Automatic log treatment system

An automatic processing and log technology, which is applied to wood processing equipment, turning devices, adjustment equipment, etc., can solve the problem of no automatic processing of logs, etc., and achieve the effects of reducing cutting accidents, improving work efficiency, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

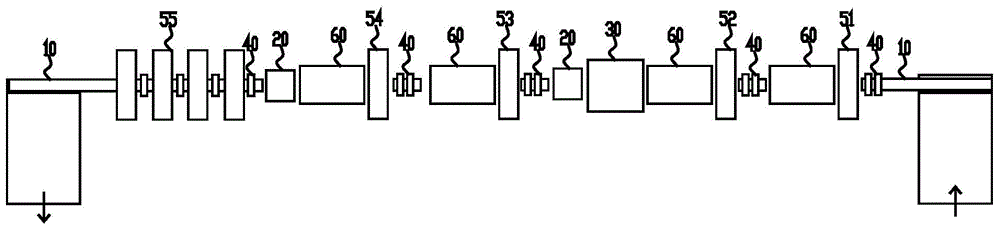

[0047] like Figure 1-6As shown, the log automatic processing system of the present invention generally includes a conveyor belt 10, a preliminary processing device and a combined cutting device. The conveyor belt 10 is used to transport logs between various devices, and includes a plurality of independent sub-conveyor belts.

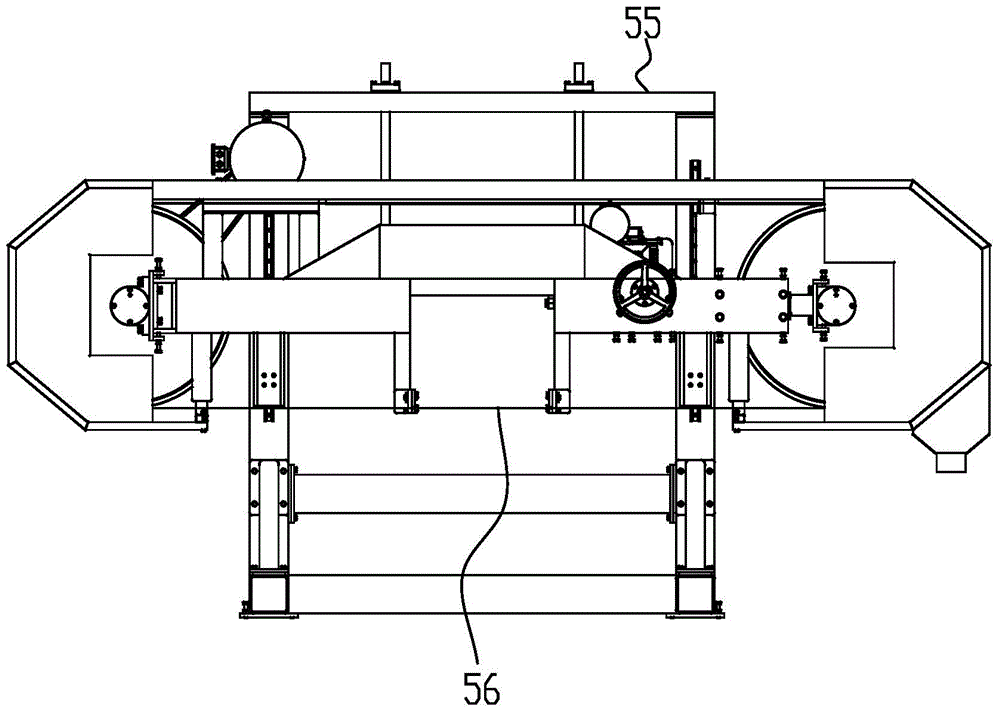

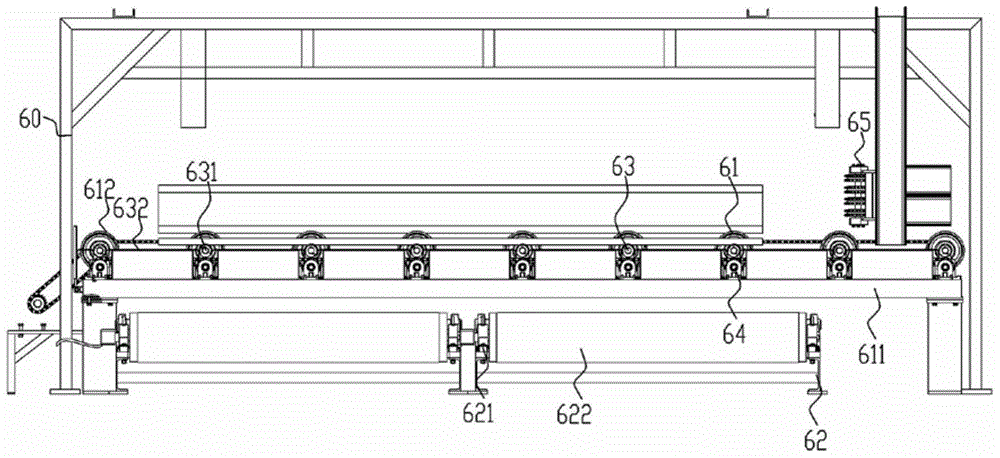

[0048] The preliminary processing device is used to remove the round edges around the log, including a plurality of vertical saws 50 for cutting the sides of the log successively and a removal device 60 for removing the leftovers after cutting; each vertical saw 50 is placed in sequence and divided into The first vertical saw 51 , the second vertical saw 52 , the third vertical saw 53 and the fourth vertical saw 54 are used to cut the log on the conveyor belt 10 step by step. The cleaning device 60 is installed behind each vertical saw 50, and is used for automatically collecting the offcuts cut by the corresponding vertical saw 50 without affecting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com