Patents

Literature

66results about How to "Implement the flip function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

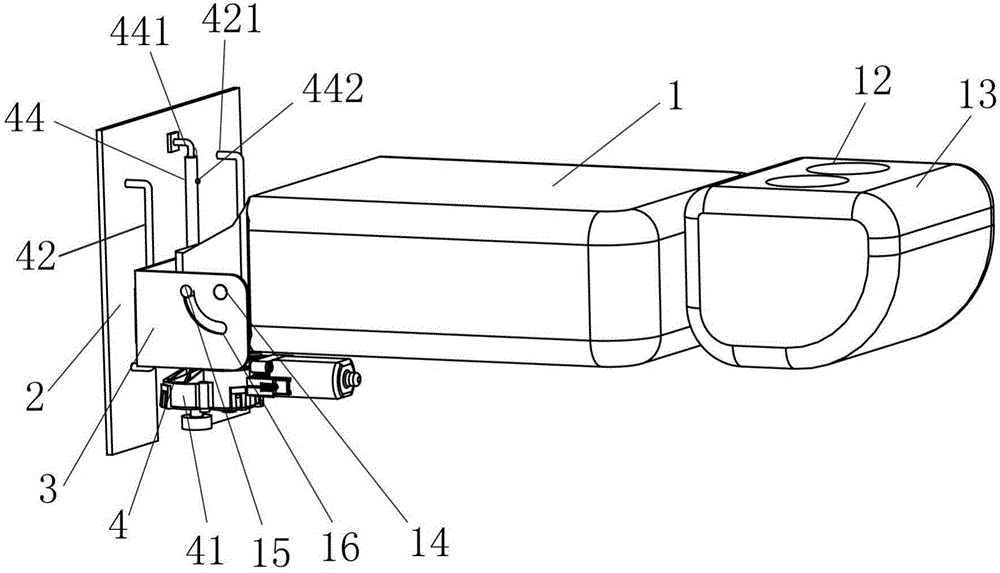

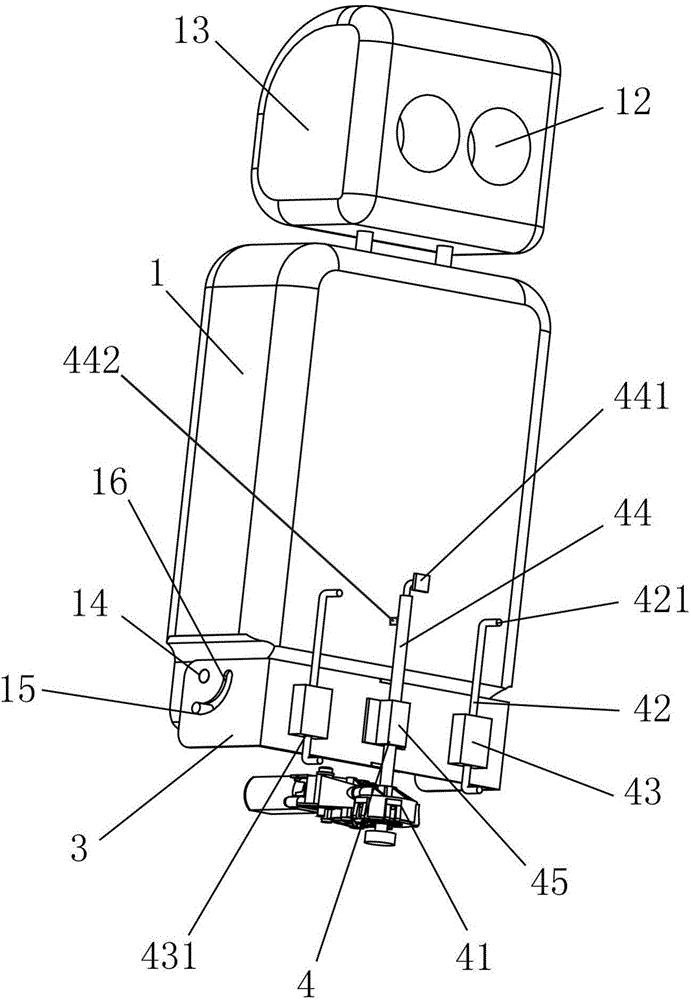

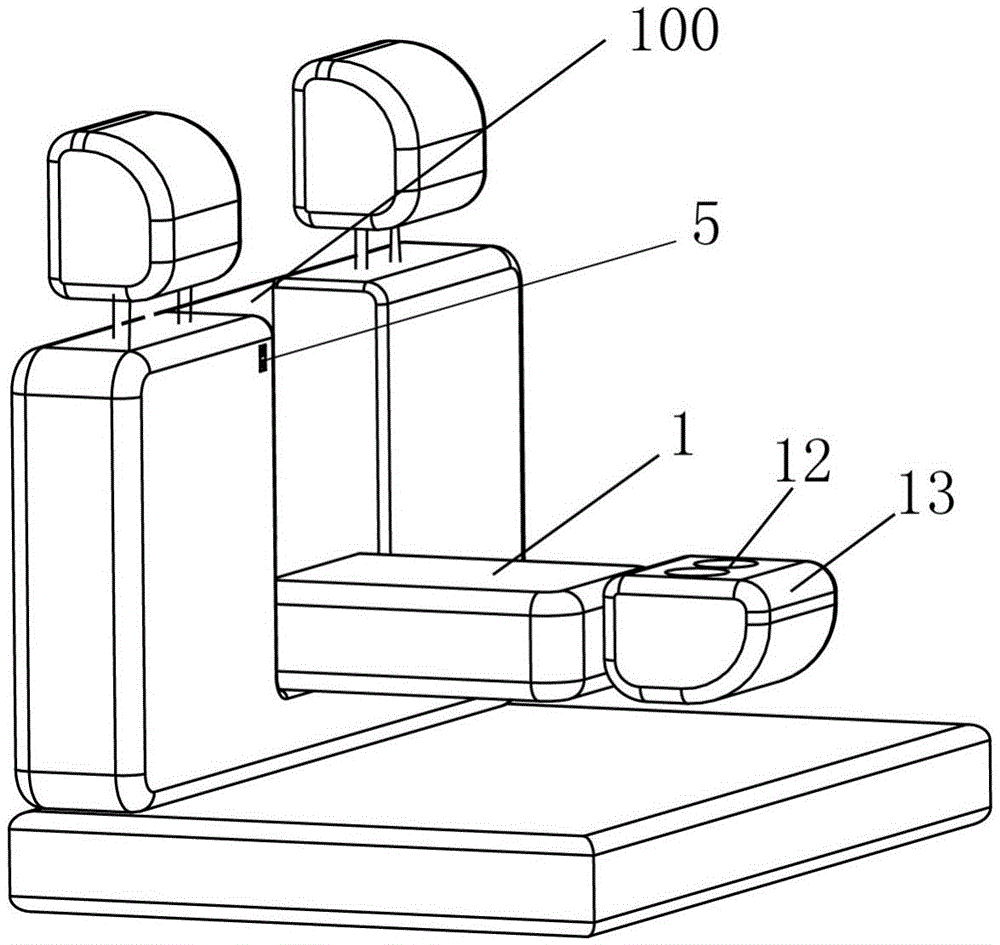

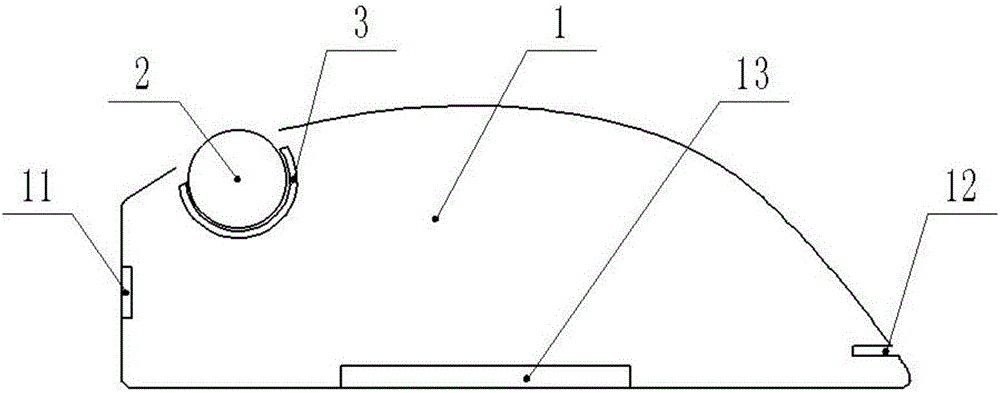

Lifting type back row seat handrail and vehicle provided with same

The invention provides a lifting type back row seat handrail and a vehicle provided with the handrail. The lifting type back row seat handrail comprises a handrail body, a fixing support, a turning support and a lifting mechanism, wherein the lifting mechanism is connected between the turning support and the fixing support, the lifting mechanism drives the turning support to do lifting movement relative to the fixing support, and the bottom end of the handrail body is hinged to the turning support and around the turning support to do the lifting movement. The turning function of the handrail body can be achieved, the lifting mechanism can realize the lifting of the handrail body, a headrest can lift simultaneously along with the handrail body, the handrail body can realize the lifting in both a horizontal state and a reset state, the height requirements of different passengers on the handrail can be satisfied, and the phenomenon that the headrest of the handrail in the reset state influences the rear vision of a driver can be avoided.

Owner:GREAT WALL MOTOR CO LTD

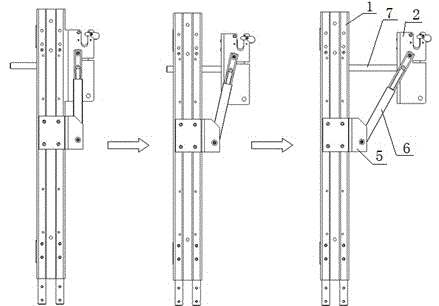

Screen pull-out overturning structure

ActiveCN103335194ASimple and reliable cooperationStable and reliable pull and flipStands/trestlesEngineering

