Patents

Literature

40results about How to "Strong deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

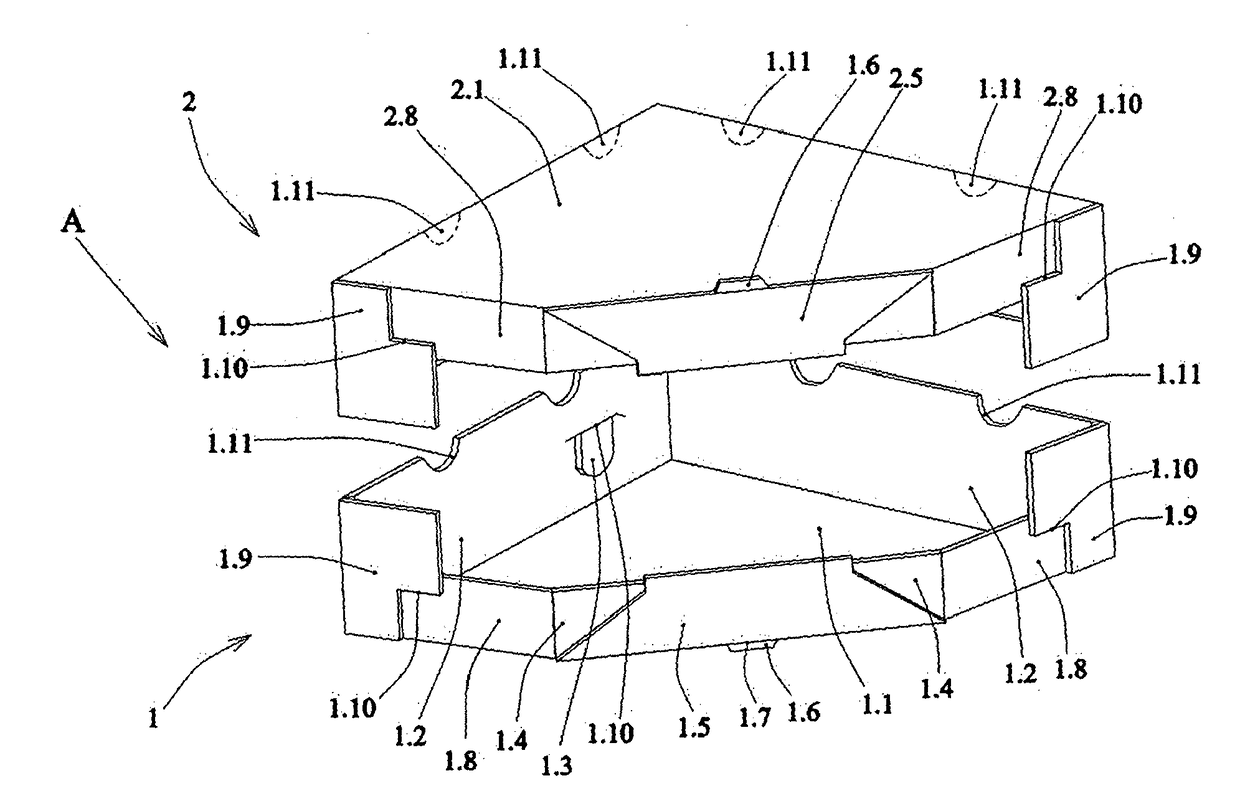

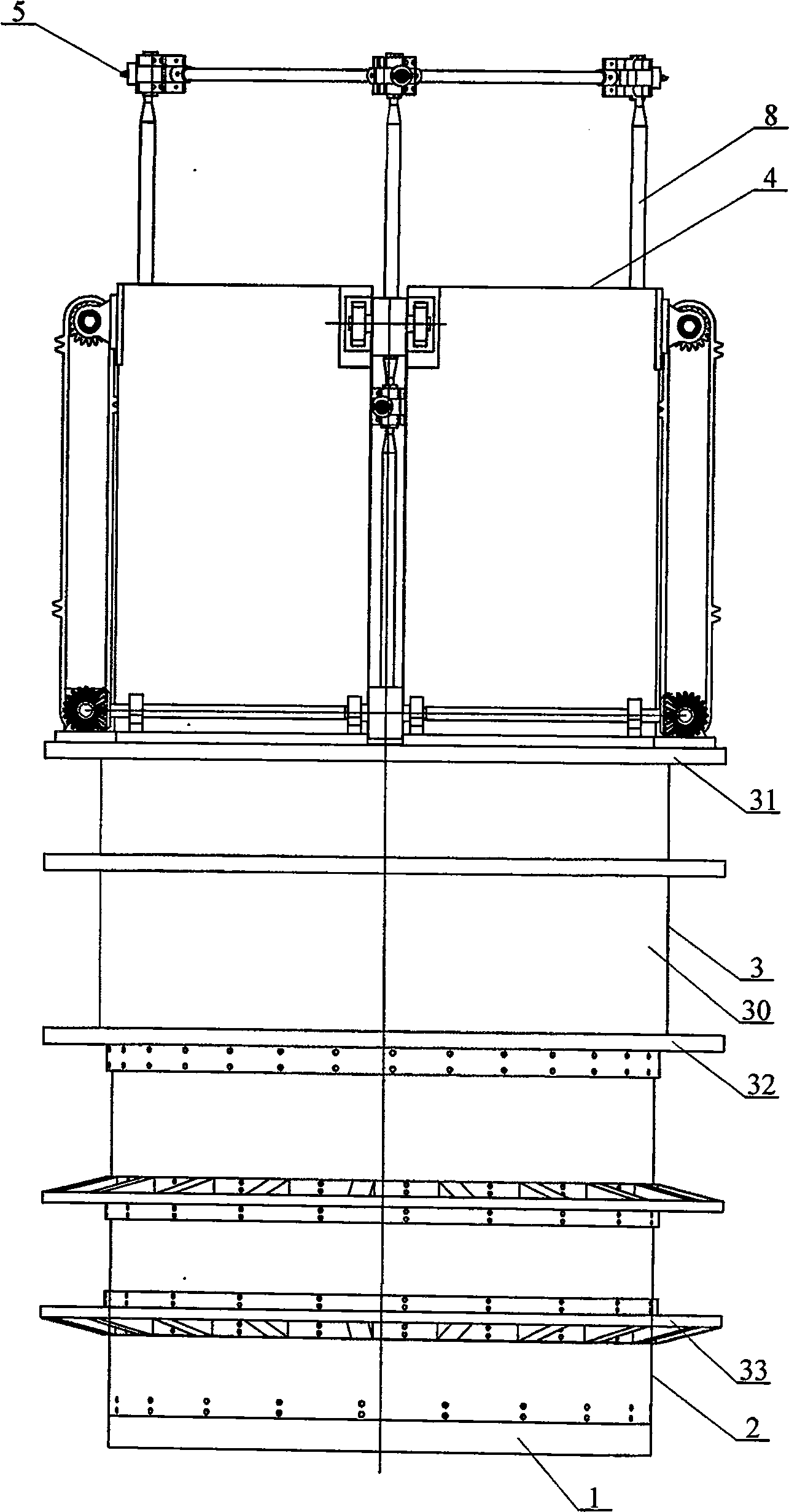

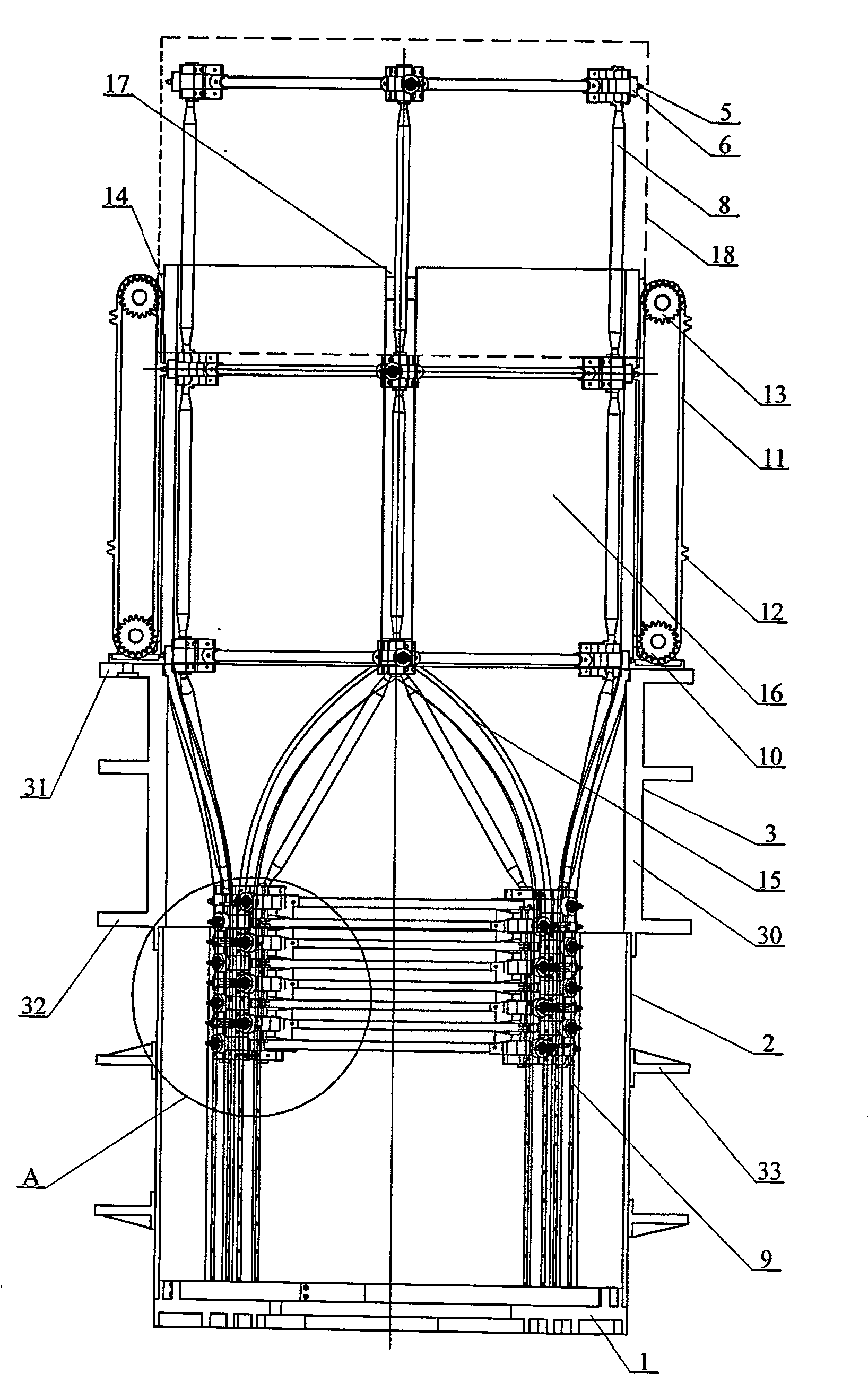

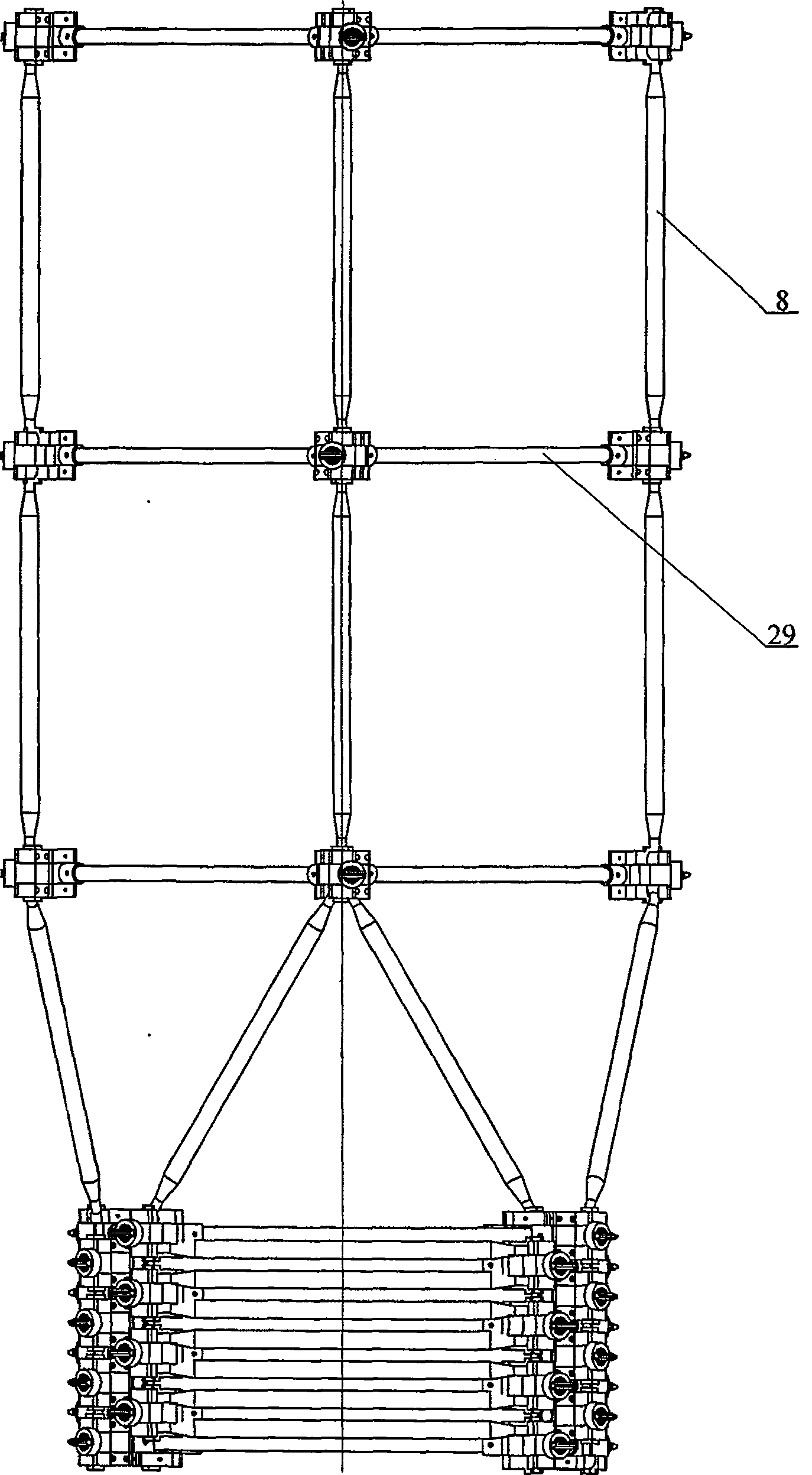

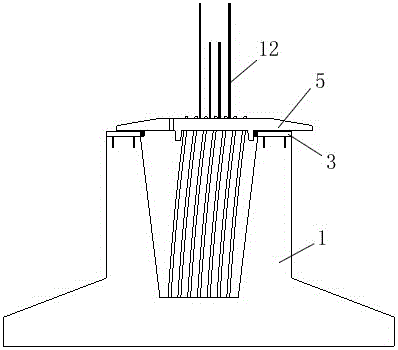

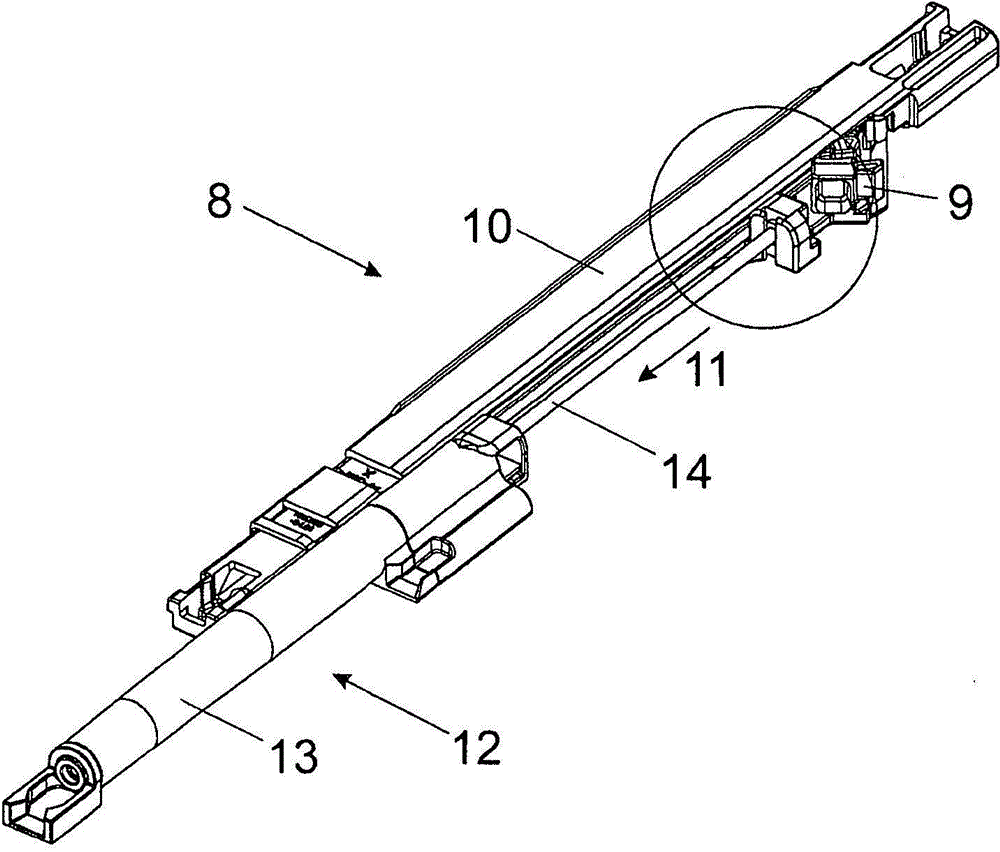

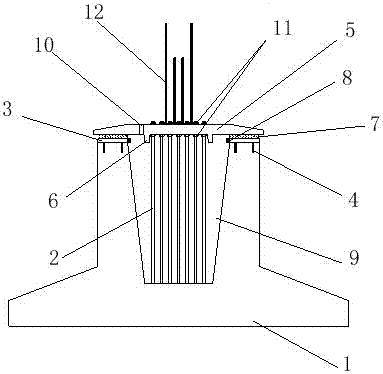

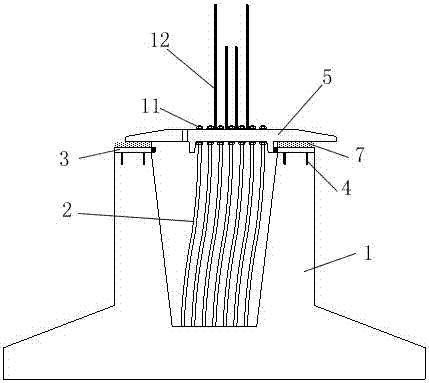

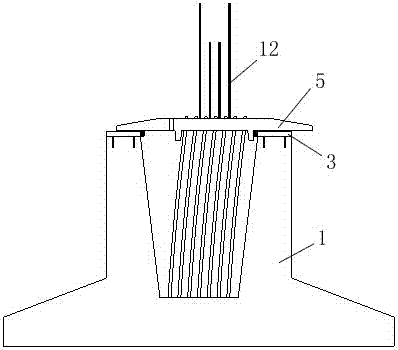

Large rod-cable extending arm extension driving mechanism

InactiveCN101289118ASimple structureStrong deformationCosmonautic vehiclesCosmonautic partsEngineeringSprocket

