Resin pouring busbar telescopic joint

A technology of resin casting and expansion joints, applied in the direction of fully enclosed busbar devices, etc., can solve the problems of poor insulation performance and waterproof performance, inability to achieve sealing effect, unreliable expansion and contraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The resin casting busbar expansion joint of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

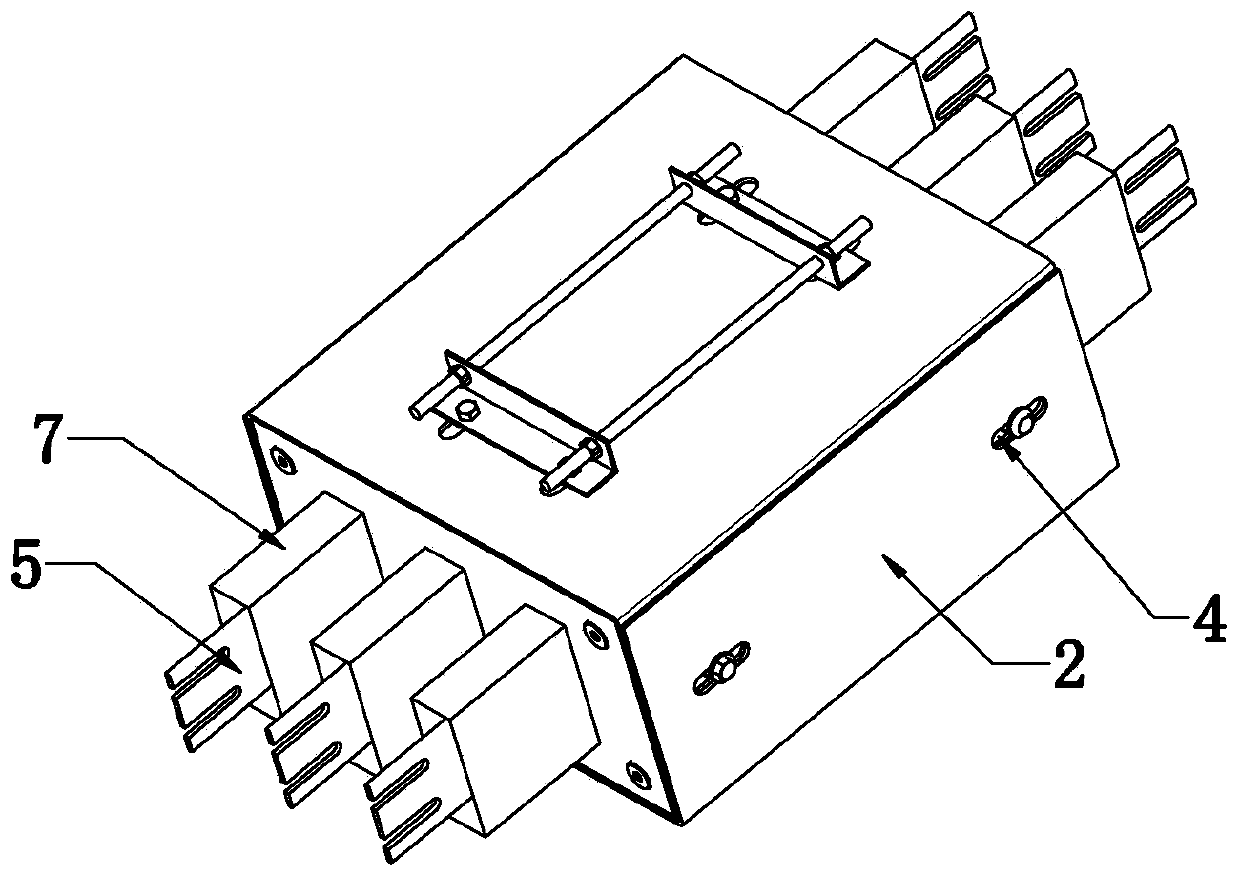