Owner:GUANGDONG VTRON TECH CO LTD

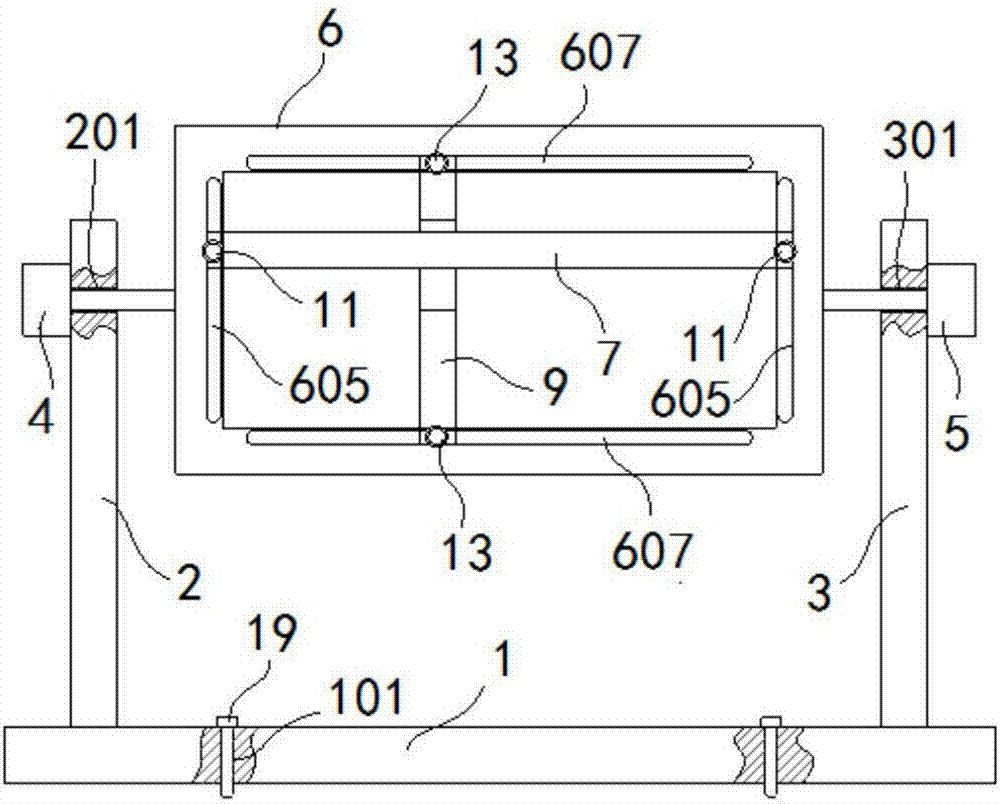

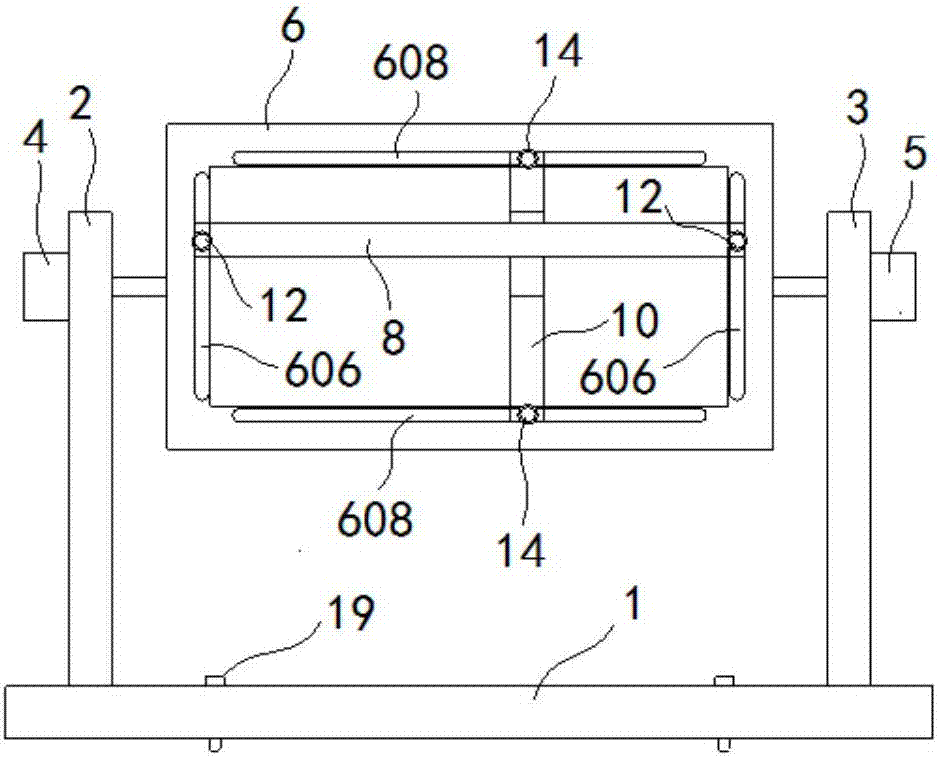

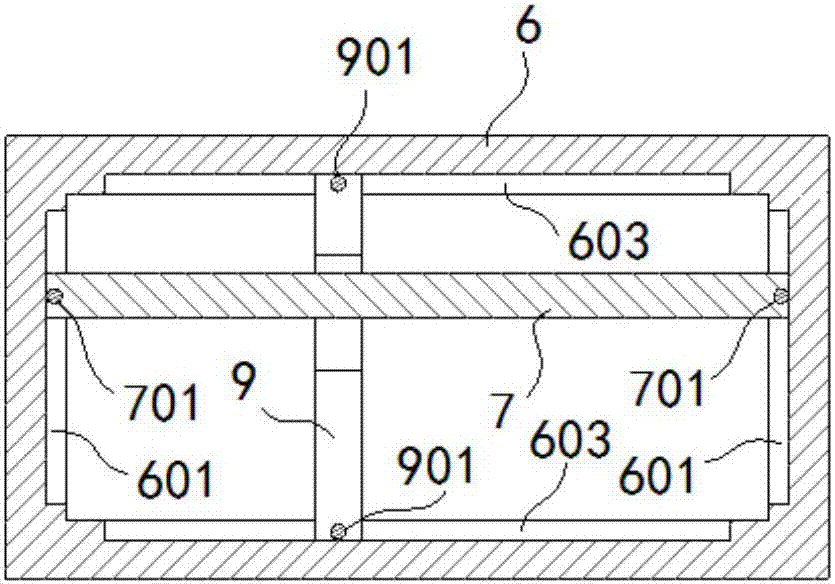

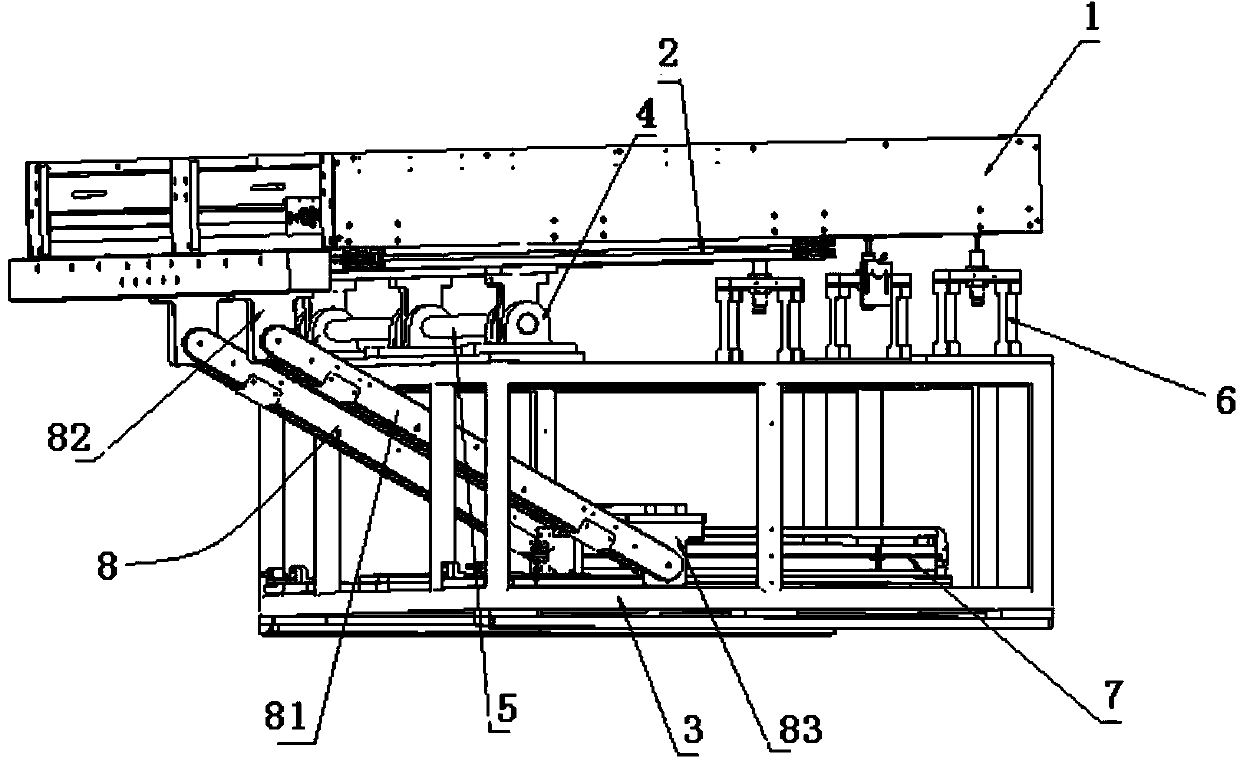

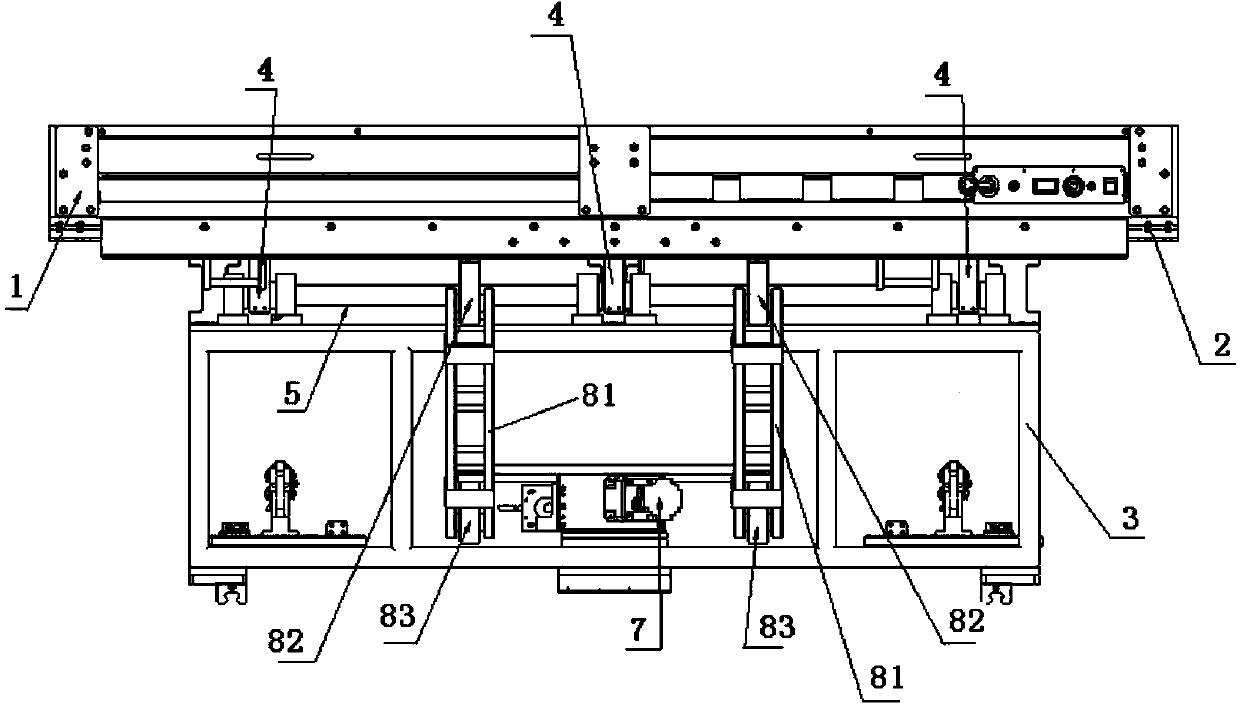