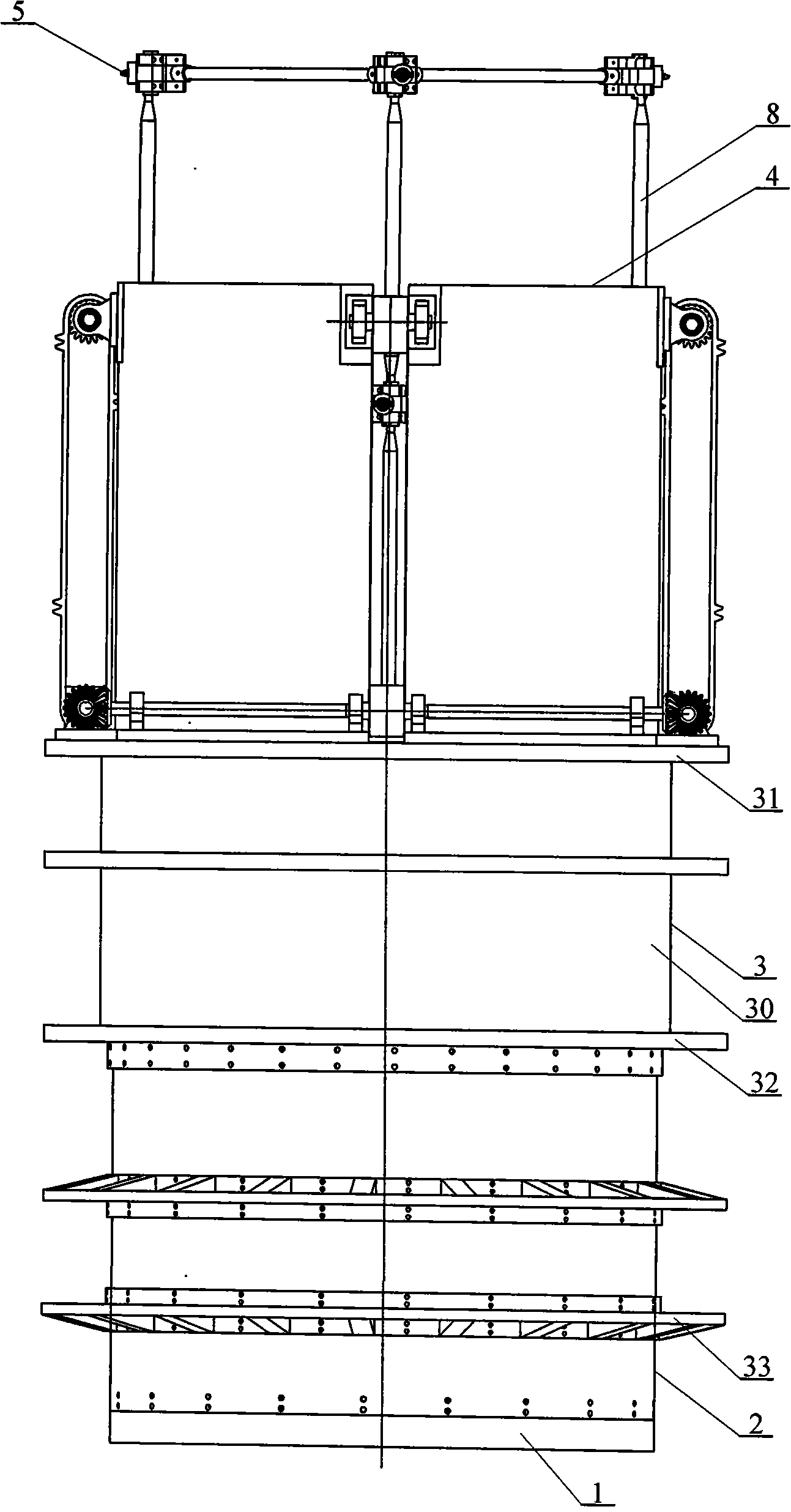

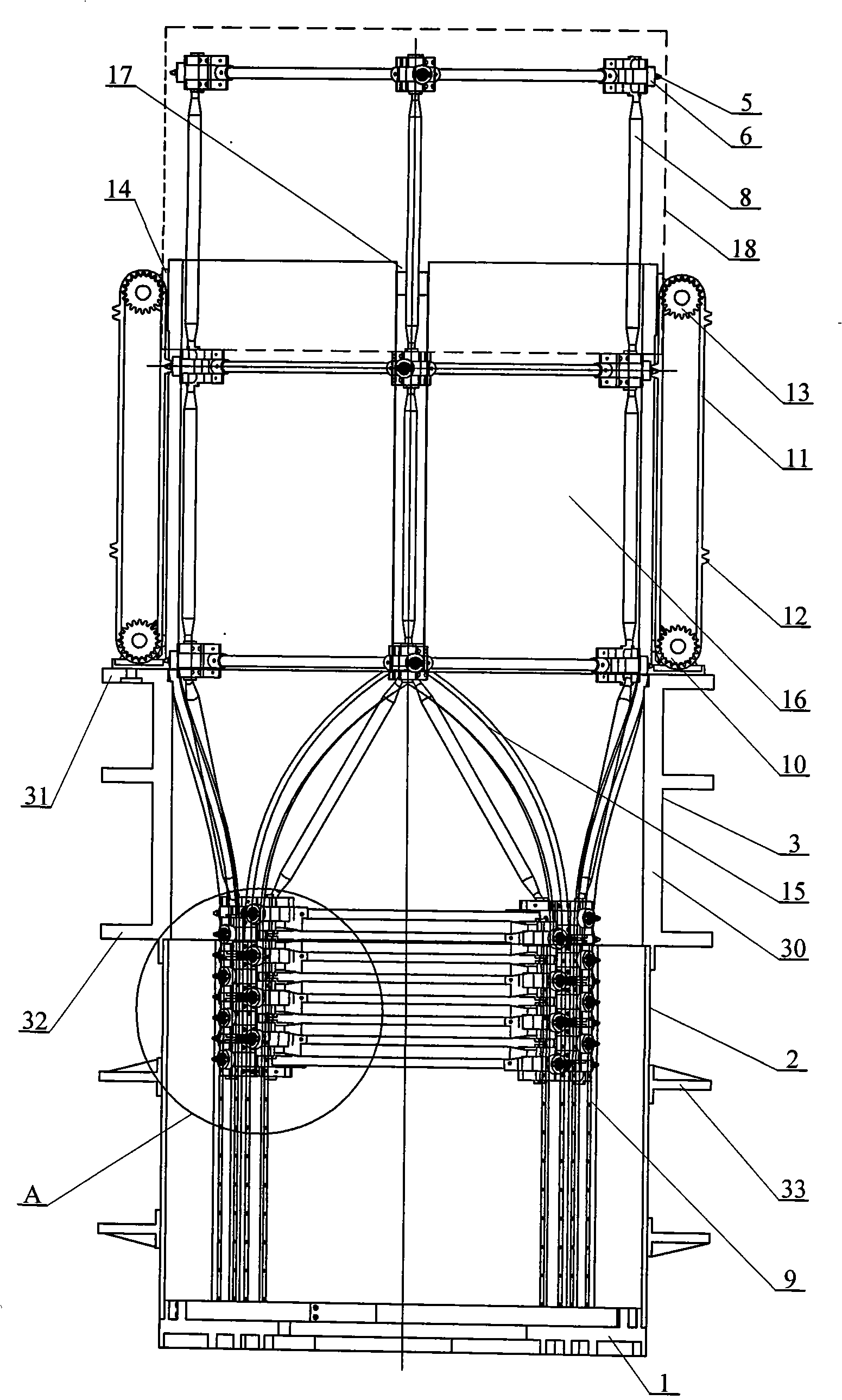

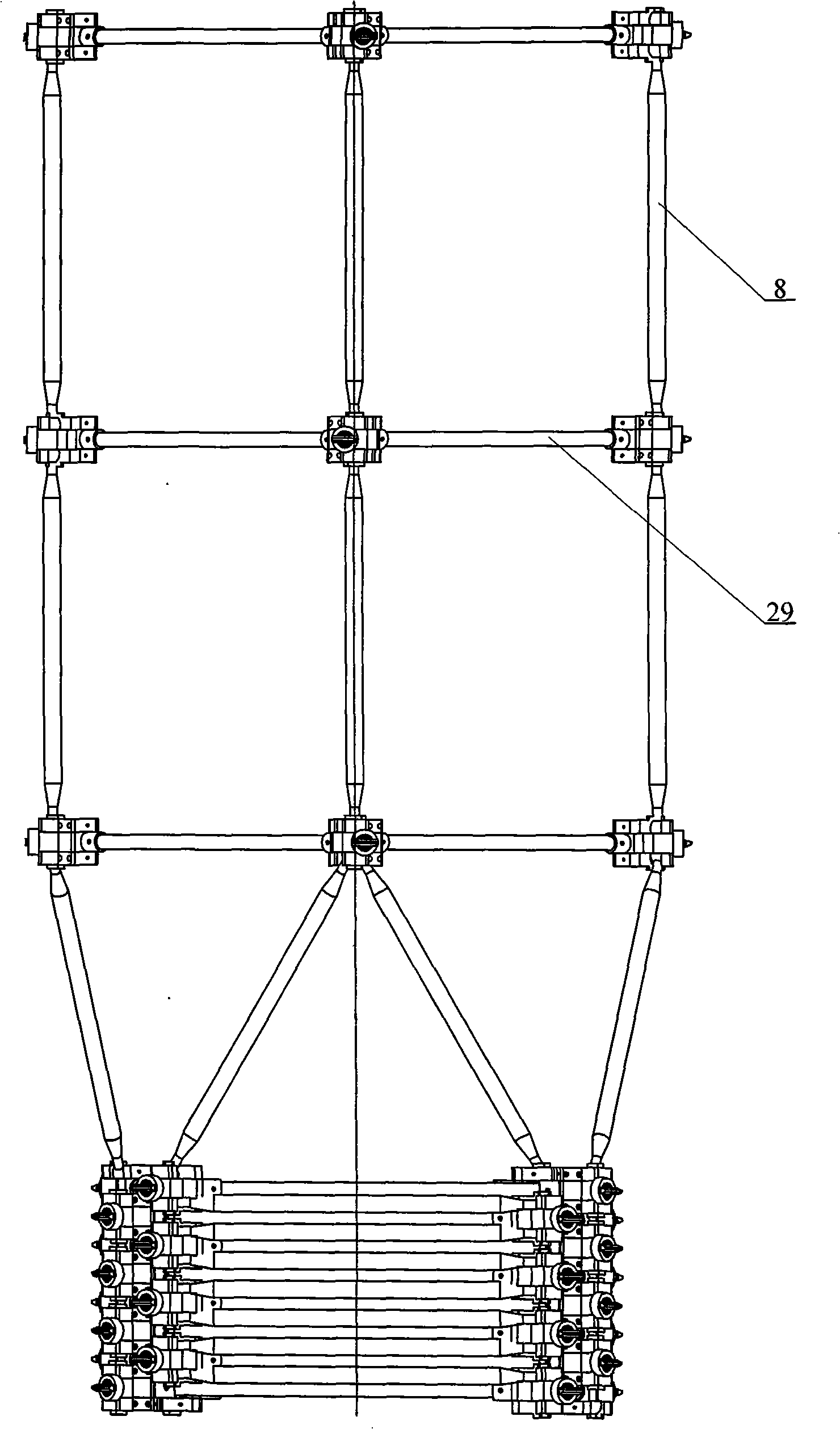

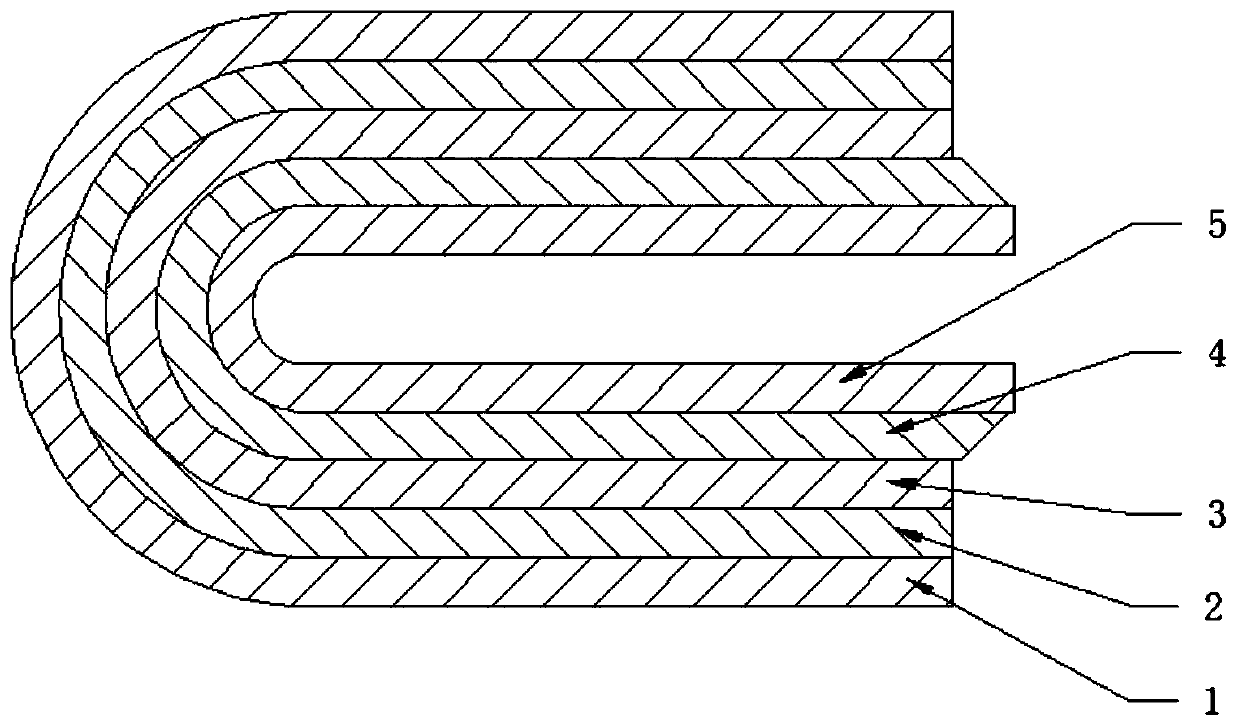

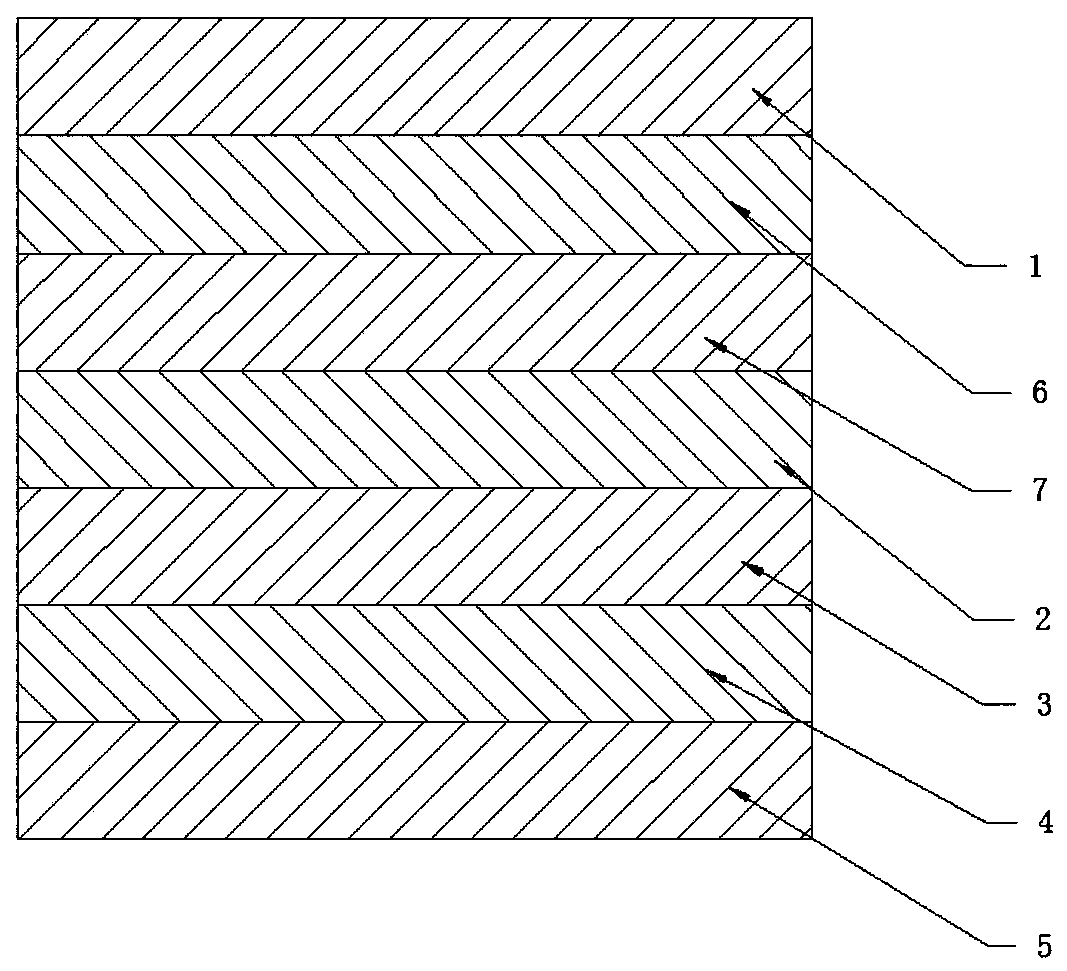

A space deployment and drive mechanism of a large-sized rod-cable type deployable arm is provided by the invention, and the mechanism relates to the space deployment and drive mechanism of the rod-cable type deployable arm. The space deployment and drive mechanism of the invention can solve the problems that the existing large-sized rod-cable type deployable arm adopts a four-thread screw lift telescopic mechanism for driving, thus requiring high manufacturing accuracy and manufacturing process and causing that the deployable arm is easy to be blocked. A bottom end cover (1), a furl sleeve (2), a racemization sleeve (3) and a drive sleeve (4) are fixedly connected together. The inner wall of the racemization sleeve (3) is provided with an eight-curve groove (15) and the inner wall of the furl sleeve (2) is fixedly provided with eight rectilinear orbits (9). A drive sprocket (10) and a driven sprocket (13) which are driven by chains (11) are fixedly connected with the drive sleeve (4). Three chain tooth slices (12) are equally spaced and arranged on each chain. Each vertex angle of the rod-cable type deployable arm component is fixedly provided with a roller wheel (6) which is embedded with a deployable arm tooth slice (5). The chain tooth slice (12) is meshed with the deployable arm tooth slice (5) and the drive sprocket (10) is connected by a reverse driving mechanism. The space deployment and drive mechanism of the invention has the advantage of the strong acceptance capacity of the deformation of the deployable arm and mismachining tolerance.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

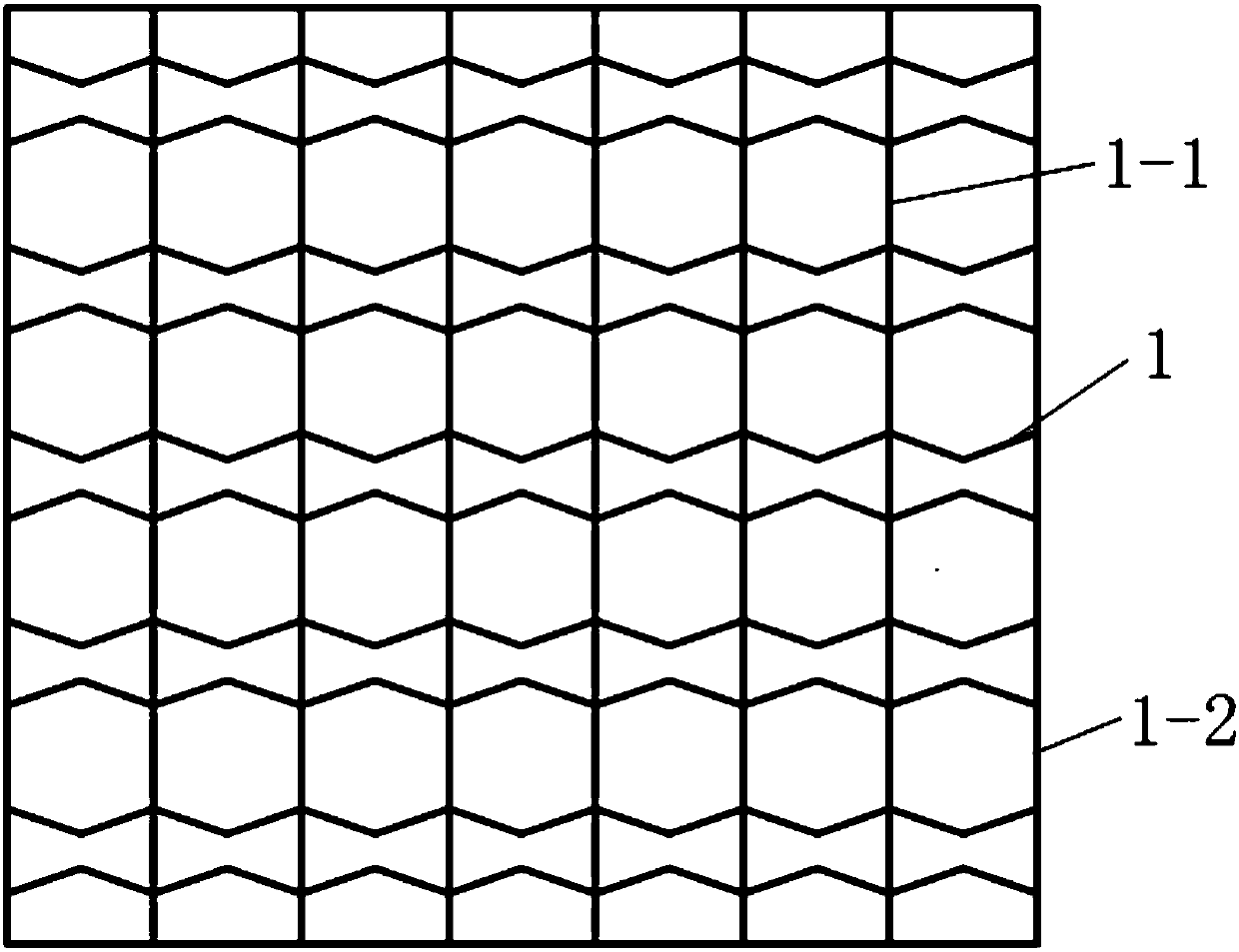

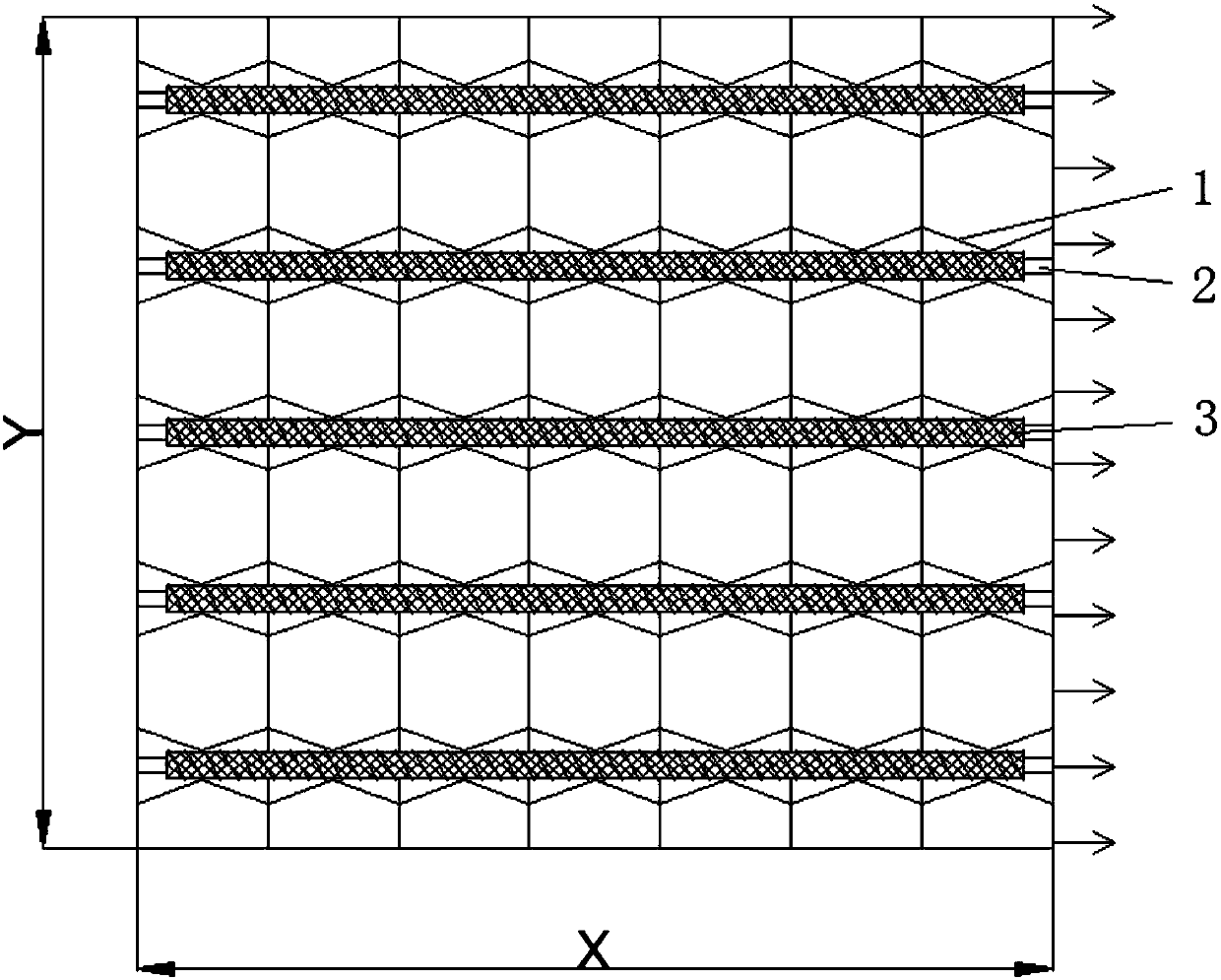

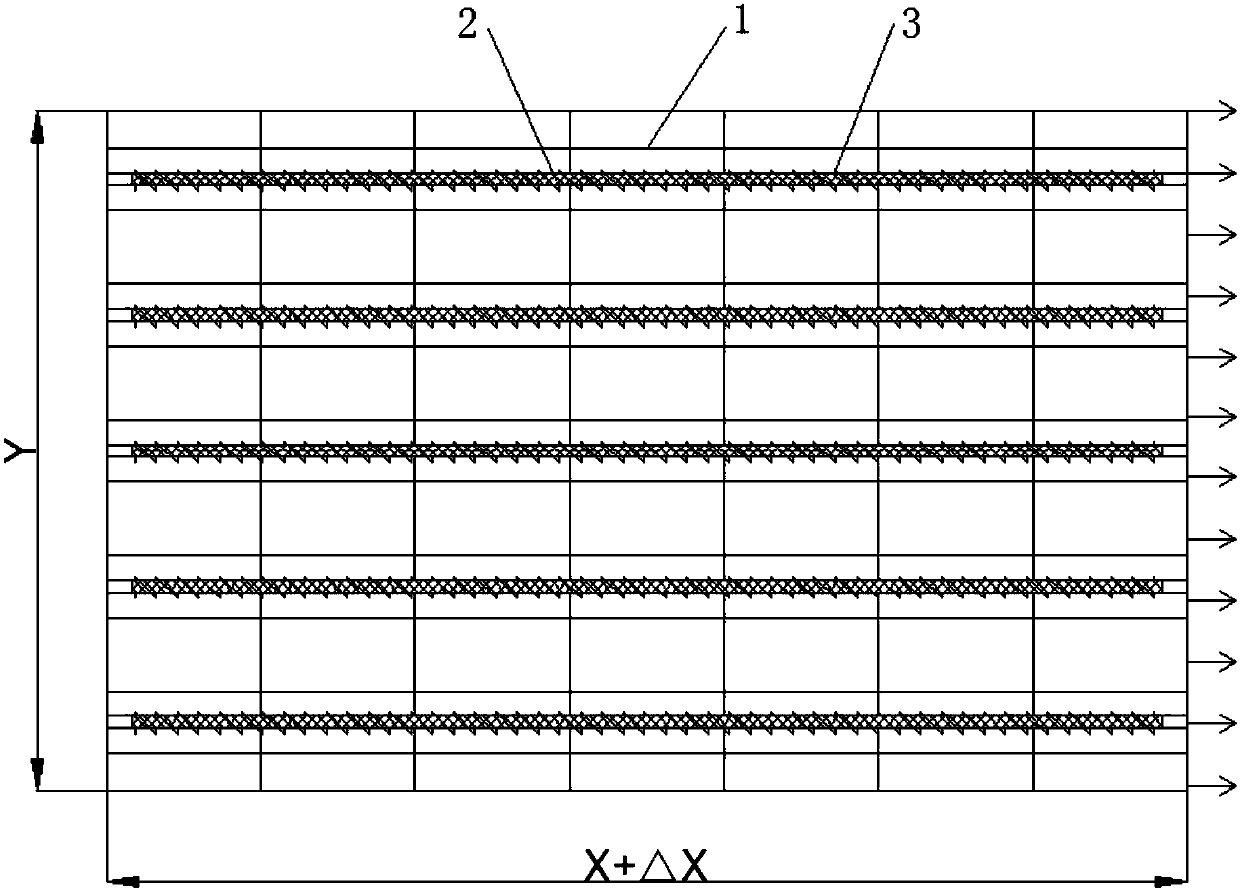

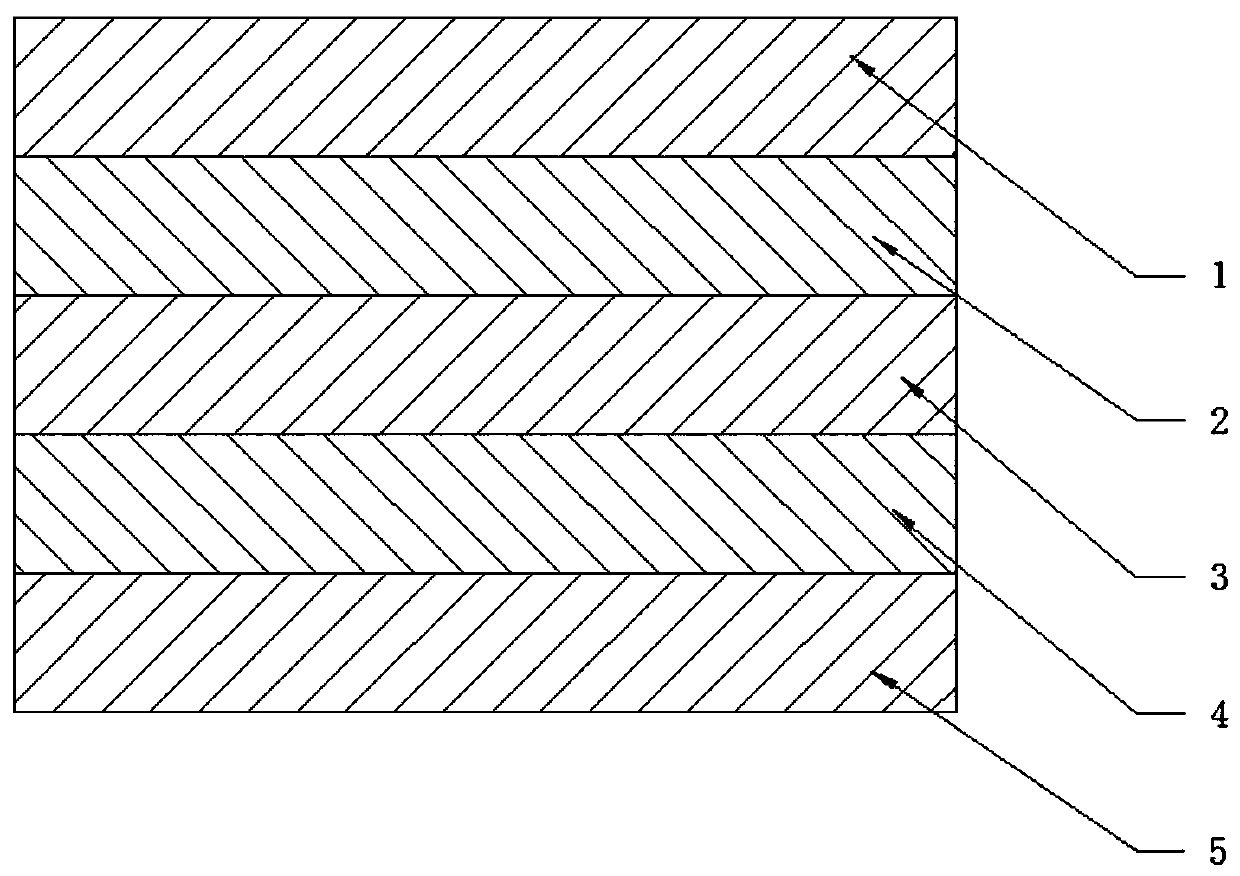

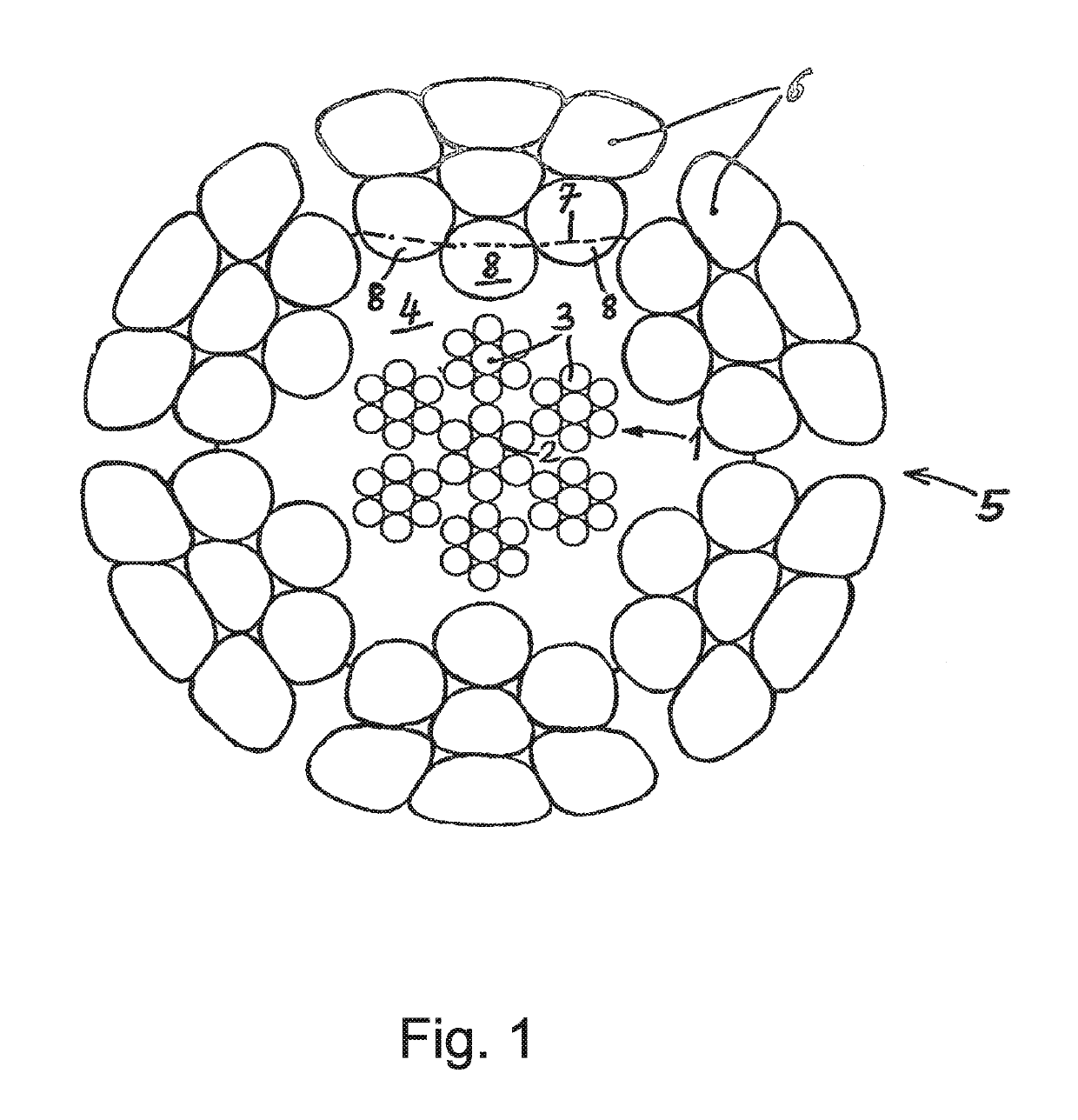

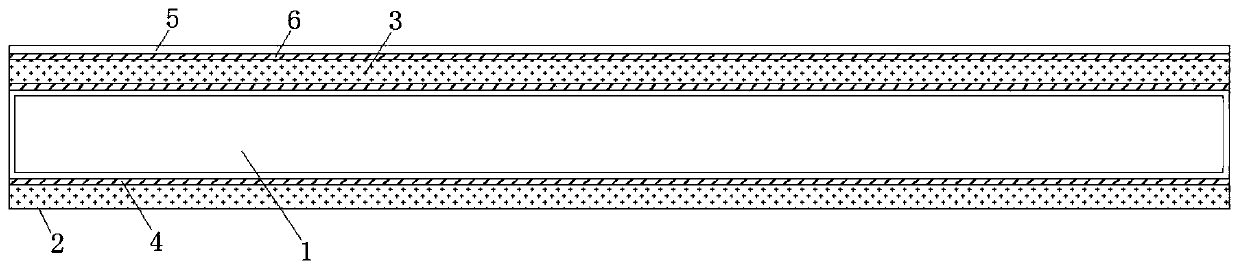

Active deformation honeycomb structure skin based on pneumatic muscle

The invention discloses active deformation honeycomb structure skin based on a pneumatic muscle, belongs to the field of deformation aircrafts, and aims to solve the problem of poor deformation performance of the conventional skin structure. The active deformation honeycomb structure skin based on the pneumatic muscle comprises a silicon rubber material, the pneumatic muscle, a spring and a zero-Poisson-ratio honeycomb structure, wherein the outer surface of the pneumatic muscle is sleeved with the spring; the pneumatic muscle sleeved with the spring is inserted into the zero-Poisson-ratio honeycomb structure; the pneumatic muscle passes through a rib piece of each honeycomb unit in the zero-Poisson-ratio honeycomb structure; two ends of pneumatic muscle are fixedly arranged on boundary rib pieces of the zero-Poisson-ratio honeycomb structure respectively; the silicon rubber material is attached to the surface of the zero-Poisson-ratio honeycomb structure to serve as a skin material. The active deformation honeycomb structure skin based on the pneumatic muscle disclosed by the invention has the advantages of high carrying capability along a vertical direction, large deformation being up to 30 to 40 percent in a deformation direction, coordinated deformation of a honeycomb and the pneumatic muscle, and easiness in control.

Owner:苏州因诺威汽车科技有限公司

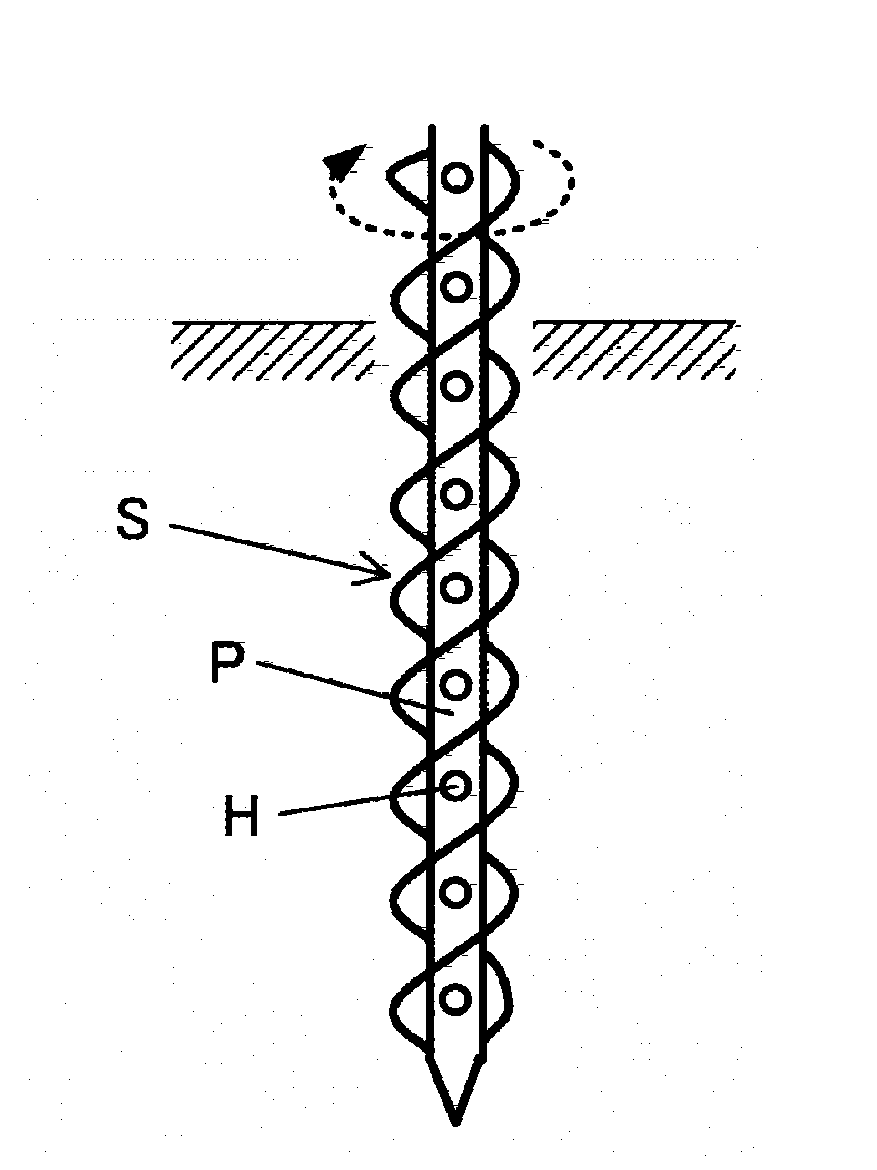

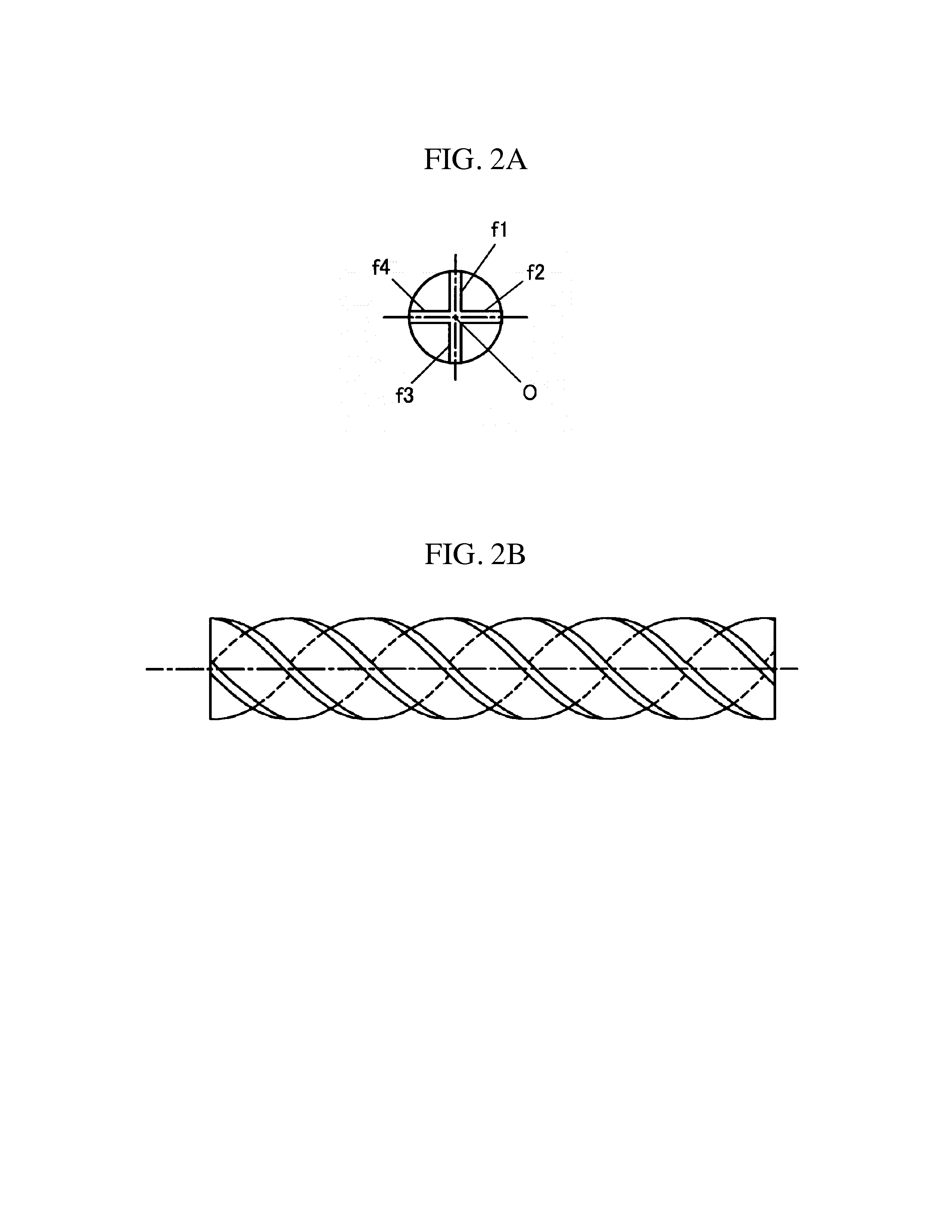

Spiral steel, application product of same, and method for manufacturing spiral steel

InactiveUS20130175017A1Increase mechanical strengthMake smallDrill bitsRotary stirring mixersEngineeringSpiral blade

A purpose of the invention is to provide a spiral piece of steel having high mechanical strength and being capable of easily making smaller the pitch intervals of twisted portions (spiral blade portions) even without changing the twist angle, and also to provide an application product thereof and a method for manufacturing the spiral piece of steel.

