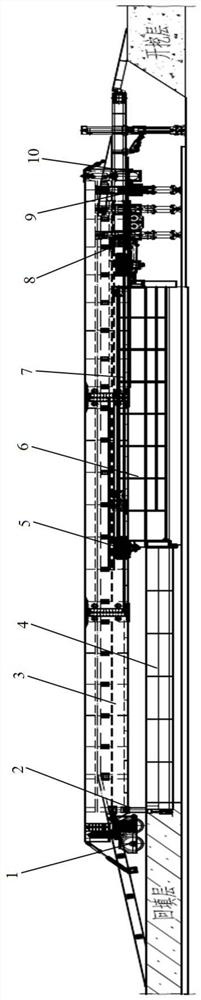

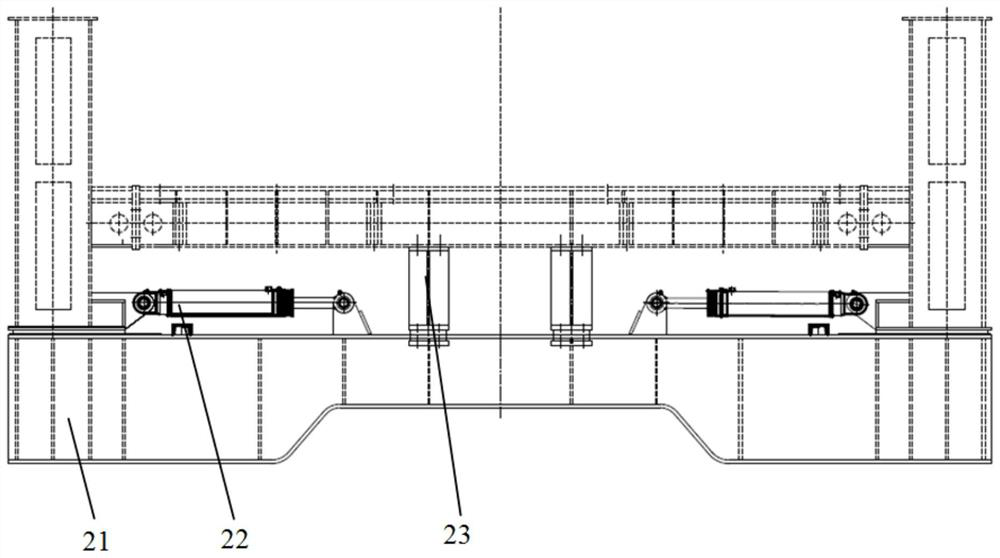

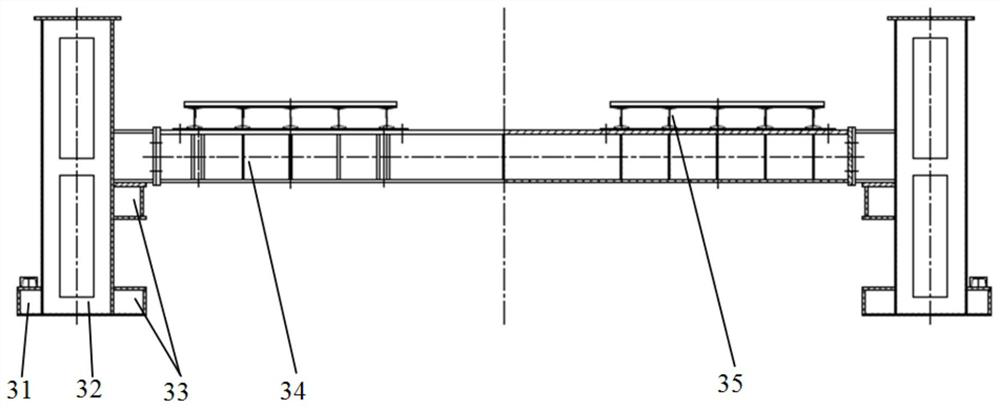

The invention provides an angle-adjustable and transverse-adjustable movable trestle. The angle-adjustable and transverse-adjustable movable trestle at least comprises a walking wheel set, a rear supporting leg, a main beam assembly, a central ditch formwork assembly, a longitudinal moving trolley, an inverted arch formwork assembly, a guide beam assembly, a middle supporting leg, a front supporting leg, a tug mechanism and an electro-hydraulic system; the rear supporting leg and the front supporting leg are fixedly installed below the tail end and the head end of the main beam respectively; the middle supporting leg is movably installed below the main beam; a main beam sliding shoe mechanism is installed between the main beam and the middle supporting leg; an auxiliary supporting leg is installed below the head end of a guide beam; and a roller mechanism is arranged at the tail end of the guide beam. According to the movable trestle, the angle of the guide beam can be adjusted according to the specific situation of an inverted arch excavation area in front of a tunnel, use is convenient, and the construction efficiency can be further improved; the extension and retraction of the guide beam are not influenced while the angle is adjusted; and the front supporting leg is used in cooperation with the rear supporting leg in the movable trestle, the overall transverse position of the main beam in the movable trestle can be adjusted, use is convenient, and the construction efficiency can be further improved.

Owner:HAN JIANG HEAVY IND CO LTD 11TH BUREAU GRP CRCC +1

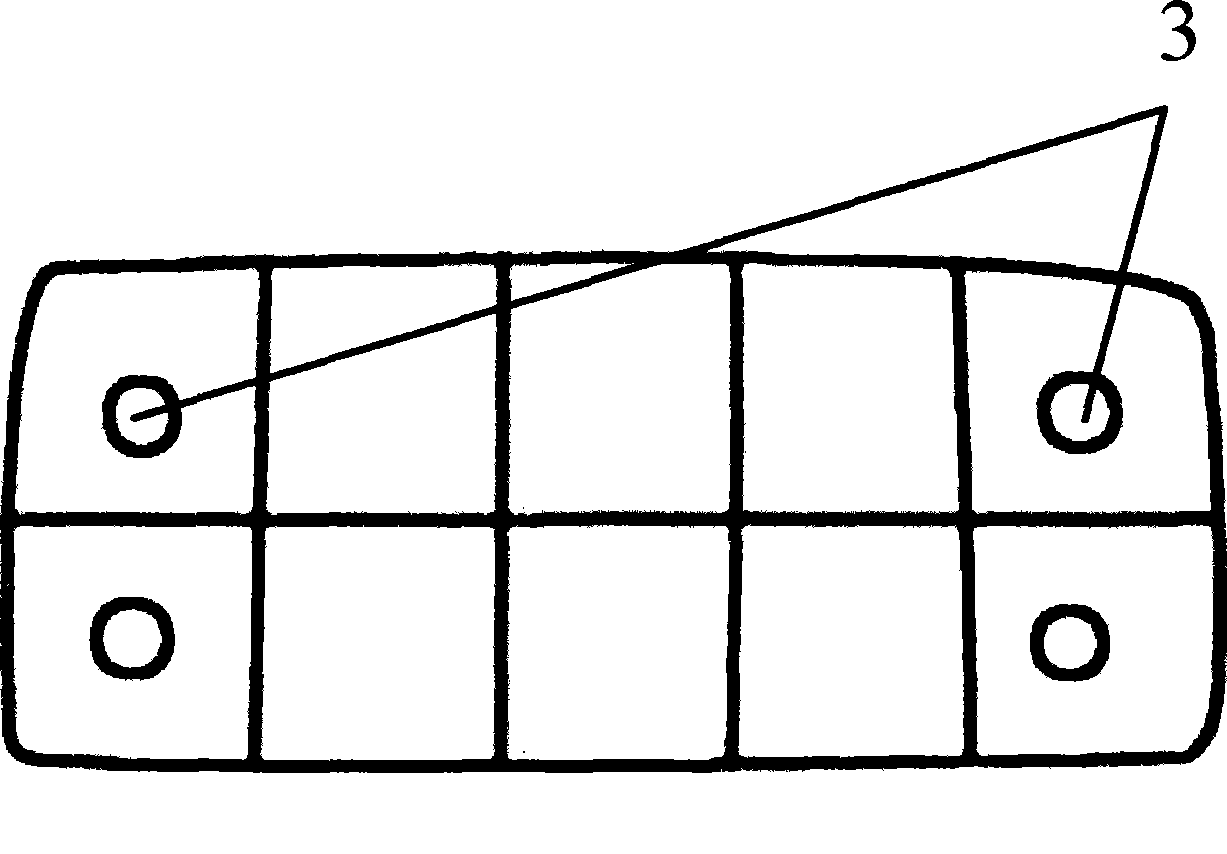

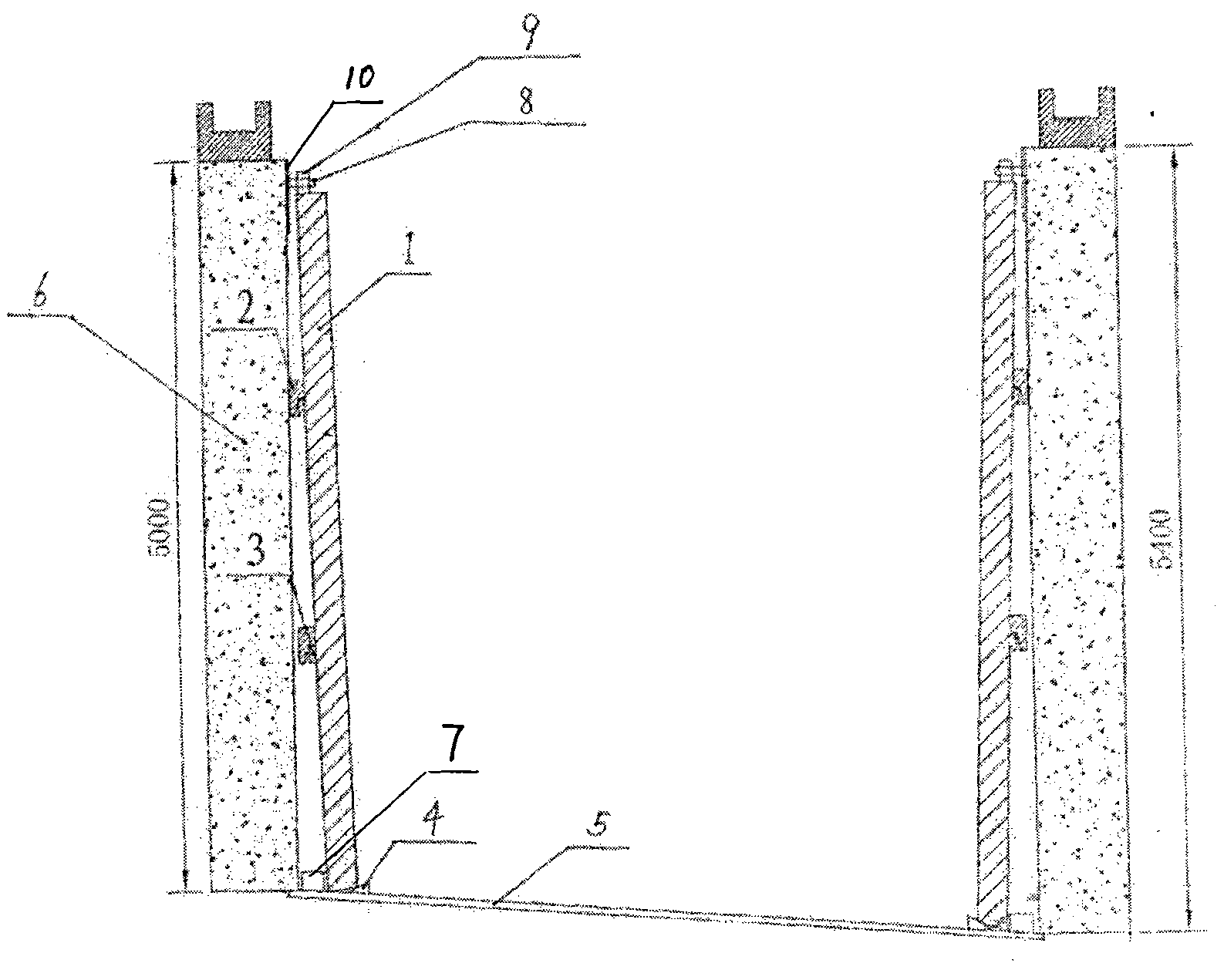

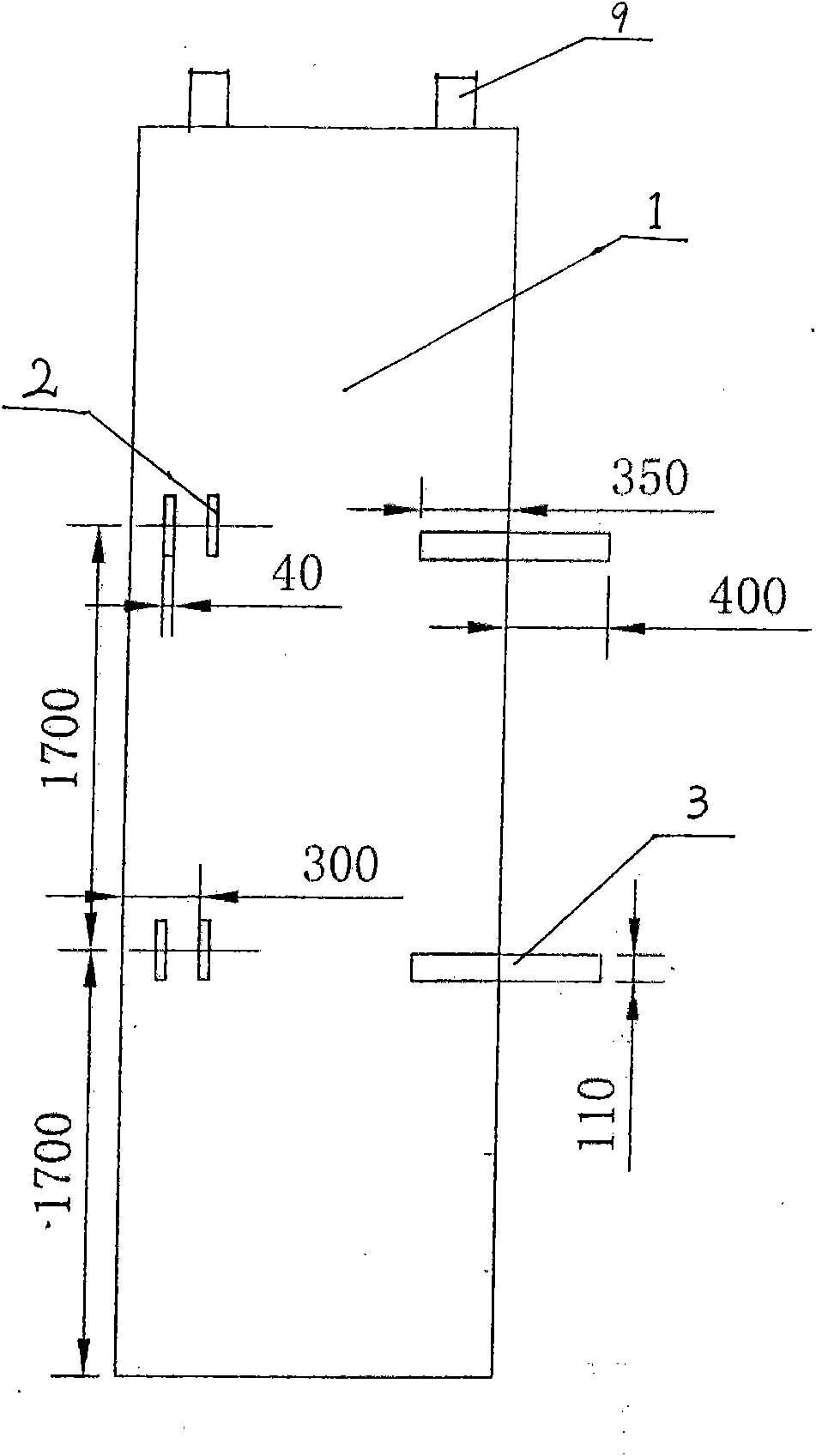

Method for installing and fixing large lining plate

InactiveCN102061344AStable structureSimple structureRecycling and recovery technologiesInsulation layerSlag

The invention relates to a method for installing and fixing a large lining plate for a metallurgical steel slag treatment hot stuffy tank. The method is characterized in that: plate blanks serving as lining plates lean against an embedded iron plate on the wall of the hot stuffy tank in certain angles and play a role in structure stabilization by using dead weight, and certain gaps are reserved on the plate blanks and the cement tank wall to form a heat insulation layer so as to play a role in protecting the tank wall. At the lower ends of the plate blanks, stop iron and wedge iron are welded close to two sides of the plate blanks by using tank bottom steel plates to form inner wedge and outer stop; and the degree of freedom of the plate blanks is controlled, and the extension of the plate blanks is not affected, so that the stress of the plate blanks is fully released and the influence of expansion with heat and contraction with cold on the lining plate is eliminated. The plate blanks are connected by hooks and iron bars to form a whole. A door shape is welded on an embedded steel plate on the upper part so as to reinforce the upper parts of the plate blanks. The method stabilizes the structure of the lining plate, enables the lining plate to resist impact, reduces the damage rate of the lining plate, prolongs the service life of the lining plate, is convenient for construction, and can save a large amount of fund.