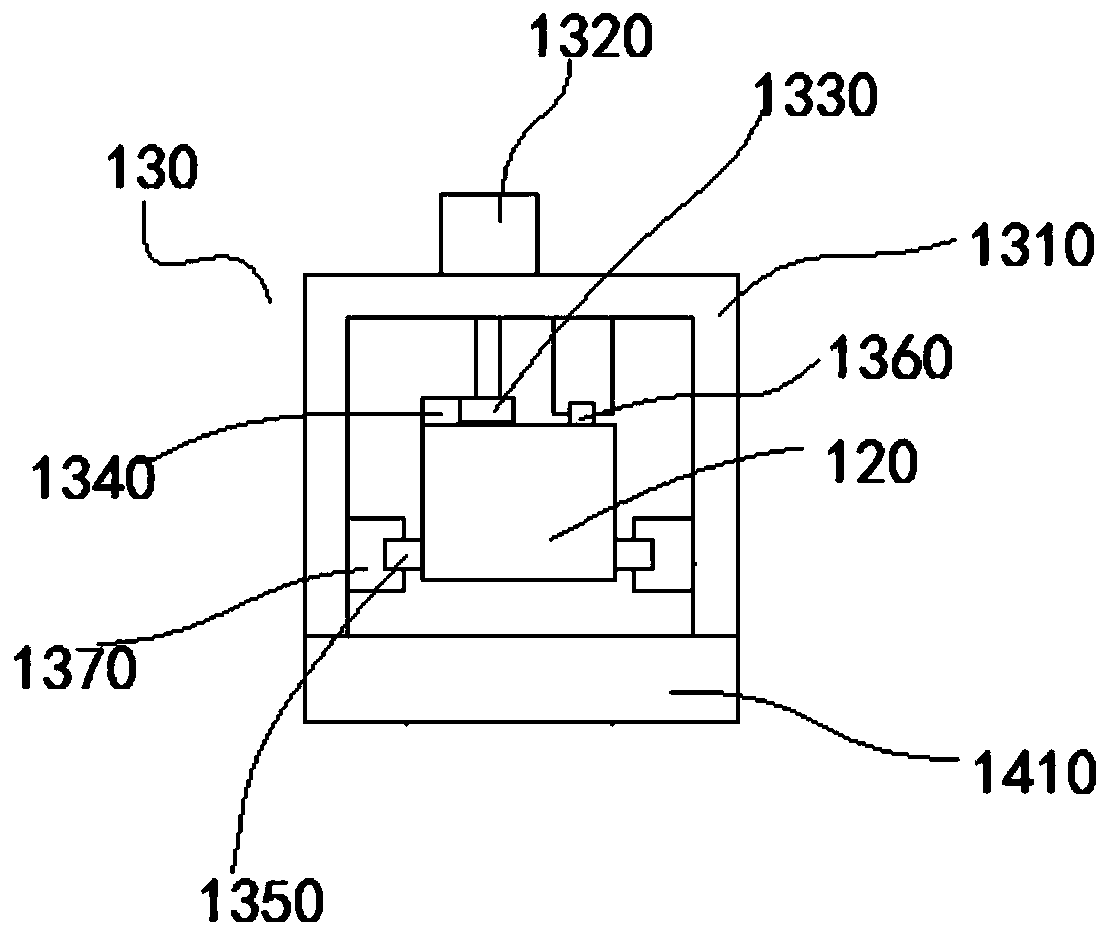

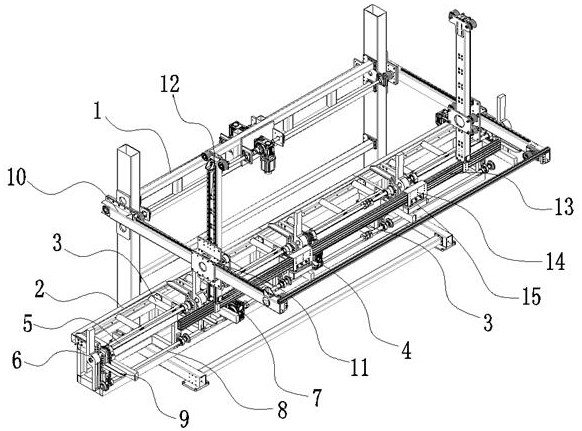

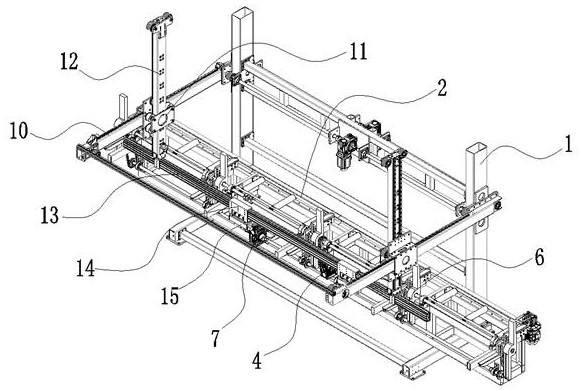

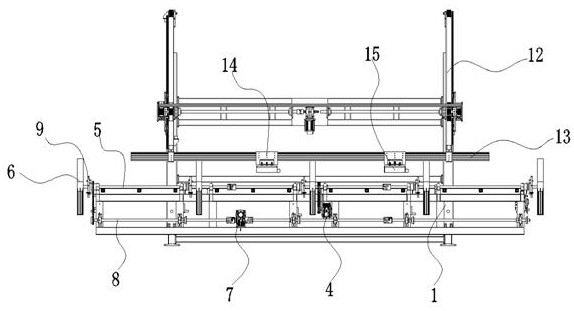

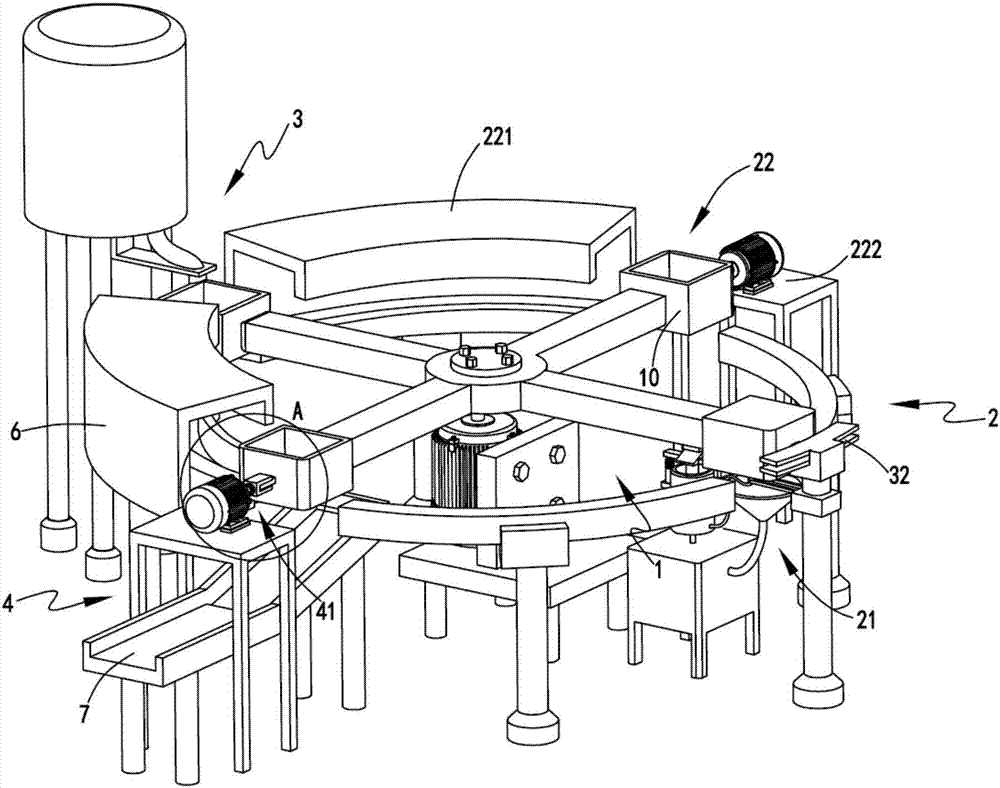

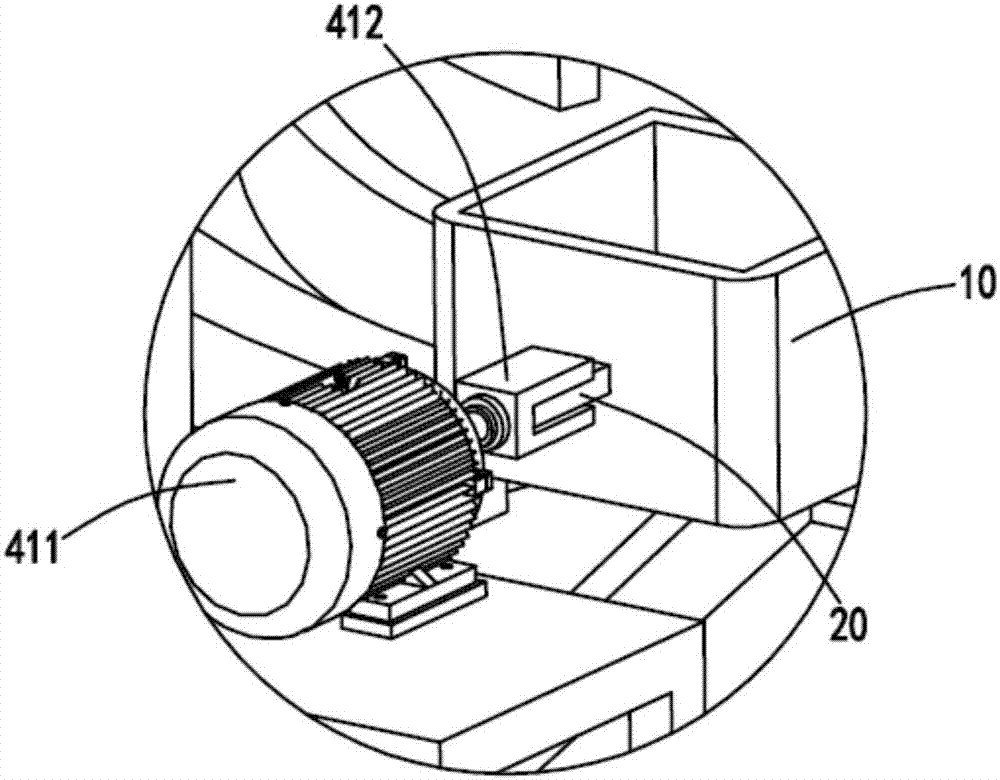

