Patents

Literature

125results about "Turning equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

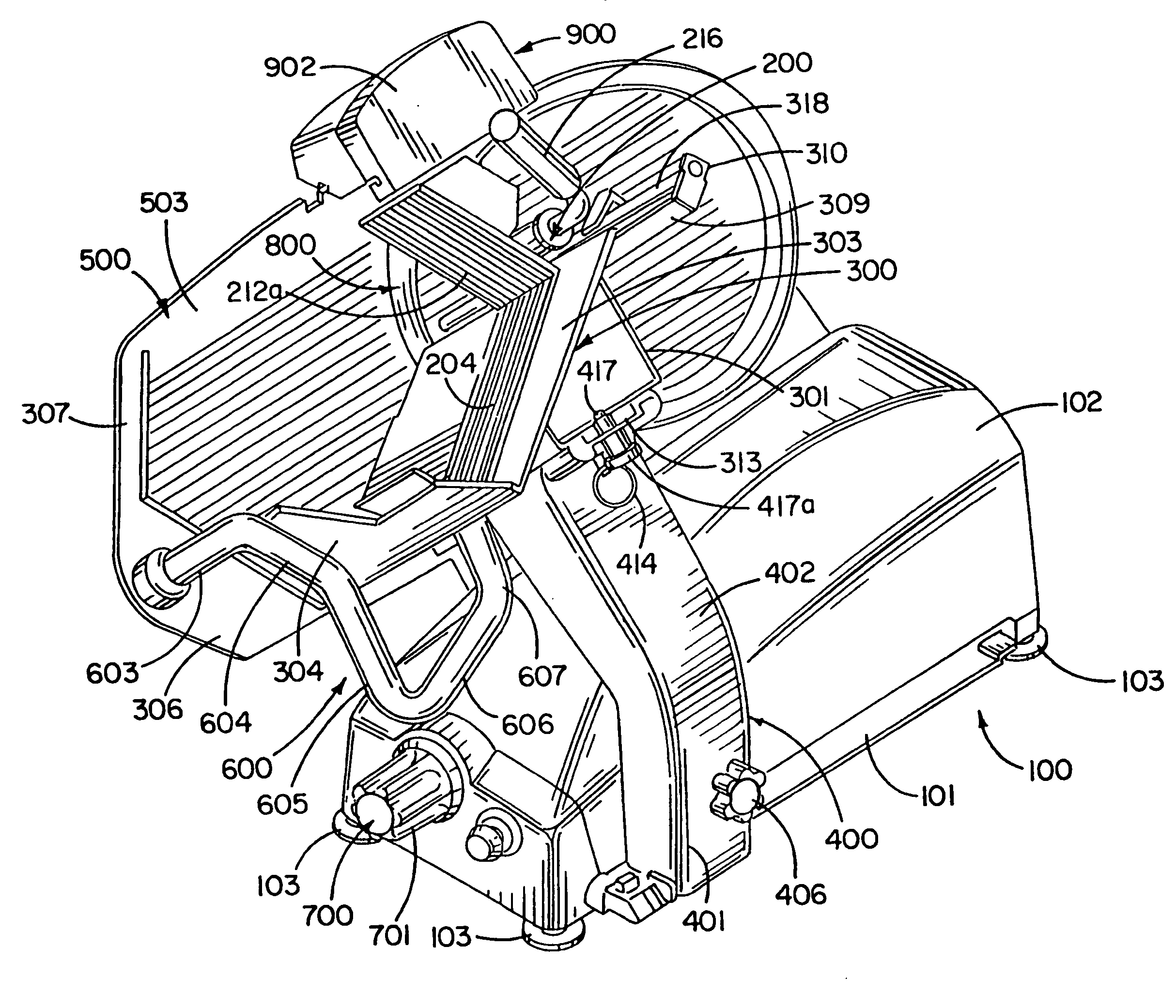

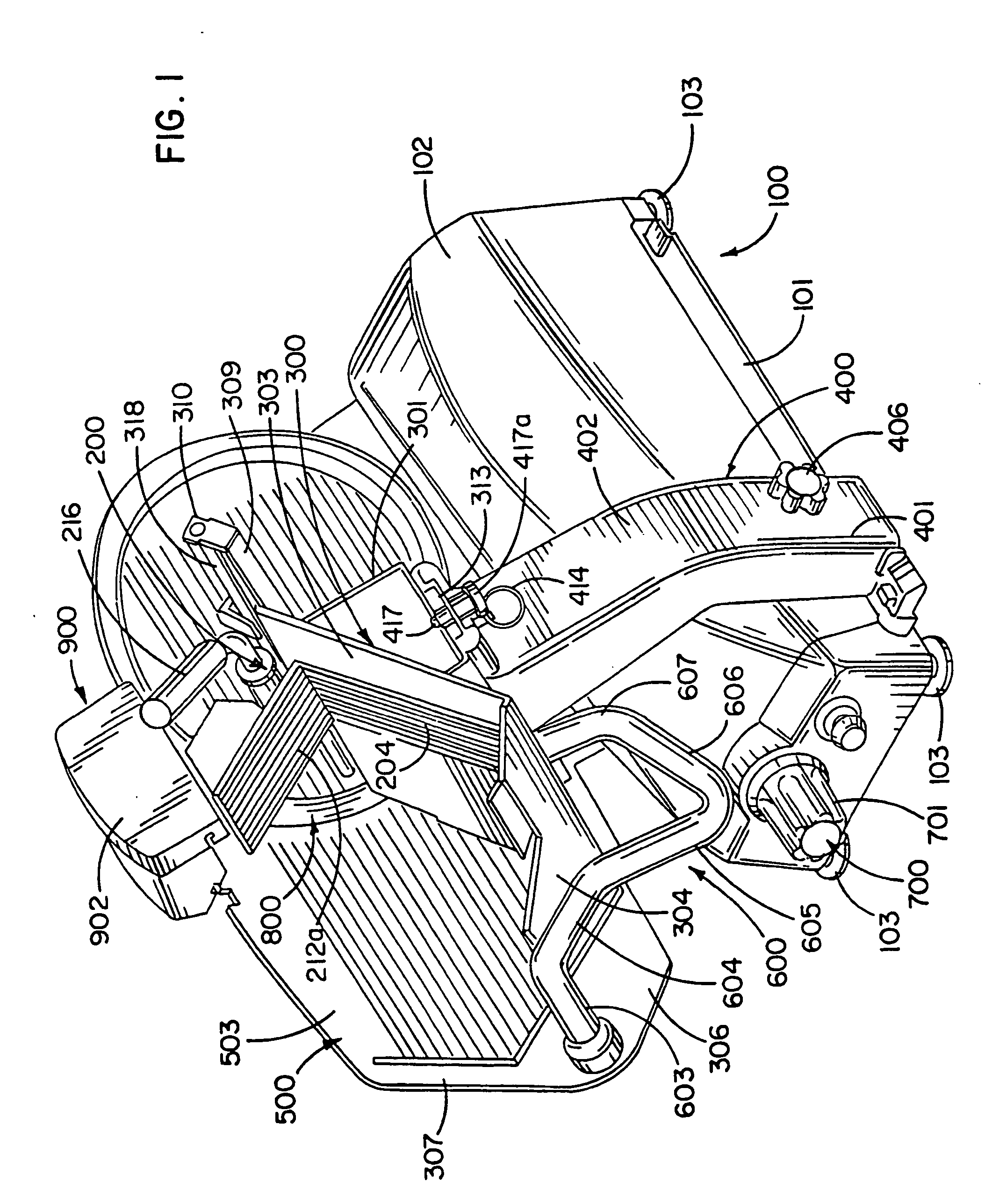

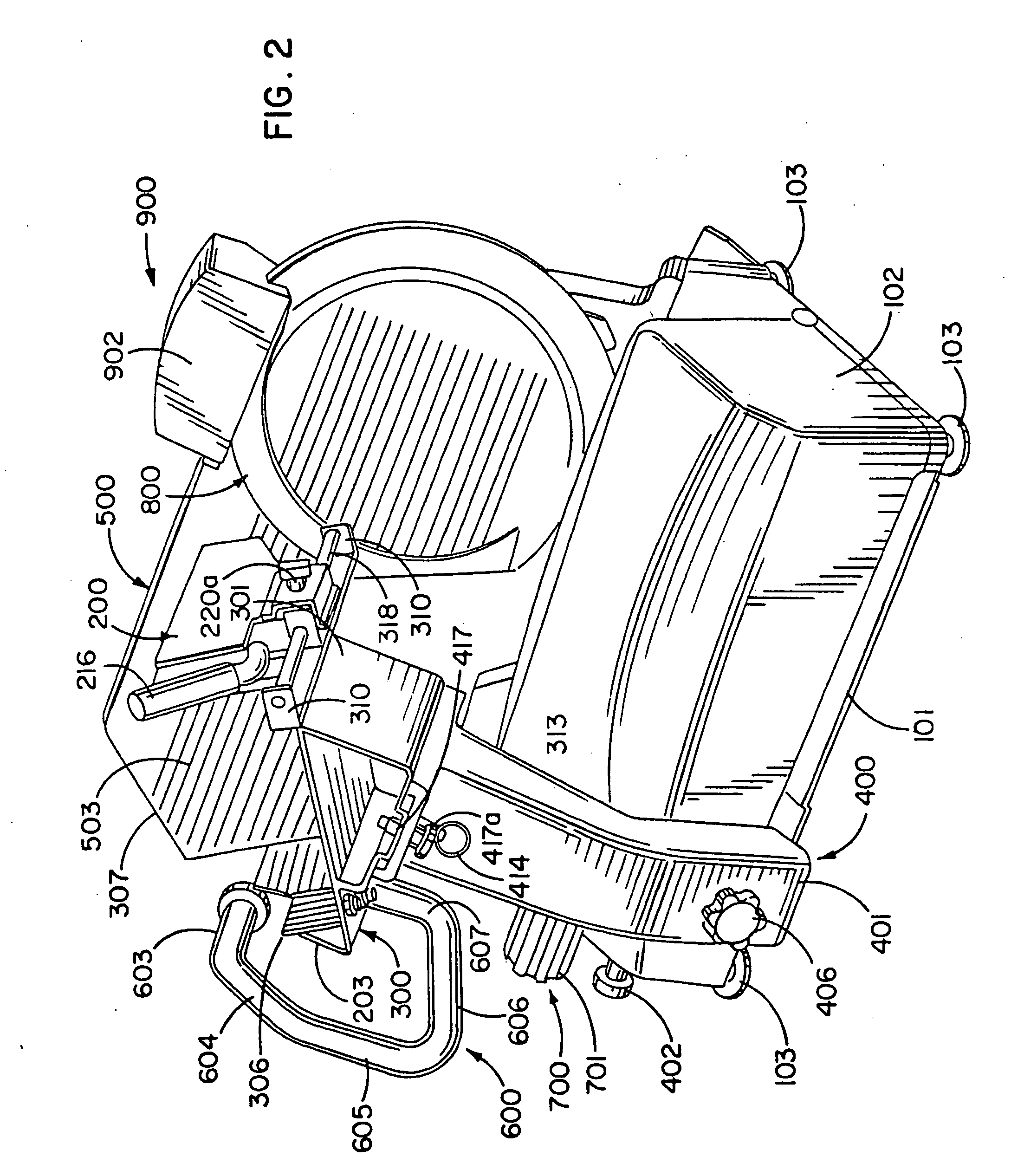

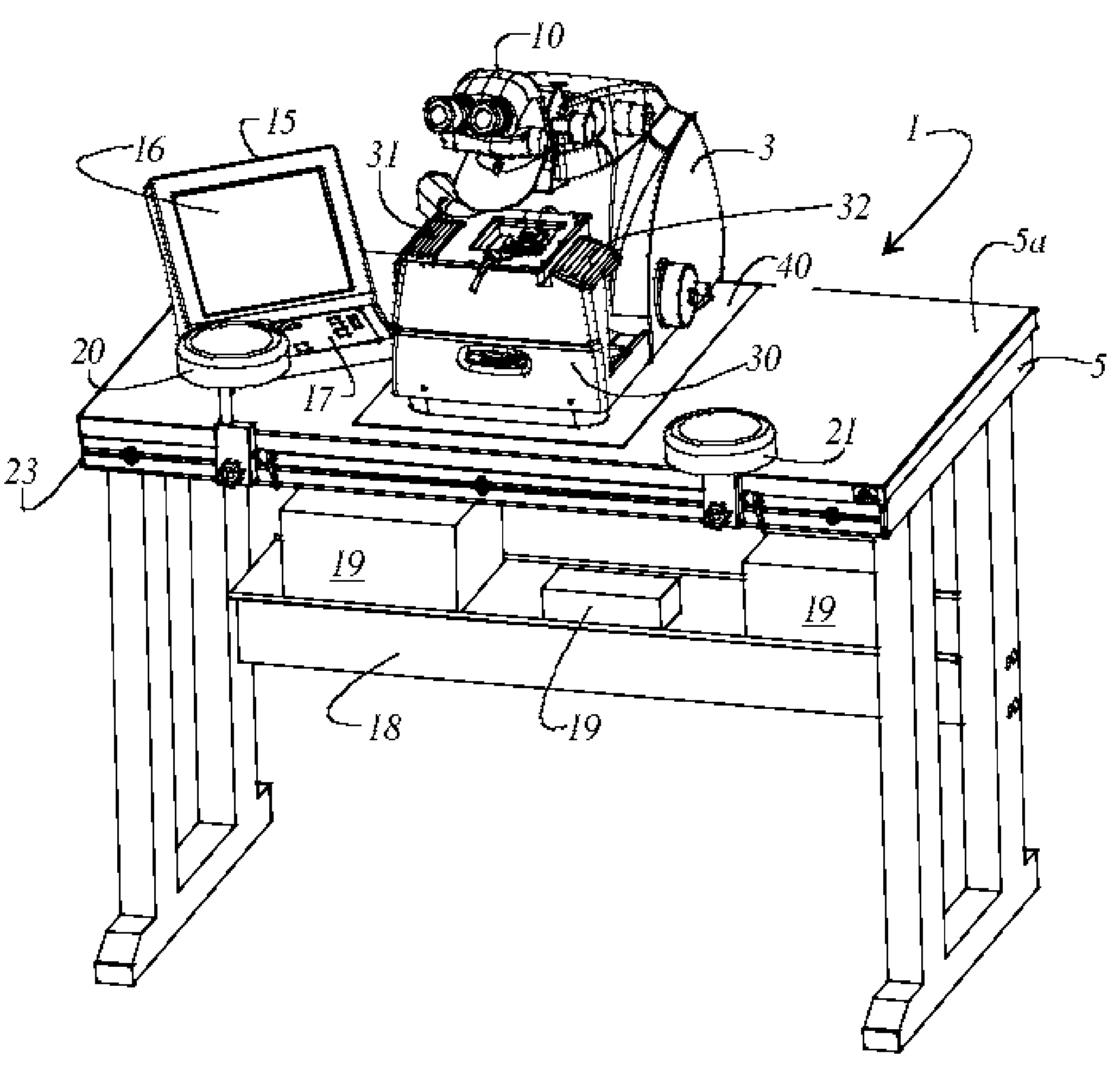

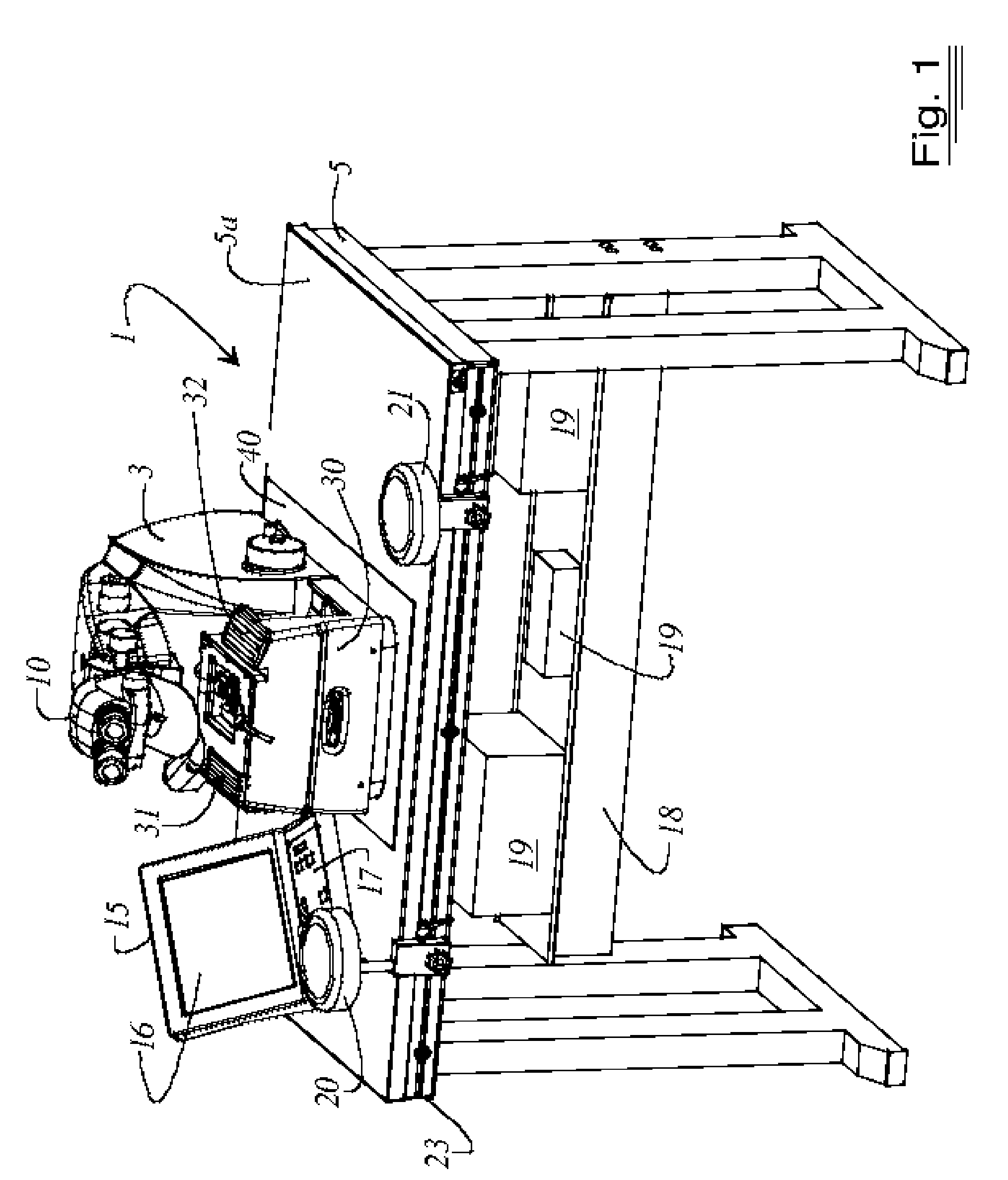

Slicing machine, method of use and components thereof

InactiveUS20060150791A1Quality improvementEasy to operateMetal sawing devicesFeeding devicesRisk strokeMechanical engineering

An ergonomically designed food slicing machine including a rotatable blade (800, 2800) for slicing bulk food product, a motor (1400, 3400) operably connected to the rotating blade (800, 2800), and a base (100) portion located below the rotatable blade (800, 2800) which defines a food slice receiving area. The machine may be provided with a sliced food receptable operably connected to a scale (3900), a visible indicia (3502) correlating to the distance between the gauge plate (2500) and rotatable blade (2800), a blade sharpening assembly (900, 2900), a sled (200) for securing the food product and an operator adjusted optimum stroke setting system for automatic operation of the slicing machine.

Owner:BERKEL & CONTRACTORS +1

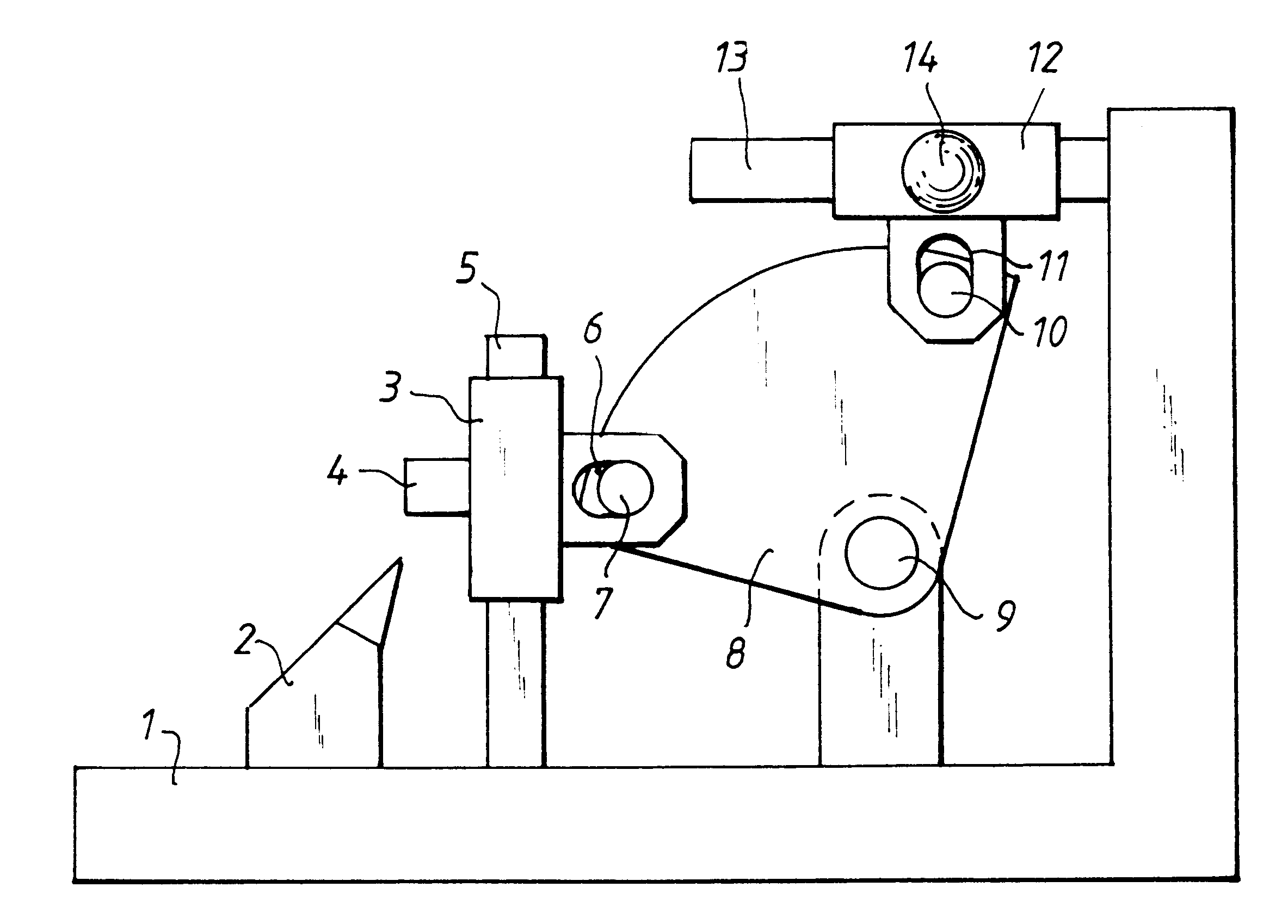

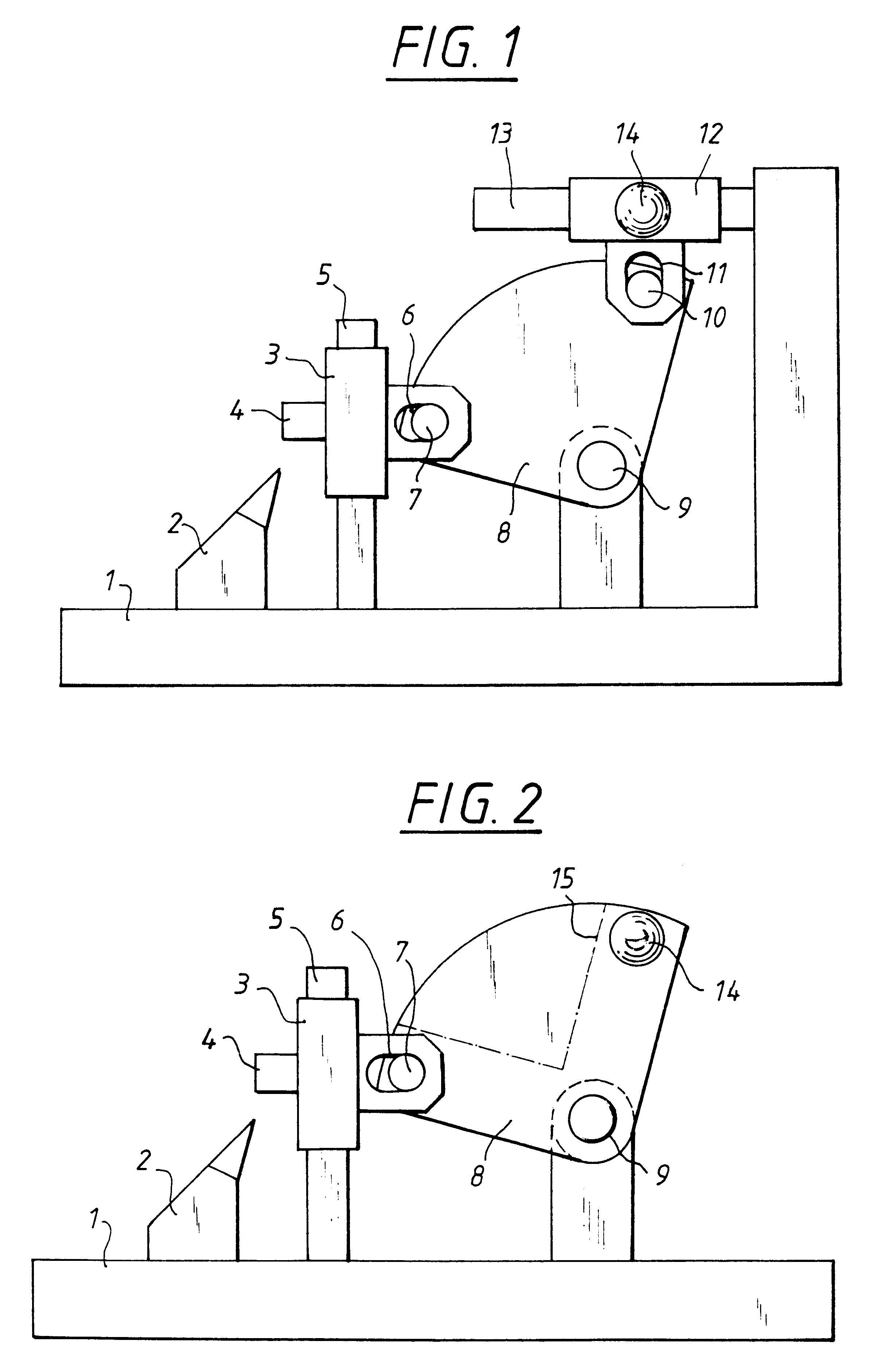

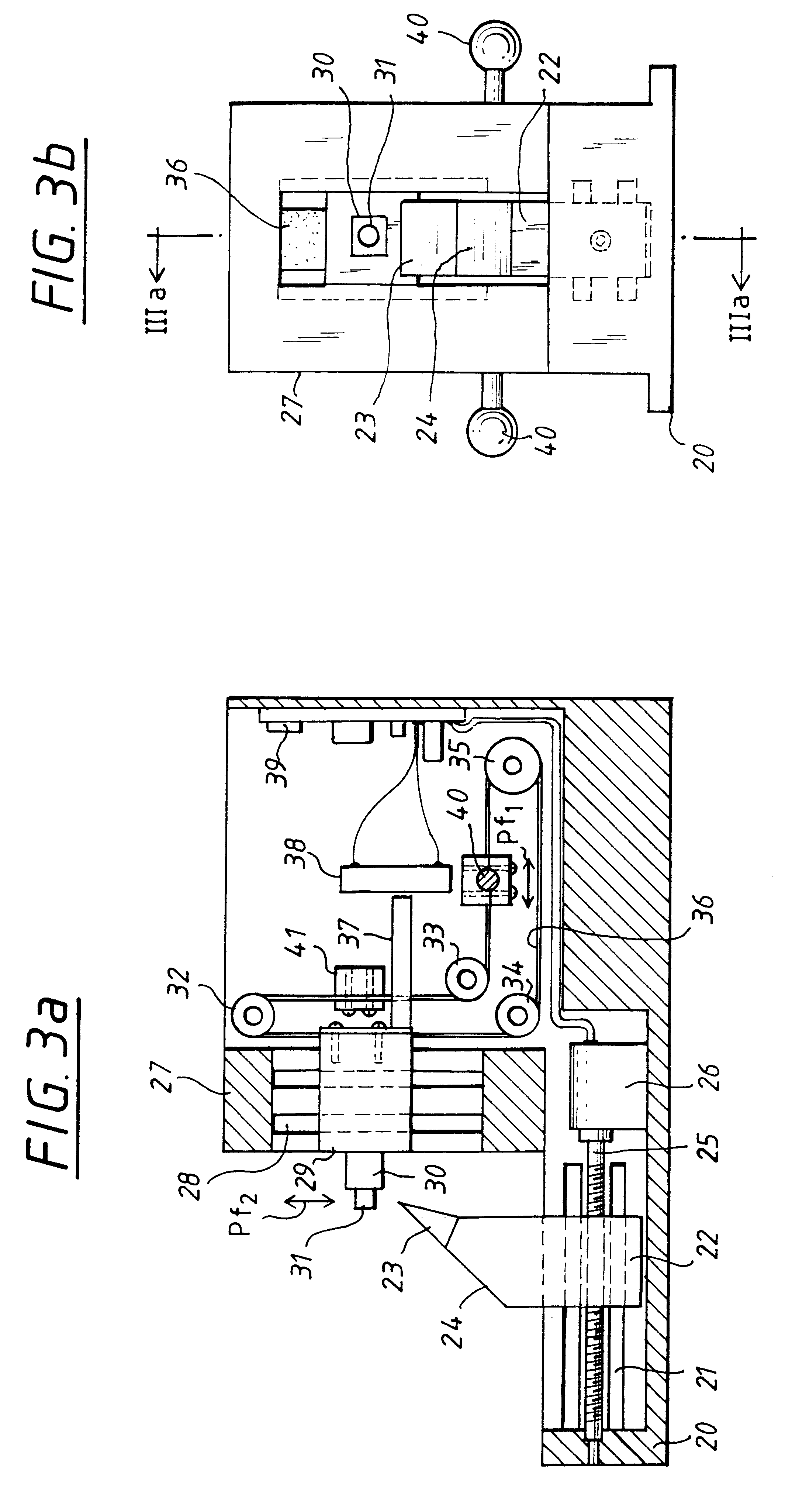

Microtome

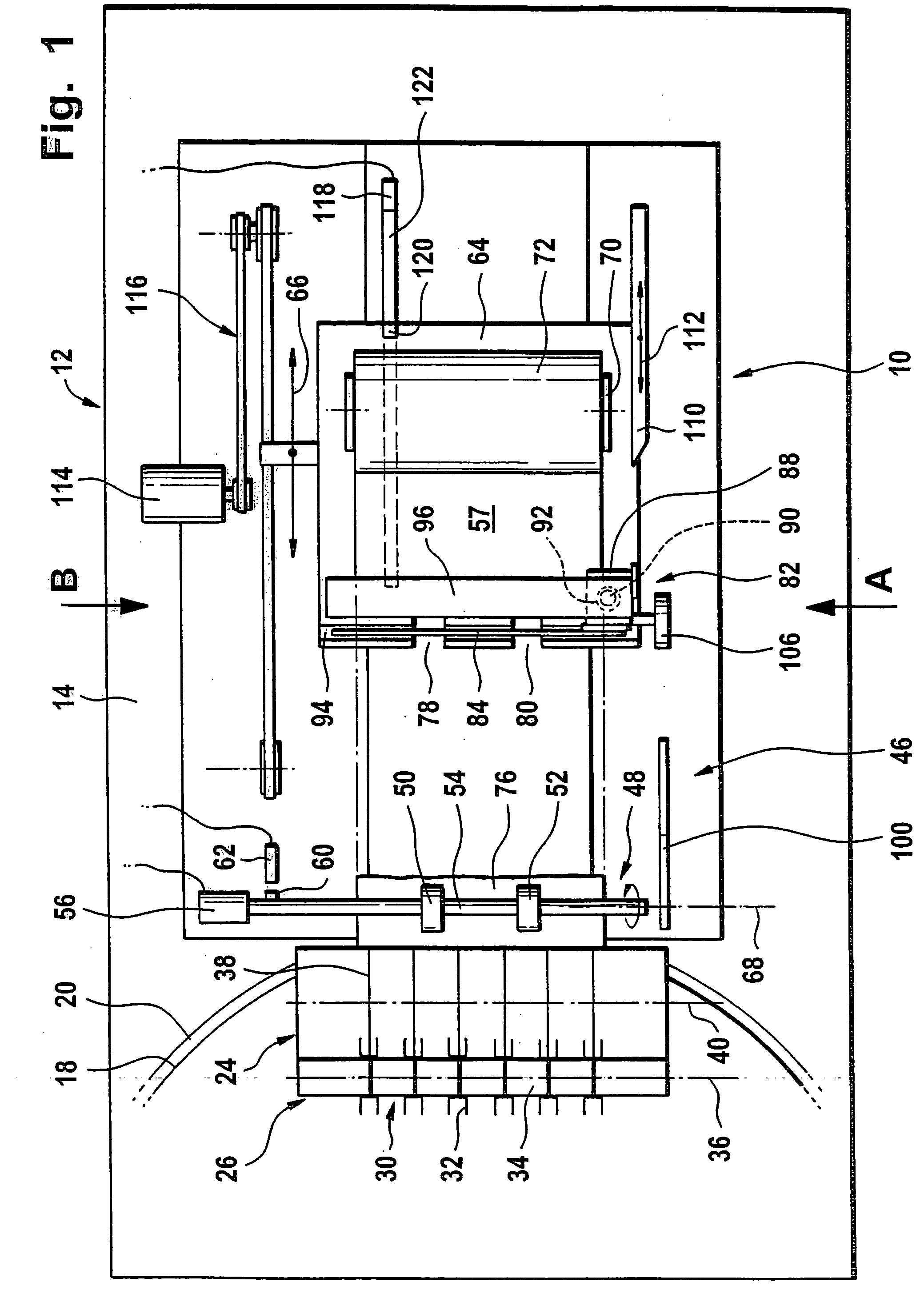

The microtome has a sample carrier movable along a first linear guide and a hand drive movable along a substantially linear path of motion that is substantially perpendicular to the direction of motion of the sample carrier. A deflecting device is provided to deflect the motion of the hand drive into a motion in the direction of the linear guide of the sample carrier. By deflection of the paths of motion between the hand drive and the sample holder, the motion of the hand drive can take place substantially horizontally forward and backward and convert the motion of the hand drive into a motion of the sample carrier which is substantially perpendicular to the motion of the hand drive. The cutting motion takes place in a substantially vertical direction, so that the sections can be removed or washed away from the inclined back surface of the cutting knife or knife carrier.