Owner:TIANJIN TIANTIE METALLURGICAL GRP

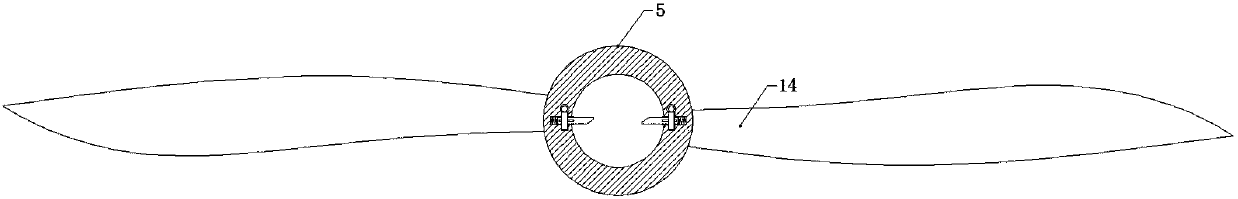

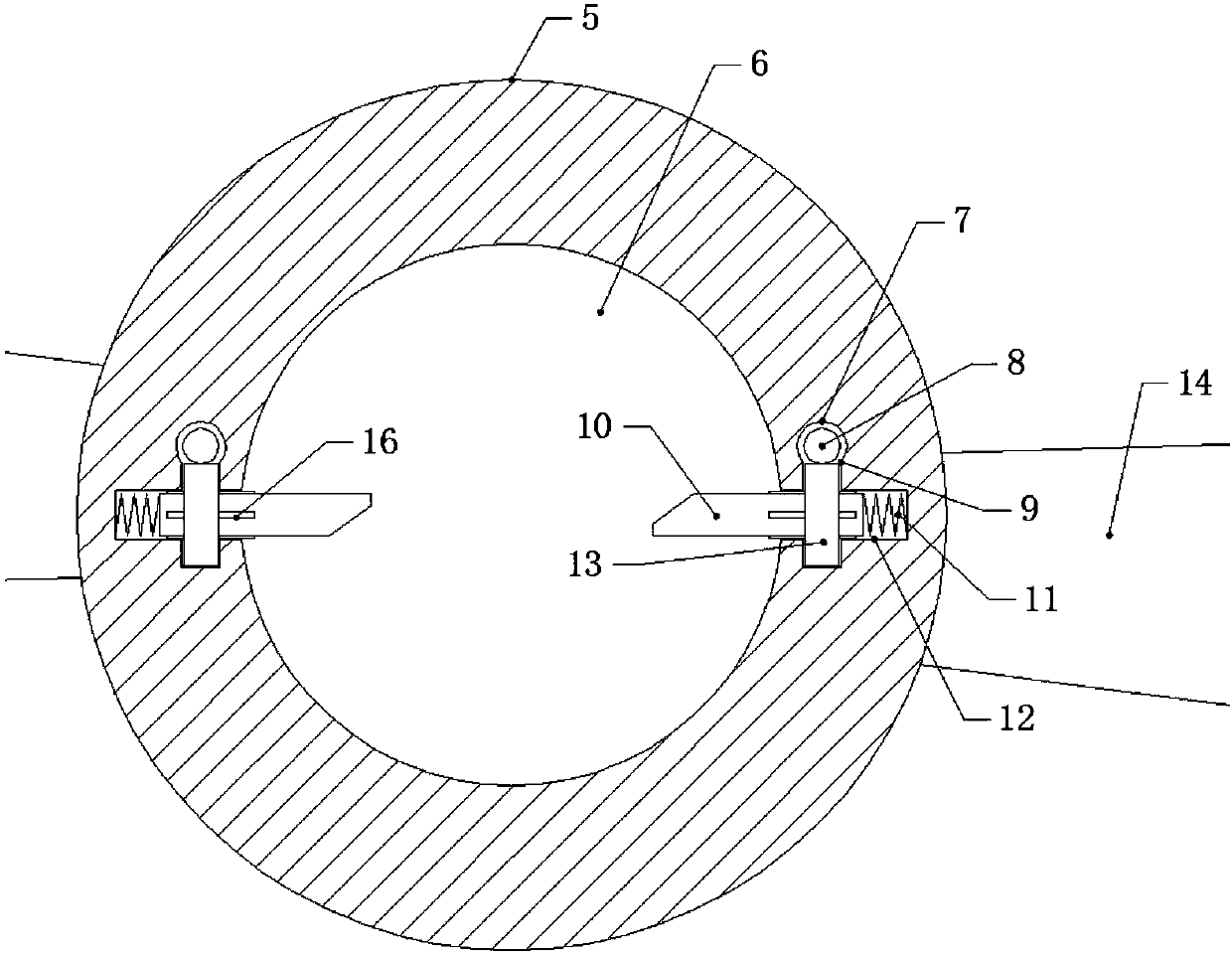

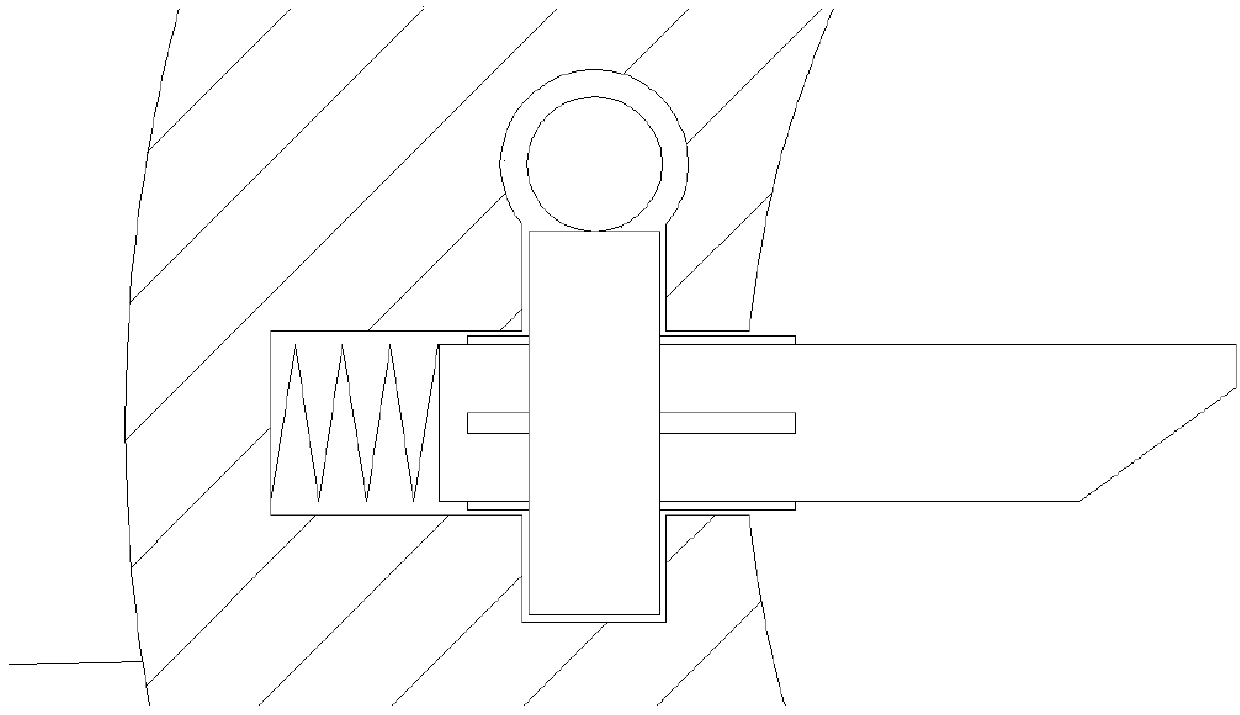

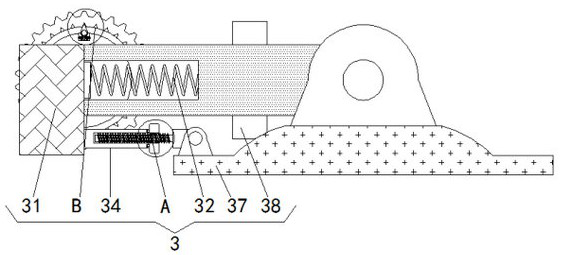

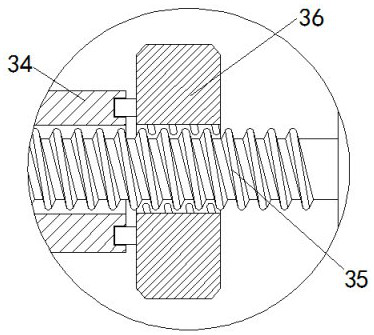

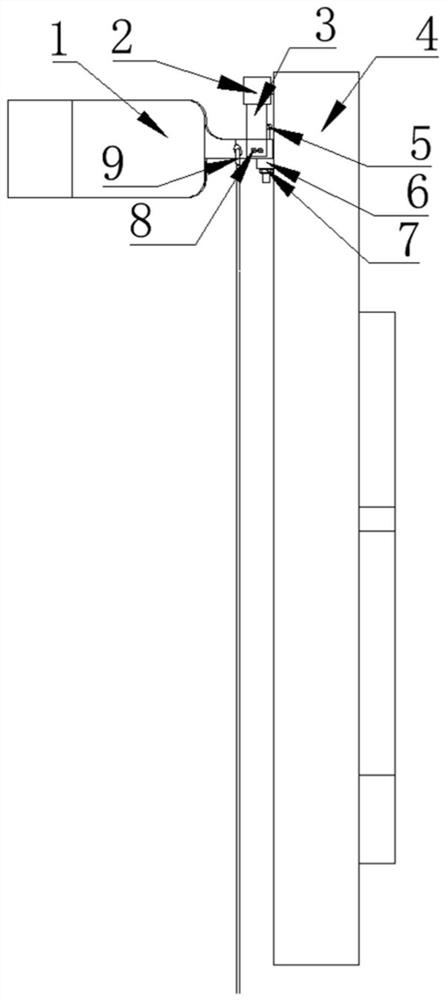

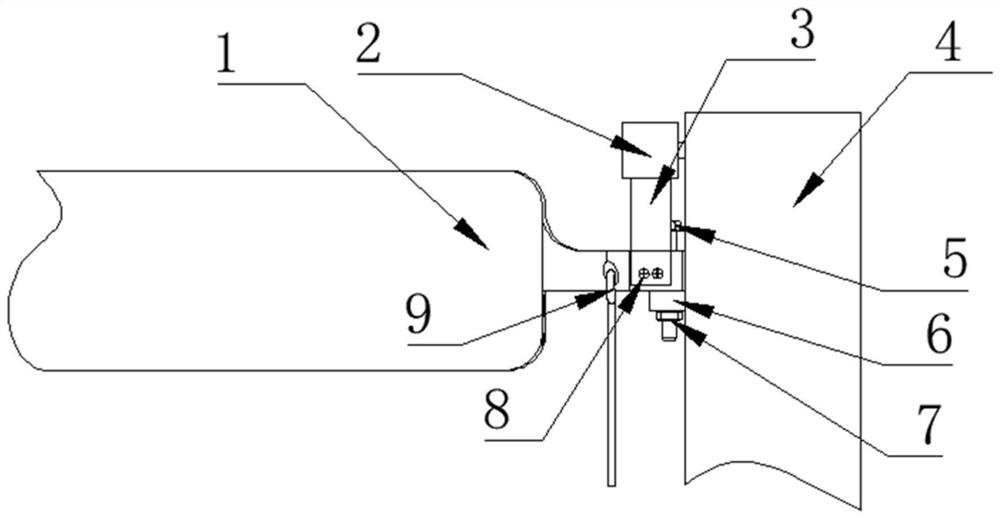

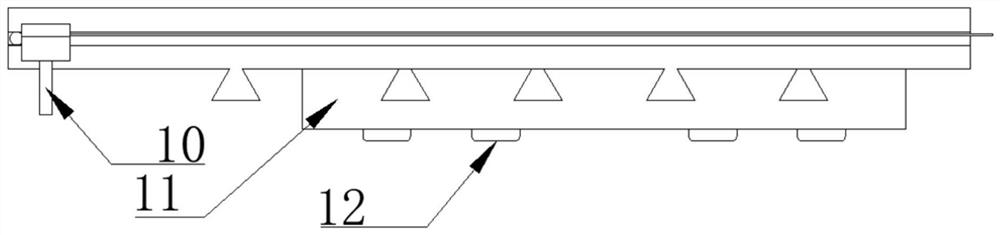

Quick-dismountable unmanned aerial vehicle propeller fixing mechanism

InactiveCN107719672ARealize self-disassemblySimple structurePropellersAircraft indicatorsPropellerEngineering

The invention discloses a quick-detachable UAV propeller fixing mechanism, relates to the technical field of propeller UAVs, and solves the problem of inconvenient disassembly and assembly of UAV propellers in the prior art. The invention includes a propeller and a rotating shaft, and the propeller includes The shaft sleeve is provided with a fixing hole, and a fixed block with a spring at the top is arranged in the fixed hole, and a worm wheel is set on the fixed block, and a locking hole with a worm is also arranged on the shaft sleeve. Cooperate, there is a chute on the rotating shaft, and a limit hole is set at the end of the chute. The fixed block is fixed by sliding into the limit hole in the chute, so as to fix the propeller. When disassembling, the worm wheel and the fixed block are driven to rotate by rotating the worm , so that the inclined plane of the fixed block is rotated to face the chute, and the fixed block shrinks into the fixed hole during the extrusion of the inclined plane and the limiting hole by rotating the propeller, so that the propeller is separated from the rotating shaft.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

Expansion joint device with sinkage preventing function of non-motor vehicle

PendingCN110144816ADoes not affect scalingThe installation structure is stableBridge structural detailsEngineeringExpansion joint

The invention relates to an expansion joint device with a sinkage preventing function of a non-motor vehicle. A cover plate for covering a first comb tooth gap and a second comb tooth gap is arrangedon a first comb plate and a second comb plate, the middle part of the cover plate covers the staggered distributed area of the first comb tooth gap and the second comb tooth gap, one side of the coverplate covers the first comb tooth plate and is limited on the first comb tooth plate through a first limiting assembly, the other side of the cover plate covers the second comb tooth plate and is limited on the second comb tooth plate through a second limiting assembly, and the cover plate and the first comb tooth plate or / and the cover plate and the second comb tooth plate can move relatively. The expansion joint device has the advantages that the cover plate covers the first and second comb tooth plates to prevent a vehicle wheel from being jammed or sinking into comb teeth; moreover, as the cover plate and the first comb tooth plate or / and the cover plate and the second comb tooth plate can move relatively, the telescopic function of the expansion joint device is not affected after thecover plate is mounted. In addition, the cover plate is quite convenient to mount and detach.

