LED (light-emitting diode) chip cutting cutter with novel structure and LED chip cutting method

A technology of LED chips and cutting tools, which is applied in the direction of manufacturing tools, fine working devices, electrical components, etc., can solve the problems of high cost, easily damaged crystal grains, multiple cutting, etc., achieve small amplitude, increase stability, The effect of simple loading and unloading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

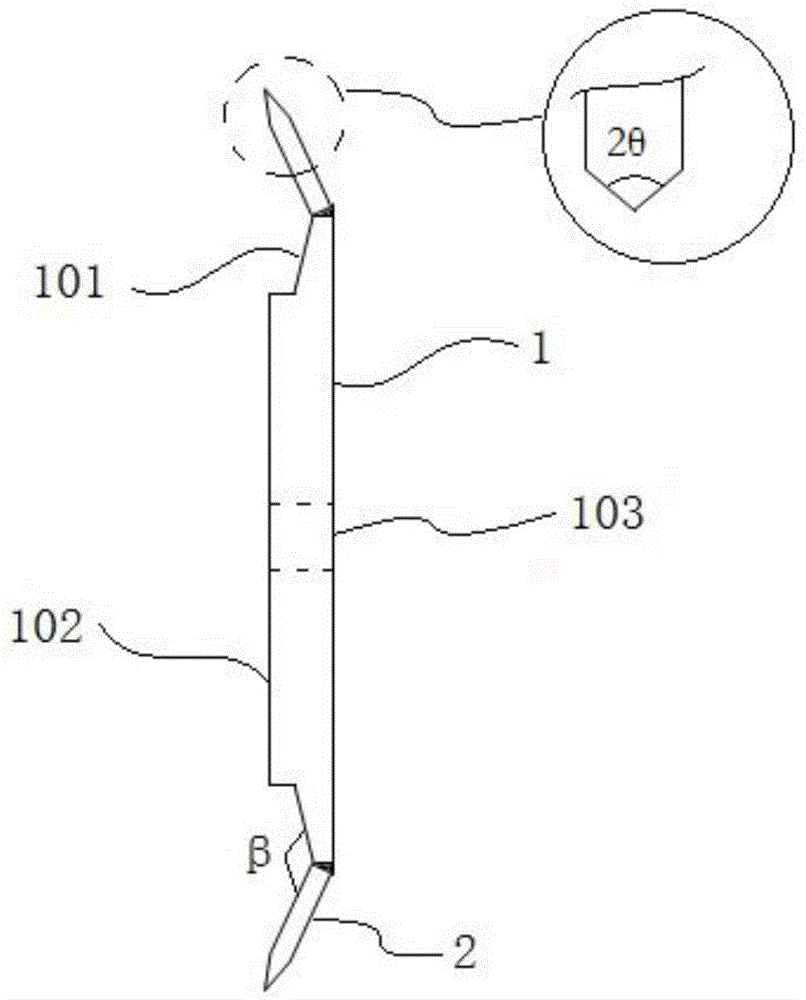

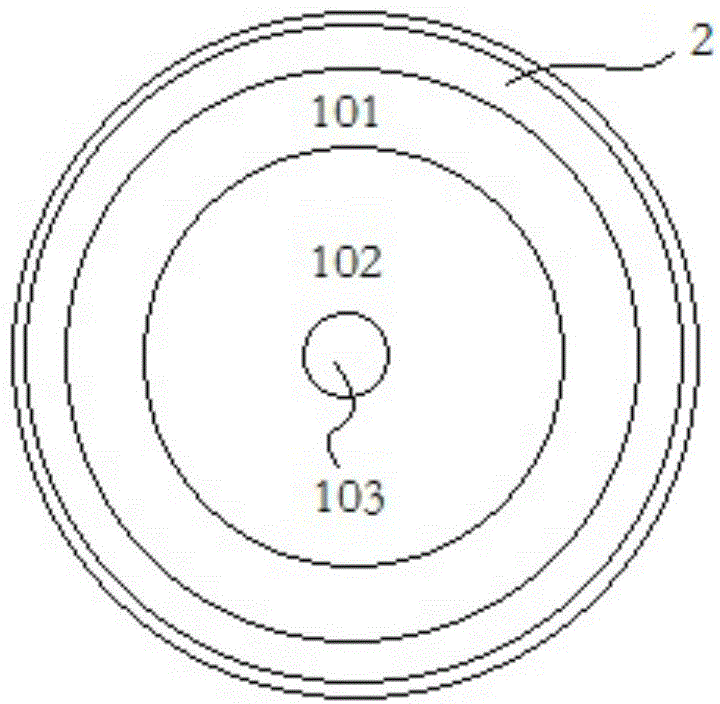

[0040] Such as figure 1 and figure 2 As shown, a LED chip cutting tool with a new structure includes a flange 1 and a blade 2. The flange 1 is disc-shaped, made of aluminum alloy, and has a flange protrusion 101 in the middle, and its thickness is uniform. The edge is provided with a flange transition 102, the thickness of which gradually decreases towards the outer edge, and the middle part of the flange protrusion 101 is provided with a mounting hole 103 with a diameter of 19mm; the blade 2 is circular and fixed on the outer edge of the flange transition 102, The angle between the blade 2 and the flange 1 is β=135°, the blade width of the blade 2 is 21 μm, and the slope θ of the blade is 20°. The diameter is 0.1-2.5 μm.

[0041] A method for cutting an LED chip, the steps of which are: using a special knife changing tool for a DISCO cutting machine to change the above-mentioned cutting knife to a cutting machine, and use a special whetstone to sharpen the knife after the ...

Embodiment 2

[0044] A LED chip cutting tool with a new structure, the structure is the same as that of Embodiment 1, the difference is that the angle between the blade 2 and the flange 1 is β=140°, the blade width of the blade 2 is 25 μm, and the slope θ of the blade is 22°. The cutting edge of the blade 2 is formed by the organic combination of diamond abrasive grains and a binder, and the diameter of the diamond abrasive grains is 2.5-5 μm.