Owner:GOTO TSUNEO

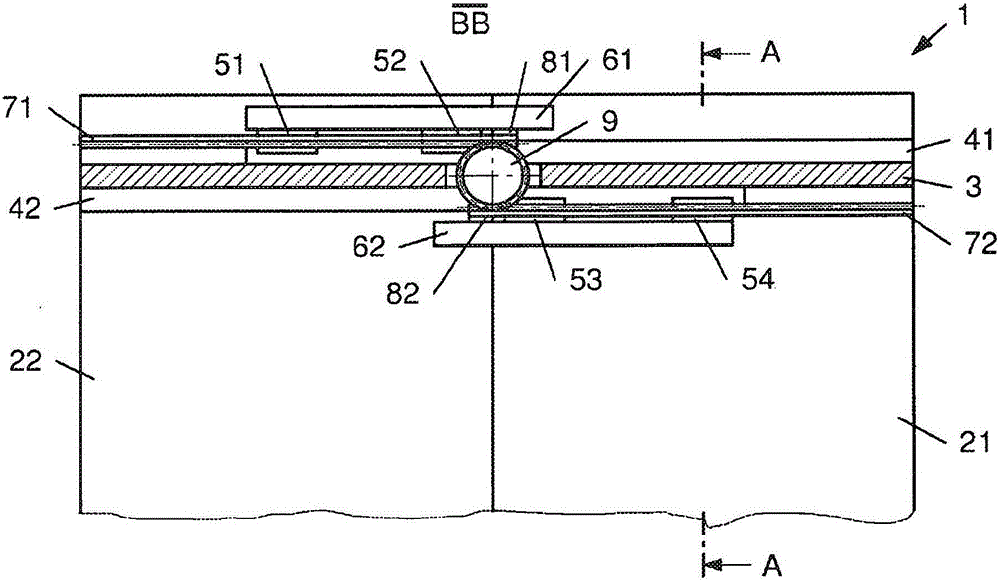

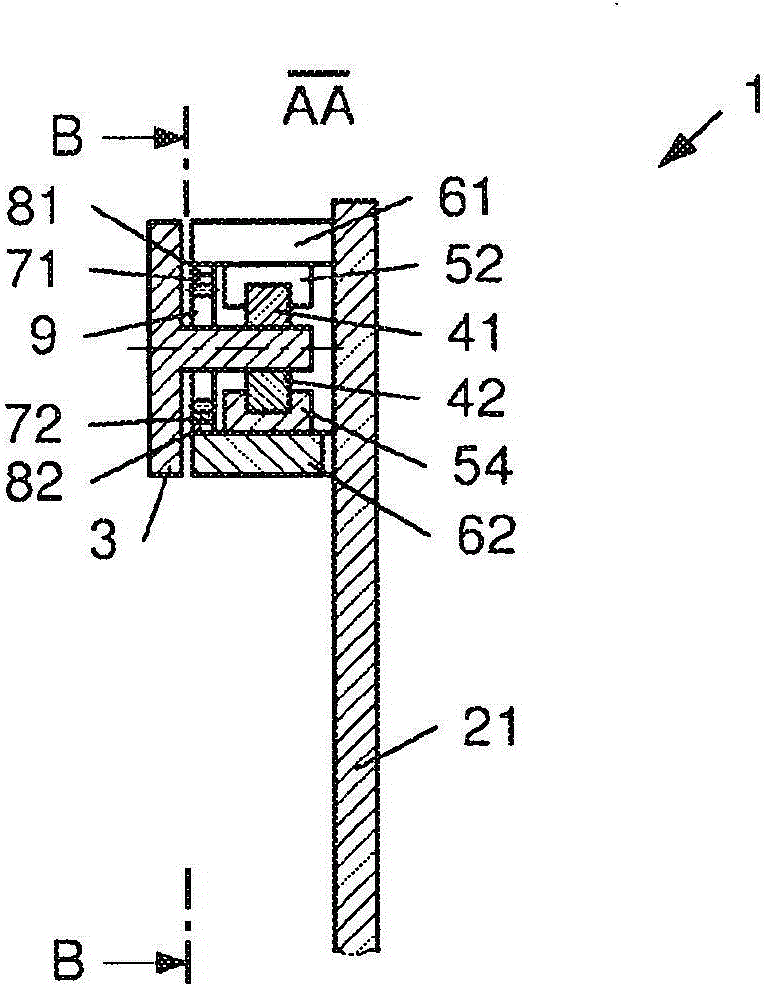

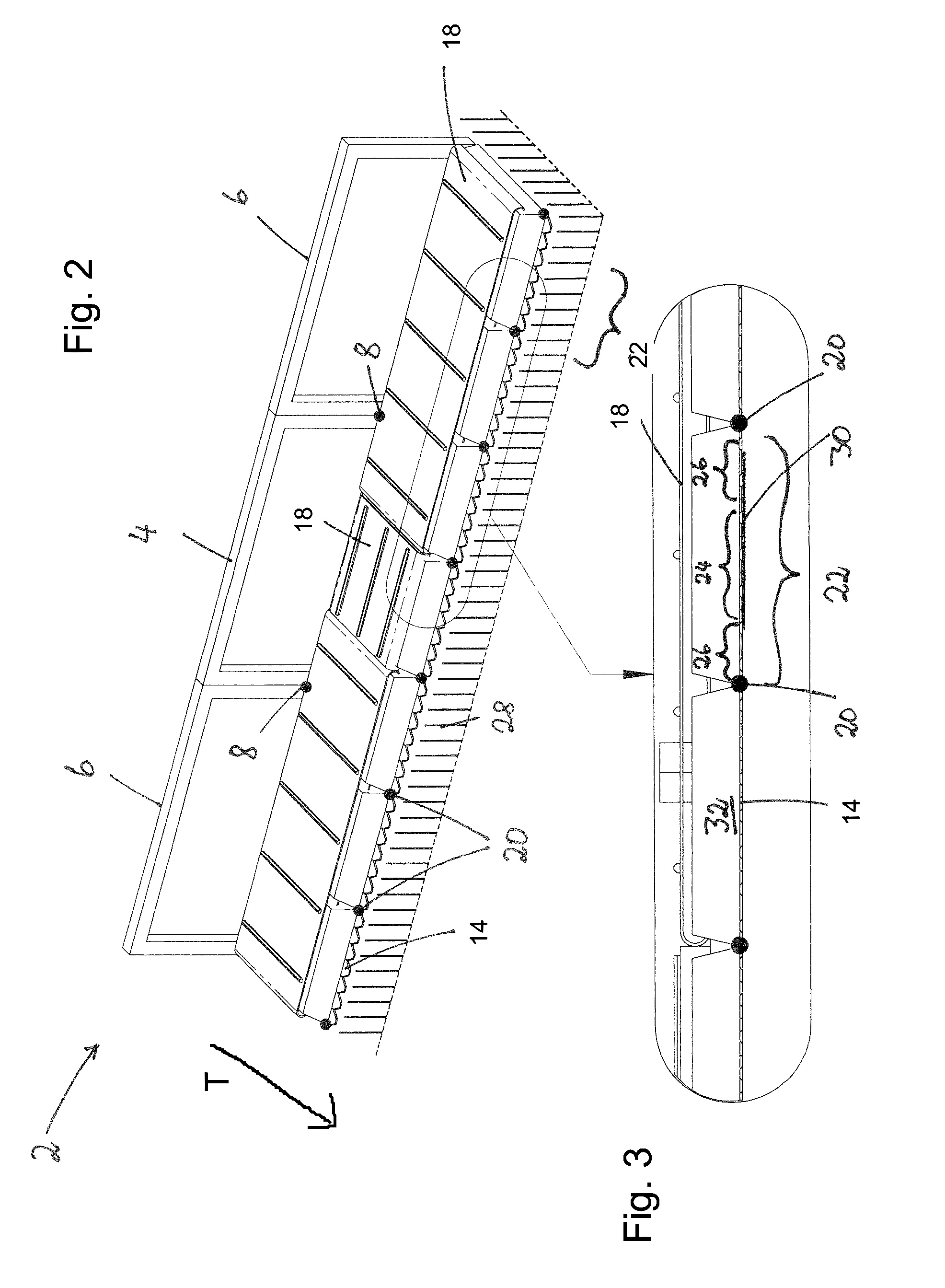

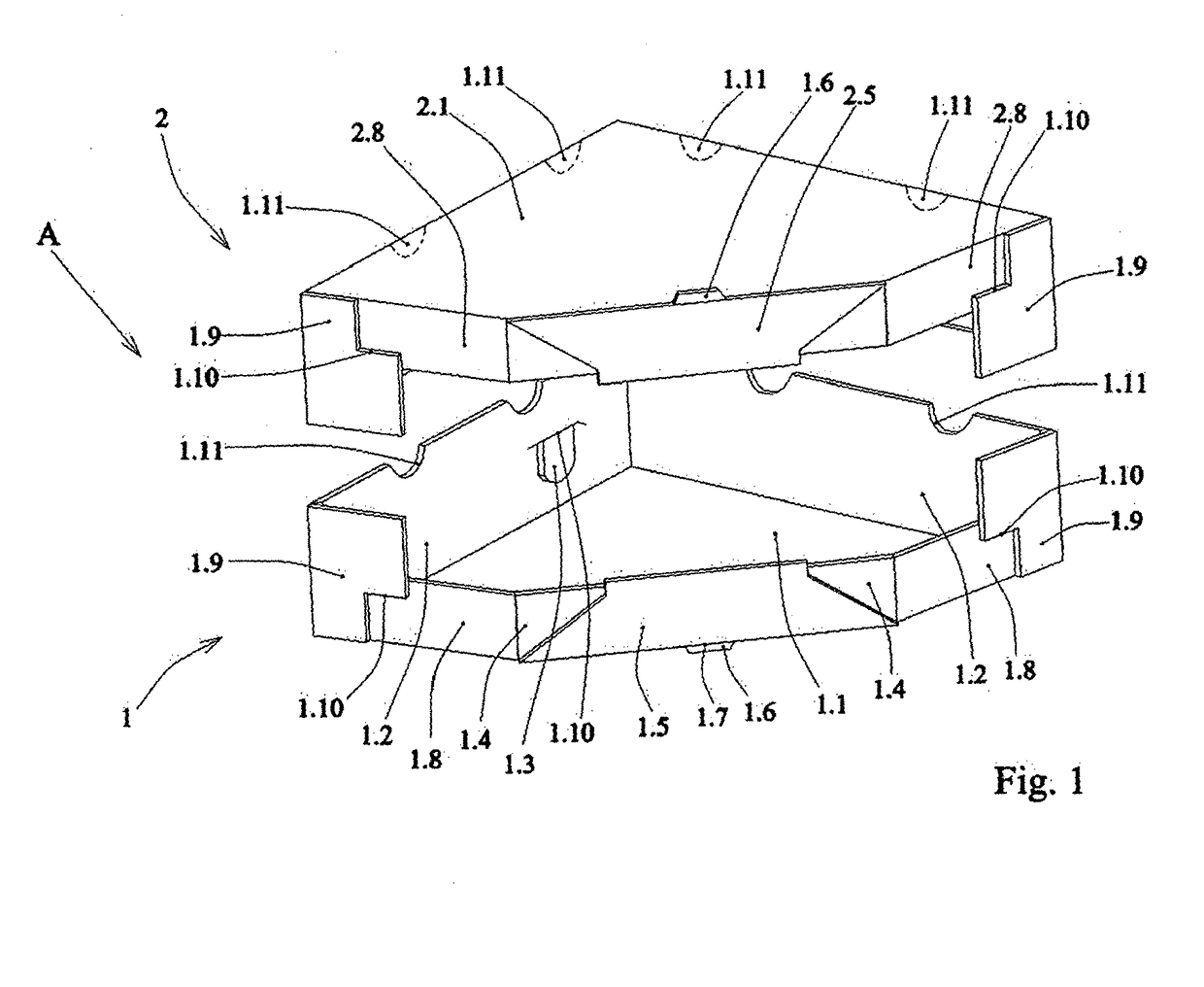

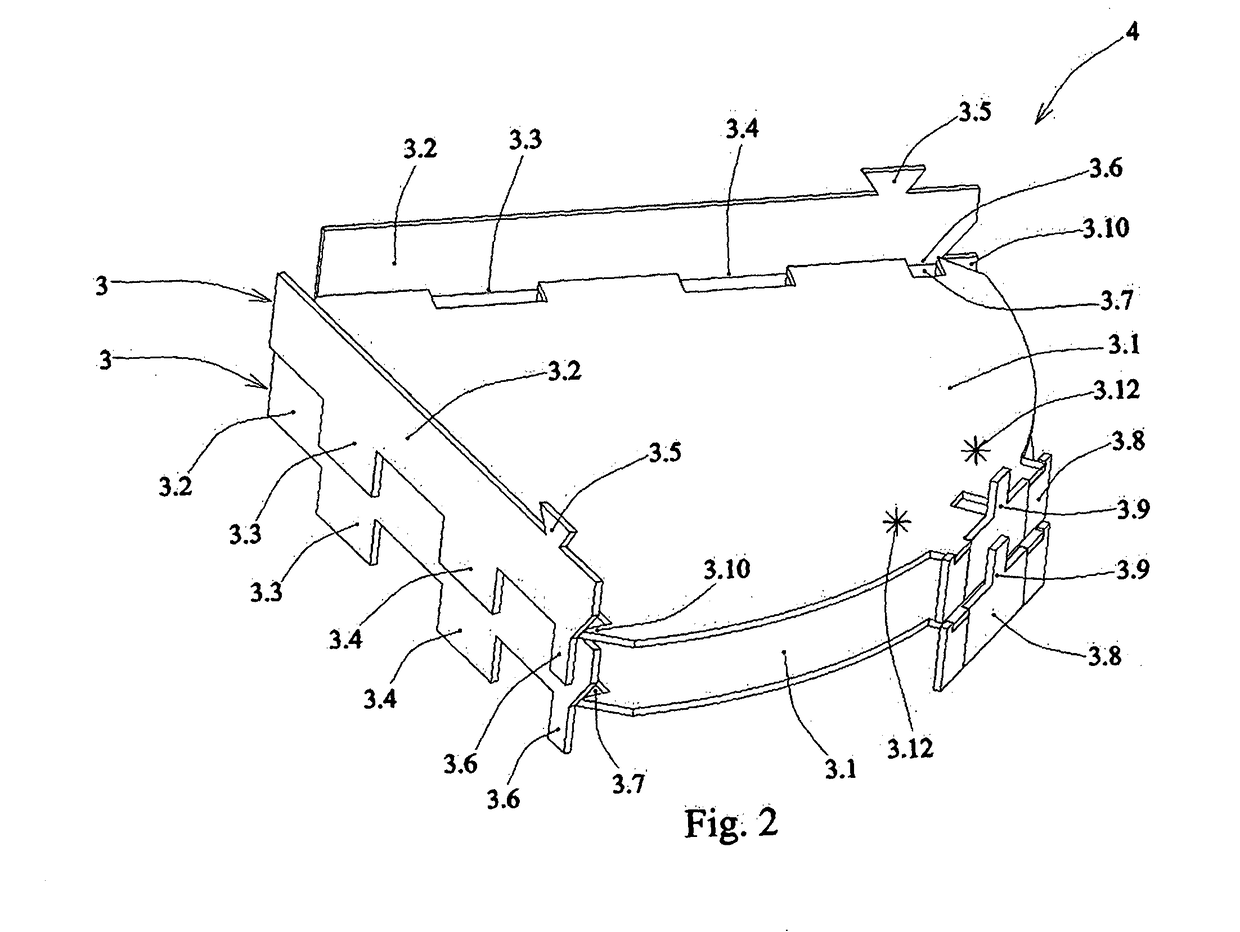

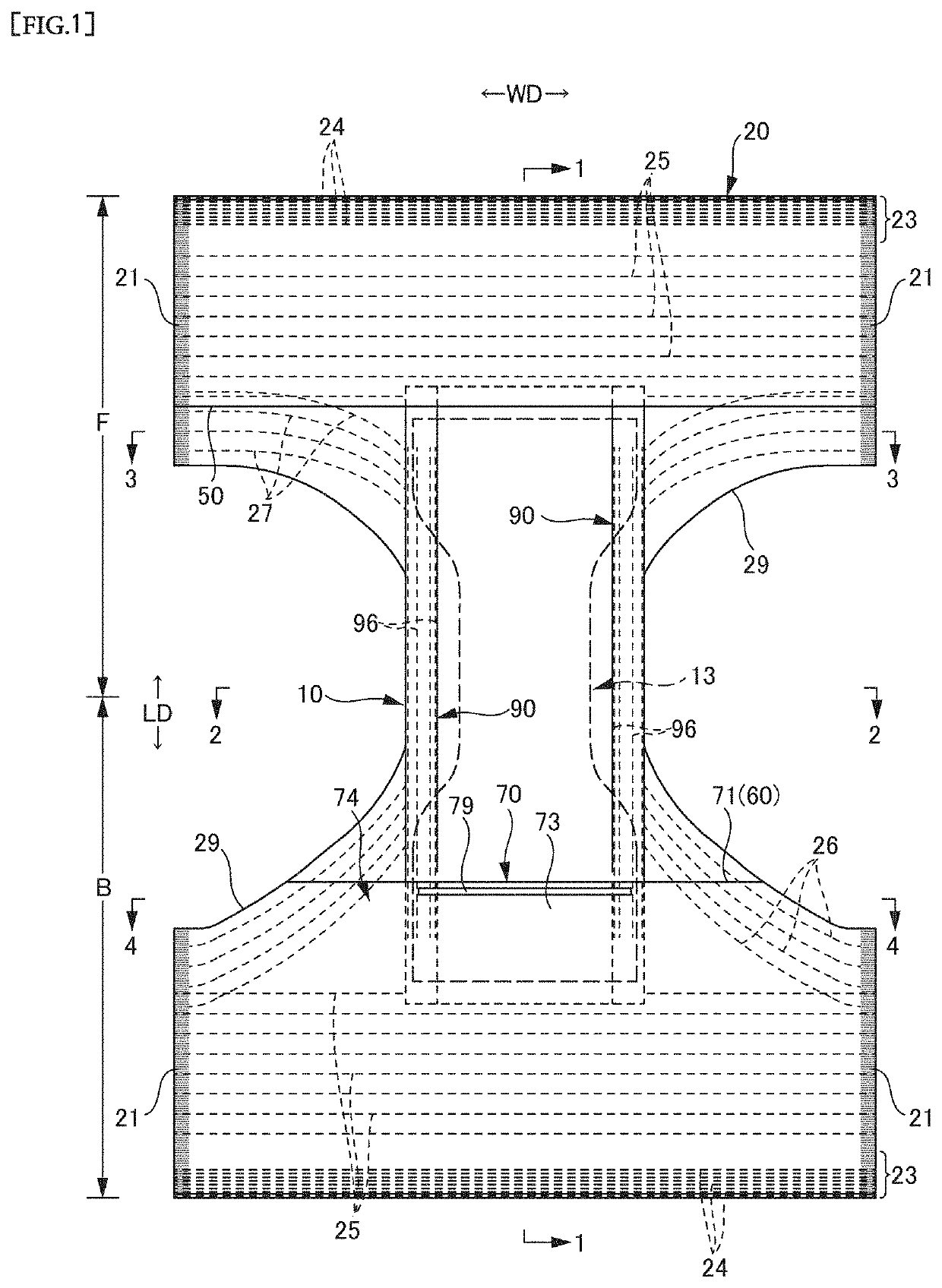

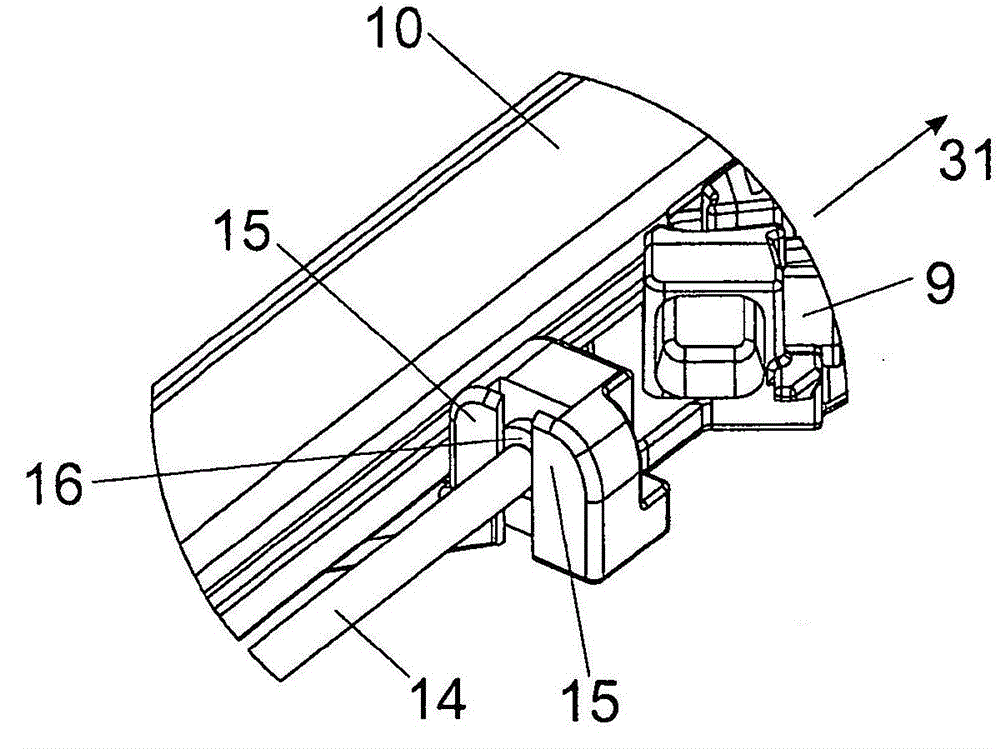

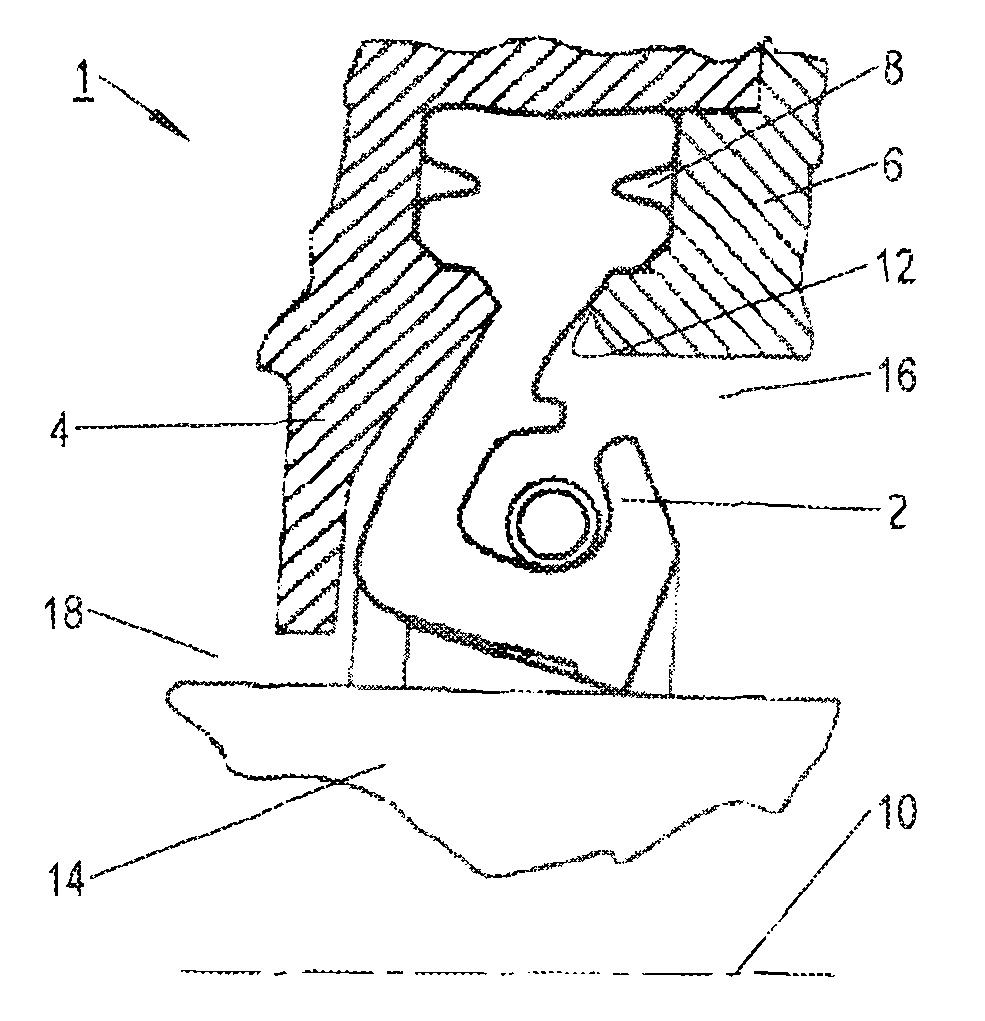

Sliding door module/pivoting sliding door module having floating mounting of a rack of a rack-and-pinion drive

InactiveCN105745136AEasy to decoupleStrong deformationPower-operated mechanismDoor arrangementEngineeringMechanical engineering

The invention relates to a sliding door module / pivoting sliding door module (1) for a rail vehicle, which comprises a door leaf (21, 22) and a support (3), which is aligned longitudinally in the sliding direction of the door leaf (21, 22) and is mounted such that the support (3) can be displaced in the horizontal direction in particular transversely to the longitudinal extent thereof. The sliding door module / pivoting sliding door module (1) also has a linear guide for mounting the door leaf (21, 22), which is fastened to or integrated in the support (3). The door leaves (21, 22) are moved with the aid of a rack-and-pinion drive. The rack-and-pinion drive has a rack (71, 72), which is coupled only in the first end region thereof to the door leaf (21, 22), and the floating end of which is engaged with a gearwheel (9) that is mounted rotatably in the support (3).

Owner:KNORR BREMSE GMBH

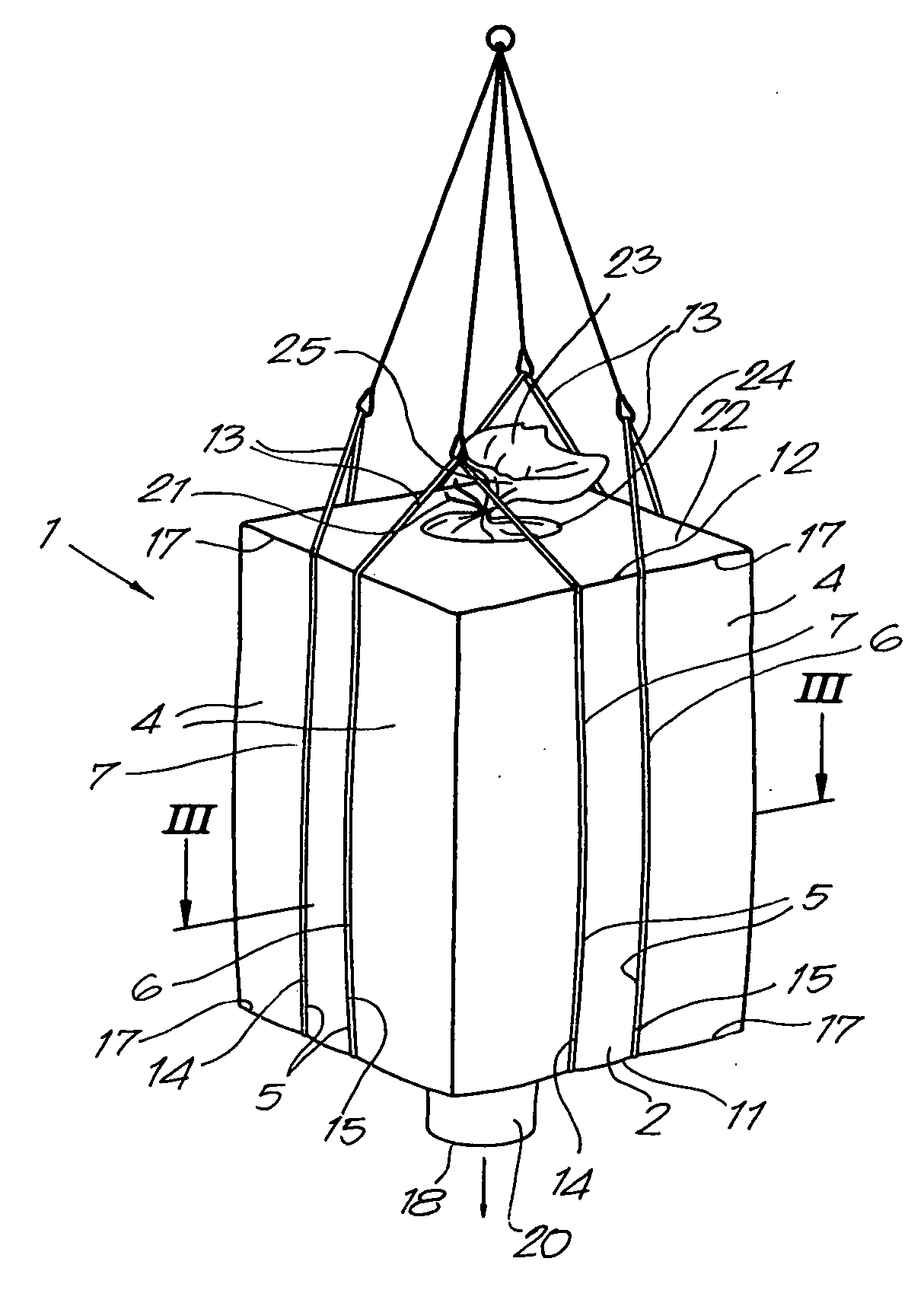

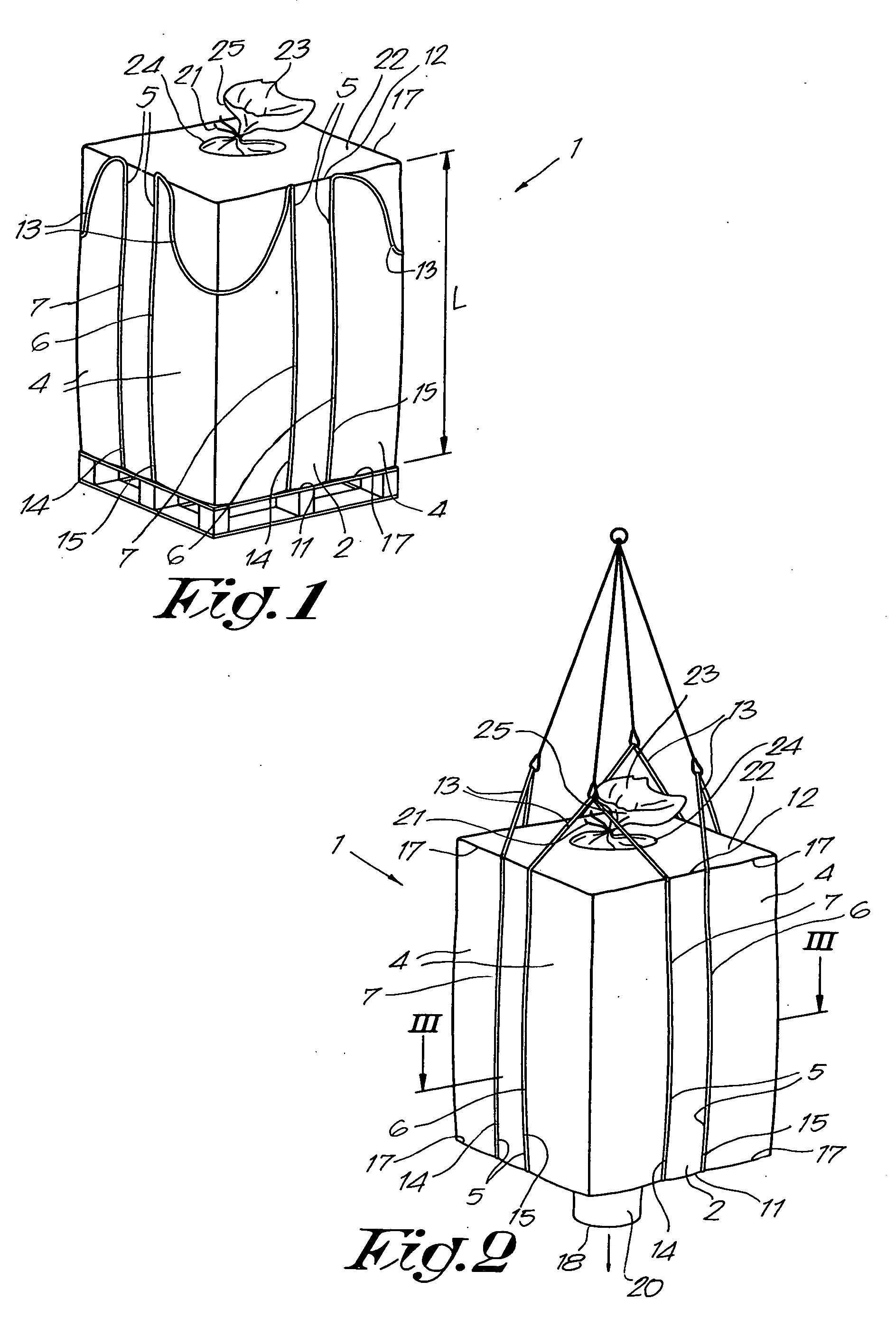

Container bag

InactiveUS20060104546A1Little risk of contaminationManufacturing a container bagBagsLarge containersMechanical engineeringEngineering