Owner:MICROM INT

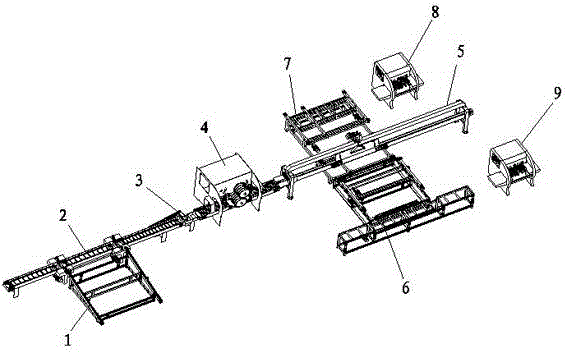

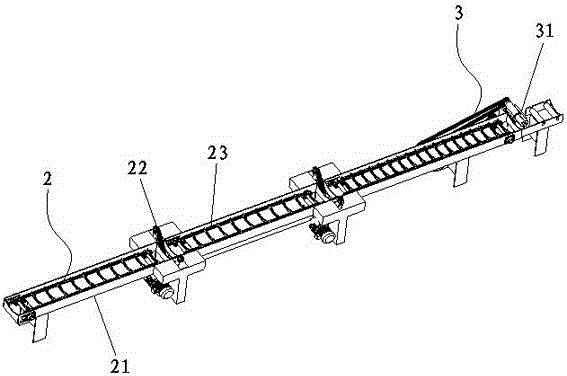

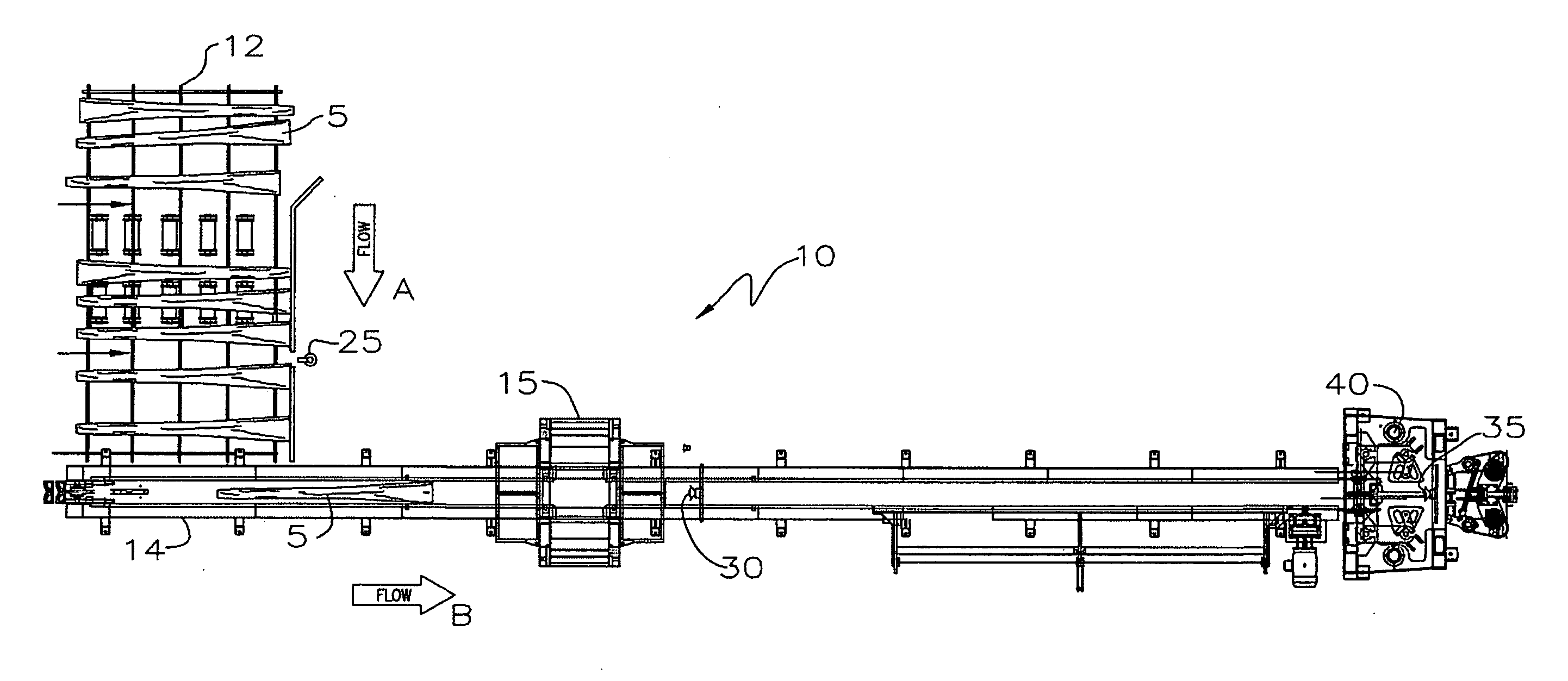

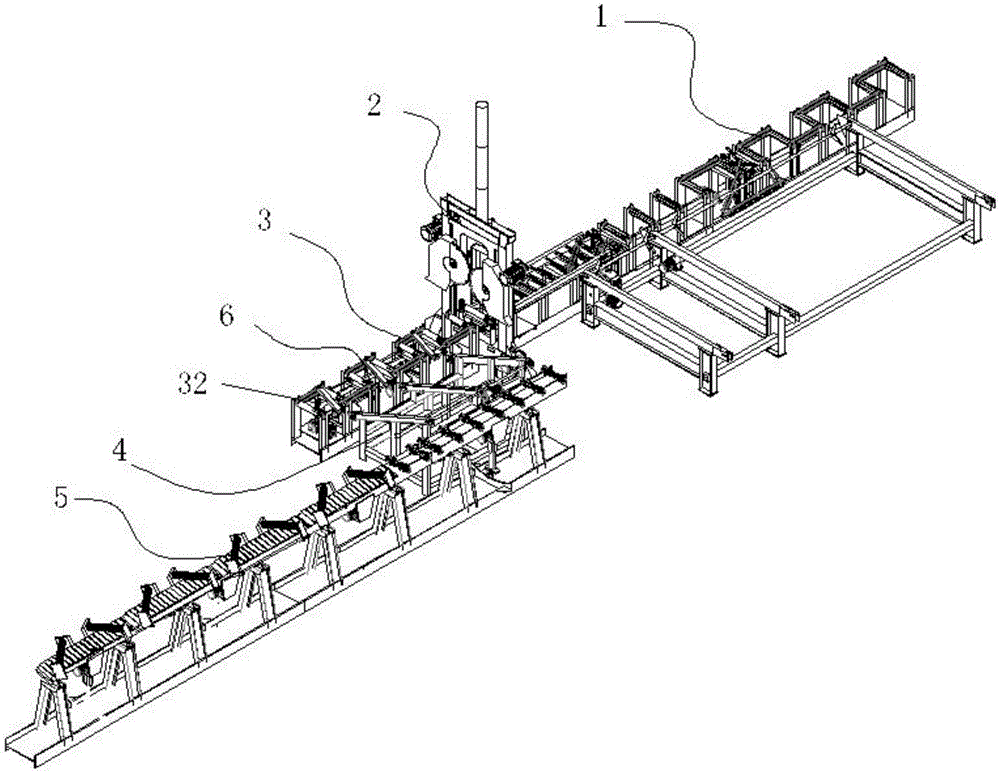

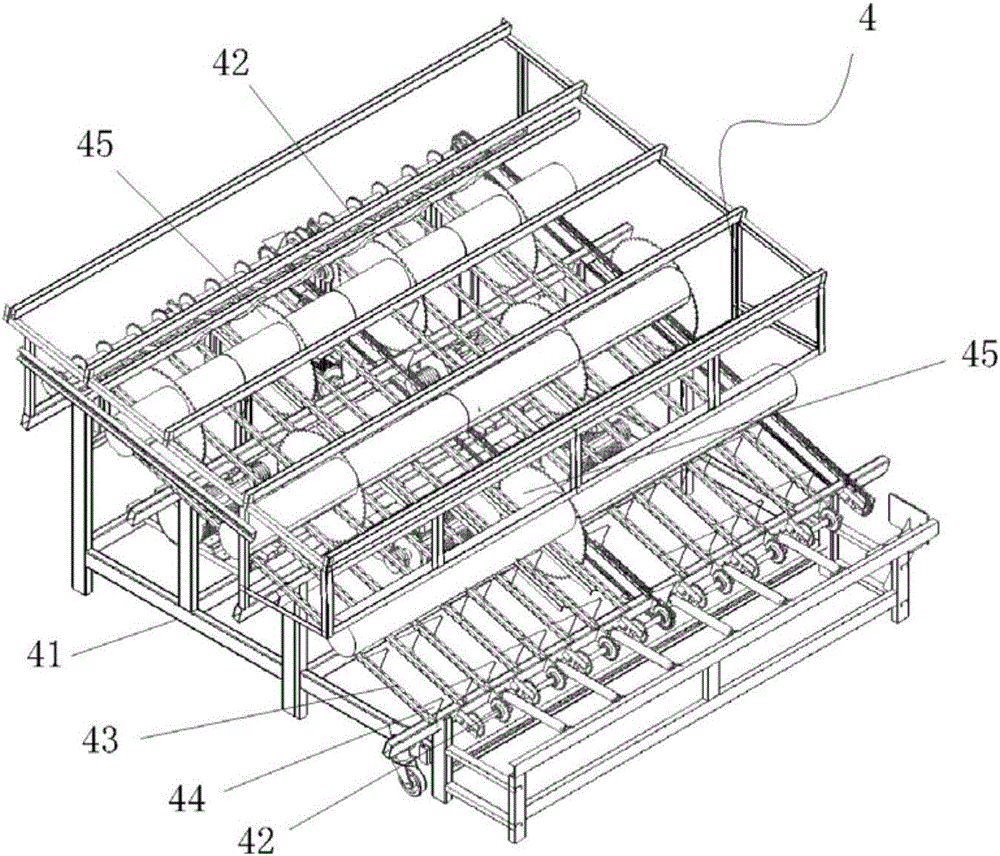

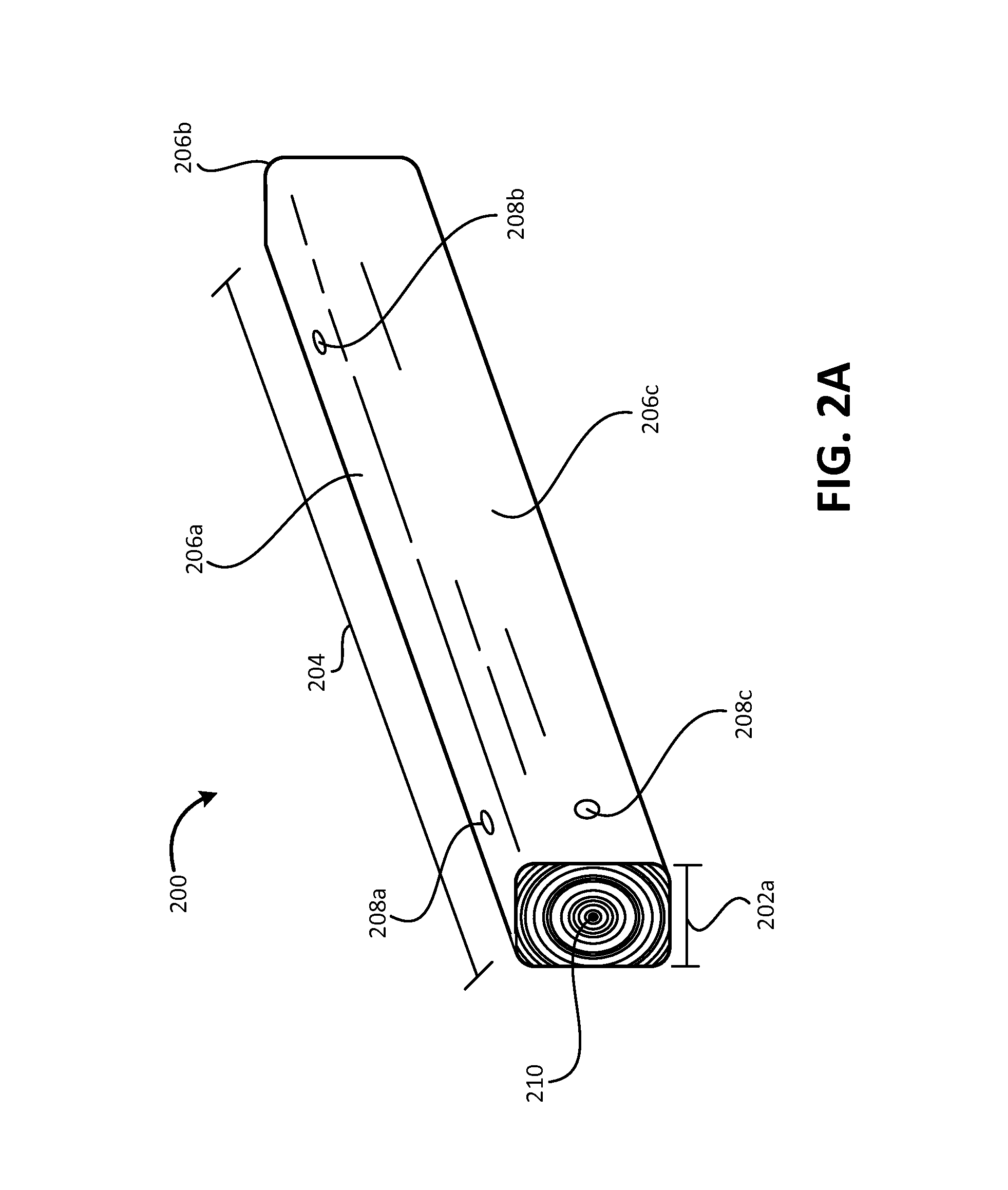

Processing line for round timber

ActiveCN104526771AReduce in quantityIncrease productivityFeeding devicesFlat surfacing machinesEngineeringMechanical engineering

The invention relates to a processing line for round timber. The processing line comprises a conveying device used for feeding, an overturning device used for centering the round timber in a rotating mode, a bottom bark planing device used for planing the bottom of the round timber to form a plane, a round timber slicing saw used for slicing the round timber in the axial direction of the round timber and a sheet sorting device used for sorting middle sheets and edge sheets of the round timber, wherein the conveying device, the overturning device, the bottom bark planing device, the round timber slicing saw and the sheet sorting device are sequentially arranged in the round timber processing advancing direction. The sheet sorting device comprises a first automatic conveying device used for conveying the middle sheets and a second automatic conveying device used for conveying the edge sheets, wherein the first automatic conveying device and the second automatic conveying device are arranged on the two sides of the sheet sorting device, and square timber slicing saws used for slicing the sheets again are arranged at the outlet of the first automatic conveying device and the outlet of the second automatic conveying device respectively. The processing line is simple in structure, low in manufacturing cost, easy to manufacture and complete in function, greatly improves the round timber working efficiency and lowers the production cost.

Owner:FUJIAN YUAN CHUANG ELECTRICAL & MECHANICAL CO LTD

Apparatus for cutting food product

InactiveUS7000518B2Improve consistencyUniform thicknessFeeding devicesTurning equipmentChipped potatoesMechanical engineering

An apparatus for cutting food product so that the product is properly oriented and stabilized before and throughout the cutting operation to produce a sliced product of uniform thickness, even if the delivered food product varies in shape and size, such as when both round and elongate potatoes are used to produce potato chips. The apparatus includes a cutting device and housing thereabove that defines a passage with an opening in proximity to the cutting device, such that food product is delivered to the cutting device in a substantially vertical direction. To improve the stability of round product during the cutting operation, the housing has an upper portion and a flared lower portion immediately below the upper portion so that at least a portion of the opening of the passage is defined by the flared region and has a larger radius of curvature than the upper portion.