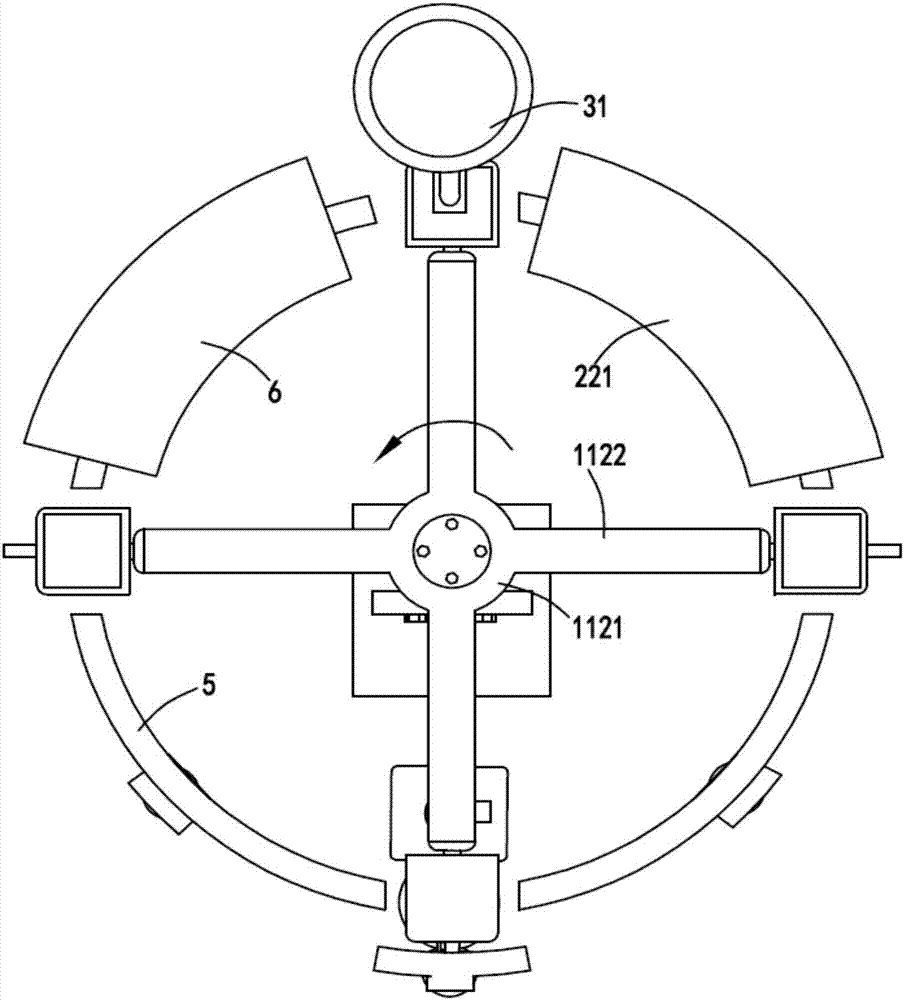

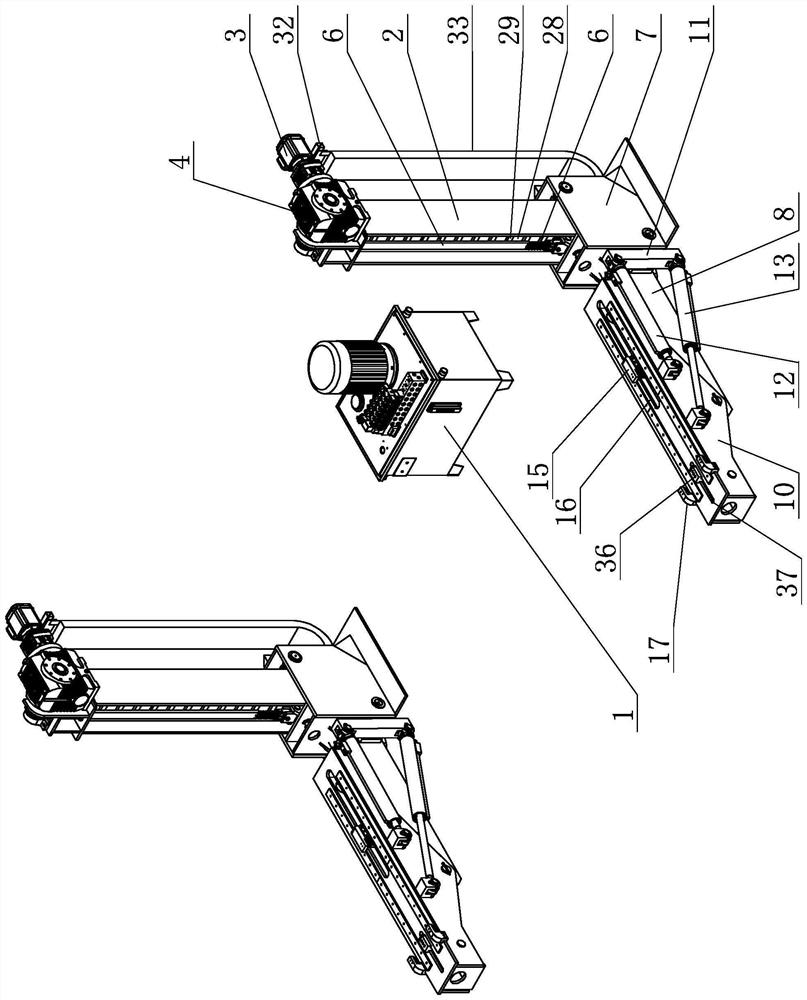

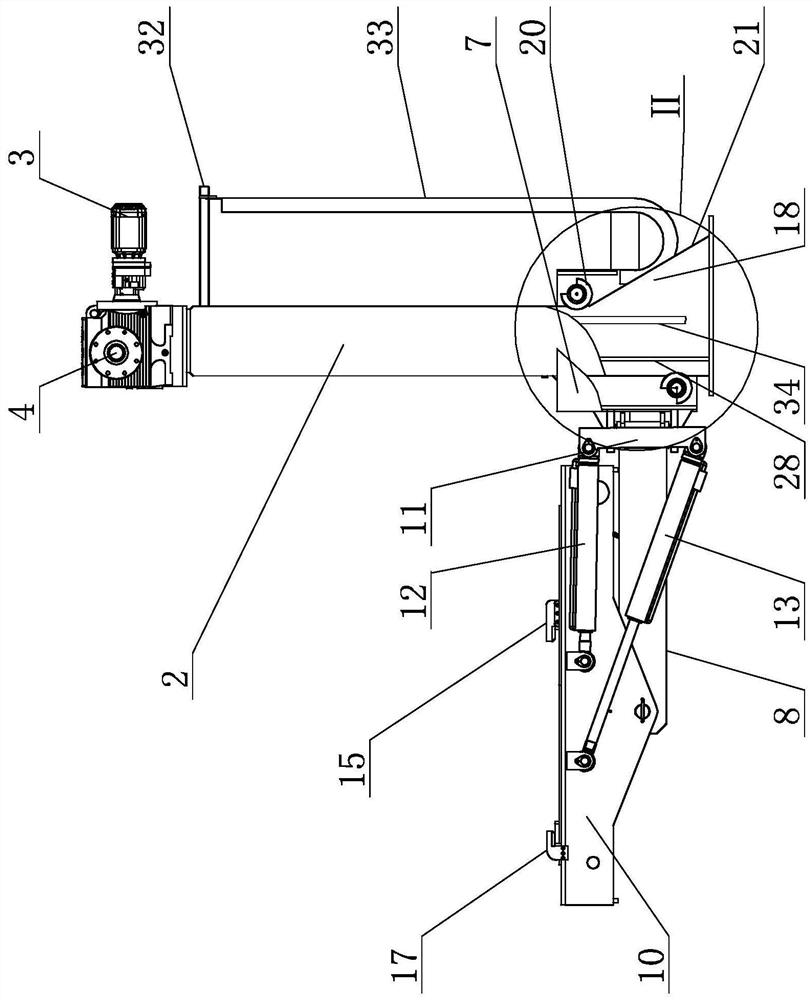

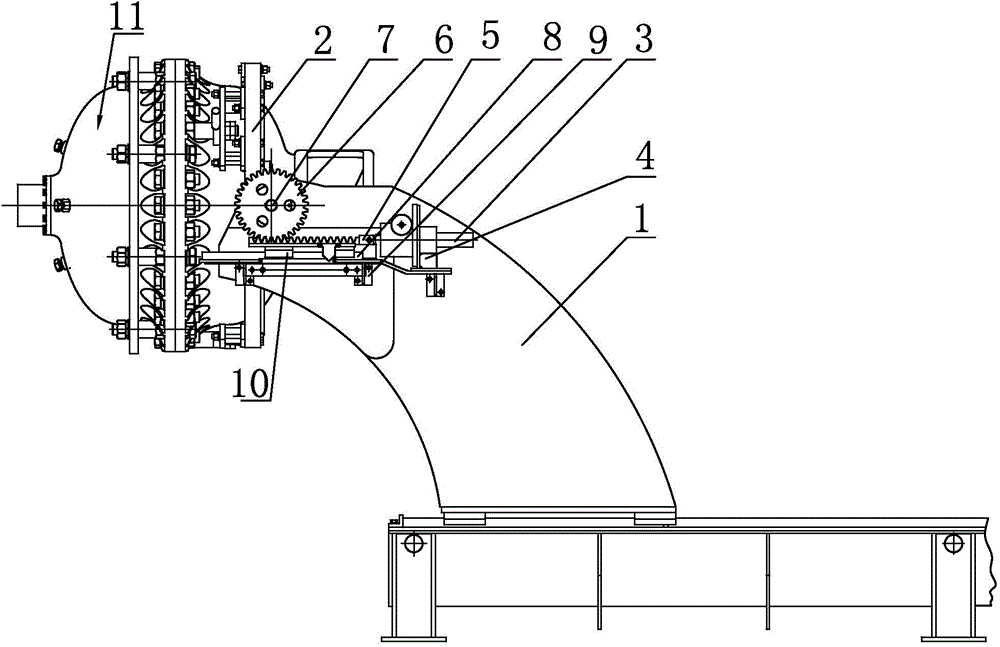

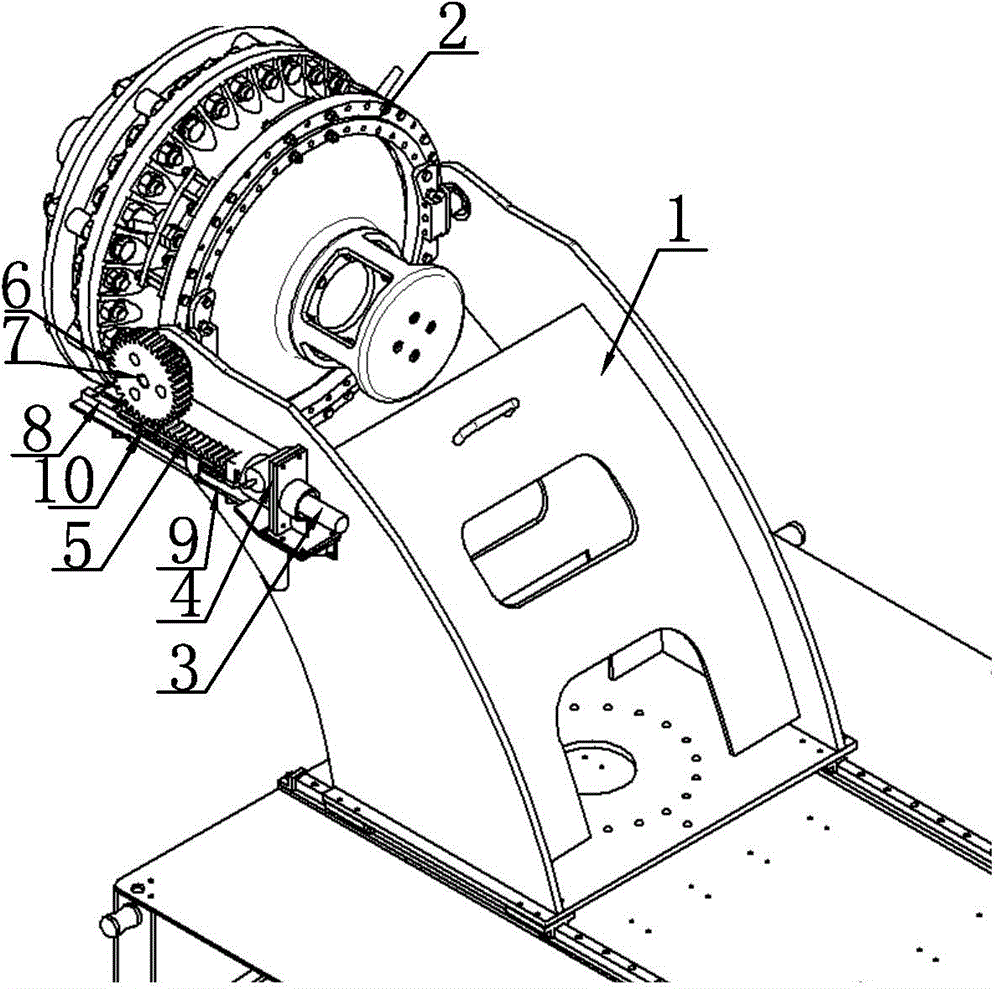

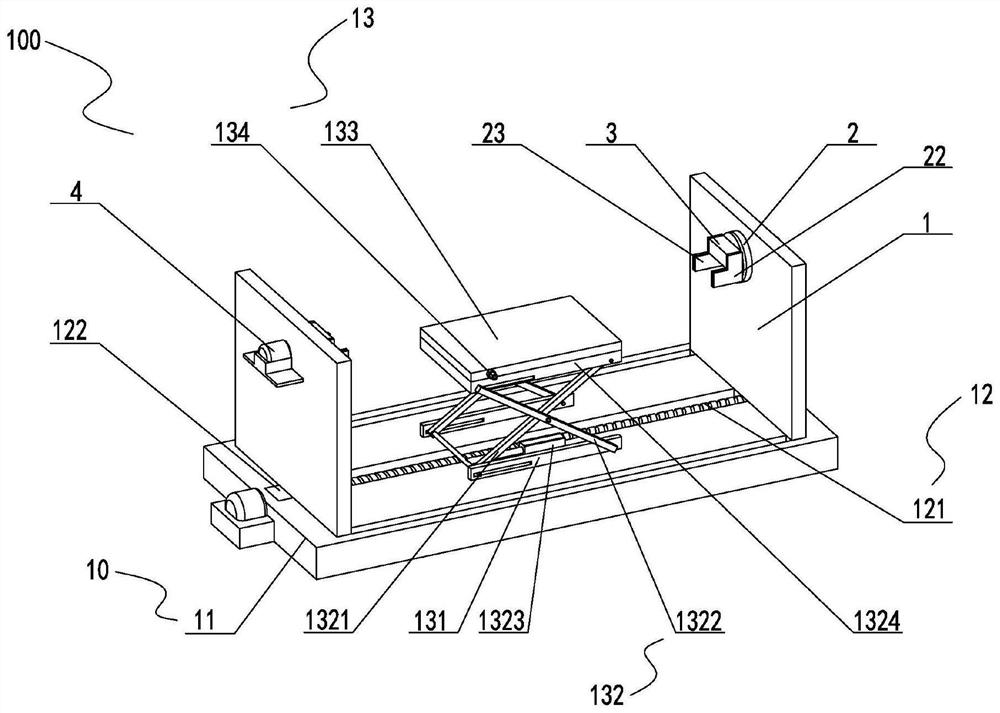

