Low-density and high-performance composite sandwich structure and preparation method thereof

A composite material, sandwich structure technology, applied in chemical instruments and methods, synthetic resin layered products, lamination and other directions, can solve the problems of small thermal expansion coefficient of aramid honeycomb core material, large variation of profile accuracy, poor thermal conductivity and so on , to achieve strong designability, stable performance and dimensional accuracy, and ensure the effect of surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

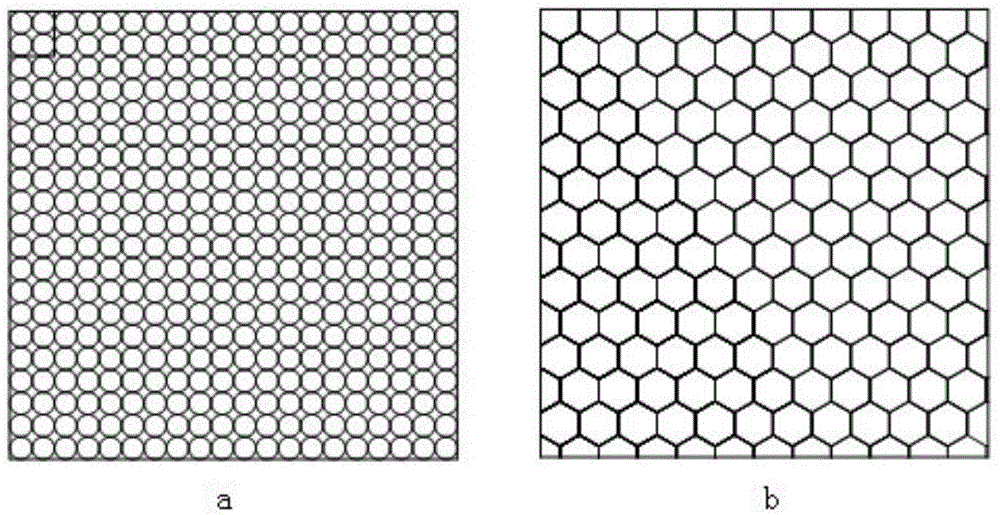

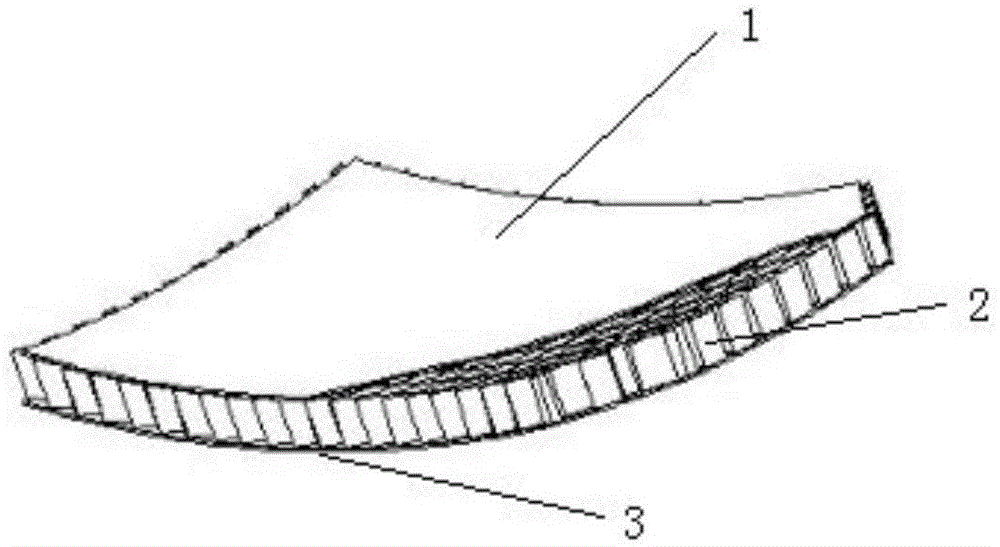

[0040] A sandwich structure formed by round rods is an example, see attached figure 1 a and figure 2 The sandwich structure is composed of an upper skin layer 1, a lower skin layer 3 and a sandwich structure 2, and both the upper skin layer and the lower skin layer are made of composite materials. The sandwich structure 2 is made up of multiple rods arranged side by side, the density of the rods is 60kg / m 3 , Flat compressive strength 3.2Mpa, thermal expansion coefficient 1.7×10 -6 .

[0041] 1) Material design

[0042] The resin matrix and reinforcement materials of the sandwich material are selected according to the requirements of use. Here, T300 / 3K carbon fiber and epoxy resin are selected; the layering method is 0 / +60 / -60.

[0043] 2) Rod forming processing

[0044] Cut a single-layer fiber-reinforced resin matrix composite prepreg with a thickness of 0.03mm into strips, one layer is 0 degrees, one layer is +60 degrees, and one layer is -60 degrees. The three-layer fiber prepreg...

Embodiment 2

[0052] A sandwich structure formed by regular hexagonal rods. As attached figure 1 b. figure 2 As shown, the density of the rod is 68kg / m 3 , Flat compressive strength 4.6Mpa, thermal expansion coefficient 1.1×10 -6 .

[0053] 1) Material design

[0054] Choose the core material resin matrix and reinforcement materials according to the use requirements, here choose M55 / 6K carbon fiber, epoxy resin; the layup method is 0 / 90 / +45 / -45.

[0055] 2) Rod forming processing

[0056] Cut a single-layer fiber-reinforced resin matrix composite prepreg with a thickness of 0.15mm into strips, one layer is 0 degrees, one layer is 90 degrees, one layer is +45 degrees, and one layer is -45 degrees, and the four layers of fiber are prepreg The material is wound on the metal mold according to the direction of 0 / 90 / +45 / -45 through the winding process. After solidification, the composite rod is demolded and machined into a short rod with a length of 60mm.

[0057] 3) Laying of skin and interlayer

[0058...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com