Plate enhanced telescopic truss arm structure

A truss structure and reinforcing structure technology, applied in the direction of cranes, etc., can solve the problems of heavy cranes, inability to expand and contract, difficult and cumbersome installation of cranes, etc., and achieve the effects of lowering the work center of gravity, reducing the self-weight, and strengthening the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

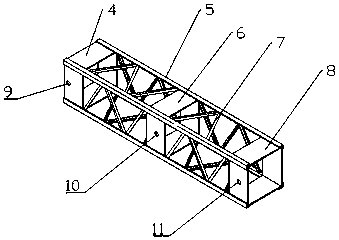

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the invention in a schematic manner, and therefore only show the configurations related to the present invention.

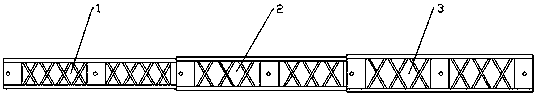

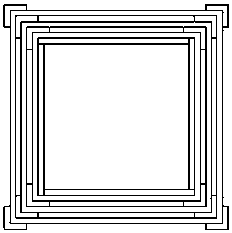

[0027] As shown in the figure, the present invention is a plate-reinforced telescopic lattice boom structure, which can be used for the topmost sections of telescopic booms of all-terrain cranes, as well as the jib of all-terrain cranes and crawler cranes. Taking the first section of the telescopic boom 1 as an example, the structure of the crane telescopic boom structure reinforced with a truss structure is as follows: the peripheral structure is a truss rod 5, and a reinforcing plate 4, a middle reinforcing plate 6 and The top reinforcing plate 8 is welded with the web 7 in the rest, and the pin hole 9 is set at the 0 position of the truss corresponding to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com