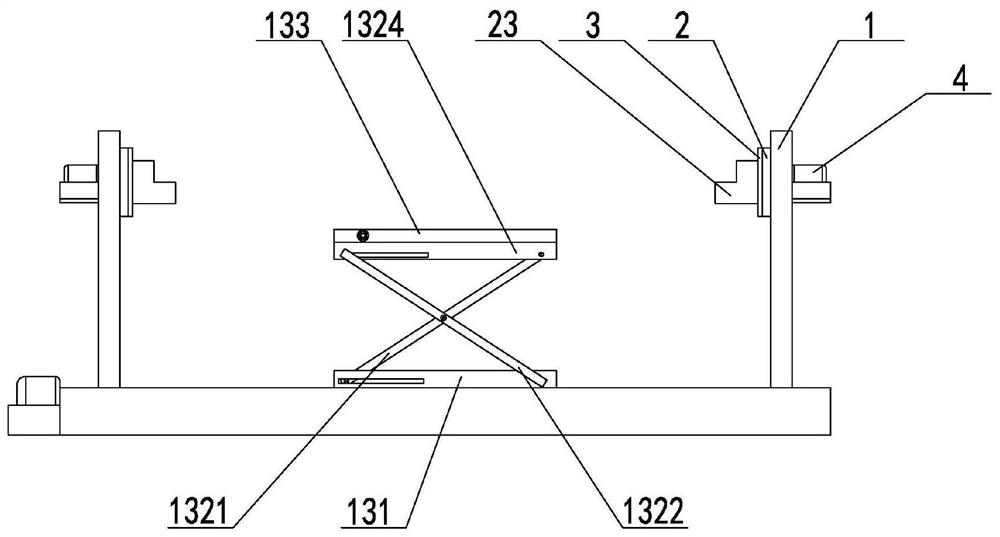

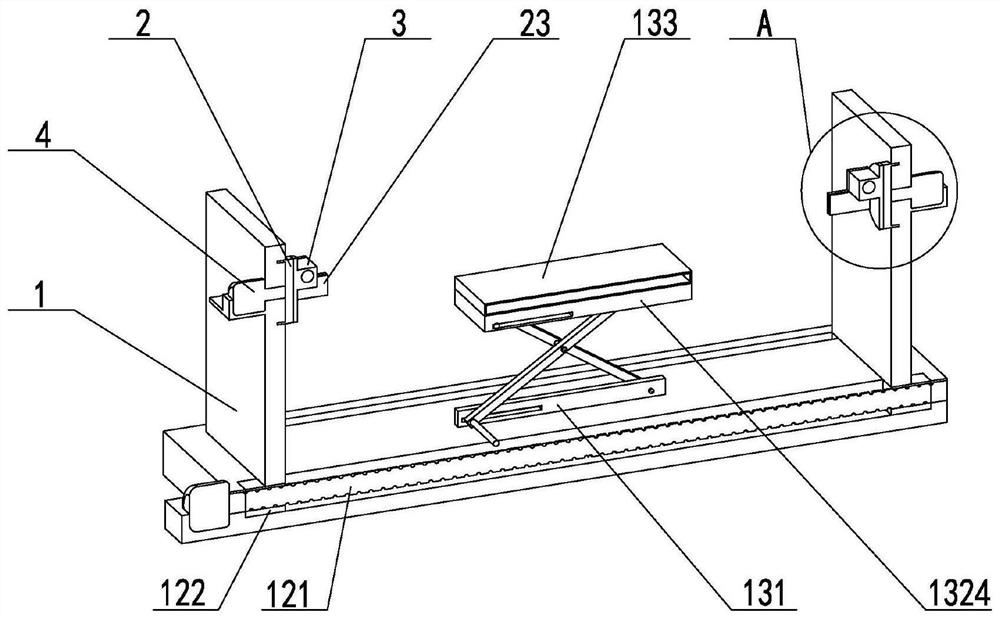

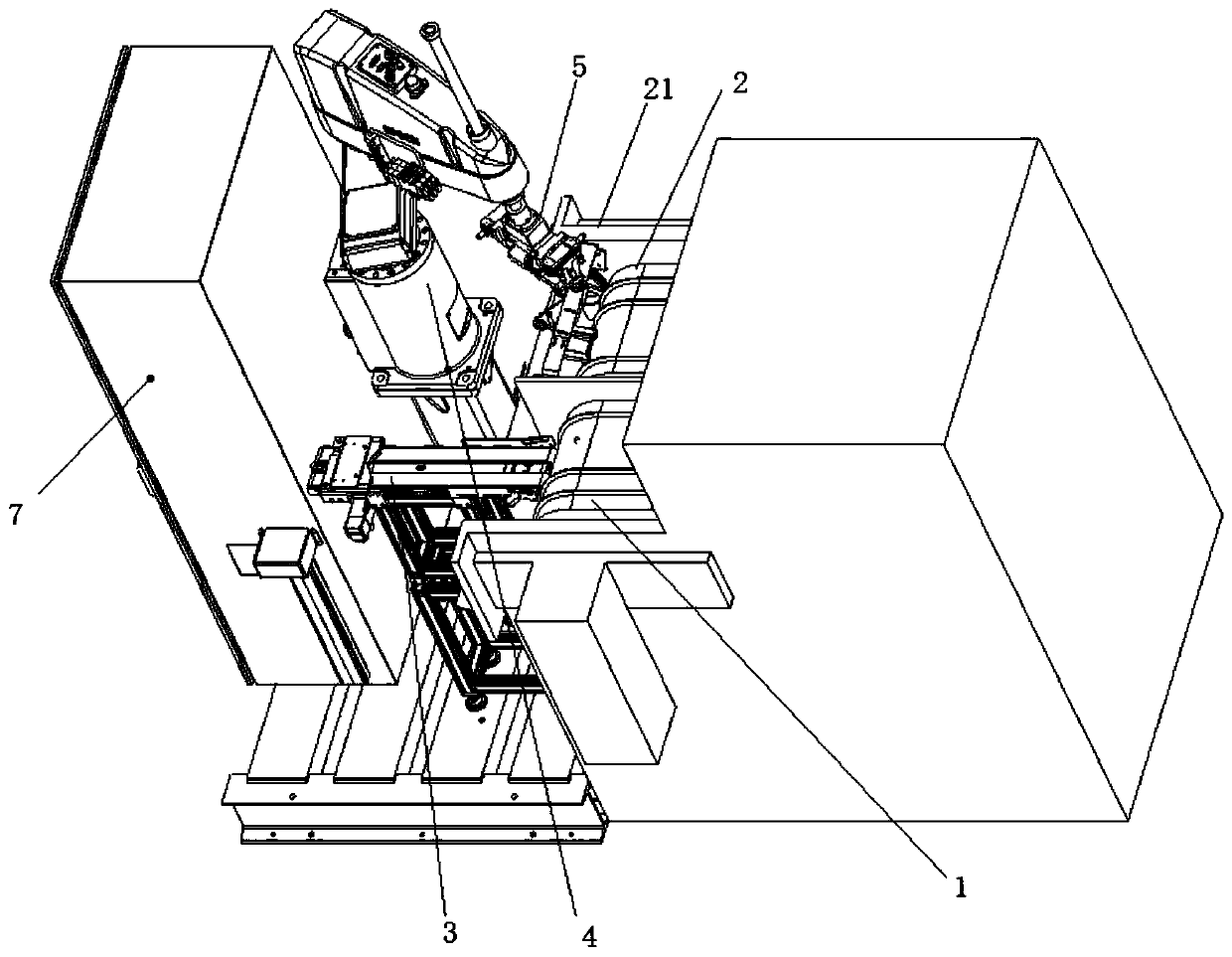

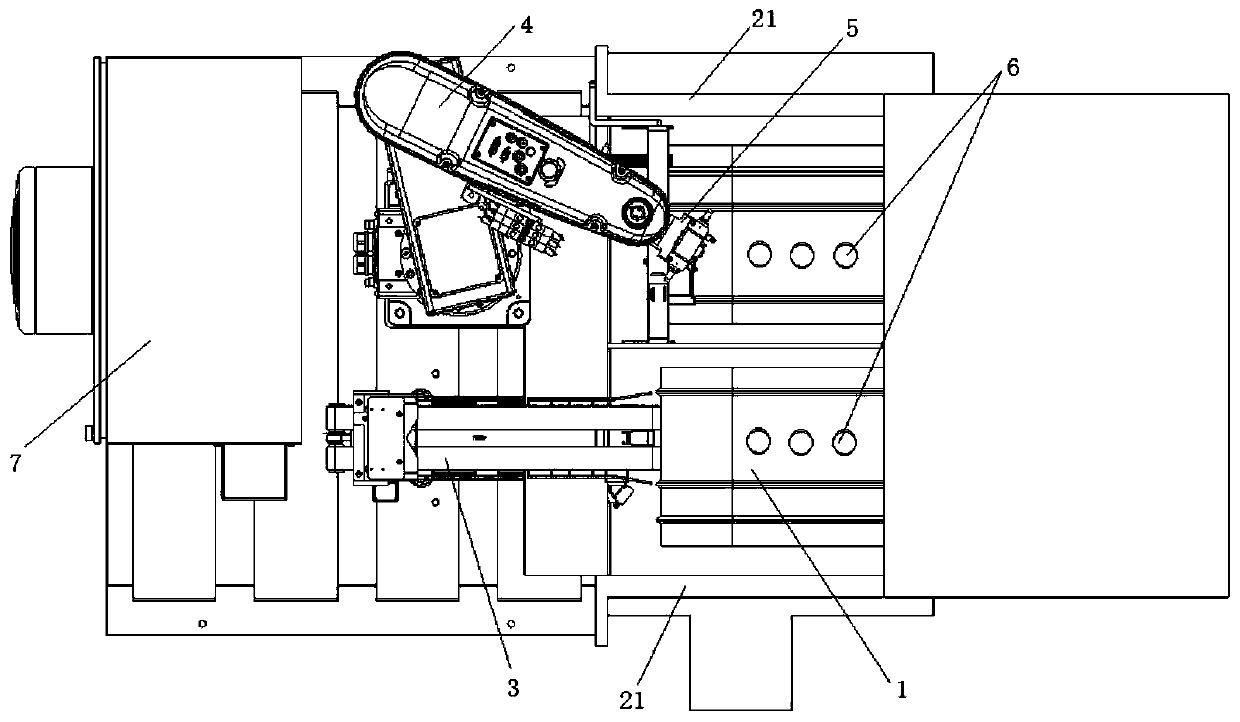

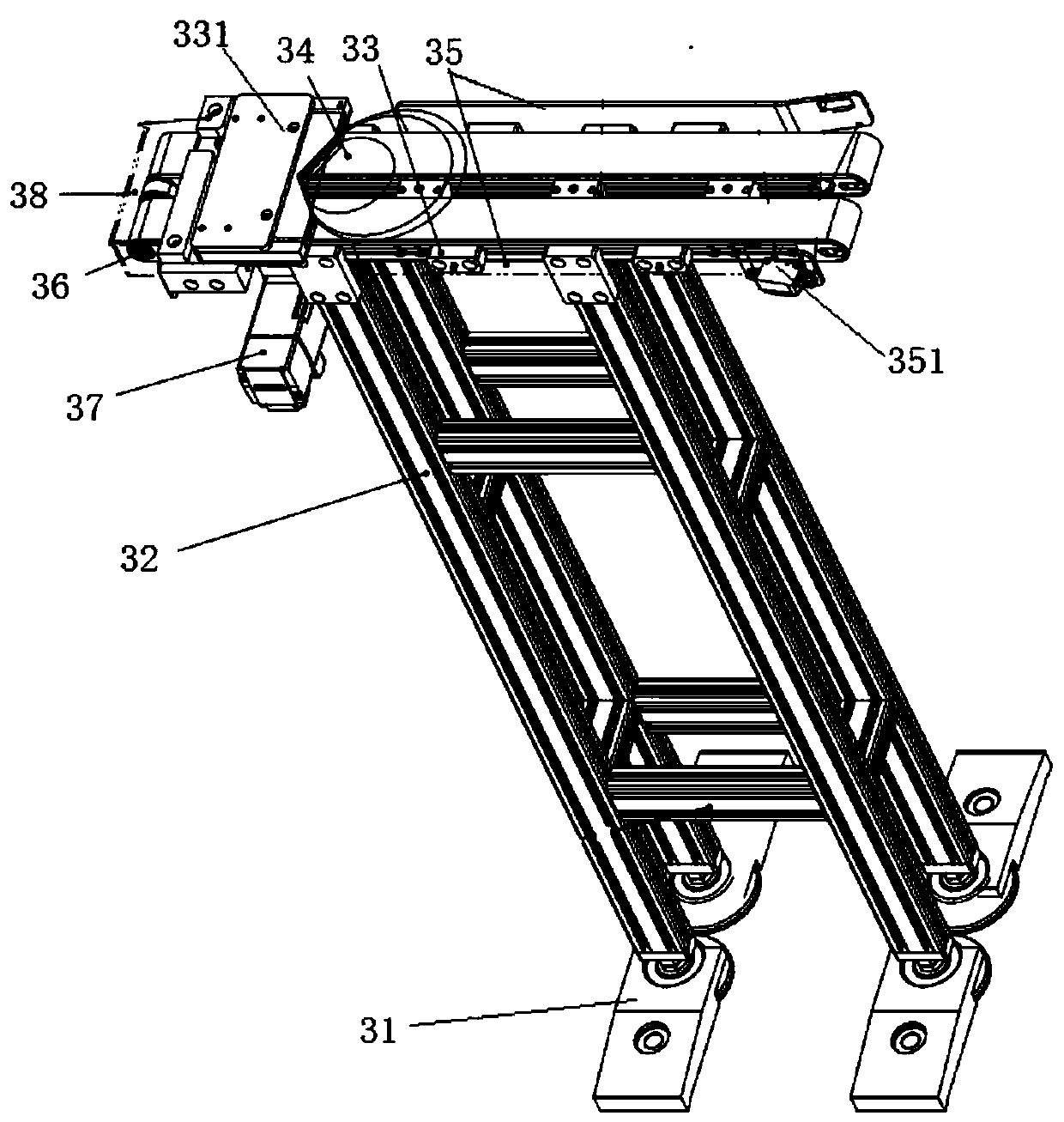