Owner:路宝高分子材料科技有限公司

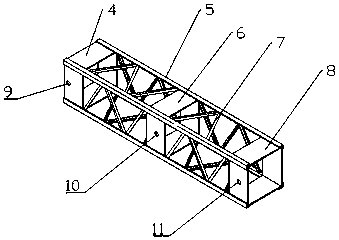

Plate enhanced telescopic truss arm structure

InactiveCN108190764AImprove stabilityImprove reliabilityCranesStructural engineeringUltimate tensile strength

The invention provides a plate enhanced telescopic truss arm structure, and relates to the field of engineering machinery. The plate enhanced telescopic truss arm structure is characterized in that plates are welded in a truss structure, so that a crane telescopic arm structure for enhancing the truss structure is formed. The plate enhanced telescopic truss arm structure can be utilized in severalsections of telescopic arms of the topmost end of an all-terrain crane and conventional combined sub arms of the all-terrain crane and a crawler crane, the plates are welded in the truss structure, the advantage that the effect of wind load on the truss structure is small is reserved, strength of the root part of the sub arm of the crane can be strengthened, the arm rising condition of the craneis improved, and the problem that the truss telescopic arm needs to be disassembled and assembled at any time and cannot quickly extend and retract is solved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

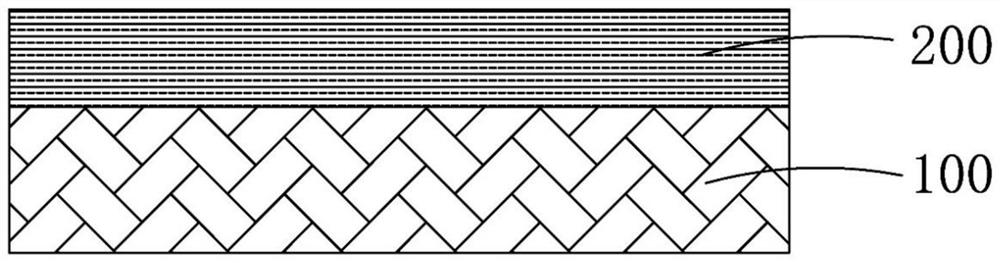

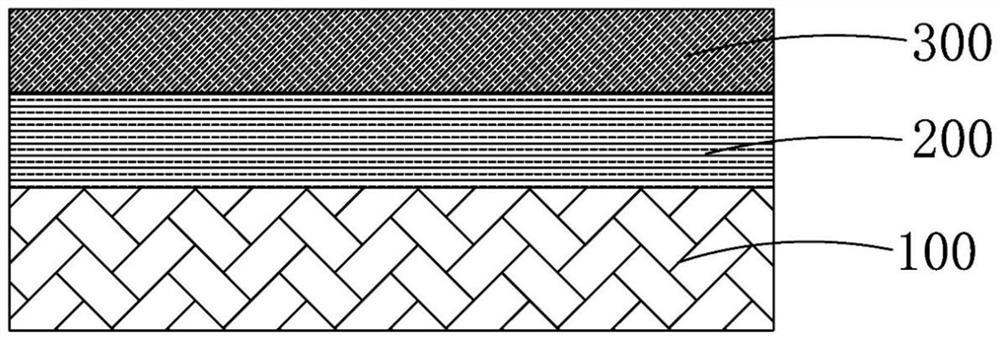

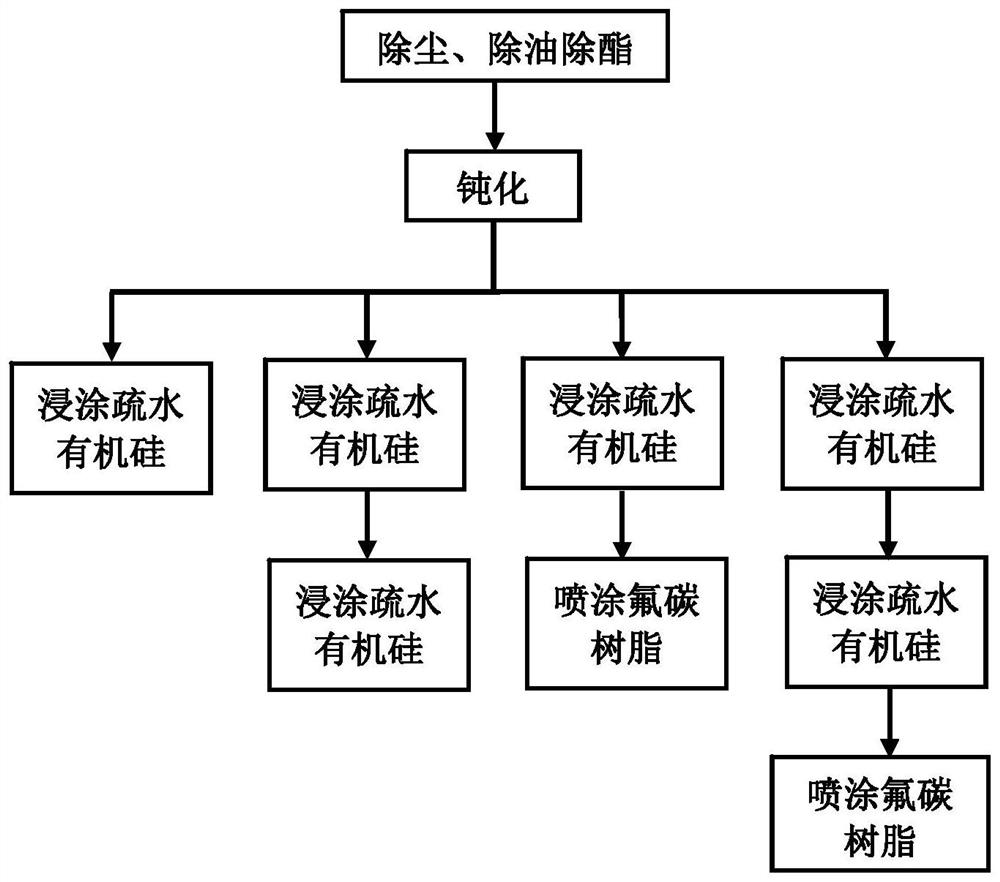

Anti-corrosion coating, heat exchanger applying anti-corrosion coating and coating method

PendingCN114316796AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsPhysical chemistryBackbone chain

According to the anti-corrosion coating, the heat exchanger applying the anti-corrosion coating and the coating method, the surface of the heat exchanger is coated with the nanometer hydrophobic coating, organic-inorganic hybrid organic silicon serves as a main component, the main chain of the organic-inorganic hybrid organic silicon is an inorganic Si-O-Si chain segment, the anti-corrosion performance is better than that of organic silicon, Si-OH and the surface of a metal base material can easily form a Si-O-Me bond, and therefore the anti-corrosion performance of the heat exchanger is improved. Therefore, the adhesive force between the coating and the metal base material can be enhanced; the branched chain is a hydrophobic organic chain segment, so that the hydrophobic organic chain segment has good hydrophobicity. On one hand, the overall uniformity of the coating is guaranteed, and on the other hand, the production process is simplified. The coating is an organic-inorganic hybrid coating and is subjected to hydrophobic functionalization or added with a hydrophobic coating, so that the coating has better corrosion resistance, the scaling period is delayed, and the heat exchange performance of the heat exchanger in long-term use is ensured. During production, the heat exchanger only needs to be immersed in the coating, so that the production efficiency is improved, the manufacturing cost is reduced, and the production period is shortened.

Owner:SHENZHEN ENVICOOL TECH

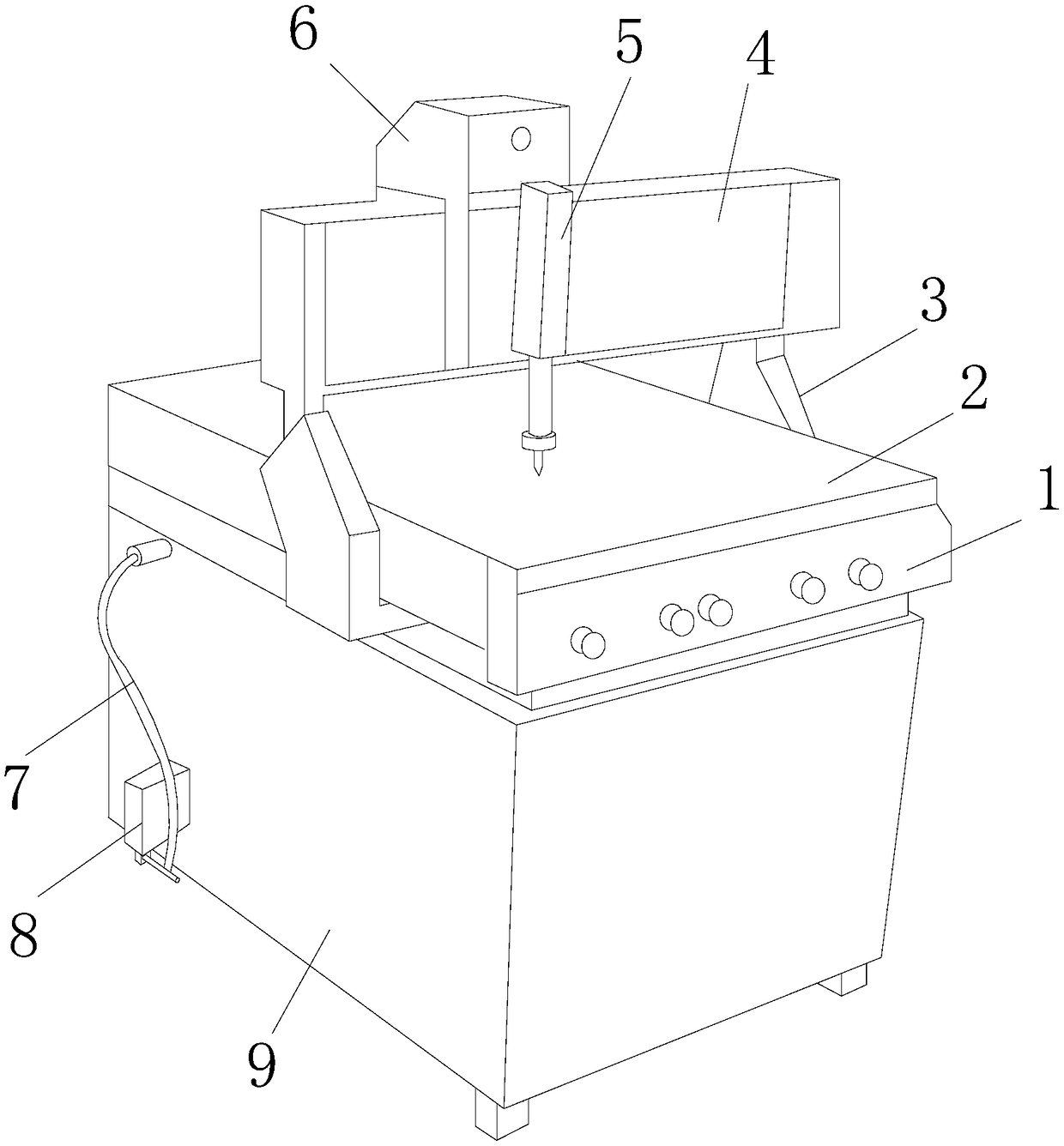

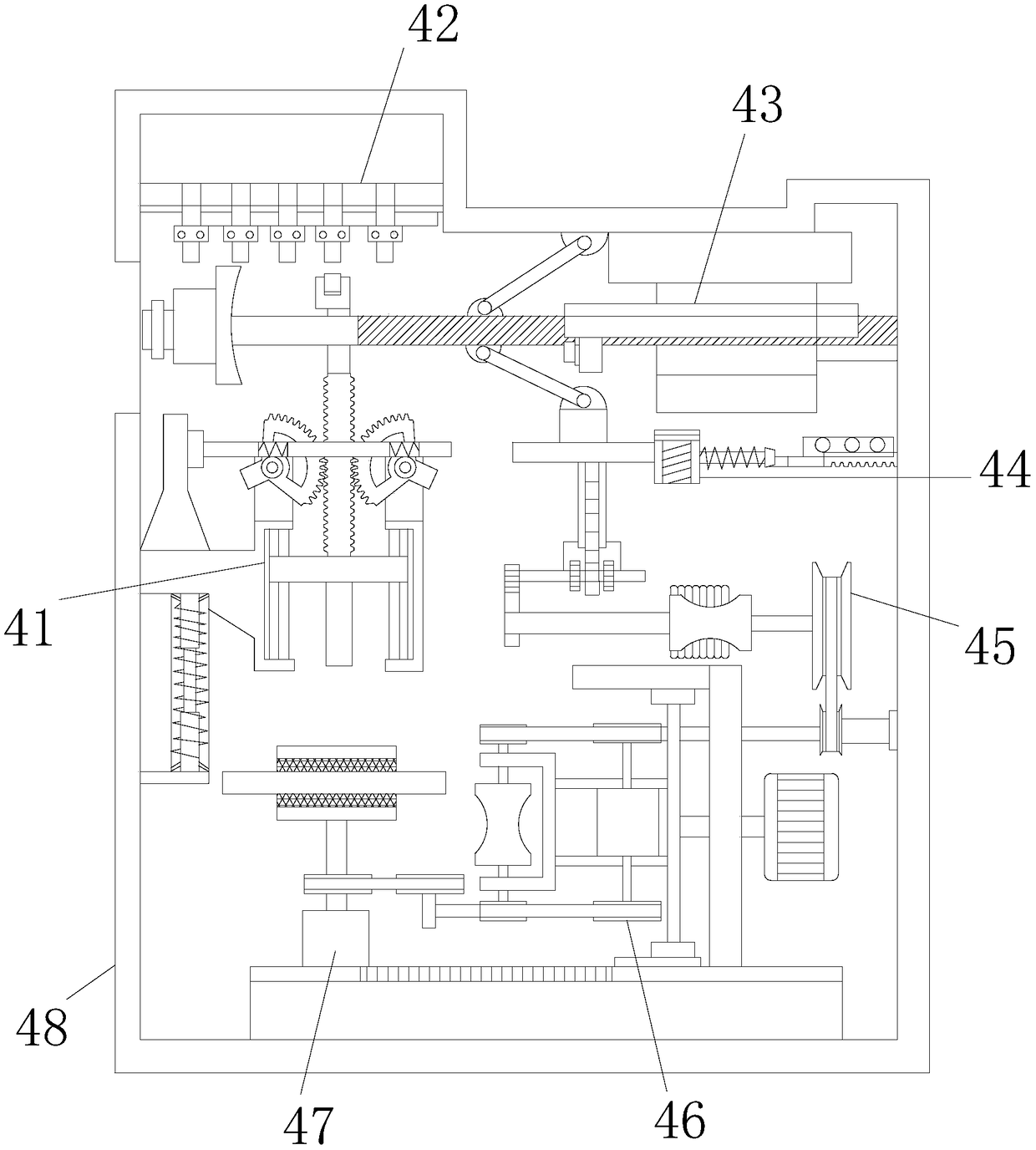

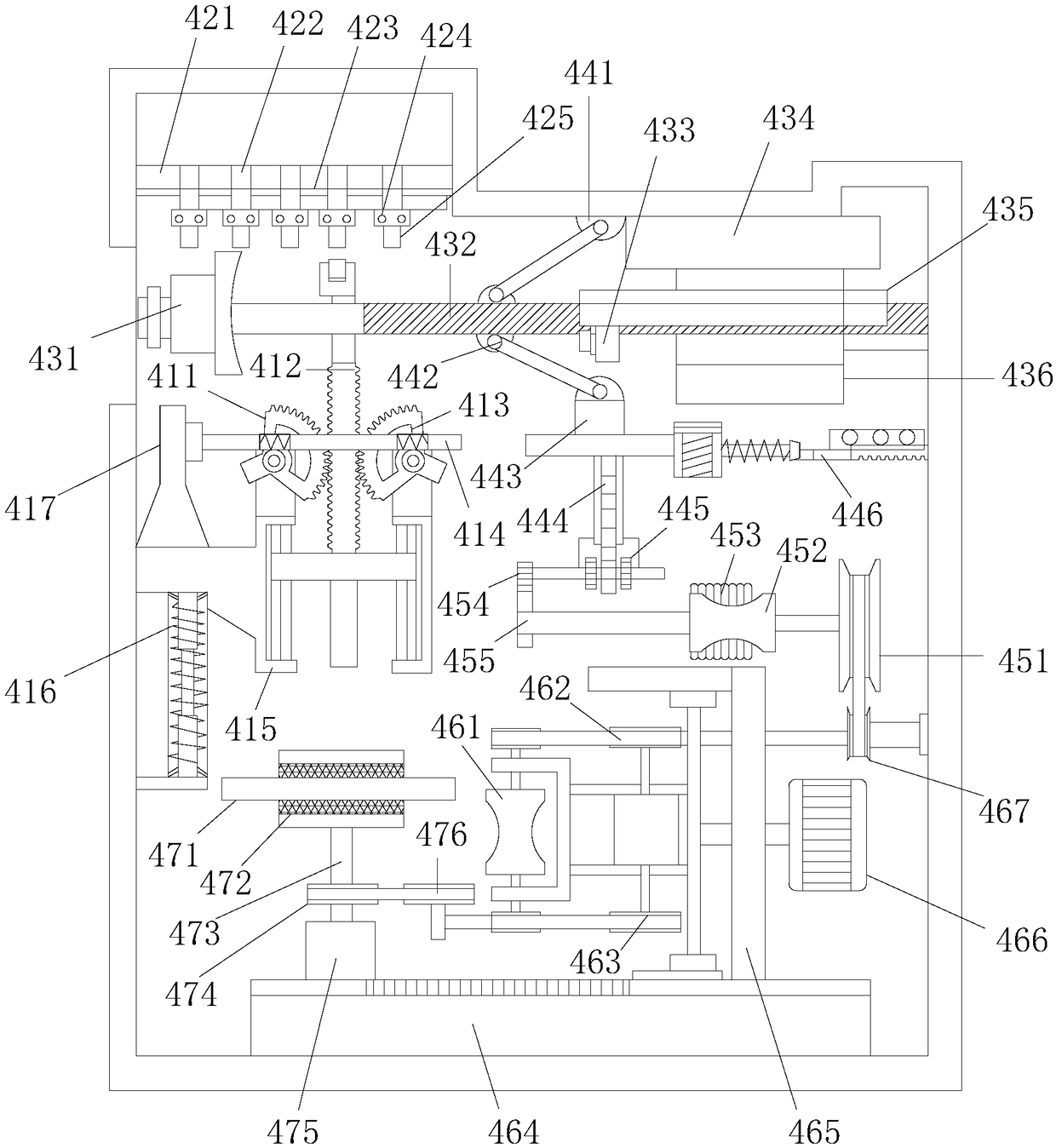

Automatic spraying equipment for hardware products

InactiveCN108772219AReduce laborWork effectively for a long timeLiquid spraying apparatusControl valvesCoating

The invention discloses automatic spraying equipment for hardware products. The automatic spraying equipment comprises a controller, an operation panel, a supporting column, a nozzle replacement mechanism, a spray gun nozzle, a motor room, a coating inlet pipe, a control valve and spraying equipment body, wherein a stress rise mechanism, a mechanical fixing mechanism, a movable adjusting mechanism, a pressure push mechanism, a mechanical linkage mechanism, an initiating trigger mechanism, a mechanical suction mechanism and a metal frame are arranged on the nozzle replacement mechanism. The automatic spraying equipment has the beneficial effects that due to the arrangement of the nozzle replacement mechanism, multiple nozzles can be arranged on the equipment, and when hardware products withrelatively complicated materials and structures of different colors need to be sprayed, internal components are triggered in a pressing manner, so that the nozzles are automatically replaced by the mechanism, the replaced nozzle has the telescopic retraction function, some hardware products of complicated structures can be sprayed, the labor amount of the staff is reduced, and the long-term effective operation of the equipment is facilitated.

