Mechanical cutting device for aircraft skin

A technology of mechanical cutting and aircraft skin, which is applied in the field of mechanical cutting and circular cutting, can solve the problems of reducing material life, affecting the accuracy and progress of repair, and inconvenient operation, so as to shorten the use performance, save cutting time, and improve The effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

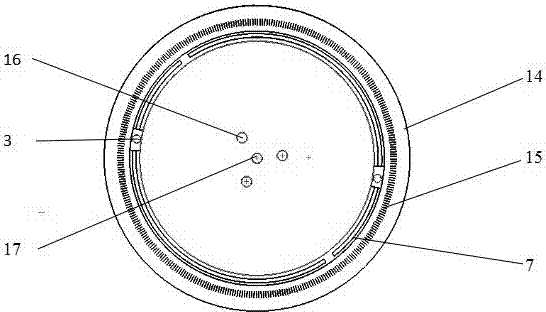

[0029] An exemplary embodiment of the invention is illustrated in detail below with the aid of 7 drawings.

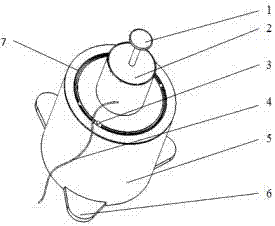

[0030] exist figure 1 In the overall schematic diagram of the shown embodiment, it can be seen that a mechanical cutting device for aircraft skin includes an upper cylinder part and a lower cylinder part; The through hole of the cover enters the inside; for the lower part of the cylinder, the outside of the bottom of the cylinder wall is fixed like figure 1 The positioning feet 6 of the shown shape are evenly distributed along the circumference at an angle of 120 degrees.

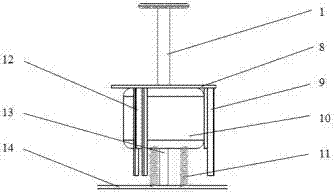

[0031] figure 2 Show the inside of the upper tube 2 in a perspective way, the operating handle 1 enters the inside of the upper tube 2 and is fixedly connected with the power device 10 to drive the power device 10 to move; the inner wall of the upper tube 2 is fixed with a chute 9, and the chute 9 is 120 degrees are evenly distributed on the inner wall of the upper cylinder; the slider 12 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com