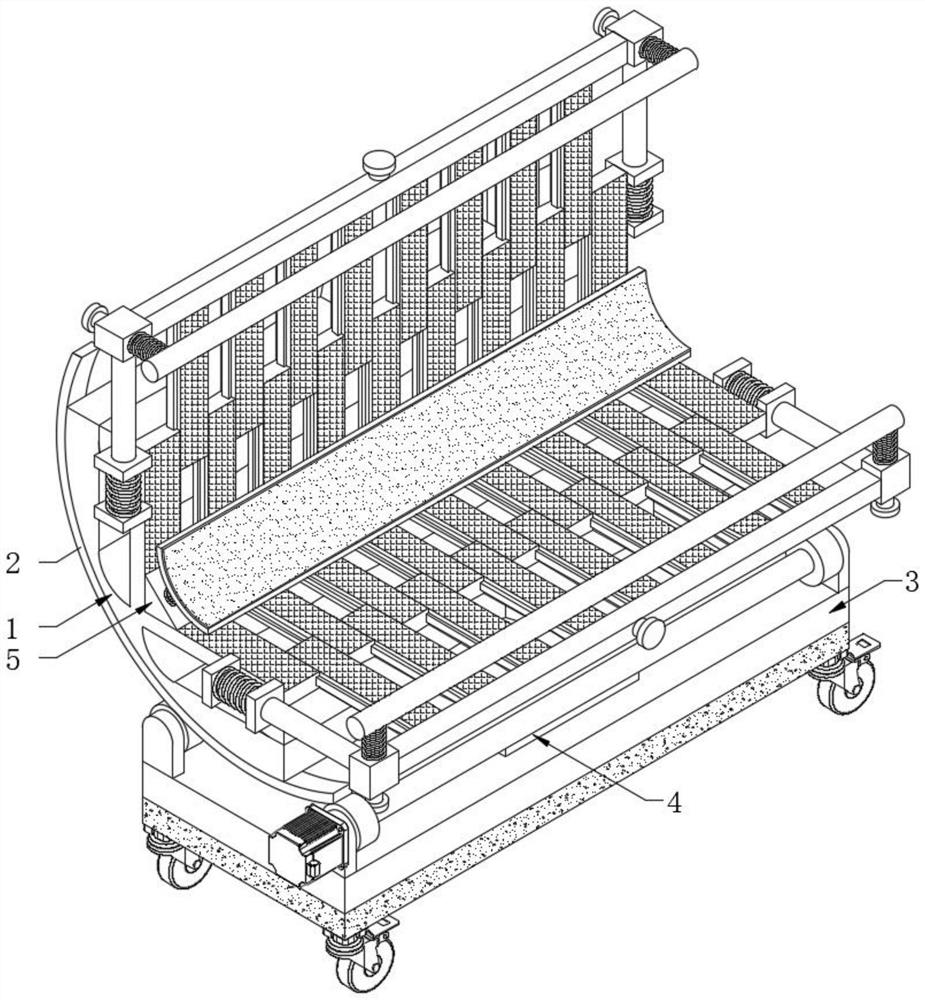

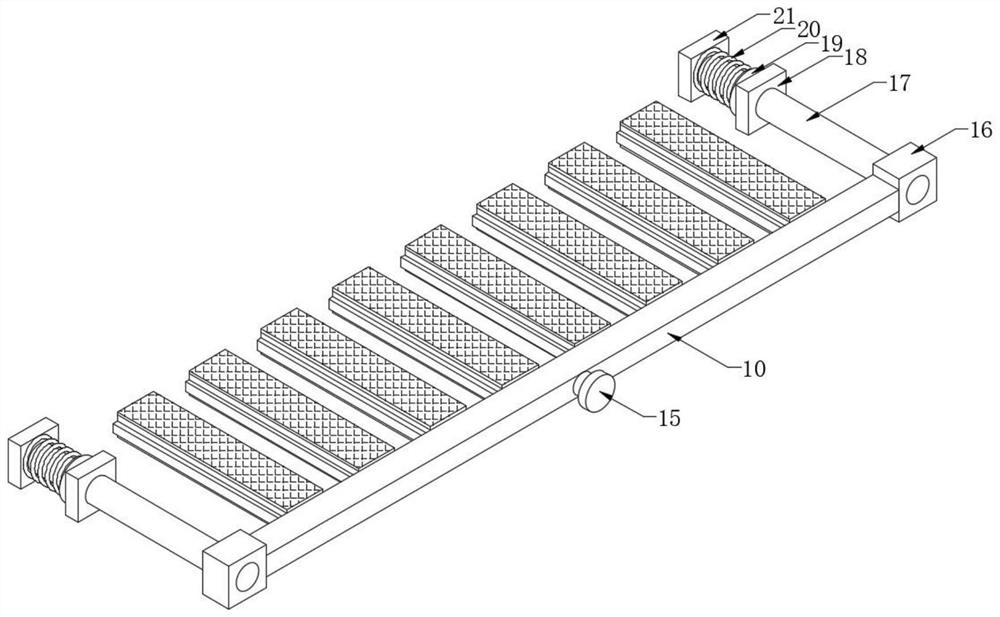

Assembling and overturning positioner

ActiveCN109759976AImplement the flip functionEasy clampingWelding/cutting auxillary devicesWork holdersMechanical engineeringEngineering