Owner:朱小龙

Telescoping revolving crane

InactiveCN106495010ADoes not affect scalingNeat wiringLoad-engaging elementsCranesEngineeringElectric control

The invention relates to the technical field of revolving cranes, specifically to a telescoping revolving crane. With tidy wiring of cables, normal operation of a telescopic boom is guaranteed. The telescoping revolving crane comprises a pedestal, on which a revolving seat is installed. A telescoping lazy arm and a support arm for supporting the telescoping lazy arm are installed on the revolving seat. the telescoping lazy arm comprises a fixed arm and a movable arm which sleeves the fixed arm, and is characterized in that the lateral part of the fixed arm is provided with a horizontal driving cylinder, a piston rod of which is connected to the lateral part of the movable arm; two first suspension rings are installed on a cylinder body of the horizontal driving cylinder; the piston rod of the horizontal driving cylinder is equipped with a second suspension ring; and a cable extends out of the fixed arm and successively bypasses the first suspension rings and the second suspension ring and finally is connected to an electric control component inside the piston rod of the horizontal driving cylinder.

Owner:WUXI SHENGOU MARINE EQUIP

Urban rail transit low-voltage power distribution system management and control equipment

InactiveCN113311746ASave spaceEasy to useProgramme controlComputer controlDistribution power systemElectrical and Electronics engineering

The invention relates to the technical field of urban rail transit power supply systems, and discloses urban rail transit low-voltage power distribution system management and control equipment which comprises a machine shell, wherein a guide rod is fixedly connected to the inner top of the machine shell, a telescopic mechanism is slidably connected to the interior of the machine shell, and a reset rope is fixedly connected to the left side of the telescopic mechanism. According to the urban rail transit low-voltage power distribution system management and control equipment, an inner wheel stops rotating when the equipment is powered off, a buffer spring drives a sleeve rod to slide leftwards, the sleeve rod drives a push rod to move leftwards, the push rod drives a screw to move leftwards, the screw drives a display to swing to a horizontal position, a reset rope drives a telescopic mechanism to slide leftwards at the moment, the telescopic mechanism drives a display to slide leftwards, meanwhile, the telescopic mechanism drives a transmission rod to swing, the transmission rod drives a supporting mechanism to swing, and then the supporting mechanism is used in cooperation with the machine shell, so that the effects of automatically stretching and retracting equipment and saving space are achieved.

Owner:CHANGCHUN VOCATIONAL INST OF TECH

Water-stop and ash-retaining structure for comb-tooth plate expansion joints

The invention discloses a waterstop and ash-damping structure used for an expansion joint of a comb plate. The structure comprises a waterstop rubber belt which is paved on the expansion joint of the comb plate, an upwarp section is formed by outwards extending the side of the waterstop rubber belt adjacent to a crash barrier, upwards extends in a gap between the crash barrier and the comb plate along the linear inner edge of the crash barrier, and is closely adhered to the crash barrier, and a thin plate which spans the gaps of the crash barrier and is linearly identical to the inner edge of the crash barrier further covers the outside of the upwarp section. According to the structure, the upwarp of a waterstop rubber belt can prevent rainwater on a bridge floor from directly dripping below the bridge, and the corrosion on a lower structure caused by surfacial waterlogging and ponding formed by dripping the rainwater to the lower structure of the bridge can be prevented; a cross stitch steel plate covers outside the waterstop rubber belt can effectively prevent garbage or dust from entering the waterstop rubber belt in the gap of the crash barrier, so that the influence on the expansion capavity of the expansion joint can be prevented.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

Capsule hole packer

PendingCN109372462AGuaranteed StrengthDoes not affect scalingGas removalSealing/packingWater pipeBiomedical engineering

The invention relates to the technical field of engineering sealing, in particular to a capsule hole packer. By using compound rubber as a capsule wall, good toughness and integrity with the capsule wall are also guaranteed while the strength of the capsule is guaranteed as the compound rubber is prepared from a metal stretching net and polyvinyl butyral, so that the capsule hole packer is used repeatedly. The capsule is in dynamic sealing connection to a water inlet pipe and a water outlet pipe, so that stretching of the capsule is not affected while the sealing property of the capsule is guaranteed. The water inlet pipe is connected to a water injection pump through a quick connector and the water outlet pipe is connected to a one-way valve by a quick connector, so that the hole packer is connected to external equipment quickly and the normal work of the hole packer is not affected. The capsule hole packer provided by the invention is simple in structure, convenient to operate and good in sealing effect and can be repeatedly used.

Owner:阳泉惠通机械制造股份有限公司 +1

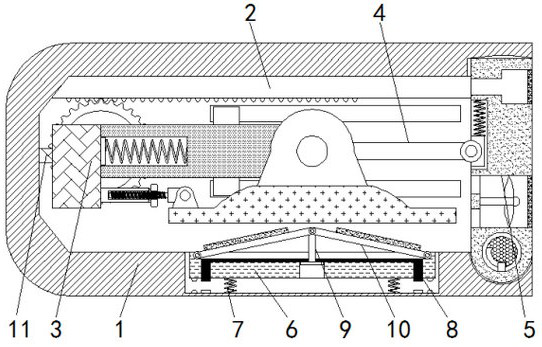

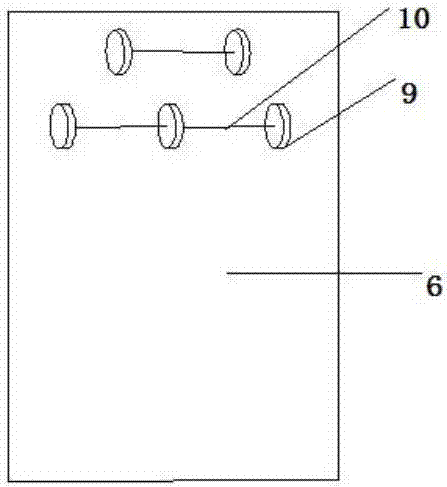

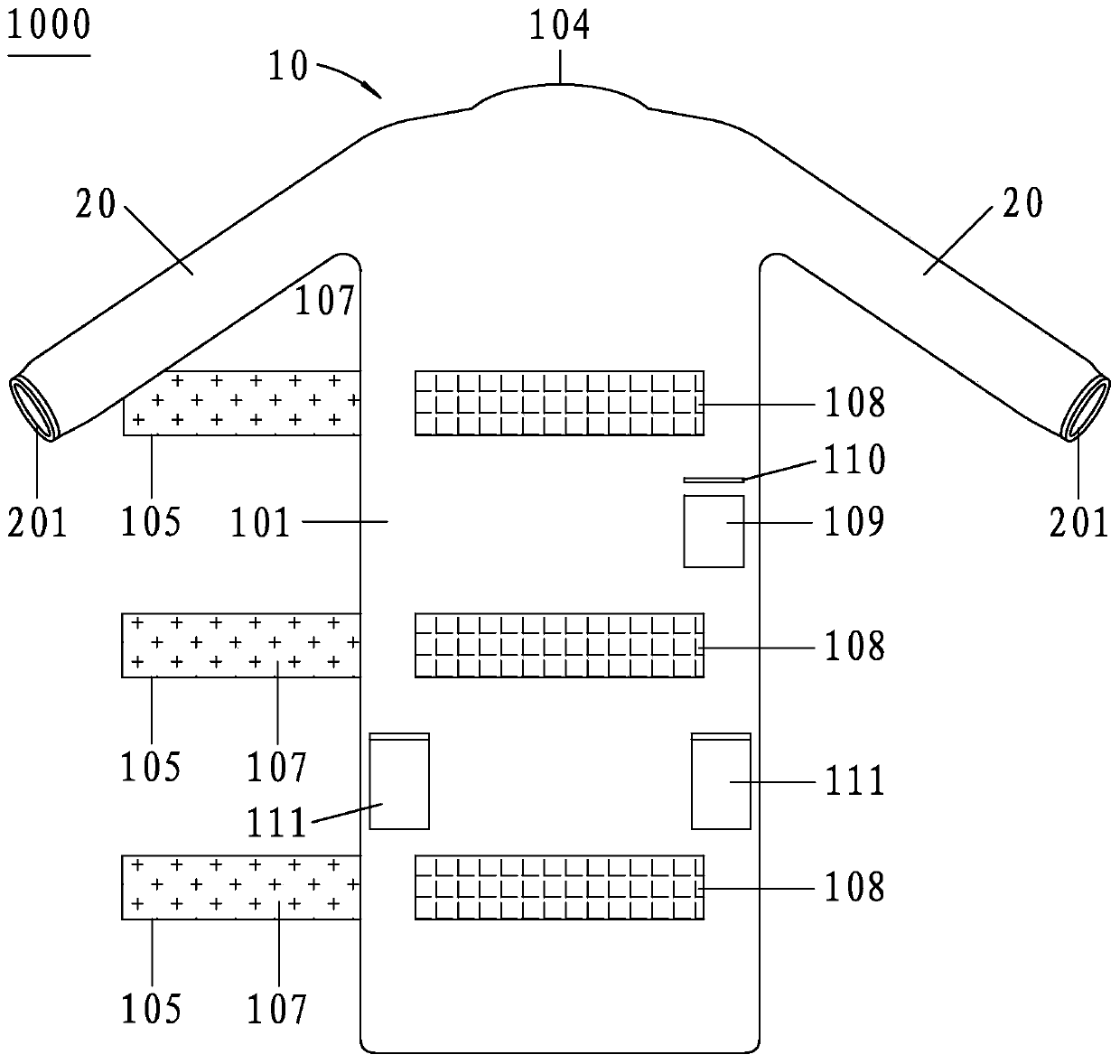

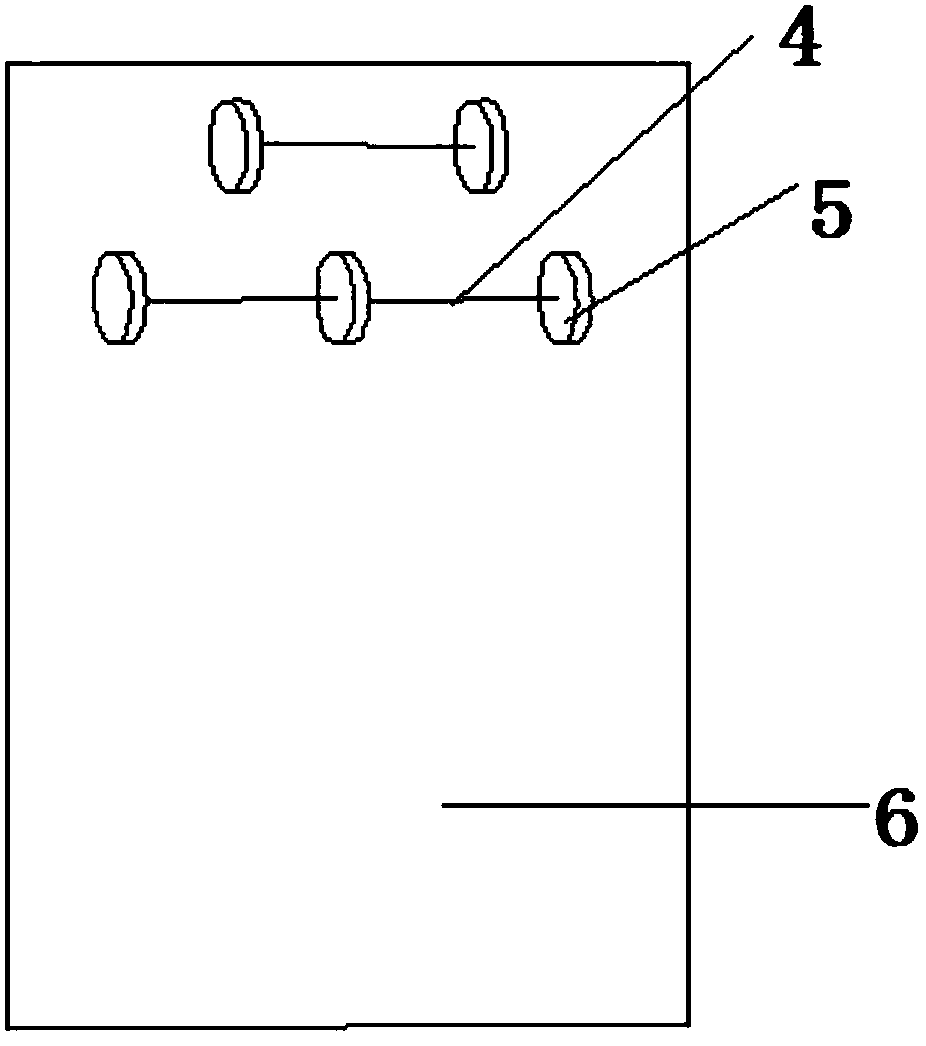

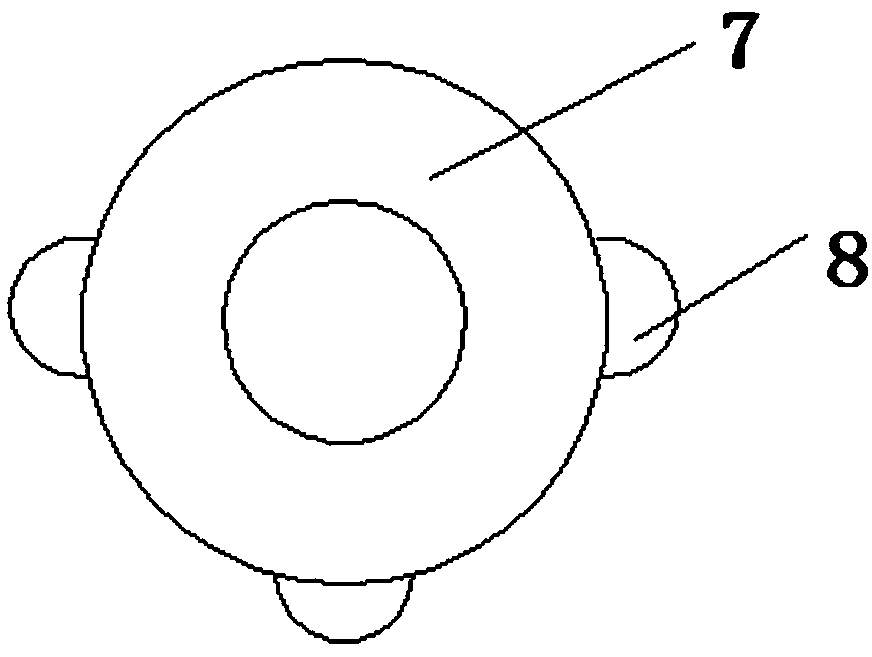

Mattress with built-in cavity base on automatic massage

InactiveCN107087930ADoes not affect scalingAlleviate shoulder and neck problemsStuffed mattressesSpring mattressesMassageEngineering

The invention discloses a mattress with a built-in cavity base on automatic massage. The mattress comprises a cellucotton layer, a spring layer and a latex layer which are in connection in sequence from bottom to top. A heating layer is arranged between the spring layer and the latex layer, and the heating layer comprises a storage cabin; the latex layer comprises a latex mattress, a circuit of aroma cavity is connected to the outer side of the latex mattress, and ventilating openings are formed in the aroma cavity; two rectangular cavities matched with massage equipment are formed in the latex mattress, and the cavities are in parallel with the width of the mattress and located on the same side; the massage equipment comprises two rolling shafts with different lengths, the longer rolling shaft is connected with 3 rollers and parallel with the side edge where the width of the mattress is located, the shorter rolling shaft is connected with 2 rollers and located between the longer rolling shaft and the side edge where the width of the mattress is located, and both the rolling shafts are connected with reducers and motors; a heating aroma device is totally embedded in the mattress, wherein an acarus killing raw material can be placed in the device, and a quilt above the mattress is put around through the ventilating holes for a better acarus killing effect.