Owner:URSCHEL LAB

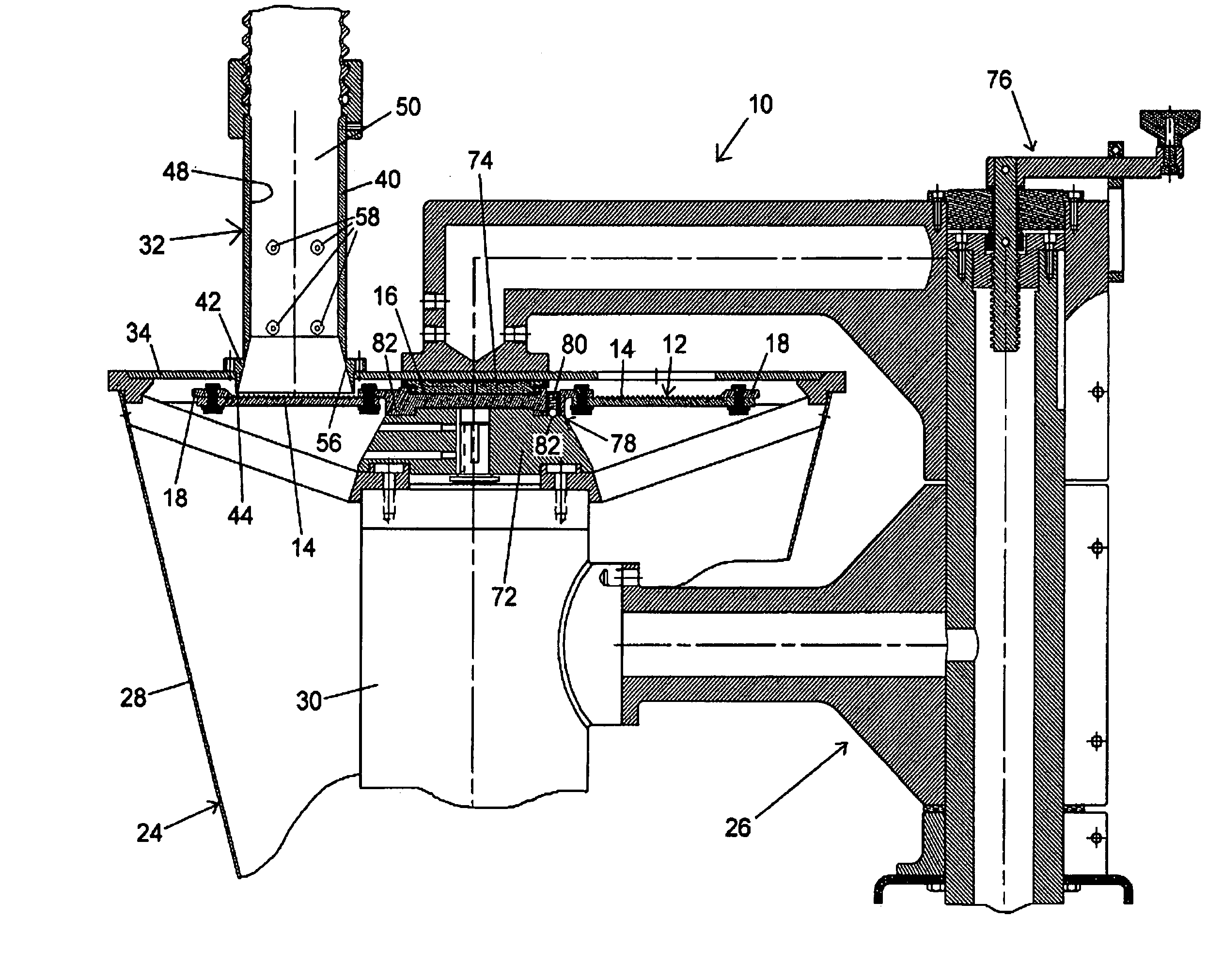

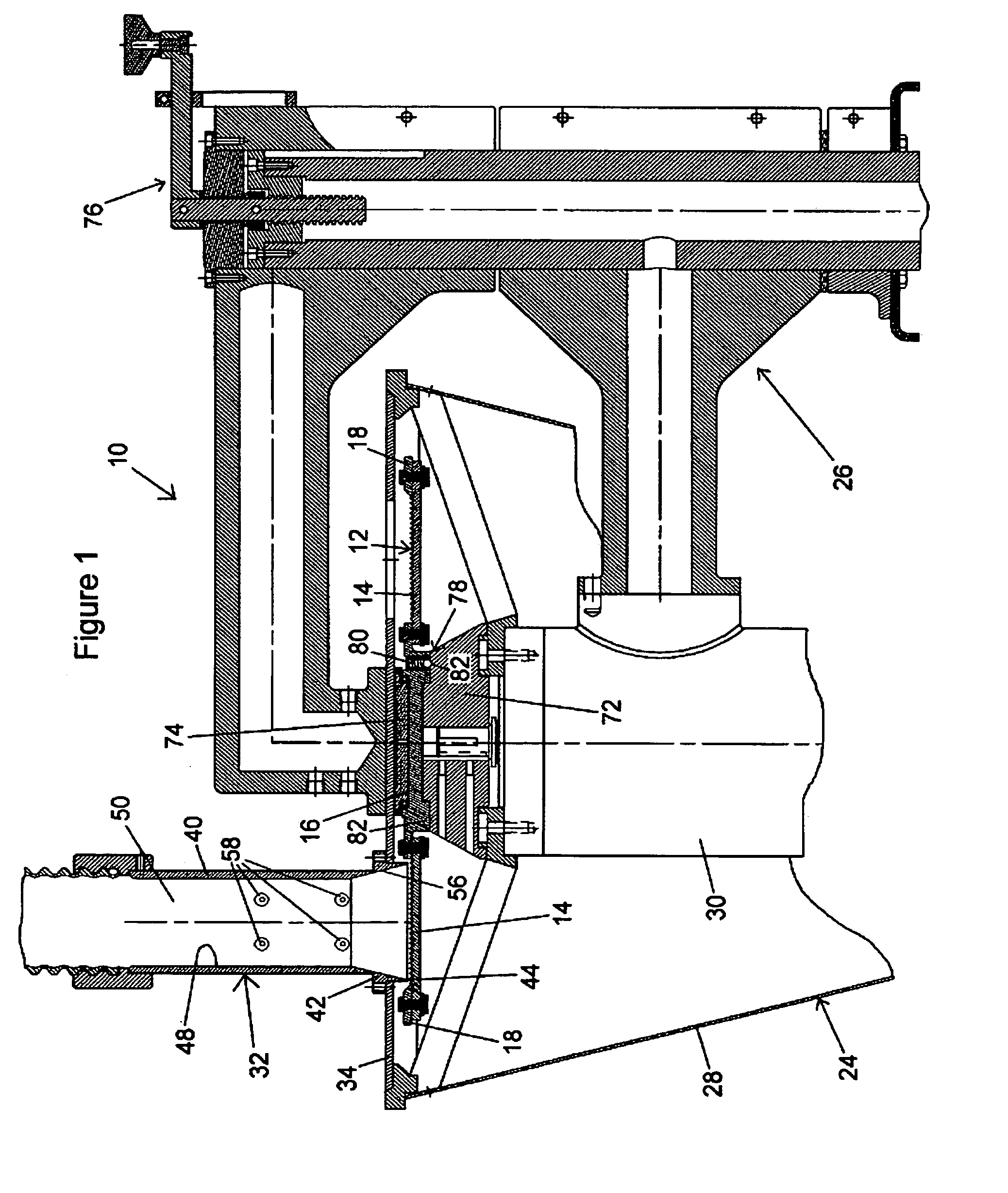

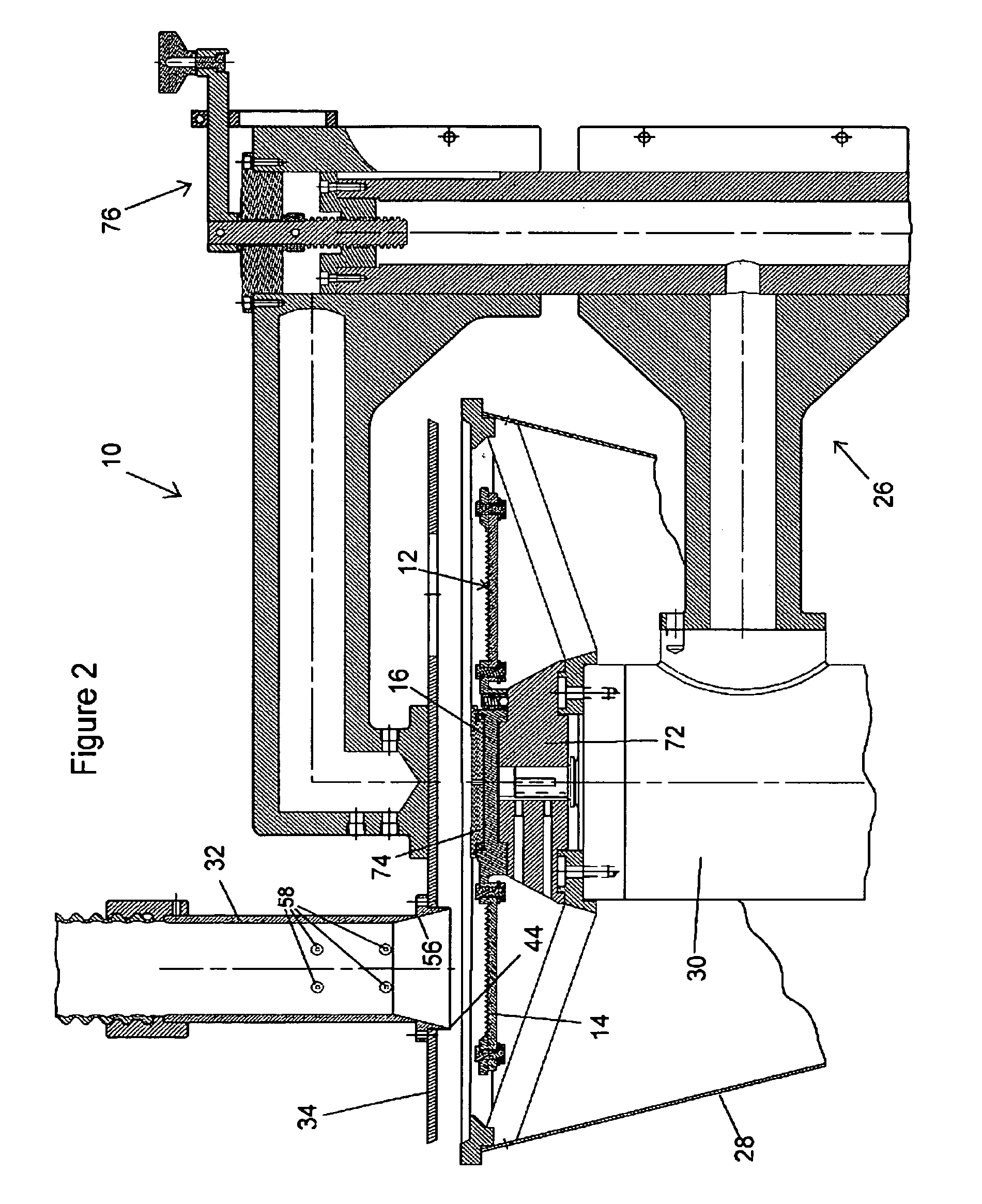

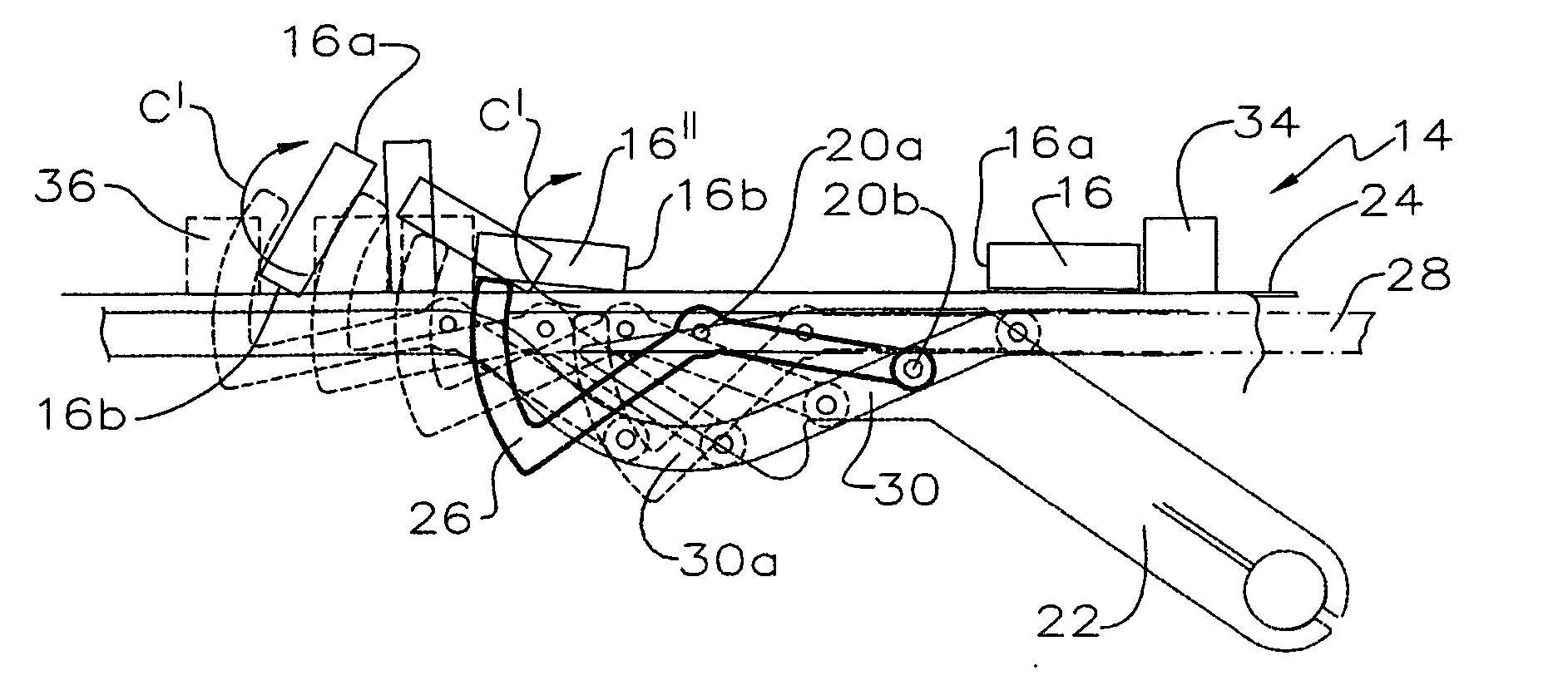

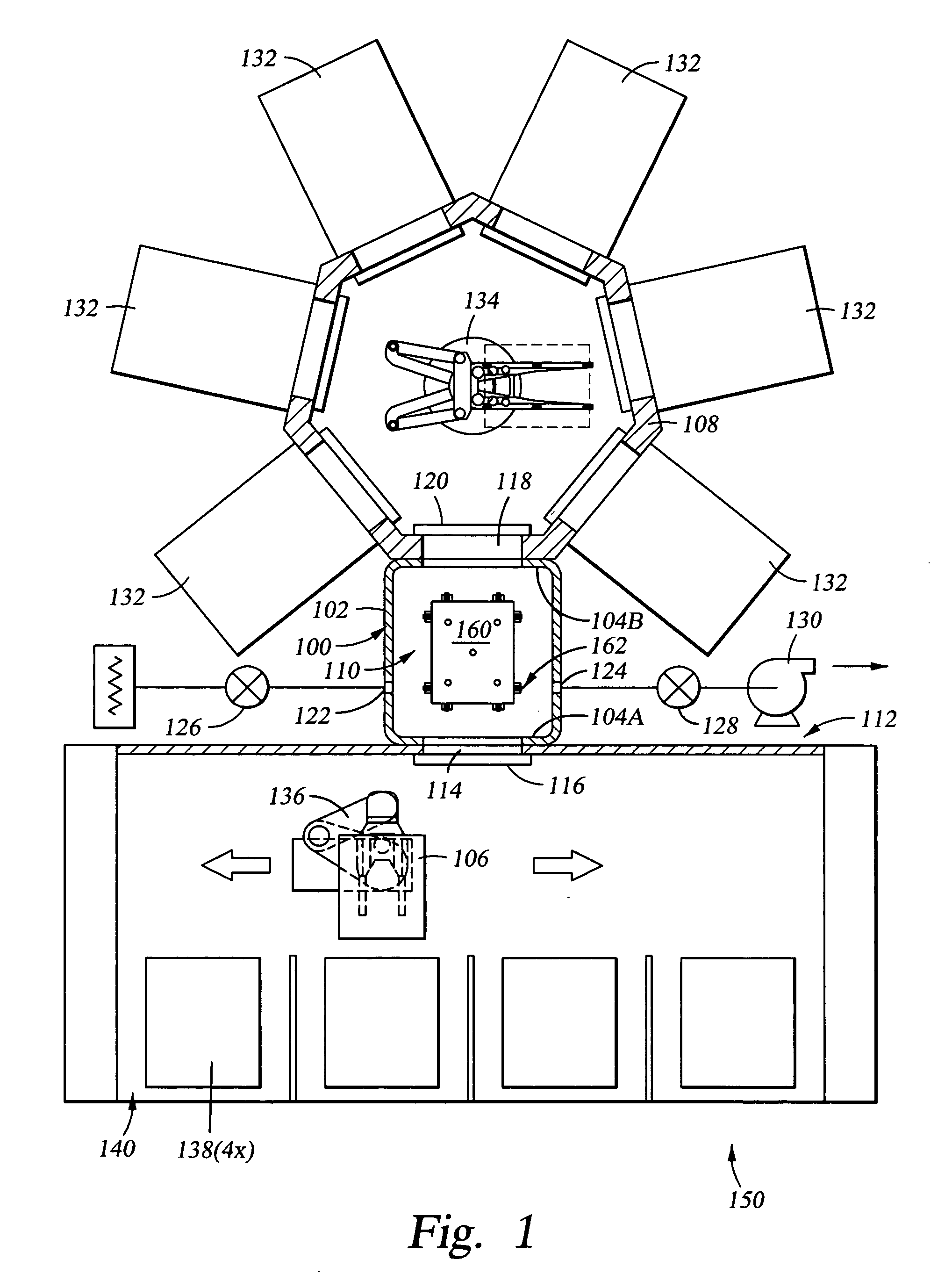

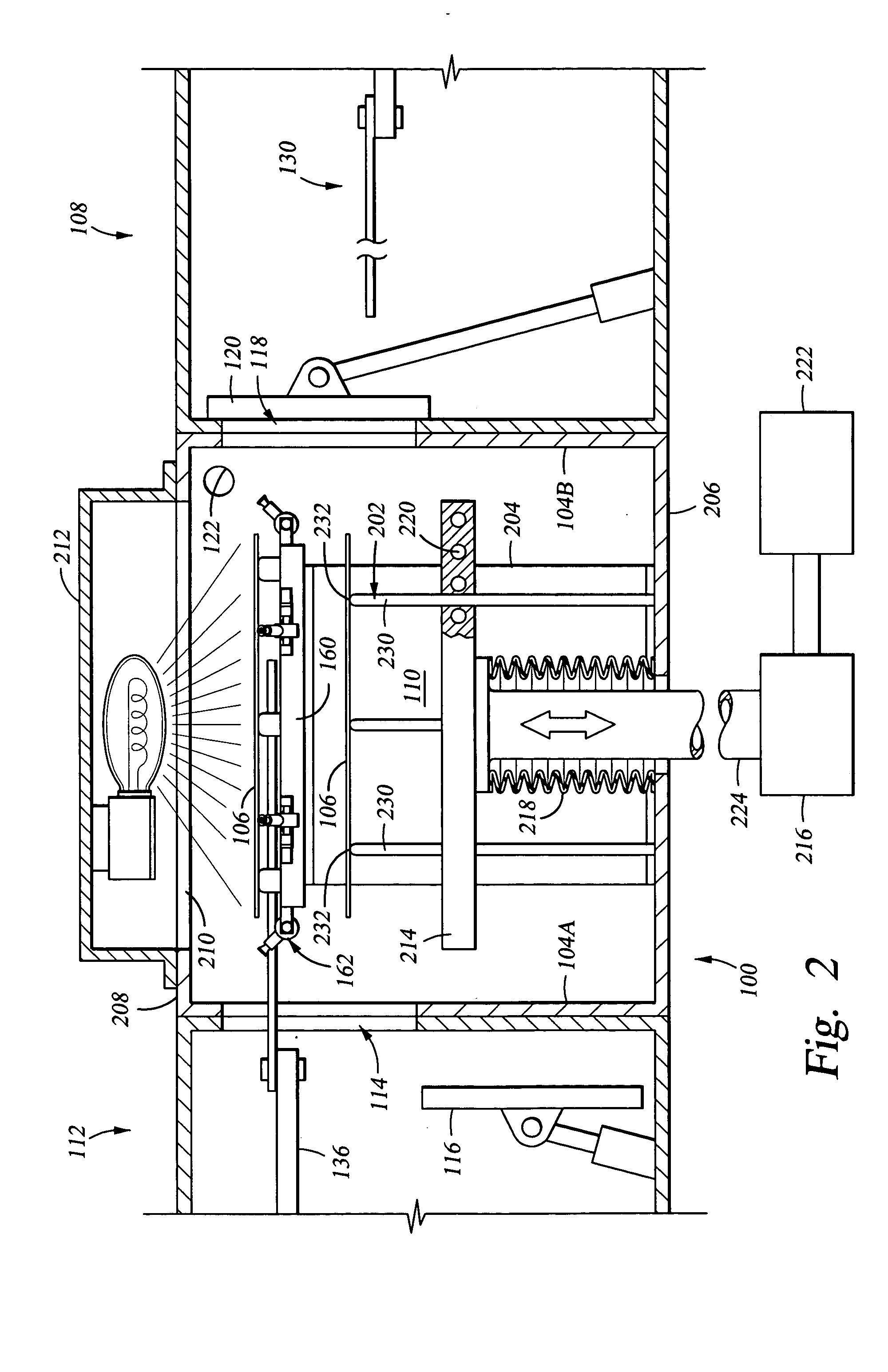

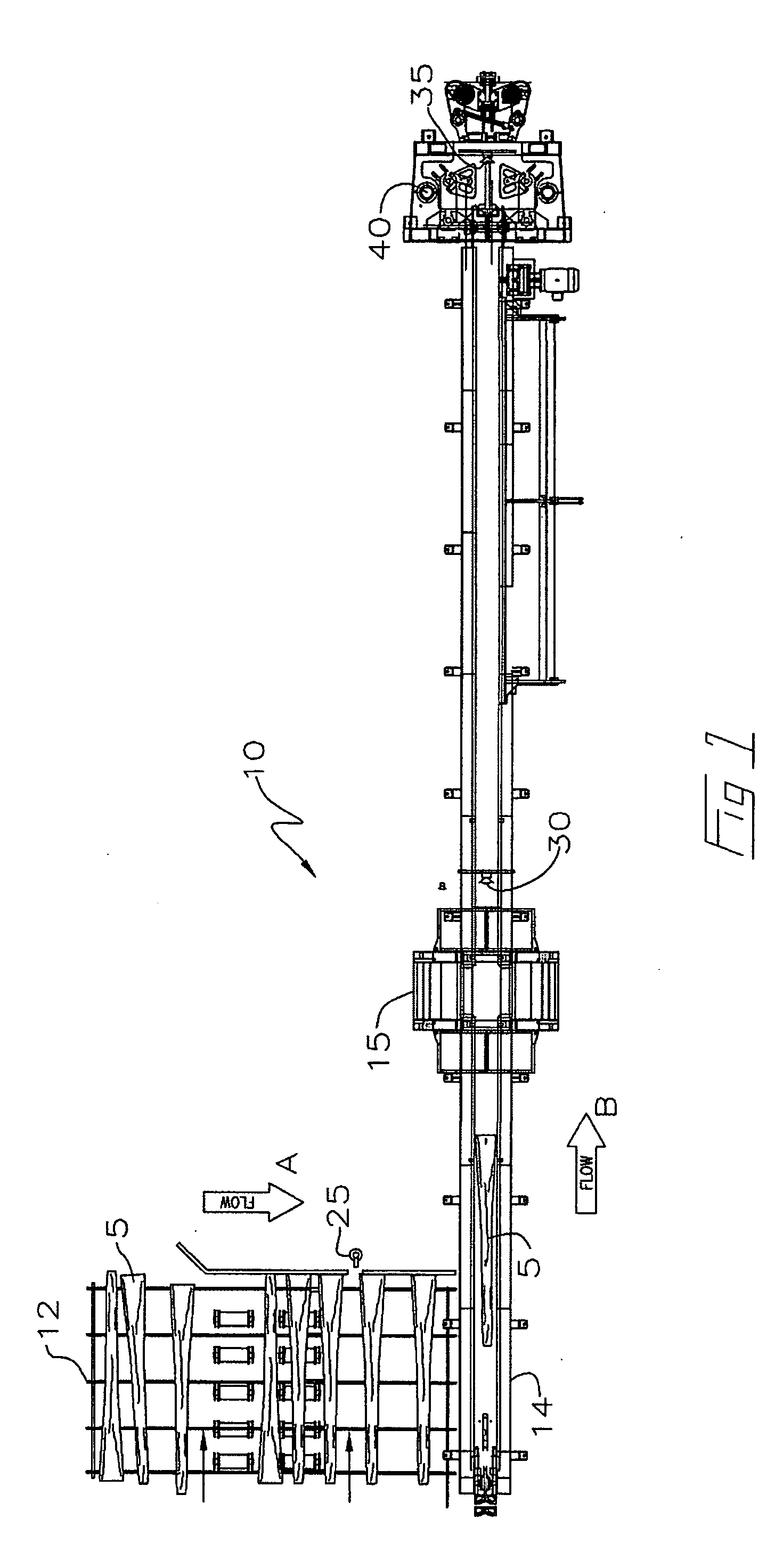

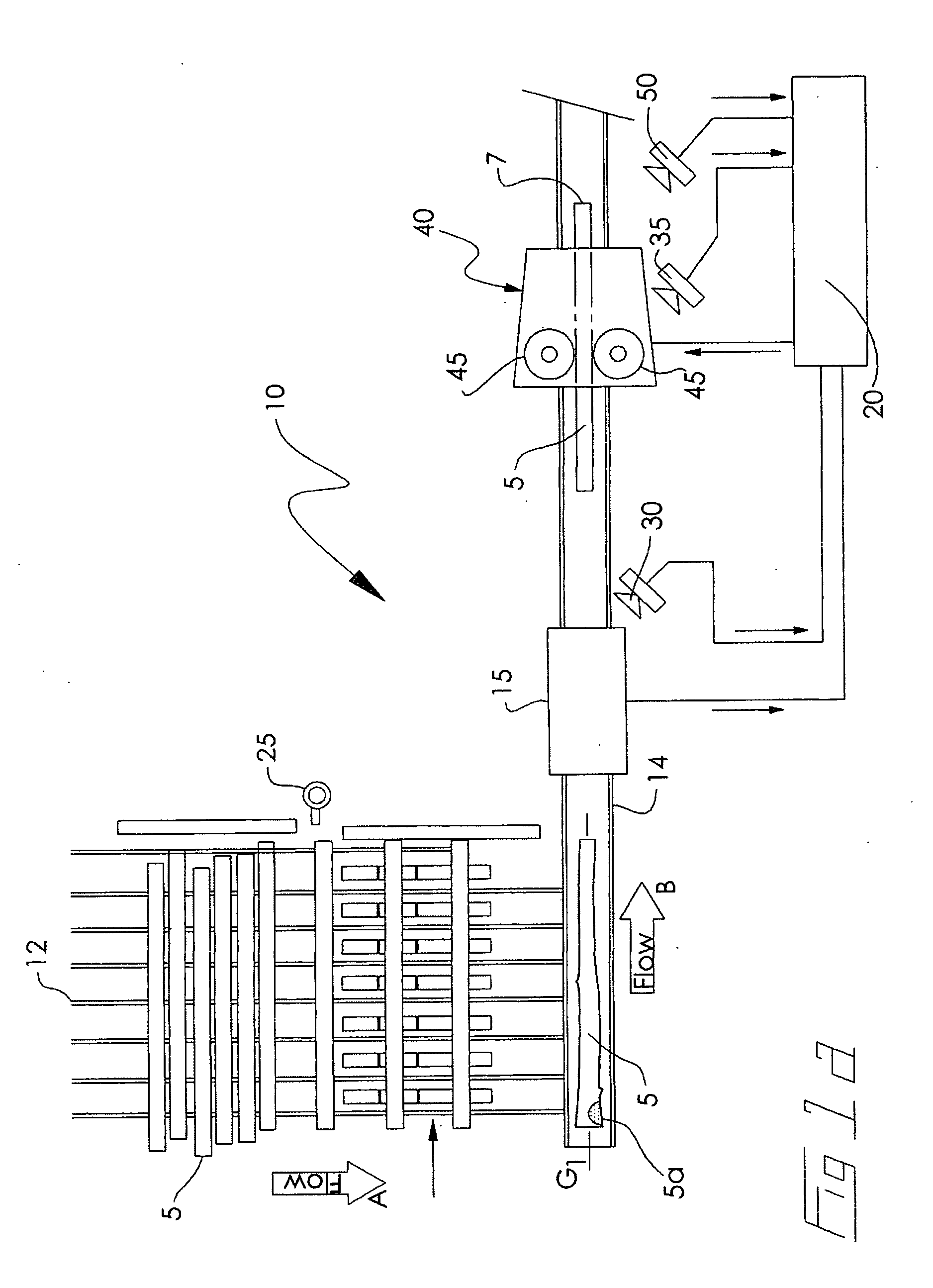

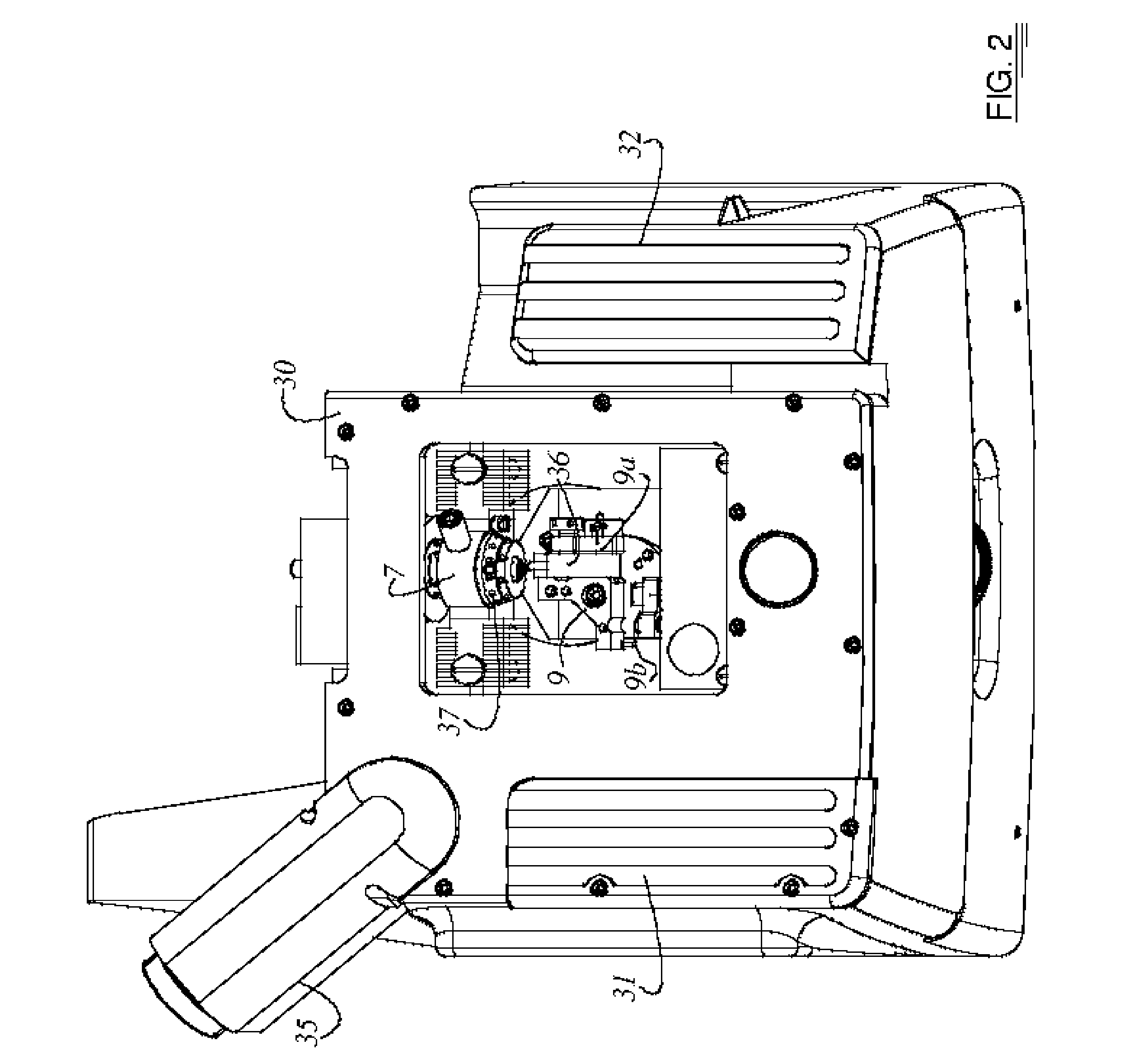

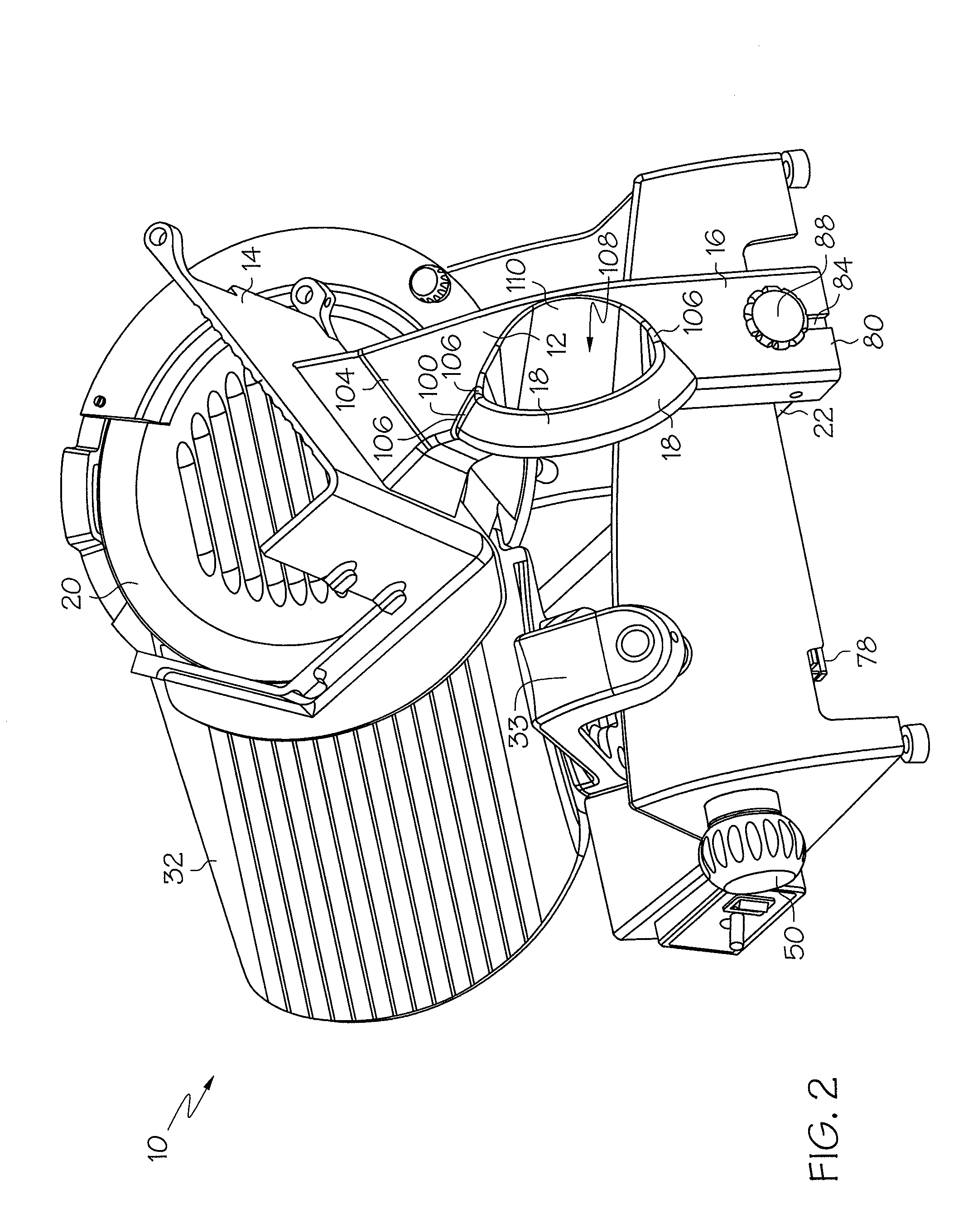

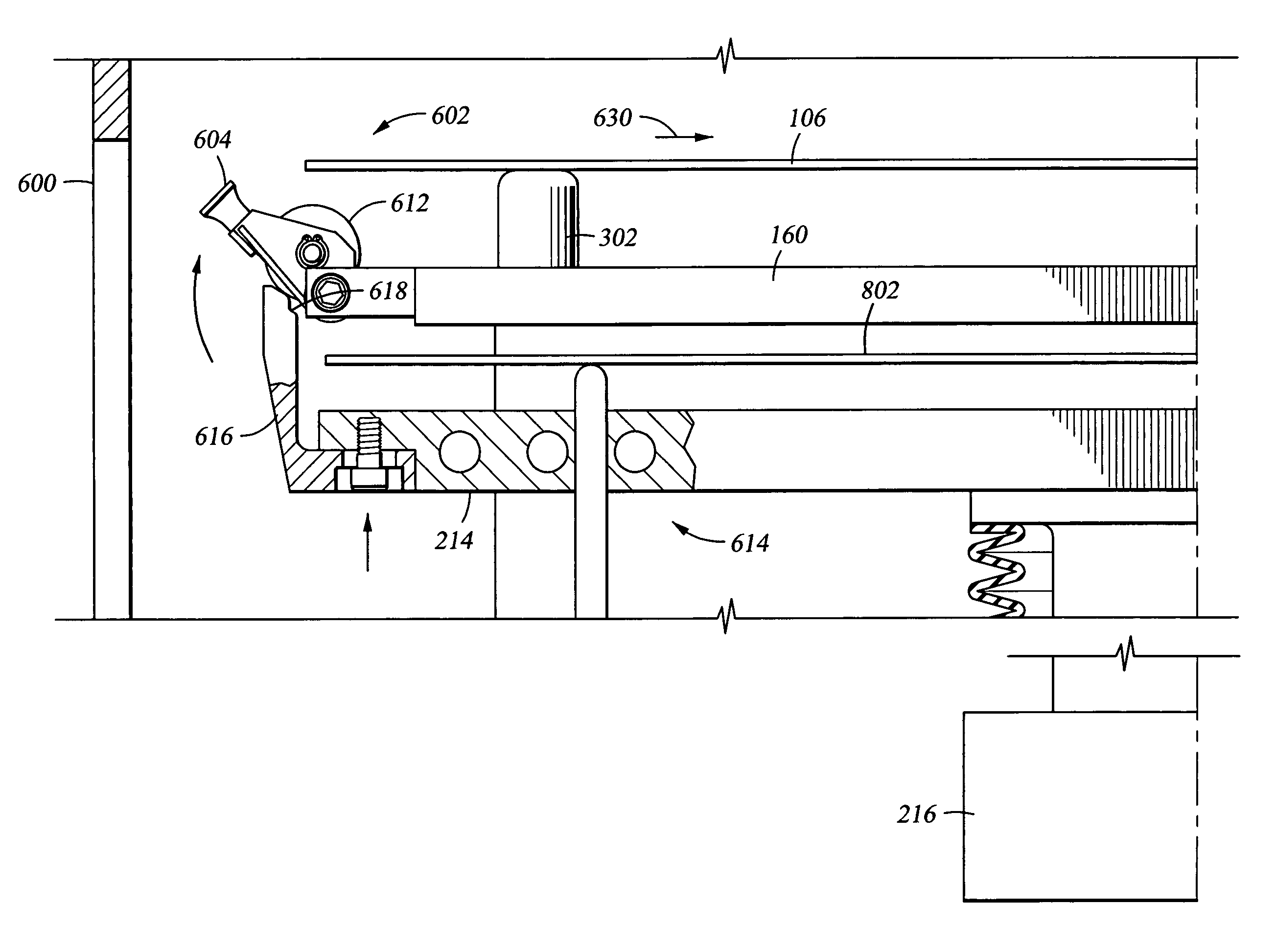

Wane orientation board turner

InactiveUS20050150743A1Increase rotation speedQuality improvementConveyorsTurning equipmentEngineeringMechanical engineering

A device for selectively inverting a workpiece about the longitudinal axis of the workpiece within a single lug space of a lugged transfer without impeding lumber flow along a flow path on the lugged transfer, wherein the device includes a workpiece speed-up for urging the workpiece at an increased translation speed along the flow path, a selectively operable workpiece brake to inhibit accelerated translation of the workpiece by the workpiece speed-up so as to selectively at least momentarily delay translation of the workpiece at the increased translation speed of the workpiece speed-up, and a workpiece turning arm mounted downstream along the workpiece speed-up. The board turning arm is selectively actuable into the flow path so as to invert the workpiece about its longitudinal axis within a corresponding lug space of the lugged transfer once the workpiece has been translated by the speed-up to a downstream end of the corresponding lug space.

Owner:USNRKOCKUMS CANCAR

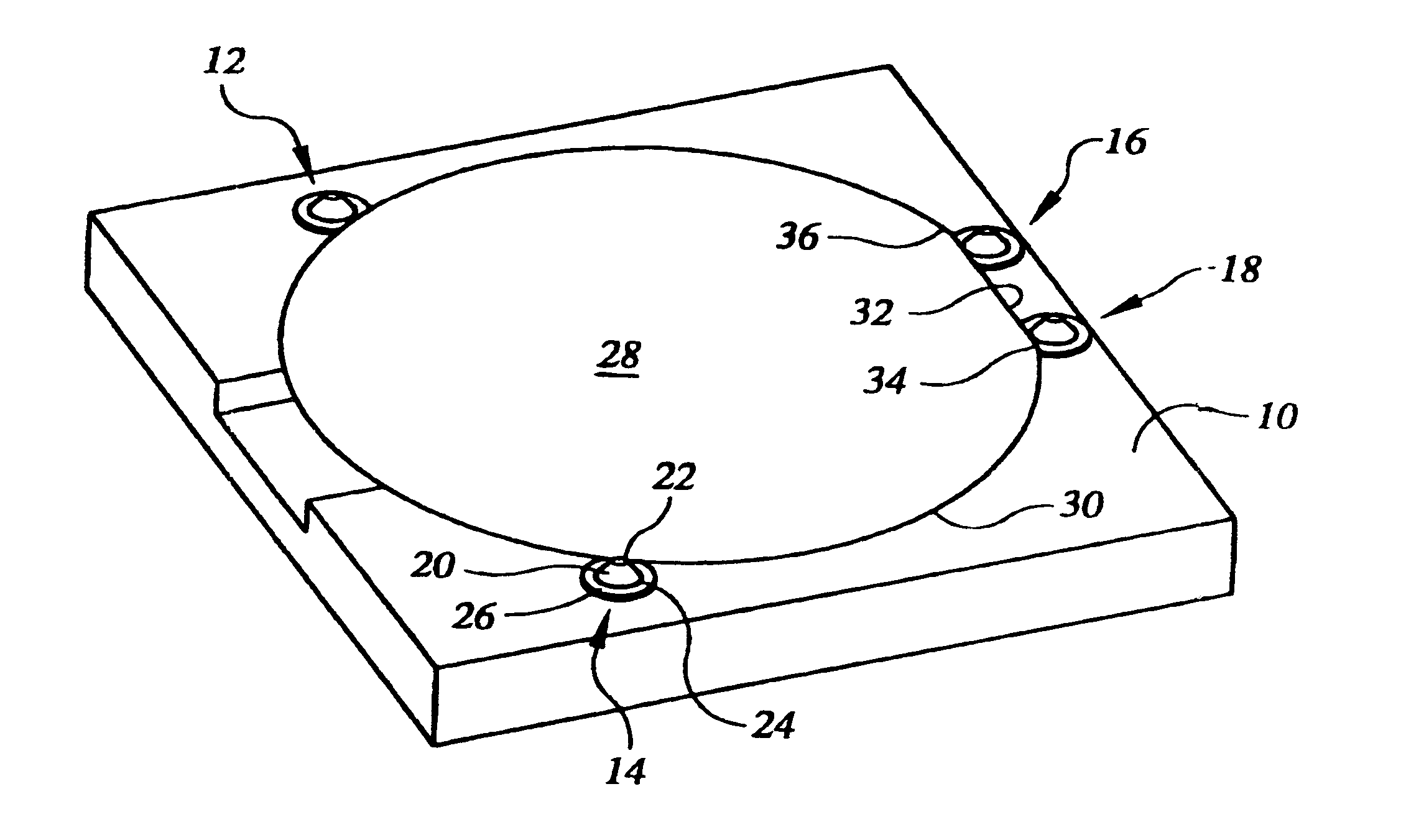

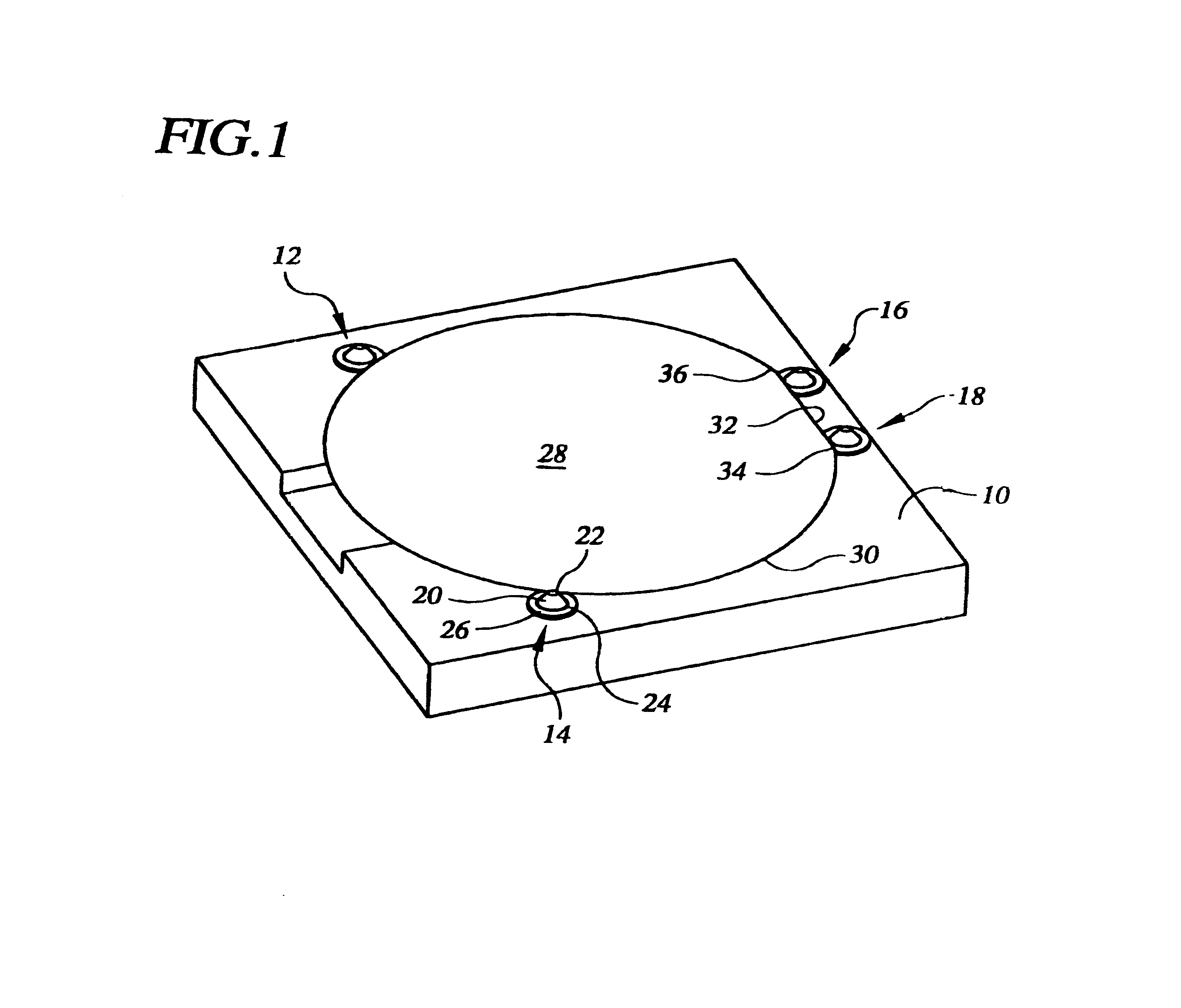

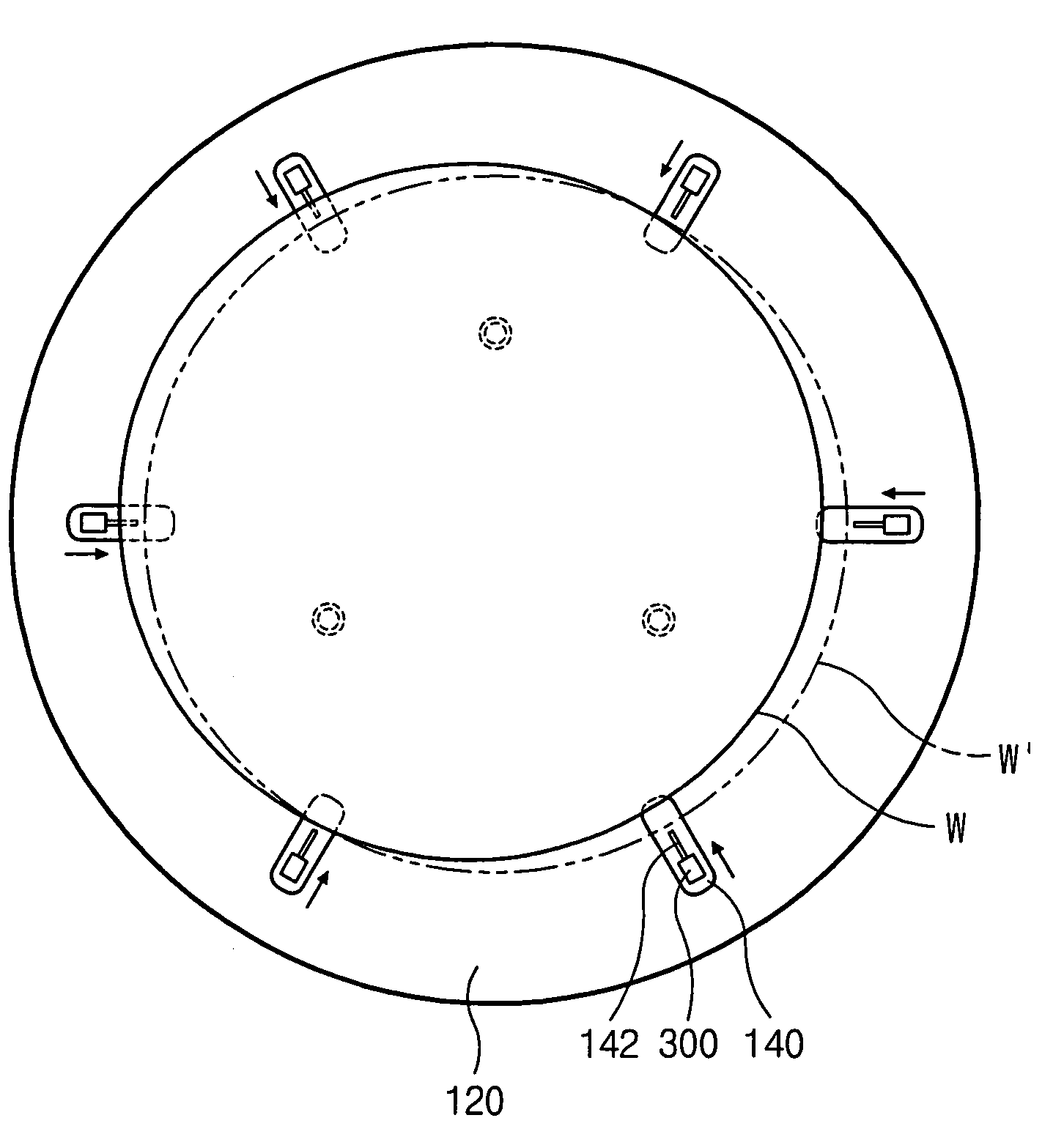

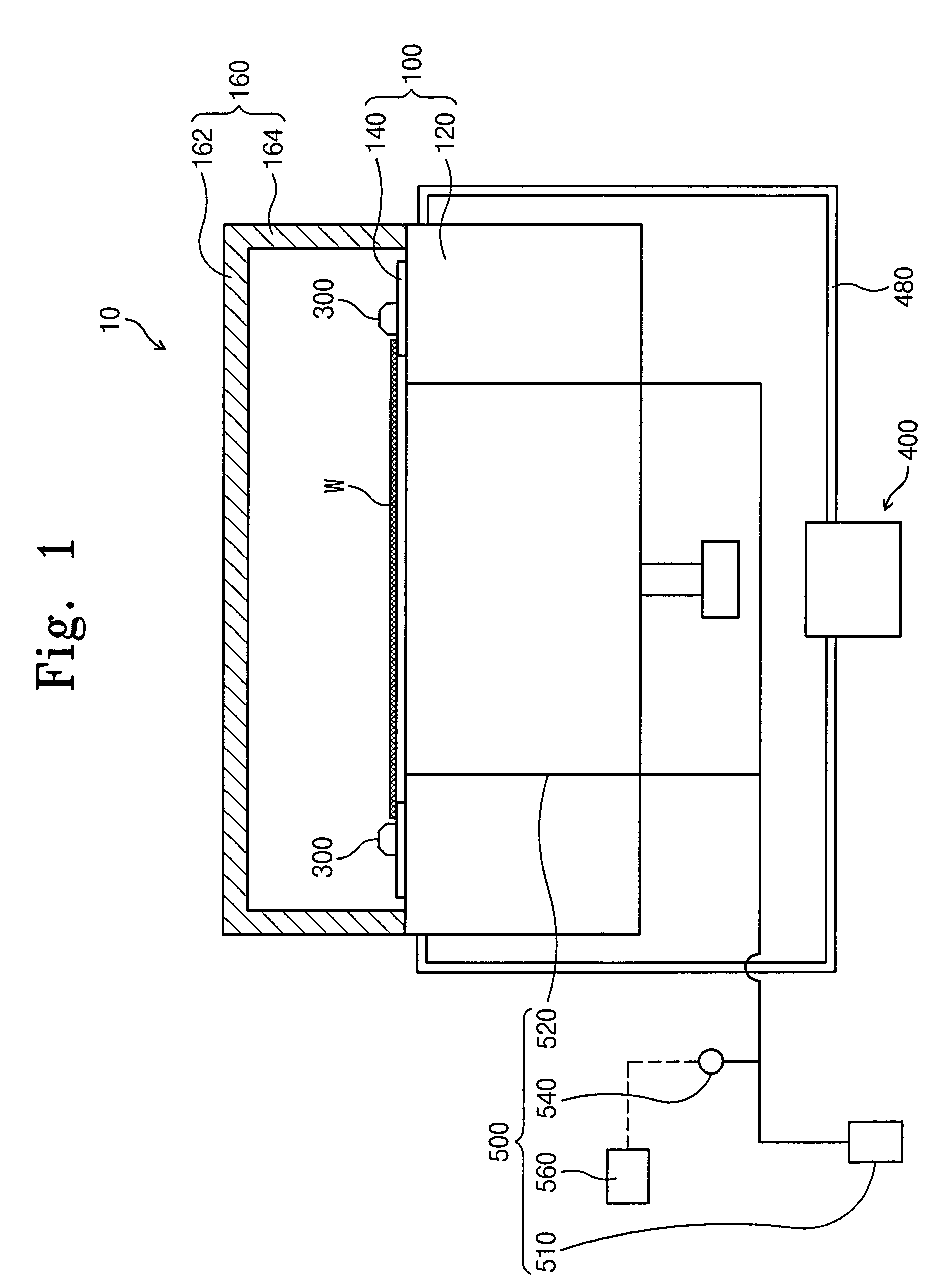

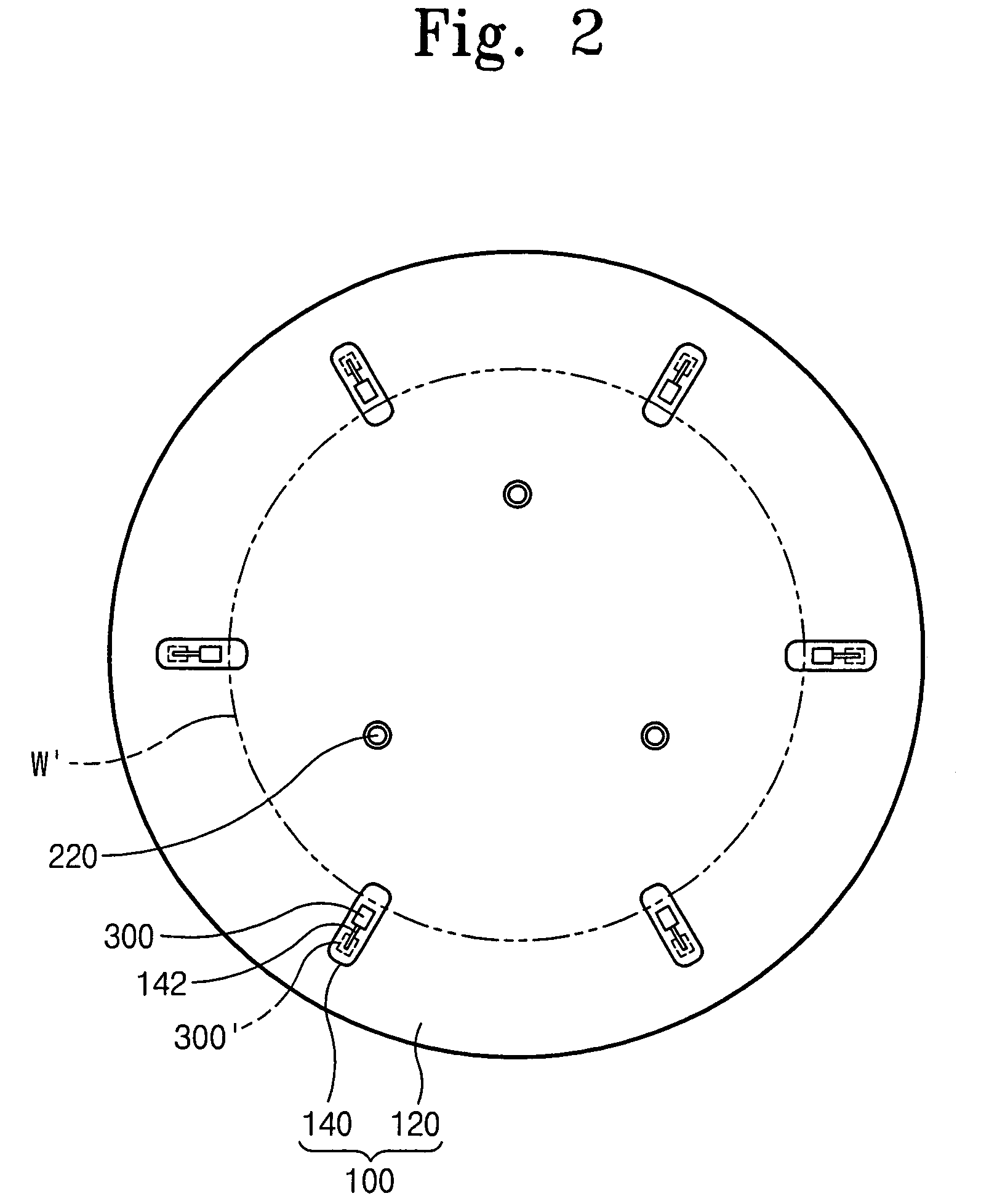

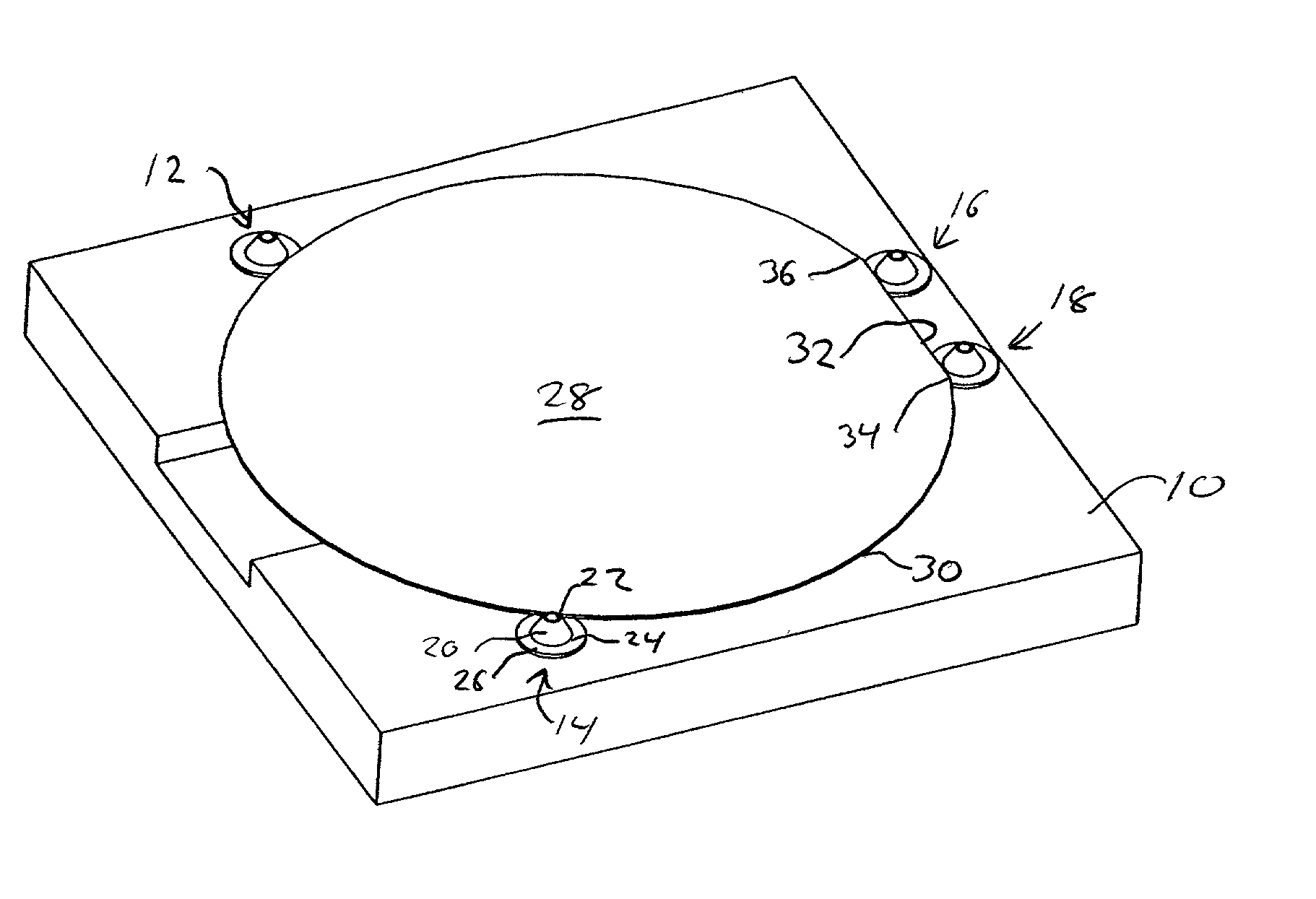

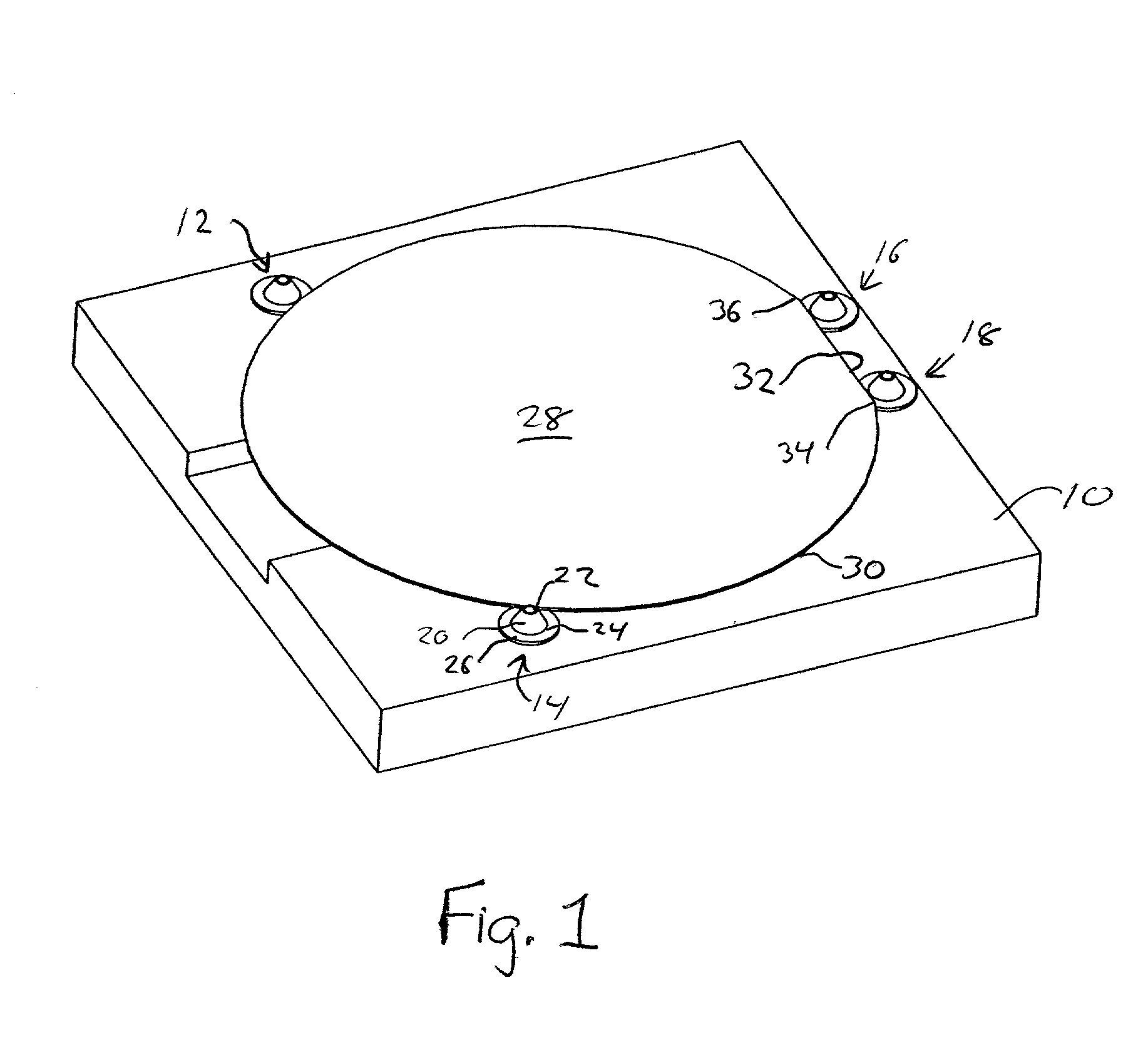

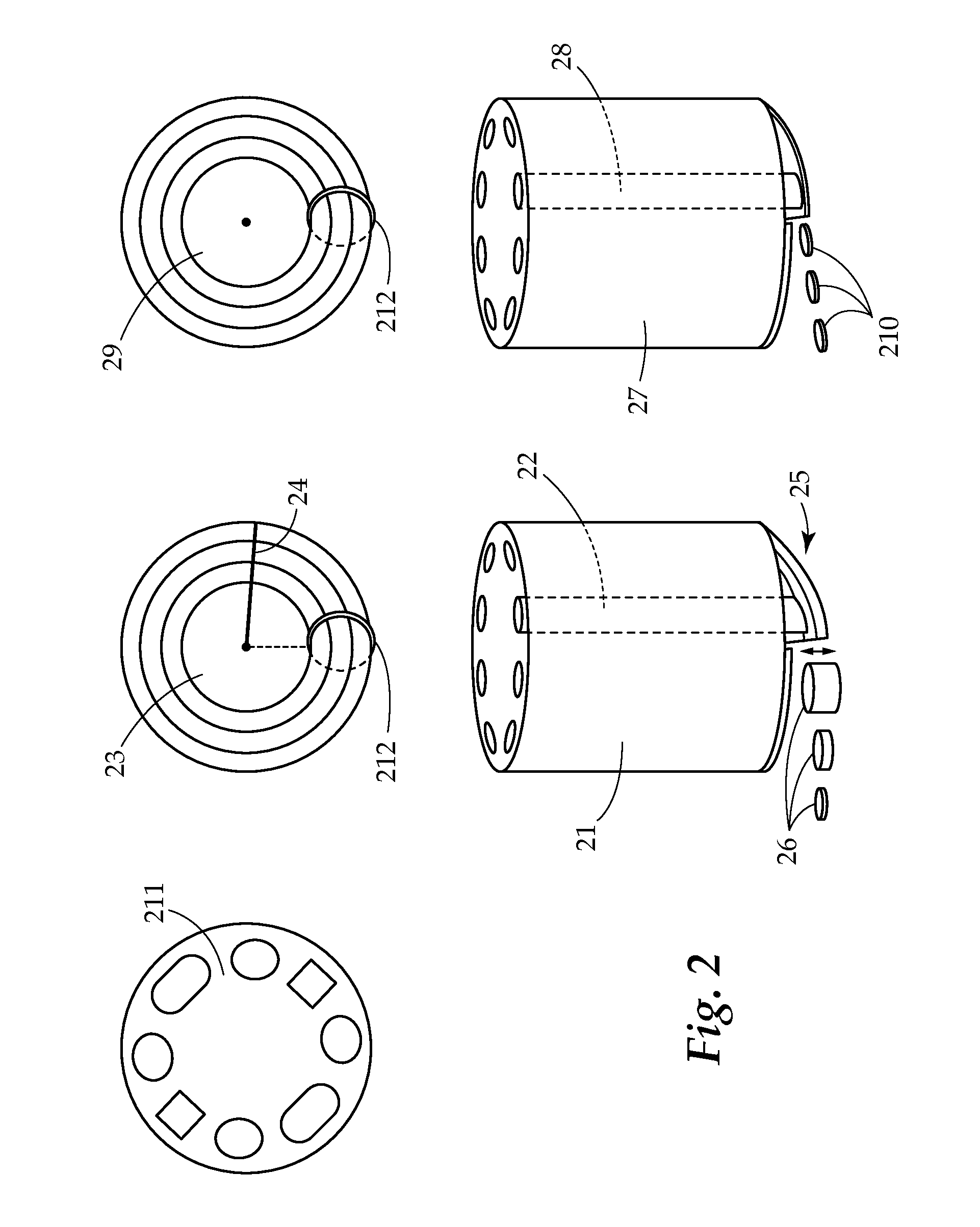

Substrate support

InactiveUS20050063800A1Welding/cutting auxillary devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A method and apparatus for supporting a substrate is generally provided. In one aspect, an apparatus for supporting a substrate includes a support plate having a first body disposed proximate thereto. A first pushing member is radially coupled to the first body and adapted to urge the substrate in a first direction parallel to the support plate when the first body rotates. In another aspect, a load lock chamber having a substrate support that supports a substrate placed thereon includes a cooling plate that is moved to actuate at least one alignment mechanism. The alignment mechanism includes a pushing member that urges the substrate in a first direction towards a center of the support. The pushing member may additionally rotate about an axis perpendicular to the first direction.

