Section structure for car side sill

A threshold and cross-section technology, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of low strength, increased cost and weight, etc., and achieve the effect of reducing deformation, reducing intrusion, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

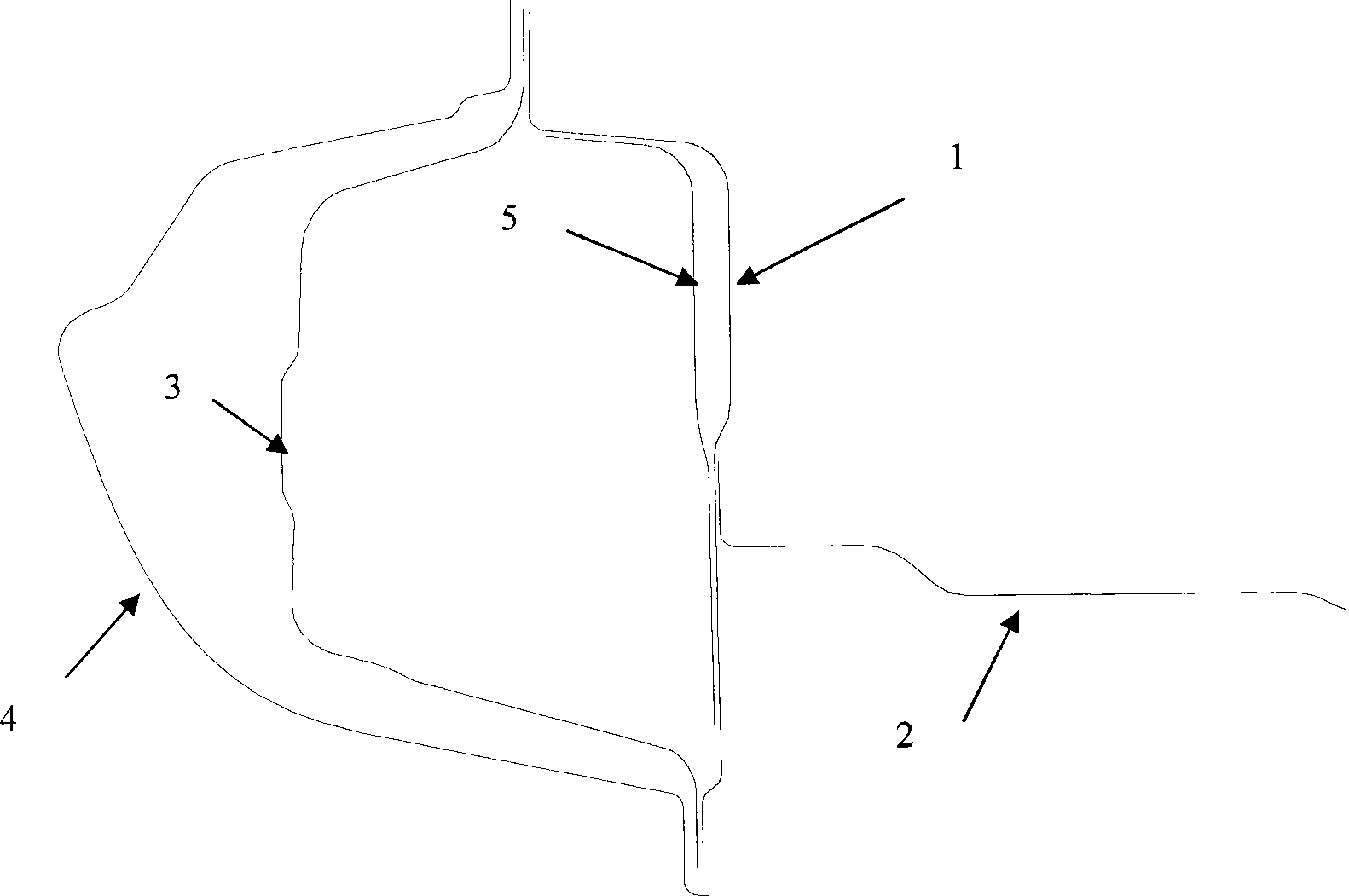

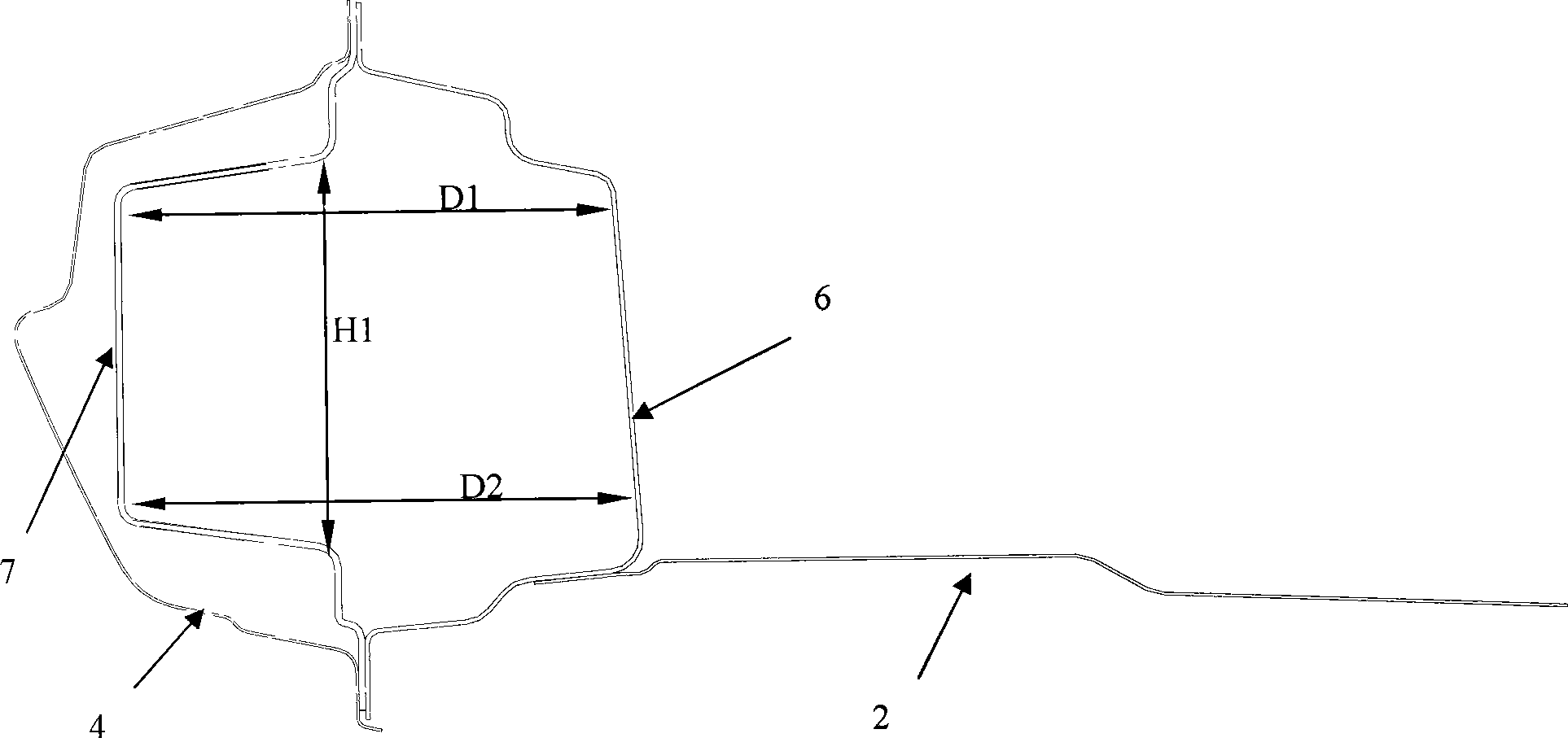

[0010] see figure 1 , the side sill reinforcement 7 of the U-shaped section and the side outer skin 4 are welded to form a part of the side wall welding assembly, and the front sill inner panel 6 of the U-shaped section and the floor 2 are welded to form the lower body welding assembly. part of it. The side wall welding assembly and the lower vehicle body welding assembly form the door sill section cavity by butt-welding the front door sill inner panel 6 of the U-shaped section and the side wall door sill reinforcement 7 of the U-shaped section.

[0011] The width dimension D1 of the upper end of the threshold section cavity is 134 mm, the width dimension D2 of the lower end of the threshold section cavity is 140 mm, and the height dimension H1 of the threshold section section is 110 mm.

[0012] See the table below for the selection of materials for threshold cavity parts:

[0013]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com