Owner:广汉市朗加家居有限公司

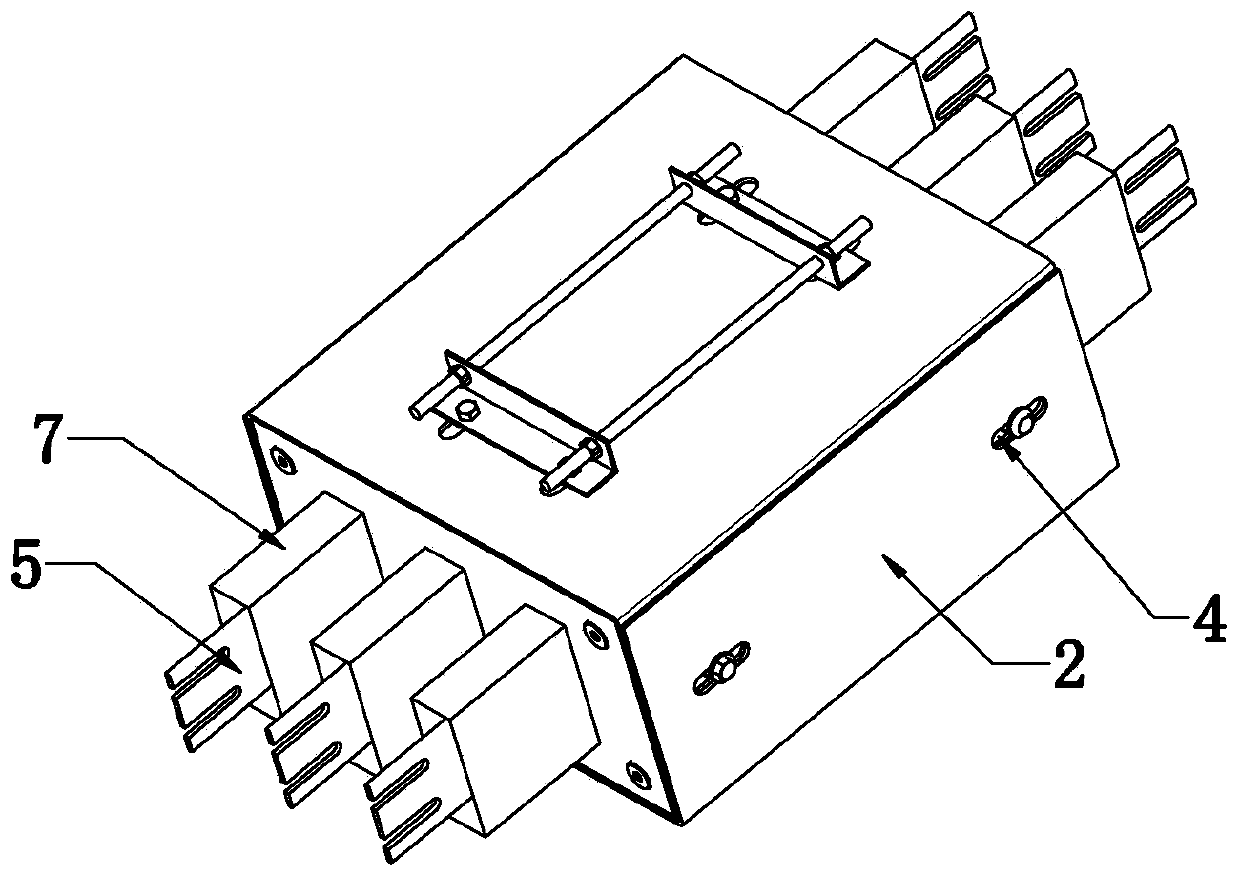

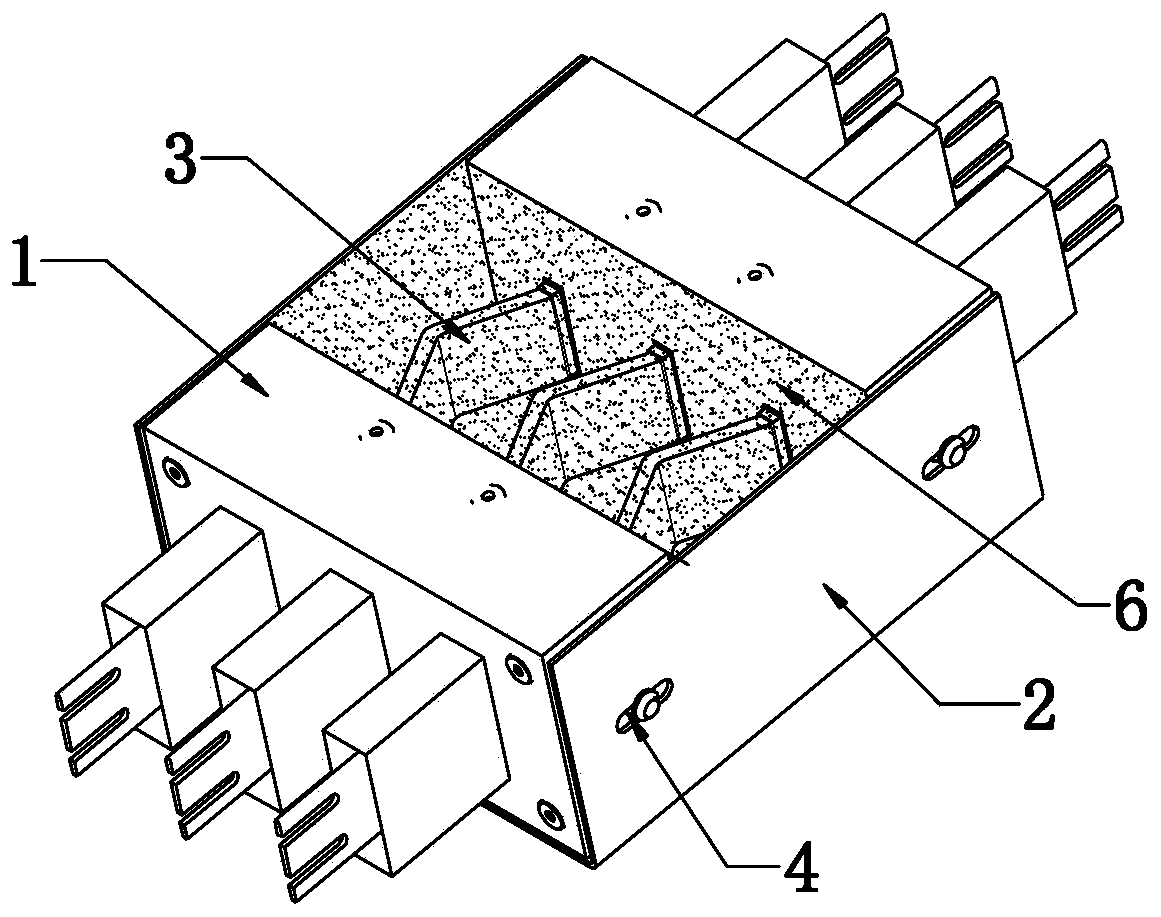

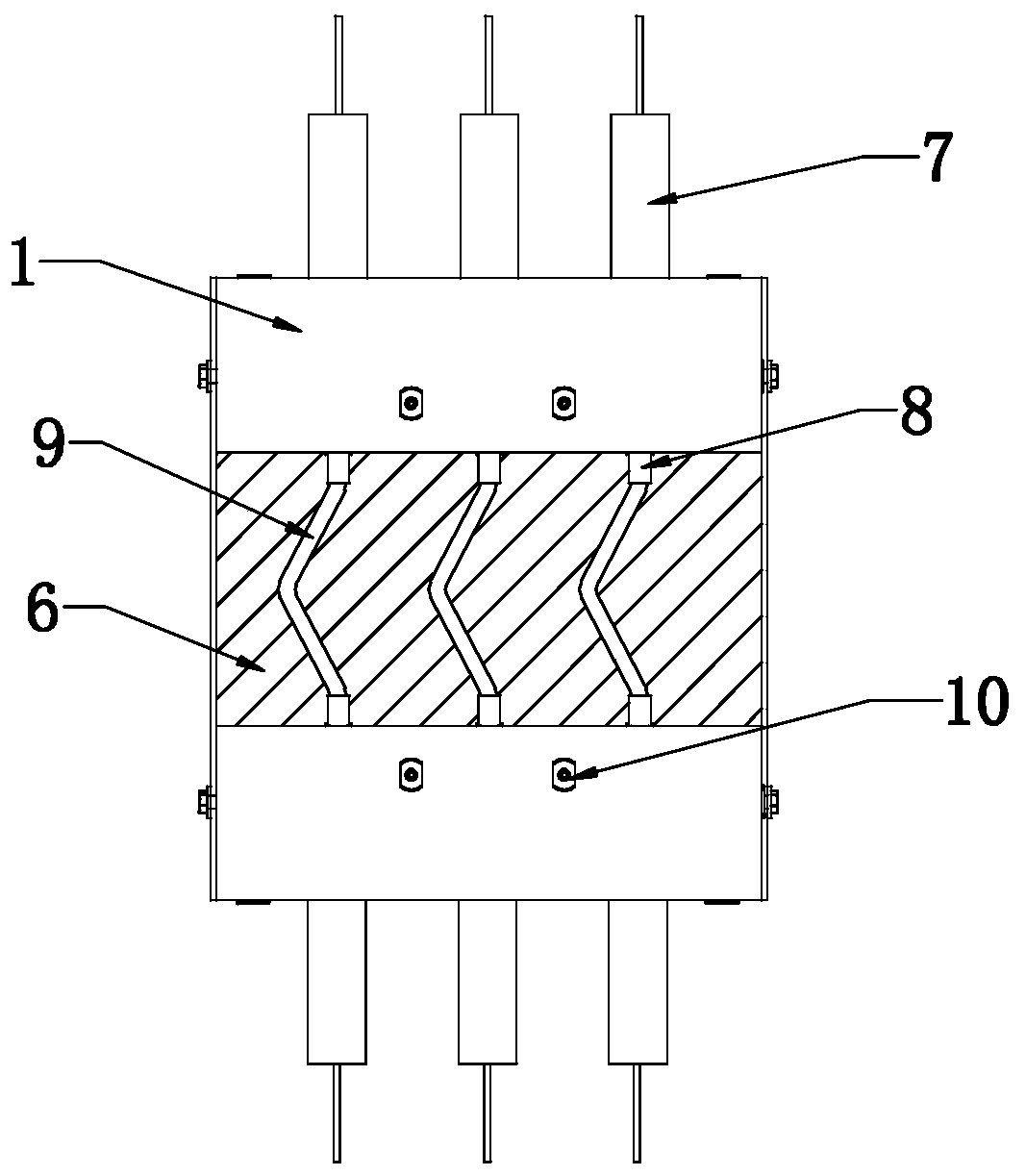

Resin pouring busbar telescopic joint

PendingCN110676783ADoes not affect scalingImprove insulation performanceTotally enclosed bus-bar installationsElectrical conductorBusbar

The invention discloses a resin pouring busbar telescopic joint comprising two insulating pouring bodies arranged at intervals and multi-phase conductors arranged in parallel between the two pouring bodies. Each phase of conductor successively penetrates through the two pouring bodies and extends out of the two ends of the two pouring bodies respectively. The multi-phase conductors form telescopicsoft connection between the two pouring bodies. The two sides of the two pouring bodies are guided and connected through movable side plates capable of moving longitudinally, and the cavity between the movable side plates and the two pouring bodies is filled with insulating elastic colloid coated outside each soft connection. With application of the structure, the space formed between the two pouring bodies and the two movable side plates is filled with the insulating elastic colloid coated outside each soft connection so that the expansion and contraction are not affected and the insulationand waterproof performance are enhanced, the overall structural design is reasonable, the expansion and contraction reliability is quite good and the service life is greatly prolonged.

Owner:WETOWN ELECTRIC GRP CO LTD

A household high-altitude interior and exterior window cleaning device

The invention relates to a household high-altitude internal and external window cleaning device, which is suitable for household, high-altitude, and cleaning of internal and external window glass. , a rubber scraper is installed on the front side of the wiping head, a hole is opened on the right side of the main body of the wiping head, and a drawstring is installed, a reel is installed on the top of the guide rail, the reel is connected to the wiping head, the front side of the guide rail is connected to the base, and the base A suction cup is installed on the front side. Compared with the prior art, the present invention uses guide rails instead of human hands to control the wiping direction, and the coil spring can automatically rebound the wiping head, which saves labor, simple structure and low cost, convenient and labor-saving cleaning, and low human participation.

Owner:SHANGHAI UNIV OF ENG SCI

Wireless image transmission device for data transmission based on network virtual live broadcast

ActiveCN113531302AFirmly connectedEasy to useTelevision system detailsColor television detailsData transmissionSight line

The invention discloses a wireless image transmission device for data transmission based on network virtual live broadcast. The wireless image transmission device comprises a wireless image transmission equipment body, a socket and a data line, the socket and the data line are arranged on the wireless image transmission equipment body, the output end of the data line is in plug-in connection with the socket, a supporting ring seat is mounted at the bottom end of the wireless image transmission equipment body, a fixed ring seat is arranged in the supporting ring seat, a cavity is formed between the fixed ring seat and the supporting ring seat, the cavity is used for accommodating a longer data line, a guide piece is mounted on the outer side of the supporting ring seat, and the guide piece is used for positioning and guiding the input end, away from one end of the socket, of the data line. According to the wireless image transmission device for data transmission based on network virtual live broadcast, the data line is limited and guided, so that the problems that the relatively long data line is intertwined with shooting equipment and the shooting sight of the shooting equipment is influenced are effectively solved, meanwhile, stable connection between the wireless image transmission equipment and the shooting equipment is realized, and additional connection equipment does not need to be used.

Owner:深圳市天擎数字有限责任公司

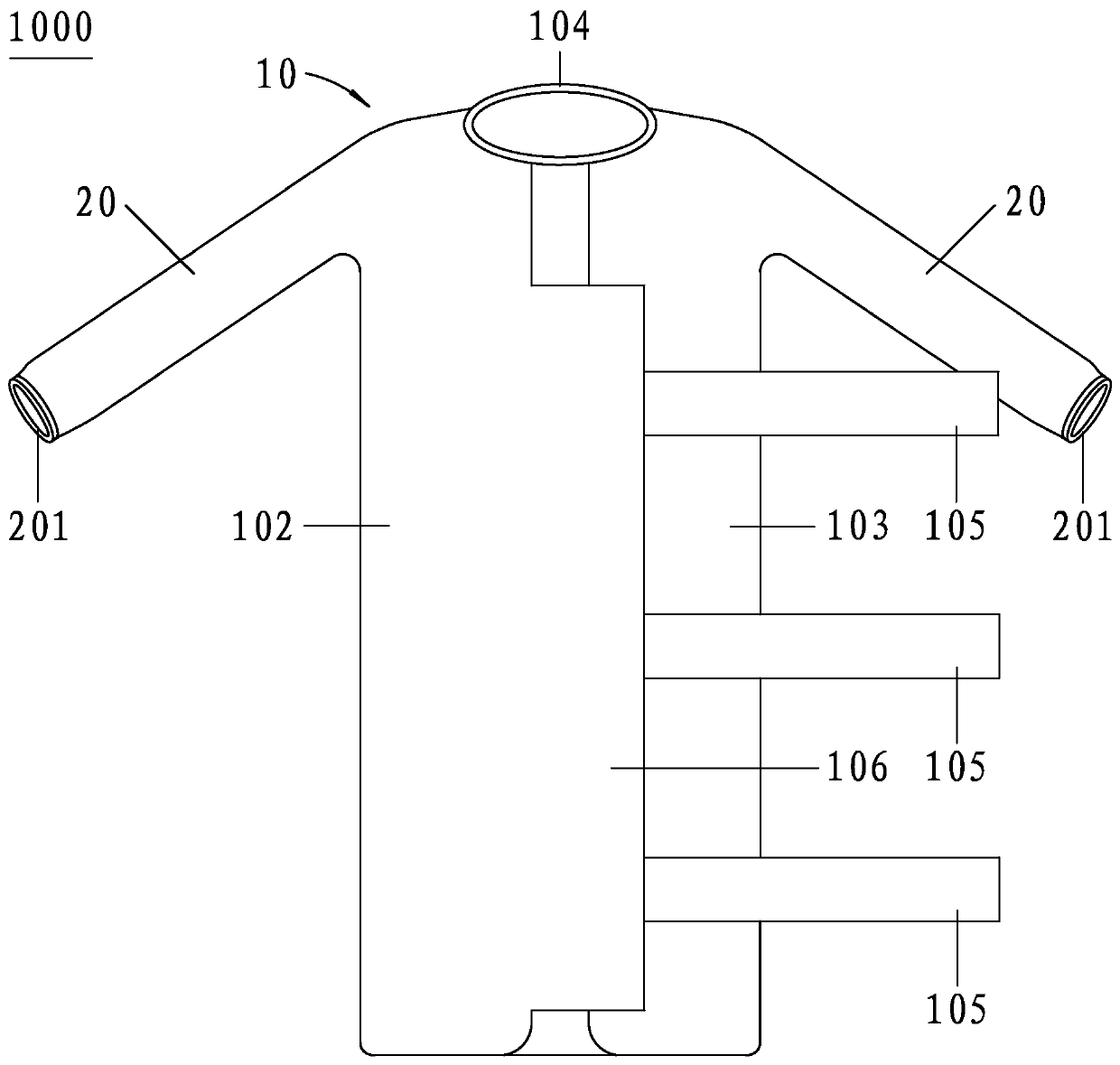

Easy-to-put on/take off isolation clothes special for doctor

The invention discloses easy-to-put on / take off isolation clothes special for a doctor. The isolation clothes comprise a clothes body and sleeves. The clothes body comprises a front clothes piece, a left rear clothes piece, a right rear clothes piece, an elastic cord and a tying piece. The middle of the upper edge of the front clothes piece and the front side of the elastic cord are connected intoa whole. The left portion of the upper edge of the left rear clothes piece and the left portion of the upper edge of the front clothes piece are connected into a whole. The right portion of the upperedge of the left rear clothes piece and the left portion of the rear side of the elastic cord are connected into a whole. The right portion of the upper edge of the right rear clothes piece and the right portion of the upper edge of the front clothes piece are connected into a whole. The left portion of the upper edge of the right rear clothes piece and the right portion of the rear side of the elastic cord are connected into a whole. Then, a closed collar is formed at the upper portion of the clothes body. The isolation clothes have the advantages that the doctor does not need to put straight the collar when putting on the clothes, the clothes cannot fall after the elastic cord is hung on the neck of the doctor, the doctor can spare two hands to operate the tying piece so as to tightly tie the left rear clothes piece and the rear right clothes piece, no other people need to assist the doctor in putting away and putting on, and the workload and work amount of other people can be greatly relieved.