Owner:COMBES TRADING

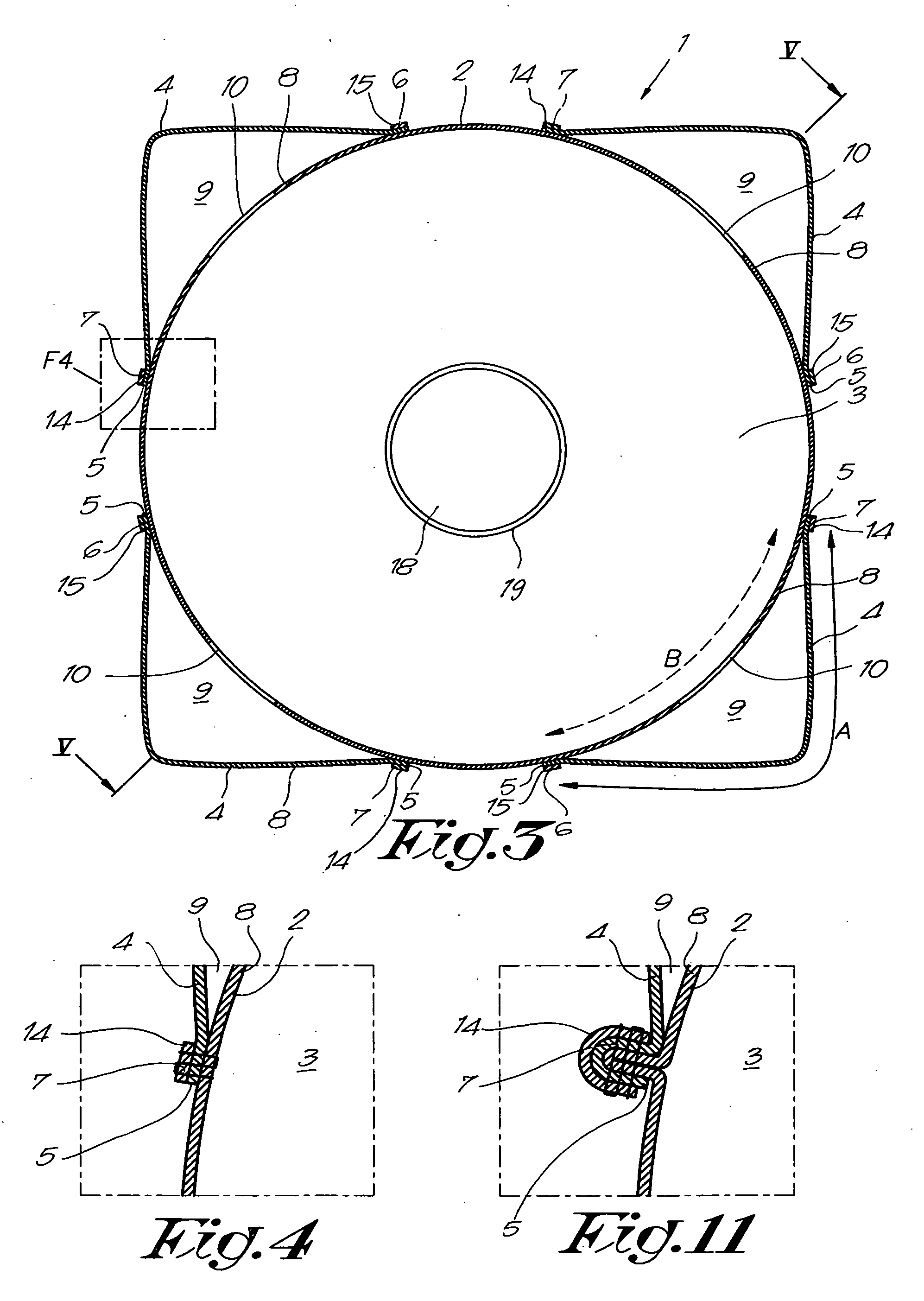

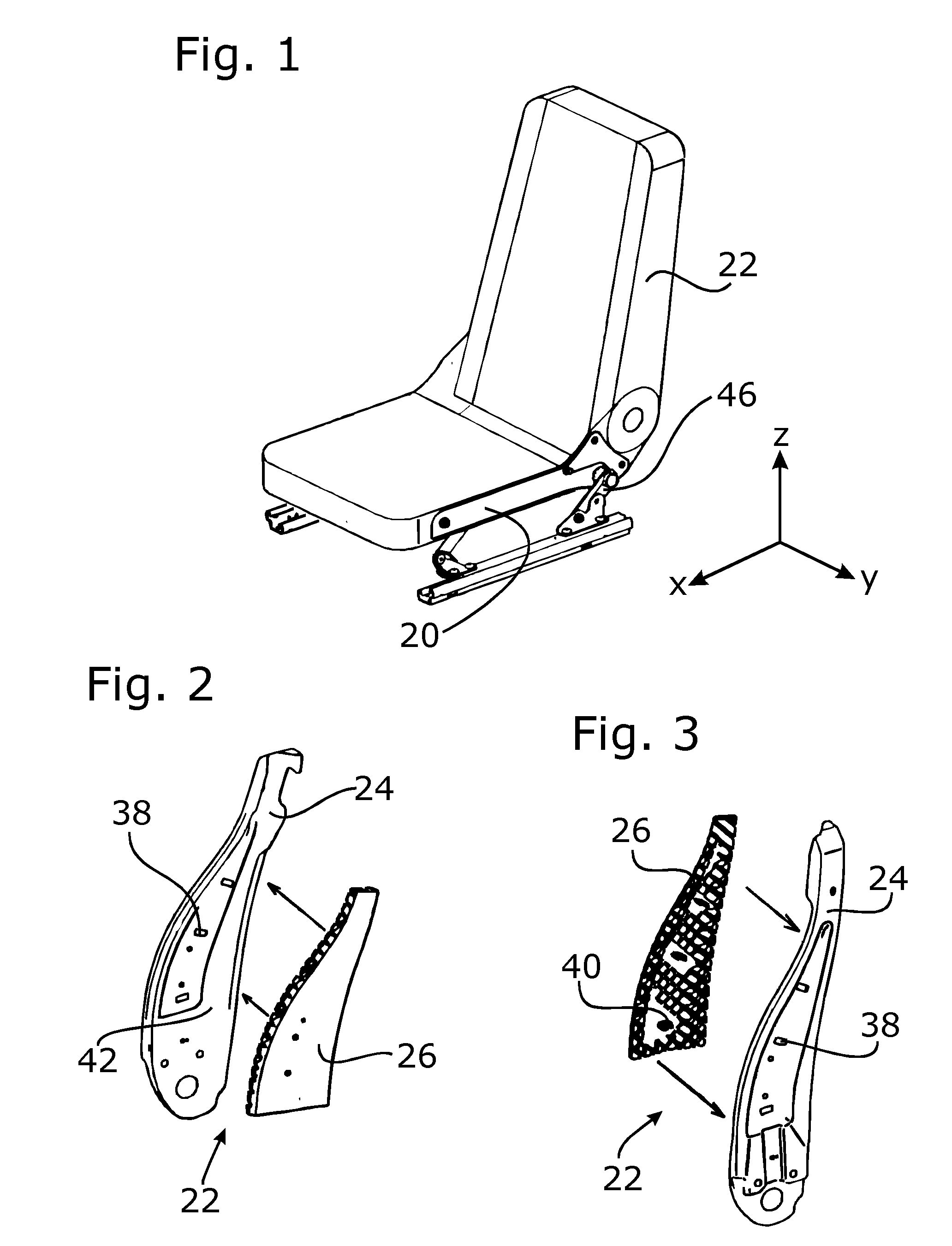

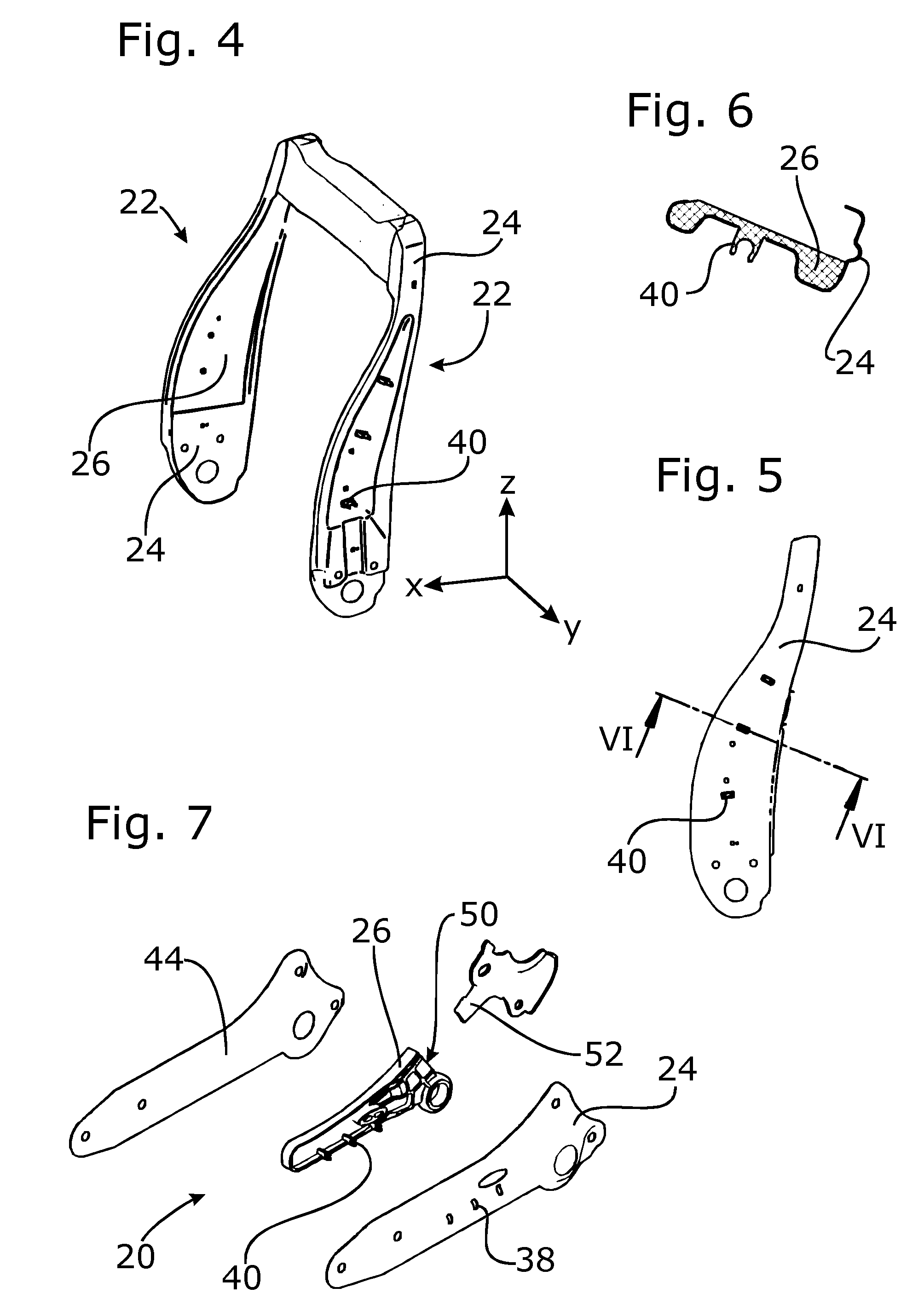

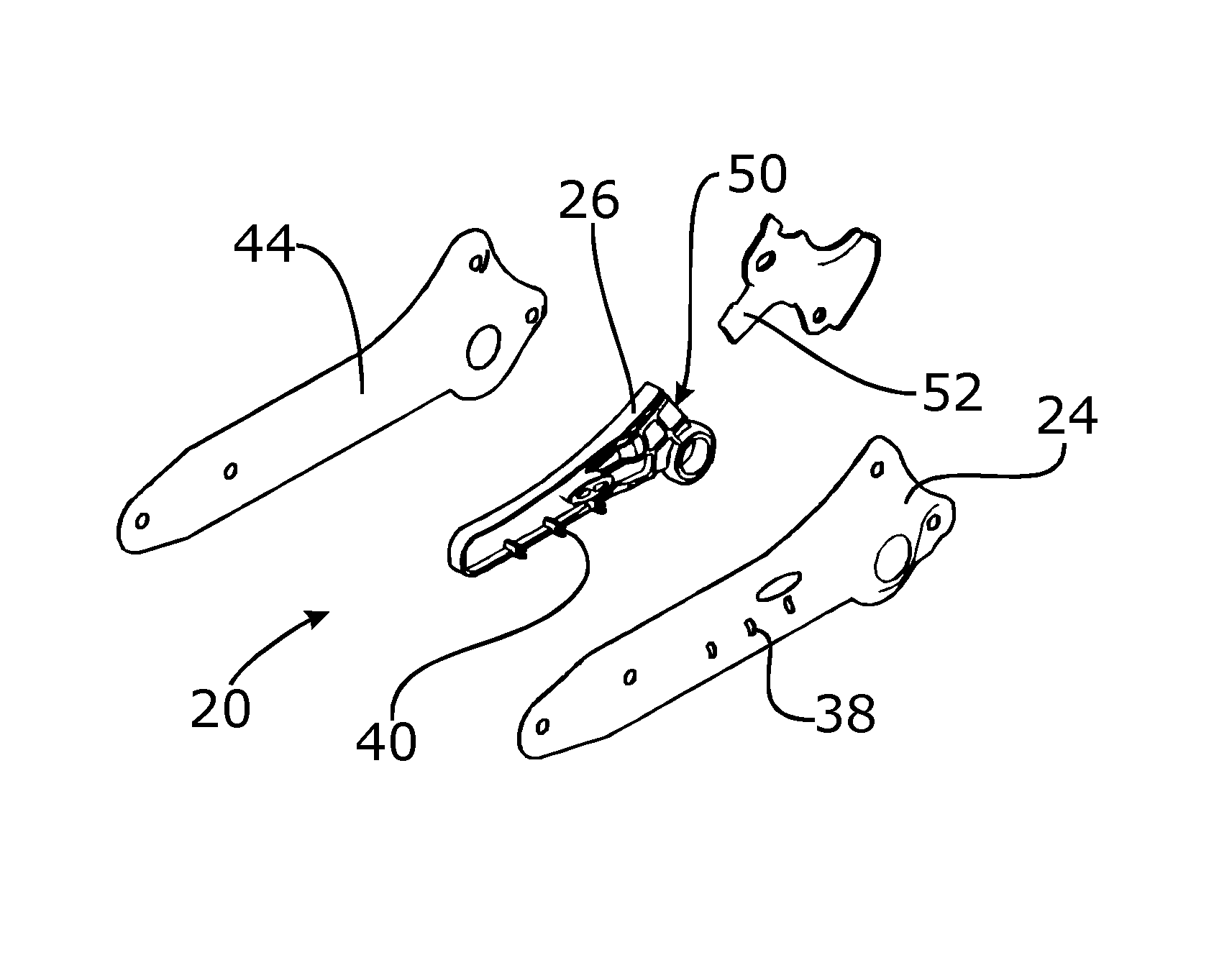

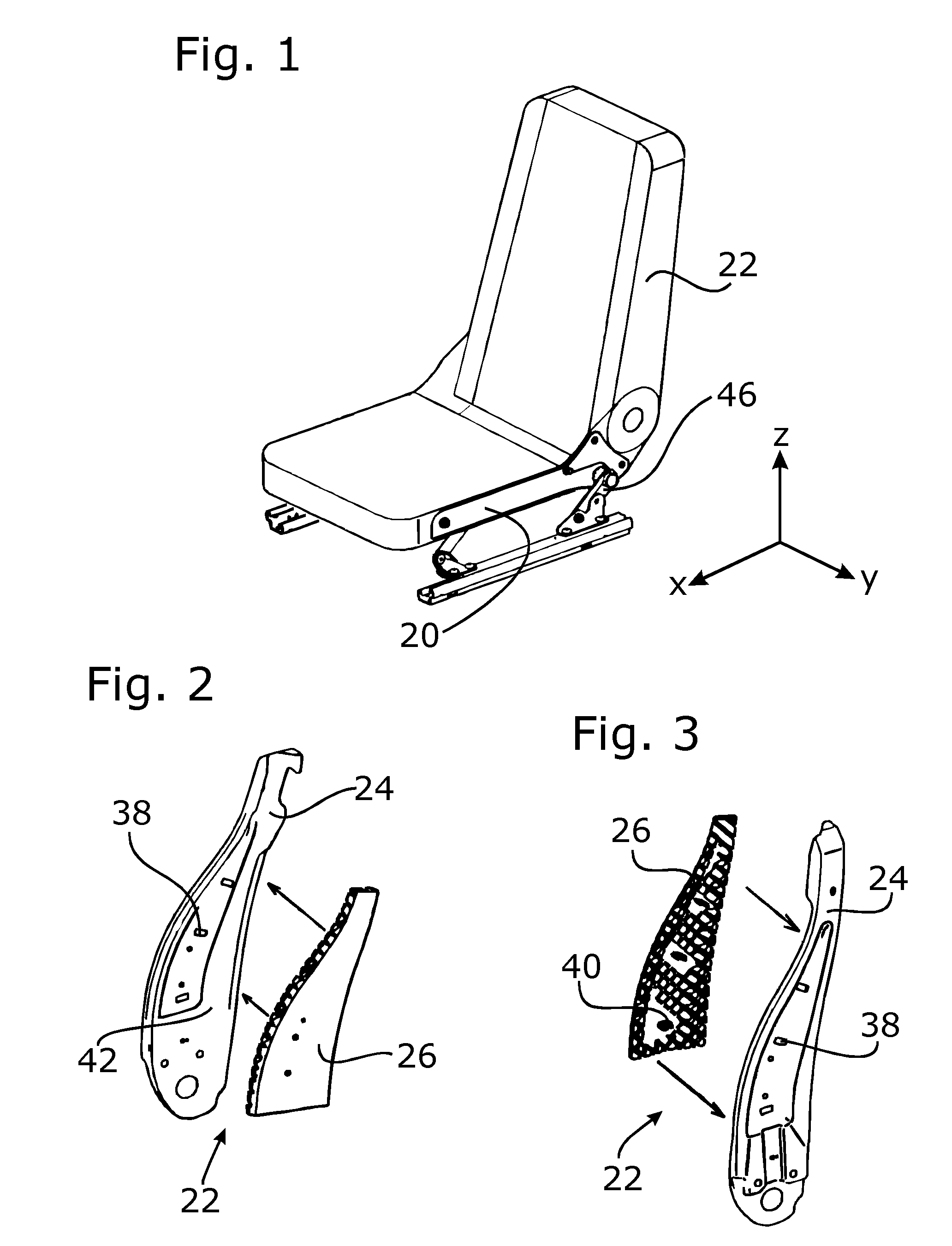

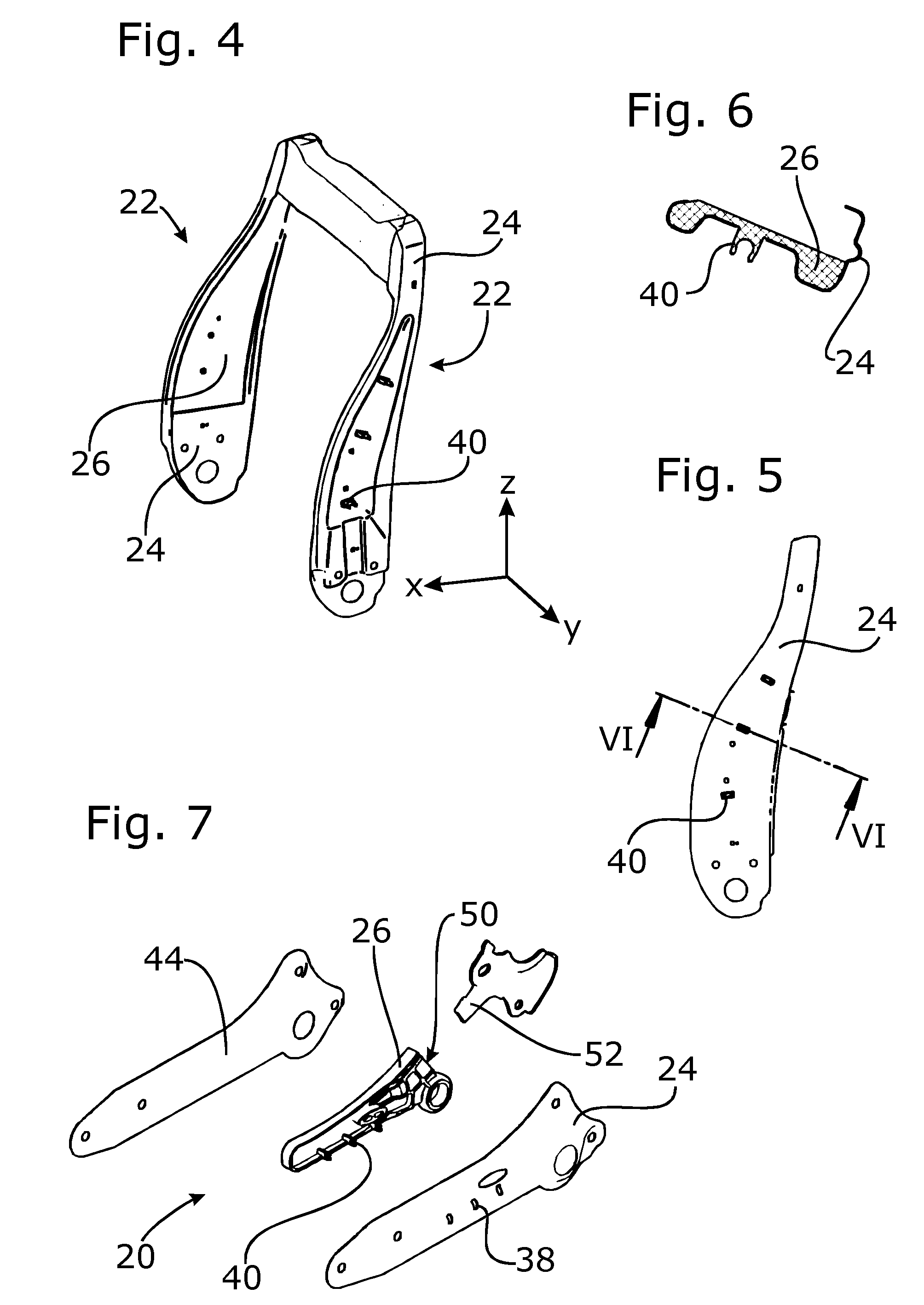

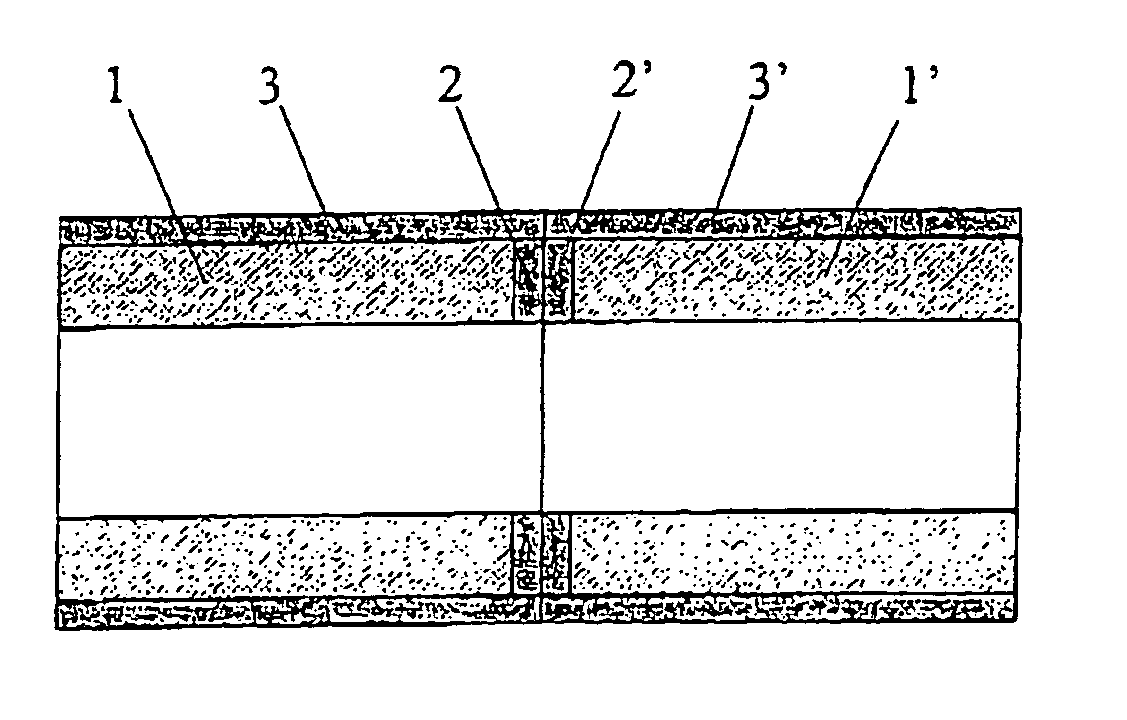

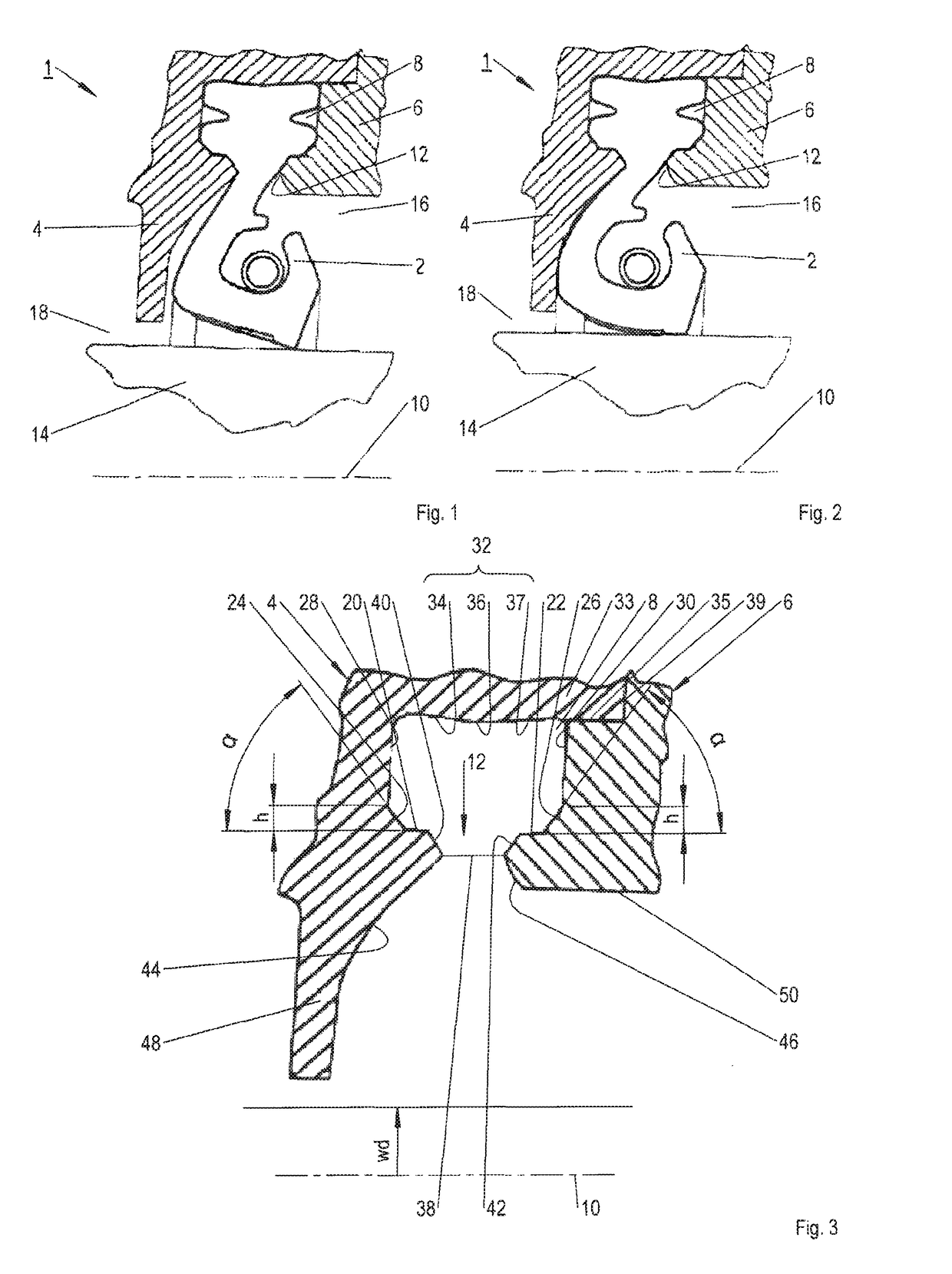

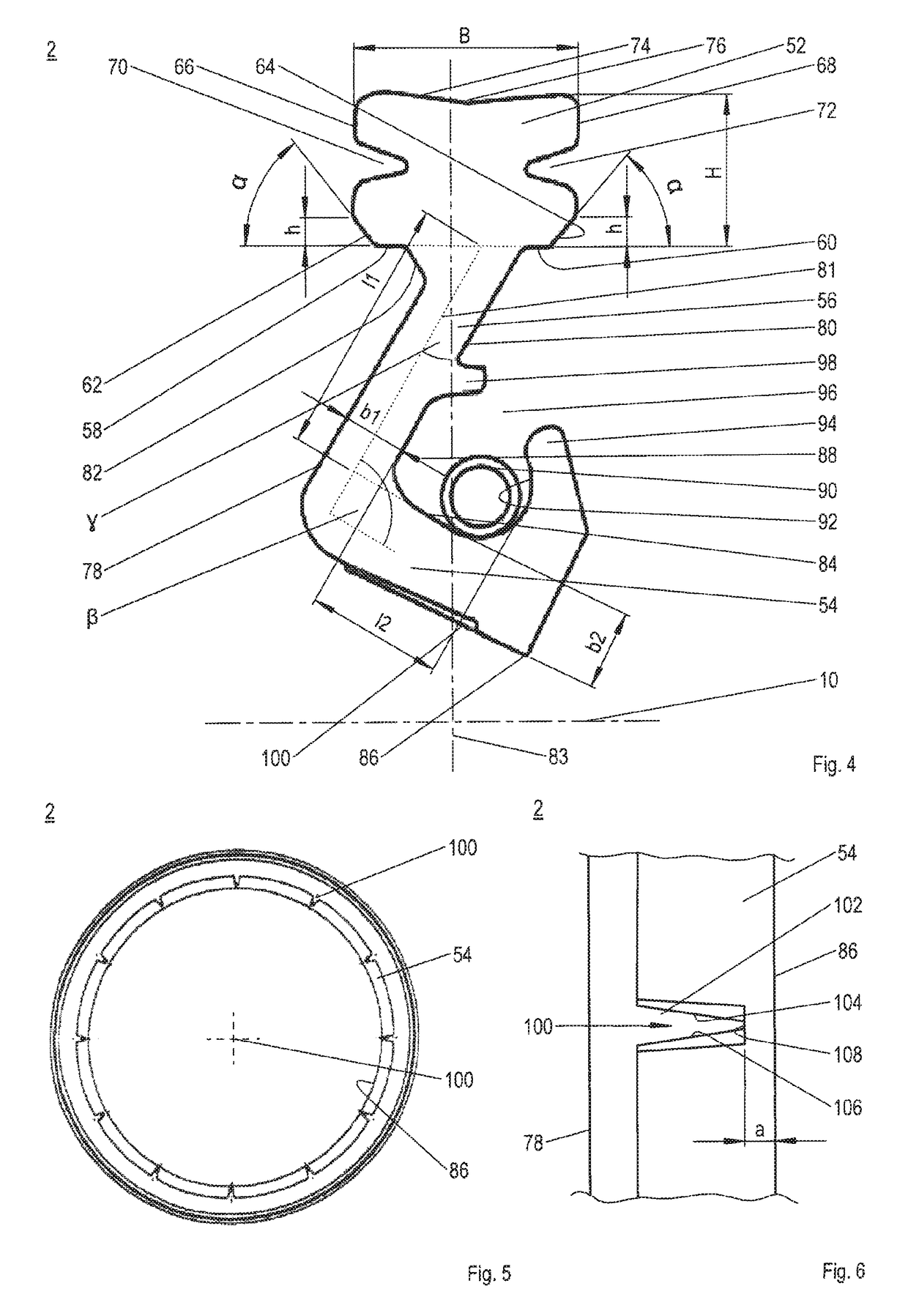

Frame side part of a vehicle seat

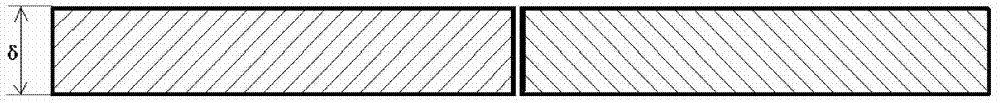

The side part of a vehicle seat, meaning either a seat side part or a side part of a seat back, comprises a layered structure. It has at least two layers. A first layer is a sheet steel part determining the shape of the side part. A second layer is a reinforcement body that has a material thickness in the y direction that is greater than the material thickness of the sheet steel part.

