Log turning and feeding machine tool

A technology for logs and machine tools, applied in the field of log turning over machine tools, can solve the problems of unfavorable occupational health of workers, tight staffing, high labor intensity, etc., and achieve the effects of shortening processing time, reducing labor intensity, and low cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

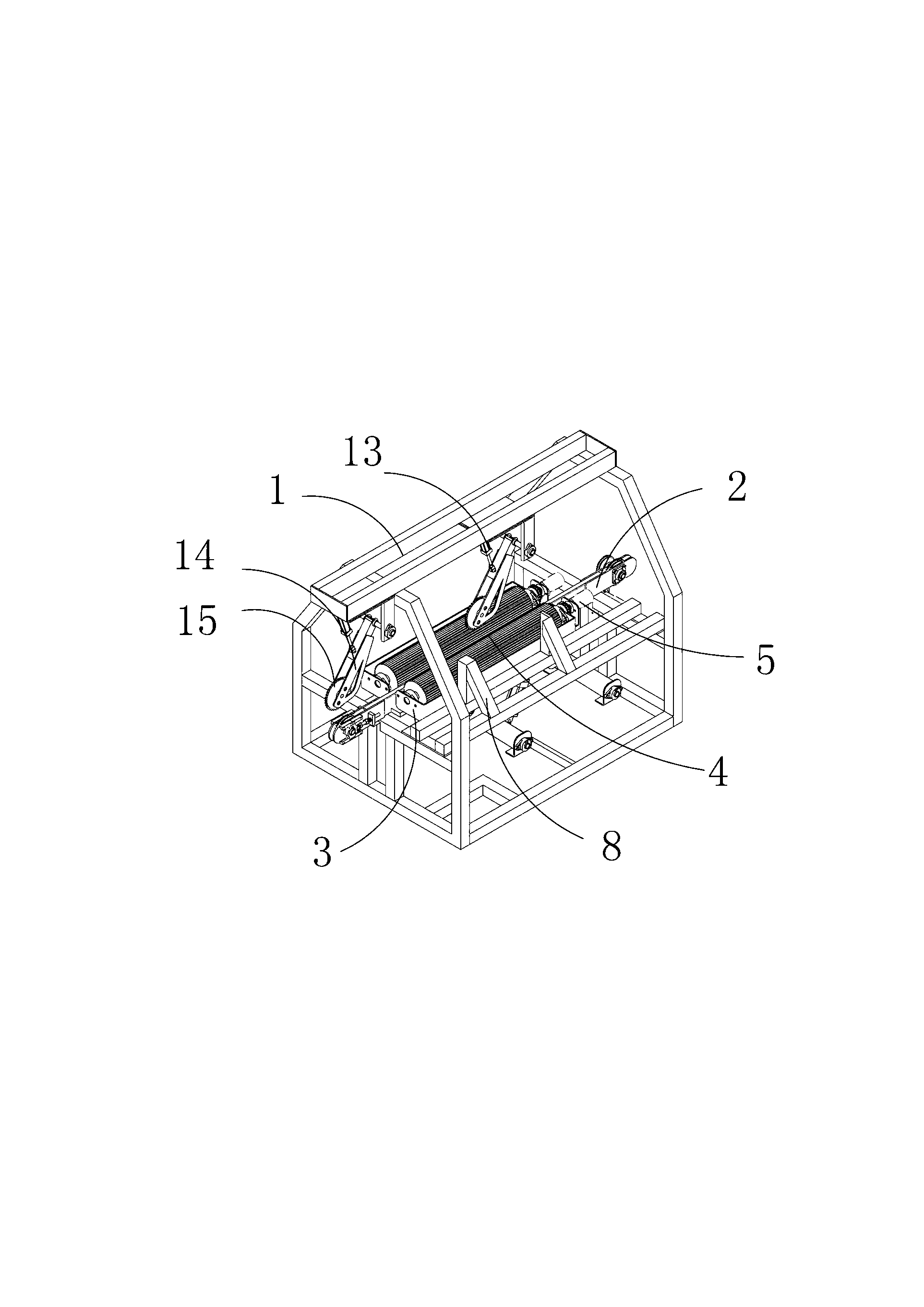

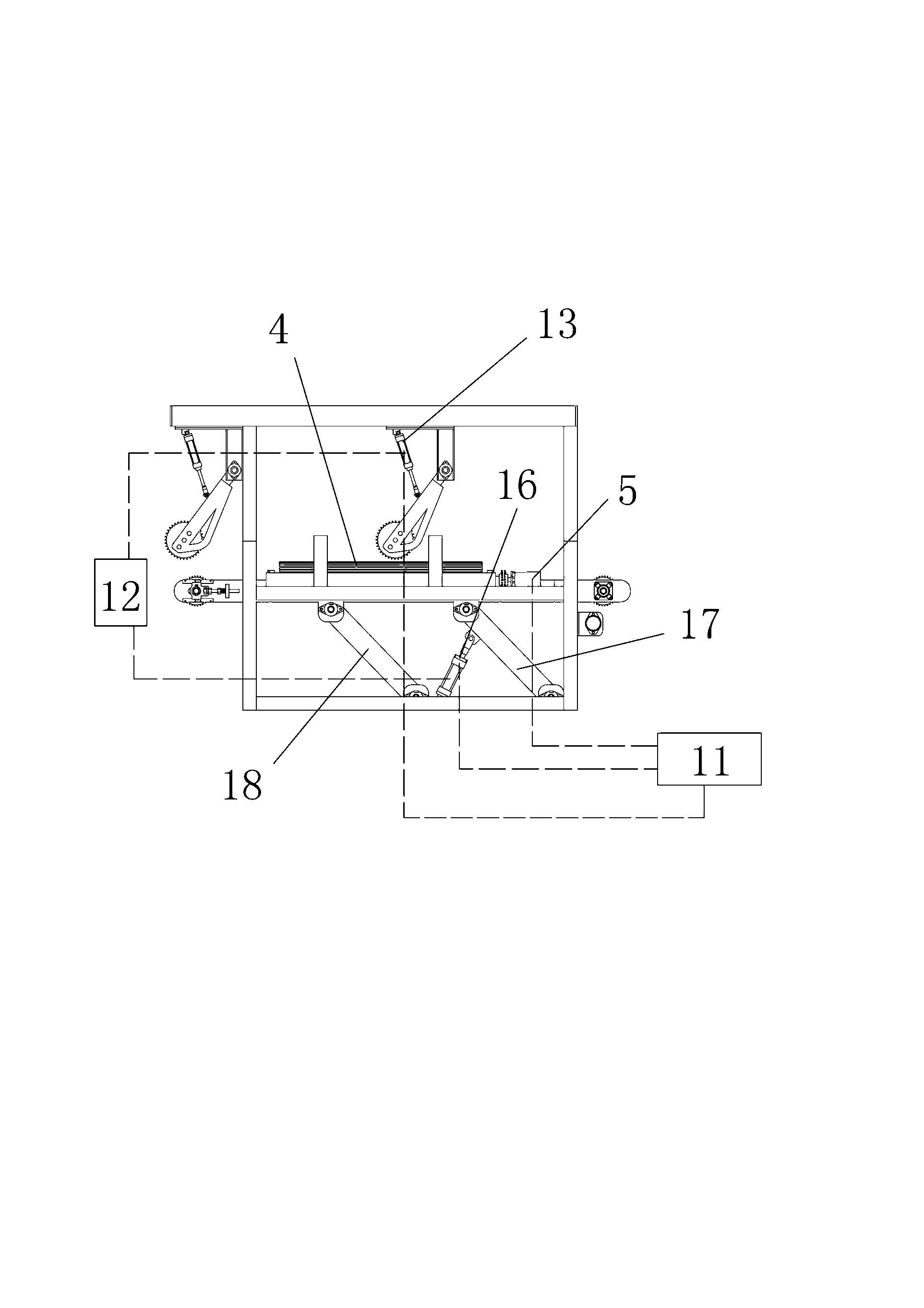

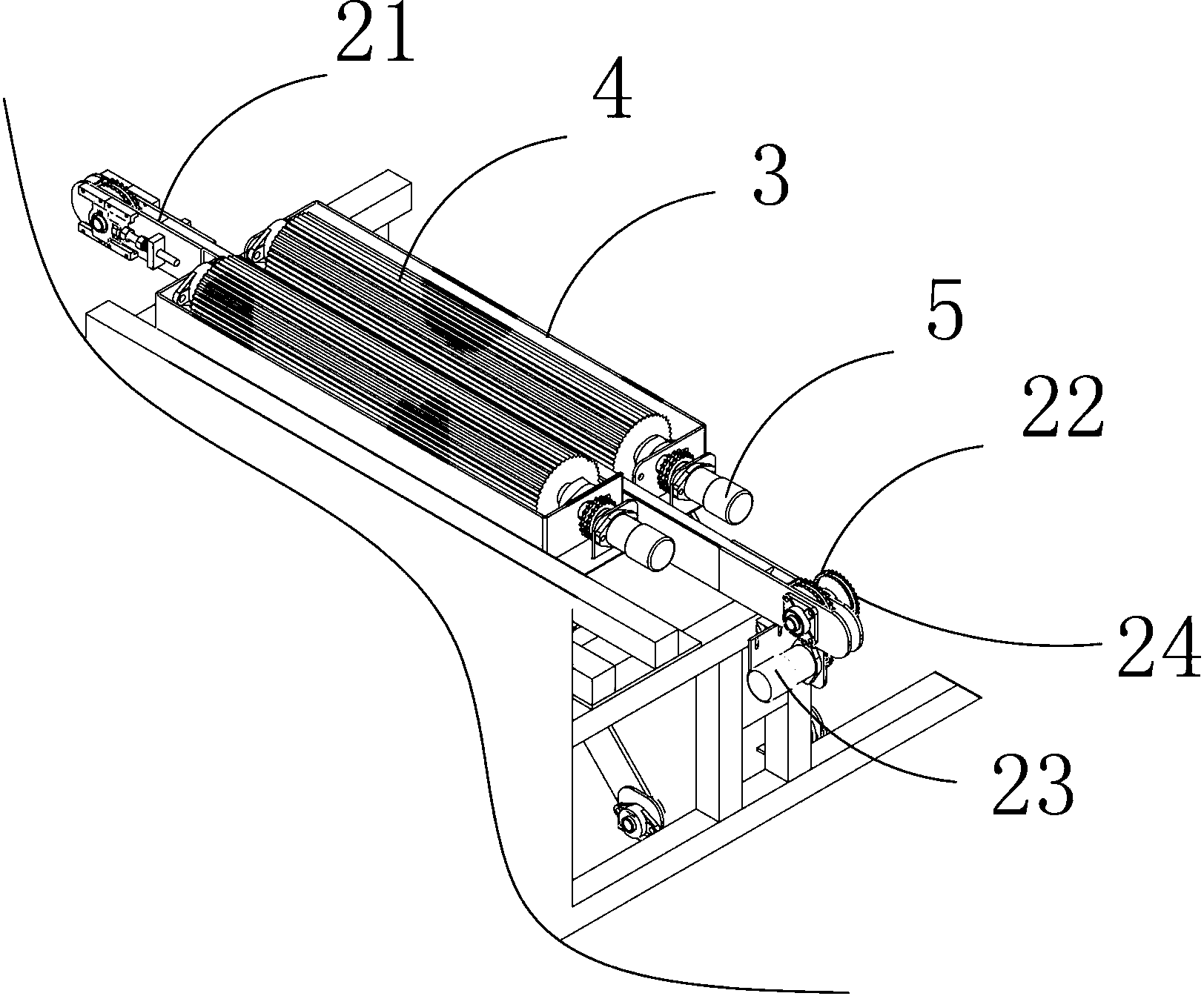

[0022] see figure 1 —5, the log turning machine tool of the present invention is made of turning device, feeding device, clamping device, control system, and the turning device of log comprises frame 1, and the feeding device 2 that log is transported to sawing device, in feeding device 2 The first roller shaft and the second roller shaft 4 are arranged symmetrically on both sides, and the log 10 is placed on the gap between the first roller shaft and the second roller shaft 4, and the first roller shaft and the second roller shaft 4 are both Installed in the mounting hole of the shaft seat 3 , one or both of the first roller shaft and the second roller shaft are connected to the rotating motor 5 . Feeding device 2 comprises elongated transmission frame 21, is provided with sprocket pair on transmission frame 21, and described sprocket pair comprises the driving chain gear 22 that is arranged on one end of transmission frame and the driven chain that is arranged on the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com