Owner:PEKING UNIV SHENZHEN HOSPITAL

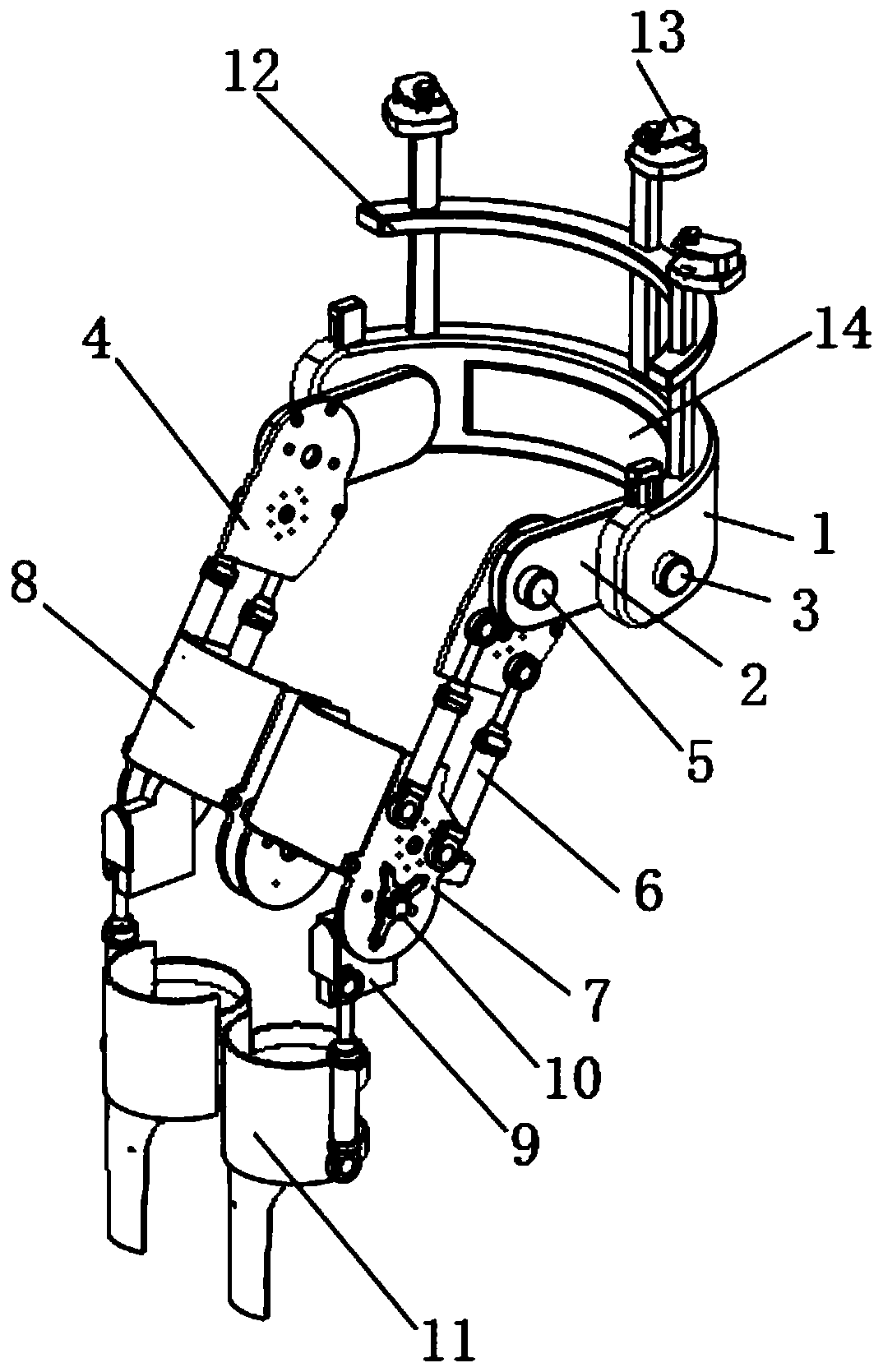

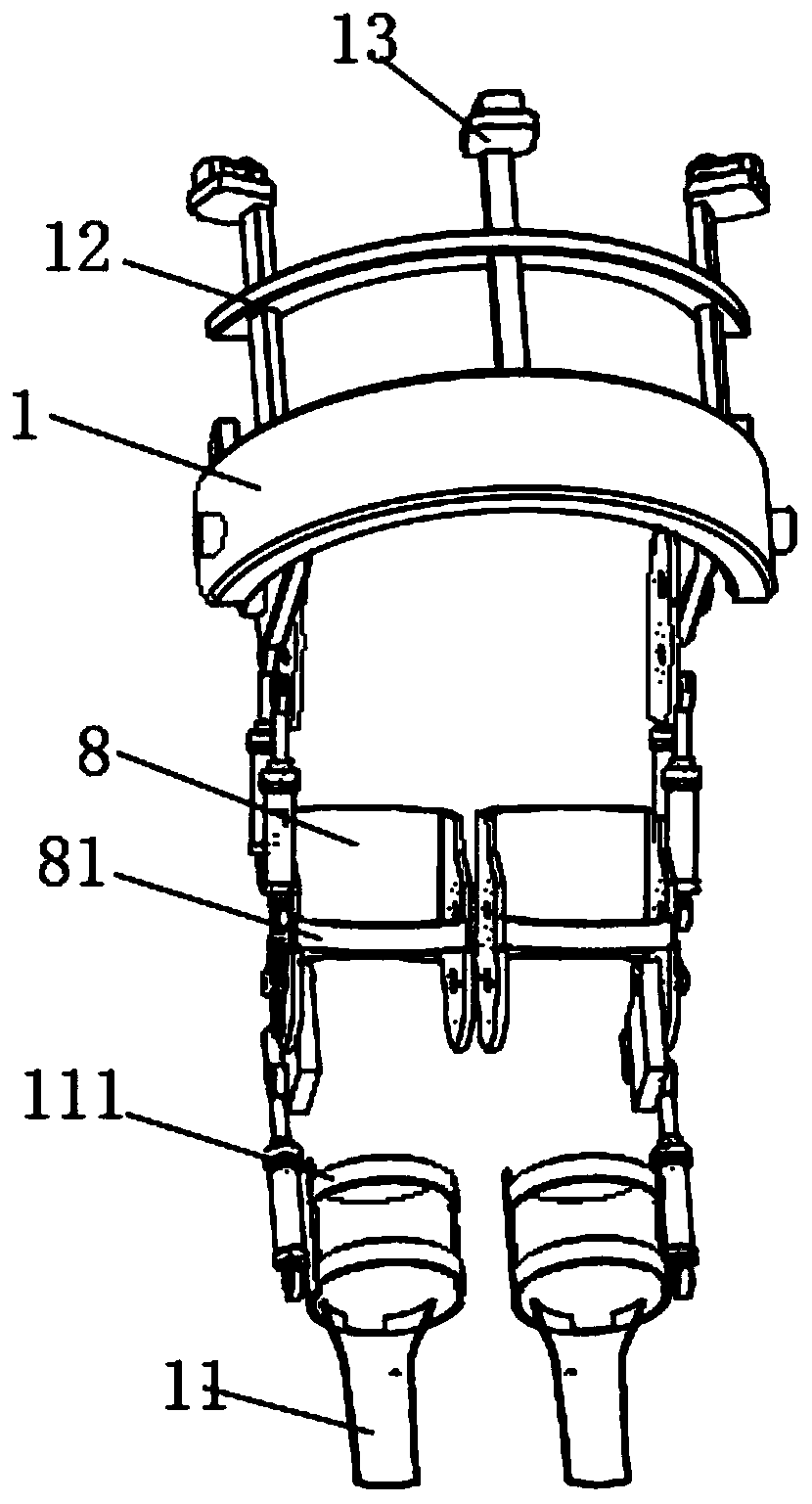

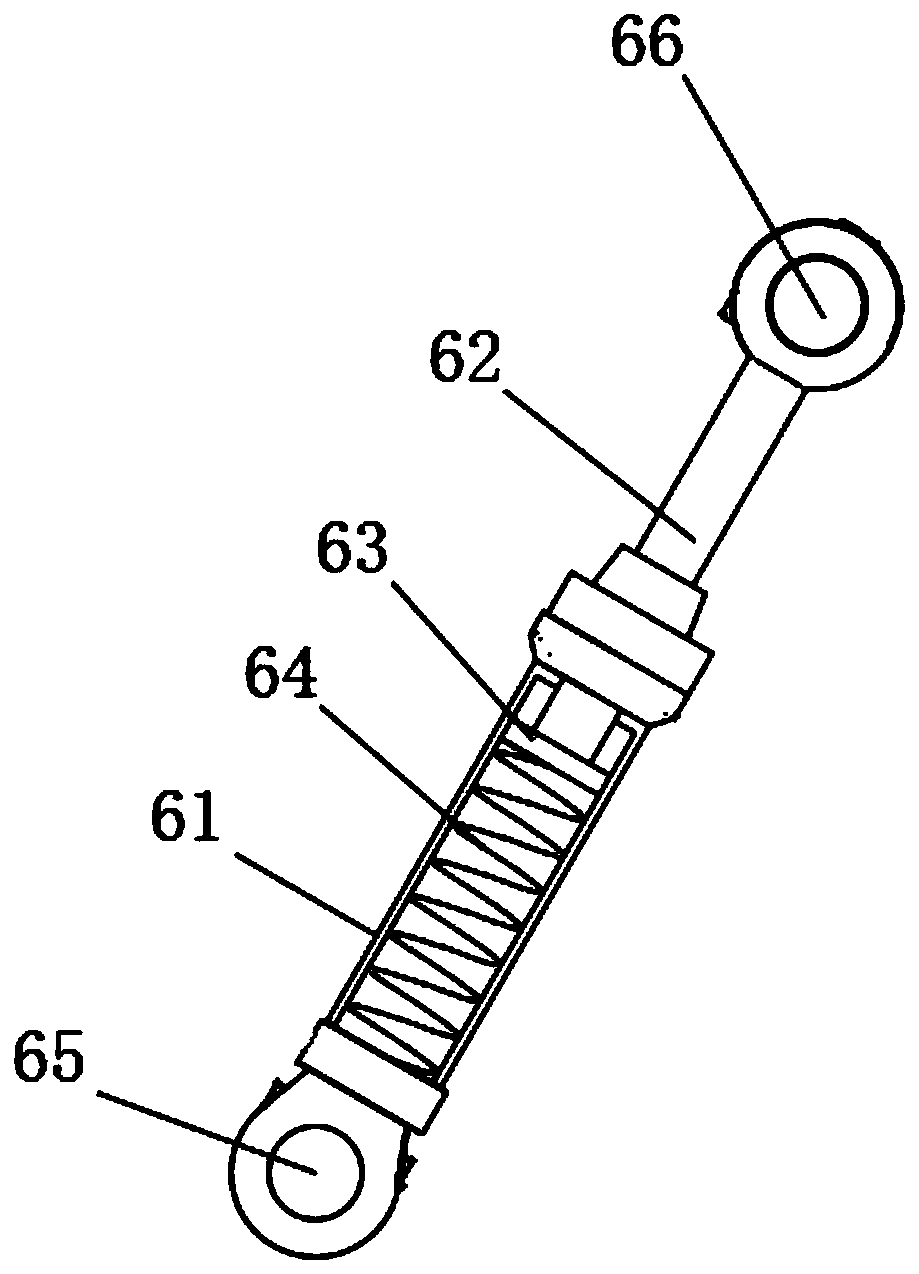

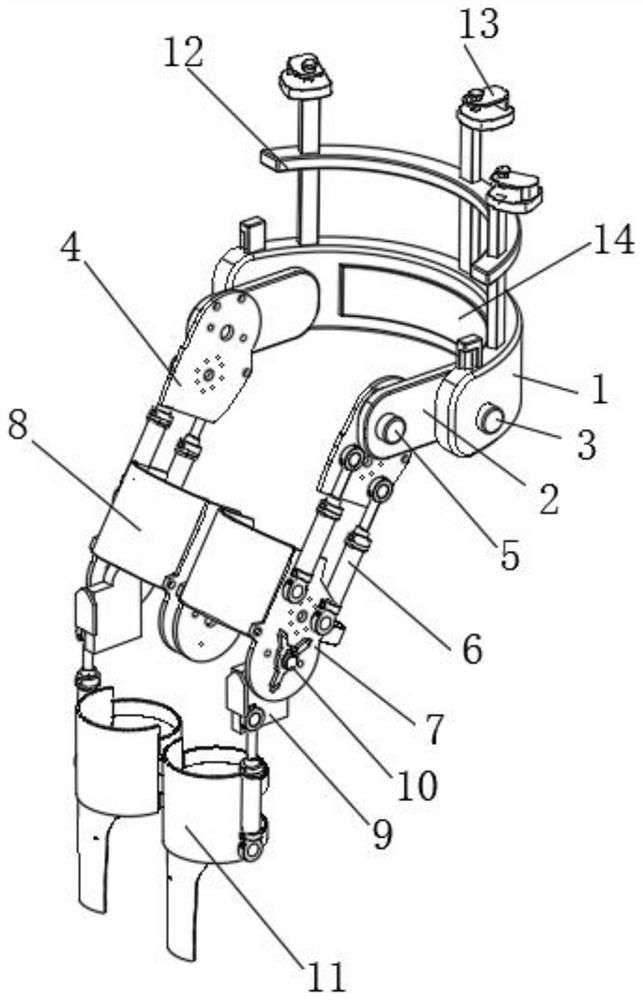

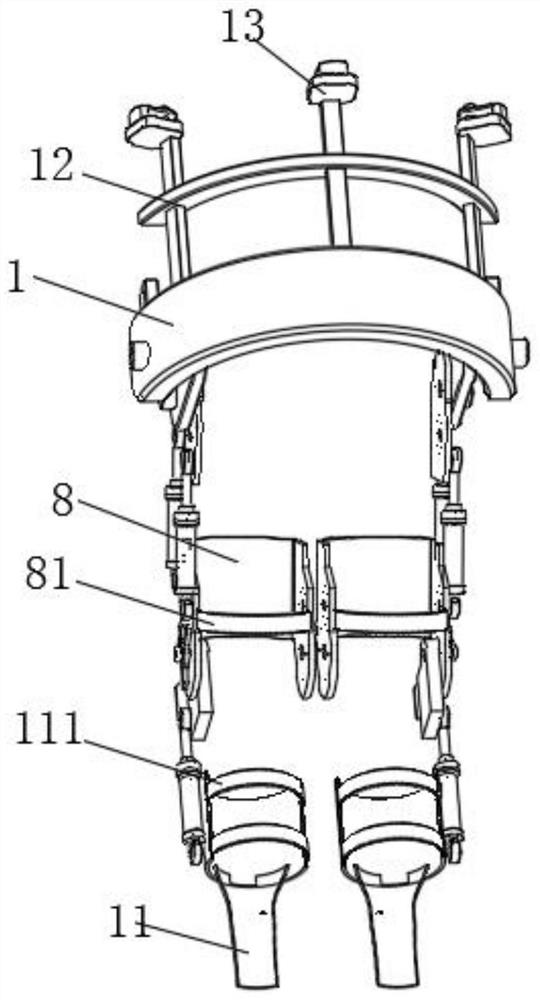

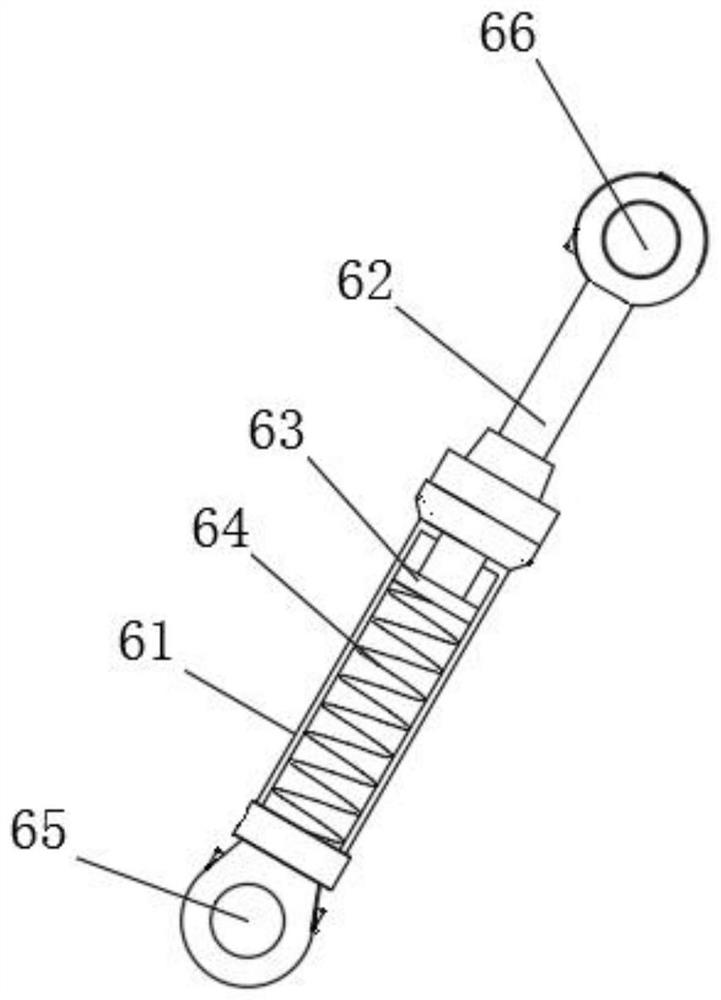

Exoskeleton auxiliary treatment rehabilitation device

ActiveCN111135020ADoes not affect scalingImprove buffering effectWalking aidsTherapy rehabilitationEngineering

The present invention relates to the field of rehabilitation devices and discloses an exoskeleton auxiliary treatment rehabilitation device. The exoskeleton auxiliary treatment rehabilitation device comprises a waist protection frame, the waist protection frame presents an arc-shaped plate shape, first connecting plates are movably arranged at inner sides of the waist protection frame close to front ends, second connecting plates are movably arranged at front ends of the first connecting plates, lower ends of the second connecting plates are connected with buffer structures, lower ends of thebuffer structures are connected with third connecting plates, first protection sleeves are arranged on outer surfaces of one sides of the third connecting plates, fourth connecting plates are movablyarranged at lower ends of the third connecting plates, second protection sleeves are arranged below the fourth connecting plates, the fourth connecting plates are movably connected with the second protection sleeves through the buffer structures, an upper protection frame is arranged on an outer surface of an upper end of the waist protection frame, and a limiting structure is arranged at the upper end of the upper protection frame. The exoskeleton auxiliary treatment rehabilitation device has functions of relatively good joint buffering effect, capability of supporting the back, convenience in installation of an additional protection pad and easiness in replacement of the protection pad.