Owner:C ROB HAMMERSTEIN GMBH & CO KG

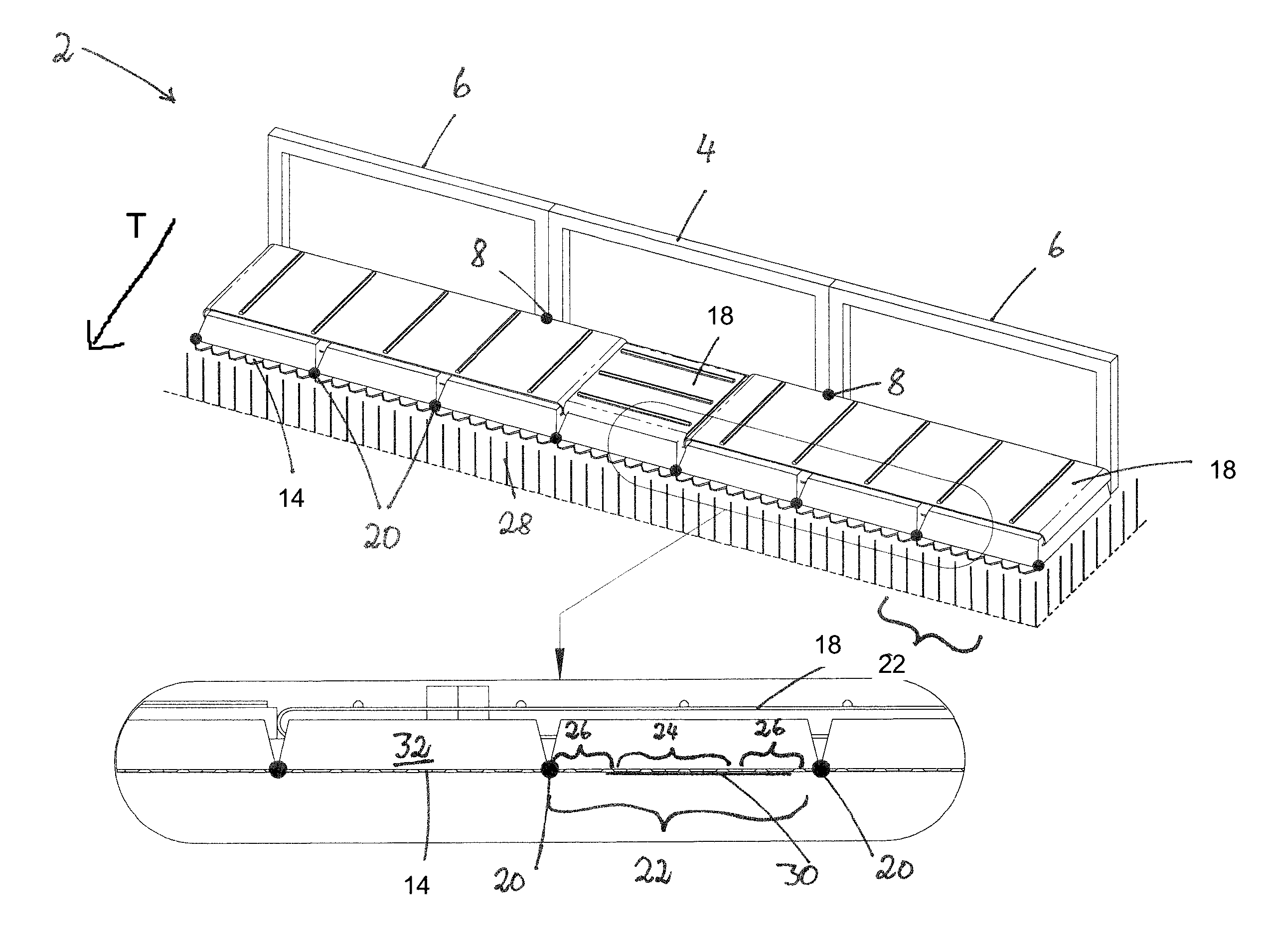

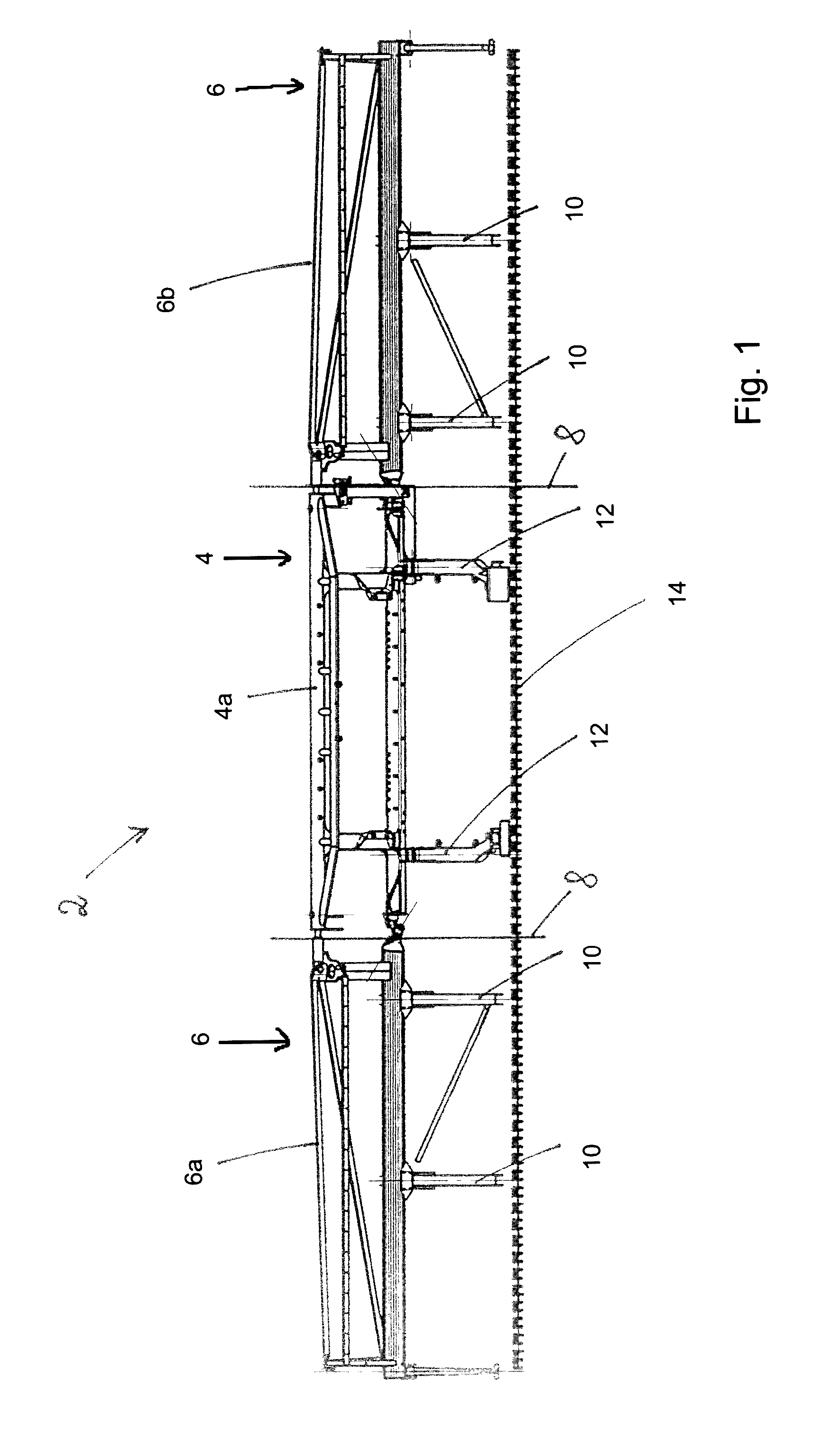

Draper platform with center section and lateral sections arranged laterally to the center section

A draper platform for a combine harvester has a center section attachable to a feed channel of the combine harvester. Lateral sections are arranged laterally on opposite ends of the center section. The center section has a center frame; the lateral sections have a lateral frame and are pivotable relative to the center section about a pivot axis that is oriented in travel direction of the draper platform. A cutter bar is provided and pivotable arms having a first end connected to the cutter bar and a second end connected to the center frame or the lateral frames connect the cutter bar pivotably to the center section and the lateral sections. Drive devices are operatively connected to the cutter bar and conveying devices that convey cut stalk material. The pivotable arms are arranged such that less than one of them is present per meter of working width of the draper platform.

Owner:CARL GERINGHOFF GMBH & CO KG

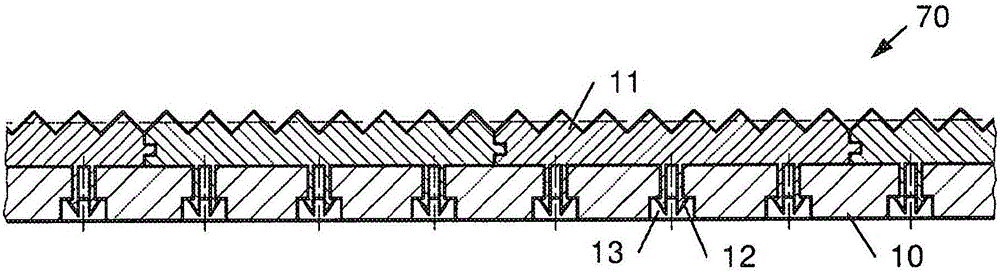

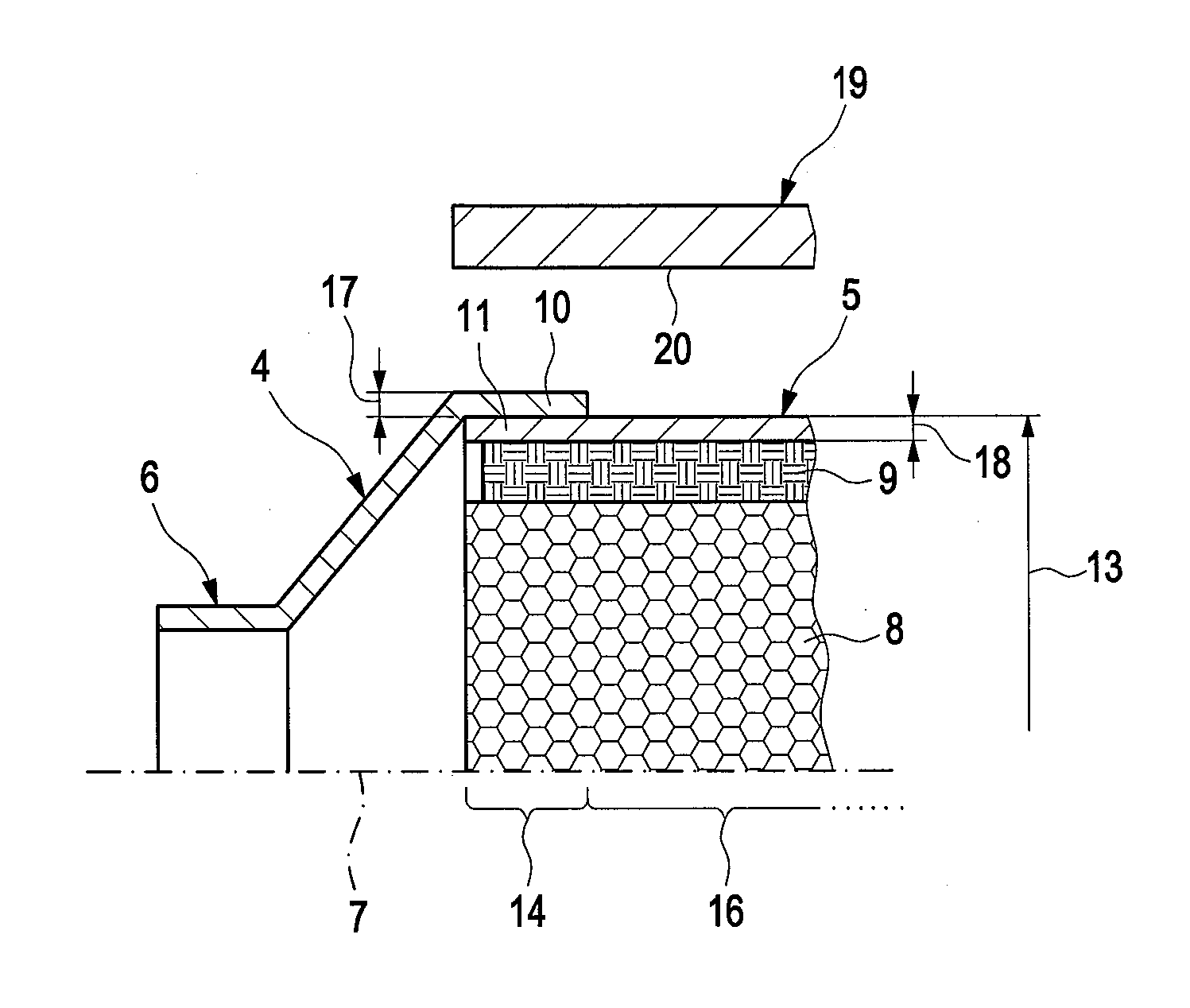

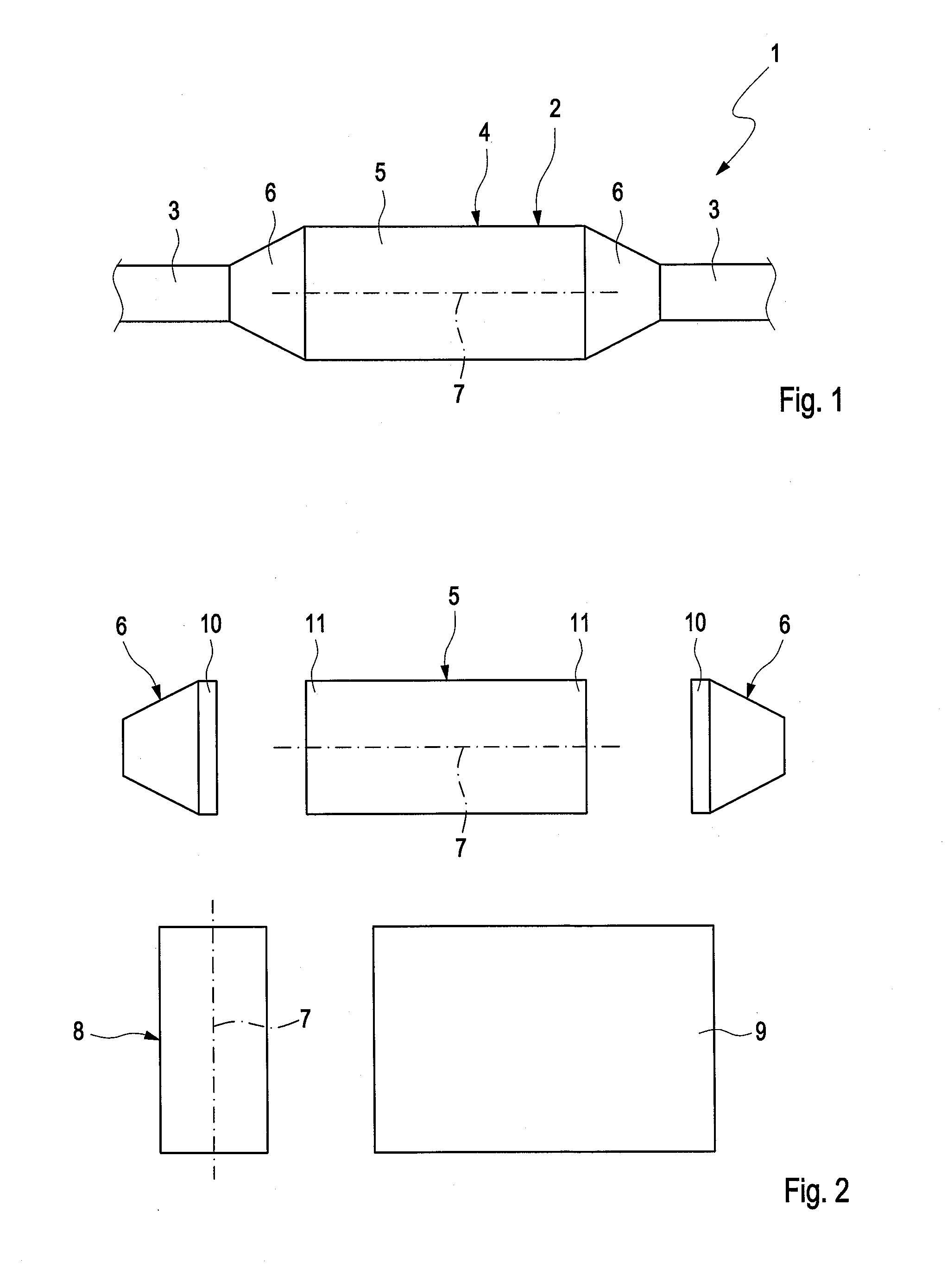

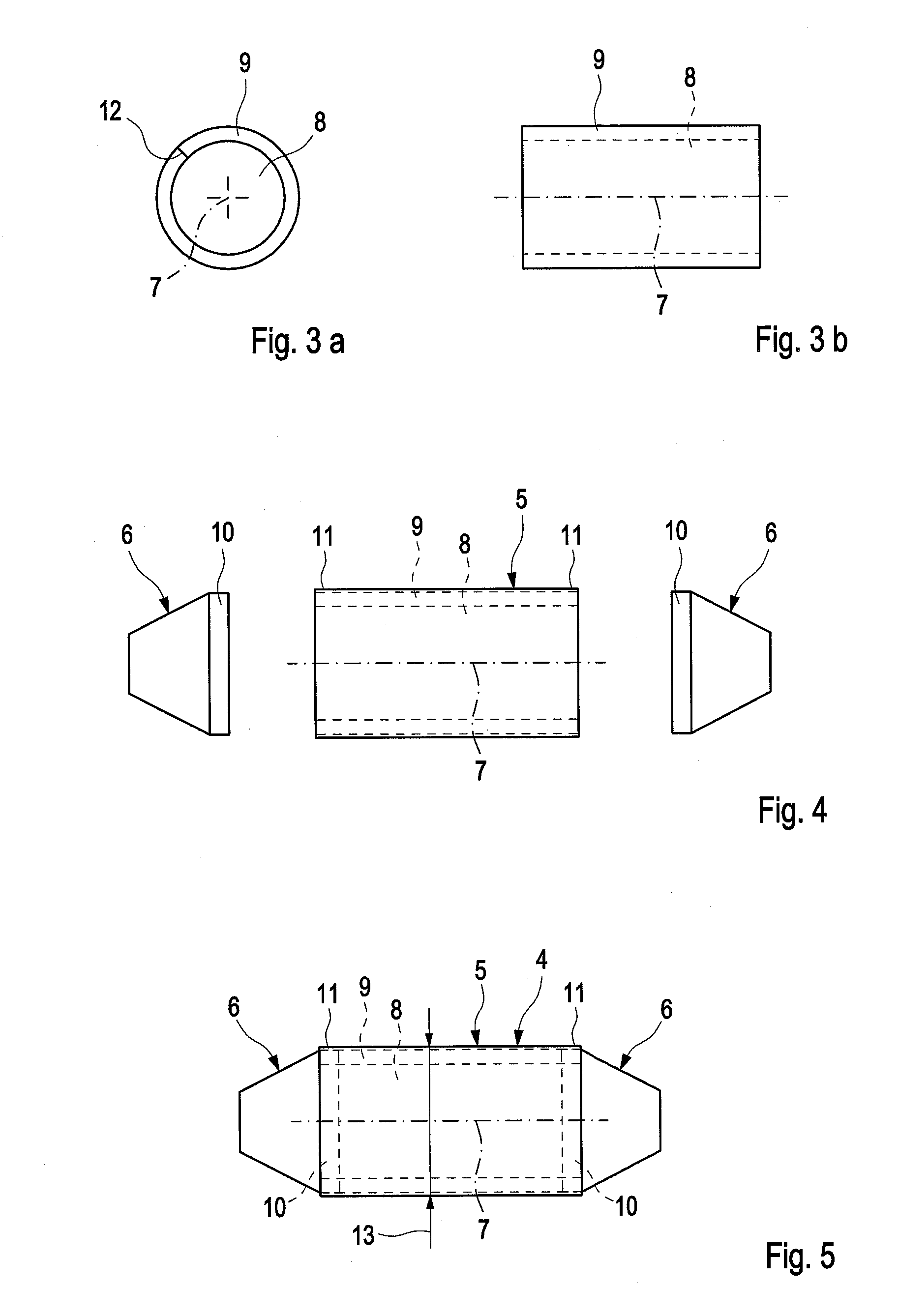

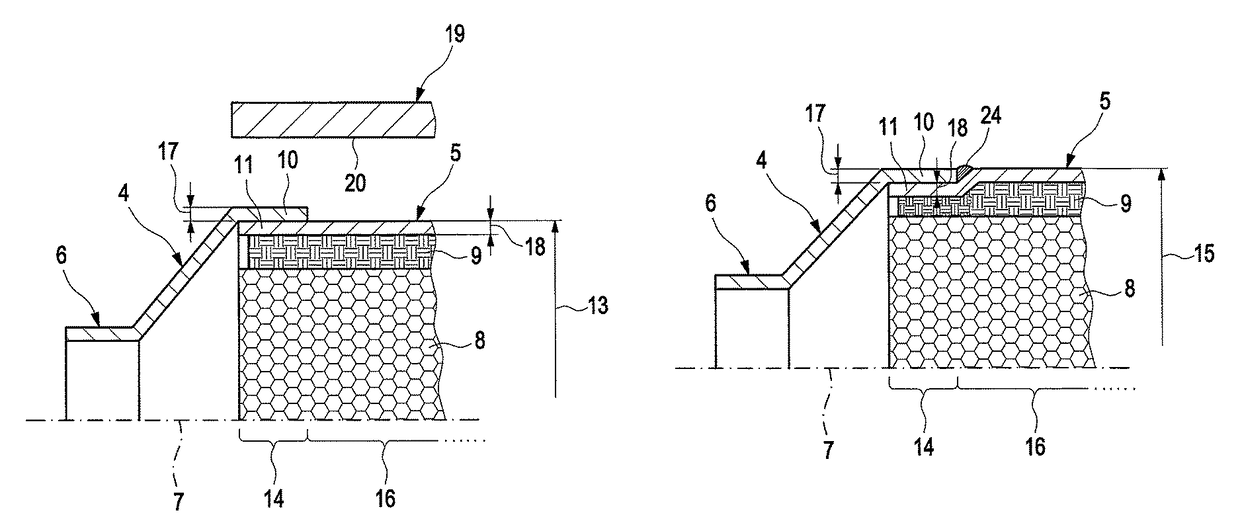

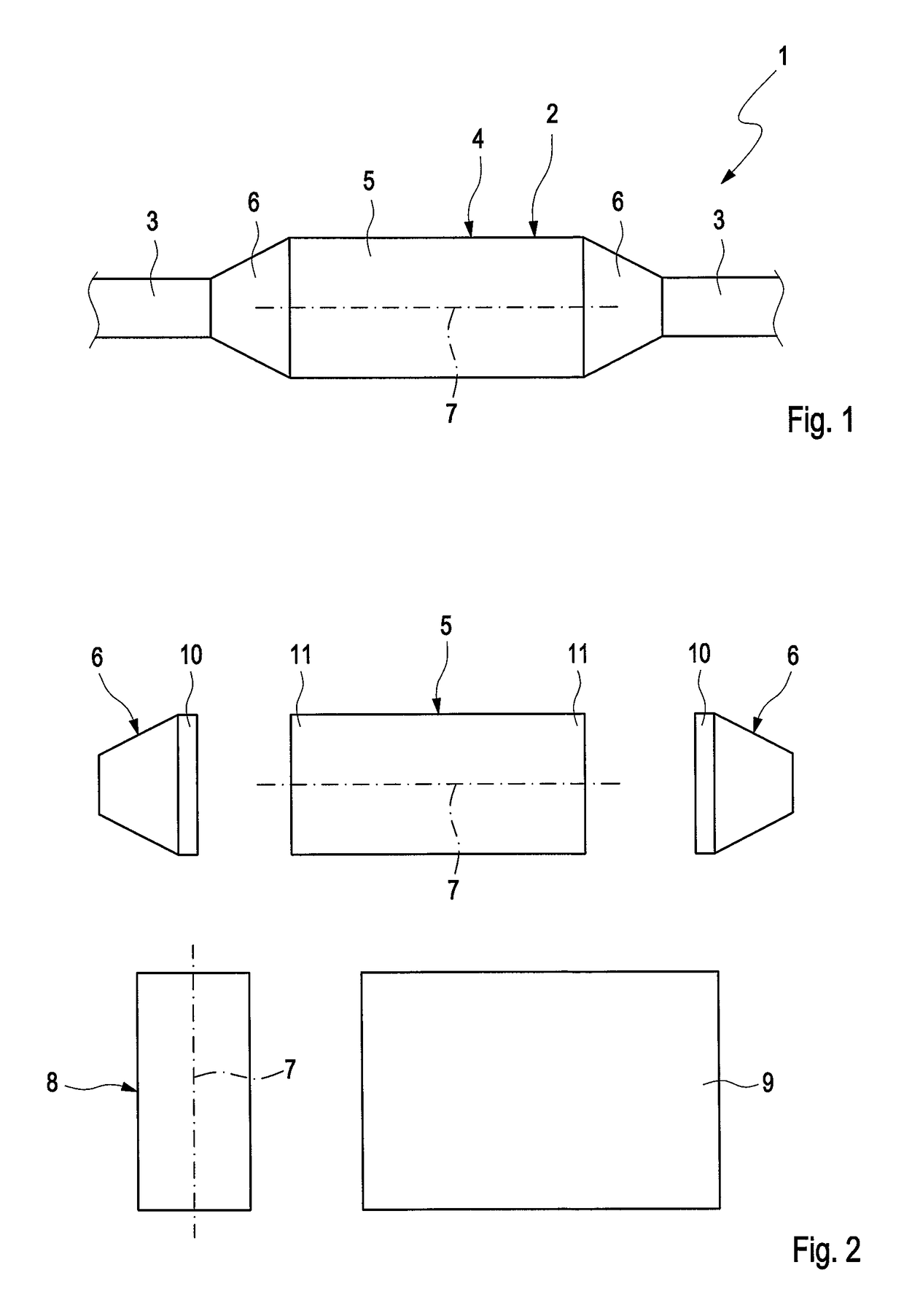

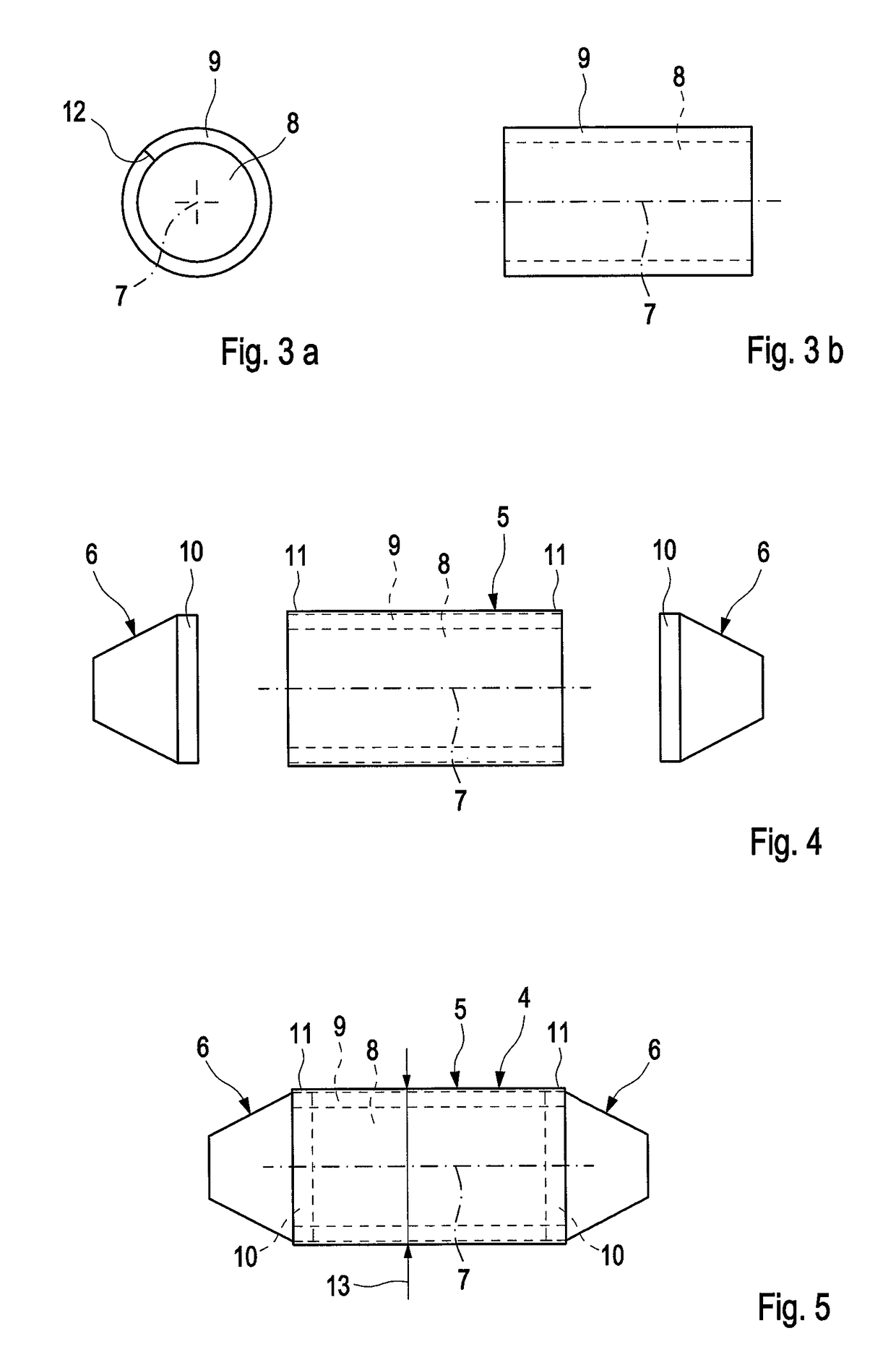

Exhaust-gas aftertreatment device and associated production method

ActiveUS20150121845A1Calibrate operation be particularly simpleIncrease radial compressionExhaust apparatusSilencing apparatusExhaust gasEngineering