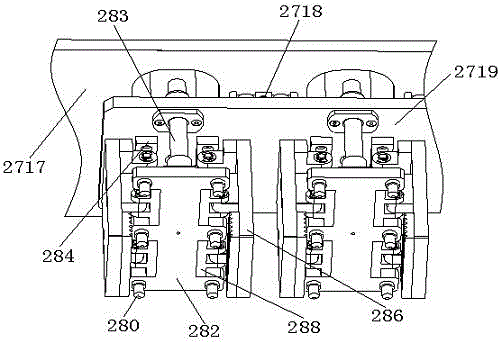

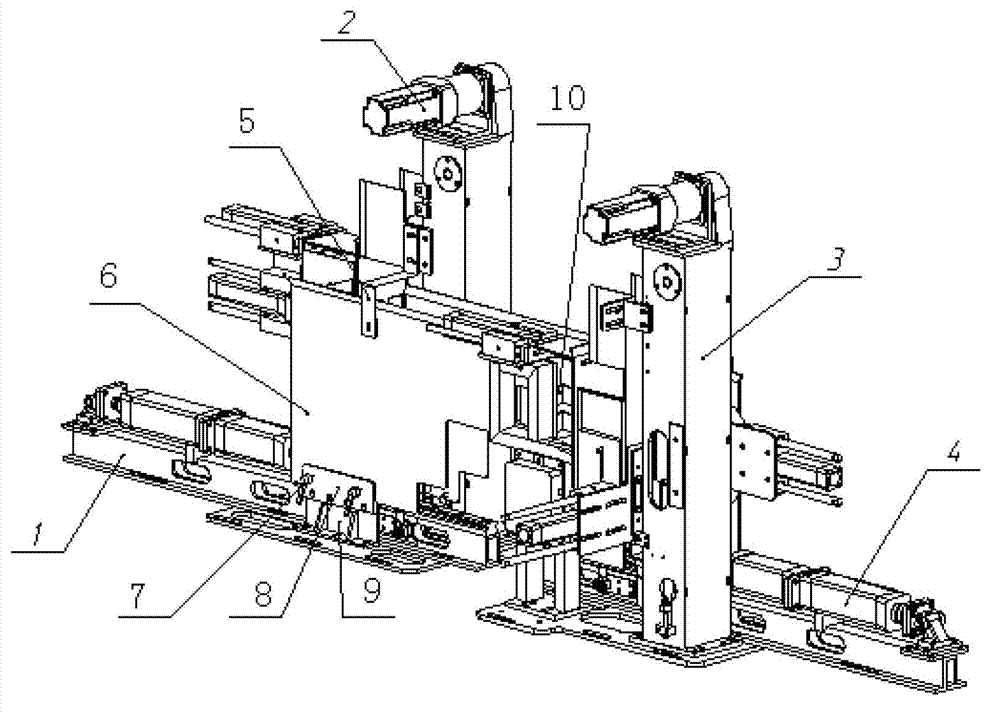

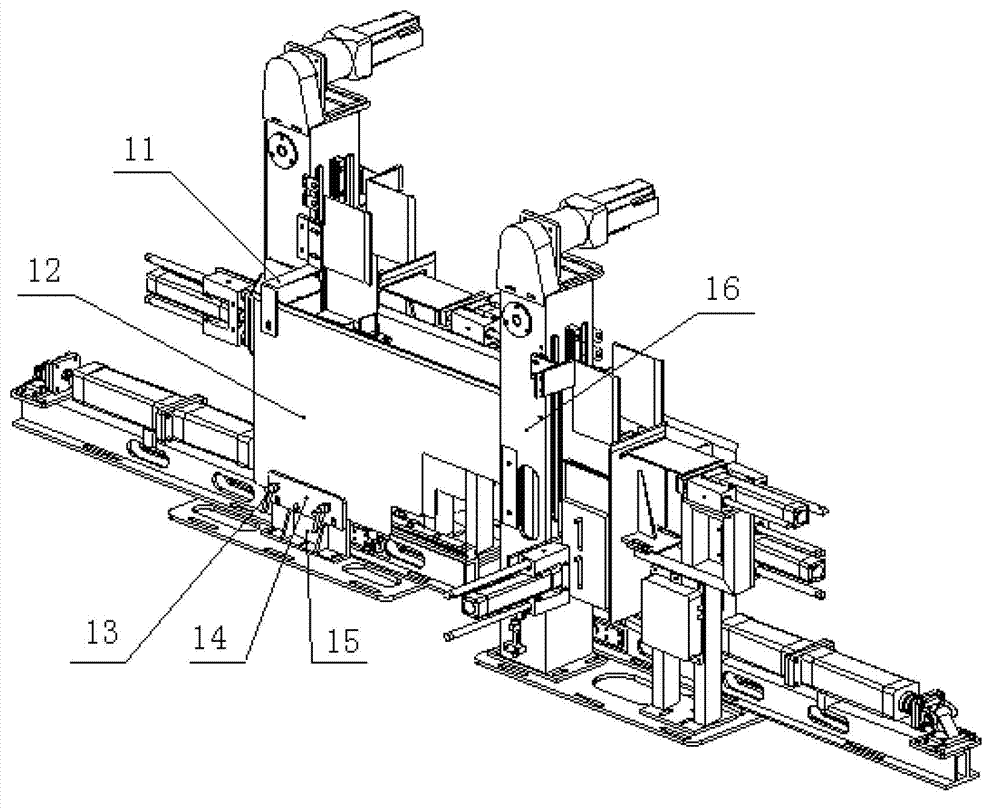

The invention discloses an assembling and overturning positioner, and relates to the technical field of workpiece assembling. The assembling and overturning positioned comprises a head frame assemblyand a tail frame assembly capable of being close to each other or away from each other, a rotating driving assembly, a rotating servo assembly, a first grabbing assembly and a second grabbing assembly, wherein one end of the rotating driving assembly is connected with the head frame assembly through a first lifting assembly, the first lifting assembly is configured to drive the rotating driving assembly to move on the head frame assembly, and the other end of the rotating driving assembly is connected with the first grabbing assembly; one end of the rotating servo assembly is connected with the tail frame assembly through a second lifting assembly, the second lifting assembly is configured to drive the rotating servo assembly to move on the tail frame assembly, and the other end of the rotating servo assembly is connected with the second grabbing assembly; and the first grabbing assembly and the second grabbing assembly are configured to grab and align the two ends of the workpiece respectively, and the rotating driving assembly and the rotating servo assembly are matched so as to drive the workpiece to rotate. The assembling and overturning positioner is high in versatility, safein operation, high in production efficiency and small in occupation of the site.

Owner:SHANTUI CONSTR MASCH CO LTD

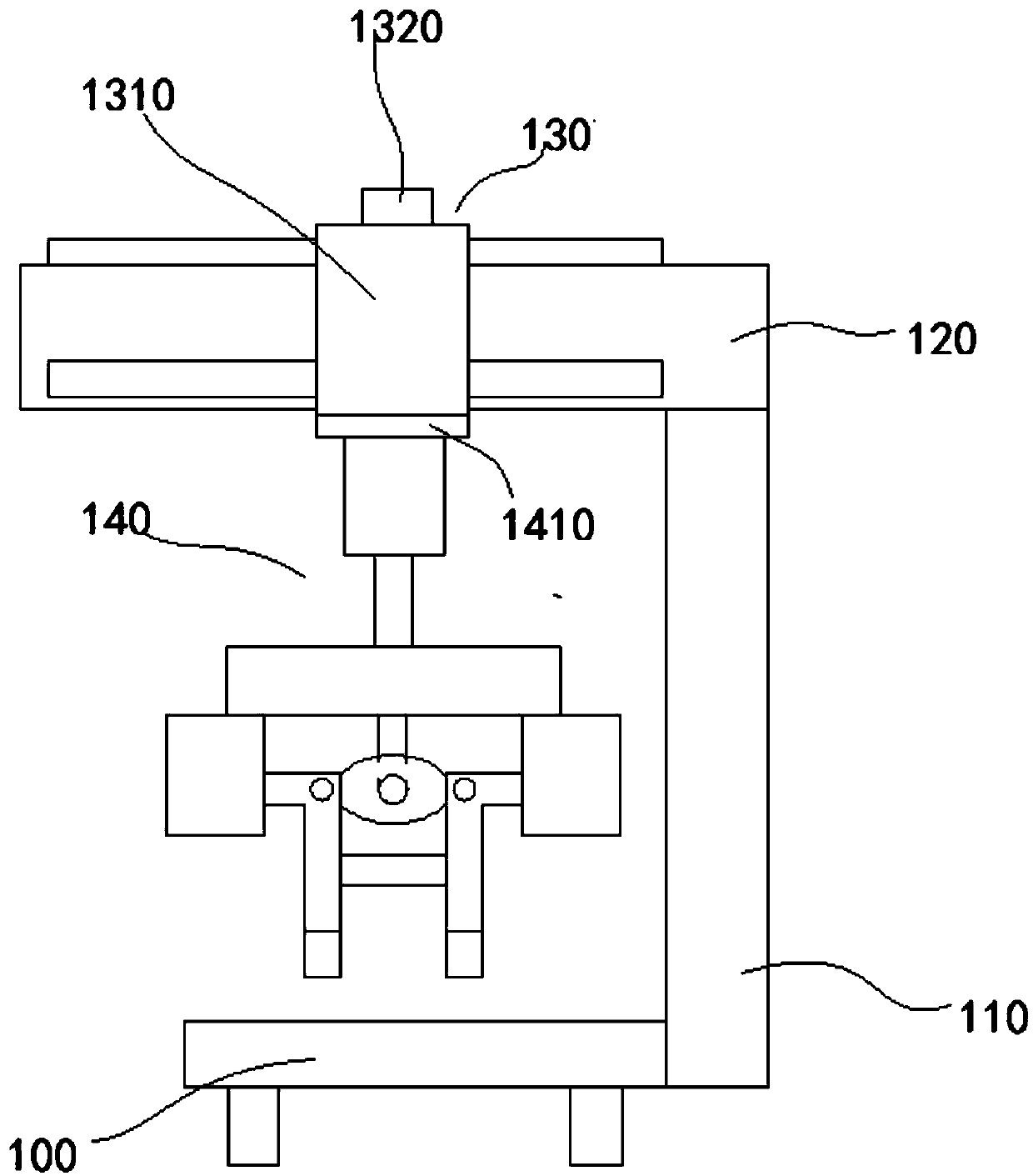

Display screen detecting mechanism

ActiveCN107271149AImplement the flip functionAvoid damageTesting optical propertiesEngineeringScreen detected

The invention discloses a display screen detecting mechanism including a bottom board, a first support, a second support, a first rotary motor, a second rotary motor, a mounting frame, a plurality of positioning boards and a plurality of fixing bolts. By arranging the first rotary motor and the second rotary motor on two ends of the mounting frame, the first rotary motor and the second rotary motor can be controlled to drive the display screen on the mounting frame to turn over, so that the turning-over function of the display screen during a detection process is realized. By arranging a transverse first positioning board and a transverse second positioning board and a vertical third positioning board and a vertical fourth positioning board on the mounting frame, the positions of the positioning boards are adjusted for display screens of different sizes and the positioning boards are finally locked with fixing bolts. Therefore, the display screen clamping operation is implemented. The detecting mechanism is applicable to display screens of different specifications. By mounting rubber pads on the positioning boards, a cushion effect can be achieved during display clamping and damage to the display screens during the clamping process is avoided.

Owner:ACCU JIANGSU CO LTD

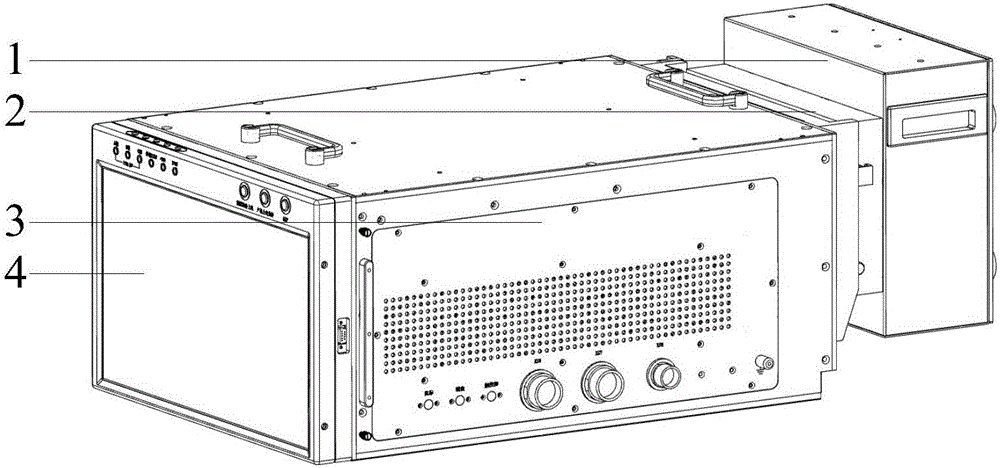

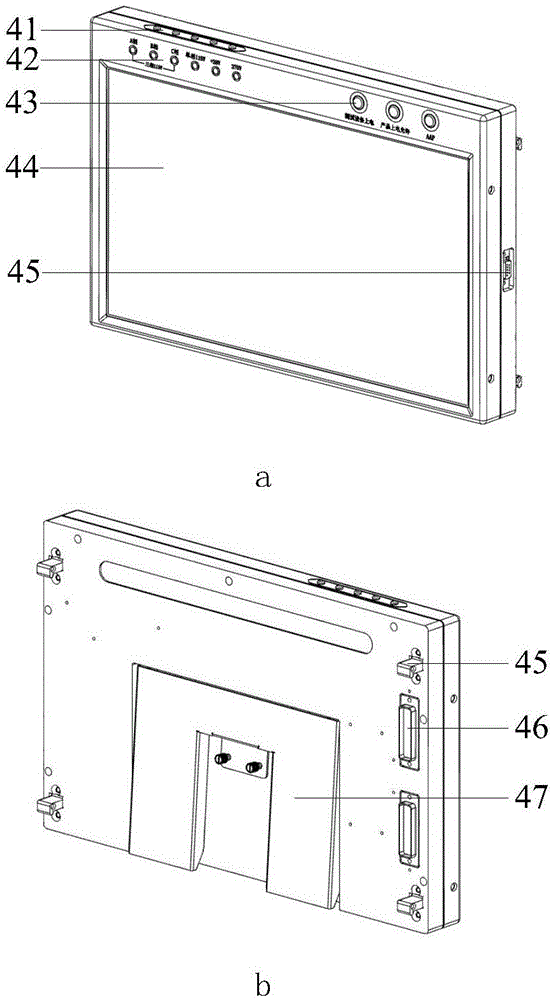

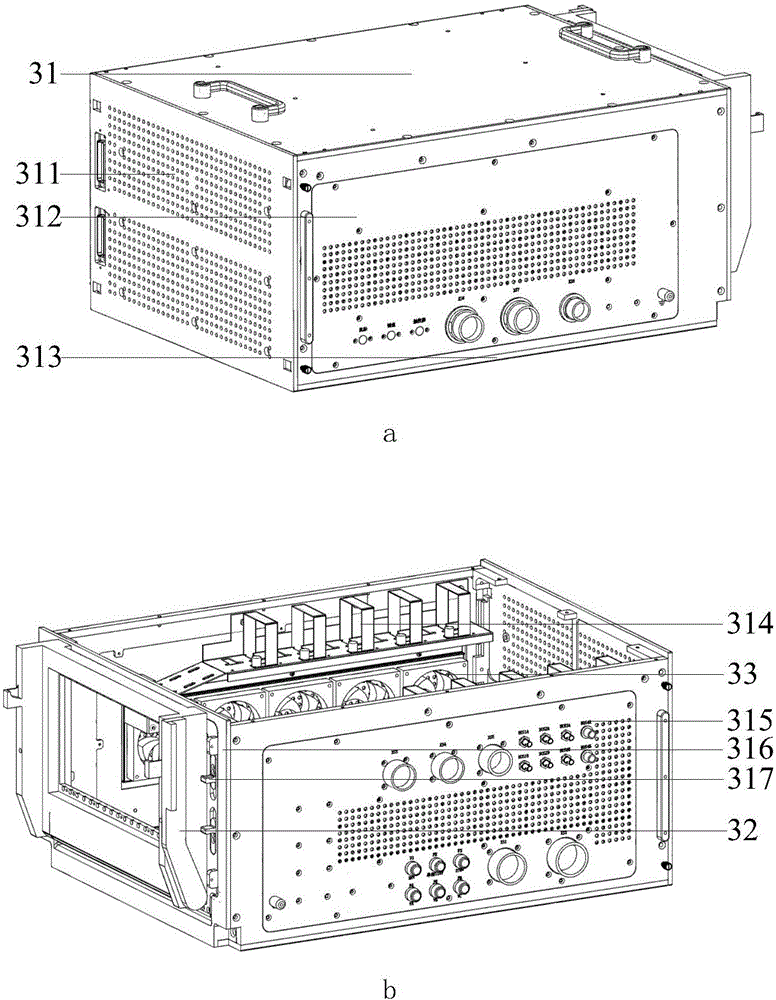

General tester for testing different types of aviation products

ActiveCN106645812AImprove convenienceEase of line maintenanceElectrical testingMeasurement instrument housingComputer caseHinge angle