Owner:郭继相

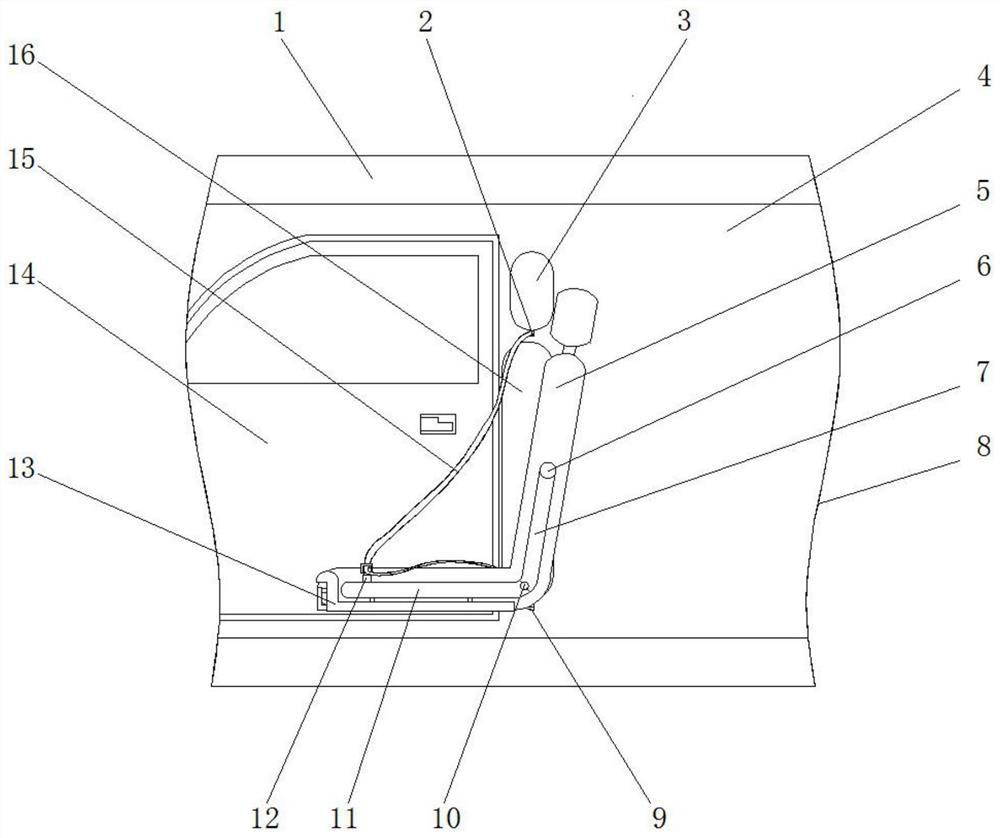

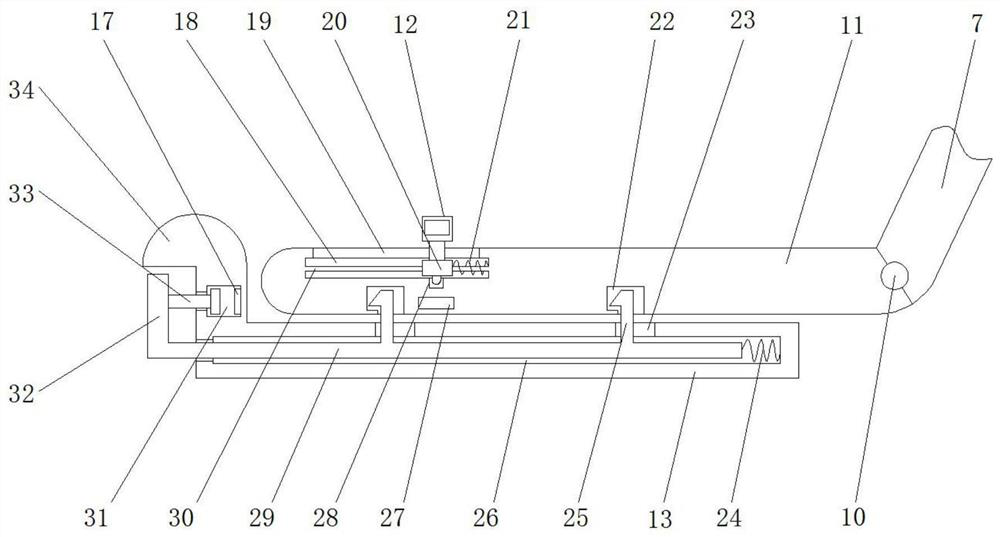

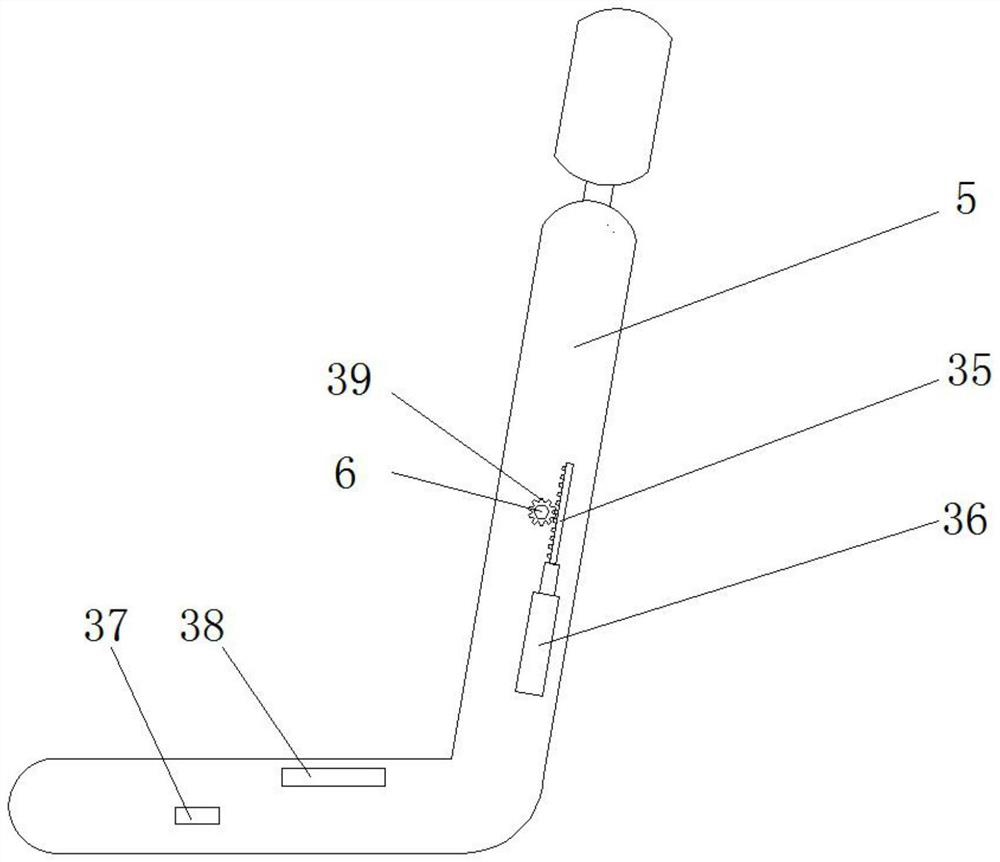

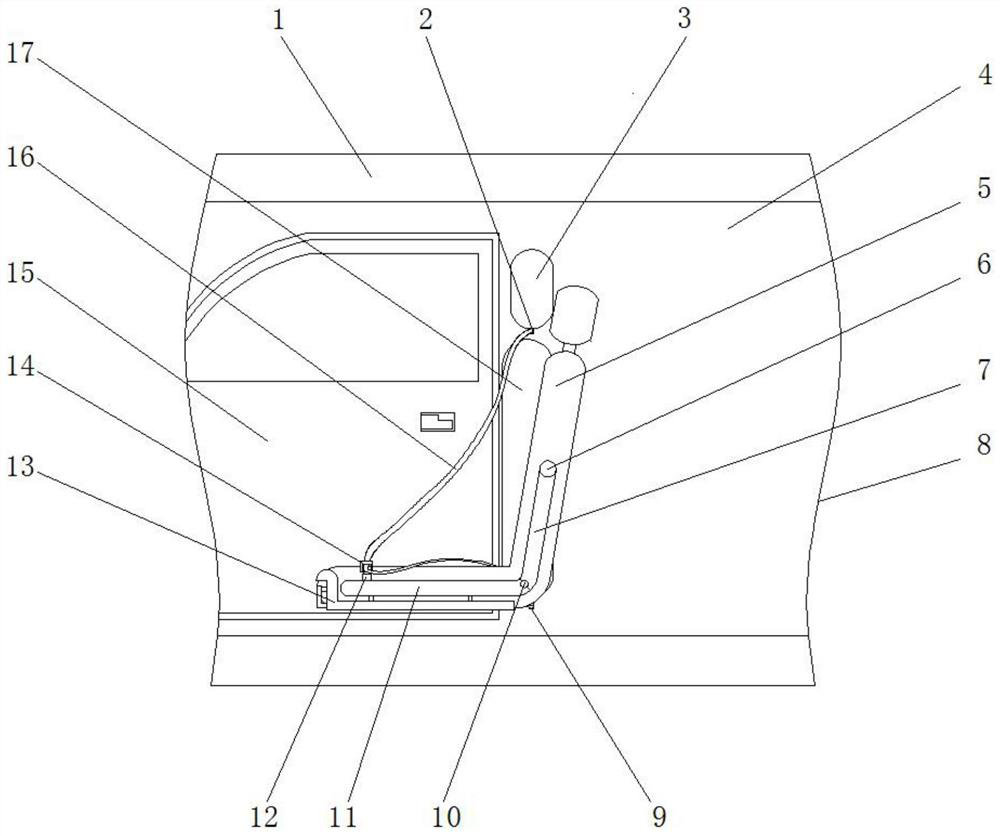

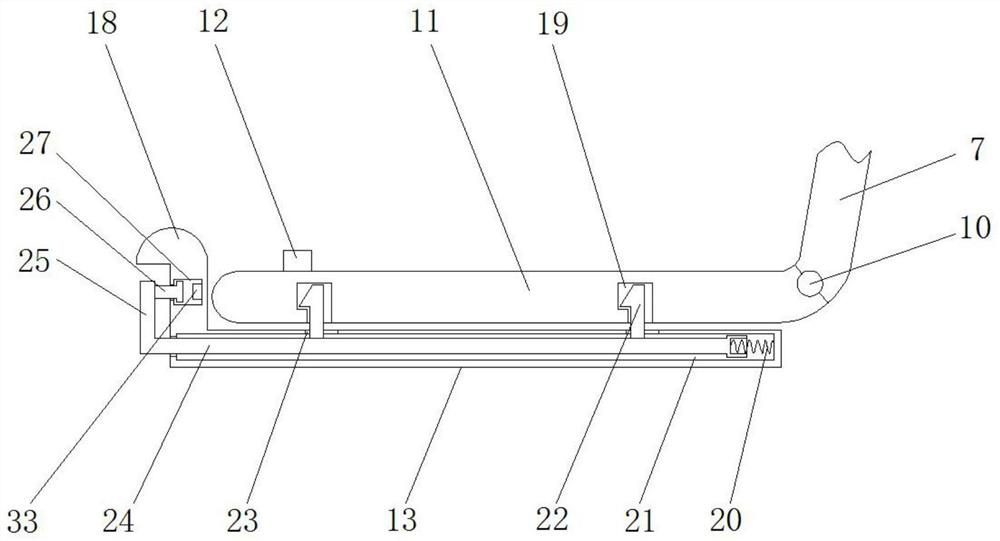

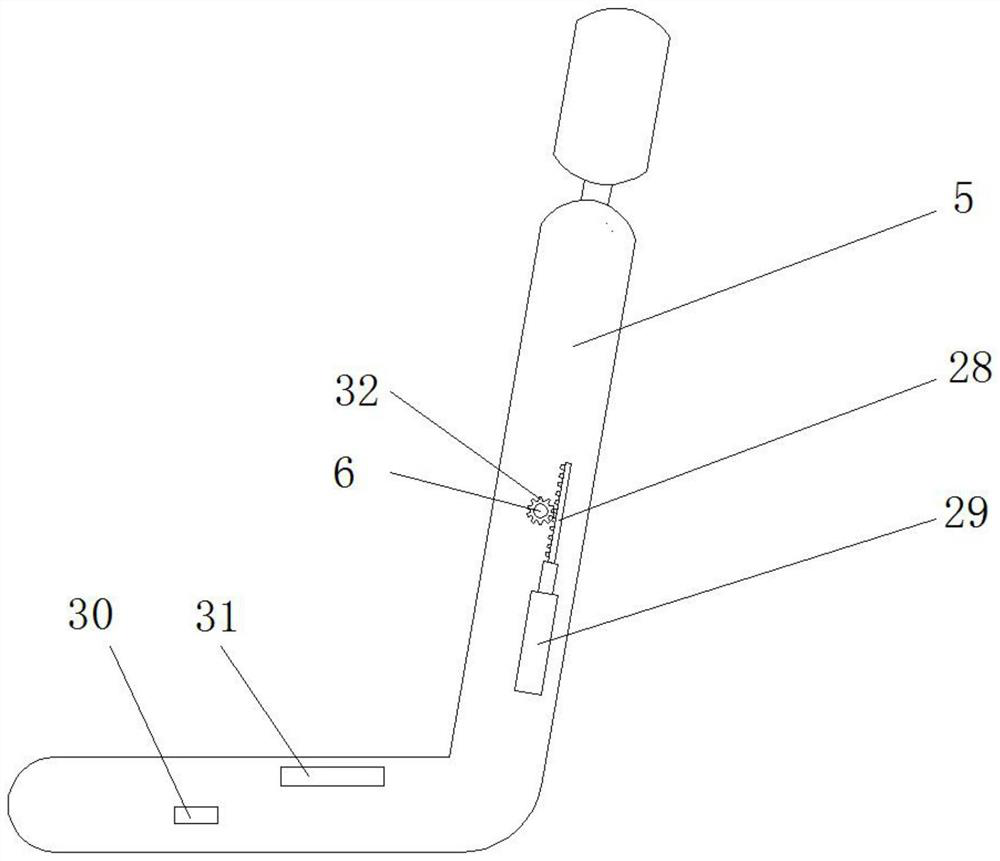

A safety belt mandatory wearing device

ActiveCN109910815BAffect normal useImprove securityBelt control systemsBelt anchoring devicesSeat beltBelt safety

The invention discloses a safety belt compulsory wearing device, which comprises a vehicle roof, a seat, a vehicle body, a vehicle door and a safety belt. The top of the vehicle body is provided with a vehicle roof, and the outside of the vehicle body is provided with a vehicle wall. A door is provided on one side of the door, and a seat is provided inside the vehicle body at the position of the door. The top of the inner wall of the vehicle wall on one side of the door is provided with a roll-up opening, and the bottom end of the inner wall of the vehicle wall directly below the roll-up opening is A fixed opening is provided, and a safety belt is arranged between the fixed opening and the roll-up opening, one end of the safety belt is fixed to the fixed opening, and the other end of the safety belt extends to the inside of the roll-up opening. In the present invention, a fixed buckle is slidably connected to the fixed rod, and in the process of use, the fixed connection effect of the fixed buckle to the seat belt is utilized, and the rotation of the connecting rod and the fixed rod drives the safety between the winding mouth and the fixed mouth. During the belt flipping process, the seat belt cannot be released arbitrarily, and the seat belt must be worn and released by the driver and passengers to increase the safety of the driver and passengers.

