Processing line for round timber

An assembly line and log technology, which is used in wood processing appliances, processing machines for manufacturing flat surfaces, circular saws, etc., can solve the problems of large equipment occupation area, increased production costs, and many operators, and achieves improved production efficiency. Productivity, the effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

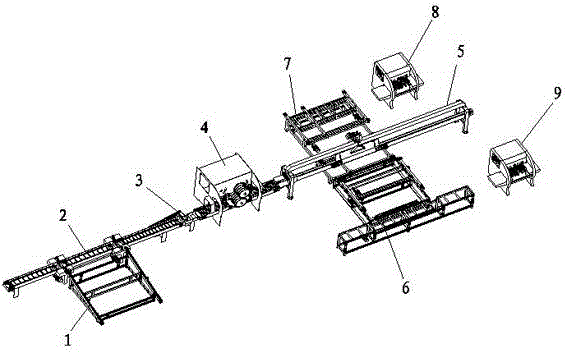

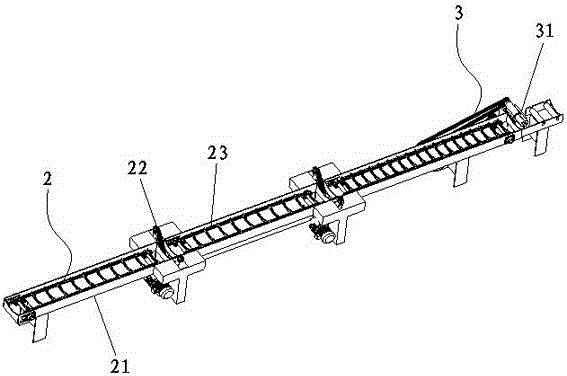

[0026] Embodiment one: if figure 1 As shown in the figure, a round log processing line includes a conveying device 1 for feeding materials arranged sequentially along the direction of log processing, a turning device 2 for rotating and centering the log, and a planer for planing the bottom of the log. Bottom skin device 3, log slicing saw 4 for cutting and slicing the log along its axial direction, sheet material sorting device 5 for sorting the middle wood chips and edge wood chips of the log, and the sheet material sorting device 5 also includes a first automatic feeding device 6 and a second automatic feeding device 7 for conveying edge wood chips arranged on both sides thereof, the first automatic feeding device 6 and the second automatic feeding device 7 The outlet of each is provided with the square wood slicing saw 8,9 that wood chips are cut and sliced again.

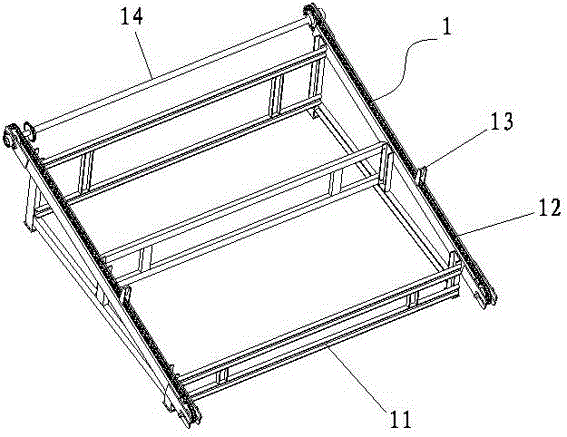

[0027] In this example, if figure 2 As shown, the conveying device 1 includes a slope-shaped frame 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com