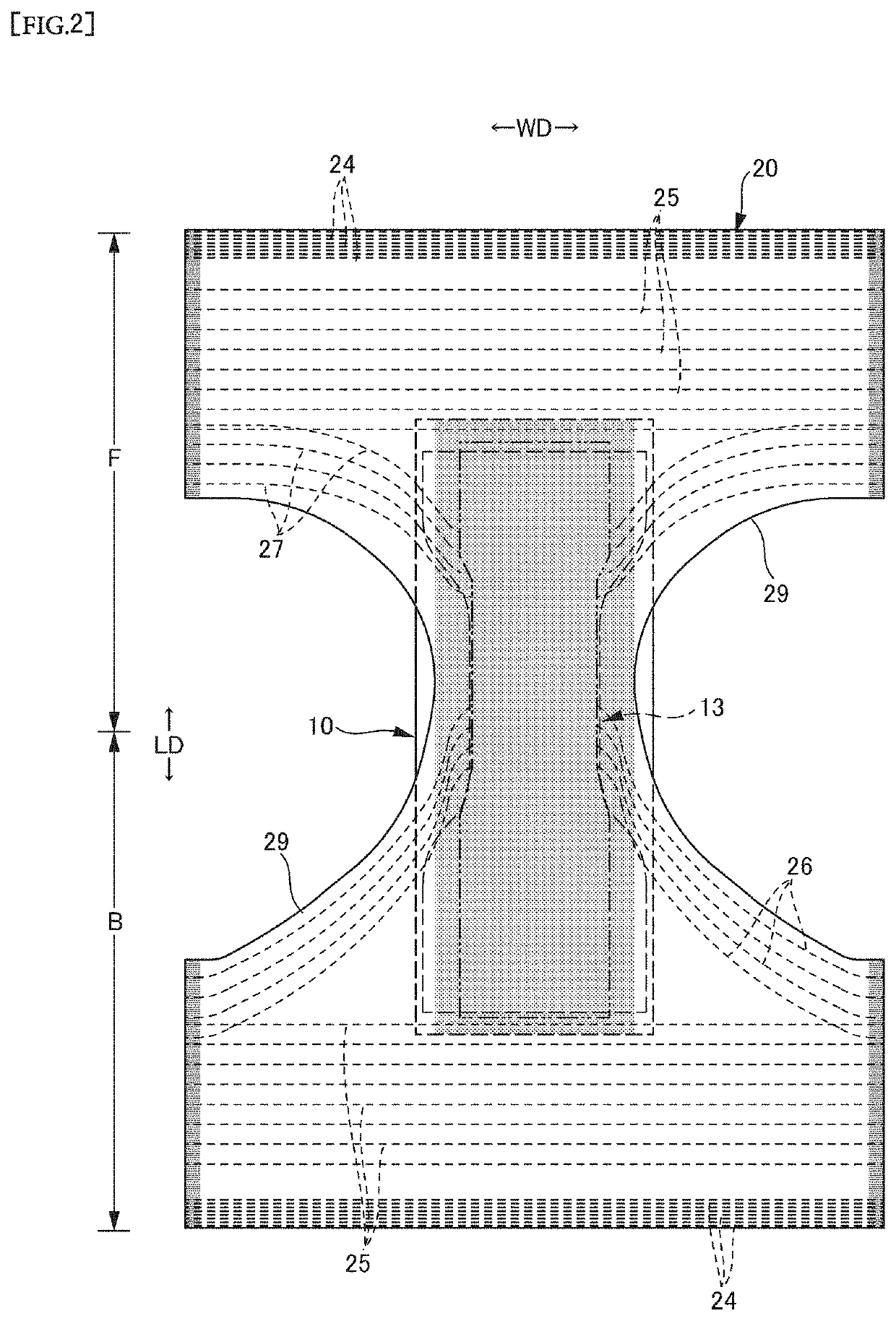

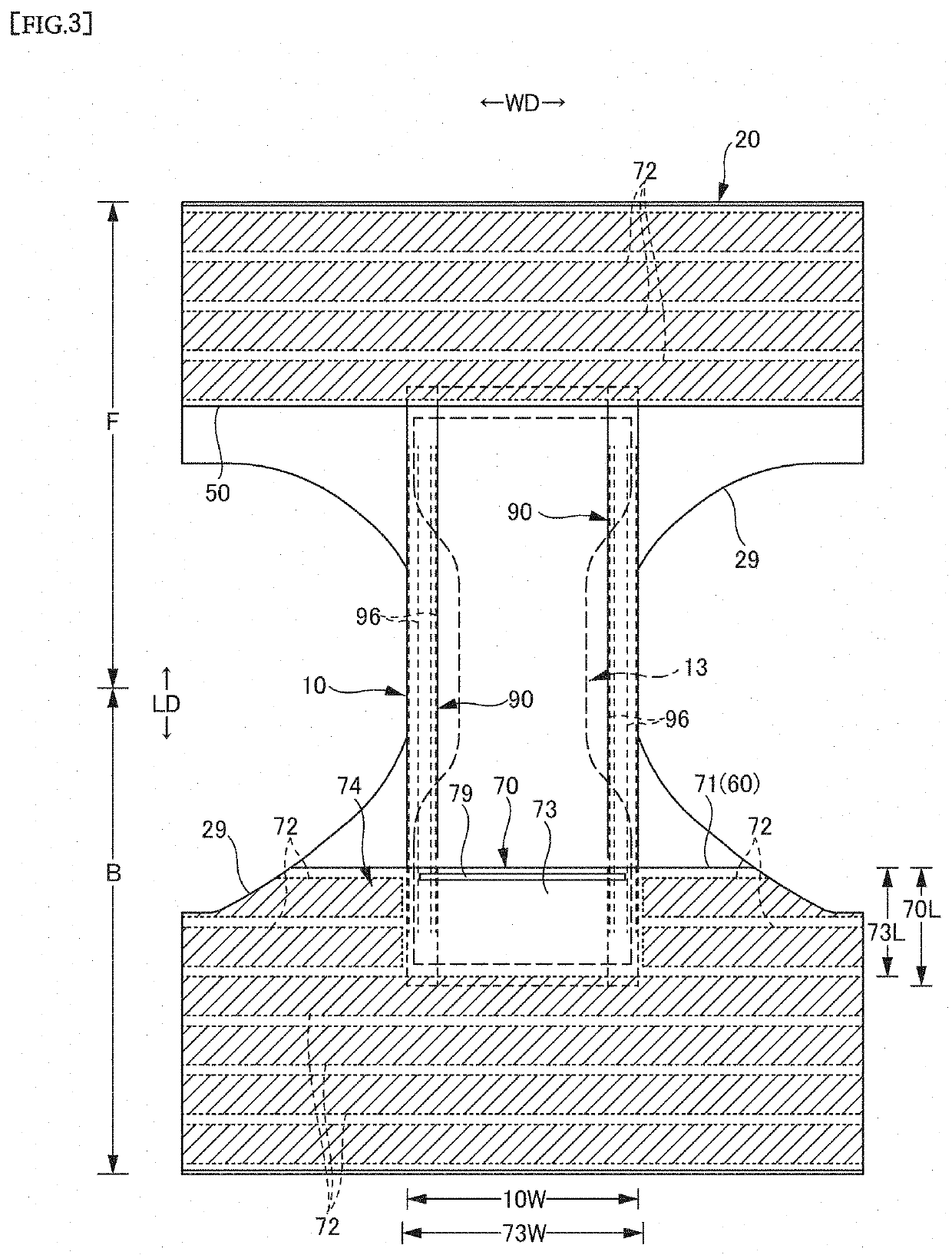

A method for producing an exhaust-gas aftertreatment device (2) inserts a monolith (8) in a housing (4), assembled from a circumferentially enclosed jacket (5) and two end funnels. The monolith (8) is axially inserted into the jacket (5) with a circumferentially enclosing support mat (9). The funnels (6) are connected to the jacket (5) via an axial connecting section (10) shaped complementary to the cross-section of the jacket (5), such that each connecting section (10) and an axial end section (25) of the support mat (9) axially overlap. The jacket (5), including the connecting sections (10) of the funnels (6) from a starting cross-section (13) to an end cross-section (15). This produces a predetermined radial preload in the support mat (9) in a support area (16) extending from the one connecting section (10) to the other connecting section (10) to retain the monolith (8) in the jacket (5).

Owner:PUREM GMBH

Frame of a vehicle seat

The side part of a vehicle seat, meaning either a seat side part or a side part of a seat back, comprises a layered structure. It has at least two layers. A first layer is a sheet steel part determining the shape of the side part. A second layer is a reinforcement body that has a material thickness in the y direction that is greater than the material thickness of the sheet steel part.

Owner:C ROB HAMMERSTEIN GMBH & CO KG

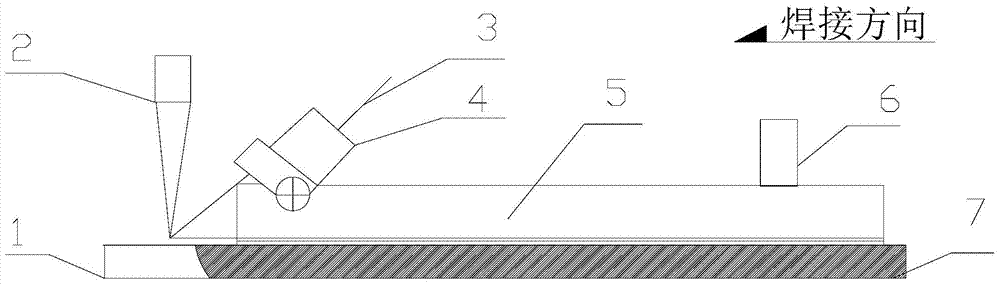

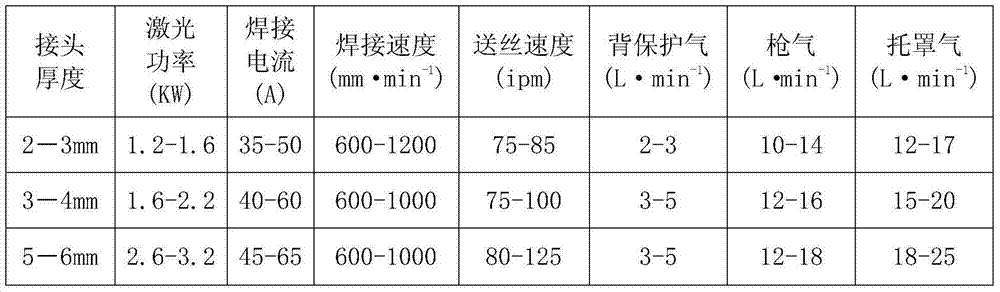

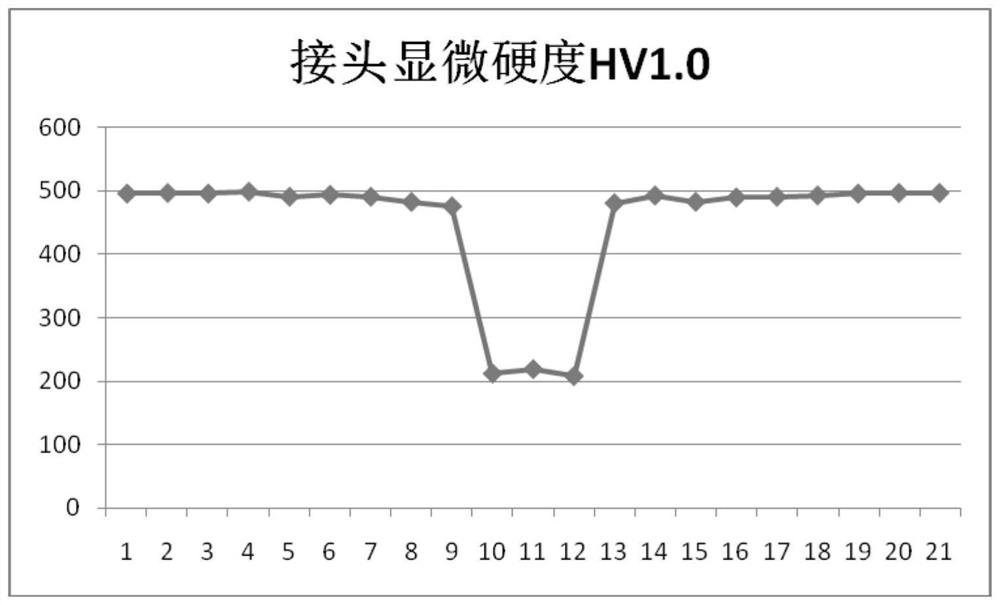

Titanium alloy laser-MIG composite welding method

InactiveCN103831533AImprove stabilityImprove welding efficiencyLaser beam welding apparatusLaser beamsArc welding

The invention discloses a titanium alloy laser-MIG composite welding method. A titanium alloy connector to be welded is machined into an I-type groove, and the connector is of a butt joint type. A weld joint protection pulling cover is fixed to an MIG gun nozzle, and a pulling cover body is arranged on the upper surface of a weld joint. Vertical incidence of a laser beam is performed from the position 0-3 mm in front of the MIG, and a welding wire is sent to the upper surface of the groove through the MIG gun nozzle. After a compound heat source melts the welding wire, a connector gap is the filled, and welding forming of a workpiece single track is achieved. The titanium alloy laser-MIG composite welding method overcomes the defects that the titanium alloy weld joint welding is prone to pollution, the requirement for laser welding assembling conditions is high, the efficiency of MIG welding is low, a weld joint heat affection zone is large, and the number of air holes, cracks and the like is increased. Under the premise that the welding efficiency is not reduced, the requirement for the assembling conditions is lowered, and the titanium alloy laser-MIG composite welding method has the advantages that the welding penetration is large, the welding speed is high, the deformation of a workpiece is small, the assembly requirement is low, the bridging capacity of a melting pool is high, the welding quality is high, the performance of the weld joint is good, and automatic welding can be easily achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

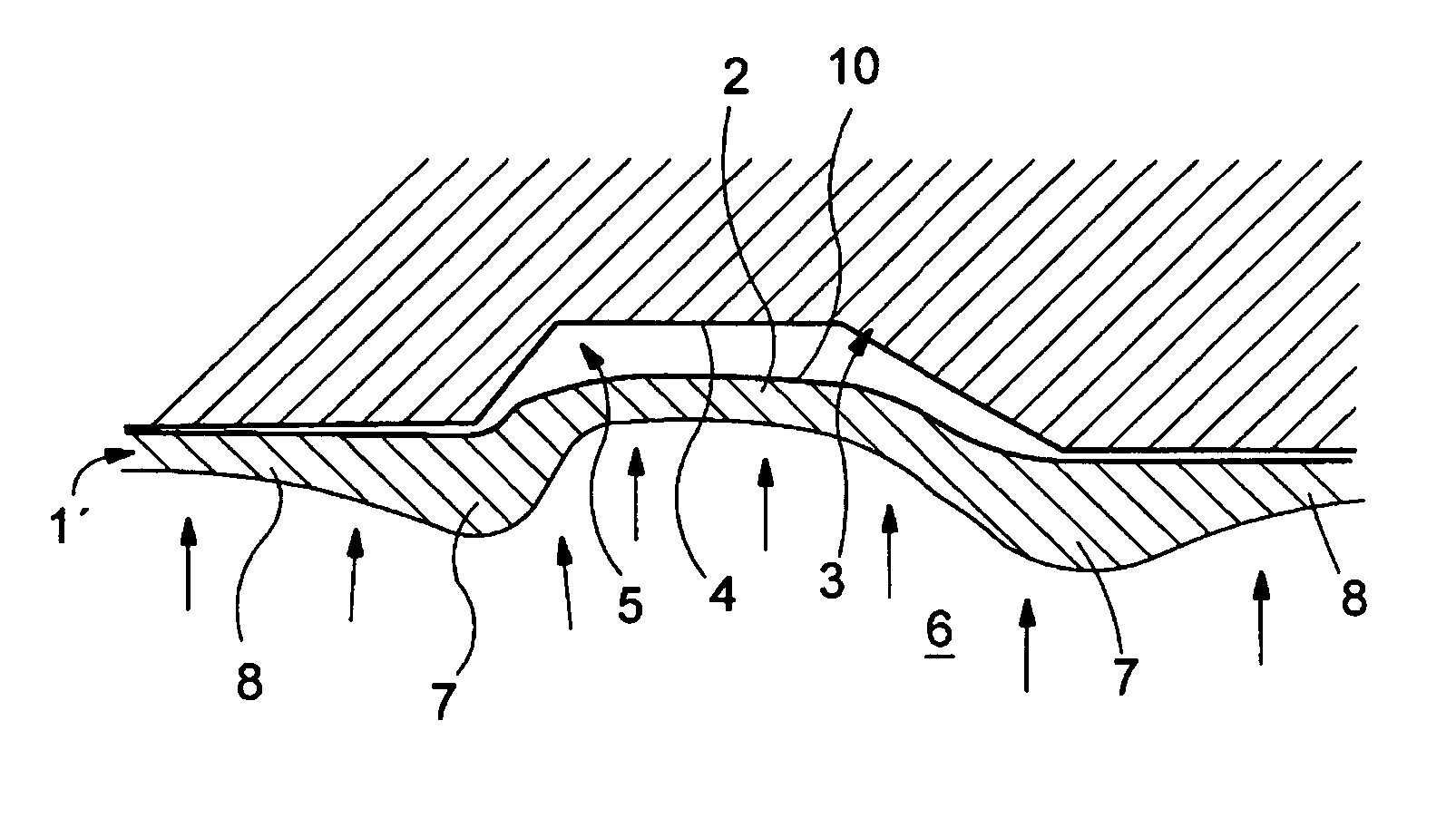

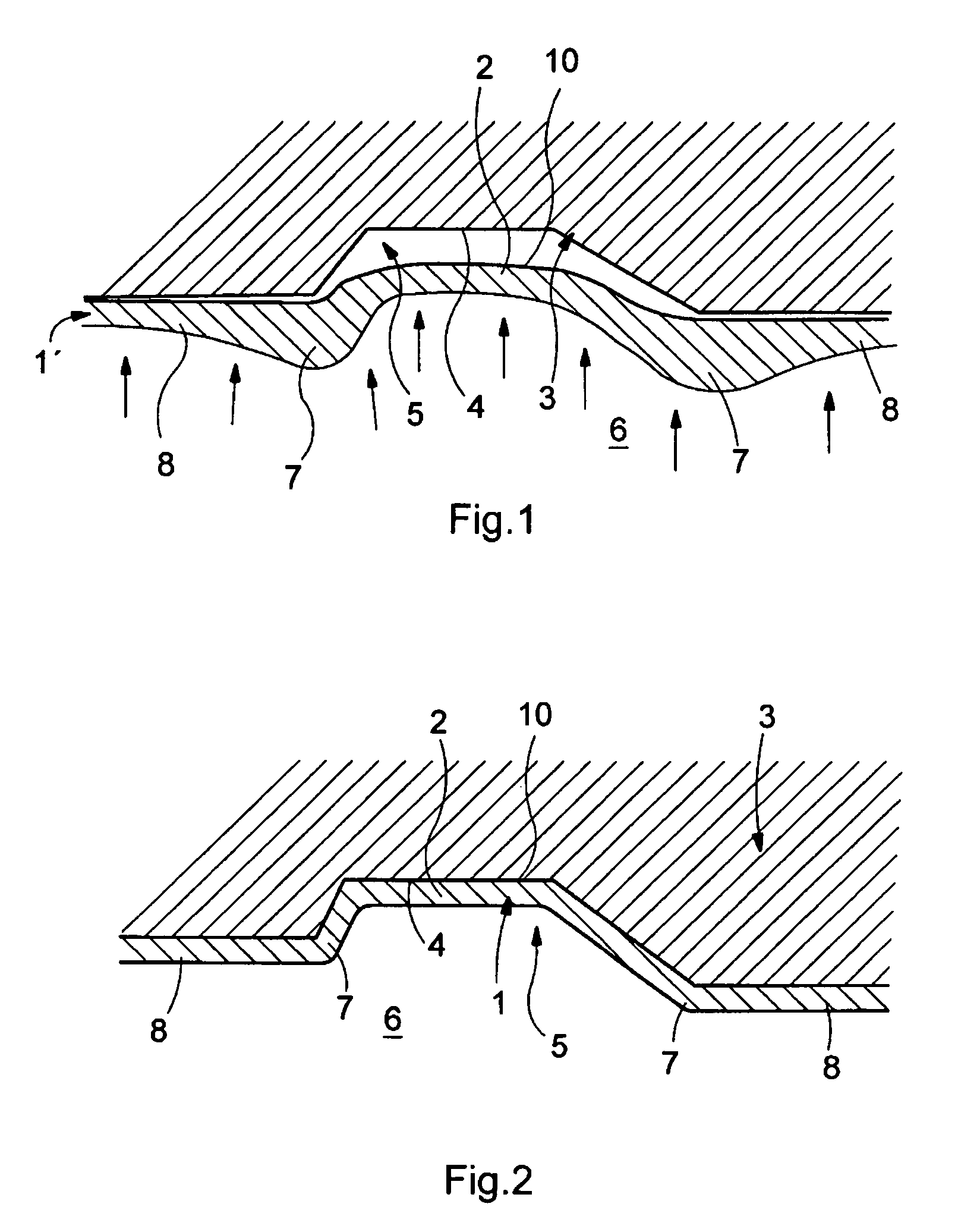

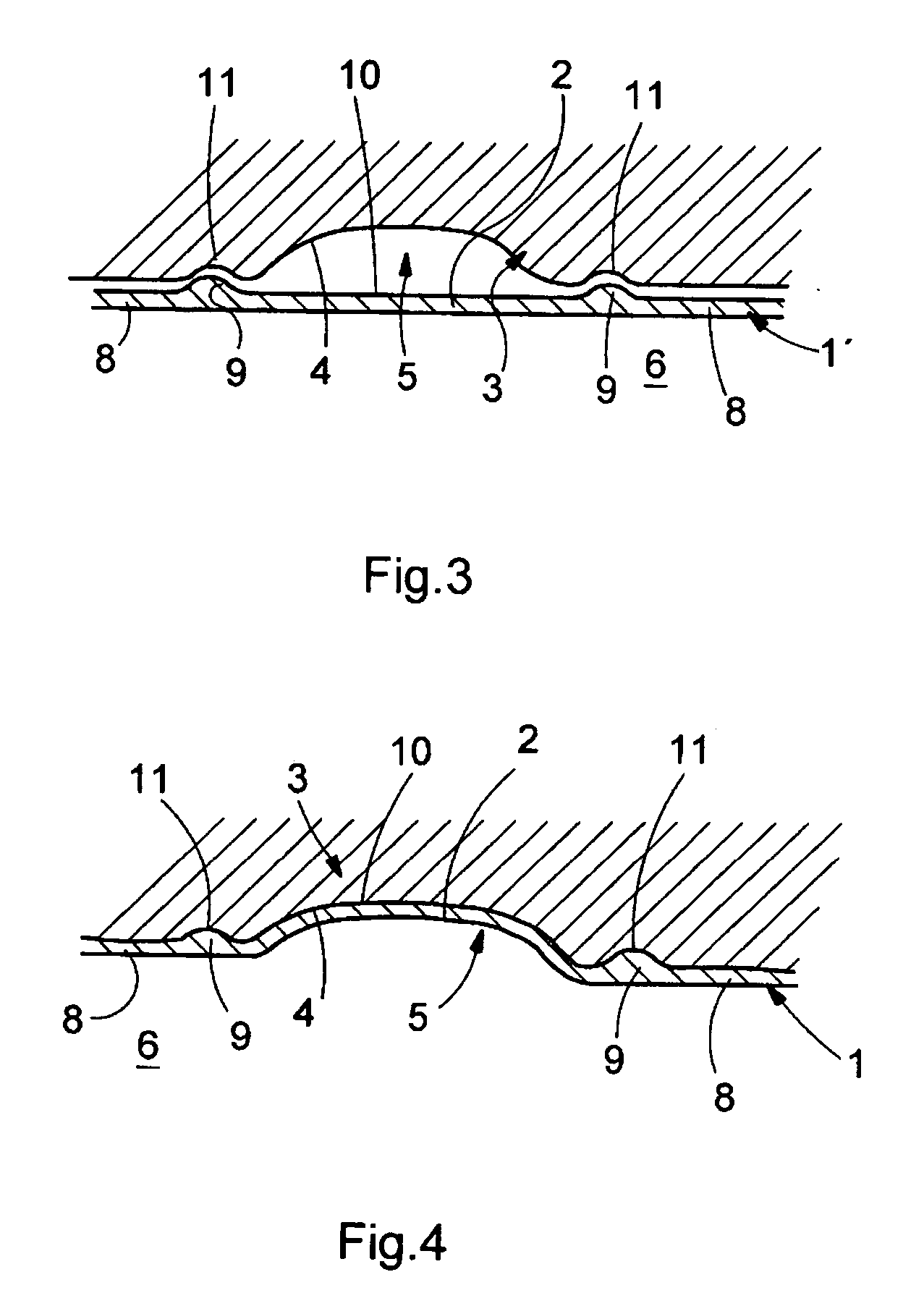

Process for producing hollow metal articles

The invention concerns a process for producing a metallic hollow body (1), in which a hollow cast part (1′) is produced by metal casting, in which the cast part (1′) is deformed by means of internal high pressure deformation in the hollow body (1). In order to improve the quality of the hollow body (1), the cast part (1′) is so produced, that it has a wall thickness distribution supporting or simplifying the internal high pressure deformation.