Owner:APPLIED MATERIALS INC

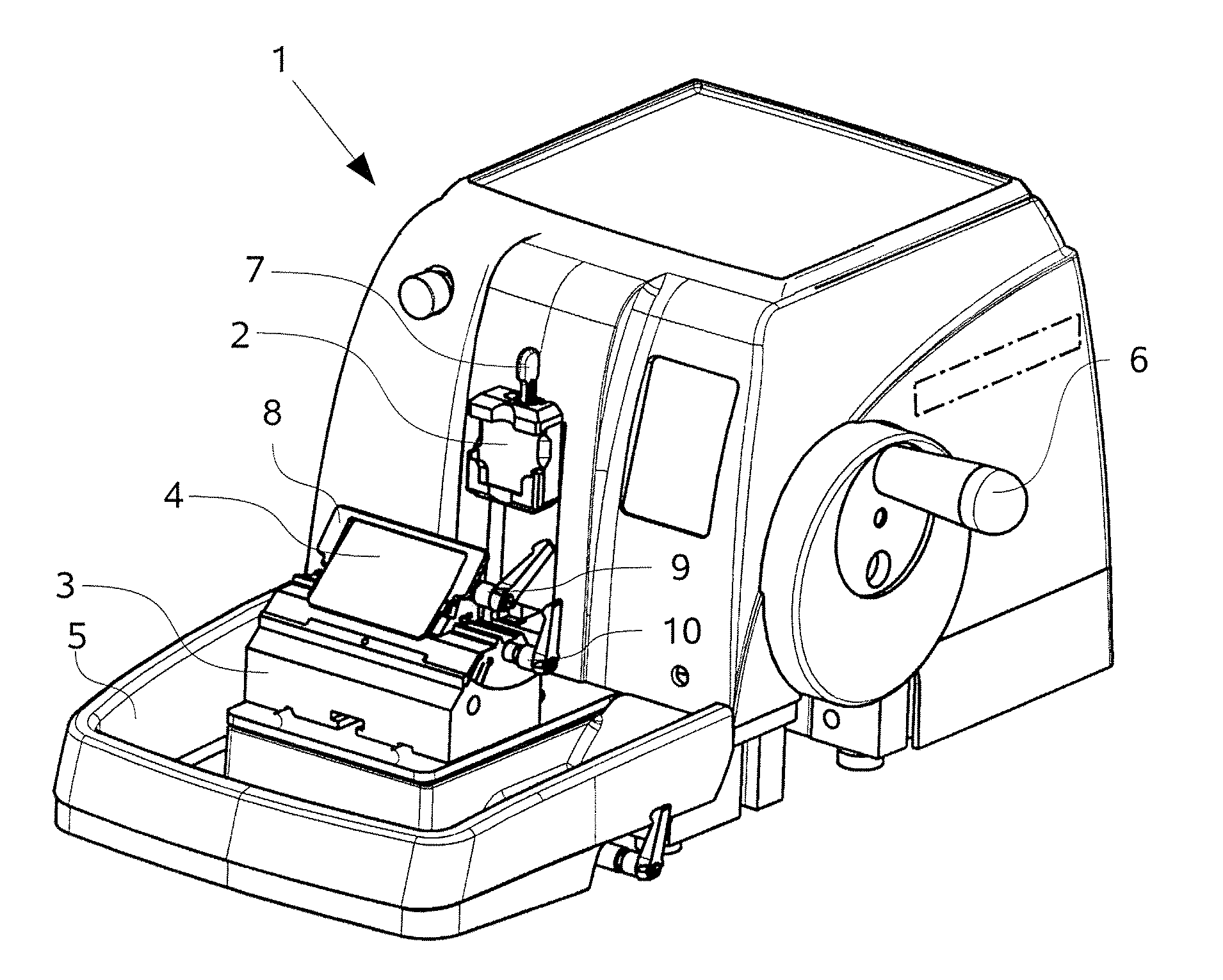

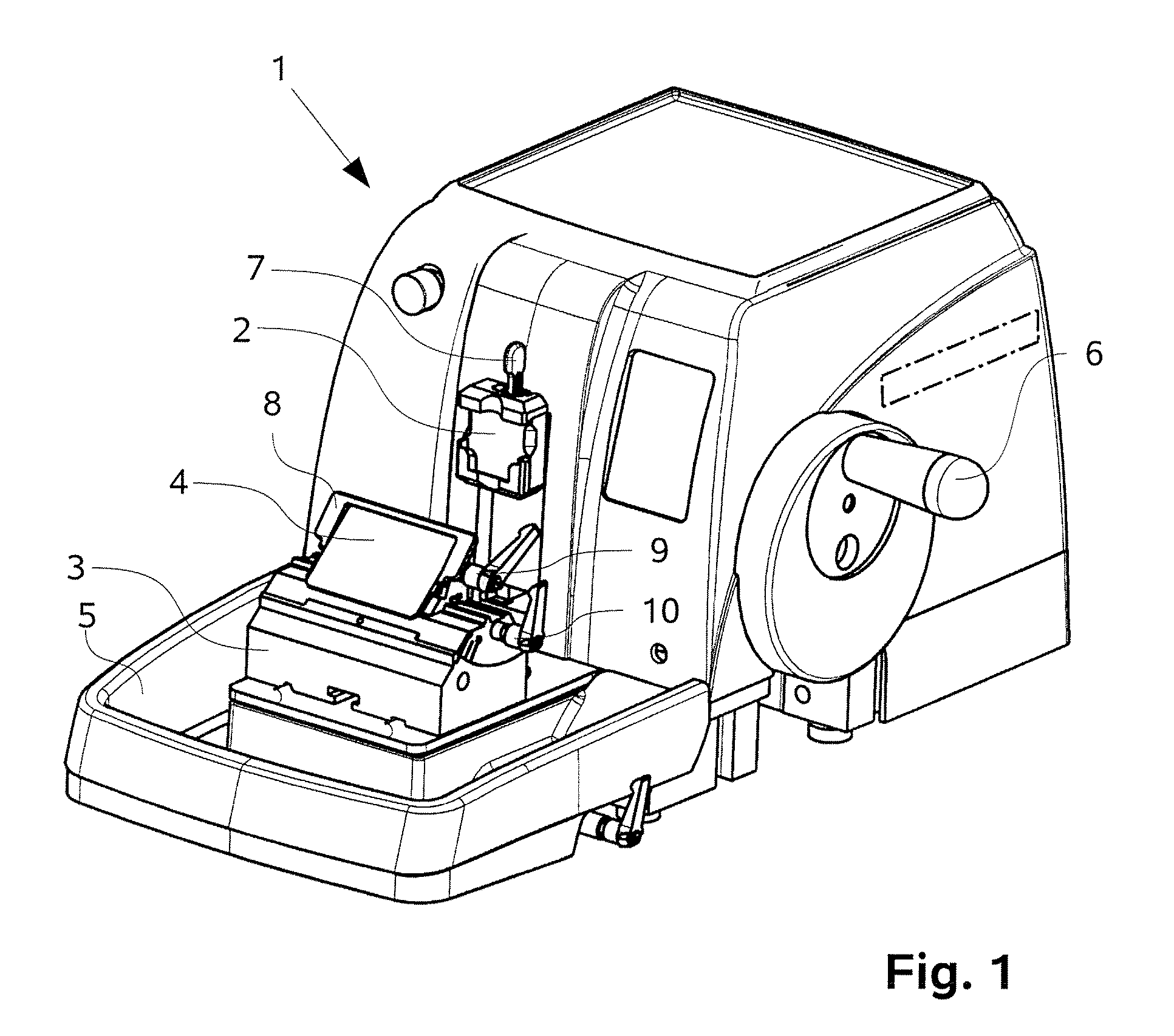

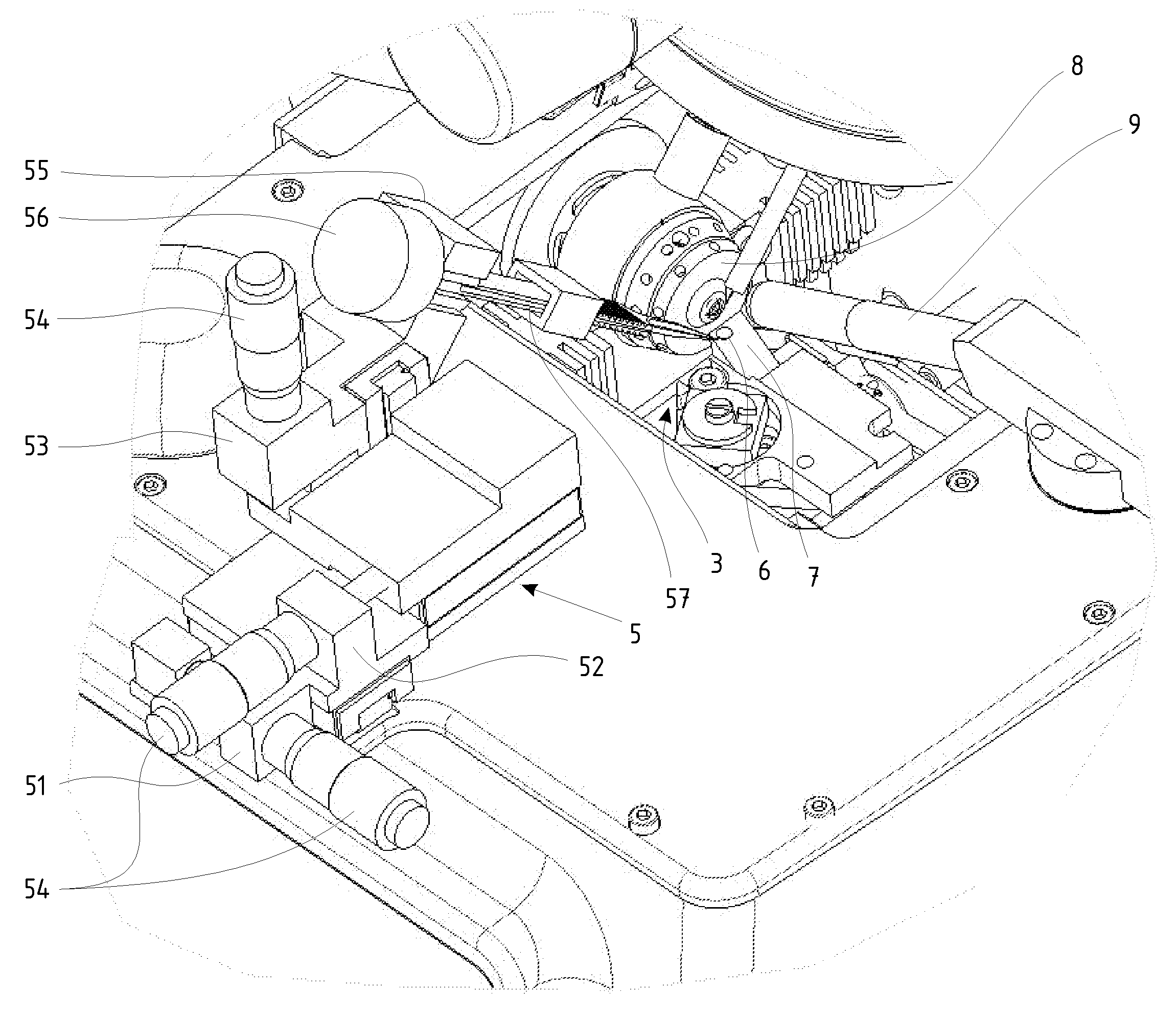

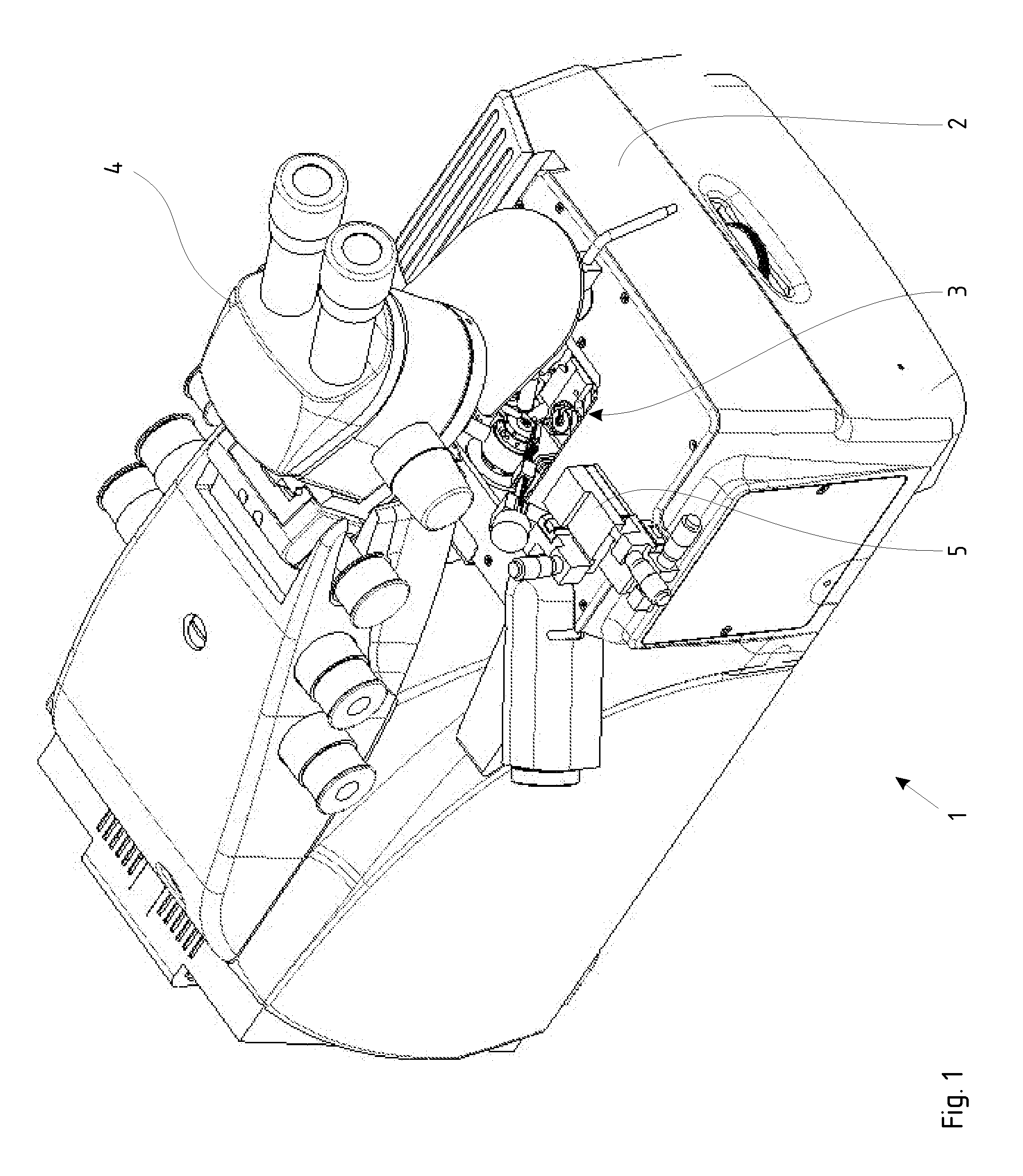

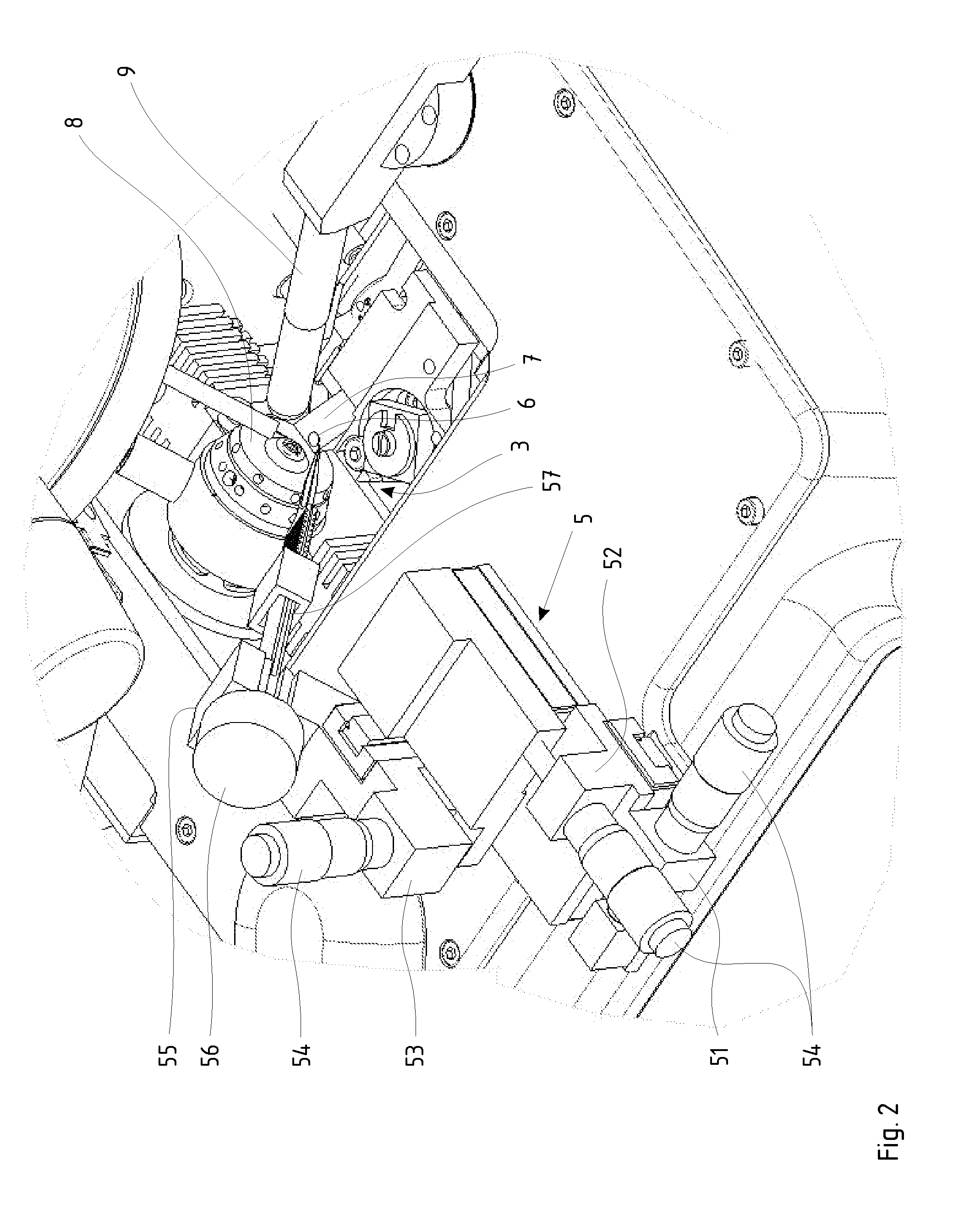

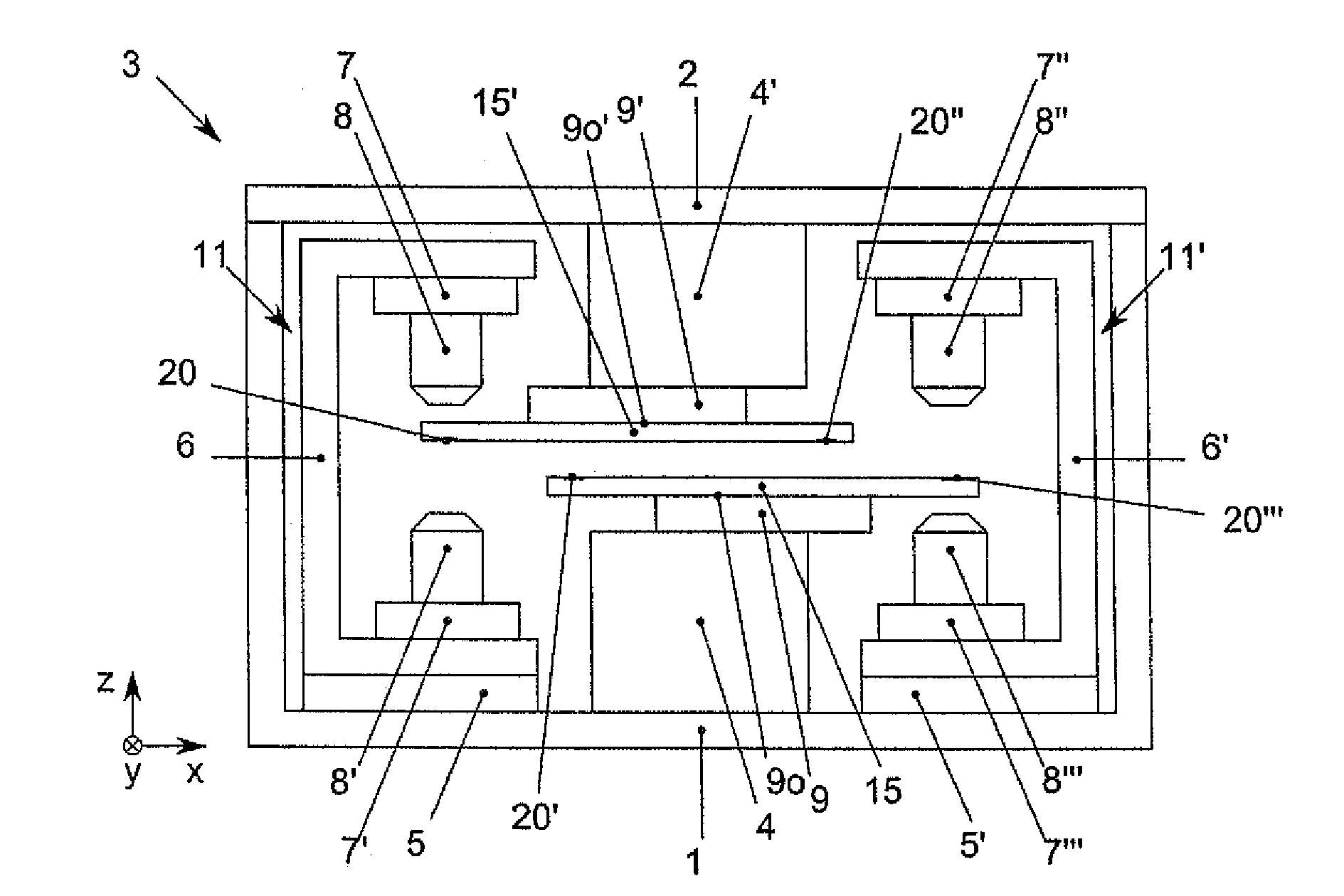

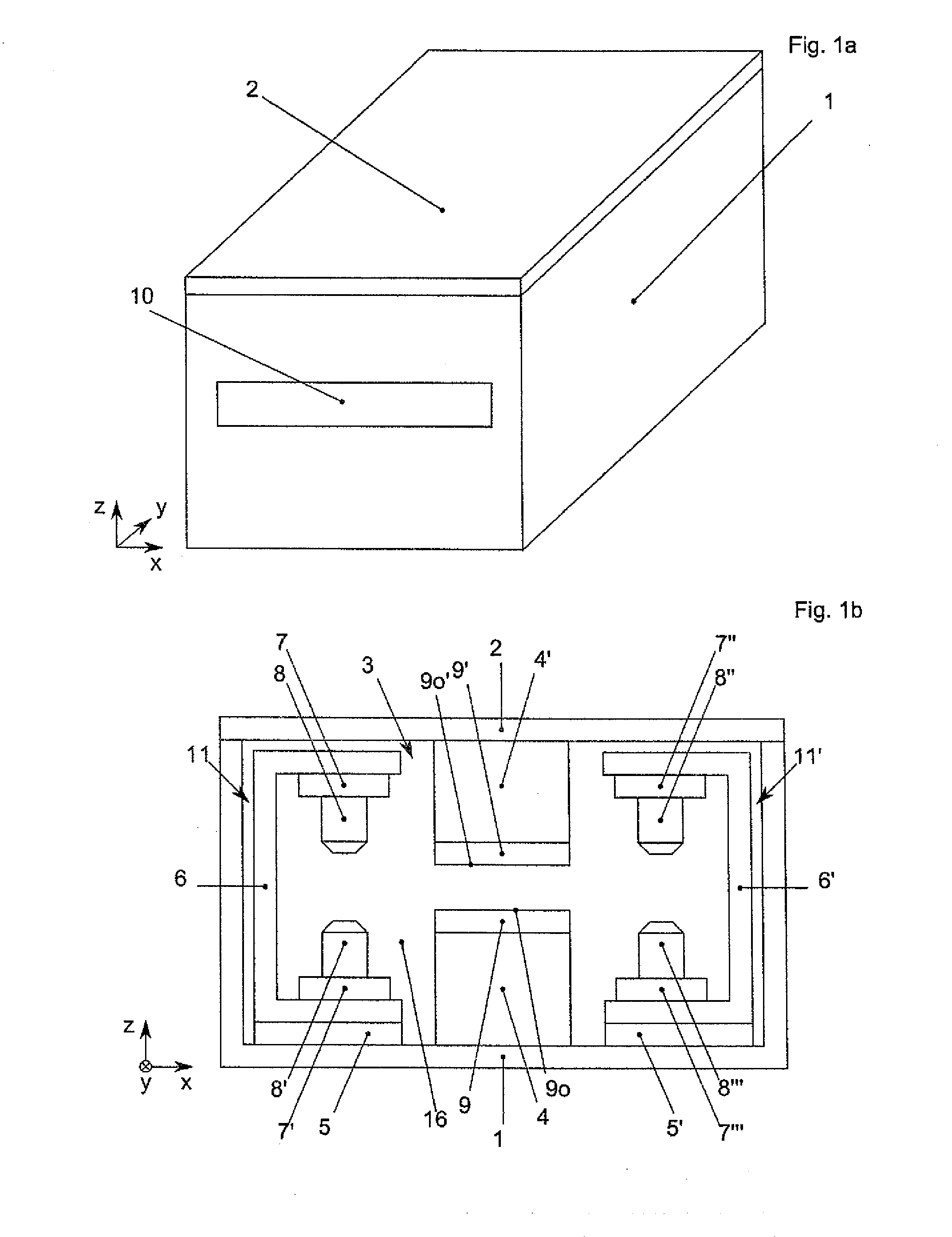

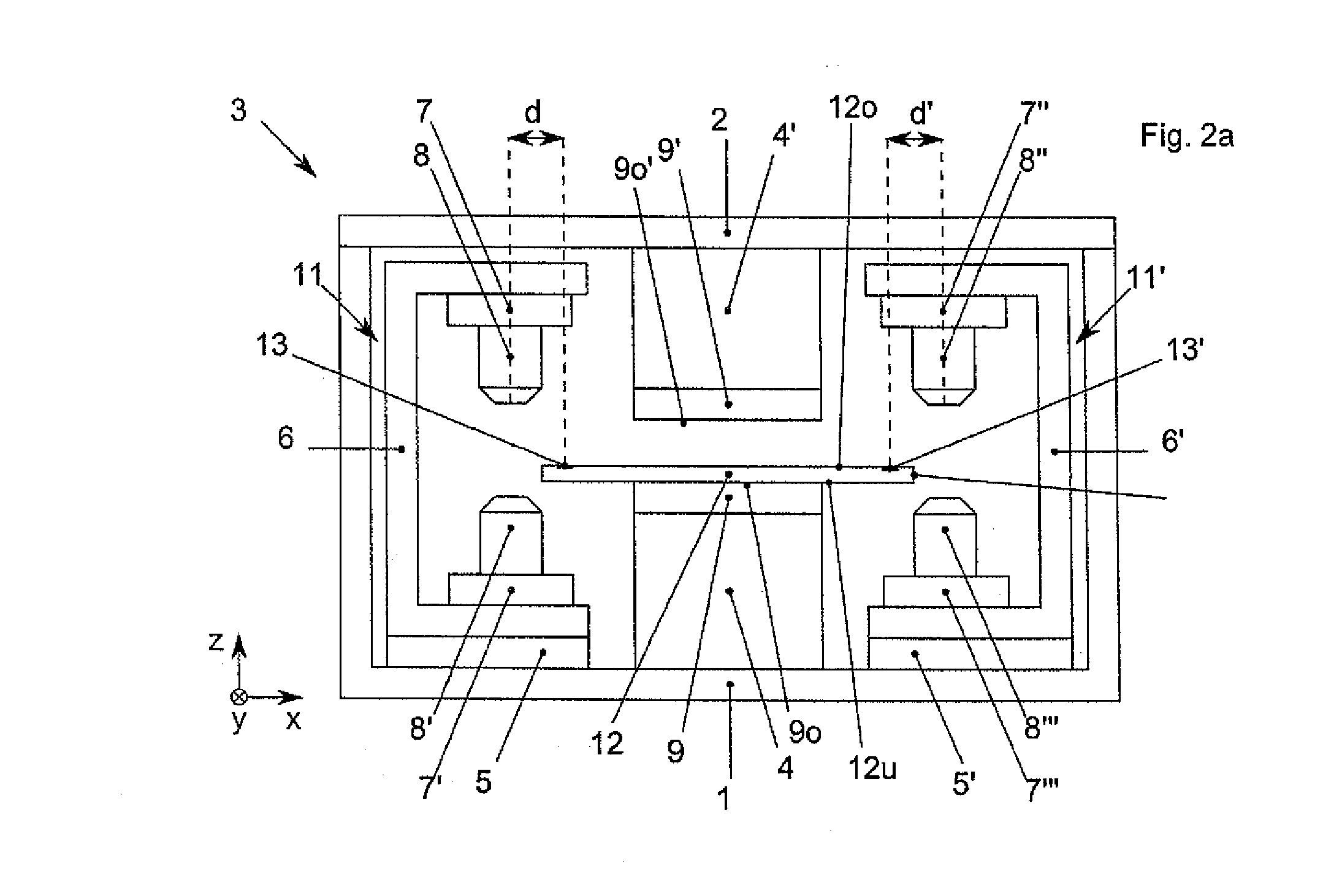

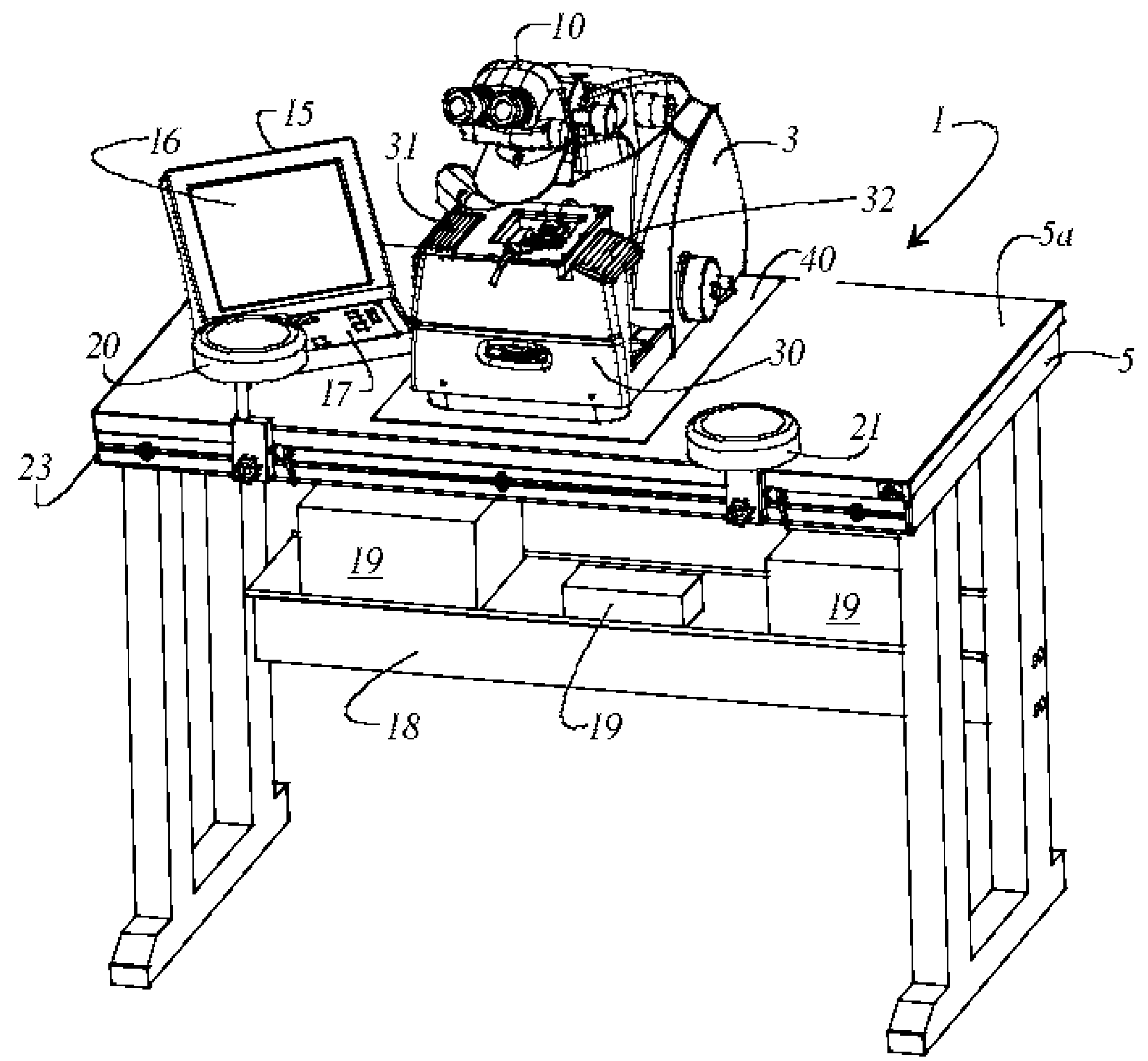

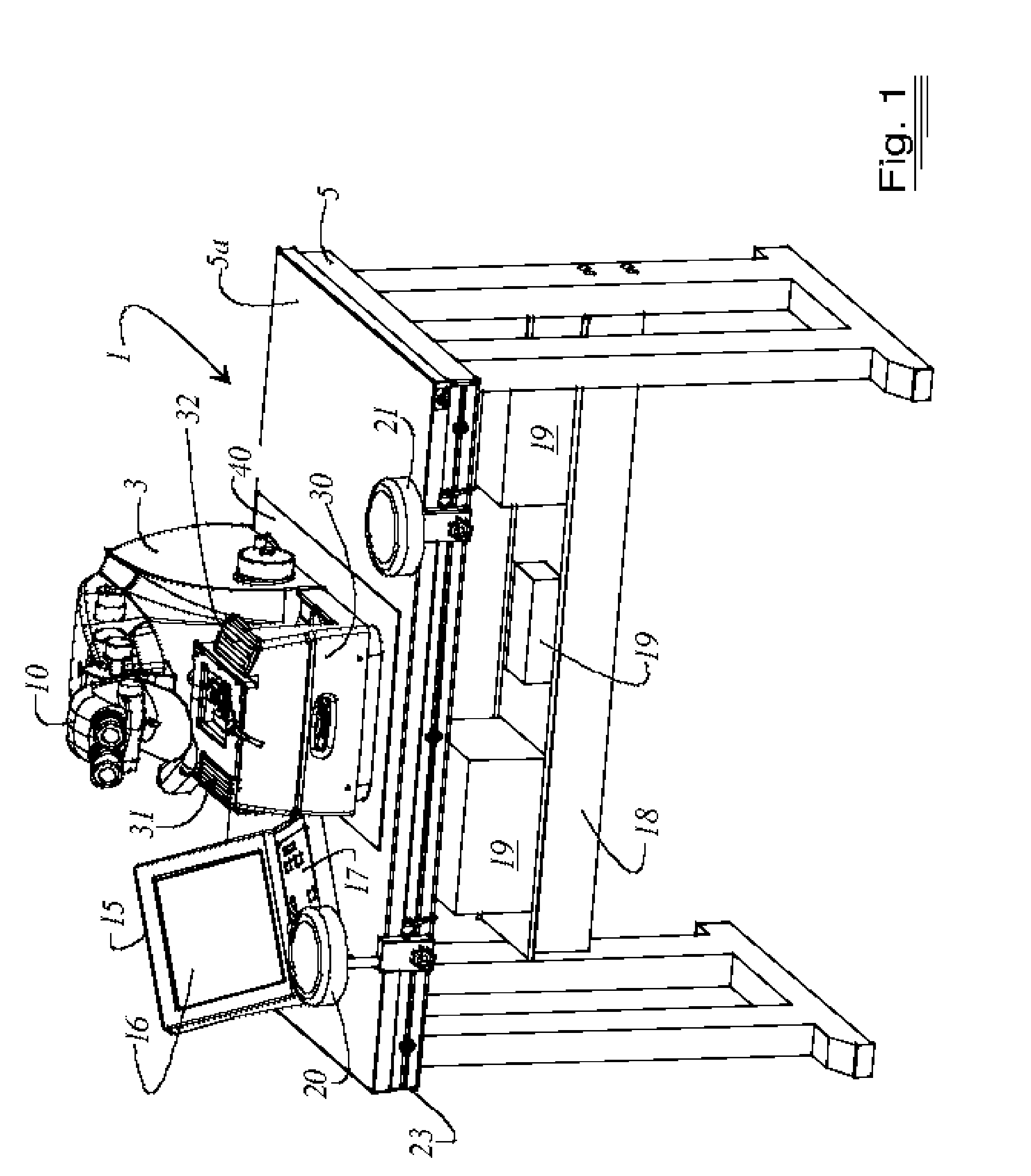

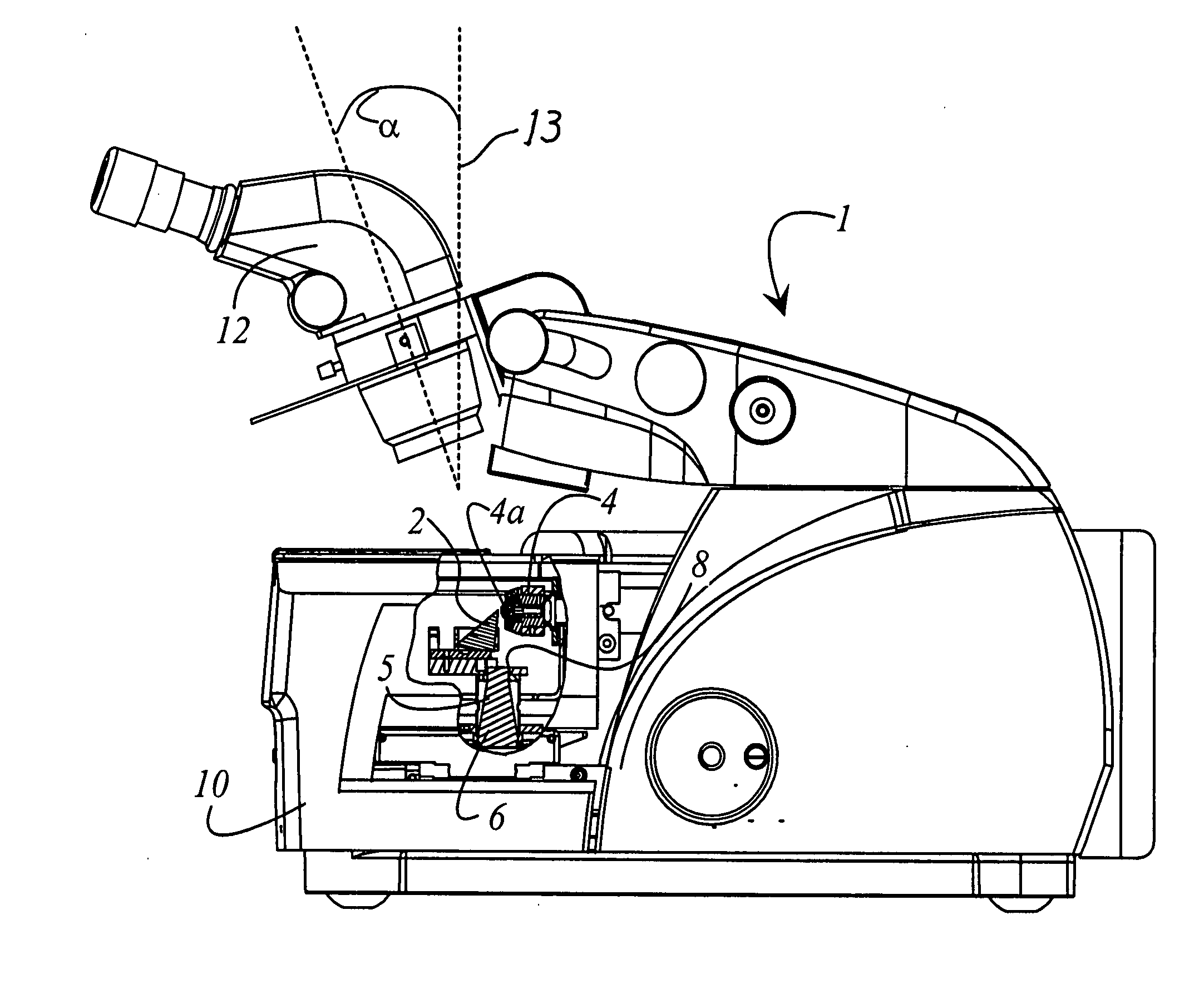

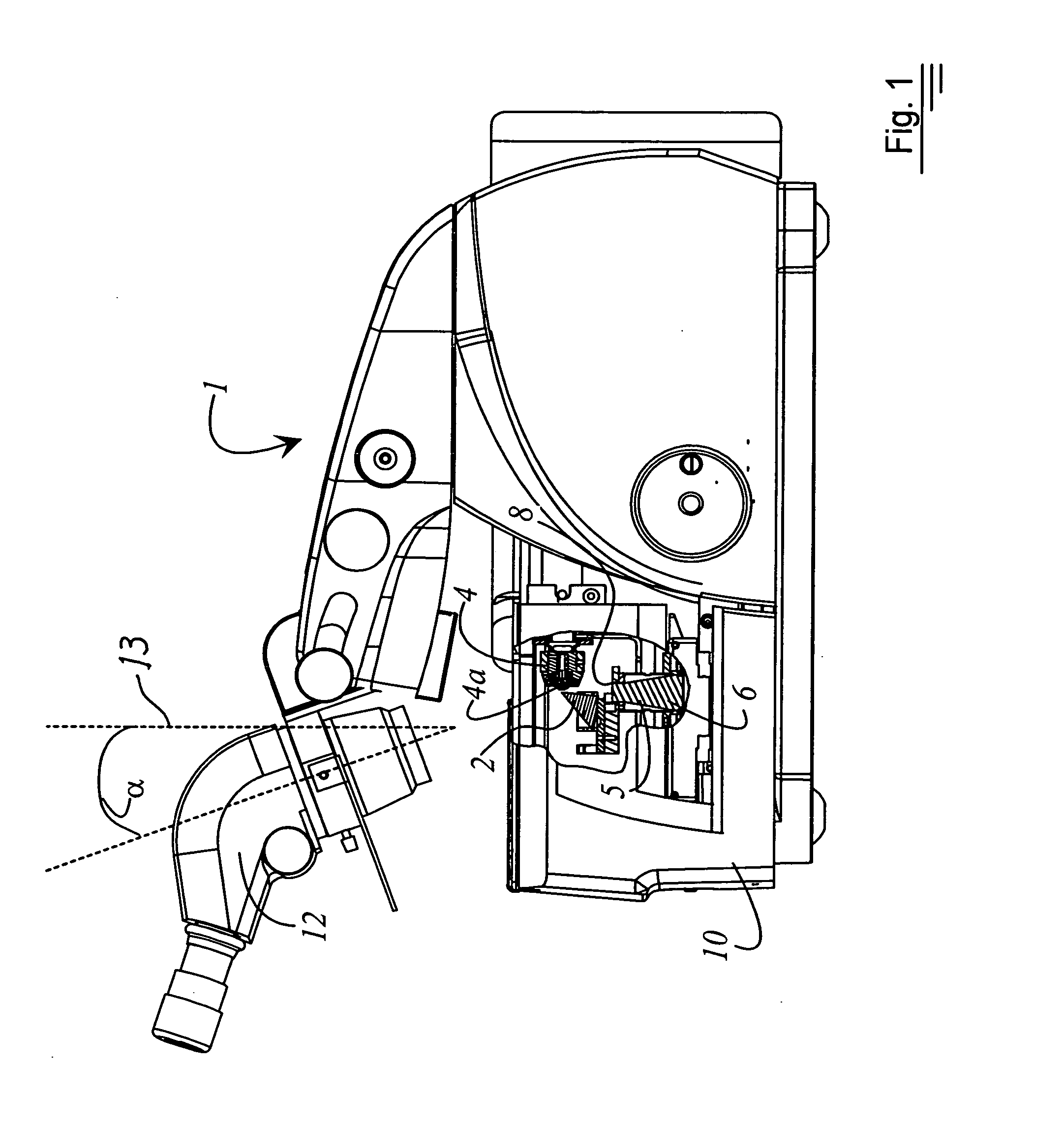

Microtome

ActiveUS20070227330A1Improve impact toughnessLow water absorptionFeeding devicesWithdrawing sample devicesParaffin sectionBiomedical engineering

The present invention relates to a microtome (1) having functional regions to be operated manually, in particular a sample holder (2), a cutting device (3), a section removal system (4), and a section collection pan (5). A microtome (1) is described in which the particularly firm contact or adhesion of sectioning waste fragments and, in particular, of thin sections can be at least largely avoided. For this purpose, the microtome (1) according to the present invention is characterized in that the components of the microtome (1) that can be brought into contact with paraffin sections are embodied in electrically conductive fashion.

