Expansion joint device with sinkage preventing function of non-motor vehicle

A technology of non-motor vehicles and expansion joints, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of reducing the service life of expansion devices, affecting driving safety, and hidden dangers of bridge safety, and achieves easy disassembly and maintenance, firm installation structure, and easy use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

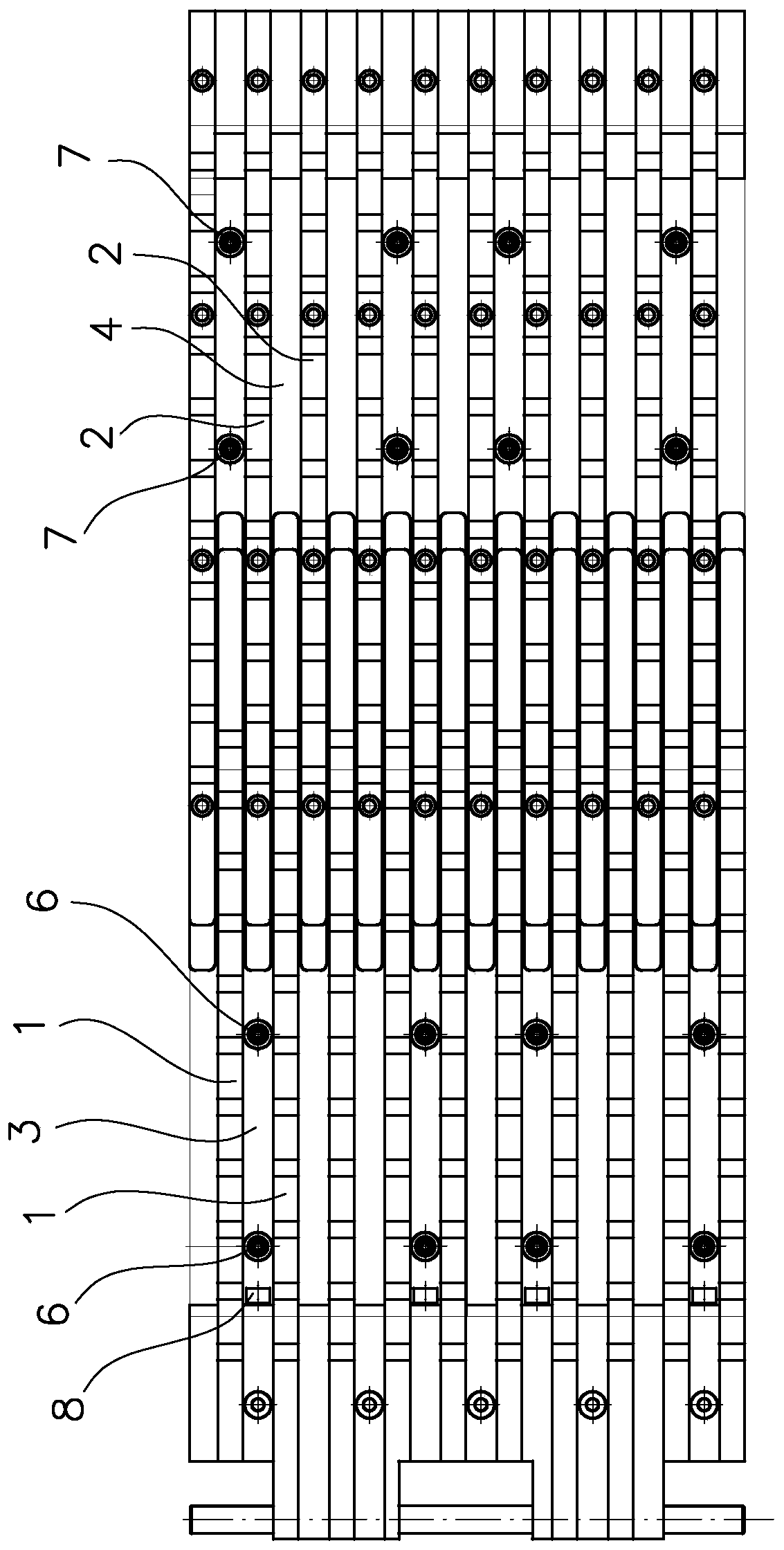

