Quick-dismountable unmanned aerial vehicle propeller fixing mechanism

A technology for fixing a mechanism and a propeller, which is applied to propellers, motor vehicles, aircraft parts, etc., can solve the problems of inconvenient disassembly and assembly of the propeller of drones, and achieve the effects of simple structure, convenient operation and corrosion prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

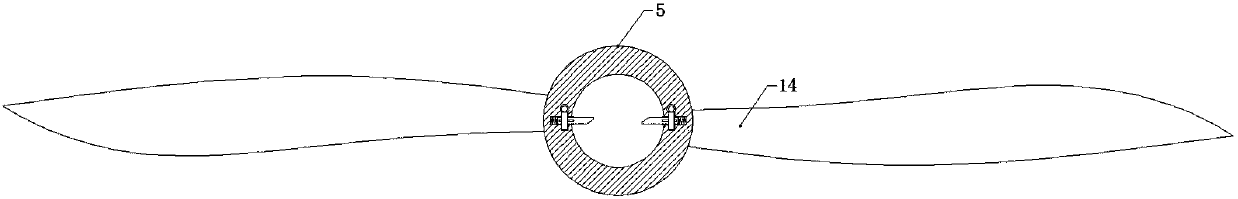

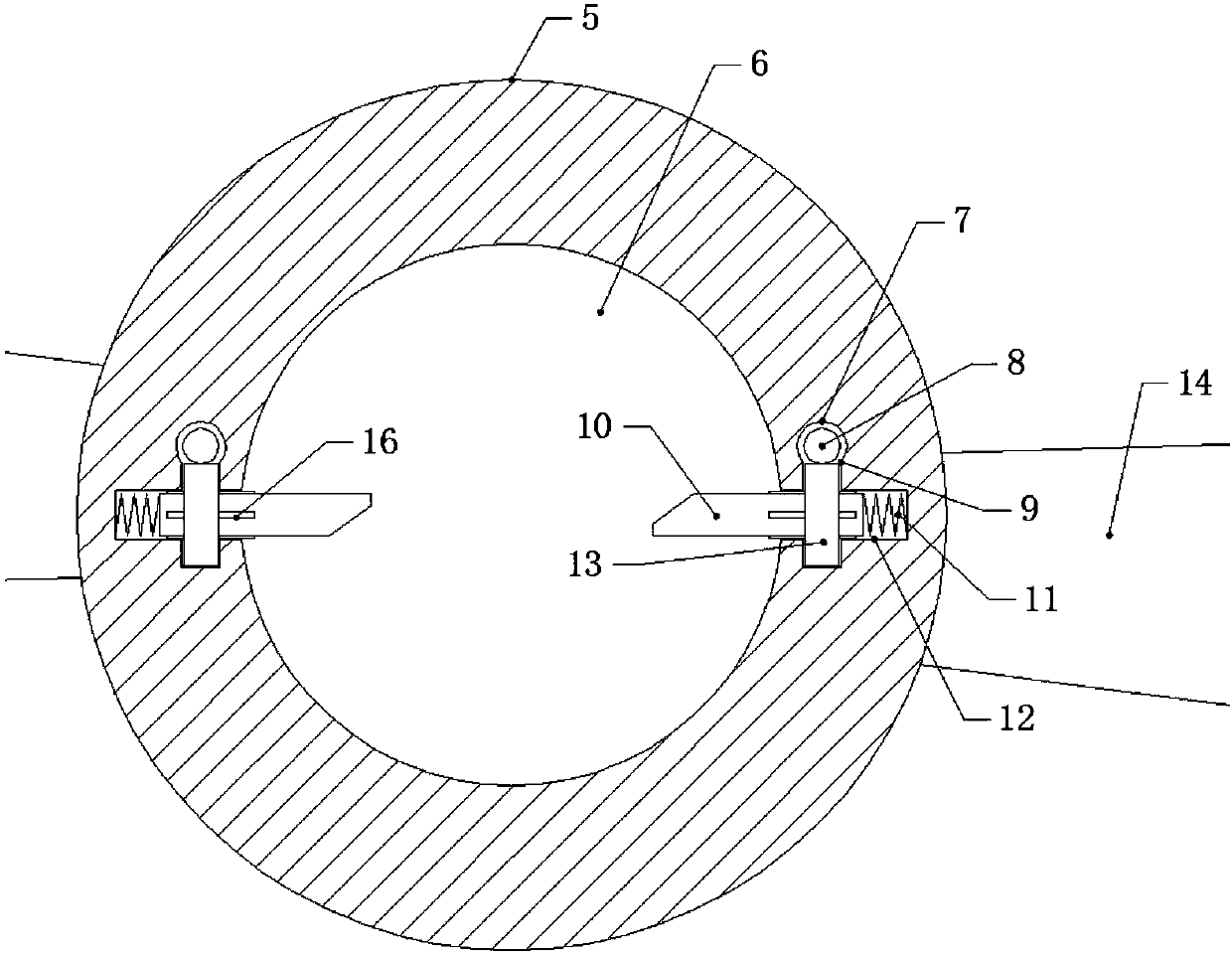

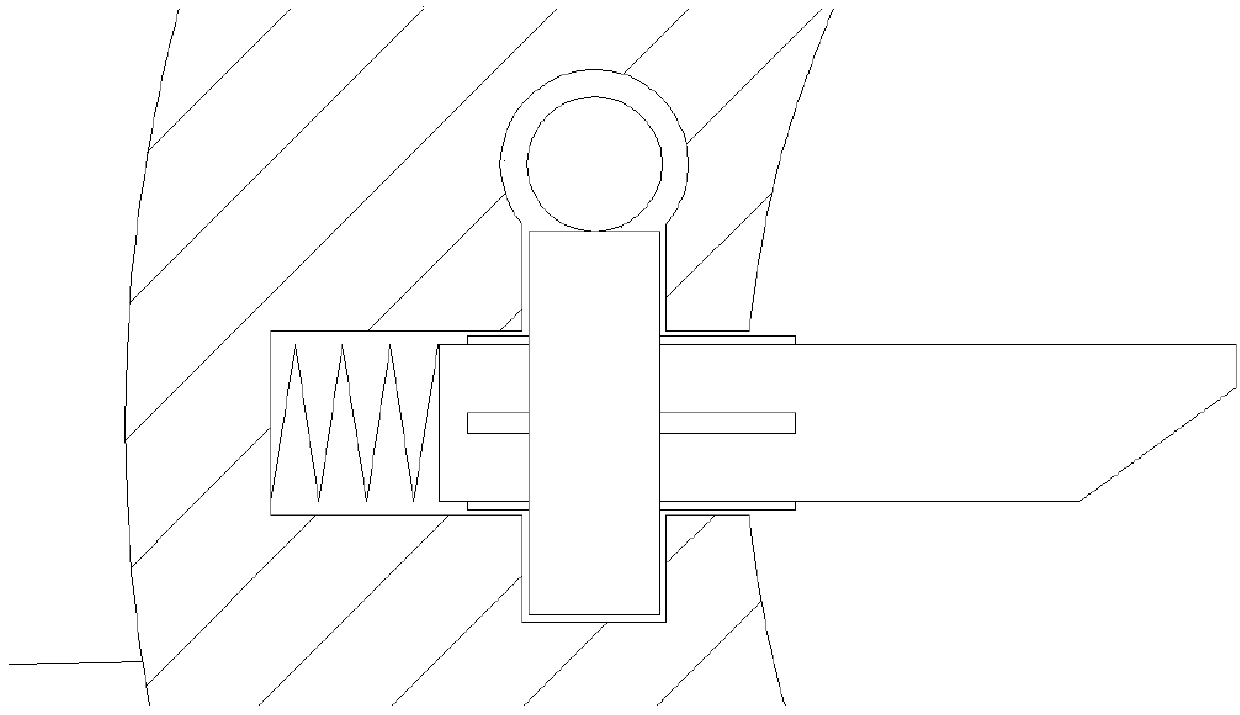

[0027] A quick-detachable UAV propeller fixing mechanism, including the propeller and the rotating shaft 1 arranged on the UAV, is characterized in that: the rotating shaft 1 is symmetrically arranged on the circumference of the rotating shaft. The ends of the chute 2 are respectively connected with a spiral chute 3, and the end of the spiral chute 3 is provided with a limit hole 4, the depth of the limit hole 4 is greater than the depth of the spiral chute 3, and the propeller includes a shaft sleeve 5 and two sides of the shaft sleeve 5. The blades 14 are symmetrically arranged, the center of the shaft sleeve 5 is a shaft hole, and the inner wall of the shaft hole 6 is horizontally and radially provided with two symmetrical fixing holes 12, and the end surface of the shaft sleeve 5 is symmetrically provided with locking holes 7 on both sides of the shaft hole 6, A cylindrical fixed block 10 is arranged in the fixed hole 12, and the end of the fixed block 10 is provided with a...

Embodiment 2

[0032] This embodiment is improved on the basis of Embodiment 1:

[0033] Splines 16 are arranged on the outer wall of the fixed block 10 , and the worm wheel 13 can slide relatively on the fixed block 10 along the splines 16 .

[0034] The advantage of the above improvements is that the spline can drive the fixed block to rotate through the rotation of the worm wheel, and at the same time can make the worm wheel slide on the surface of the fixed block, so as not to affect the expansion and contraction of the fixed block in the fixed hole.

Embodiment 3

[0036] This embodiment is improved on the basis of the above embodiments:

[0037] The top of the worm 8 is provided with a rotary handle 18, and the shaft sleeve 5 is provided with an openable and closable protective cover 17 on the side end face provided with the locking hole 7.

[0038] The advantages of the above improvements are that the protective cover can protect the fixing device on the shaft sleeve during the flight of the UAV, prevent foreign matter from entering the device and affect the normal function of the device, and also prevent the device from being corroded by water ingress in rainy days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com