Owner:LEICA BIOSYST NUSSLOCH

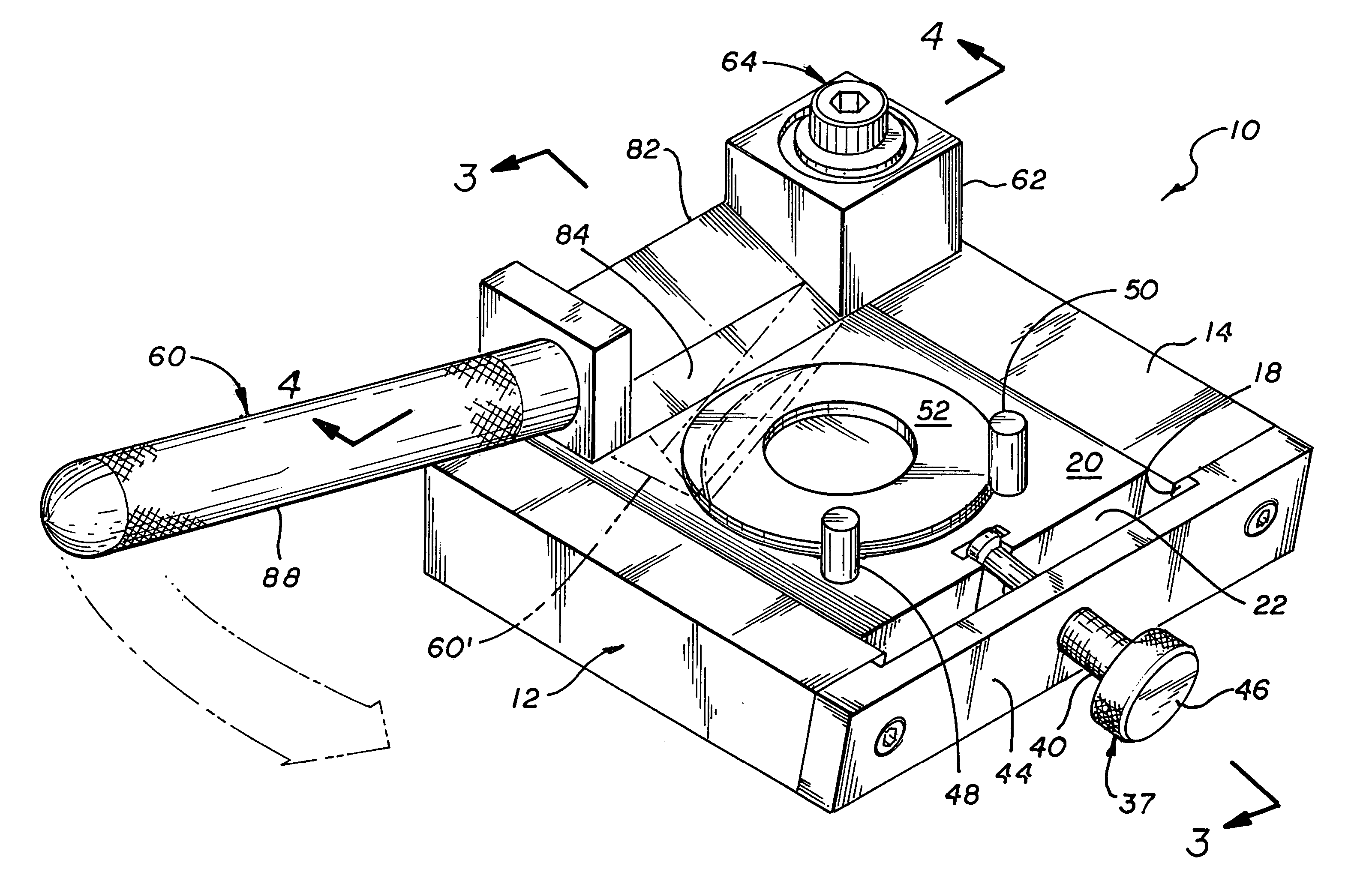

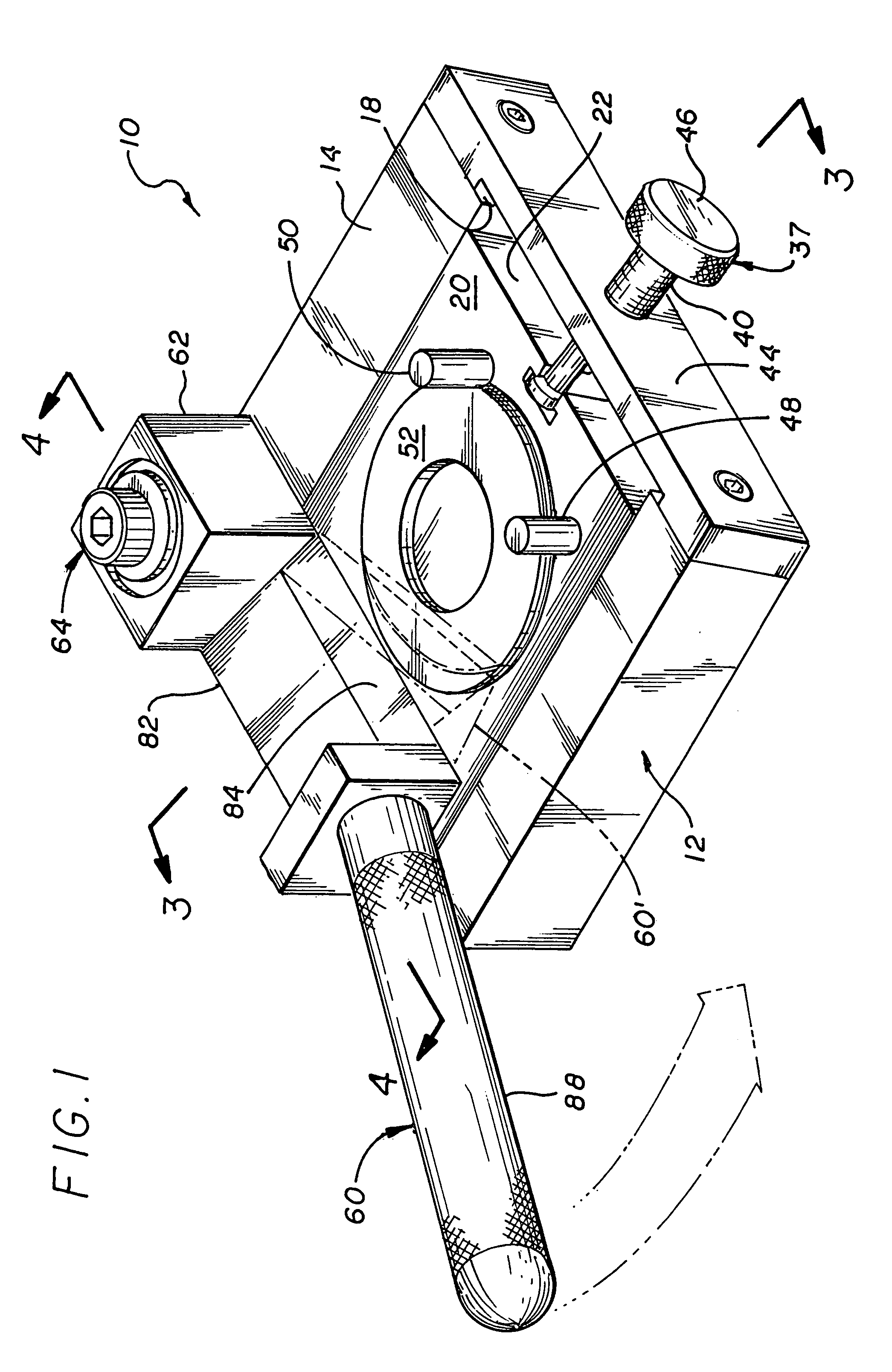

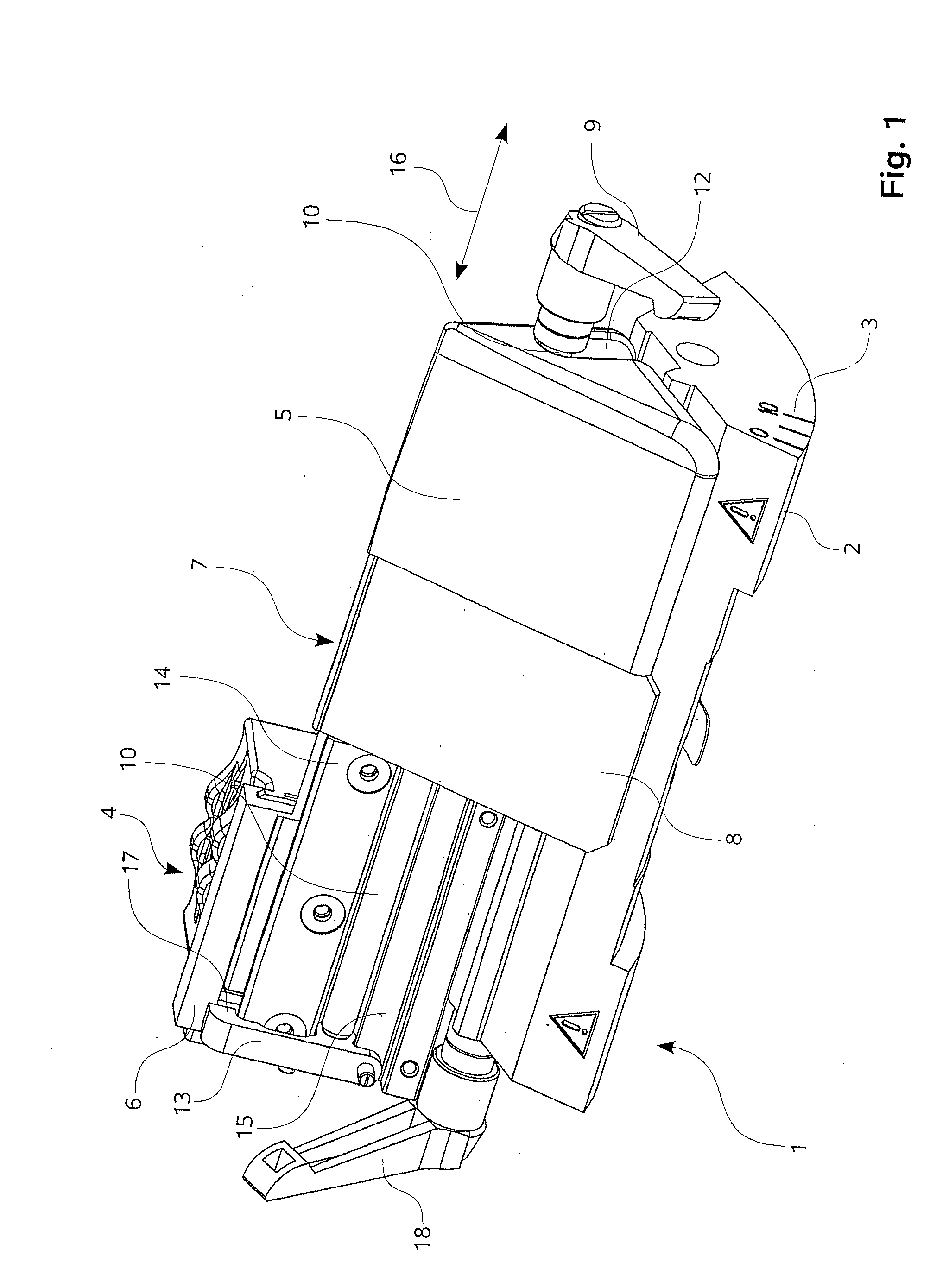

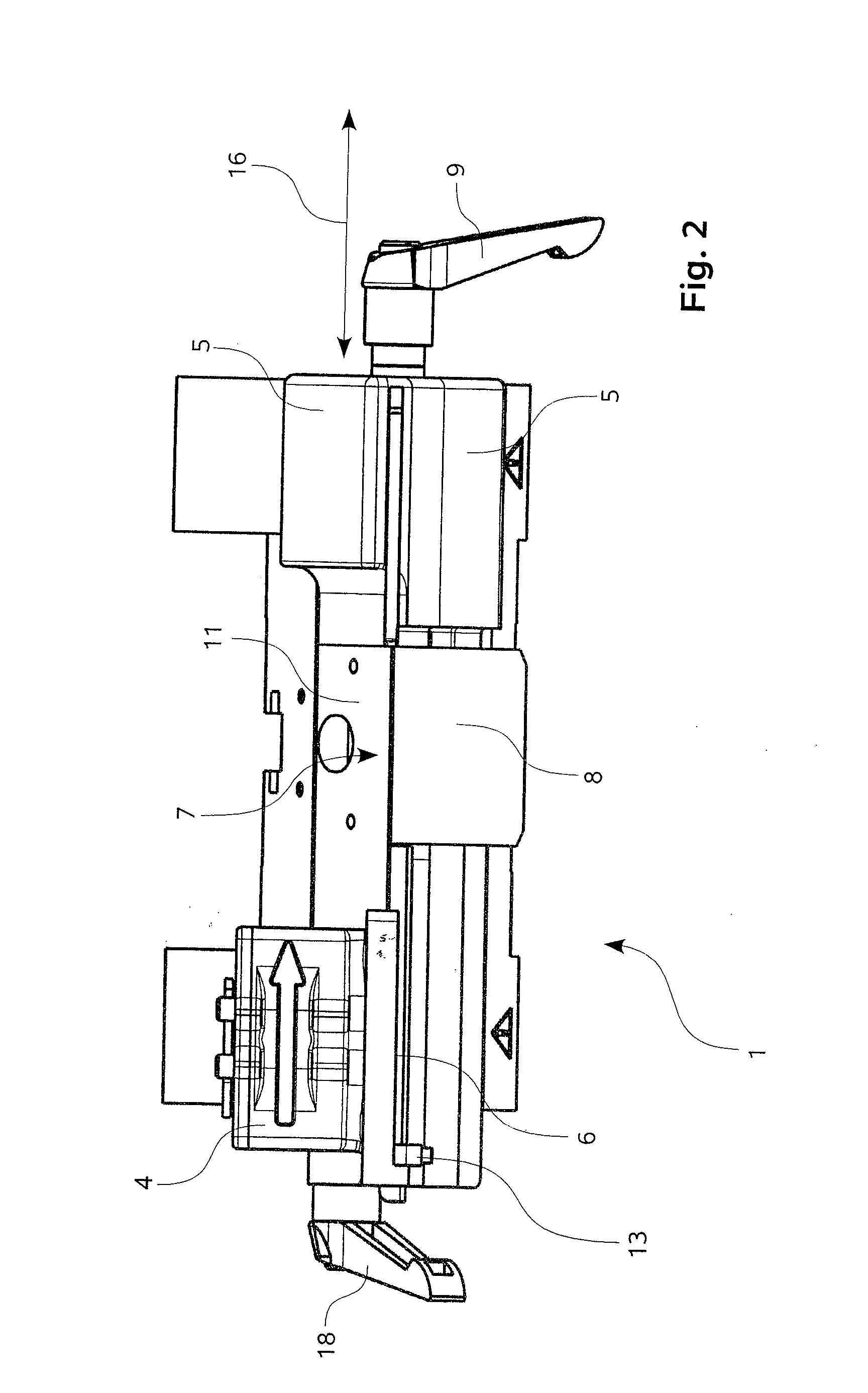

Micromanipulator for a cryomicrotome

InactiveUS20090183613A1Improved and precise positioningImprove operational convenienceFeeding devicesWithdrawing sample devicesBiomedical engineeringWorking space

A microtome system has a cryomicrotome with a sectioning device in which is provided a preparation holder and a knife edge that are guided past one another inside a working space during a sectioning operation, in order to produce thin sections of a preparation retained in the preparation holder. A micromanipulator is operable outside the working space. With the micromanipulator, a tool for retention of a specimen support is positioned proximate the knife edge during a sectioning operation in order to receive the sections that are produced, preferably for substantially stationary retention of the specimen support.

Owner:LEICA MICROSYSTEMS GMBH

Device and method for aligning substrates

ActiveUS20160148826A1Semiconductor/solid-state device testing/measurementFeeding devicesElectrical and Electronics engineering

Owner:EV GRP E THALLNER GMBH

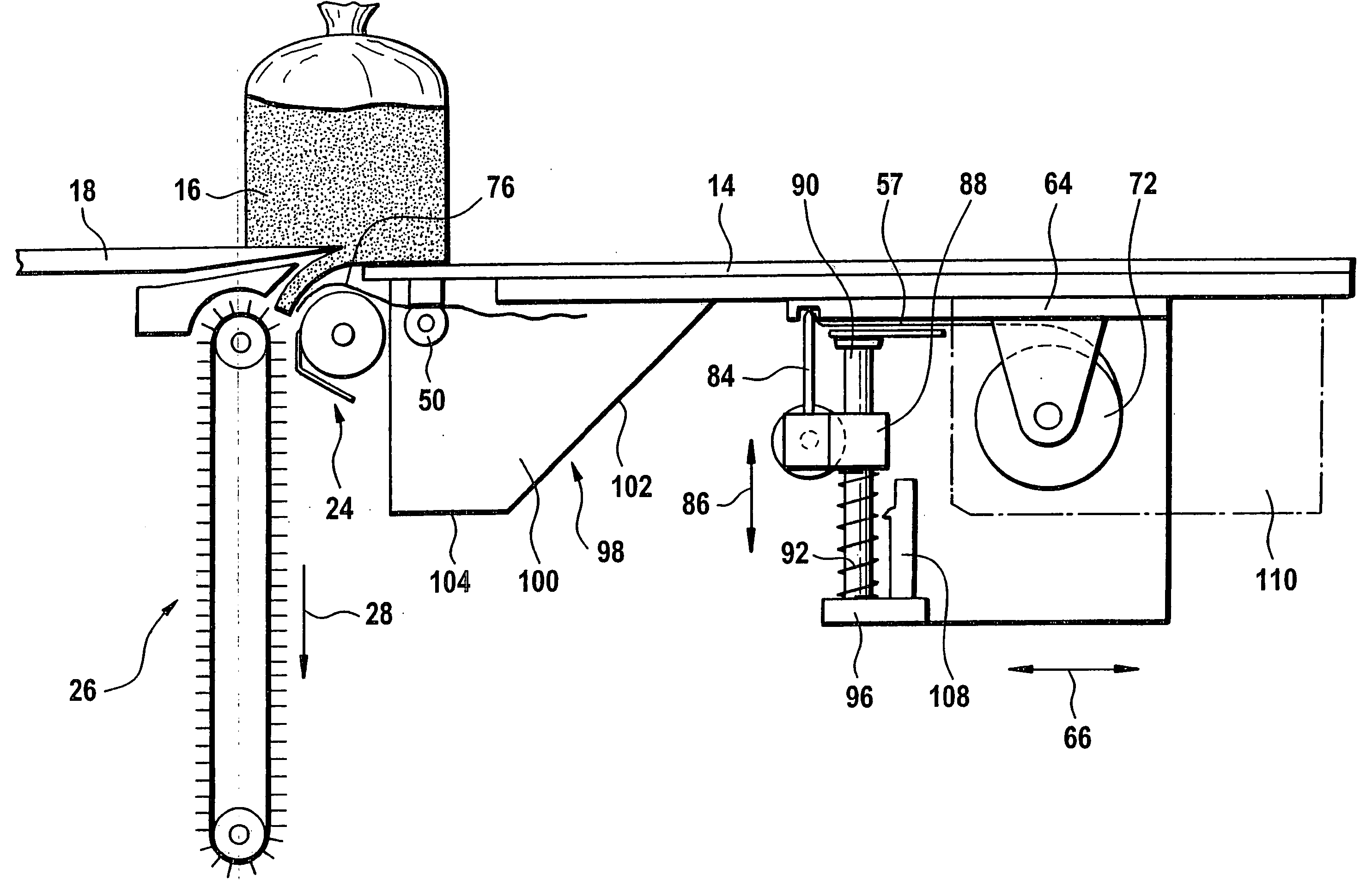

Separating-sheet dispenser, and dispensing method for dispensing separating sheets

InactiveUS20050034588A1Easy to useReduce usageRegistering devicesFeeding devicesEngineeringMechanical engineering

A separating-sheet dispenser for cut slices, in particular for sliced foodstuff, is provided, such dispenser comprising a holder for separating material, a cutting device for producing separating sheets, and a transporting device with at least one rotatable transporting roller for transporting web-like separating material, wherein the at least one transporting roller is positioned toward a deflecting device for cut material.

Owner:BIZERBA

Flatted object passive aligner

InactiveUS6682295B2Feeding devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:NOVELLUS SYSTEMS

Apparatus and method for positioning semiconductor substrate

InactiveUS7458762B2Safely positioningFeeding devicesSemiconductor/solid-state device manufacturingSusceptorEngineering

The disclosure is a baking apparatus including a susceptor, lift pins, and guiding blocks positioned at the edge of the susceptor to lead a wafer to be exactly positioned on the susceptor. The guiding blocks are linearly movable within a range of a semidiameter of a plate. A wafer is partially mounted on a wafer guide, being inclined against the susceptor, and thereby may heats uniformly.

