Polishing method and device of fine structure

A microstructure and polishing device technology, which is applied to polishing compositions containing abrasives, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as the inability to balance surface quality and surface shape accuracy, and achieve easy operation and Effects of maintenance, high reliability, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

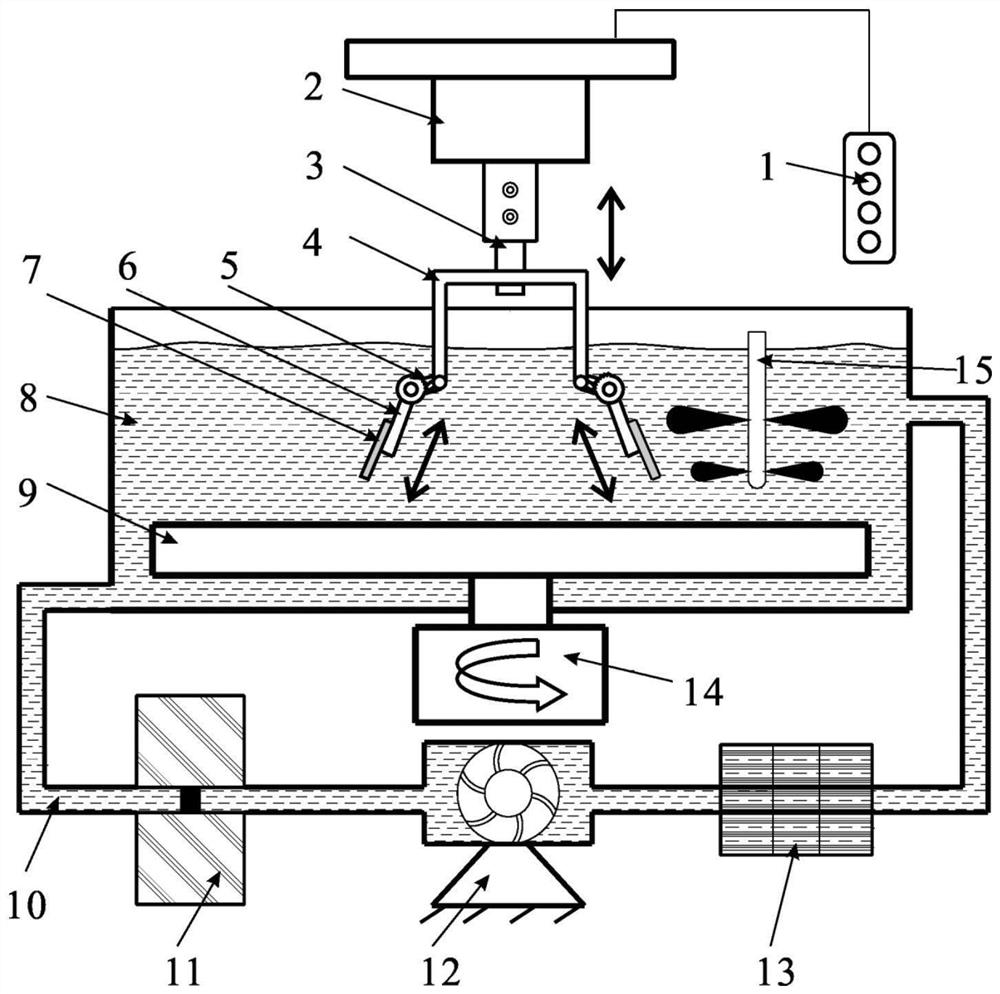

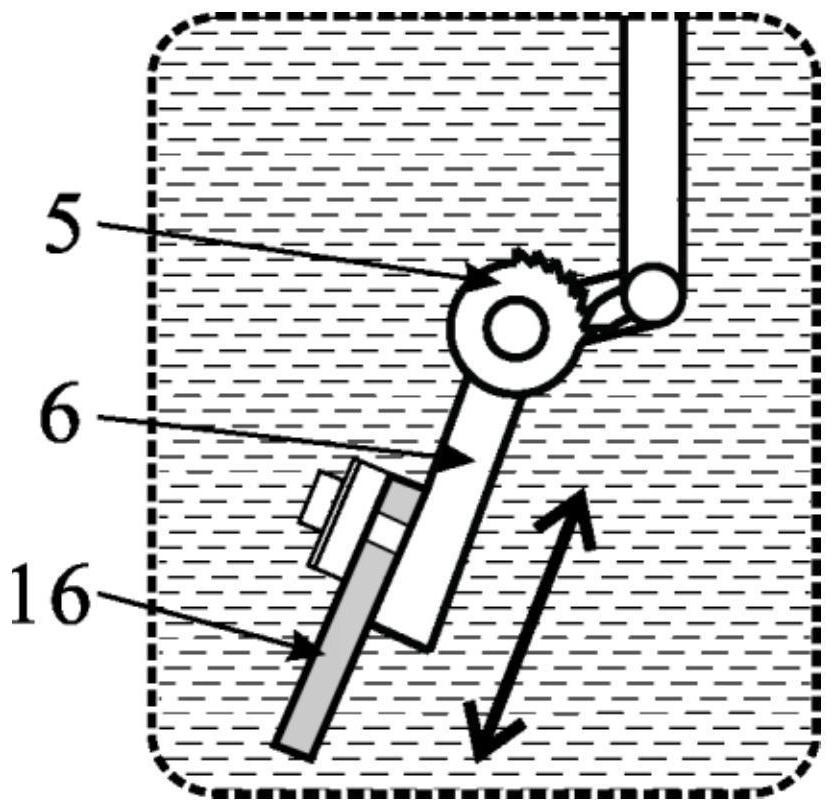

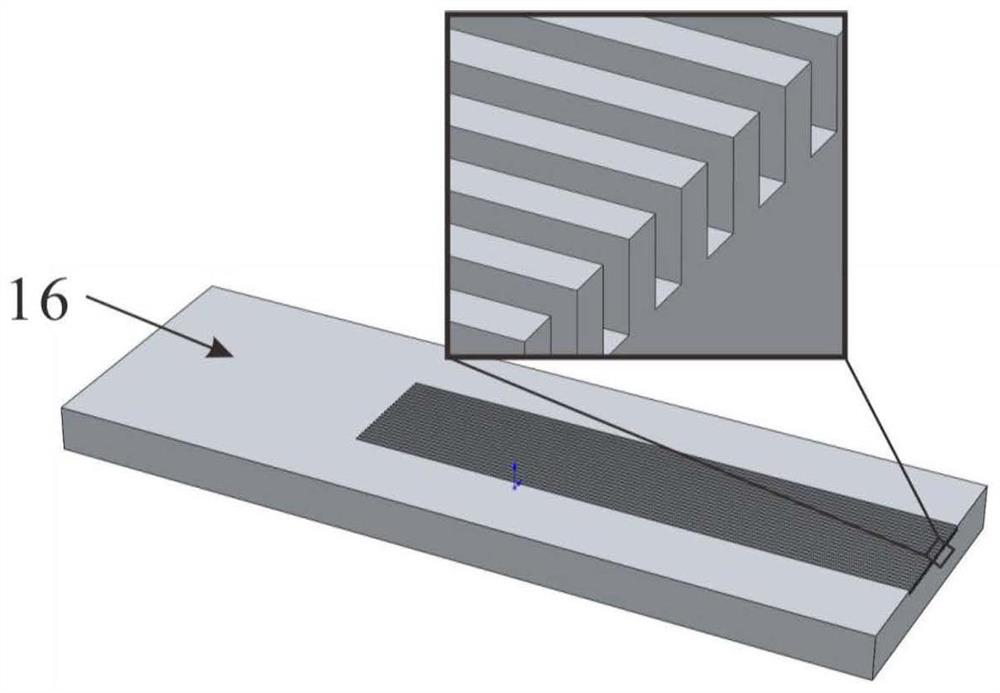

[0040] refer to figure 1 , Figure 2(a), Figure 2(b) and Figure 4(a), Figure 4(b), Figure 4(c), and use figure 1 The shown apparatus performs shear thickening and chemical synergistic polishing on a rectangular grating waveguide slow wave microstructure workpiece 16 . The rectangular grating waveguide slow-wave microstructure workpiece 16 is the core part of the electric vacuum device of the terahertz radiation source. Its structural length period is 50 μm and has a high aspect ratio. The width and depth of the rectangular grooves are 25 μm and 60 μm, respectively.

[0041] The device for vibrating and polishing the rectangular grid waveguide slow wave microstructure workpiece 16 based on shear thickening and chemical composite effect includes a polishing system, a polishing liquid circulation device, a vibration device and an angle adjustment device.

[0042] The polishing system includes a polishing liquid 8 , a rotating device and a stirring device 15 . The rotary table 9 ...

Embodiment 2

[0053] refer to figure 1 , Figure 3(a), Figure 3(b) and Figure 4(a), Figure 4(b), Figure 4(c), and use the attached figure 1 The illustrated apparatus achieves shear thickening polishing of a V-groove microstructured workpiece 17 . The V-groove microstructure workpiece 17 is used in optical fiber connectors for precise alignment of the core pitch between optical fibers, and its length period is 250 μm, and the V-groove valley depth is 100 μm. Its structure is similar to the device in Example 1, including a polishing system, a polishing liquid circulation device, a vibration device and an angle adjustment device. The difference is that the device for vibrating and polishing the V-groove microstructure workpiece 17 based on shear thickening and chemical compounding effects adjusts the workpiece to a vertical direction during polishing. The method for vibrating polishing a V-groove microstructure workpiece 17 based on shear thickening and chemical composite effects, comprising ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com