Owner:DAIMLER AG

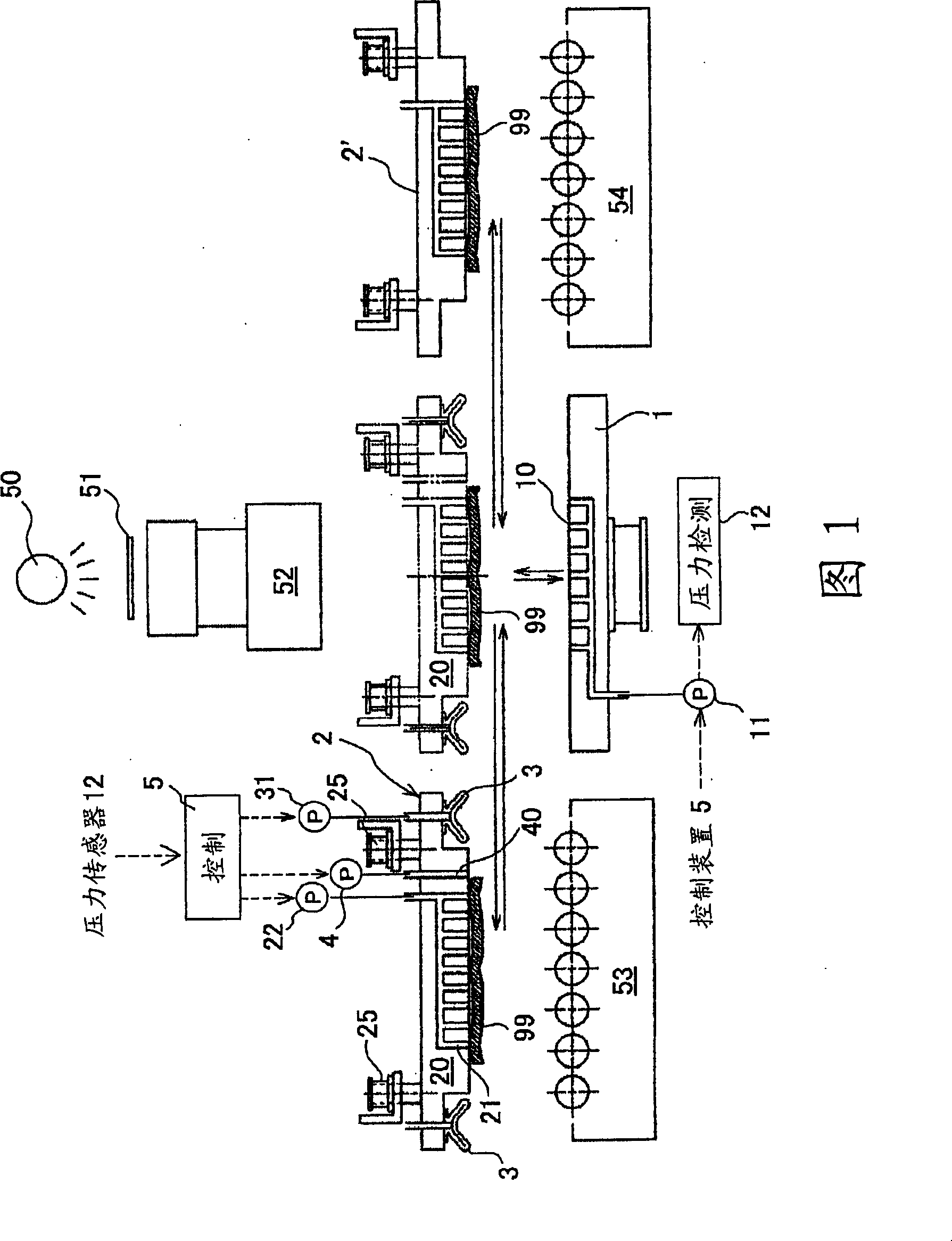

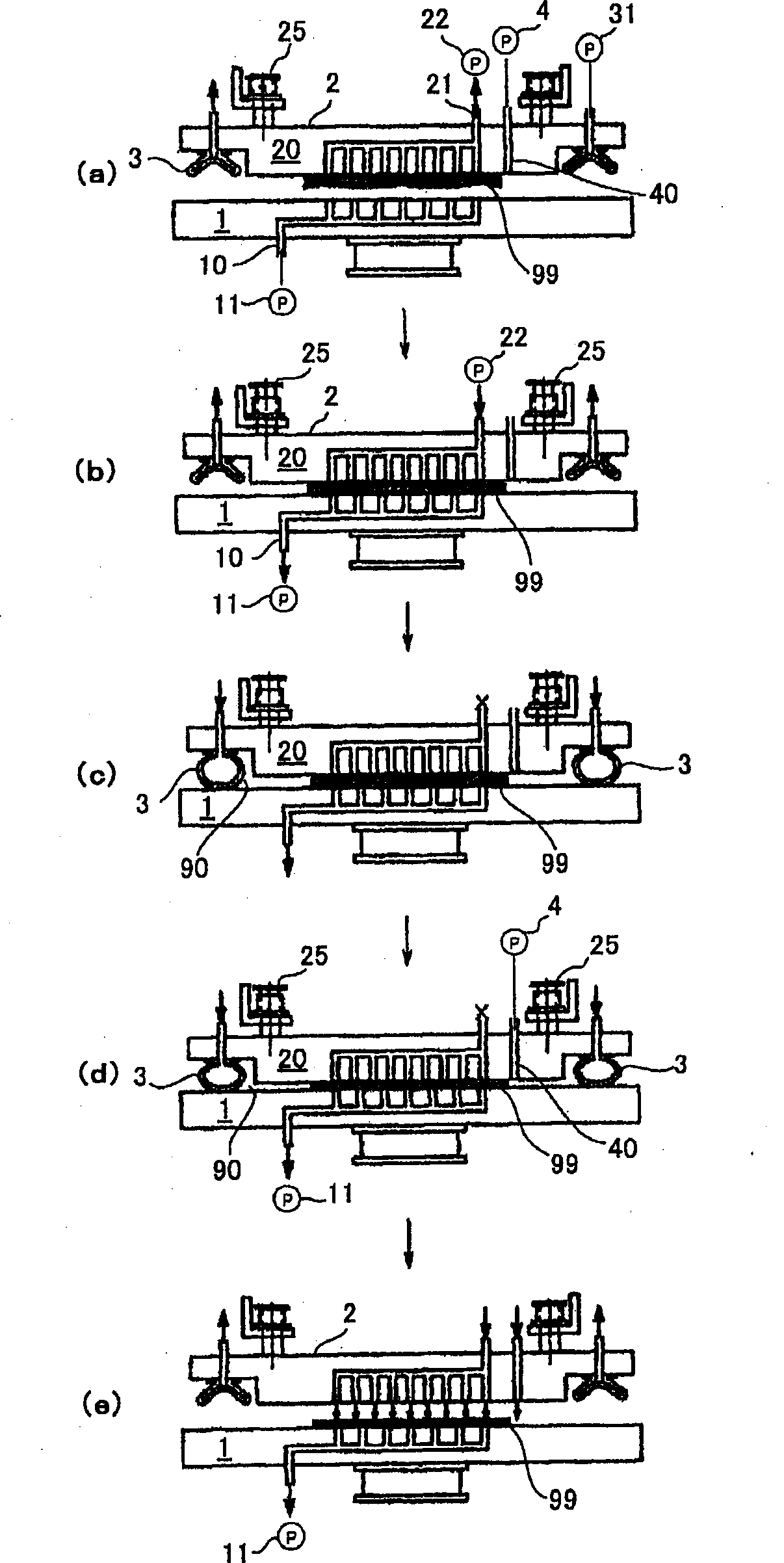

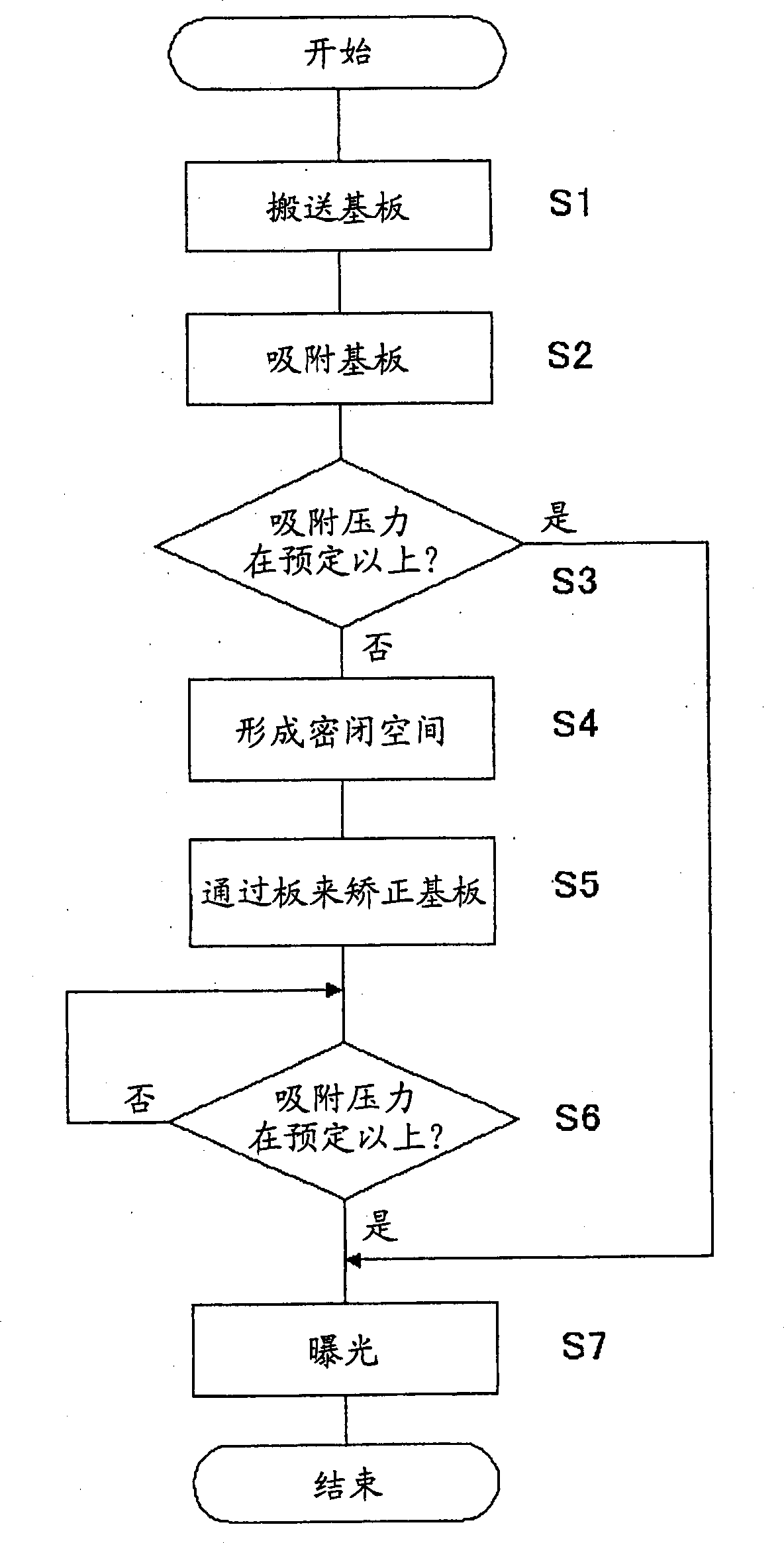

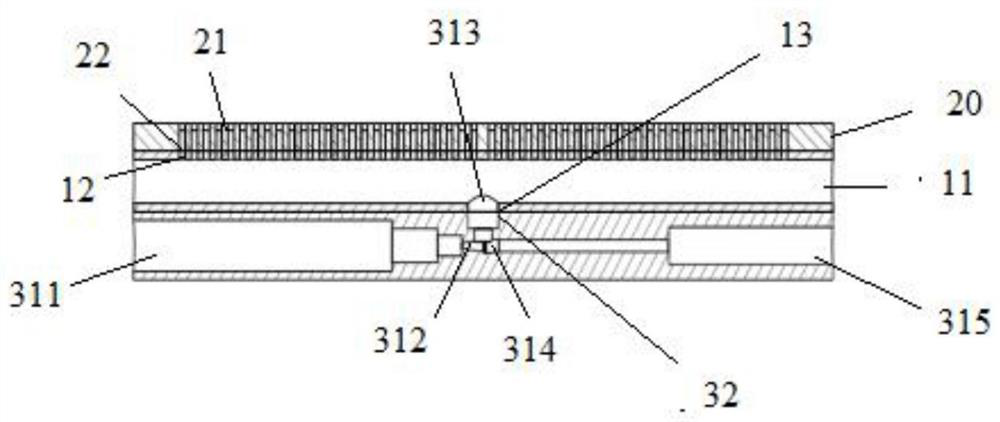

Exposure device and rectification device of baseal plate

ActiveCN101419409ACorrective reaction forceCorrecting the deformation of the reaction forceFlood exposureSemiconductor/solid-state device manufacturingPositive pressureEngineering

The invention provides an exposure device and a correction device of a base plate, characterized in that the exposure device may correct the base plate. A sealing piece (3) is exerted with positive pressure to stretch such that it is contacted with an exposure worktable (1) so as to generate a sealed space (90); the sealed space (90) is sucked by a vacuum sucking hole (40) and a vacuum pump (4); a plate (20) is pressed by atmospheric pressure; a base plate (99) is exerted with loads by the plate (20) and the exposure worktable (1) so as to correct the base plate (99). The vacuum pump (4) is stopped, the sealing piece (3) is shrank, a handling device (2) is withdrawn to a carrying-in conveyer (53), and exposure is them executed if the base plate of a sucking pump (11) is provided with an adsorptive pressure reaching a predetermined set value.

Owner:ADTEC ENG

A Self Folding Box With A Carrier For Packing Pizzas And A Tool For Forming The Box

Owner:NIKOLIC IVAN

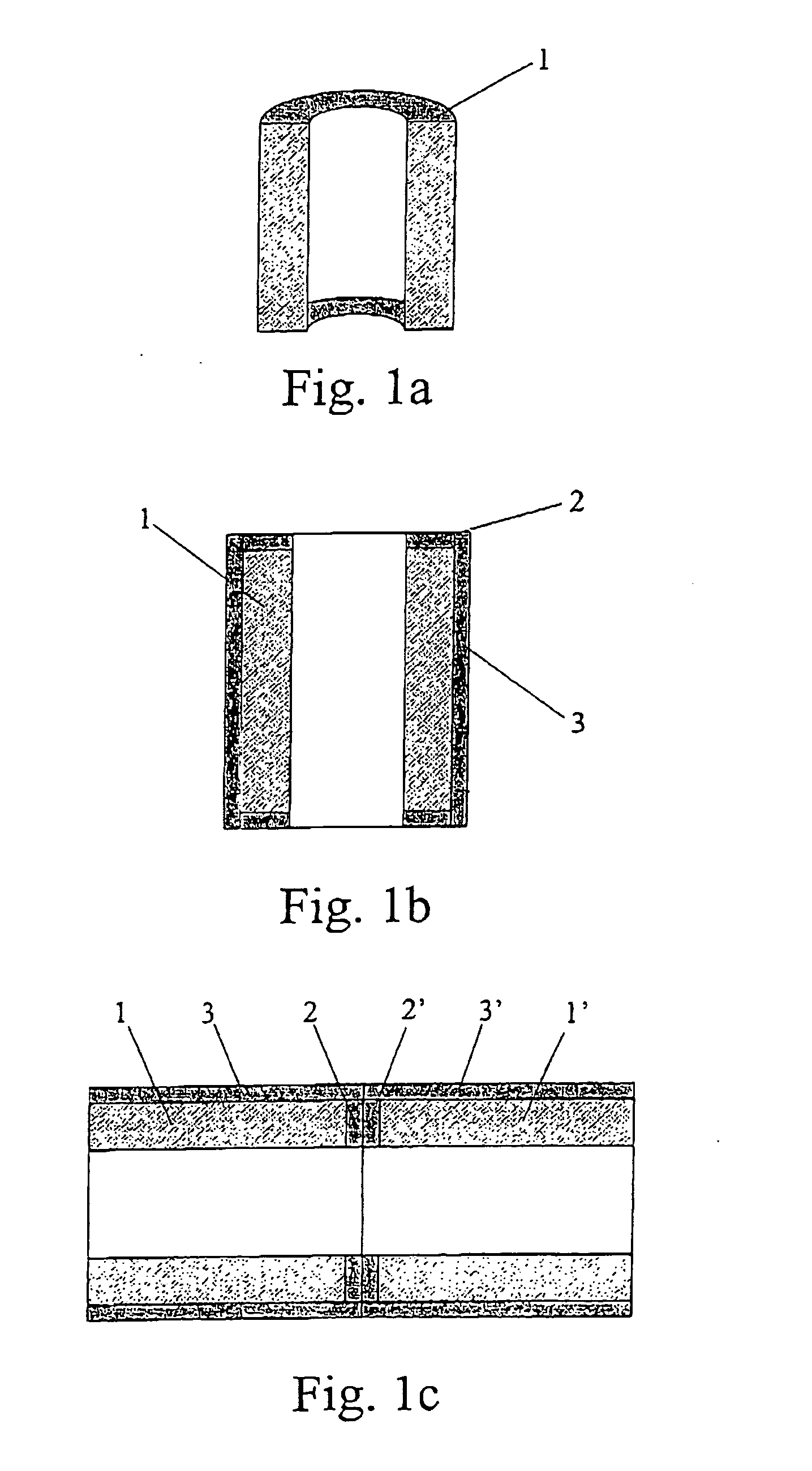

Method for manufacturing roll type products

A method for manufacturing cylinder-like products, wherein pipe billets or pipe billet segments are fabricated of solid material and a layer of one solid material or of a plurality of solid materials, of powder material or of a combination thereof is attached onto the inner and / or outer surface of the pipe billets or pipe billet segments.

Owner:METSO POWDERMET

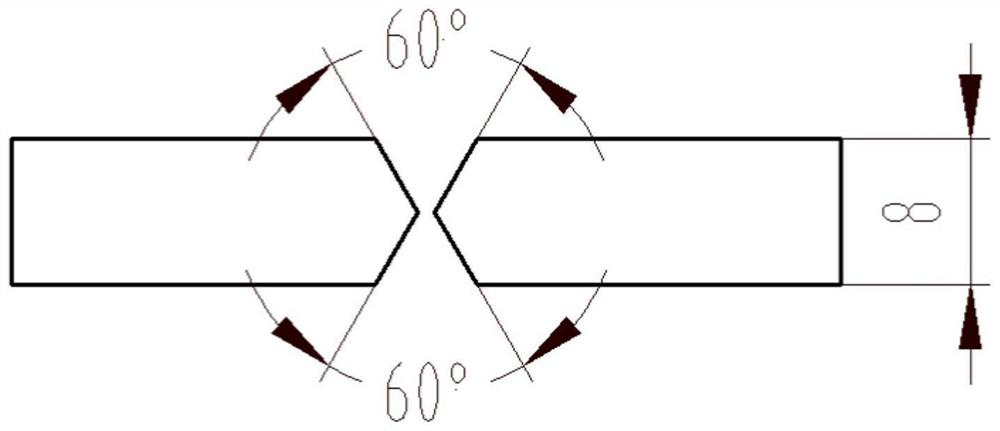

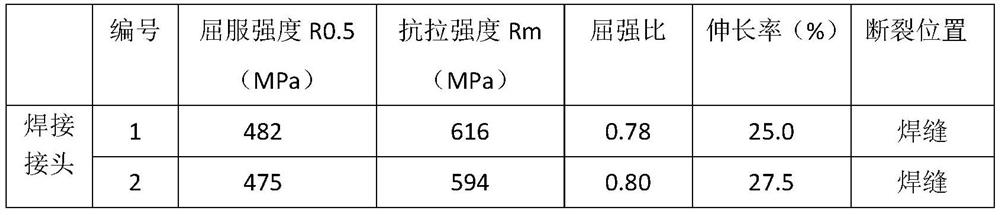

Welding process for ultrahigh-strength steel plate with yield strength larger than or equal to 1250 MPa

The invention relates to a welding process for an ultrahigh-strength steel plate with the yield strength larger than or equal to 1250 MPa, and belongs to the technical field of ultrahigh-strength steel welding. The welding process comprises the following steps: 1, a small iron research test is carried out, and the pre-welding preheating temperature of the ultrahigh-strength steel is determined; 2,the preheating temperature of welding test plates is obtained according to the small iron research test, and the welding test plates are overall preheated; 3, the welding test plates are in butt joint, argon-rich gas is selected as protective gas, and austenitic stainless steel MIG welding wires are adopted for forward welding and reverse welding, wherein the temperature between welding bead layers and between welding beads is controlled to be smaller than or equal to 150 DEG C, and the welding heat input is controlled to be 8-12 KJ / cm; and 4, post-welding inspection and flaw detection are carried out. Welding is conducted in a butt-joint mode, the preheating temperature of the welding test plates is obtained by selecting the austenitic stainless steel MIG welding wires and carrying out the small iron research test, reasonable welding technological parameters are designed, the welding process is strictly controlled, weldability is high, welded joints have good ductility, toughness andcrack resistance after welding, welding joint deformation is small, and welding defects are avoided.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

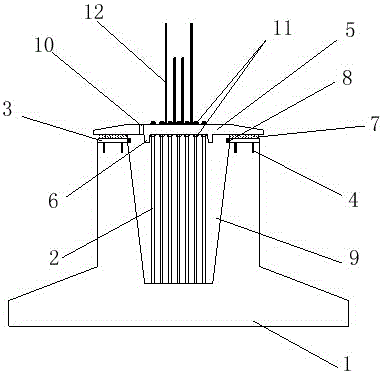

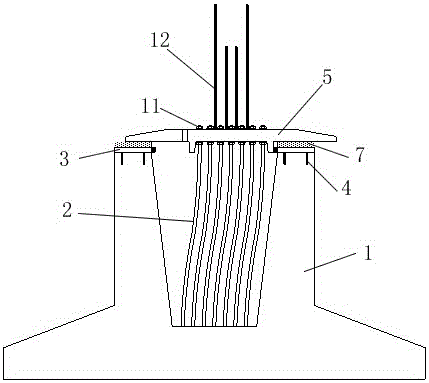

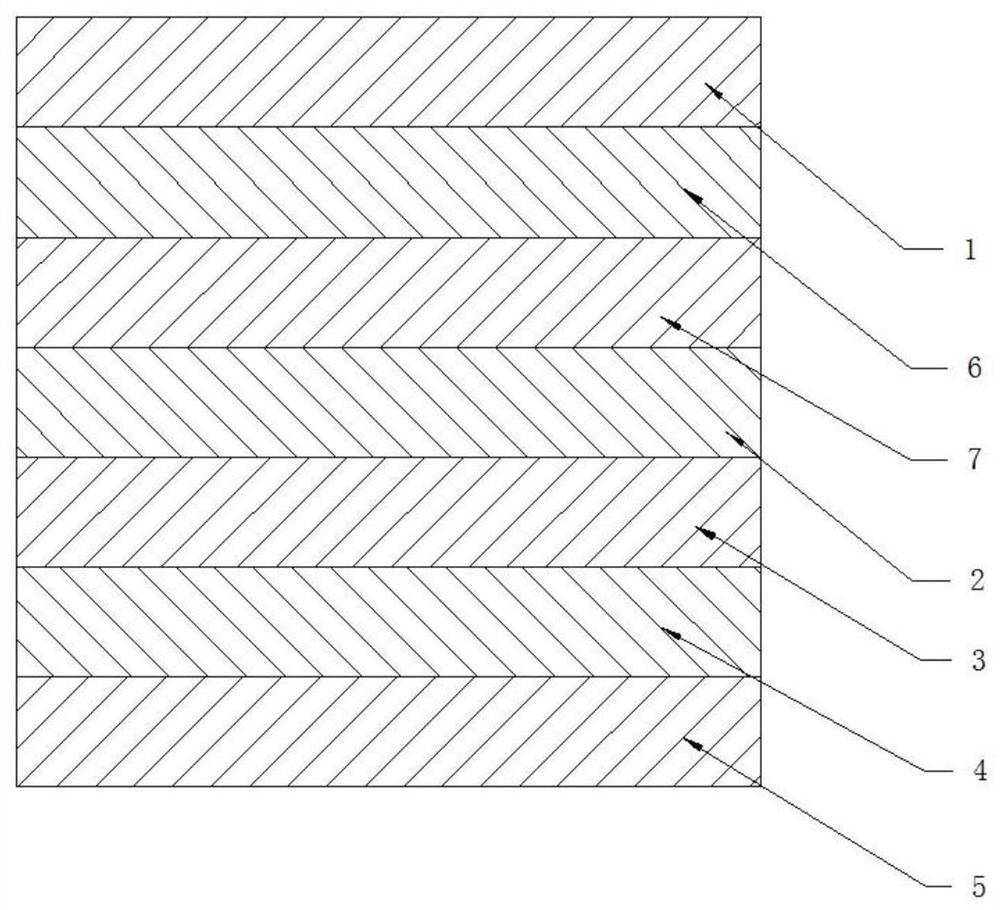

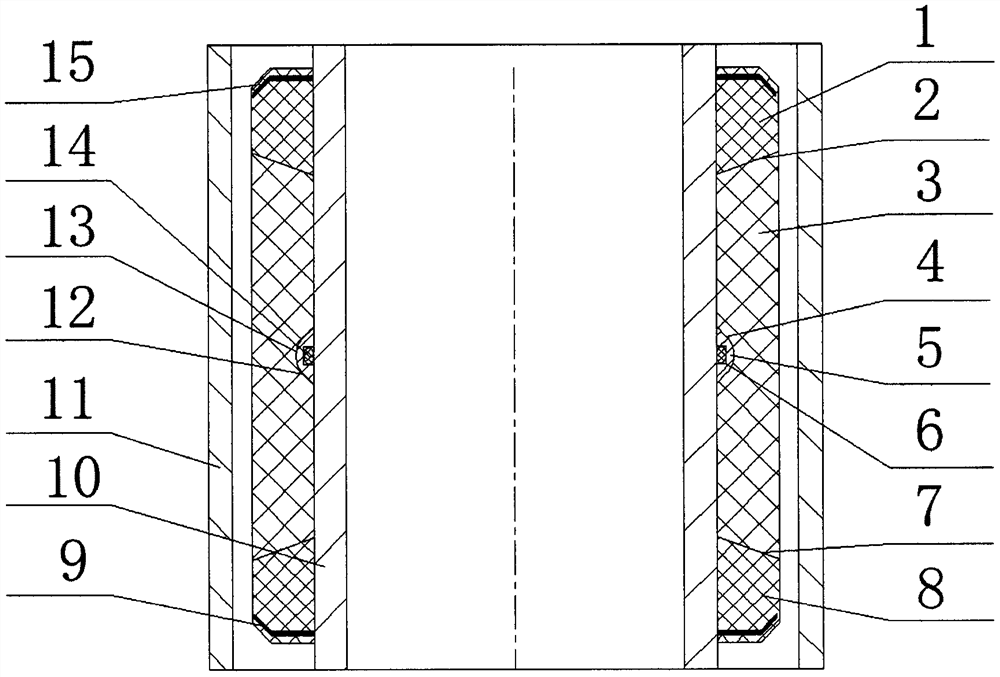

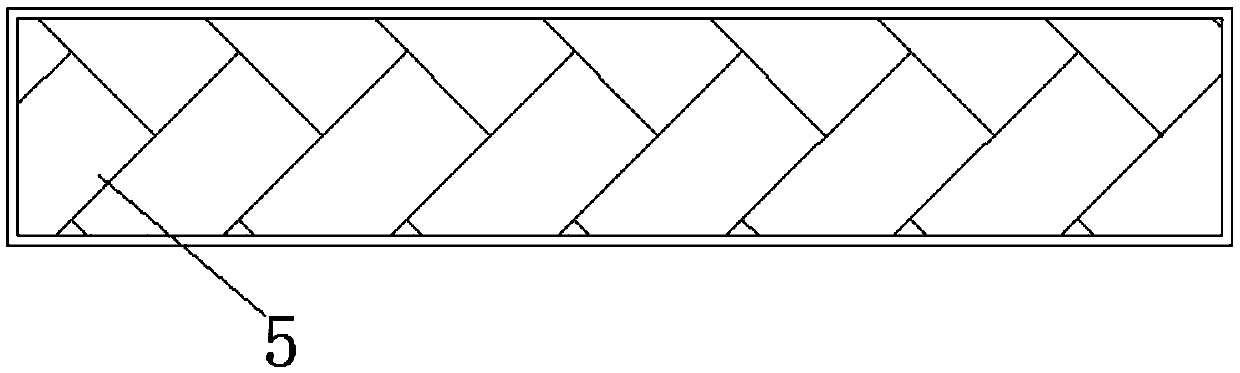

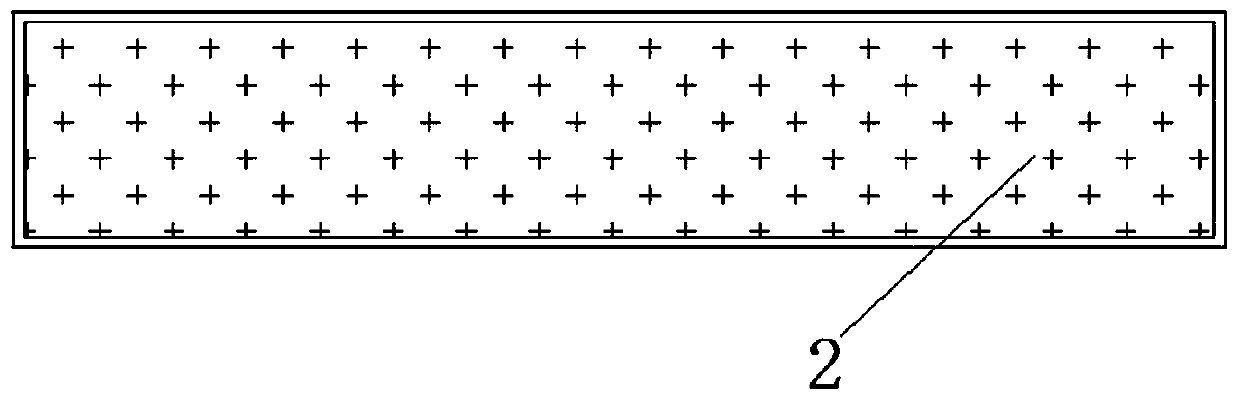

Large rod-cable extending arm extension driving mechanism

InactiveCN100532201CSimple structureStrong deformationCosmonautic vehiclesCosmonautic partsTransducerSprocket

The utility model relates to a large-scale cable rod type extension arm expansion drive mechanism, which relates to a space cable rod type extension arm expansion drive mechanism. It can solve the problem that the large cable-rod extension arm in the existing space is driven by a four-thread spiral lifting sleeve mechanism, which has high manufacturing precision and high manufacturing process requirements, and the extension arm is easy to "stuck". The bottom end cover (1), the retracting sleeve (2), the derotation sleeve (3), and the driving sleeve (4) are fixed together, and the inner wall of the derotation sleeve (3) is provided with eight curved grooves ( 15), eight linear tracks (9) are fixedly installed on the inner wall of the retracting sleeve (2), and the driving sprocket (10) and driven sprocket (13) driven by the chain (11) and the driving sleeve (4) Fixed connection, three chain tooth pieces (12) are equidistantly installed on each chain (11), and rollers (6) are fixedly installed on each top angle of the cable-bar type extension arm assembly, and the rollers (6) are inlaid with The stretch arm tooth piece (5), the chain tooth piece (12) meshes with the stretch arm tooth piece (5), and the driving sprocket (10) is connected by a reversing transmission mechanism. The invention has the advantage of strong ability to accommodate the deformation and processing errors of the extension arm.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

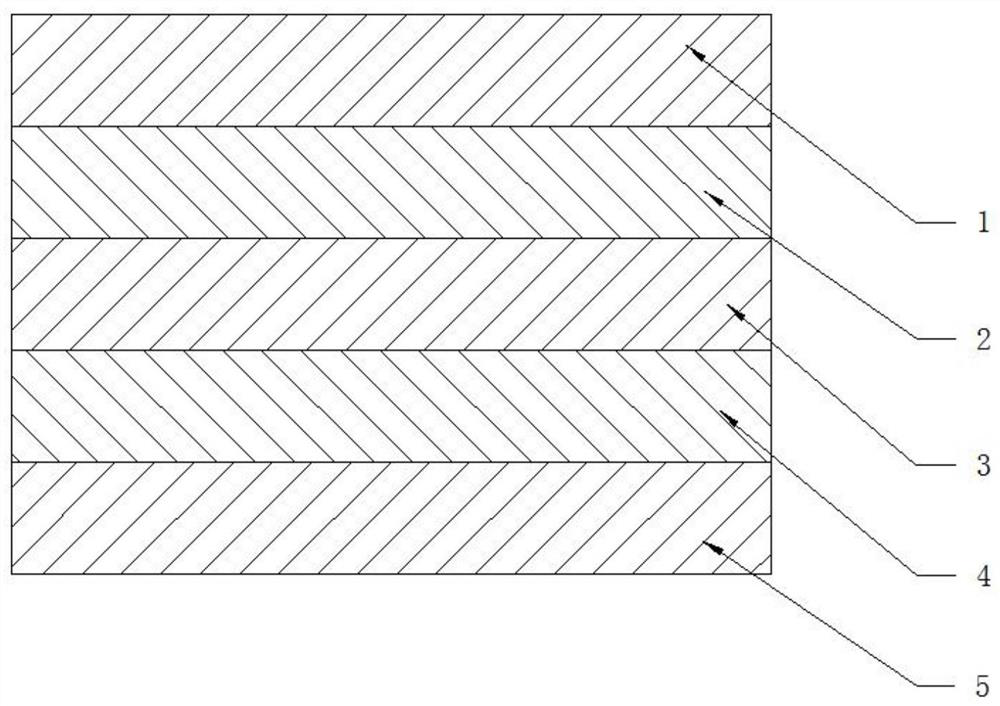

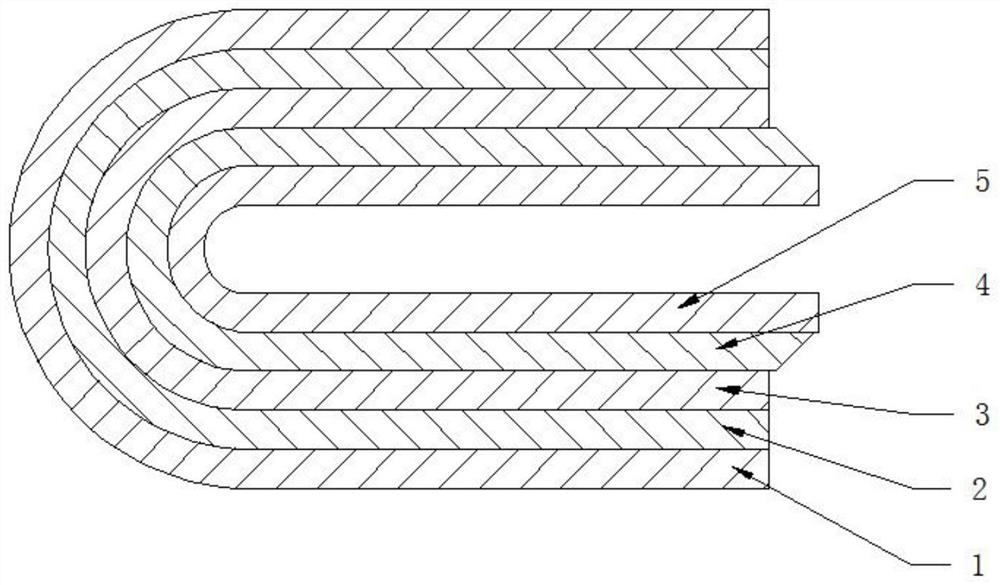

OLED folding or winding type screen and manufacturing process thereof

ActiveCN111147634AAvoid sticky edgesTo achieve the perfect effectTelephone set constructionsEngineeringLight transmission

The invention provides an OLED folding or winding type screen and a manufacturing process thereof, and the OLED folding or winding type screen comprises an OLED display screen layer, a flexible glue layer, a printing layer, a base material and a hardening layer when the screen is folded. When the screen is outside, a hardening layer is arranged below the base material, a printing layer is arrangedabove the base material, a flexible glue layer is arranged above the printing layer, and an OLED display screen layer is arranged above the flexible glue layer; wherein the light transmittance of thebase material should be greater than 88%; the purpose of hardening the surface of the base material is to improve the scratch resistance and fingerprint resistance of the base material; the purpose of printing treatment on the surface of the base material is to improve the flexibility and adherence between the base material and the flexible glue; the beneficial effects of the invention are that the flexible glue design enables the substrate not to be stretched and contracted when the substrate is bent, and guarantees that the protection film, the TP and the OLED cannot be layered and folded;and edge dust adhesion in the deformation process of the flexible glue layer is avoided by reducing the size of the flexible glue.

Owner:SHENZHEN HORAE TECH

Reinforced concrete vibration-isolated foundation

ActiveCN105649101AExtend the natural vibration periodStrong deformationFoundation engineeringReinforced concreteFilling materials

The invention relates to a reinforced concrete vibration-isolated foundation. The reinforced concrete vibration-isolated foundation comprises a ring-shaped foundation, high-elasticity reinforcing steel bars, a cup-mouth steel plate, anchoring pins, a steel cover plate, a limiting baffle bar, sealing grease, buffer cushions, a damping filling material, positioning holes, nuts, injection holes and column joint bars, wherein the ring-shaped cavity of the foundation is filled with the damping filling material to achieve the energy-dissipating damping effect. According to the reinforced concrete vibration-isolated foundation, the foundation in the conventional vibration-isolated foundation and a vibration-isolated supporting base are integrated to achieve the dual functions of foundation stress and vibration isolation, so that relatively great uplift force can be borne; the reinforced concrete vibration-isolated foundation has capacity of damping energy dissipation, can be limited and automatically returned, can obtain required horizontal stiffness by adopting different working modes, and can realize the vibration-isolating effect without mounting the vibration-isolated supporting base, so that the engineering cost can be reduced, and the building space can be saved.

Owner:福建省中禹水利水电工程有限公司

Method for producing an exhaust-gas aftertreatment device

ActiveUS9765681B2Easy to compressEasy to operateExhaust apparatusSilencing apparatusEngineeringExhaust gas

A method for producing an exhaust-gas aftertreatment device inserts a monolith in a housing, assembled from a circumferentially enclosed jacket and two end funnels. The monolith is axially inserted into the jacket with a circumferentially enclosing support mat. The funnels are connected to the jacket via an axial connecting section shaped complementary to the cross-section of the jacket, such that each connecting section and an axial end section of the support mat axially overlap. The jacket, including the connecting sections of the funnels are reduced from a starting cross-section to an end cross-section. This produces a predetermined radial preload in the support mat in a support area extending from the one connecting section to the other connecting section to retain the monolith in the jacket.

