A Vacuum Suction Cup for Ultra-thin Optical Parts

A technology for optical parts and vacuum suction cups, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of large deformation of the sucked object, large deformation of the vacuum suction cup, large space occupation, etc., to achieve high tensile strength, Space-saving, firm adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

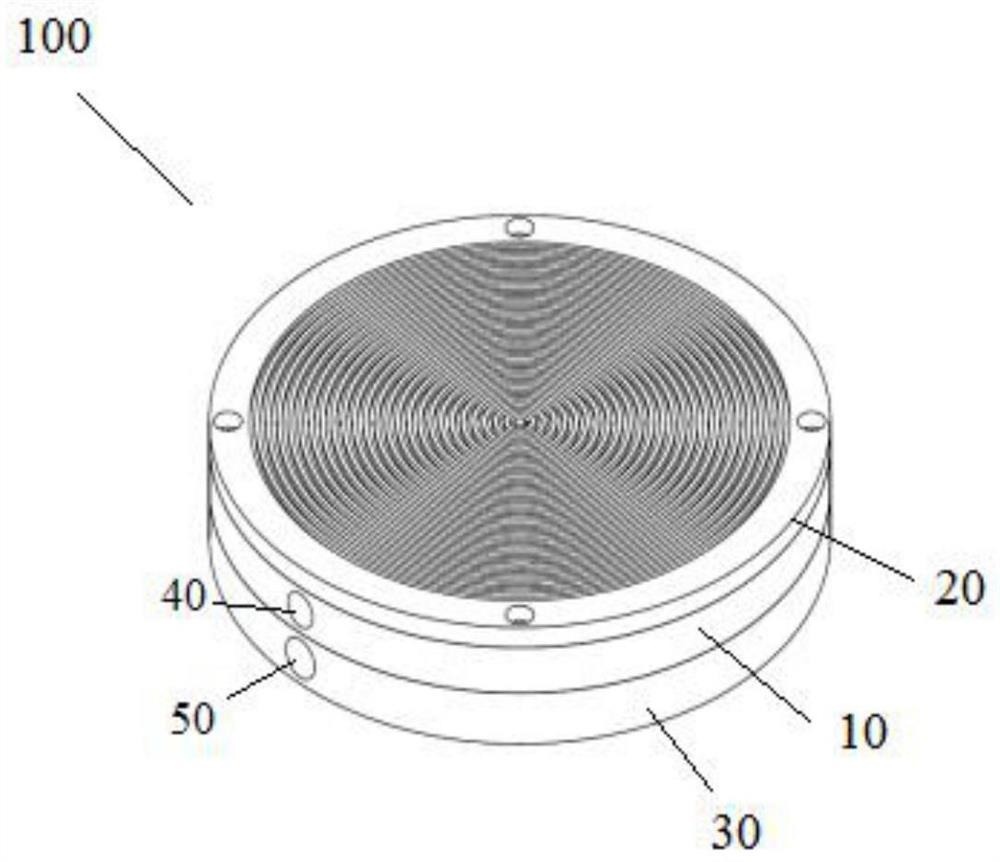

[0017] figure 1 It is a schematic diagram of the overall structure of a vacuum chuck for sucking ultra-thin optical parts in an embodiment of the present invention.

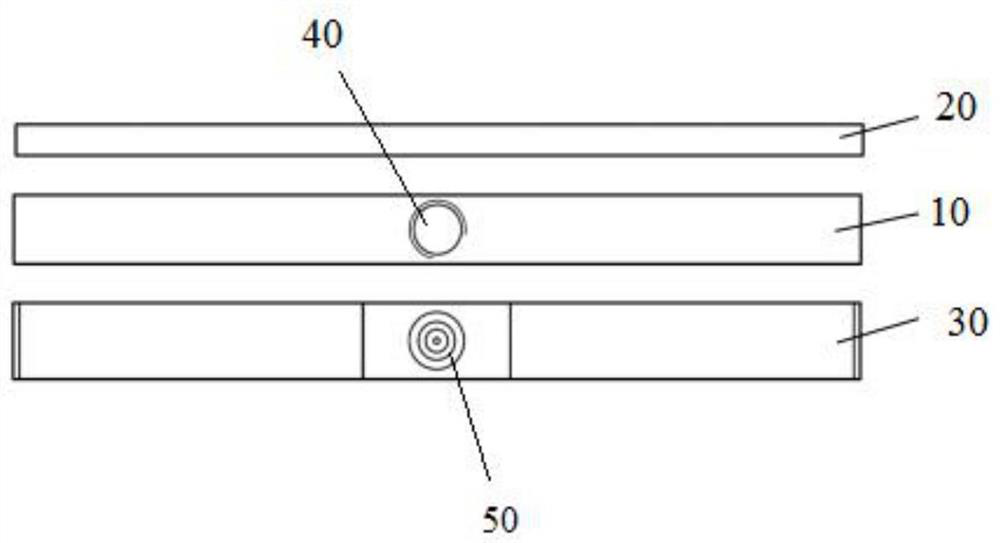

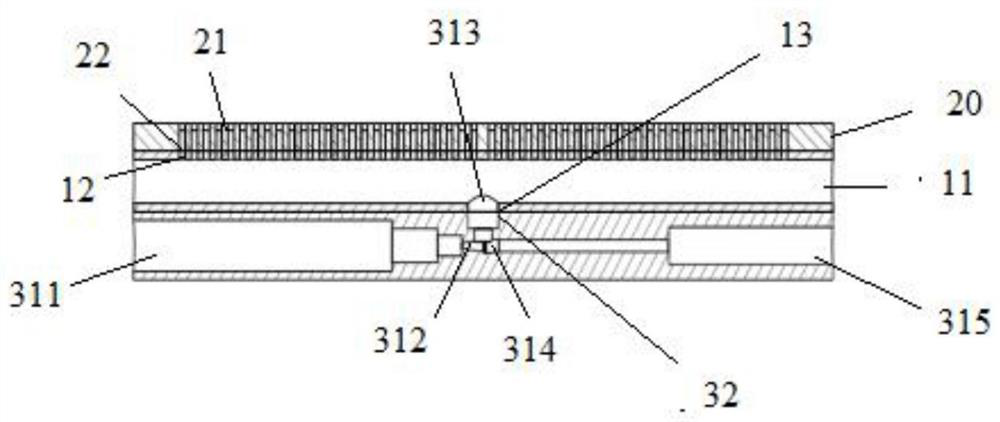

[0018] Such as figure 1 As shown, a vacuum chuck 100 for picking up ultra-thin optical components in this embodiment includes a vacuum passage portion 10 , a rubber suction portion 20 and a vacuum generator portion 30 .

[0019] The vacuum generator part 10, the rubber adsorption part 20 and the vacuum passage part 30 are sealed with a sealant, and screwed and fixed with screws and nuts to form an integrated structure.

[0020] The materials of the vacuum channel part 10 and the vacuum generator part 30 are both stainless steel, and the material of the rubber adsorption part 20 is iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com