Owner:SAMSUNG ELECTRONICS CO LTD

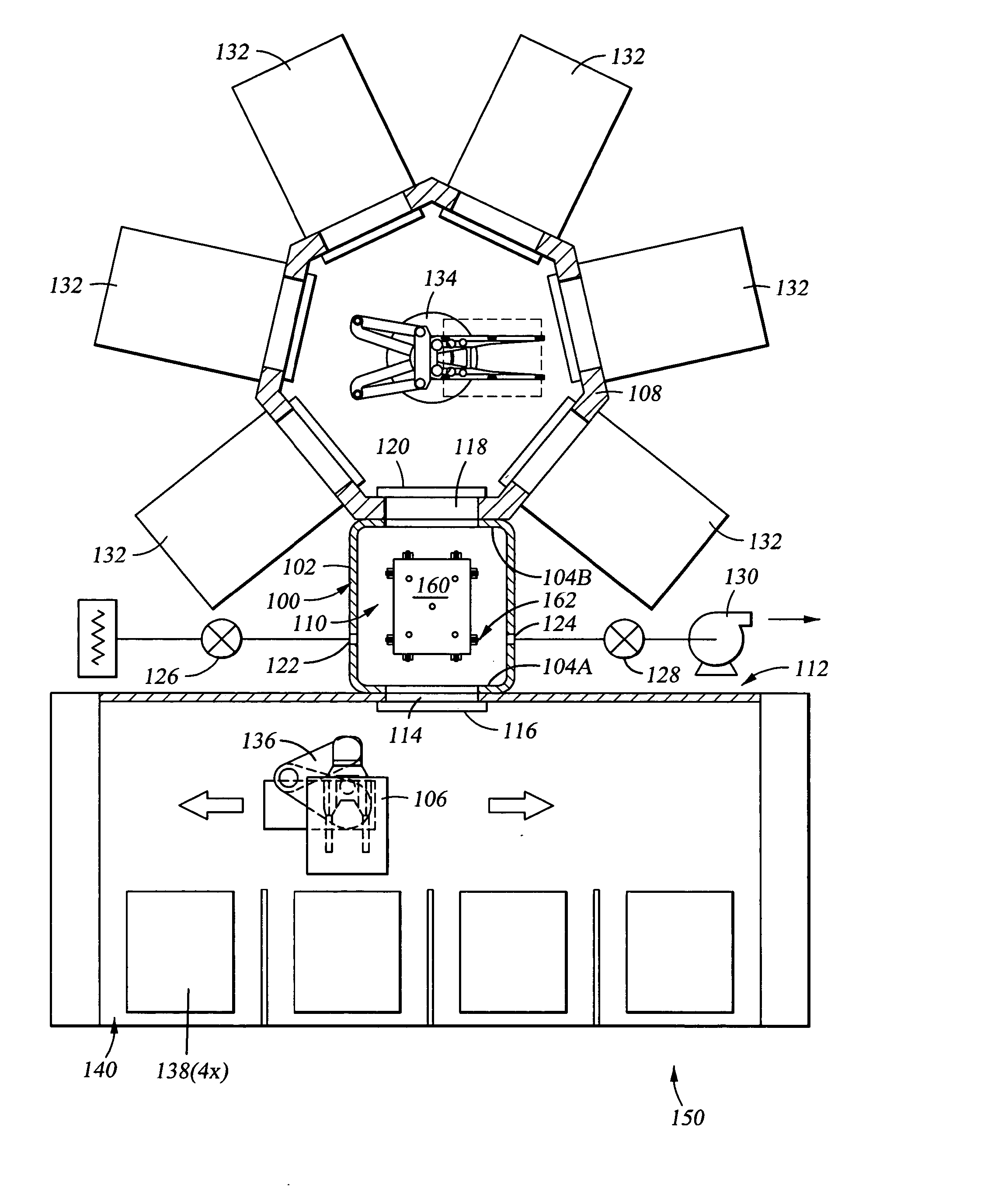

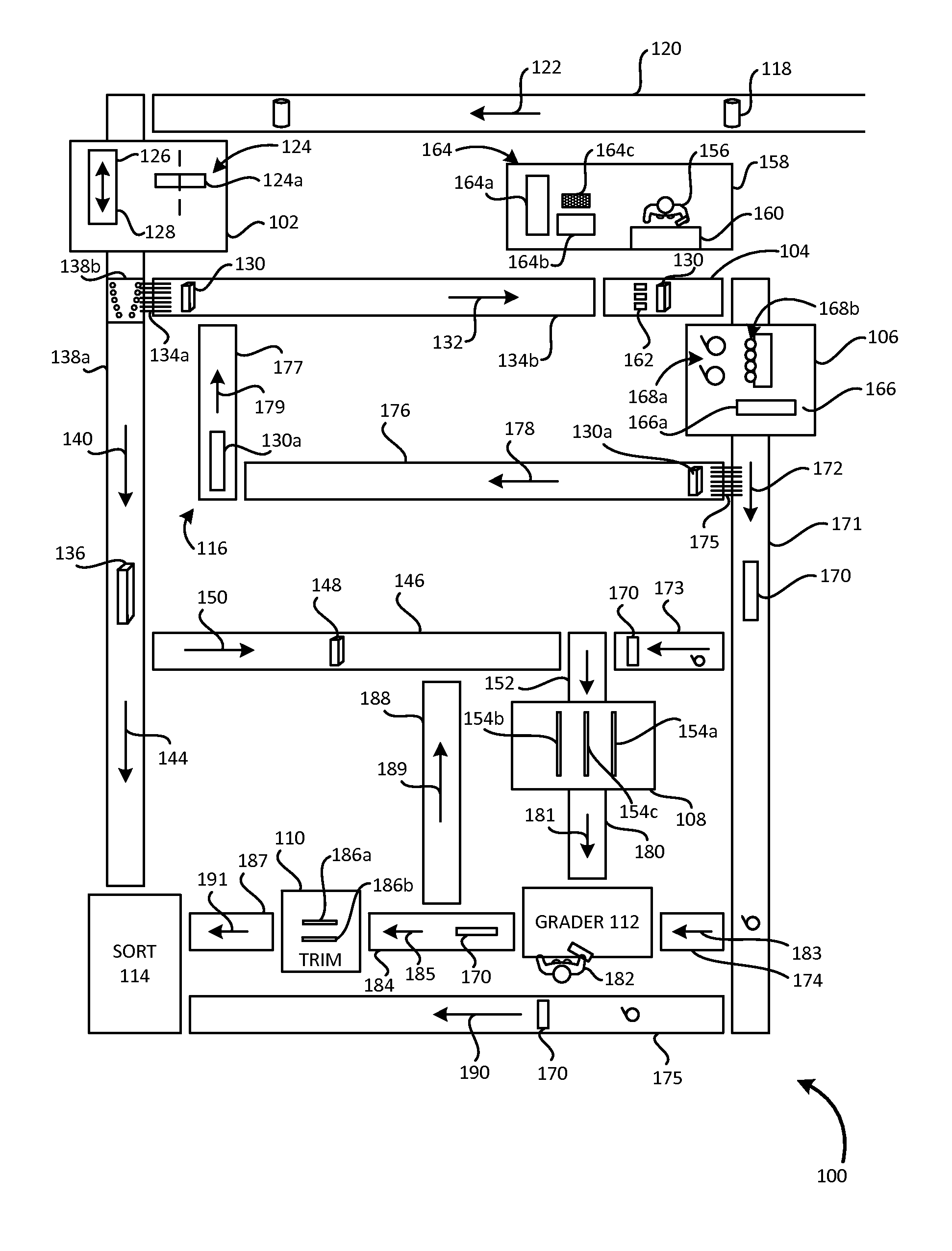

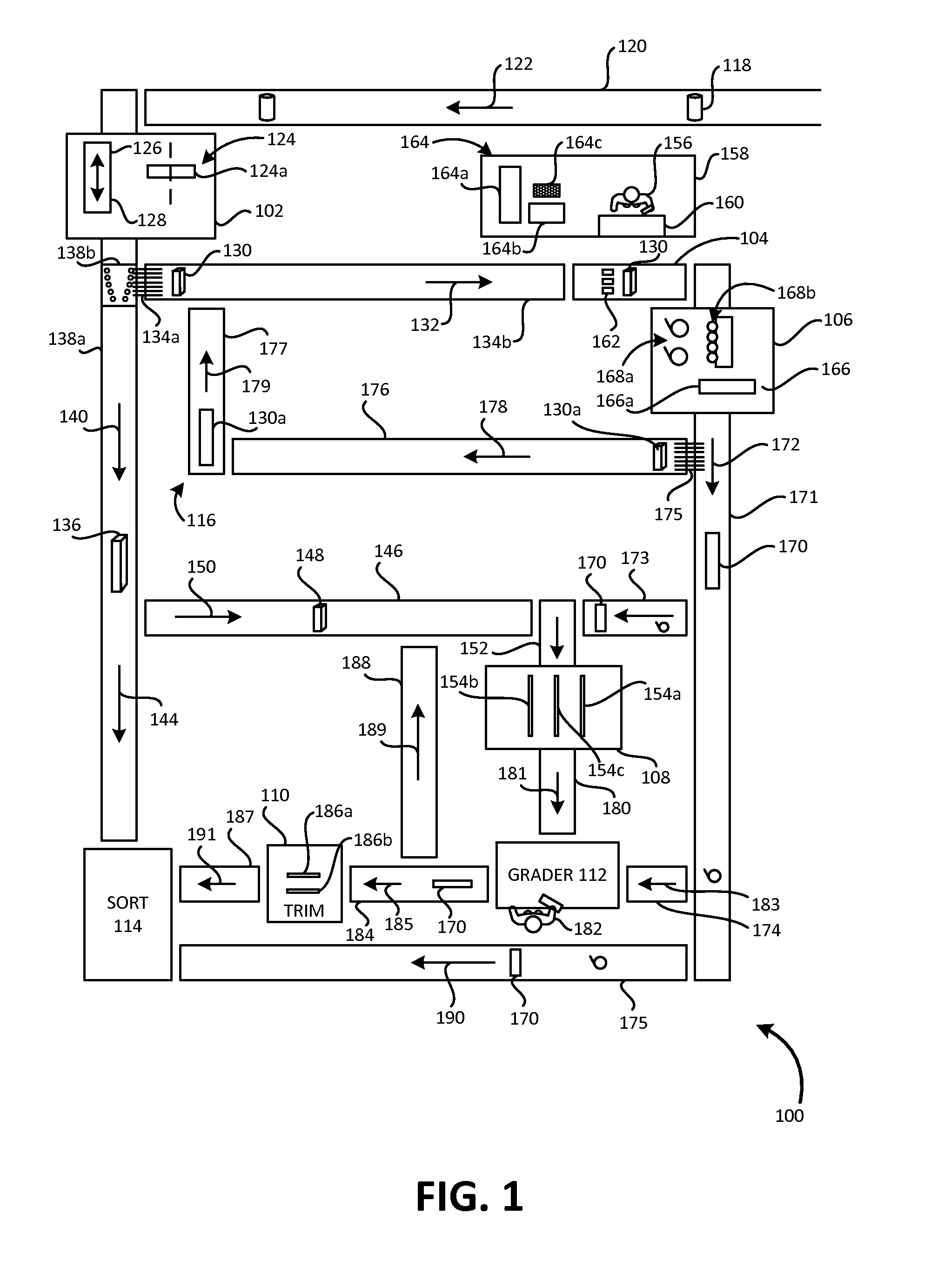

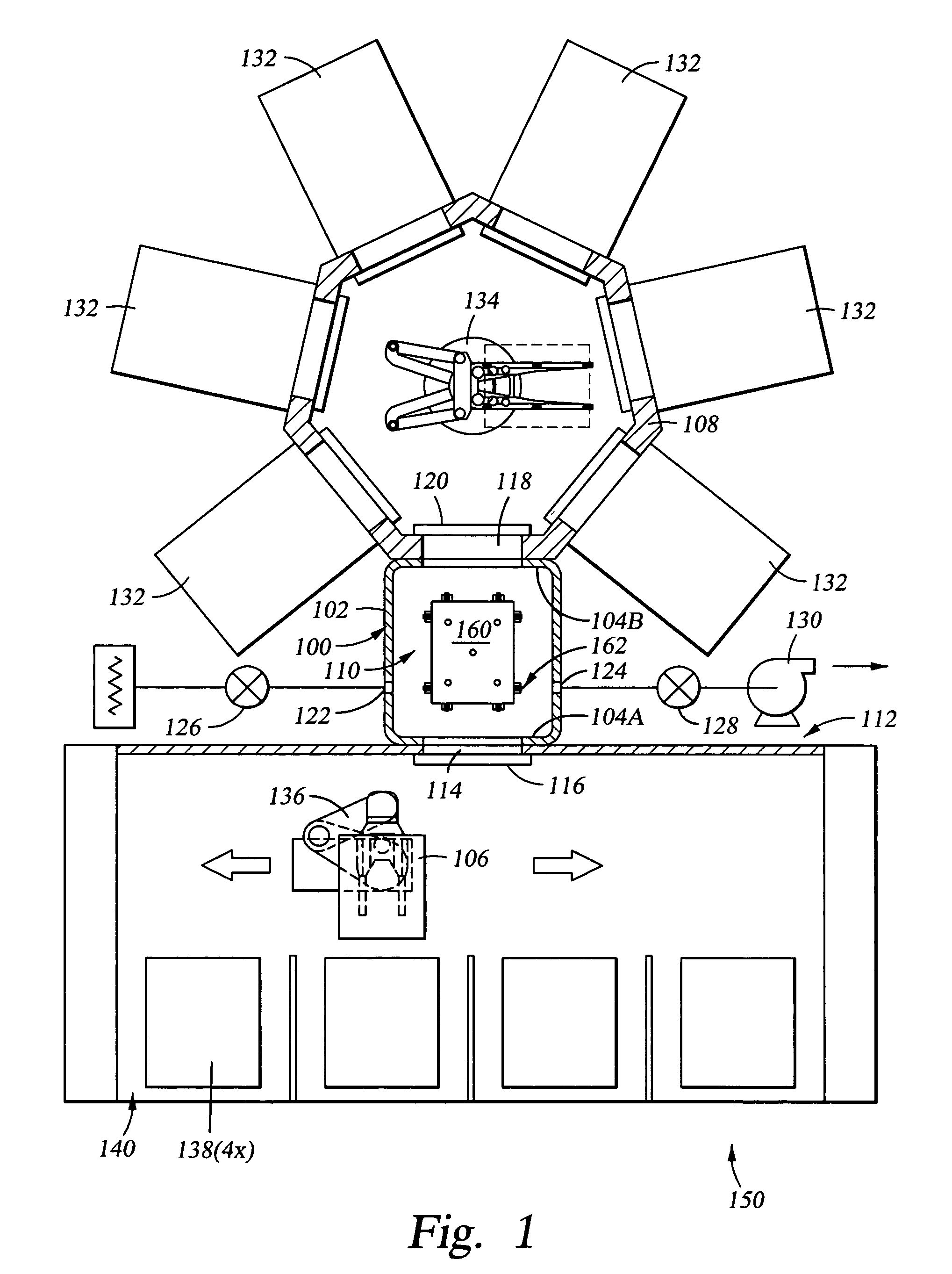

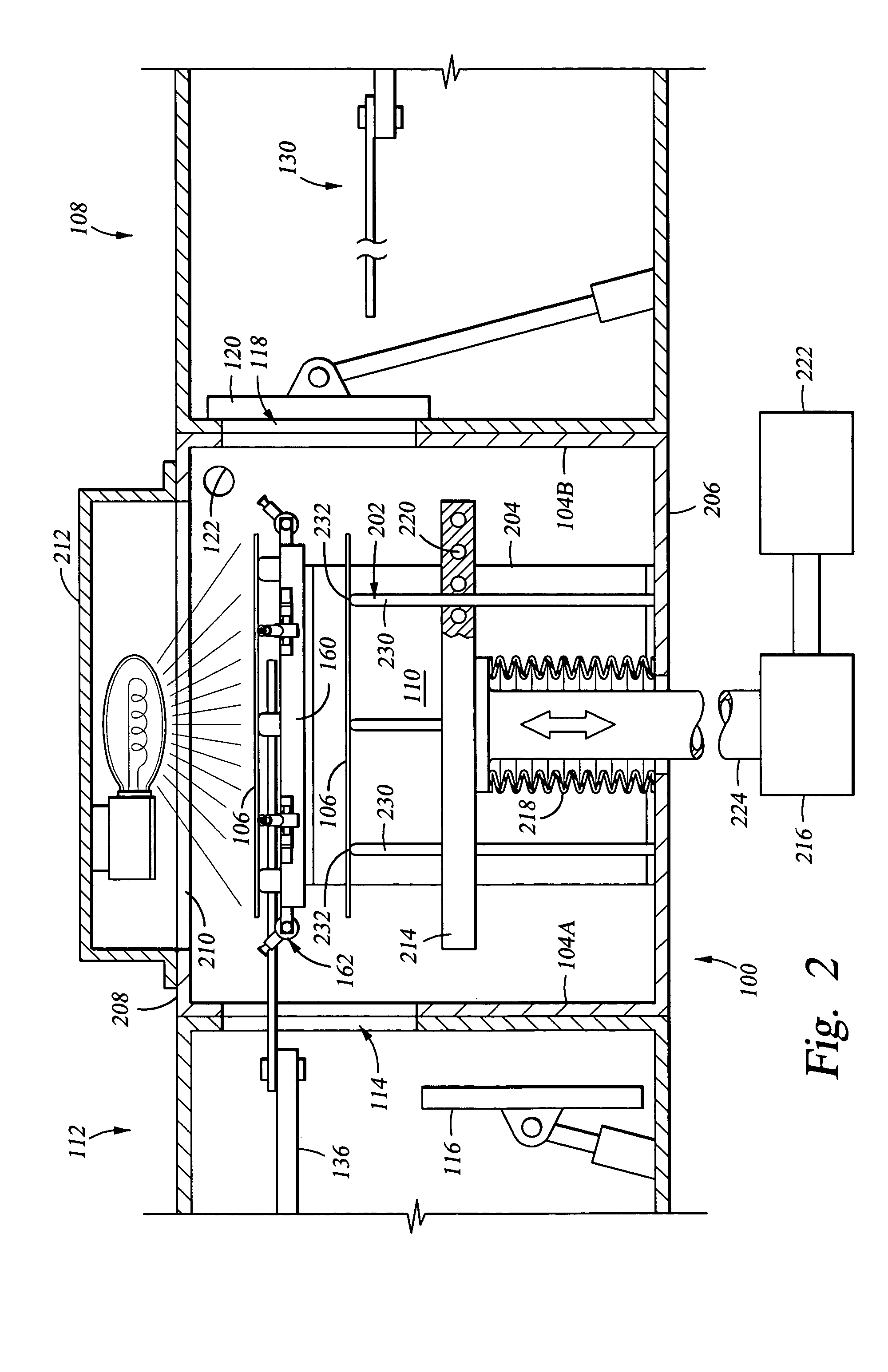

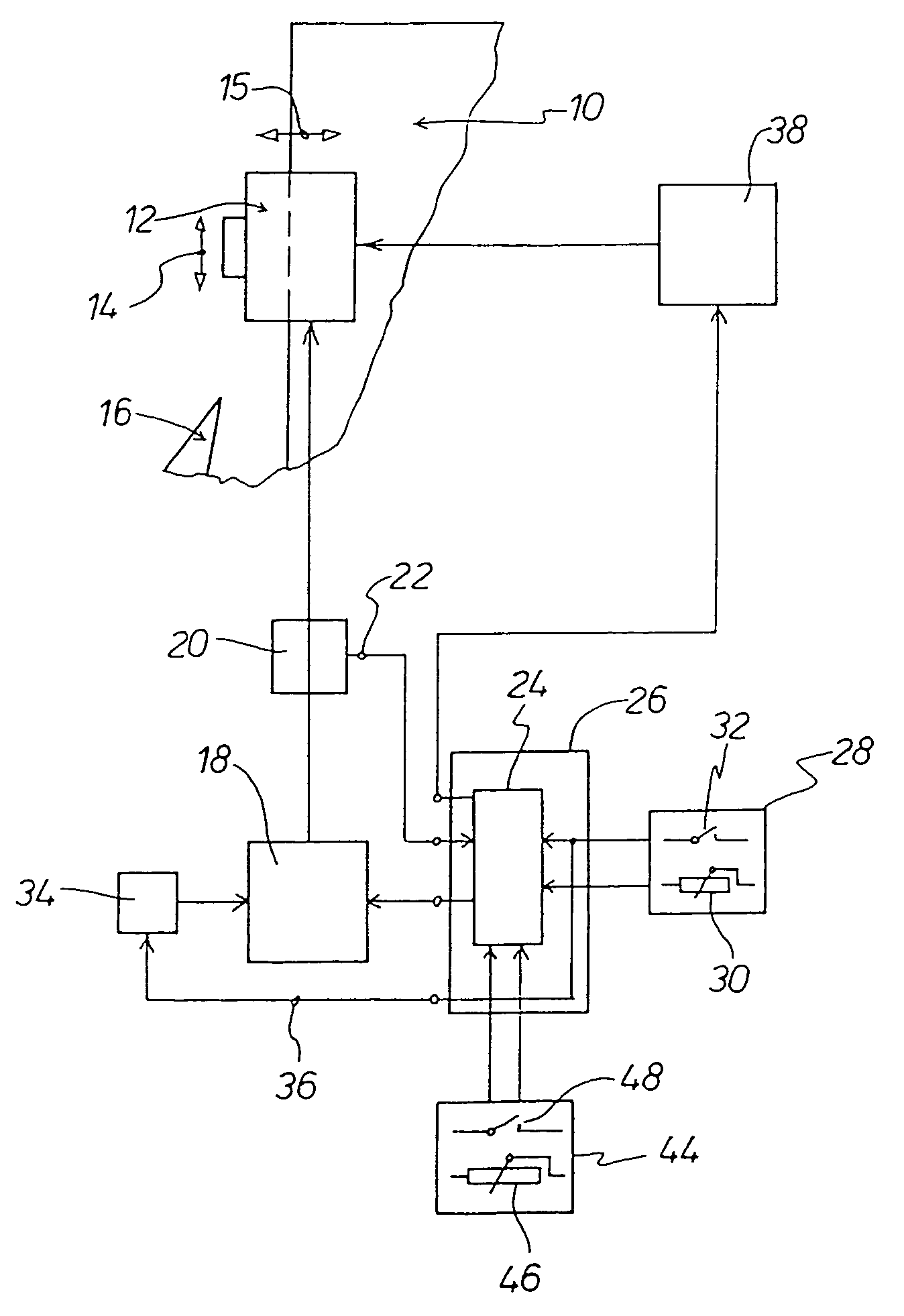

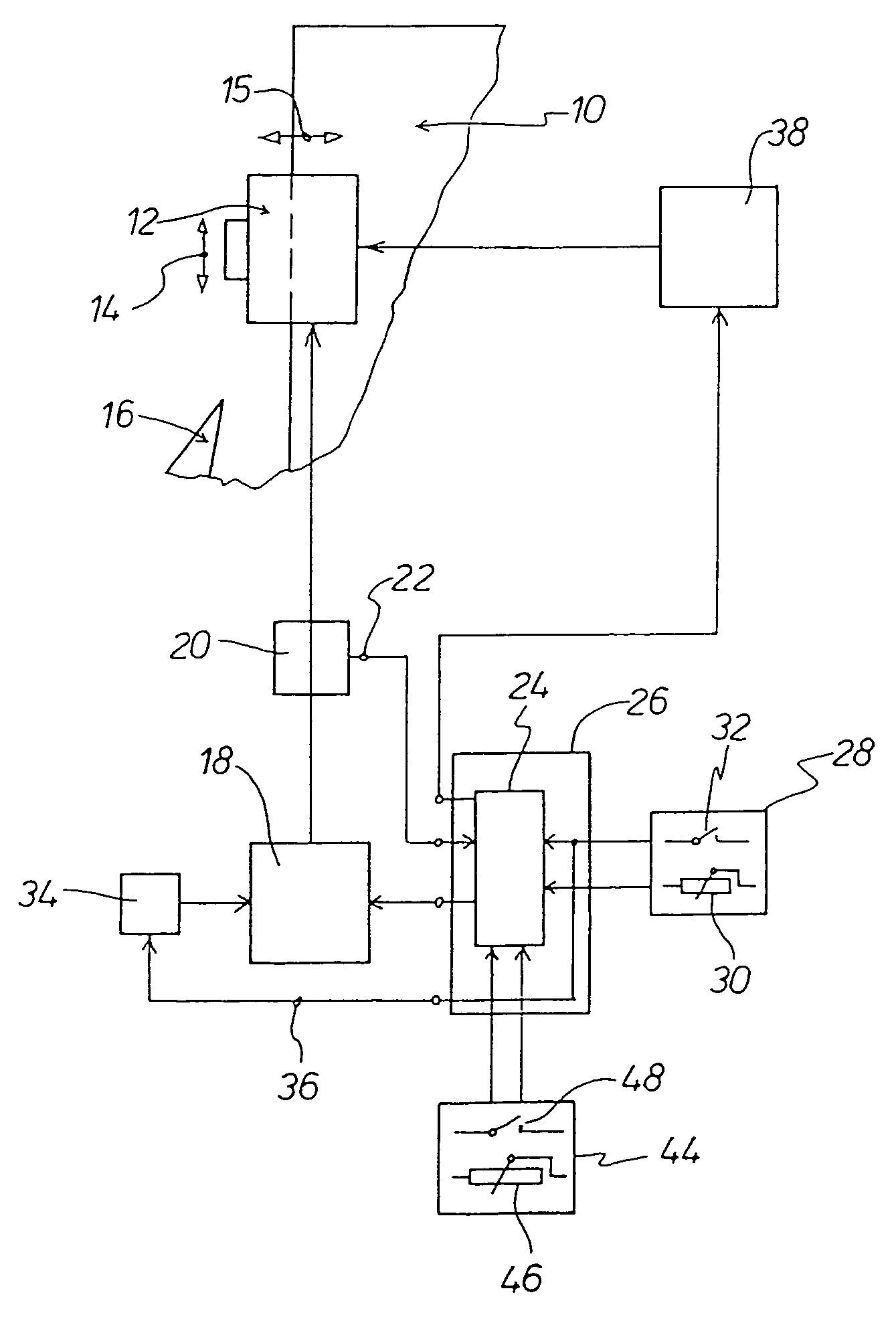

System for positioning a workpiece

ActiveUS20060048853A1Optimize locationPromote recoveryProgramme controlAutomatic control devicesEngineeringMechanical engineering

A system for positioning a workpiece in an optimized position. In one embodiment a marking device places a mark on the workpiece prior to the workpiece passing through a scanner cooperating with an optimizer. The optimizer determines the optimized position of the workpiece. The orientation of the workpiece is identified by a first camera. The mark may be used as a point of reference such that the workpiece may be positioned in the optimized position by rotating the workpiece relative to the orientation of the mark. A turning mechanism rotates the workpiece to position it in the optimized position. A further camera identifies the orientation of the mark while the workpiece is being rotated. A processor compares in real time the orientation of the workpiece with the optimized position to determine if the workpiece is in the optimized position.

Owner:USNRKOCKUMS CANCAR

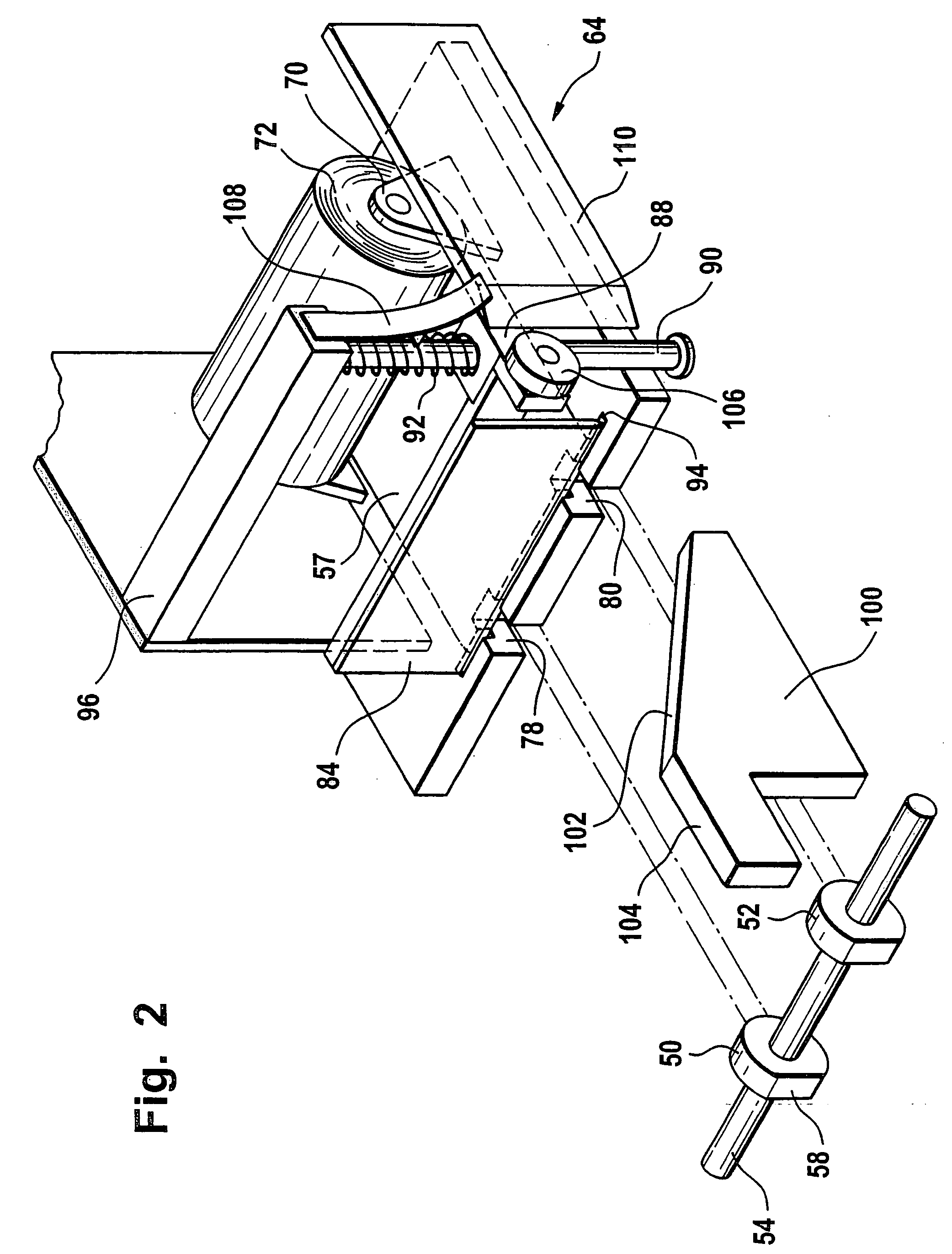

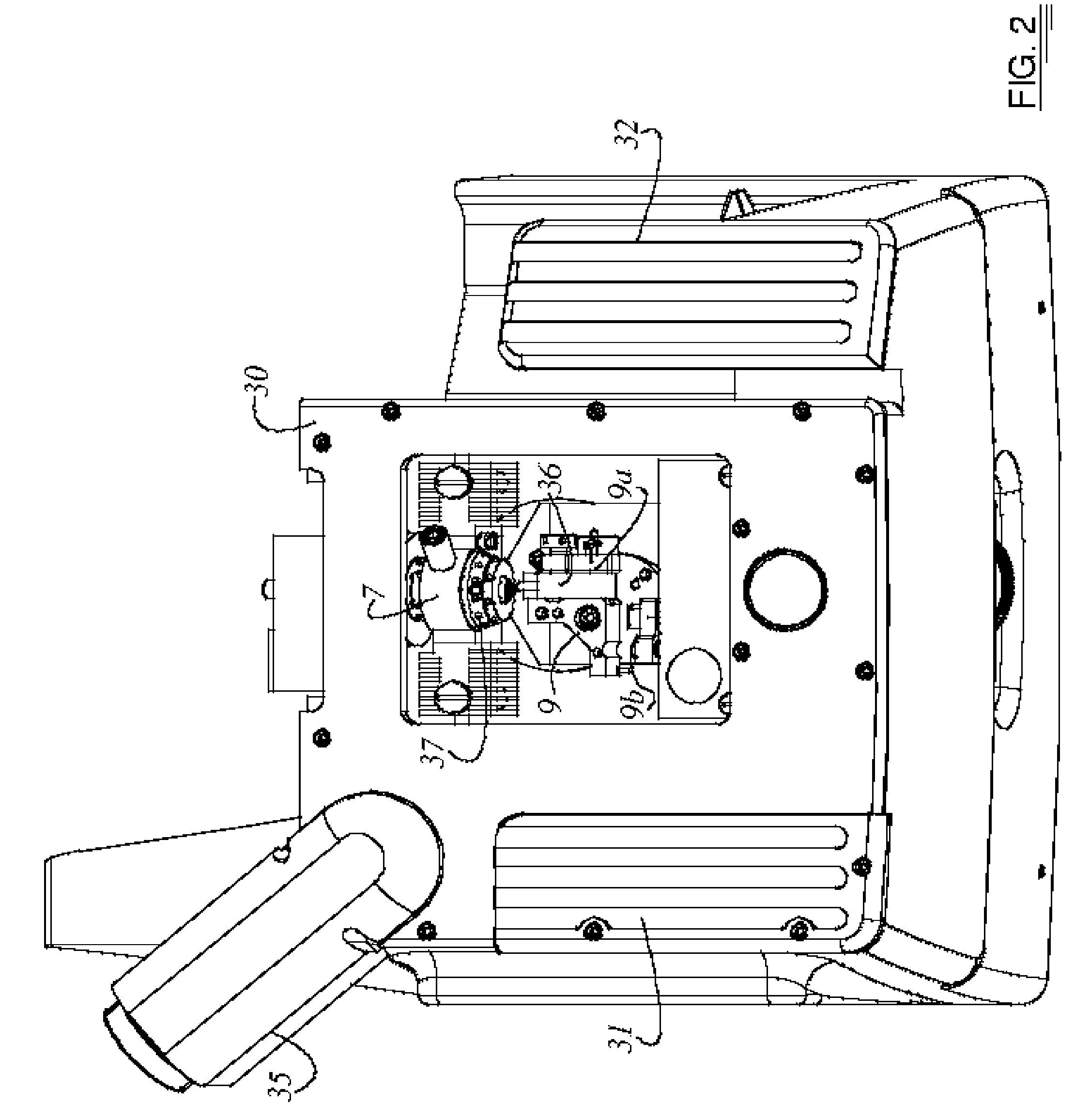

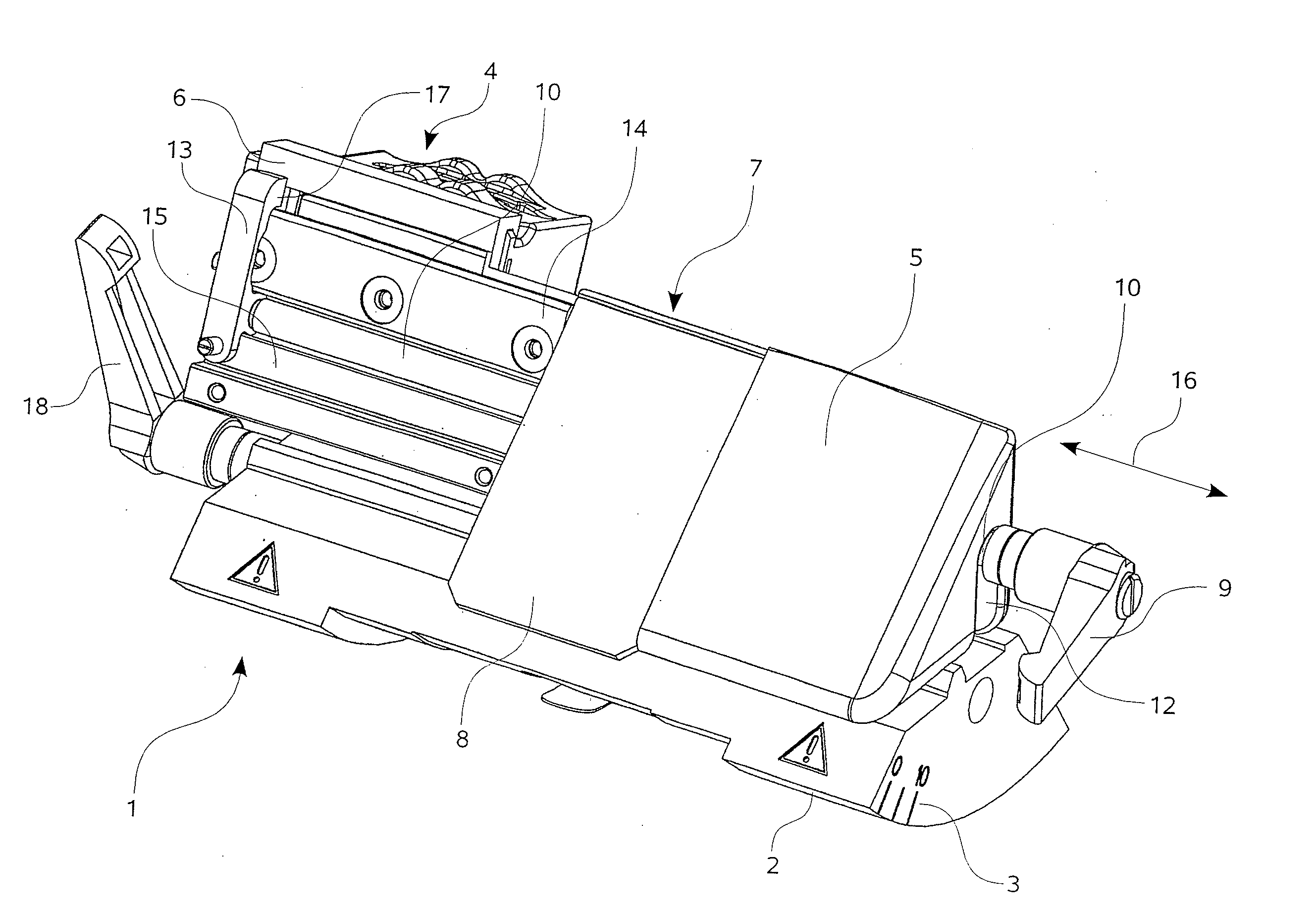

Device and method for trimming samples

ActiveUS20050152760A1Little oversightRapid productionAutomatic control devicesFeeding devicesEngineeringKnife holder

A device 1 and a method for trimming samples 38 are disclosed. The device 1 encompasses a knife holder 9 and a sample holder 7, the knife holder 9 carrying at least one trimming knife 36. A first motor 60 and a second motor 61 are provided, which move the knife holder 9 in an X-Y plane. Also provided is a control unit 15 that controls the motion of the knife holder 9. The first and the second motor 60, 61 are each equipped with a measurement means 62, 63 that measures the position of the knife holder 9 in the X direction (X) and Y direction (Y).

Owner:LEICA MICROSYSTEMS GMBH

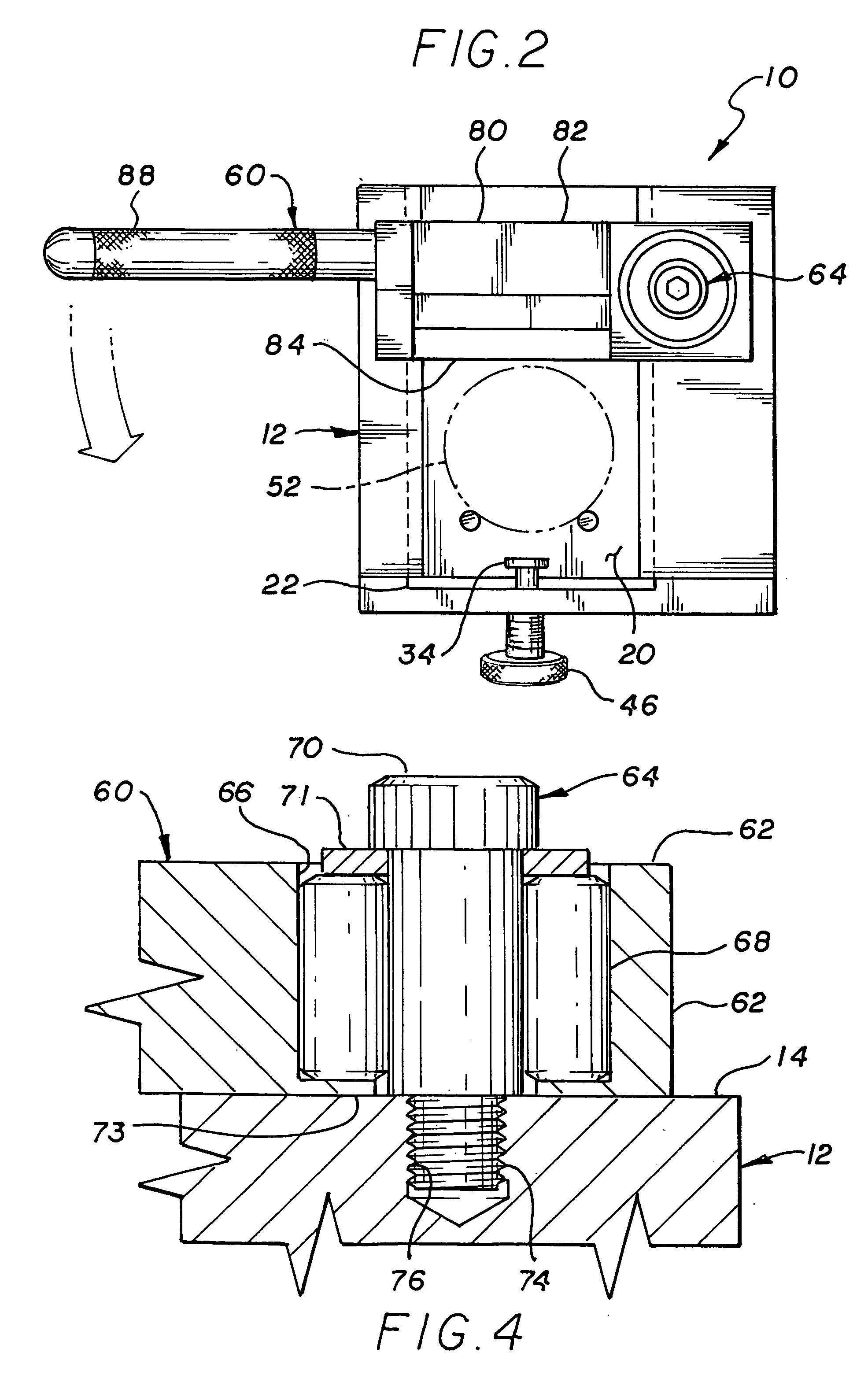

Multilayer shim peeling device

The invention is a device for peeling one or more individual layers of a multilayer shim. In detail the device includes a platform having a surface with a recess. A mechanism is mounted in the recess for mounting the shim and a moving the shim upward such that a portion of the shim is above the surface. A blade assembly is rotatably mounted to the platform, which is rotatable in a plane parallel to the surface. The blade assembly includes a cutting blade mounted thereon, such that said blade is in slidable contact with the surface and movable over the recess. Thus shim can be raised by the mechanism and the portion of the shim requiring removal can be raised above the surface and the blade assembly thereafter can be rotated causing the cutting blade to shear off the portion of the shim above the surface.

Owner:NORTHROP GRUMMAN SYST CORP

Flatted object passive aligner

InactiveUS20020197144A1Free rotationFeeding devicesSemiconductor/solid-state device manufacturingMechanical engineeringSilicon

A device for aligning a flatted object to a desired orientation. The flatted object has a substantially circular perimeter and a flatted chord portion and may be a silicon wafer or a cover for an electrostatic chuck. The device includes multiple conically shaped rollers that center and rotationally align the object, each roller having a bottom lip for supporting the object. Centering rollers are mounted so that they contact the circular perimeter of the object when it is in the desired orientation. Rotational alignment rollers are mounted so that they contact the flatted chord portion of the object when it is in the desired orientation. When placed on the alignment device, the flatted object passively moves to the desired orientation under the force of gravity.

Owner:NOVELLUS SYSTEMS

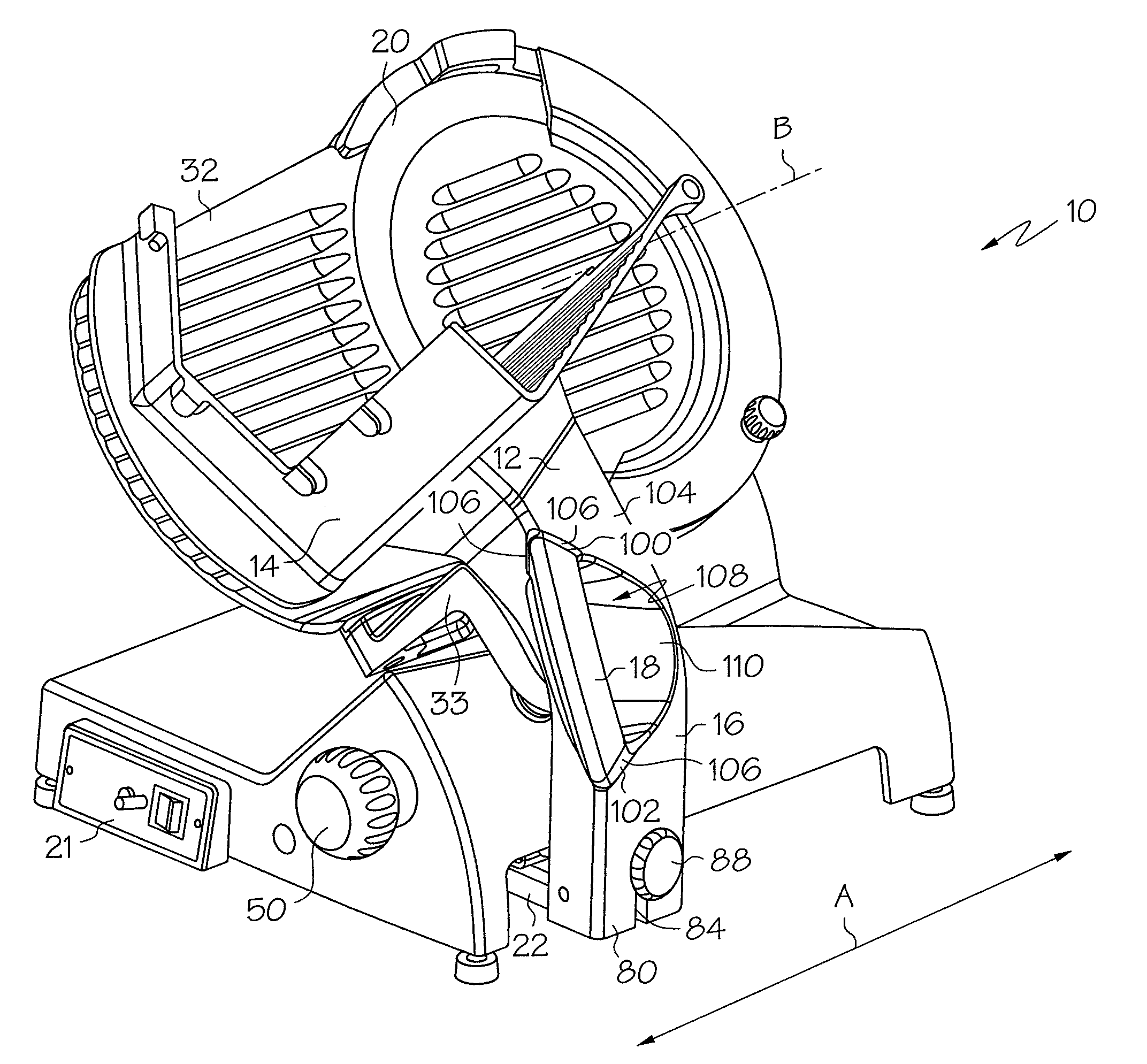

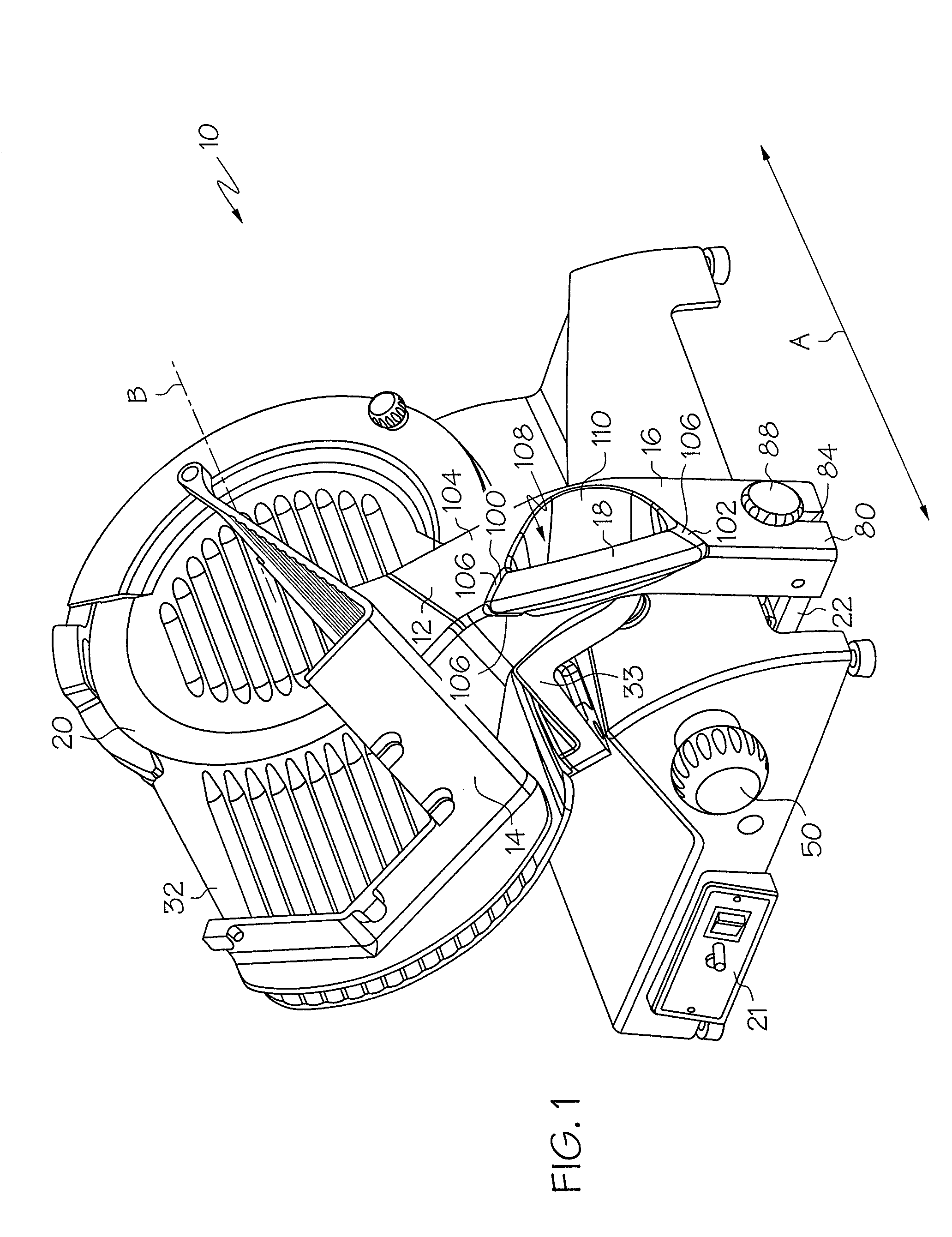

Slicer with unitary handle

InactiveUS7234382B2Easy to cleanHigh strengthMetal sawing devicesFeeding devicesReciprocating motionEngineering

A slicer comprising a slicer body including a rotatable blade for slicing a product, and a tray mounted for reciprocal movement relative the slicer body and for supporting and moving the product relative the blade. The tray includes a tray body and a unitary handle. In another embodiment, the invention is a slicer including a slicer body having a rotatable blade for slicing a product and a tray for supporting the product and moving the product relative the blade. The slicer further includes a handle unitary with the tray, the handle providing a surface which a user may grip to manually move the tray.