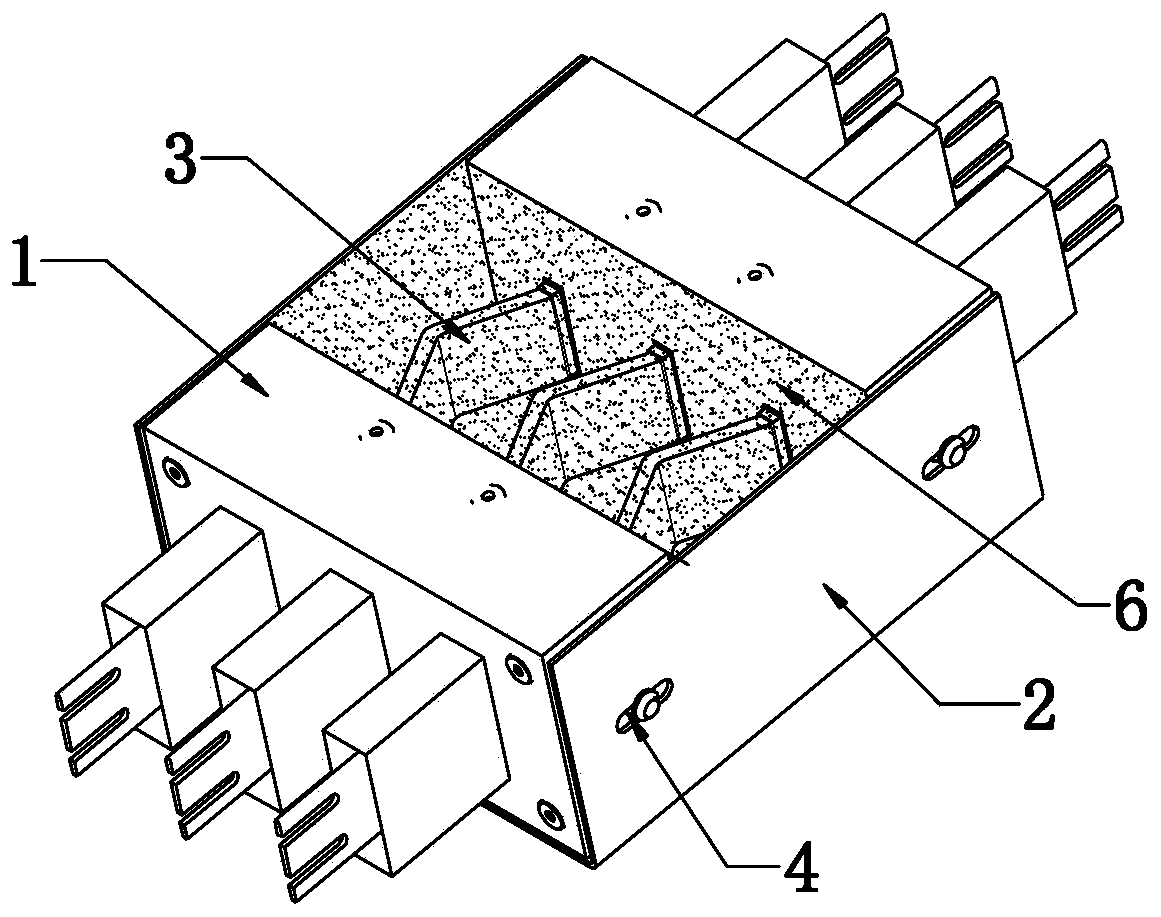

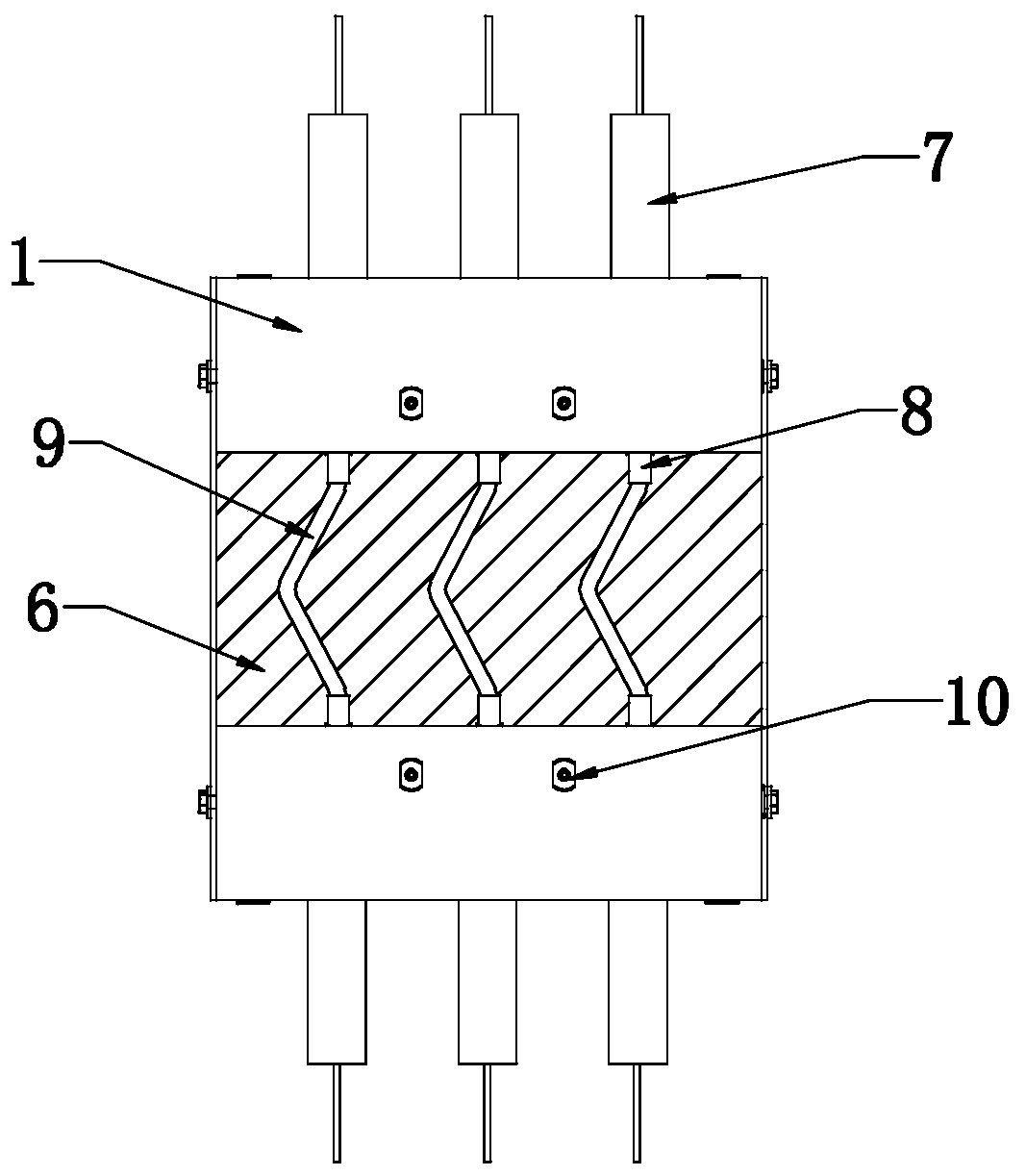

[0018] As shown in the figure, the resin casting busbar expansion joint of the present invention includes two casting bodies 1 arranged at intervals, two movable side plates 2 that can move longitudinally on the left and right sides of the two casting bodies, and two movable side plates 2 arranged in parallel on the two sides of the casting body. The multi-phase conductors 3 with flexible functions between the pouring bodies. The conductors 3 of each phase pass through the two pouring bodies in turn and are solidified with the pouring bodies. The conductors 3 of each phase extend out of the two pouring bodies 1 respectively to form a connection Terminal 5, each phase conductor 3 is set as a stretchable soft connection (conductor flexible area) between the two sections of cast body, the soft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com