Owner:PUREM GMBH

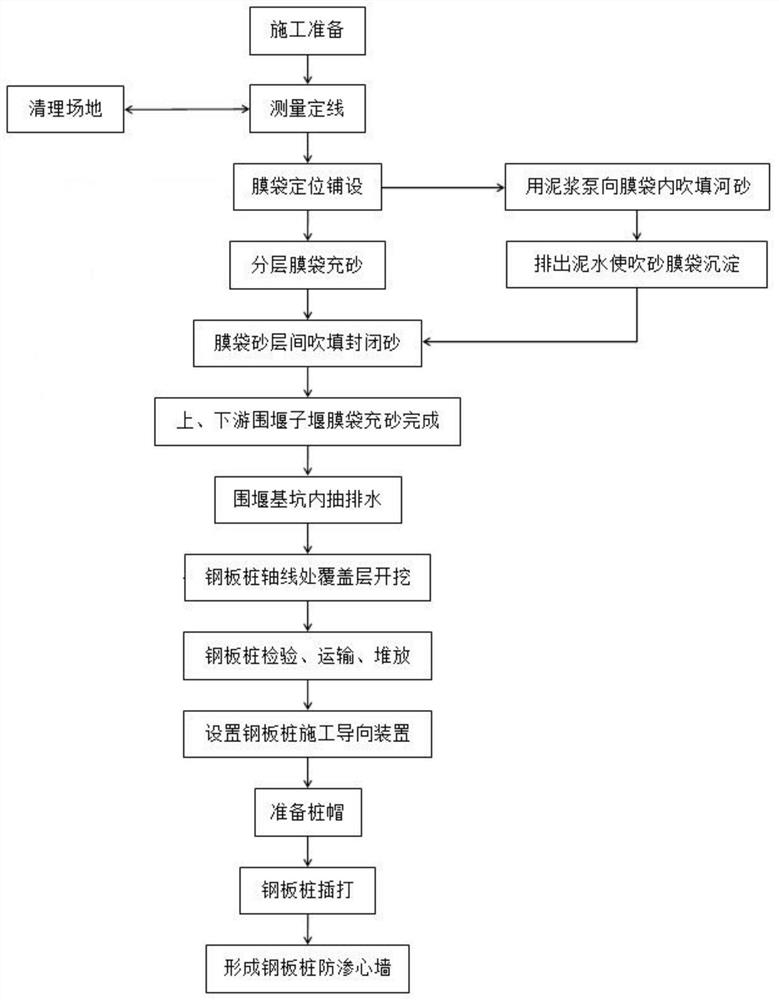

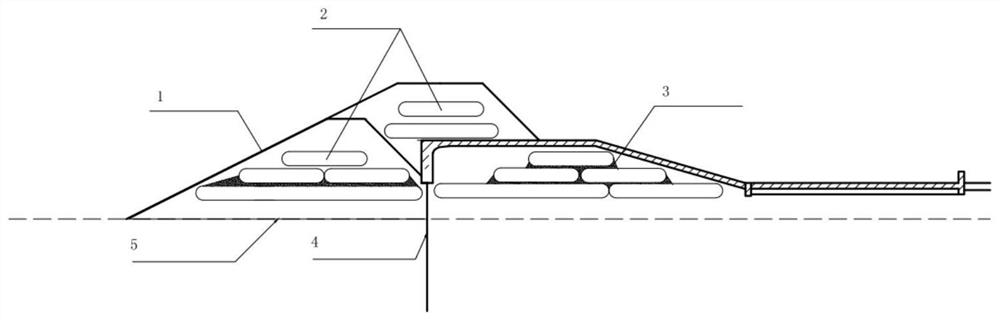

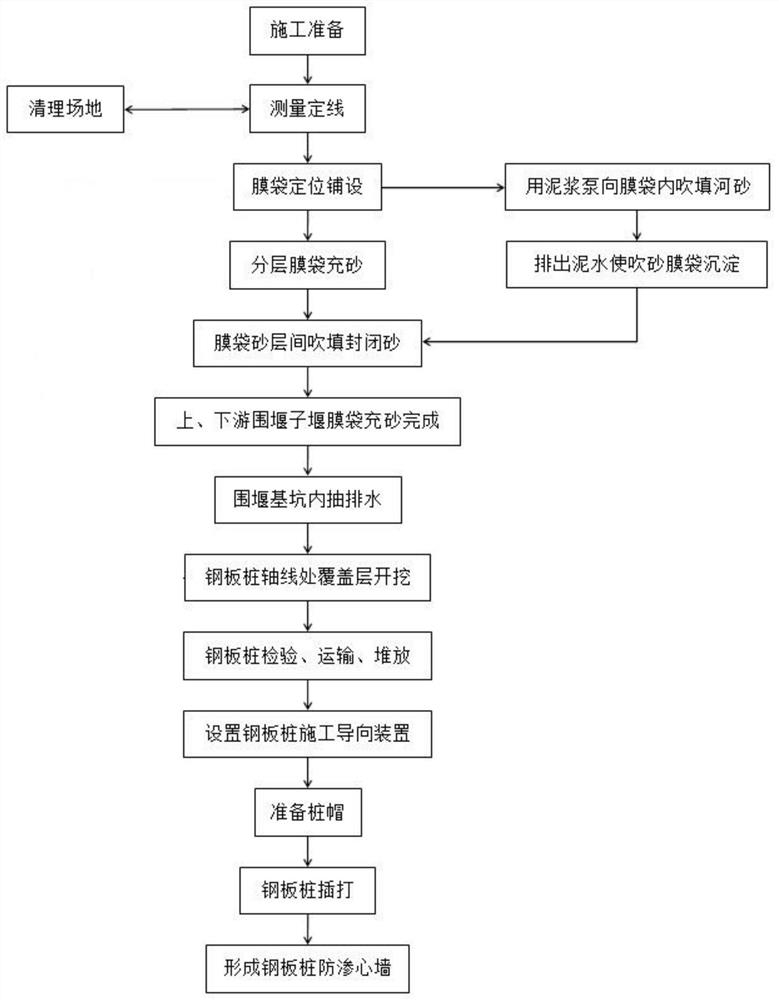

Cofferdam construction method combining film bag sand filling with steel sheet pile

PendingCN113957913AImprove integrityImprove stabilityProtective foundationExcavationsWater dischargeCofferdam

The invention discloses a cofferdam construction method combining film bag sand filling with a steel sheet pile. The cofferdam construction method comprises the steps of measurement and alignment, film bag positioning and laying, layer-by-layer film bag sand filling, muddy water discharging to enable a film bag sand cofferdam to precipitate, blow filling of closed sand between two layers of film bag sand, water pumping and drainage in a cofferdam foundation pit, steel sheet pile anti-seepage core wall construction and the like. According to the construction method, the film bag sand filling is combined with the steel sheet pile anti-seepage full-section cofferdam, the upper portion of the cofferdam is piled up with the film bag wrapped with sand soil, the lower portion of the cofferdam is anti-seepage through the steel sheet piles, the whole cofferdam becomes a whole, so that the cofferdam is high in integrity, good in self stability, high in adaptability to foundation, high in water pressure resistance and good in anti-seepage effect. The problem that the construction cofferdam is constructed under complex underwater geological conditions can be basically and effectively solved, the overall stability of a cofferdam structure is improved, and the cofferdam construction method has the advantages of being simple in process, fast in construction progress, low in cost and the like and has wide application prospects in the field of cofferdam construction of water conservancy projects.

Owner:广西建工集团海河水利建设有限责任公司

Underpants-type disposable diaper

PendingUS20210236350A1Easy to openEasily opened widerAbsorbent padsBandagesEngineeringMechanical engineering

An underpants-type disposable diaper in which an inlet of a dorsal side barrier is easily opened wider. The above problem is solved by an underpants-type disposable diaper in which a barrier sheet extends to a back side of a position on a front side of a back end of an absorber from the position and extends outward in a width direction from positions of both side edges of the absorber in the width direction is included, the barrier sheet has a free part not bonded to a member on a back surface side and a fixed part bonded to the member on the back surface side, a pocket-shaped dorsal side barrier having an inlet opening to a crotch side is formed by the free part of the barrier sheet, and a torsion hardness of a predetermined part including a back end portion of the absorber is 0.18 to 0.32 N·cm / cm.

Owner:DAIO PAPER CORP

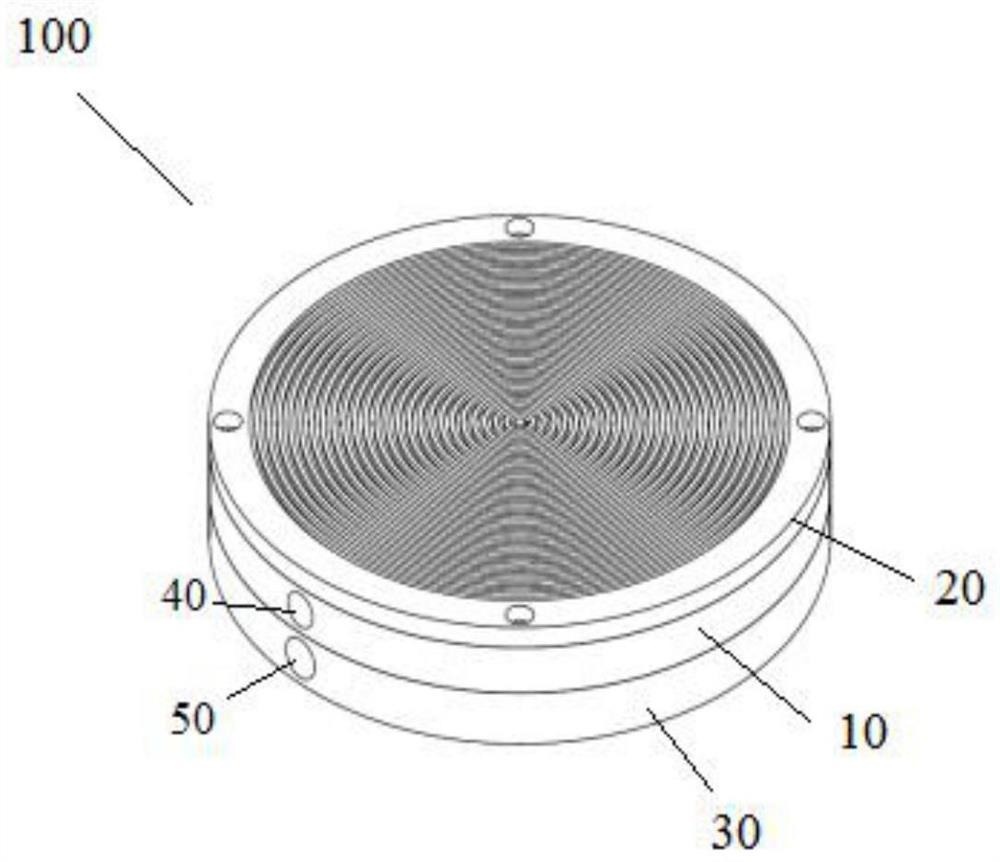

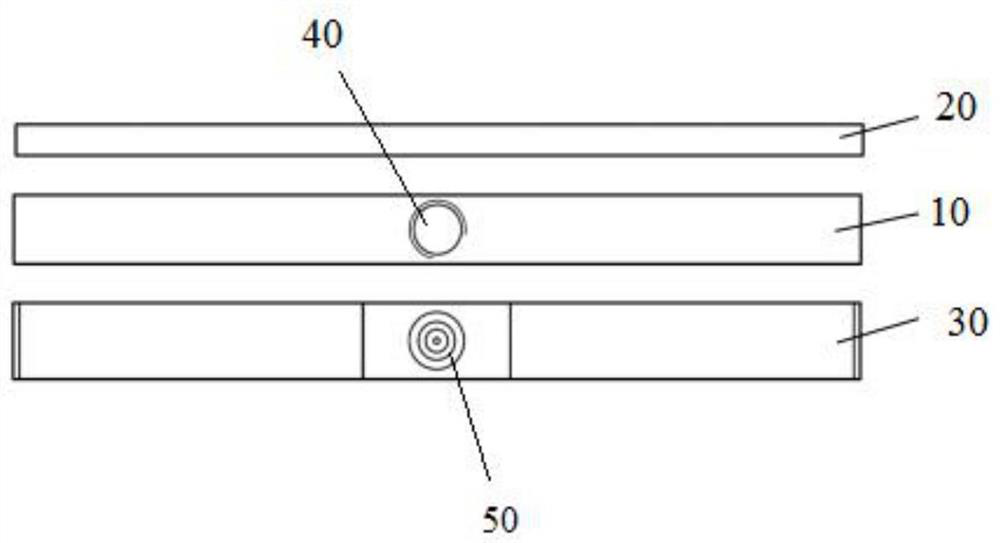

A Vacuum Suction Cup for Ultra-thin Optical Parts

The invention provides a vacuum suction cup for absorbing ultra-thin optical parts, comprising: a vacuum passage part, which is disc-shaped, has a vacuum chamber arranged inside, and is arranged on the upper surface of the vacuum chamber through the center of the circle and uniformly arranged along the diameter direction The first through hole and the second through hole arranged in the center of the lower surface of the vacuum chamber; the rubber adsorption part is arranged above the vacuum passage part, which is disc-shaped, has an annular groove and is arranged below the annular groove with the The first through hole is aligned with the through hole; and the vacuum generator part is arranged under the vacuum passage part, which is disc-shaped, and the vacuum generator is arranged inside, and the center of the upper surface is provided with the second through hole. Aligned round holes, wherein the vacuum generator part, the rubber suction part and the vacuum passage part are sealed with sealant, and screwed and fixed with screws and nuts to form an integrated structure.

Owner:FUDAN UNIV

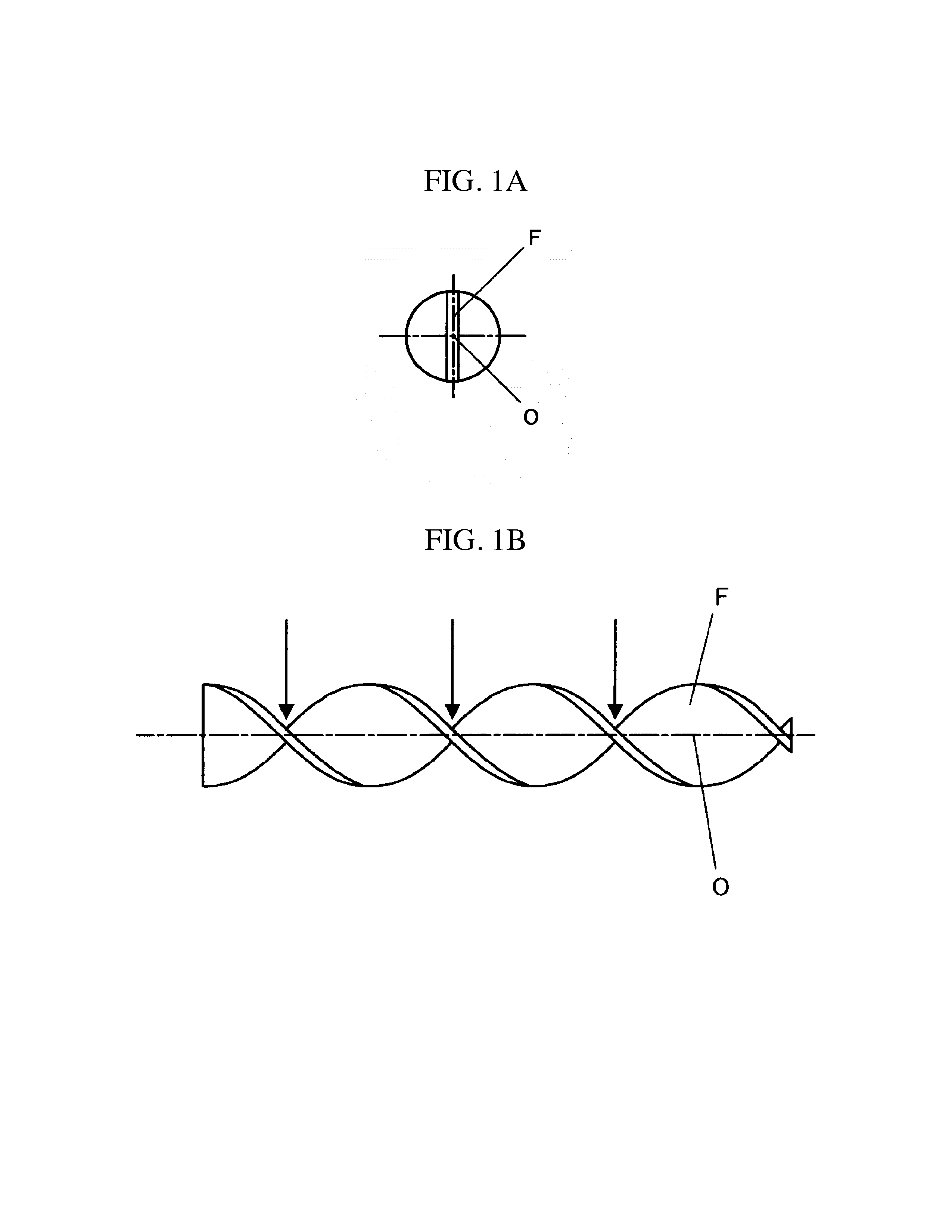

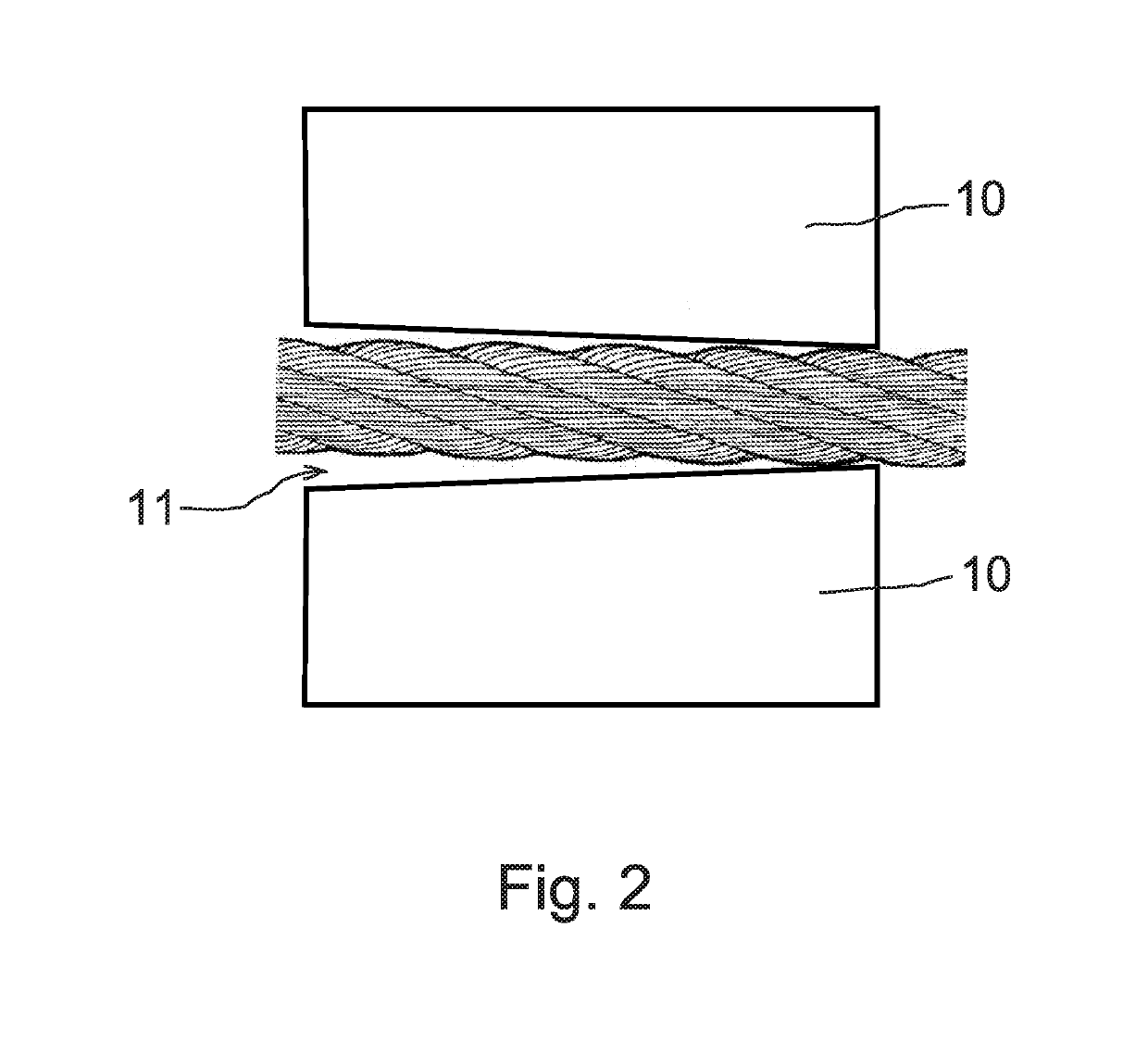

Method for producing a wire cable

ActiveUS10260198B2Avoid wire damageDeformation can be impairedRope making machinesThin material handlingPlastic materialsEngineering

A method for producing a wire cable with a core cable or core strand, the method including the steps of: prior to stranding an outer strand layer, applying an intermediate layer of a plastic material to the core cable or core strand; pressing the outer layer into the plastic material during stranding; and, hammering the wire cable, after the outer strand layer has been stranded, to increase the space factor of the wire cable, wherein the hammering step includes hammering with hammers that are moved from different sides toward the wire cable and essentially completely surround the wire cable with adapted curvatures at the instant of their simultaneous impact.

Owner:WIRECO GERMANY GMBH

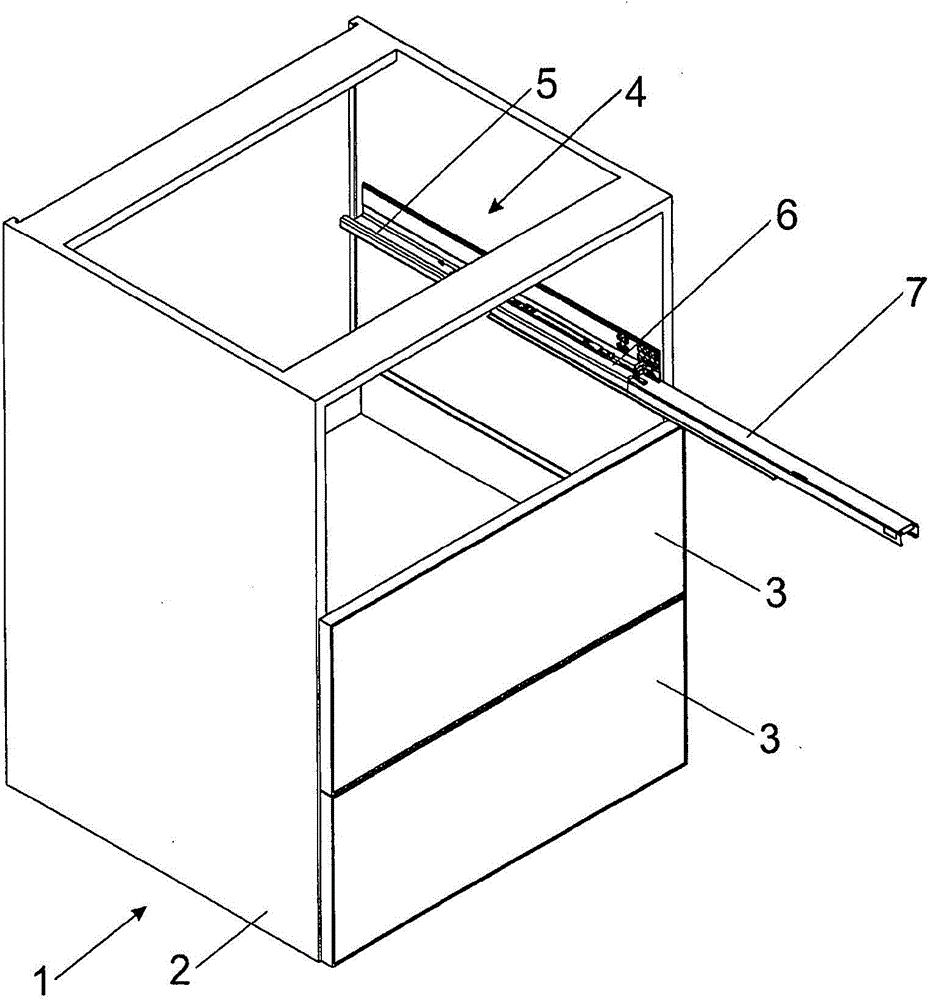

Damping device for movable furniture parts

The invention relates to a damping device (12) for movable furniture parts (3), comprising at least one fluid chamber (29), at least one piston (19) movable in the fluid chamber (29), wherein the piston (19) has at least one opening (20) for passage of a damping fluid provided in the fluid chamber (29), at least one movable covering plate (22), which is mounted at a bearing (23) so as to pivot or bend relative to the passage opening (20) of the piston (19), wherein during a damping stroke of the piston (19) the covering plate (22) at least partially covers or closes the at least one passage opening (20) of the piston (19). The bearing (23) is arranged at an edge region of the covering plate (22). In cross-section the piston (19) and the fluid chamber (29) are symmetrical around a longitudinal axis (L) and the at least one covering plate (22) is held by the bearing (23) asymmetrically in relation to said longitudinal axis (L).

Owner:JULIUS BLUM GMBH

An oled folding or windable screen and its manufacturing process

ActiveCN111147634BStrong deformationResponse ability is strongTelephone set constructionsEngineeringMechanical engineering

The invention provides an OLED folding or wrapping screen and a manufacturing process thereof. When the screen is folded, it includes an OLED display screen layer, a soft glue layer, a printing layer, a base material and a hardened layer; There is a hardened layer, a printing layer is arranged above the substrate, a soft adhesive layer is arranged above the printing layer, and an OLED display layer is arranged above the soft adhesive layer; the light transmittance of the substrate should be >88%; the surface of the substrate is hardened The purpose is to increase the scratch resistance and anti-fingerprint performance of the substrate; the purpose of the surface printing treatment of the substrate is to increase the flexibility and adhesion between the substrate and the soft glue; the beneficial effect of the present invention is: through the design of the soft glue, the The substrate does not stretch and shrink when it is bent, ensuring that there will be no delamination and crease between the protective film, TP and OLED; by reducing the size of the soft glue, the edges of the soft glue layer are prevented from sticking to dust during the deformation process.

Owner:SHENZHEN HORAE TECH

Novel combined compression type packer rubber sleeve

The invention provides a novel combined compression type packer rubber sleeve. The novel combined compression type packer rubber sleeve comprises an upper rubber sleeve, a middle rubber sleeve and a lower rubber sleeve, all of which are arranged between a central pipe and a casing pipe. The middle rubber sleeve is a trapezoidal section with the interior narrower than the exterior, the upper end and the lower end of the middle rubber sleeve are symmetrically sleeved with the upper rubber sleeve and the lower rubber sleeve, wedge-shaped slope structures consistent with the two sides of the rubber sleeve in shape are arranged at the contact positions of the upper rubber sleeve and lower rubber sleeve with the middle rubber sleeve, and the ends away from the rubber sleeve are planes. Metal elastic rings are wrapped and vulcanized in the shoulder portions of the upper rubber sleeve and the lower rubber sleeve, the metal elastic rings are of dish-shaped structures, and dish openings face inwards. A special-shaped annular groove is formed in the middle position of the inner side of the middle rubber sleeve and is formed by combining a trapezoid section and a semicircular section, a metalsupporting piece is arranged in the special-shaped annular groove, the section shape of the metal supporting piece is consistent with that of the special-shaped annular groove, a rectangular groove isformed in the supporting piece, and an O-shaped sealing ring is arranged in the rectangular groove in a sleeved manner. The novel combined compression type packer rubber sleeve is compact in structure, scientific and reasonable in design and good in sealing effect, unsealing is easy, and the sealing reliability of the rubber sleeve under high-temperature and high-pressure working conditions can be improved.

Owner:TIANJIN UNIV OF SCI & TECH

A sandwich sealant strip

ActiveCN109322600BStrong deformationNovel structureSealing arrangementsAgricultural engineeringSelf adhesive

The invention discloses a sandwich sealing rubber strip. The sandwich sealing rubber strip comprises an outer sponge block, a lower EVA block, an upper EVA block, self-adhesive glue blocks, a decorative film and a strong glue block; the lower EVA block is arranged on the lower part of the outer sponge block, the upper EVA block is arranged on the upper part of the outer sponge block, the upper EVAblock and the outer sponge block are fixed through the corresponding self-adhesive glue block, and the lower EVA block and the outer sponge block are fixed through the corresponding self-adhesive glue block; and the decorative film is arranged on the upper part of the upper EVA block, and the decorative film and the upper EVA block are fixed through the strong glue block. According to the sandwich sealing rubber strip, the outer sponge block, the lower EVA block, the upper EVA block, the self-adhesive glue blocks, the decorative film and the strong glue block are attached together, thus a five-in-one structure is achieved and is first innovation in the field, the sandwich sealing rubber strip is novel in structure, meanwhile, the sandwich sealing rubber strip has self-adhesive glue and high elasticity, thus the sandwich sealing rubber strip is close and firm in connection, has quite high deformation, and is not prone to being damaged, operation is easy, convenient and quick, and the sandwich sealing rubber strip looks high-grade and attractive by arranging the decorative film.

Owner:李杰敏

A kind of production method of yarn-dyed plaid fabric

InactiveCN103590164BBeautiful appearanceStrong color fastnessWoven fabricsLiquid/gas/vapor yarns/filaments treatmentYarnFiber

The invention discloses a processing method of a yarn-dyed plaid fabric. The production method comprises the following steps: (1) Firstly, select the raw material, select 4 fibers formed by twisting 50D / 72F semi-gloss DTY colored yarn as the warp yarn, and select 4 fibers formed by twisting 50D / 72F semi-gloss DTY colored yarns are used as wefts; (2) inspect the selected warp and weft; (3) inspect the qualified warp and weft according to the warping process It is required to make a warp beam through a warping machine; (4) sizing; (5) drafting; (6) weaving; (7) inspect the cloth through a cloth inspection machine, and if there are defects, manually repair the defects. The fabric produced by the invention has beautiful appearance, strong color fastness, low hygroscopicity, and its impact resistance is 4 times higher than that of nylon and 20 times higher than that of viscose fiber; it has good elasticity, strong wrinkle resistance and strong dimensional stability; The color is strong, not easy to fade, and can be fully restored when stretched by 5% to 6%.

Owner:TIANXI TEXTILE PROD +1

Sealing system and sealing ring

A sealing system for sealing shafts against liquid media, for example propeller shafts, impeller shafts, rudder stocks of ships and the like. Opposing corner regions of the sealing system that are located radially inside of a clamping space, for clamping at least one sealing ring, are formed by inclined run-on surfaces that diverge when viewed radially from the inside towards the outside. For accommodation in the clamping space, a clamping section of the sealing ring comprises two opposite edge regions that are formed by inclined surfaces that correspond to the run-on surfaces.

Owner:SKF MARINE GMBH +1

Reinforced Concrete Seismic Isolation Foundation

ActiveCN105649101BExtend the natural vibration periodStrong deformationFoundation engineeringReinforced concreteFilling materials

The invention relates to a reinforced concrete vibration-isolated foundation. The reinforced concrete vibration-isolated foundation comprises a ring-shaped foundation, high-elasticity reinforcing steel bars, a cup-mouth steel plate, anchoring pins, a steel cover plate, a limiting baffle bar, sealing grease, buffer cushions, a damping filling material, positioning holes, nuts, injection holes and column joint bars, wherein the ring-shaped cavity of the foundation is filled with the damping filling material to achieve the energy-dissipating damping effect. According to the reinforced concrete vibration-isolated foundation, the foundation in the conventional vibration-isolated foundation and a vibration-isolated supporting base are integrated to achieve the dual functions of foundation stress and vibration isolation, so that relatively great uplift force can be borne; the reinforced concrete vibration-isolated foundation has capacity of damping energy dissipation, can be limited and automatically returned, can obtain required horizontal stiffness by adopting different working modes, and can realize the vibration-isolating effect without mounting the vibration-isolated supporting base, so that the engineering cost can be reduced, and the building space can be saved.

Owner:福建省中禹水利水电工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com