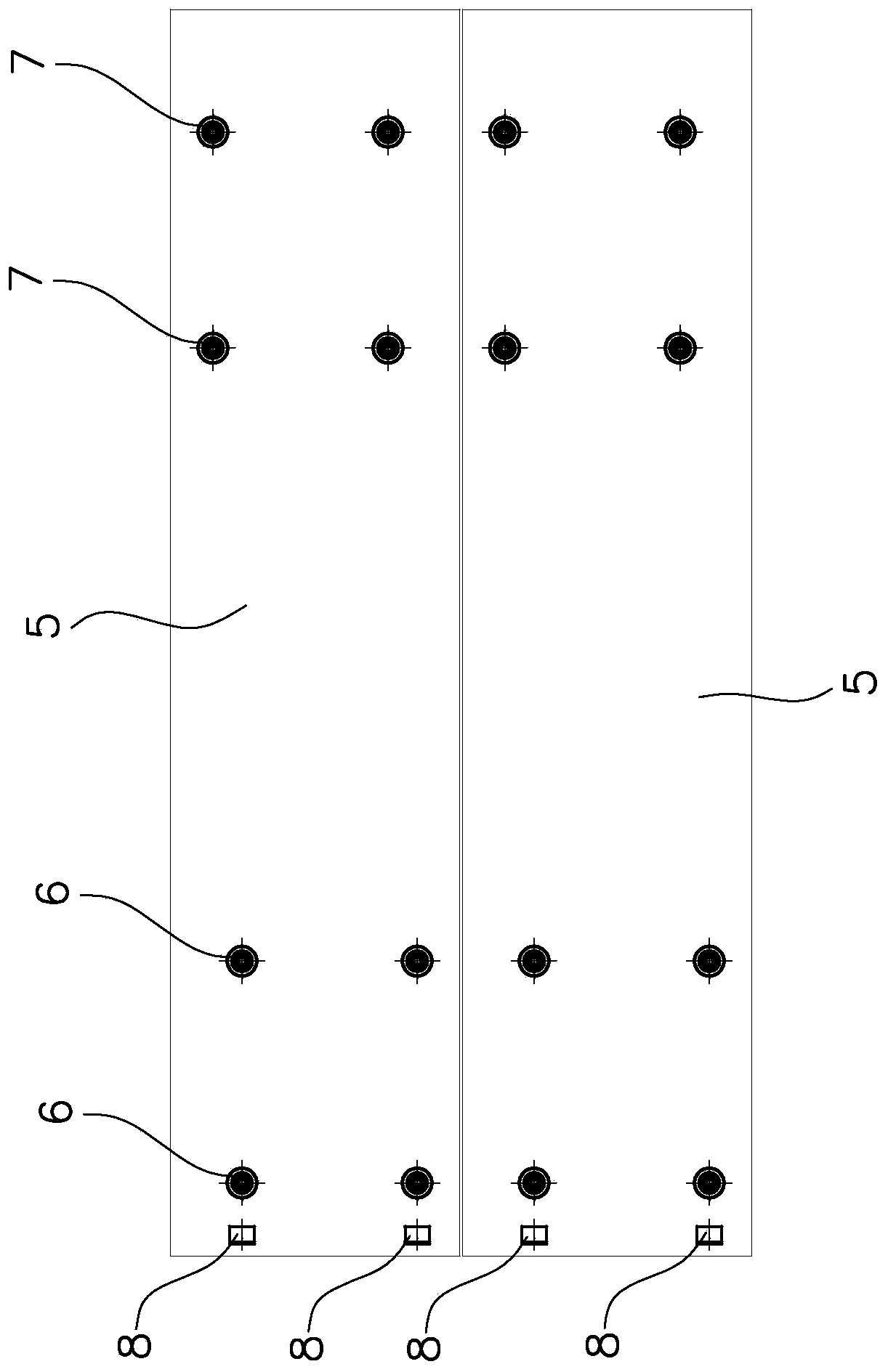

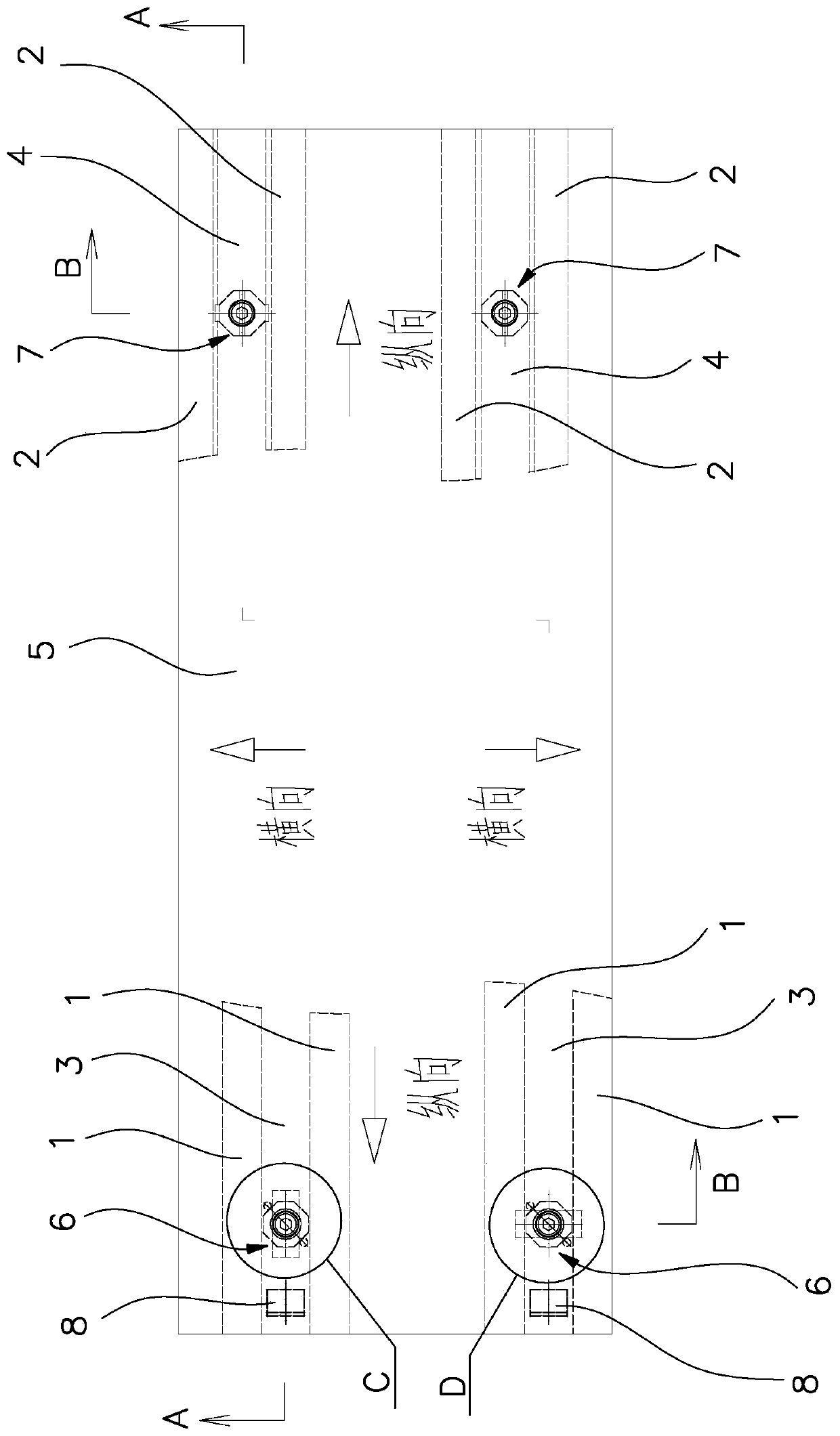

[0030] Such as Figure 1 to Figure 14 As shown, the expansion joint device with anti-sagging function for non-motor vehicles of this embodiment includes a first comb-tooth plate 1 and a second comb-tooth plate 2 that are staggered and can be relatively telescopic. Among them, the first comb-tooth plate 1 It is a cross seam plate, and the second comb-tooth plate 2 is a fixed plate. A first comb tooth gap 3 is formed between the comb teeth of the first comb tooth plate 1, and a second comb tooth gap 4 is formed between each comb tooth of the second comb tooth plate 1. The above-mentioned structure is the same as the existing expansion joint device, and the description will not be expanded here. Of course, it is also possible to adopt a structure in which the first comb-tooth plate 1 is a fixed plate, and the second comb-tooth plate 2 is a cross seam plate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com