Owner:PREMARK FEG L L C

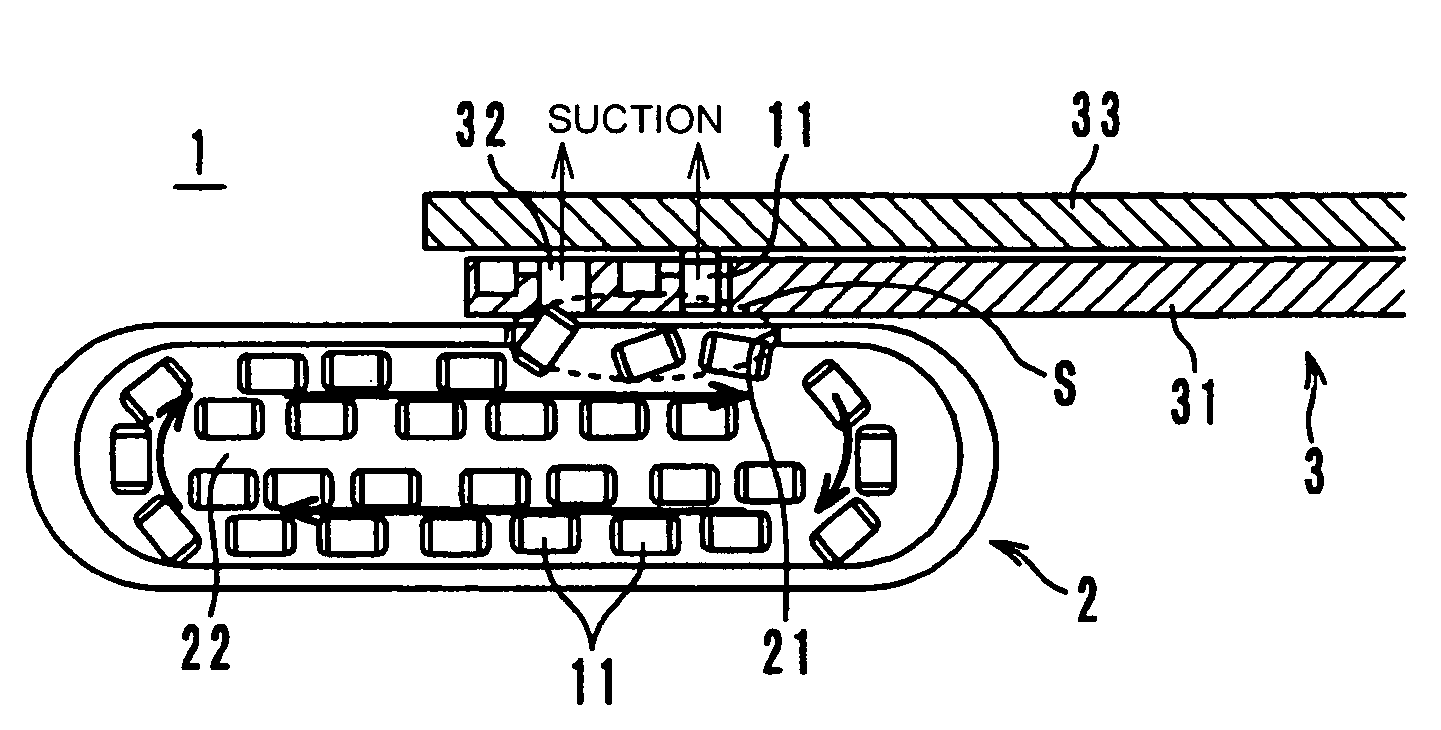

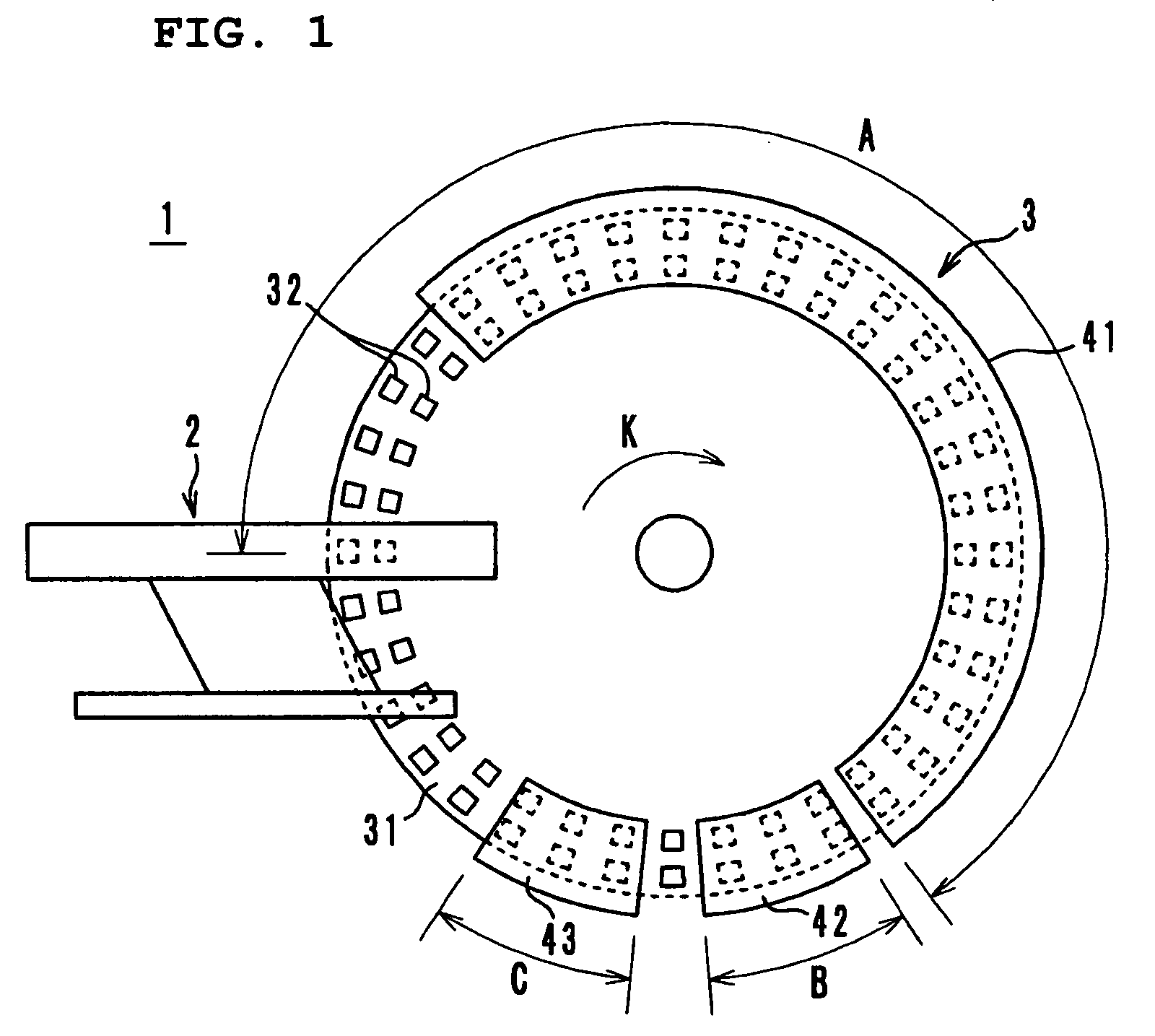

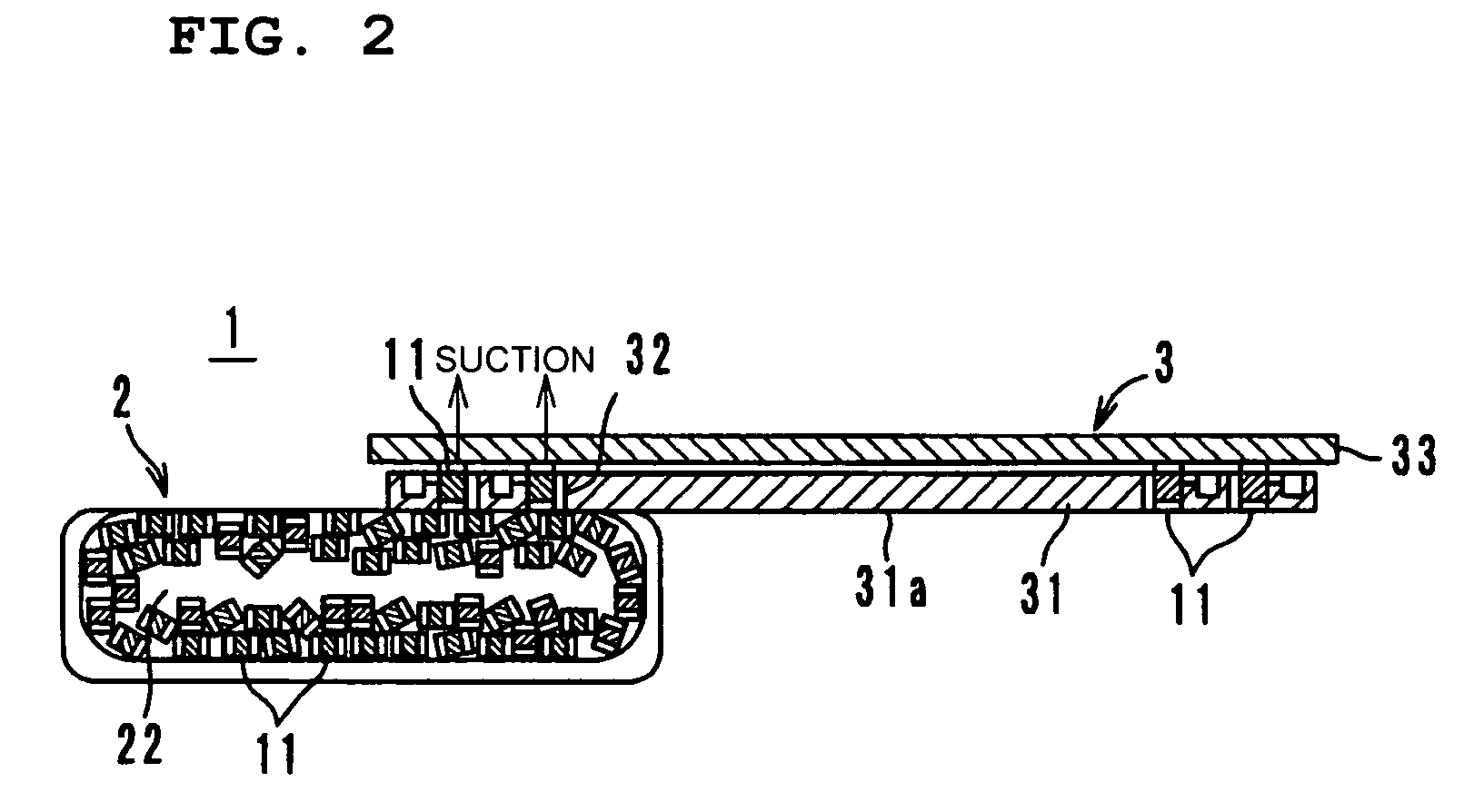

Handling device for electronic chip components and handling method for electronic chip components

ActiveUS7390158B2Quick measurementAvoid damageSolid-state devicesElectrical testingEngineeringElectronic chip

A handling device for electronic chip components includes an indexing table having a plurality of cavities for holding electronic chip components therein and a circulatory feeder for supplying the electronic chip components to the indexing table. One or more cavities are simultaneously disposed at a location which comes close to the circulatory feeder and, by performing a suction operation in the cavities, the electronic chip components are directly put into the cavities, without moving the electronic chip components along the main surface of the indexing table.

Owner:MURATA MFG CO LTD

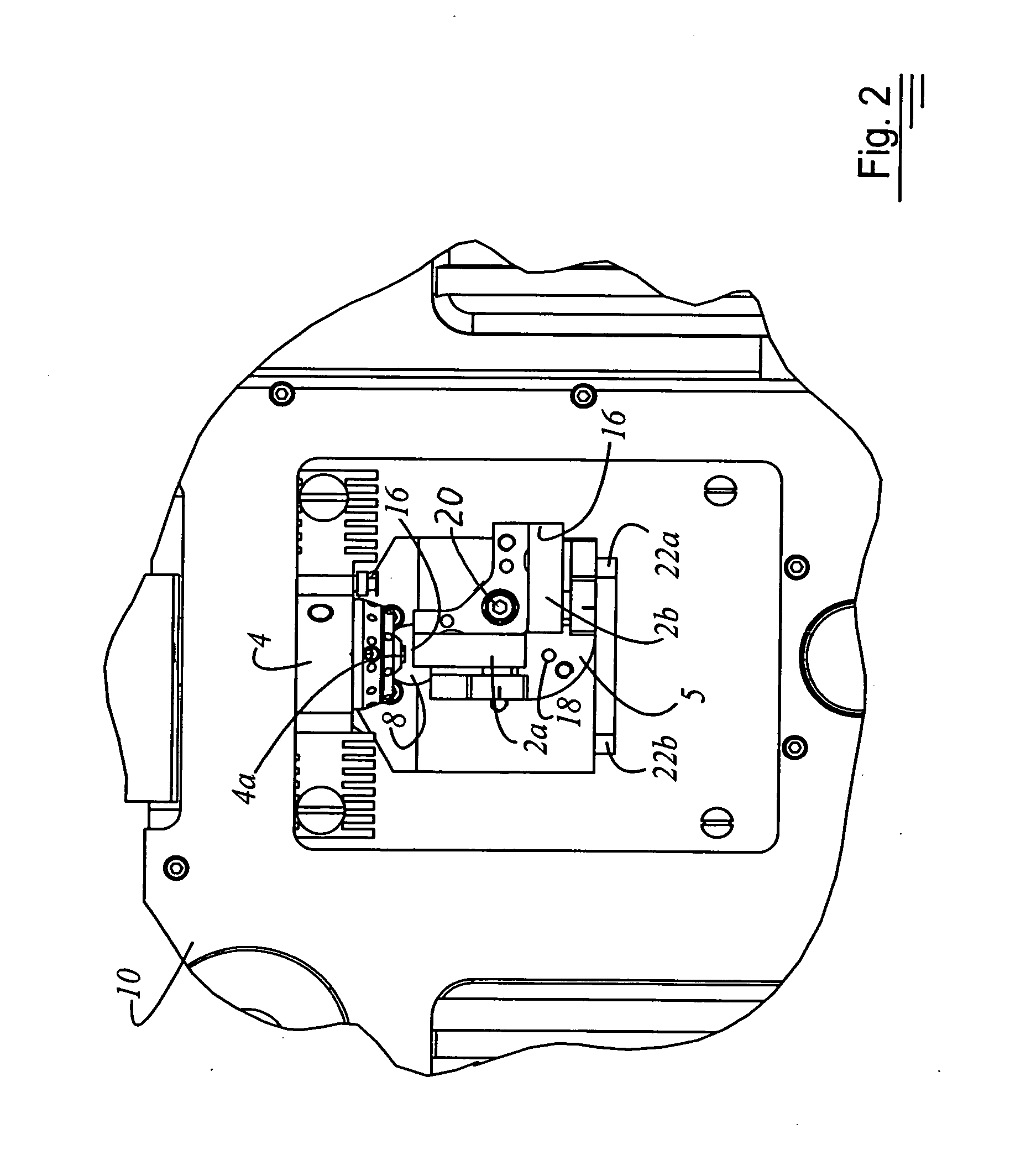

Knife holder for microtome knives and microtome

ActiveUS20050072285A1Simple and precise fashionEasy and fast changeoverMetal sawing devicesFeeding devicesKnife holderMicrotome

A knife holder (5) for a microtome for cutting samples (4a) is disclosed. The knife holder (5) encompasses several knives (2a, 2b) each of which defines a cutting edge (16). The knife holder (5) is arranged pivotably about a shaft (18); and the shaft (18) is arranged substantially perpendicularly to each cutting edge (16) of the knives (2a, 2b).

Owner:LEICA MICROSYSTEMS GMBH

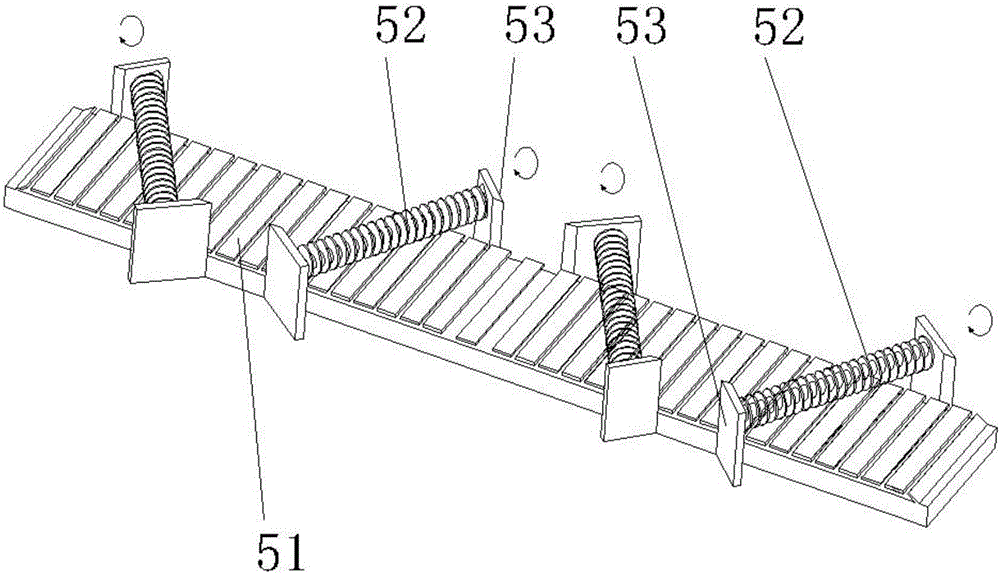

Log cut-off sorting machine based on diameter

ActiveCN106738069AImprove cutting and sorting efficiencyFacilitate subsequent processingGuide fencesFeeding devicesComputer engineering

The invention discloses a log cut-off sorting machine based on the diameter. The log cut-off sorting machine sequentially comprises a feeding frame, a first cut-off device, a conveying device, a second cut-off device and a sorting device in the log conveying direction. A long log is cut into the required specification through the first cut-off device and the second cut-off device and sorted through the sorting device, the whole process is completed automatically, the cutting and sorting efficiency of the log is greatly improved, and subsequent processing of the log is facilitated.

Owner:FUJIAN YUAN CHUANG ELECTRICAL & MECHANICAL CO LTD

Device and method for trimming samples

ActiveUS7168901B2Little oversightRapid productionAutomatic control devicesFeeding devicesEngineeringKnife holder

A device 1 and a method for trimming samples 38 are disclosed. The device 1 encompasses a knife holder 9 and a sample holder 7, the knife holder 9 carrying at least one trimming knife 36. A first motor 60 and a second motor 61 are provided, which move the knife holder 9 in an X-Y plane. Also provided is a control unit 15 that controls the motion of the knife holder 9. The first and the second motor 60, 61 are each equipped with a measurement means 62, 63 that measures the position of the knife holder 9 in the X direction (X) and Y direction (Y).

Owner:LEICA MICROSYSTEMS GMBH

Systems and methods of orienting a cant in lumber mills

InactiveUS20140238546A1Automatic control devicesPrecision positioning equipmentEngineeringHuman operator

Processing of a cant may include determining a rotational orientation about a longitudinal axis of the cant that optimizes a recovery from the cant from subsequent sawing operations. Such may include optimizing a width of a board that will be produced dependent on the particular rotational longitudinal orientation. Such may include determining a surface area of a board which would be produced, a thickness of a board that would be produced, and / or a volume of a board that would be produced. Such may include accounting for any premium associated with various width categories in which a board that would be produced would fit. Such may account for any premium associated with grade or quality of a board that would be produced. A corresponding signal may provide information to a human operator and / or automated machinery to orient the cant in an optimized orientation.

Owner:WEYERHAEUSER NR CO

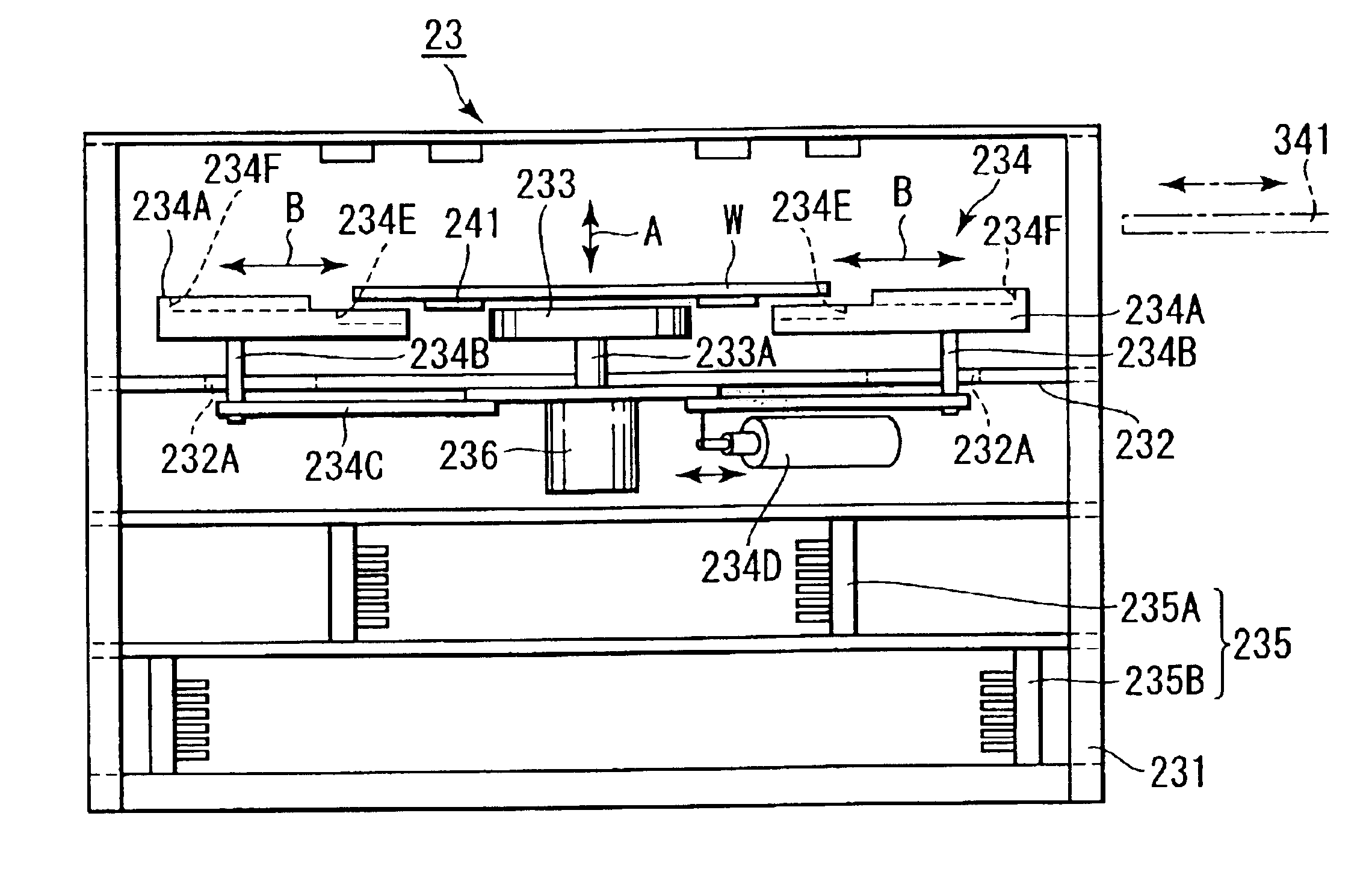

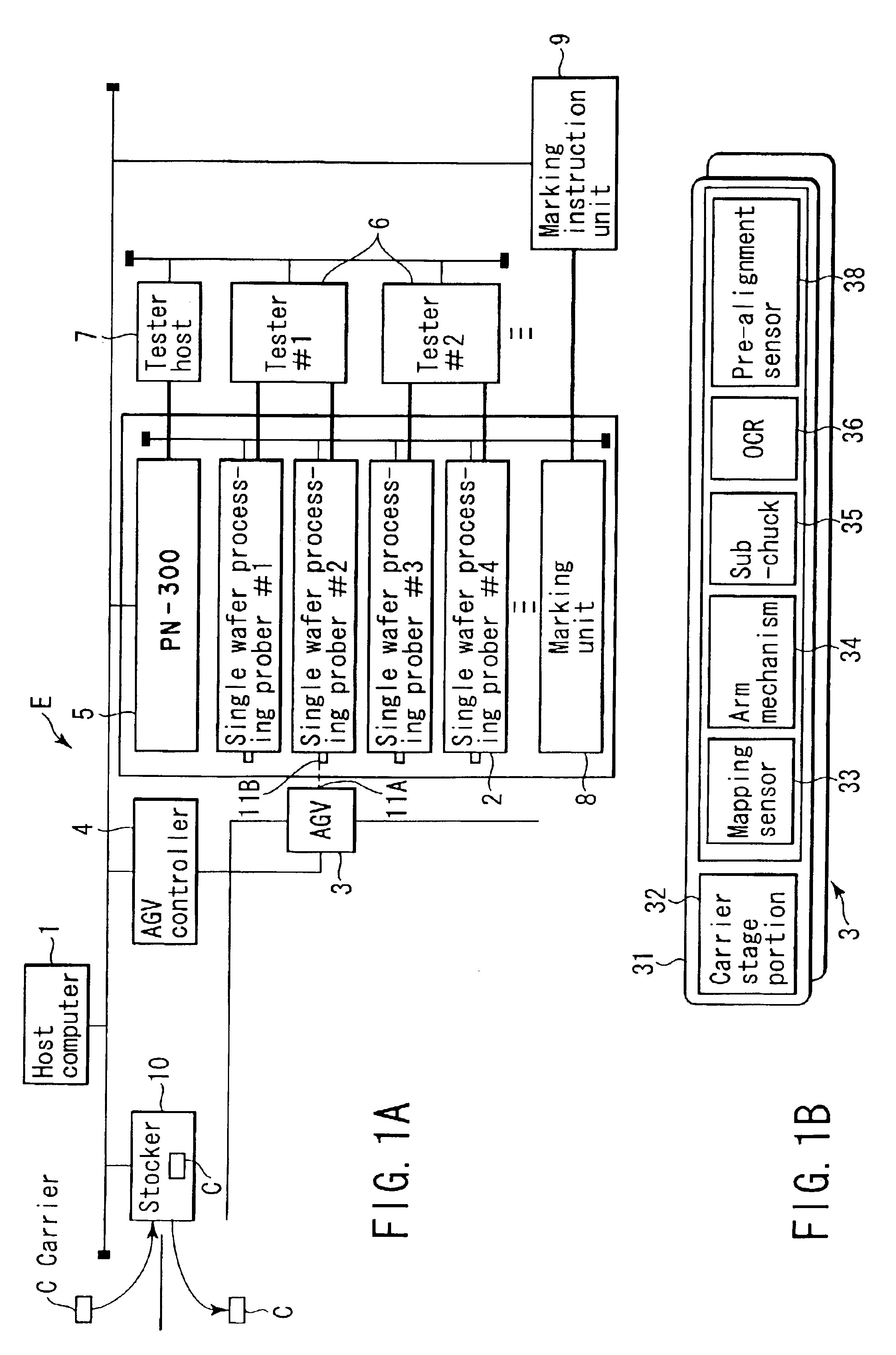

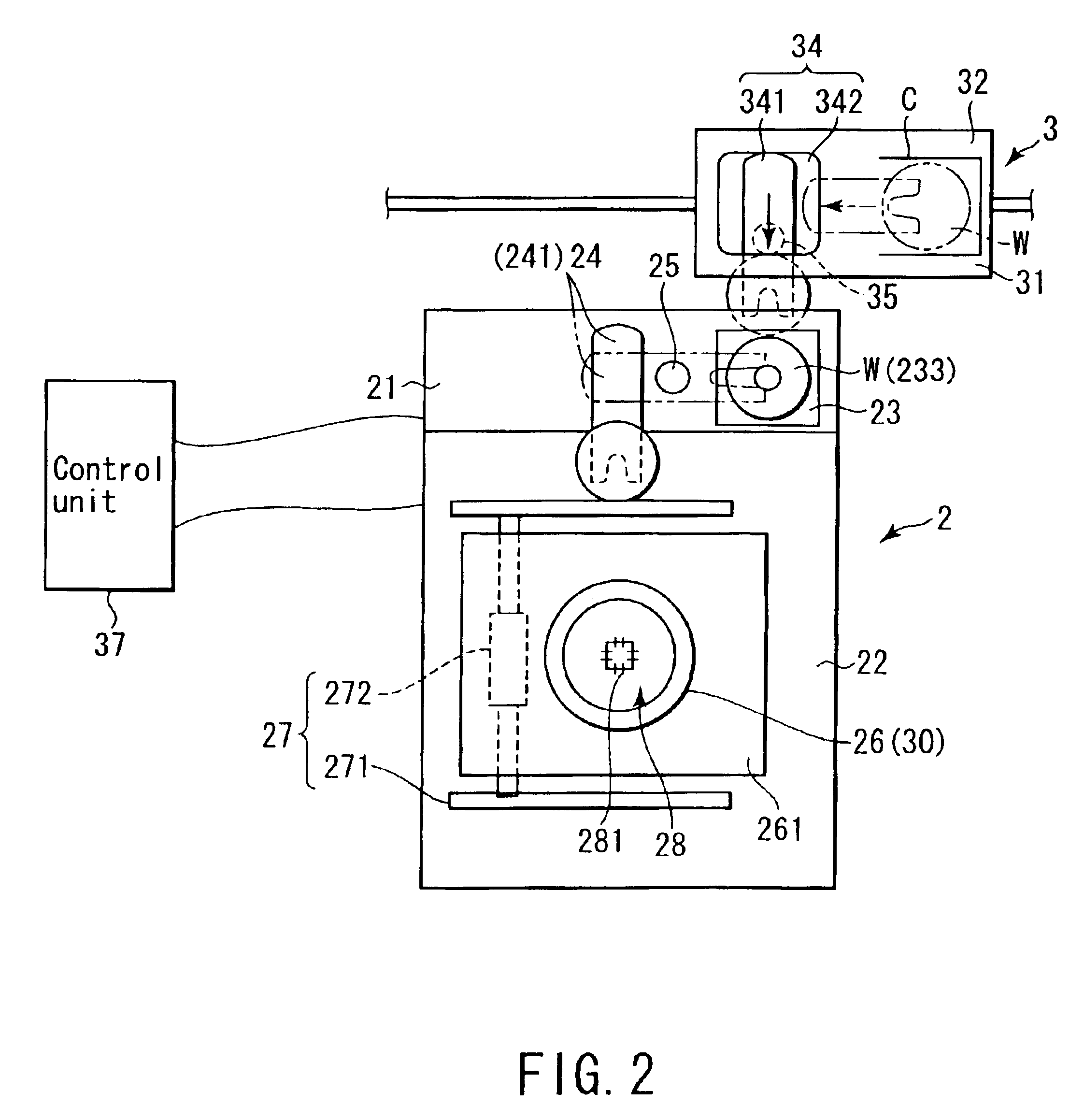

Centering mechanism, centering unit, semiconductor manufacturing apparatus, and centering method

InactiveUS7153087B2Raise and low supportSecure deliverySleeve/socket jointsComputer controlManufactured apparatusEngineering

A centering unit comprises a plate, centering mechanism, link mechanism, and cylinder mechanism. The plate vertically divides the interior of a frame. The support table is located substantially on the center of the plate. The centering mechanism can center each wafer on the support table. Centering plates of the centering mechanism are located on either side of the support table and have engaging surfaces and that extend along the outer peripheral surface of the wafer. The link mechanism and the cylinder mechanism serve to extend and contract the space between the centering plates.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Substrate support

InactiveUS7735710B2Welding/cutting auxillary devicesSemiconductor/solid-state device manufacturingMechanical engineering

A method and apparatus for supporting a substrate is generally provided. In one aspect, an apparatus for supporting a substrate includes a support plate having a first body disposed proximate thereto. A first pushing member is radially coupled to the first body and adapted to urge the substrate in a first direction parallel to the support plate when the first body rotates. In another aspect, a load lock chamber having a substrate support that supports a substrate placed thereon includes a cooling plate that is moved to actuate at least one alignment mechanism. The alignment mechanism includes a pushing member that urges the substrate in a first direction towards a center of the support. The pushing member may additionally rotate about an axis perpendicular to the first direction.