[0045] A LED chip cutting method, the steps are the same as in Example 1, the difference is: when cutting the chip in half, the cutting height is set to 0.180mm, the cutting knife speed is set to 40mm / s; the baking temperature is 80°C, and the baking time 20 minutes; when cutting through the chip, the cutting height is set to 0.080mm, and the cutting knife speed is set to 10mm / s.

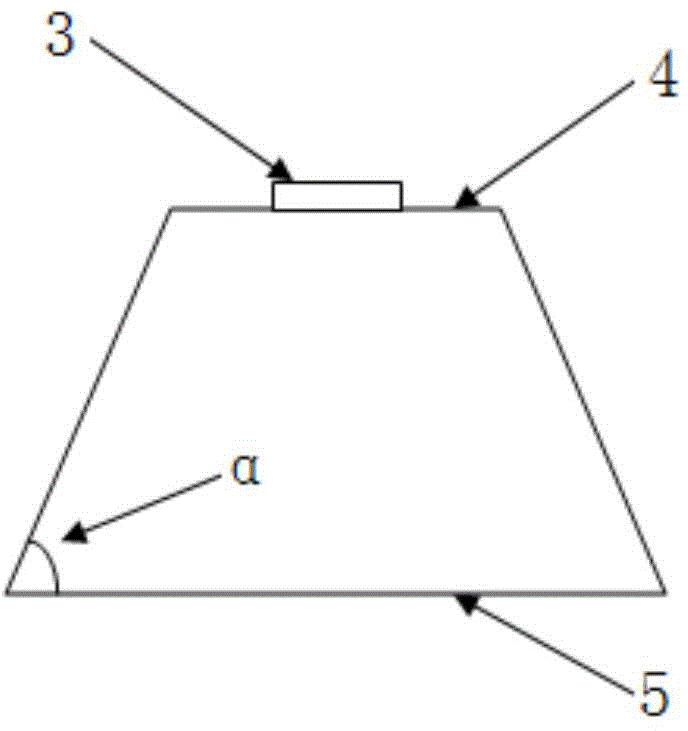

[0046] The angle between the slope of the chip cut in this embodiment and the N surface is 40°. The chip with this structure can shorten the path of light propagating ins...

Embodiment 3

[0048] A LED chip cutting tool with a new structure, the structure is the same as that of Embodiment 1, the difference is: the angle β between the blade 2 and the flange 1=145°, the blade width of the blade 2 is 23 μm, and the slope θ of the blade is 25°, The cutting edge of the blade 2 is formed by the organic combination of diamond abrasive grains and a binder, and the diameter of the diamond abrasive grains is 5-8 μm.

[0049] A LED chip cutting method, the steps are the same as in Example 1, the difference is: when cutting the chip in half, the cutting height is set to 0.250mm, the cutting knife speed is set to 30mm / s; the baking temperature is 100°C, and the baking time 10 minutes; when cutting through the chip, the cutting height is set to 0.070mm, and the cutting speed is set to 40mm / s.

[0050] The included angle between the slope of the chip cut in this embodiment and the N surface is 35°. The chip with this structure can shorten the path of light propagating inside t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com