Owner:ANHUI POLYTECHNIC UNIV

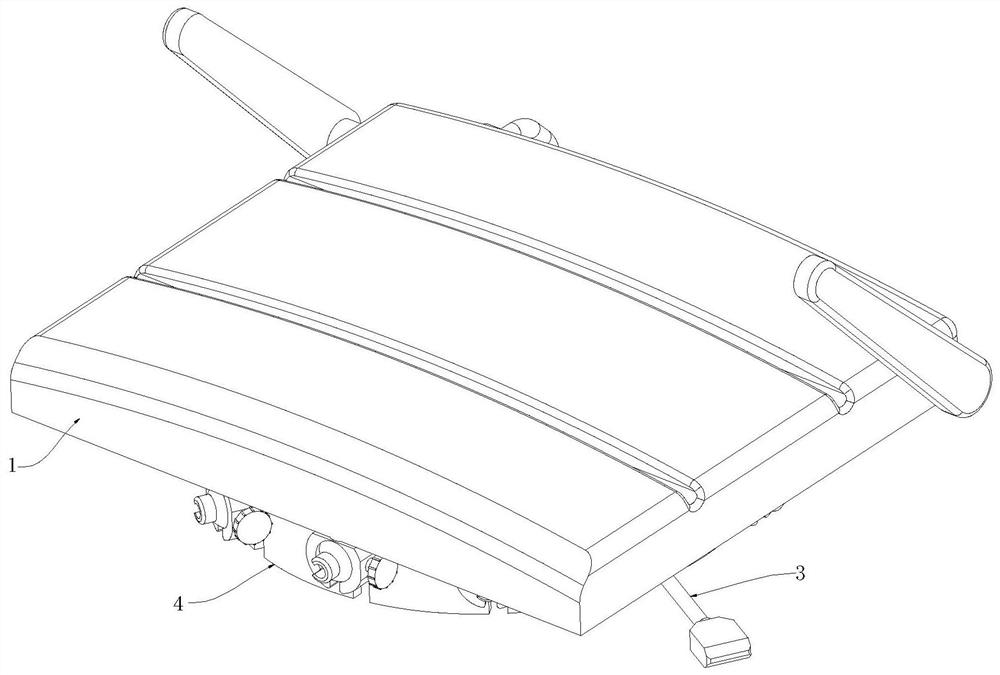

Multifunctional mattress with manually adjustable massage force

InactiveCN109419216ASolve shoulder and neck problemsGood value for moneyStuffed mattressesSpring mattressesMedicineMassage

The invention discloses a multifunctional mattress with manually adjustable massage force. The multifunctional mattress with manually adjustable massage force comprises a mattress main body; the mattress main body comprises a knitted layer, a massage layer, and an accommodating cabin layer from top to bottom successively; the massage layer comprises a massage sponge; the massage sponge is providedwith two rectangular cavities matching massage equipment; the rectangular cavities are arranged to be parallel to the width direction of the multifunctional mattress, and are arranged at the same side; the massage equipment comprises two rolling shafts of different length; the longer rolling shaft is connected with three rollers, and is parallel to the side edge of the width of the multifunctional mattress; the shorter rolling shaft is connected with two rollers, and is arranged between the longer rolling shaft and the side edge of the width of the multifunctional mattress; and each rolling shaft is connected with a decelerator and a motor. Conventional mattress is only capable of solving sleeping problems, material hardness is taken into consideration in processing production, a few mattresses are provided with massage function, the whole massage is designed to be a massage bed based on massage chair principles, and the effect is better.

Owner:李志蓉

Plate-shell type heat exchanger

ActiveCN100501292CImprove reliabilityDoes not affect scalingStationary conduit assembliesStationary plate conduit assembliesPlate heat exchangerHeat transmission

The invention relates to a board heat exchanger, which uses ripple sheet as heat transmission element, wherein the invention comprises a frame, a board medium entrance connecting tube, and a board medium entrance tube; said frame is arranged with sheet beam, whose lower end via board medium entrance connecting tube is connected to the fixing expanding valve, and upper end via board medium outlet connecting tube is connected to the free expanding valve; two expanding valves absorb the thermal expansion displacements between sheet and frame, sheet beam frame and cylinder frame, without bearing the weight of sheet beam, to improve the reliability of board heat exchanger; the sheet beam frame compresses the layered sheet to bear the pressure difference between mediums, without affecting the flexibility; and the outer frame is cylinder, to bear higher medium pressure; one or two ends of sheet beam frame are arranged with side open; the invention can improve the application of board heat exchanger.

Owner:GANSU LANPEC TECH +2

A drawing and measuring device suitable for road design in windy and sandy areas

ActiveCN112706543BQuality improvementEasy reference drawingMeasurement apparatus componentsBathroom accessoriesAgricultural scienceAgricultural engineering

The invention discloses a painting and measuring device for highway design in the technical field of highway design, which is suitable for road design in windy and sandy areas. Hinged sand-proof shell, the inner middle of the U-shaped seat is slidably connected with two sets of connecting guide plates, a transparent plate is fixedly arranged between the two sets of connecting guide plates, and the top of the organ-type dust-proof folding cloth is located in the U-shaped seat. One inner; cleaning automatic assembly, the cleaning automatic assembly is arranged on the left side of the bottom of the support plate, the present invention is provided with a painting assembly, the hand-held painting pen passes through the sleeve to draw the paper in the sand-proof shell, and the organ-type dust-proof folding The setting of the cloth is convenient for the user to hold the drawing pen and move the transparent plate to the left or right to draw, and the paper in the sand-proof shell will not be affected by the external wind and sand, thus avoiding the paper being soiled or damaged. The quality of the user's painting.

Owner:广东瑾诚城市规划勘测设计有限公司

A mobile trestle with adjustable angle and horizontal adjustment

ActiveCN111663430BDoes not affect scalingEasy to usePortable bridgeUnderground chambersClassical mechanicsStructural engineering

The invention provides a mobile trestle with adjustable angle and horizontal direction, which at least includes a walking wheel set, a rear outrigger, a main girder assembly, a central gutter formwork assembly, a longitudinal moving trolley, an inverted arch formwork assembly, a guide Beam assembly, middle outrigger, front outrigger, tugboat mechanism and electro-hydraulic system, rear outrigger and front outrigger are fixedly installed under the tail end and head end of the main beam respectively, middle outrigger is movably installed under the main beam, main The beam sliding shoe mechanism is installed between the main beam and the middle outrigger; the auxiliary outrigger is installed under the head end of the guide beam, and the end of the guide beam is provided with a roller mechanism. The mobile trestle can adjust the angle of the guide beam according to the specific conditions of the inverted arch excavation area in front of the tunnel, which is convenient to use and can further improve the construction efficiency; while adjusting the angle, it will not affect the expansion and contraction of the guide beam; the front outrigger When used in conjunction with the rear outriggers in the mobile trestle, the overall lateral position of the main girder in the mobile trestle can be adjusted, which is convenient to use and can further improve construction efficiency.

Owner:HAN JIANG HEAVY IND CO LTD 11TH BUREAU GRP CRCC +1

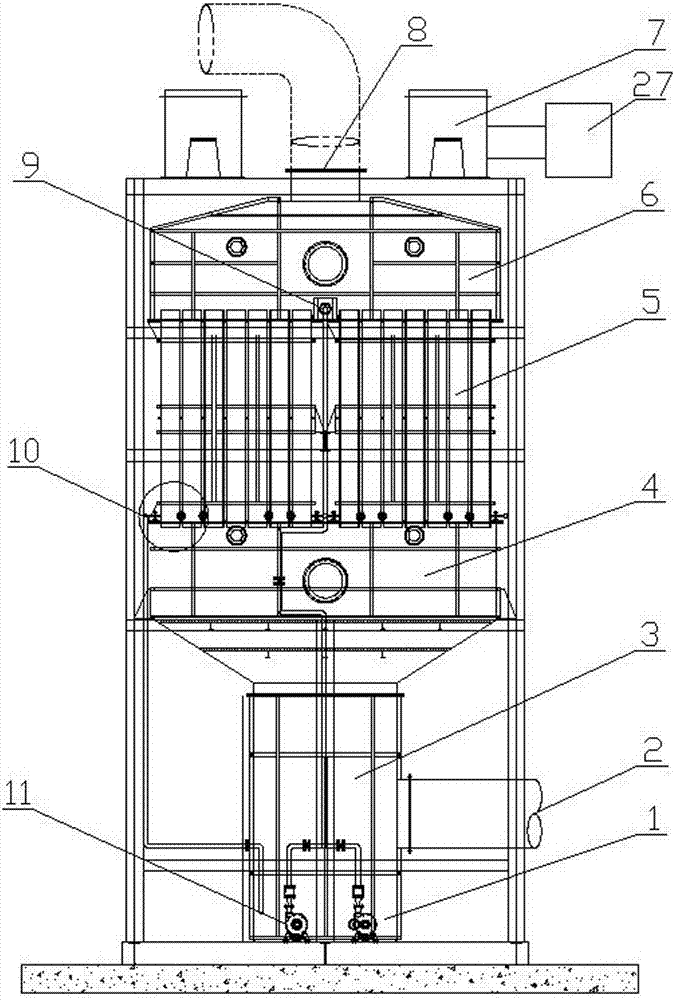

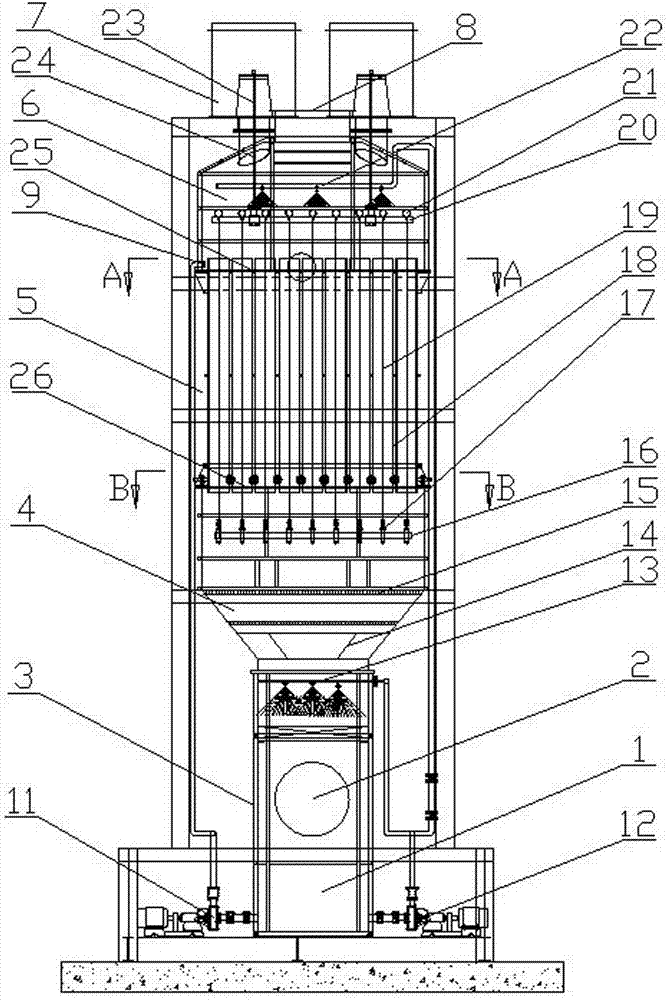

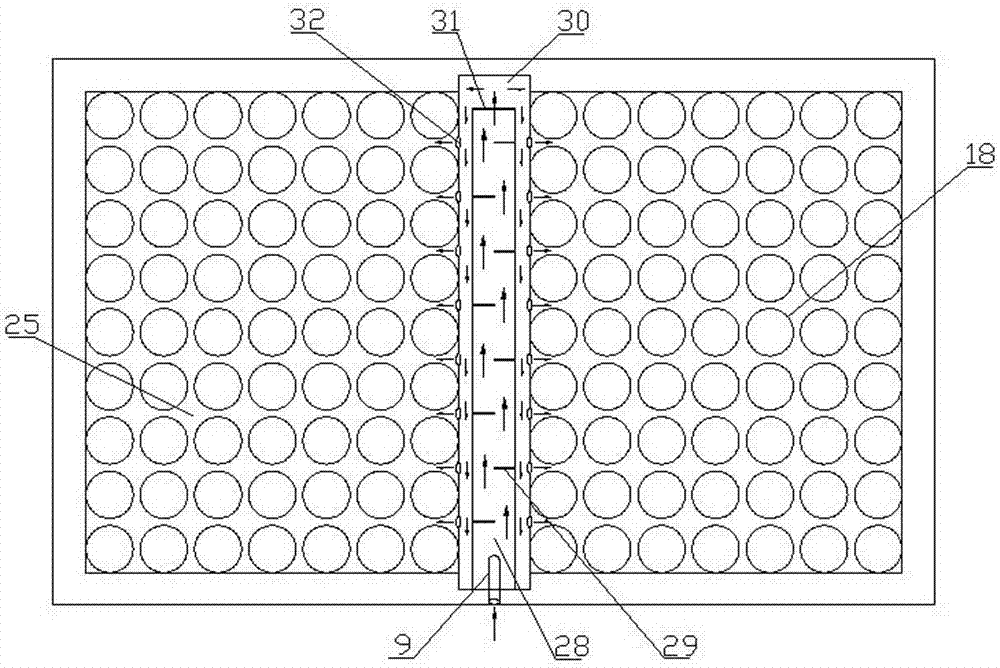

Wet electrostatic precipitator to prevent fouling of anode tubes

ActiveCN105478236BDoes not affect scalingNo foulingExternal electric electrostatic seperatorElectrodes cleaningEngineeringProduct gas

The invention relates to a wet-type electric dust remover capable of preventing anode pipes from scaling. The wet-type electric dust remover comprises a shell. A gas inflow chamber, a gas distribution chamber, an anode chamber and a gas outflow chamber are sequentially arranged in the shell from bottom to top. The gas inflow chamber is provided with a gas inlet. A gas distribution board is arranged in the gas distribution chamber. The anode pipes are evenly distributed in the anode chamber. Cathode lines are suspended in the anode pipes respectively. A gas outlet is formed in the top of the gas outflow chamber. An insulation box is arranged on the shell. The wet-type electric dust remover is characterized in that a liquid collection box is arranged at the bottom of the gas inflow chamber and connected with a first circulating pump and a second circulating pump. A second spray pipe is arranged at the top of the gas inflow chamber and connected with the first circulating pump. An upper water carrying board and a lower water carrying board are arranged in the anode chamber and an overflow pipe is arranged on the upper water carrying board and connected with the second circulating pump. Water collection grooves are formed in the lower ends of the anode pipes and water outlets are formed in the pipe walls of the anode pipes. The shell is provided with water outflow pipes and the water outflow pipes are lower than the water outlets. By the adoption of the wet-type electric dust remover, crystals on the inner walls of the anode pipes can be removed in real time, scale is prevented from being generated, and it is guaranteed that the dust removing efficiency of equipment is not affected.

Owner:JIANGSU XINFUTE ENVIRONMENTAL PROTECTION TECH

An exoskeleton assisted therapy rehabilitation device

ActiveCN111135020BDoes not affect scalingImprove buffering effectWalking aidsTherapy rehabilitationExoskeleton

Owner:郭继相

A safety belt automatic wearing device

ActiveCN109866730BAffect normal useHas a mandatory wearing effectPassive restraint systemsSeat beltControl theory

The invention discloses an automatic safety belt wearing device, comprising a vehicle roof, a seat, a body, a door and a safety belt. A car door is arranged on one side of the car door, and a seat is arranged inside the vehicle body at the position of the car door, and a roll-up opening is arranged on the top of the inner side wall of the car wall on one side of the car door. In the present invention, limiting grooves are arranged on both sides of the bottom of the fixing rod, which are matched with the limiting blocks, and the same end of the top of the limiting block is arranged in an inclined plane. When the fixing rod is lowered to the horizontal position, the limiting The beveled end of the position slot squeezes the limit block to force the limit block and the sliding rod to integrally squeeze the return spring to retract, and the cooperation between the limit groove and the limit block is used when the fixed rod descends to the lowest point, no longer A squeezing force is generated on the limit block, so that the limit block rebounds and locks the fixing rod, which fixes the seat belt, increases the stability of the seat belt, and improves the safety protection effect.

Owner:ANHUI POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com