Owner:APPLIED MATERIALS INC

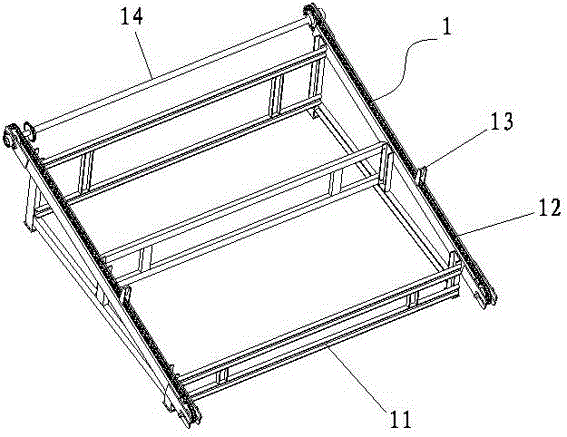

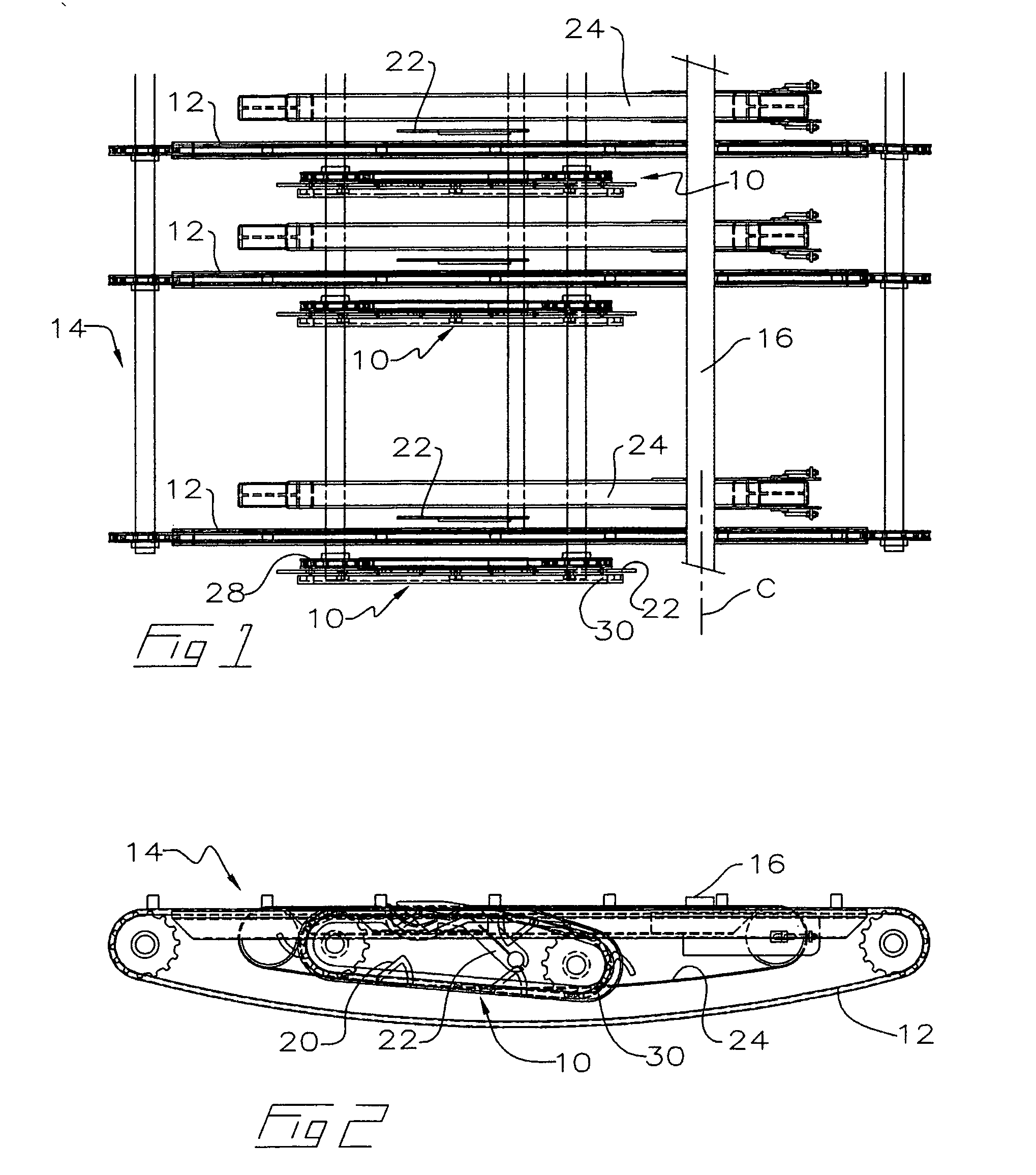

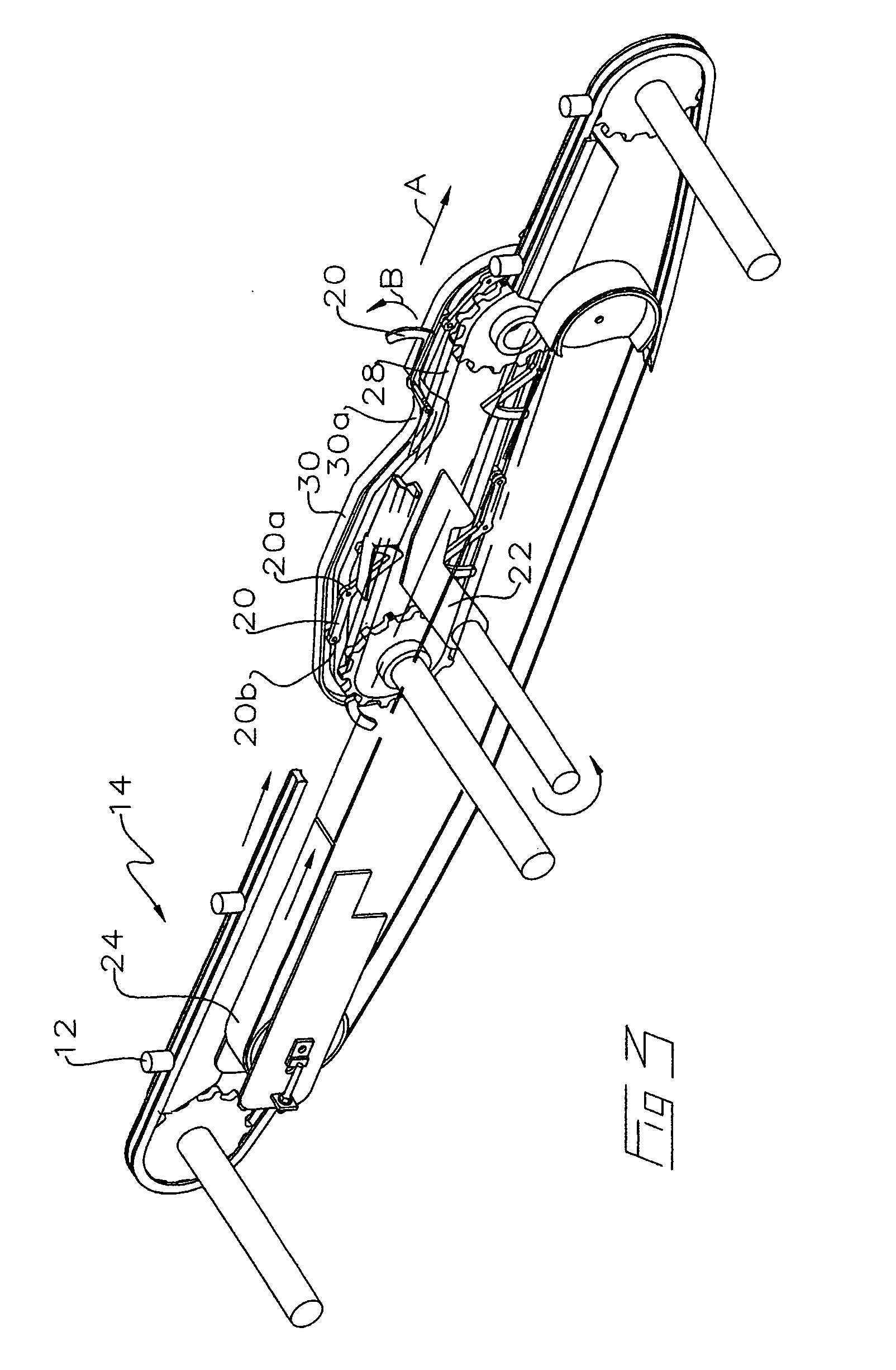

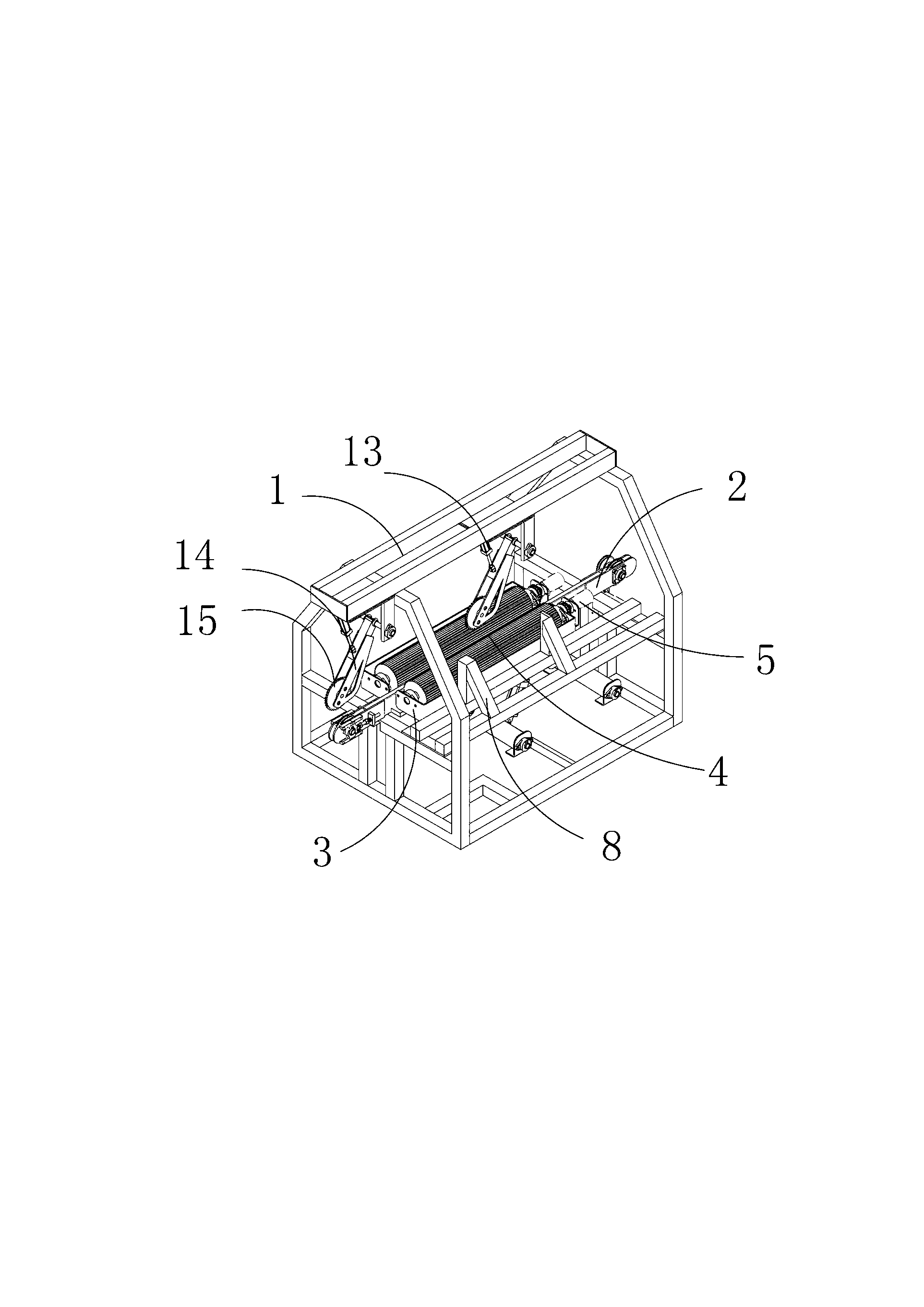

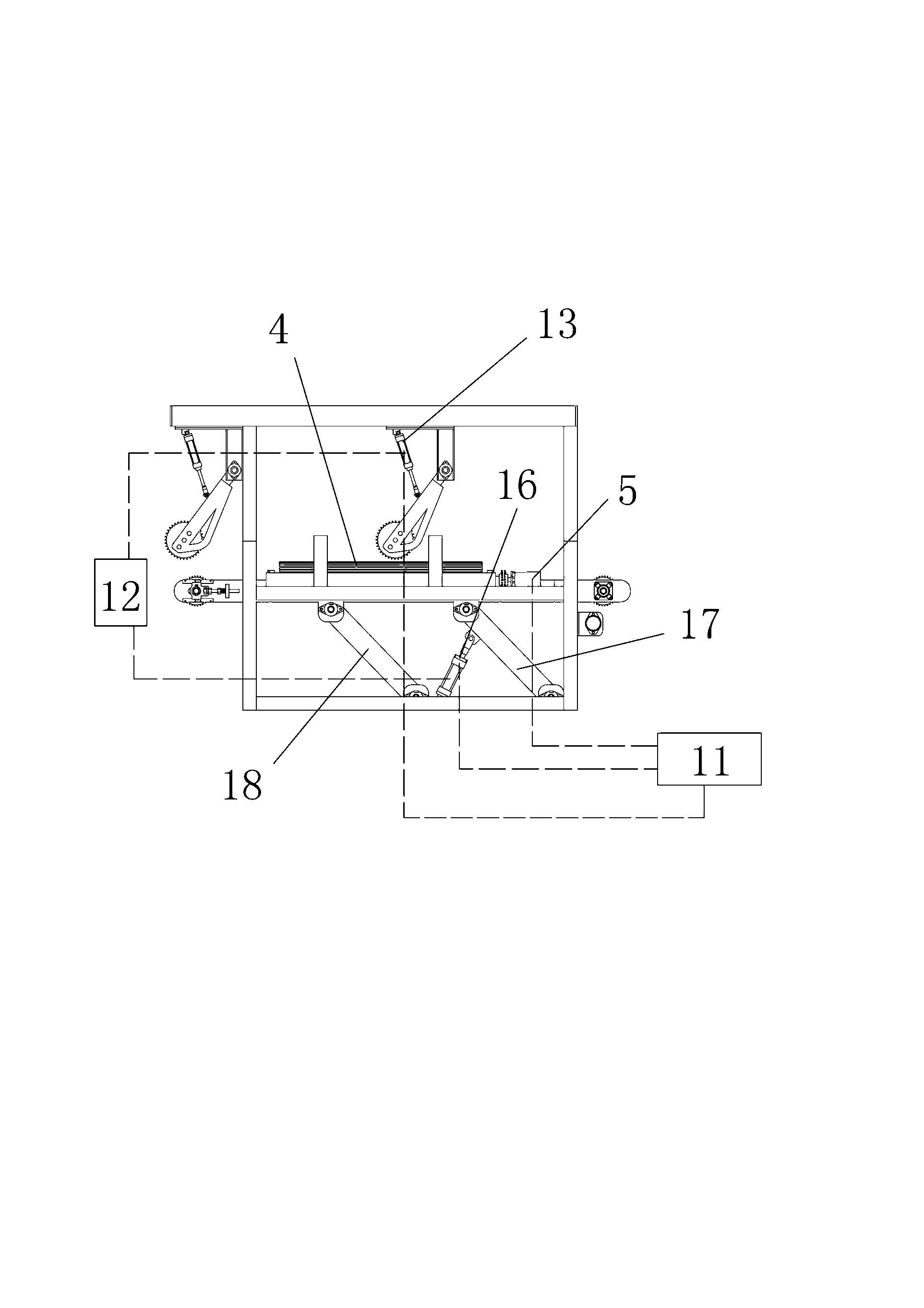

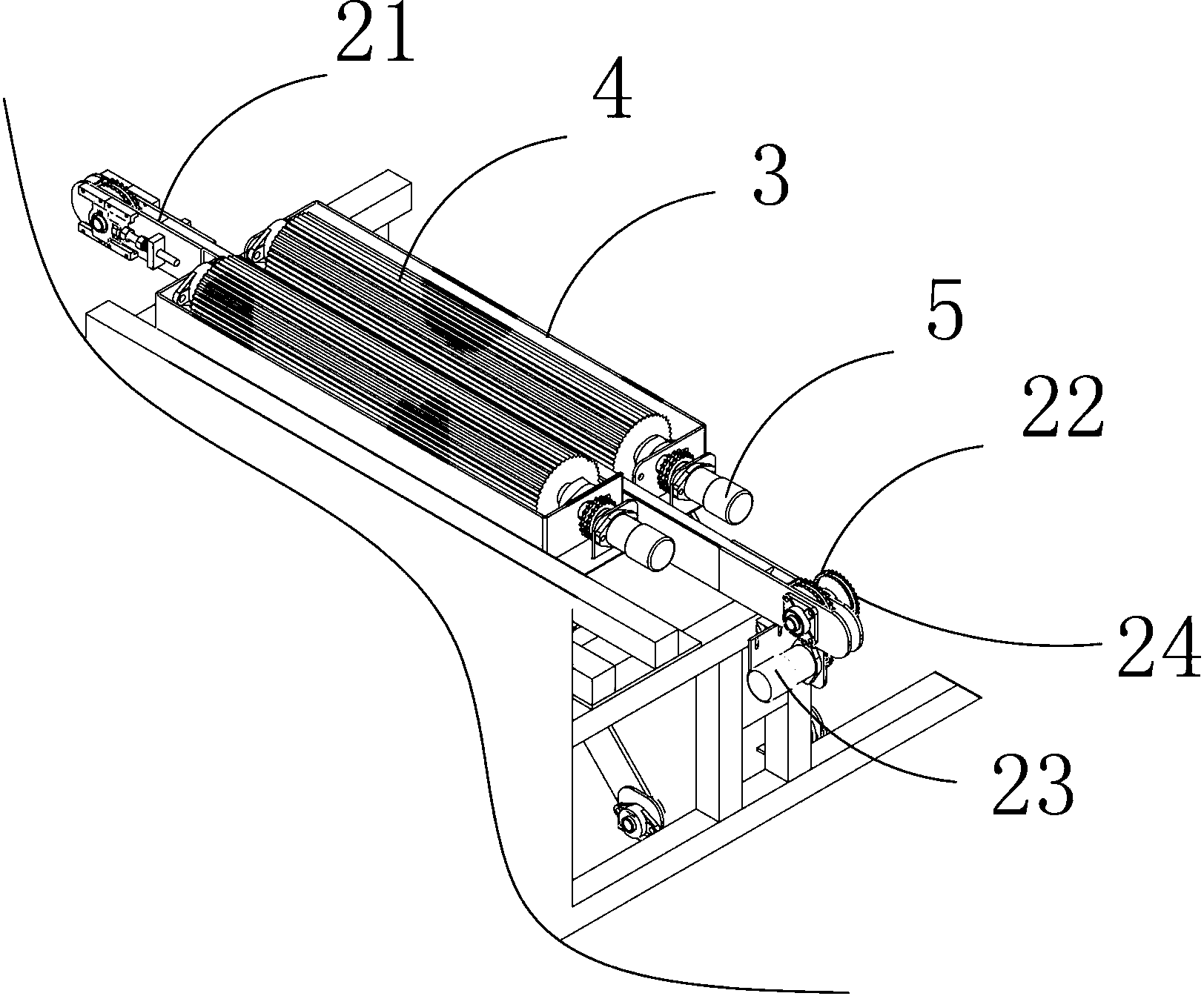

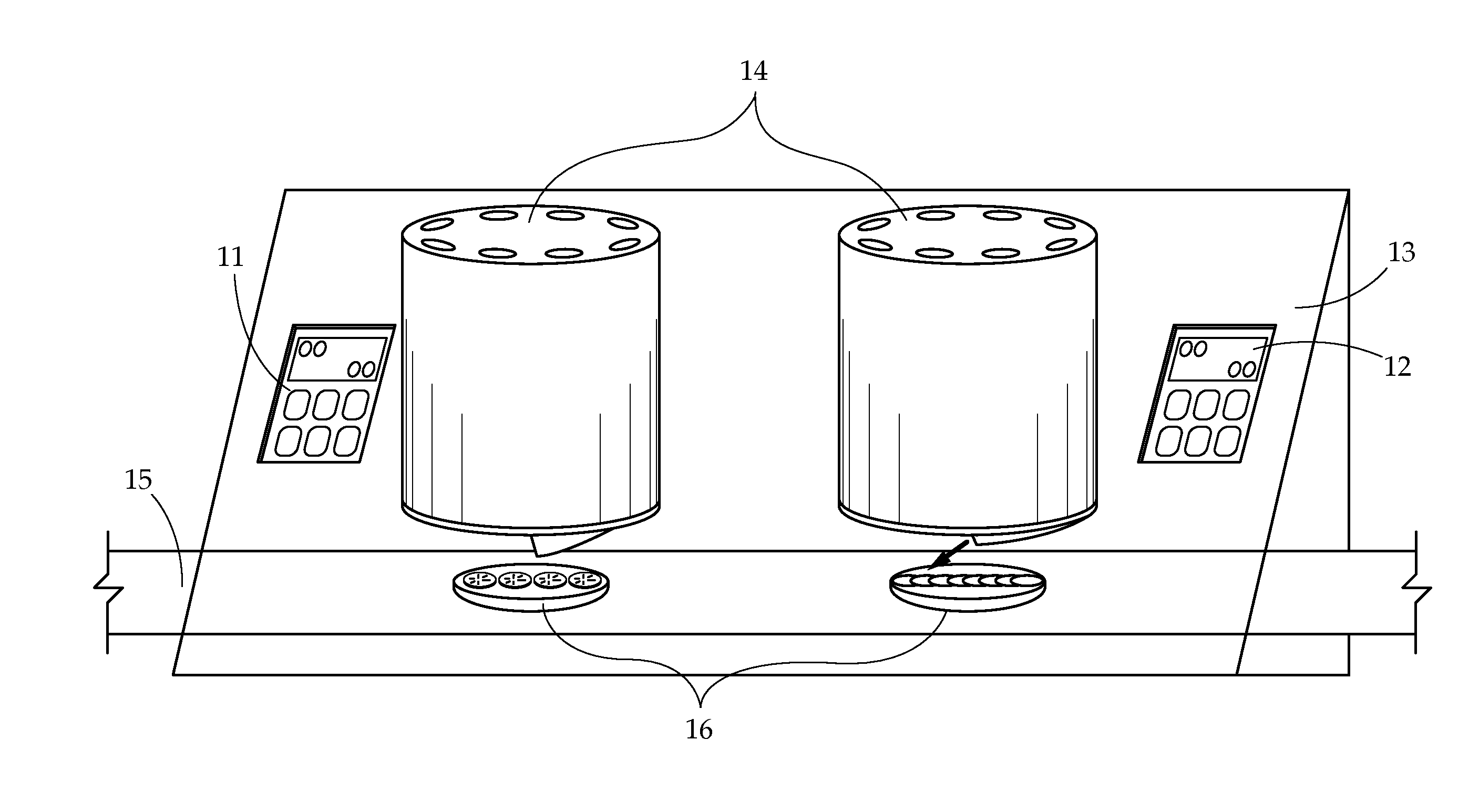

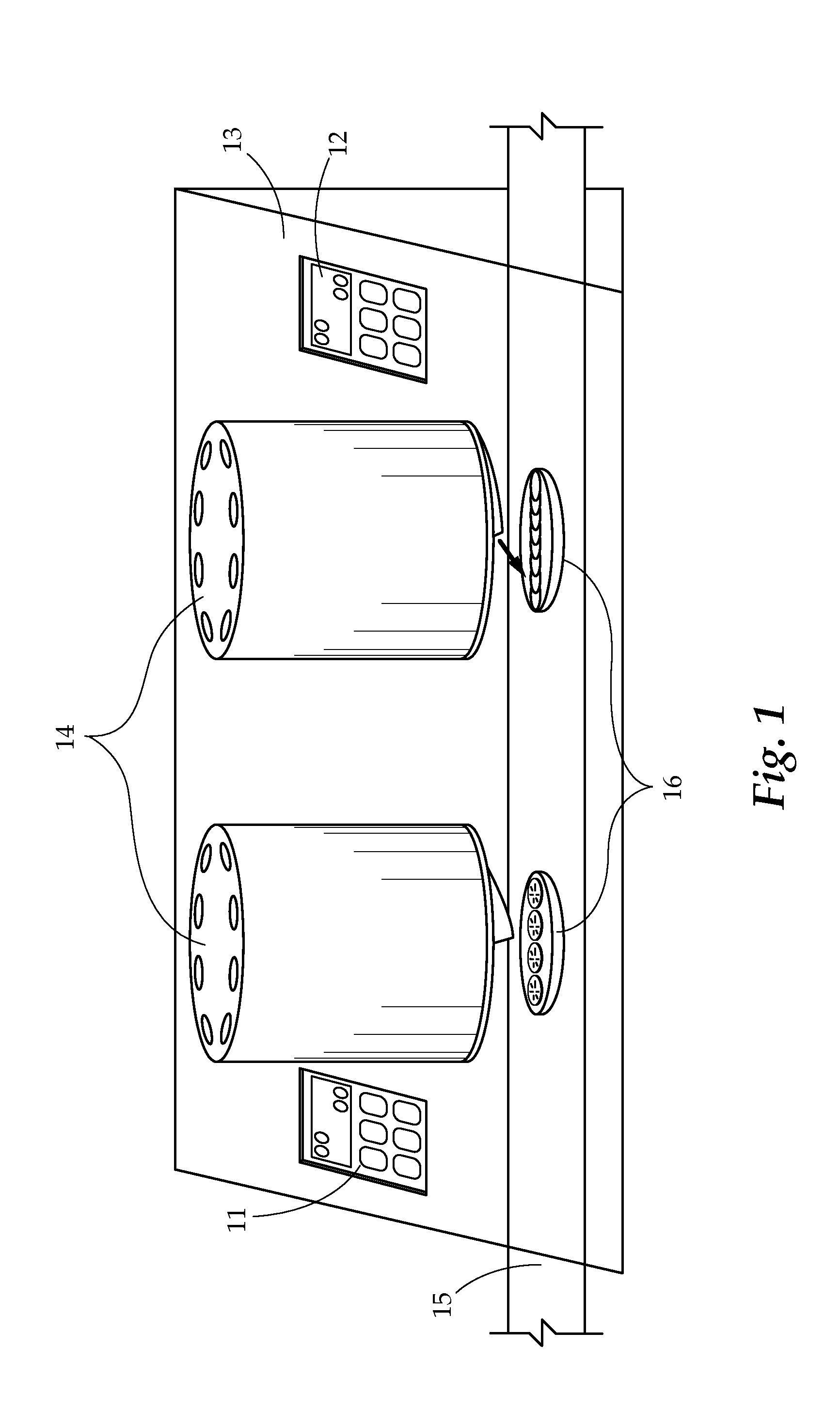

Log turning and feeding machine tool

InactiveCN103170999ARealize automatic flip functionHigh degree of automationFeeding devicesTurning equipmentEngineeringUltimate tensile strength

The invention discloses a log turning and feeding machine tool which comprises a rack and a feeding device used for conveying logs to a sawing device. A first roller shaft and a second roller shaft are symmetrically arranged on the two sides of the feeding device, the two roller shafts are installed in installing holes formed in shaft seats, the shaft seats are connected with a lifting device, a clamping device is arranged on the upper portion of the rack, one of or both the two roller shafts are connected with rotary motors, and the rotary motors are electrically connected with a handle switch. The log turning and feeding machine tool achieves the automatic turning function of the logs, and feeding and clamping processes are accomplished automatically, the automation degree of woodworking sawing machinery is improved, and meanwhile, labor intensity is relieved, working efficiency is improved, and the whole machining time is shortened.

Owner:钱旭荣

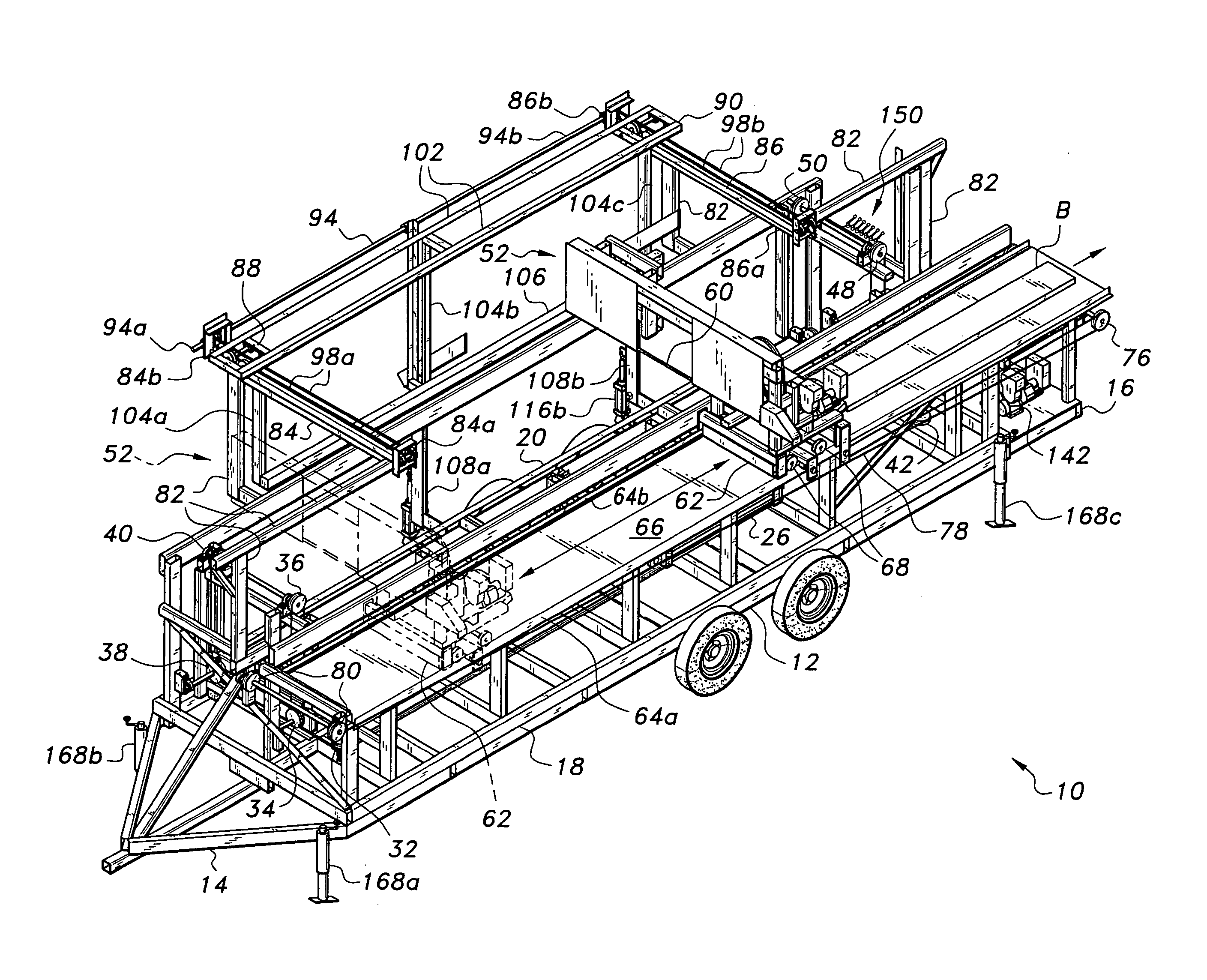

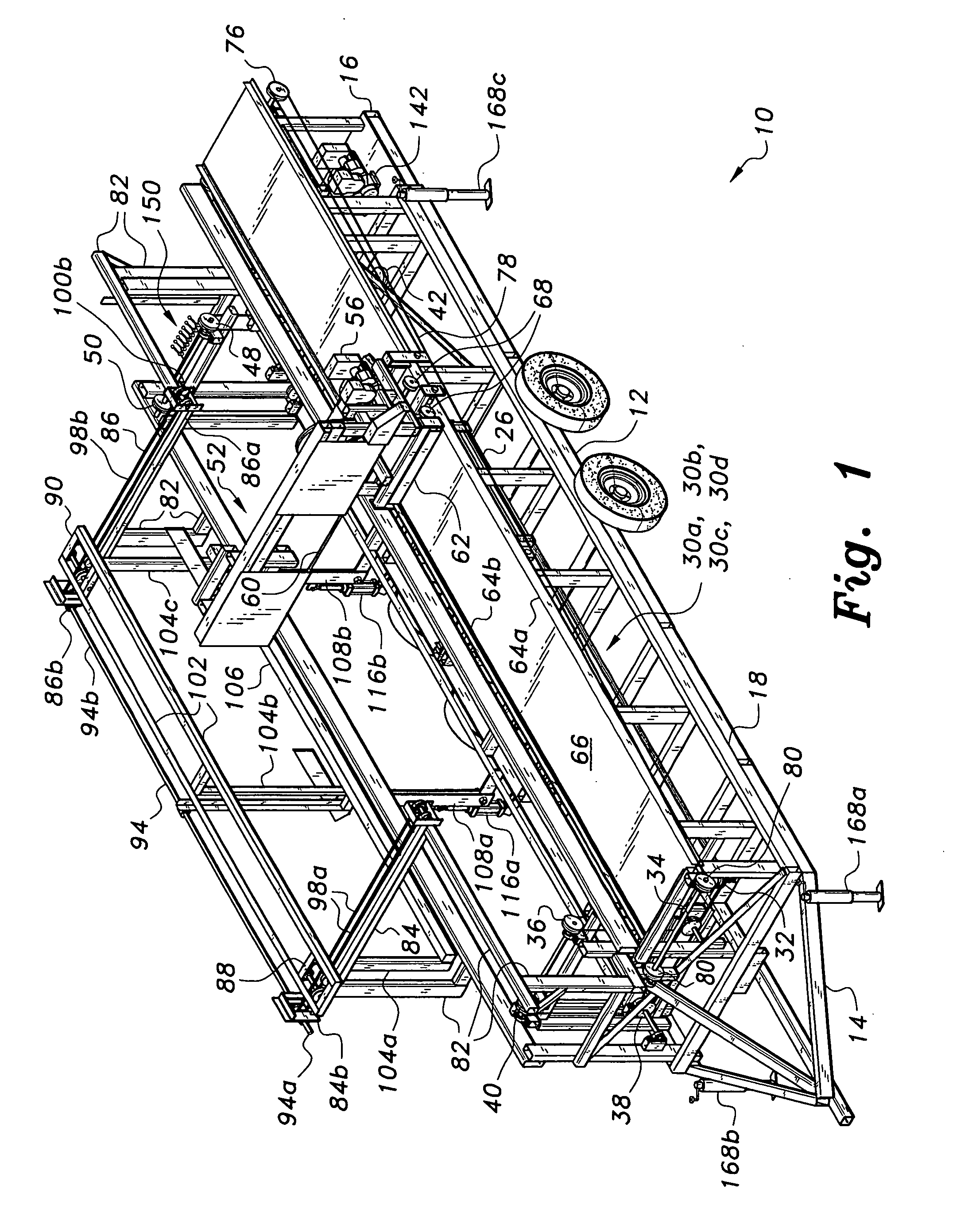

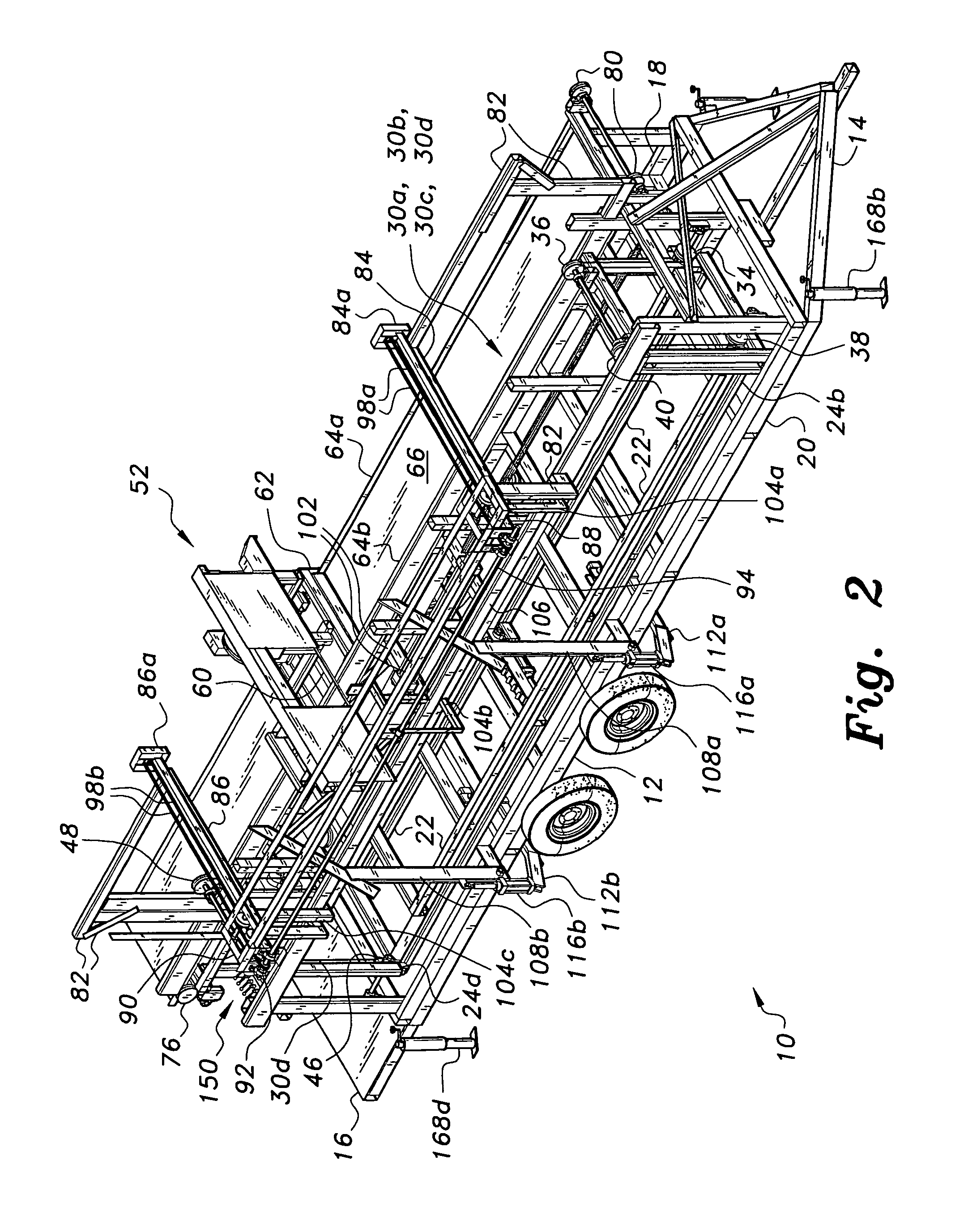

Portable sawmill

The portable sawmill is constructed on a frame having a series of mechanisms for loading and manipulating a log thereon and removing boards cut from the log. Powered tines load a log onto a vertically adjustable log deck, the deck including powered mechanisms for turning and securing the log in the desired orientation for cutting. Cuts are made by a horizontally traveling band saw. The saw has no vertical adjustment. Board thickness is determined by the height of the vertically adjustable log deck. Cut boards are removed by a board sweep that pushes the board laterally from the top of the log onto a tray. The saw travels along the tray to push the board longitudinally onto a suitable platform for transport. All of the above mechanisms are controlled hydraulically from a single operator station on the mill, thus freeing the operator from many manual tasks and increasing production.

Owner:BURTON LARRY C

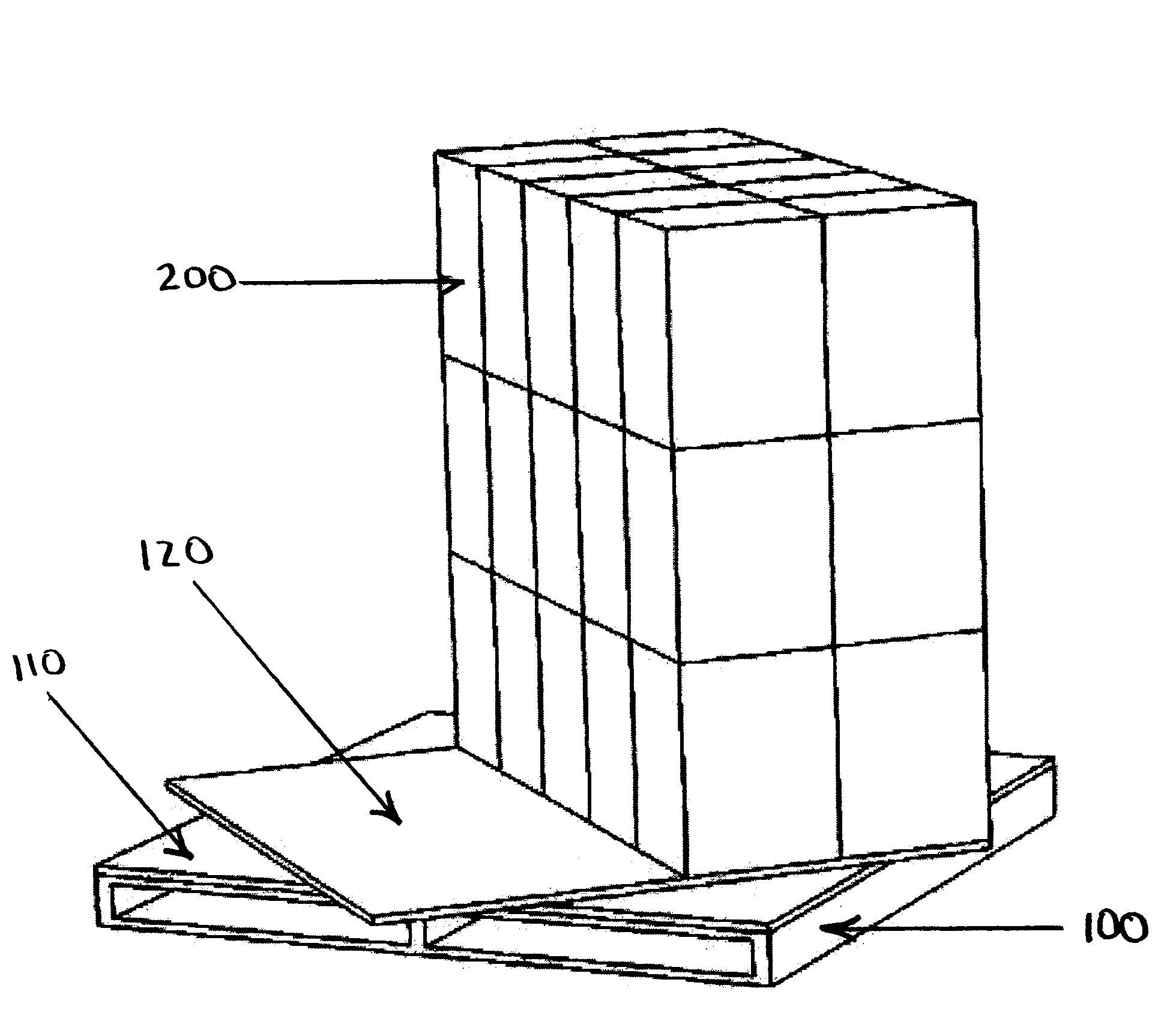

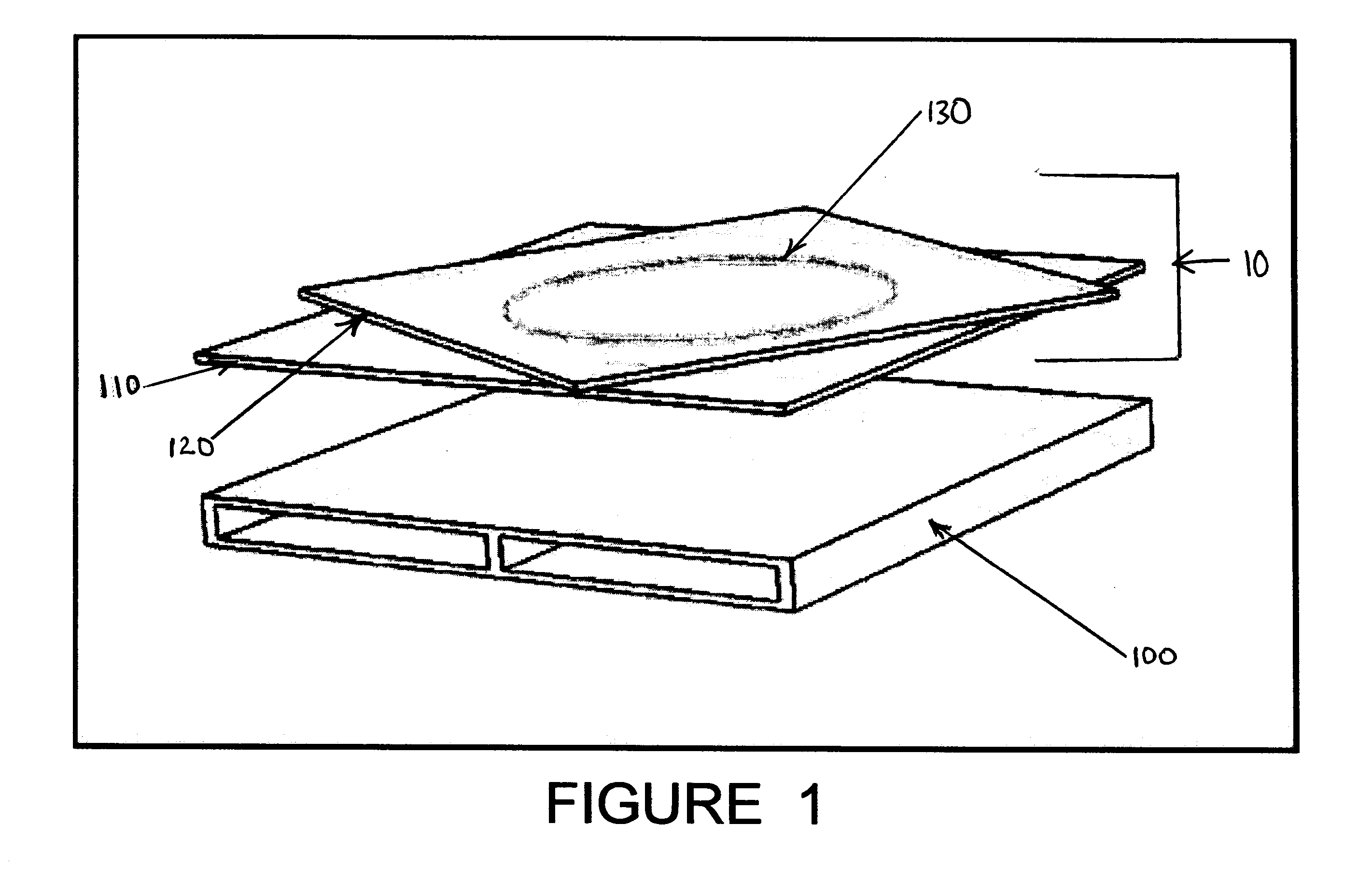

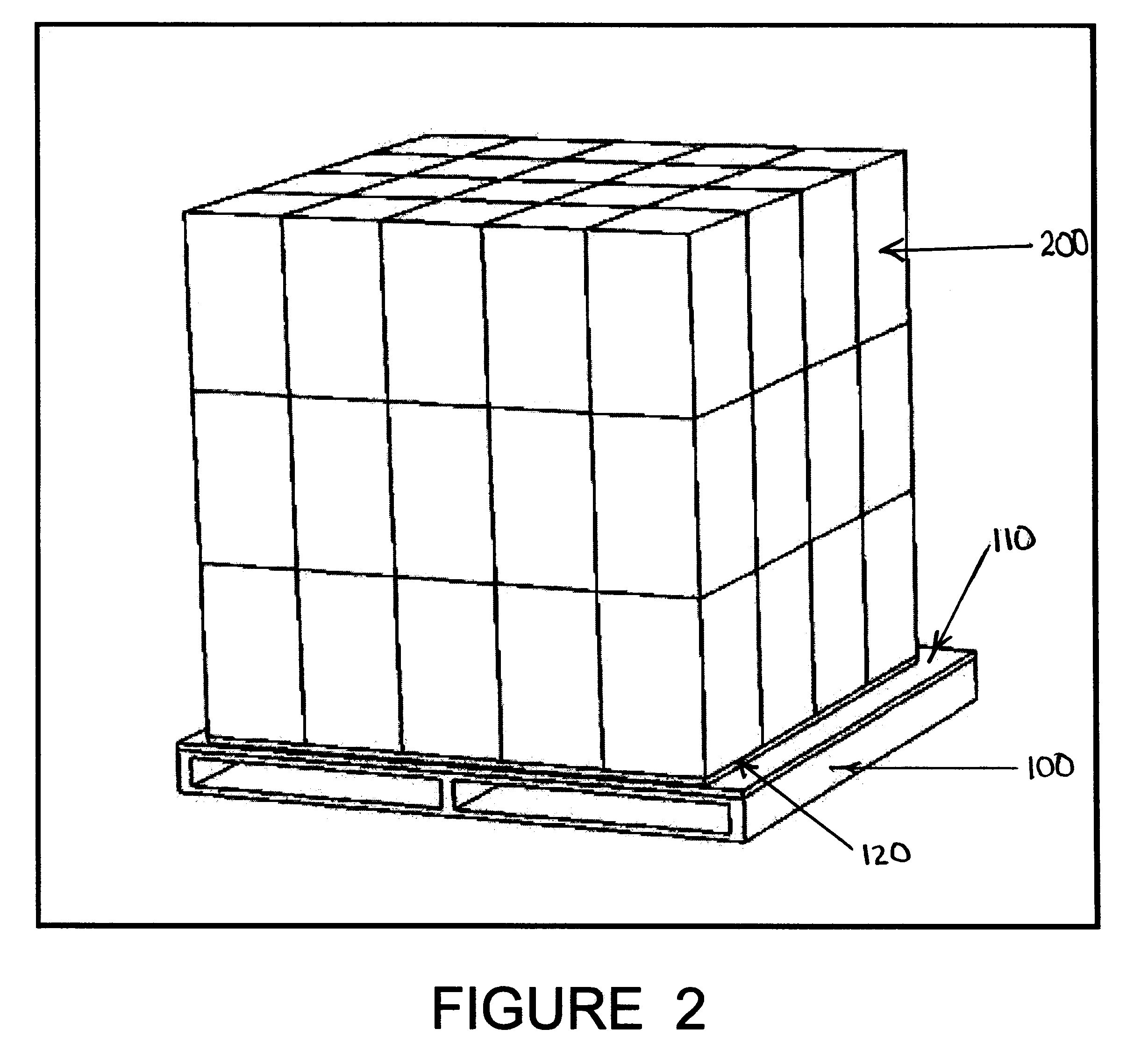

Method and apparatus for rotating articles on a pallet

ActiveUS20110070061A1Precise positioningPrevent movementFeeding devicesStands/trestlesEngineeringPallet

An apparatus and method for rotating articles stored on a pallet without rotating the entire pallet. The turntable of the present invention is located on the pallet or integrated into the top surface of the pallet. By rotating the pallet within the rack, the articles thereon may be loaded and unloaded from a position directly in front of the picker.

Owner:UNEX MFG

Microtome Blade Changing Apparatus For A Knife Holder Of A Microtome, And Microtome

ActiveUS20080148918A1Simple and reliable fashionEconomically manufacturedFeeding devicesWithdrawing sample devicesEngineeringKnife blades

A microtome blade changing apparatus for a knife holder (1) of a microtome comprises a blade dispenser (4) storing unused blades and a blade container (5) for receiving used blades. The blade dispenser (4) and blade container (5) are respectively arranged adjacent to the knife holder (1). To reduce the risk of injury to an operator in the context of a blade changing operation, enable operation of the microtome blade changing apparatus reliably and in simple fashion, and allow economical manufacture of the microtome blade changing apparatus, the microtome blade changing apparatus is characterized in that an entraining element (13) manually actuable by an operator is provided, and is configured in such a way that an unused blade is transferable with the entraining element (13) from the blade dispenser (4) to the knife holder (1), and a used blade is thereby conveyable into the blade container (5).

Owner:LEICA BIOSYST NUSSLOCH

System and method for making food items

A food preparation system is provided. The food preparation system includes a revolving slicer configured to slice a plurality of different food items. The revolving slicer comprises a rotating barrel having a number of chambers along its length. A blade is positioned adjacent to a bottom face of the rotating barrel. When a chamber rotates past the blade, food within it may be sliced by the blade.

Owner:SACCONE JR KEVIN

Microtome

Owner:HESS CONSULTGMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com