The invention relates to a general tester for testing different types of aviation products. The tester is composed of a detachable touch control display screen, a test cabinet, a mass interconnection device and an adapter. A hard connector in the back of the detachable touch control display screen is connected with a hard connector of a cabinet part, the cabinet part is connected and fixed via L-shaped buckles and quickly-detached screws, and after that the quickly-detached screws are opened and the display screen is dismounted, the display screen can be moved by only connecting a switching cable of the display screen and the cabinet part. When the adapter is connected to the test cabinet via the mass interconnection device and all cables are connected, the different types of products can be tested. The cabinet part is modularized in design, different panels can be mounted and dismounted rapidly, the rear panel is provided with a overturn panel, and an overturning function can be realized by connecting the rear panel and the overturn panel via a rotating shaft. The adapter installing handle is placed transversely, and the front panel of the adapter is connected to a frame via hinges to realize the overturning function.

Owner:中航洛阳光电技术有限公司

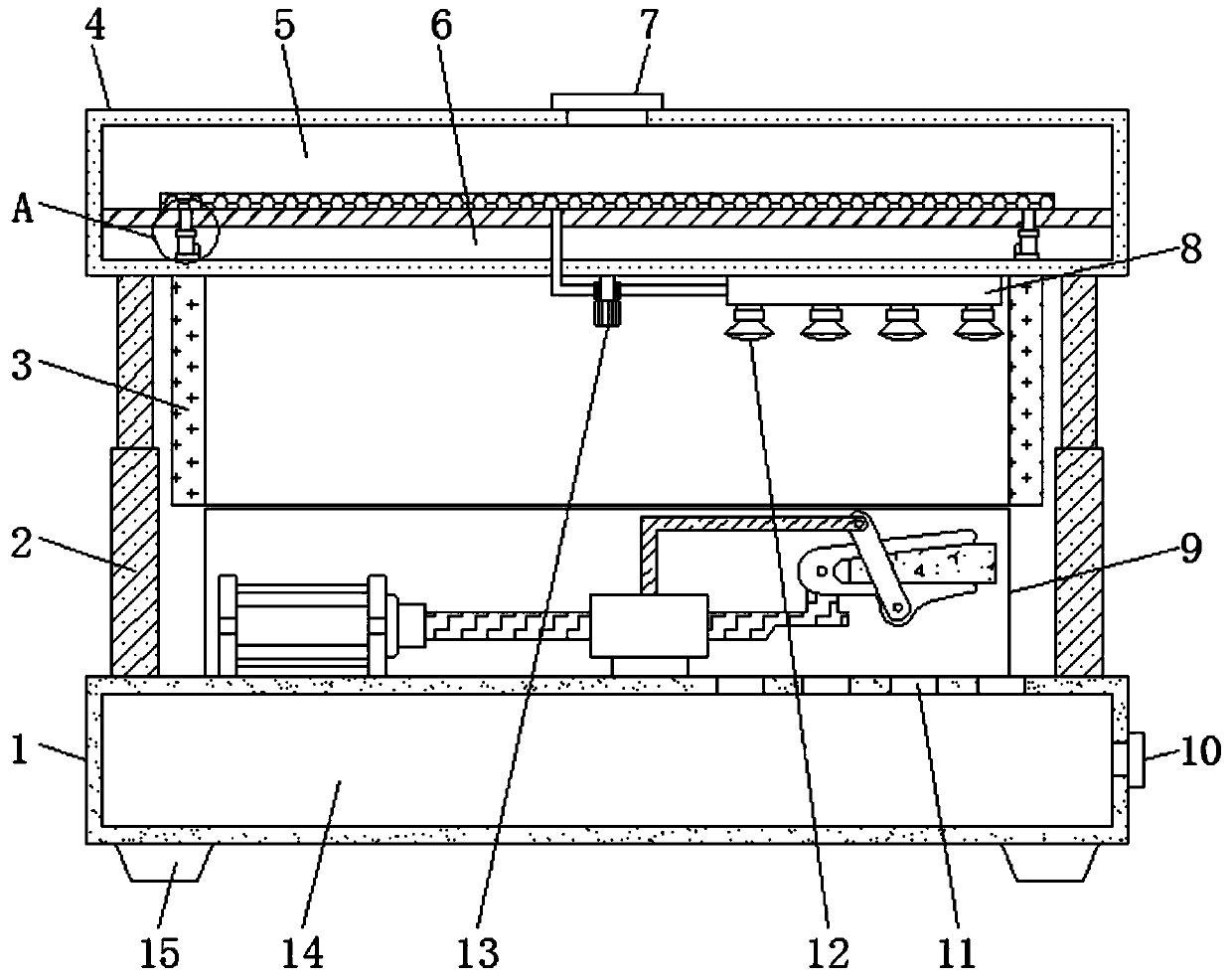

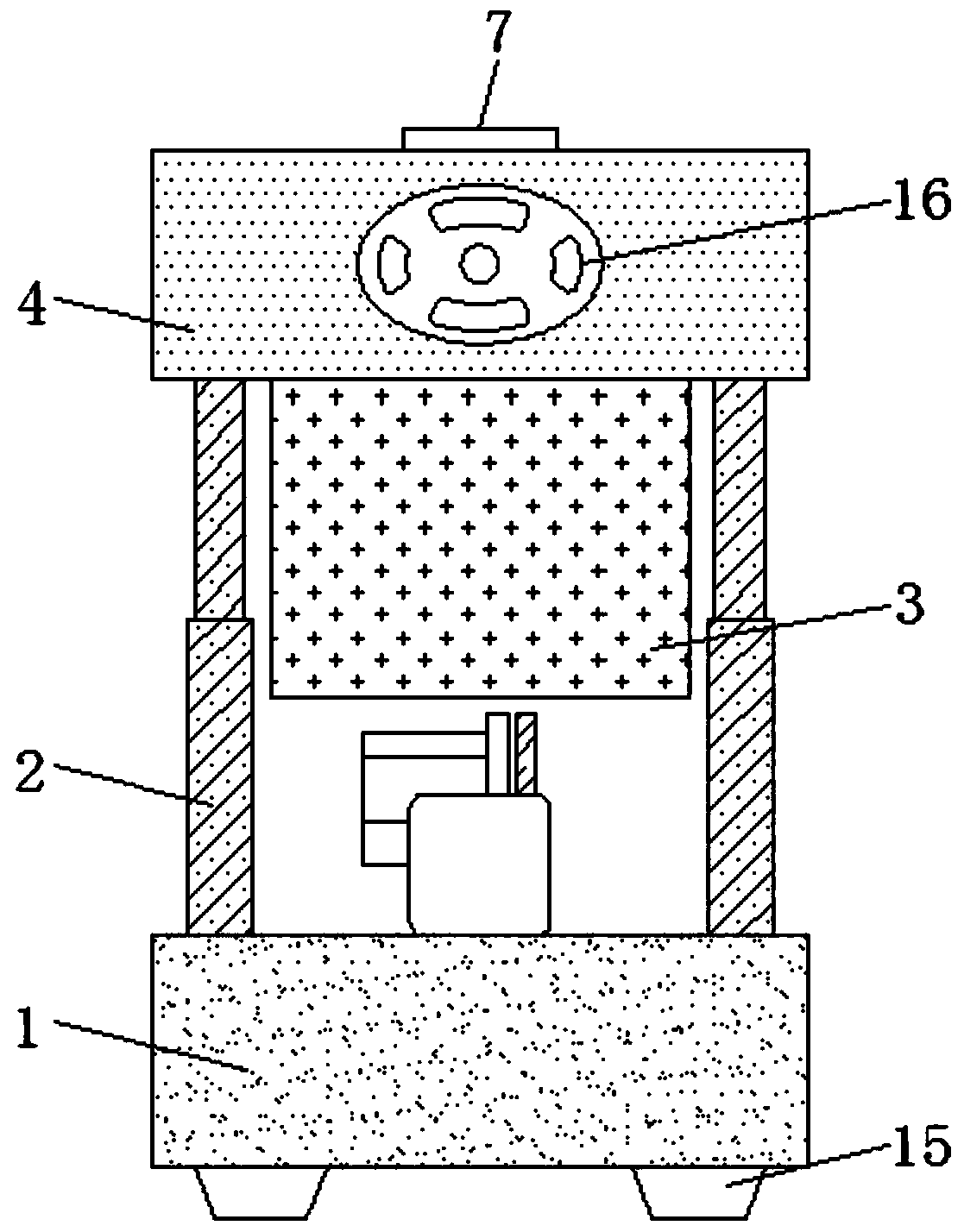

Overturning mechanism used for conducting picture inspection on liquid crystal panel

ActiveCN104176528AImplement the flip functionRealize reciprocating motionOverturning articlesLiquid-crystal displayEngineering

The invention discloses an overturning mechanism used for conducting picture inspection on a liquid crystal panel. The overturning mechanism comprises a light box, a light box base fixedly arranged at the bottom of the light box and a support frame arranged under the light box base, wherein one side at the top of the support frame is fixedly connected with a support shaft through a bearing; the middle at the bottom of the light box base is fixedly connected with the support shaft through the bearing; a buffering device is fixedly arranged on the other side at the top of the support frame; a power device is fixedly arranged in the support frame; a connecting rod device is arranged and is connected with the power device and one side of the light box base; the light box is supported by the connecting rod device, the support shaft and the buffering device jointly; the power device can drive the connecting rod device, and drive the light box to rotate repeatedly by a set angle surrounding the support shaft to enable the light box to divorce from and contact with the buffering device. According to the invention, required capacity to fulfill overturning motion is relatively low; required time to fulfill the overturning motion is relatively short; the overturning angle required by the overturning mechanism can be realized; the work efficiency is improved.

Owner:SUZHOU JINGLAI OPTO CO LTD

Automatic production line based on intelligent industrial robot

ActiveCN109625915ASmooth and easy movementRealize handlingConveyor partsProduction lineIndustrial engineering

The invention relates to the technical field of production lines, in particular to an automatic production line based on an intelligent industrial robot. The automatic production line comprises a production line body, wherein the production line body is equipped with a carrying mechanism; the carrying mechanism is equipped with an assembly clamping mechanism; the carrying mechanism comprises a conveying table; the right side part of the conveying table is equipped with a supporting post; the top end of the supporting post is equipped with a beam; a first movable device can be arranged on the beam in a left-right sliding mode; a carrying mechanism is arranged below the first movable device; the assembly clamping mechanism comprises a clamp body; the clamp body comprises a first clamp mounting plate, a baffle plate is arranged at one side of the top end surface of the clamp mounting plate, the middle part of the clamp mounting plate is downs sunken to form a mounting slot; a first clamping plate capable of sliding left and right is arranged in the mounting slot; and a second clamping plate capable of turning over is arranged at the inner side of the baffle plate. The automatic production line is simple in structure, is low in manufacturing cost, is good in stability in a carrying process, can automatically regulate according to different workpieces, guarantees assembly quality and improves assembly efficiency.

Owner:义乌市丹航科技有限公司

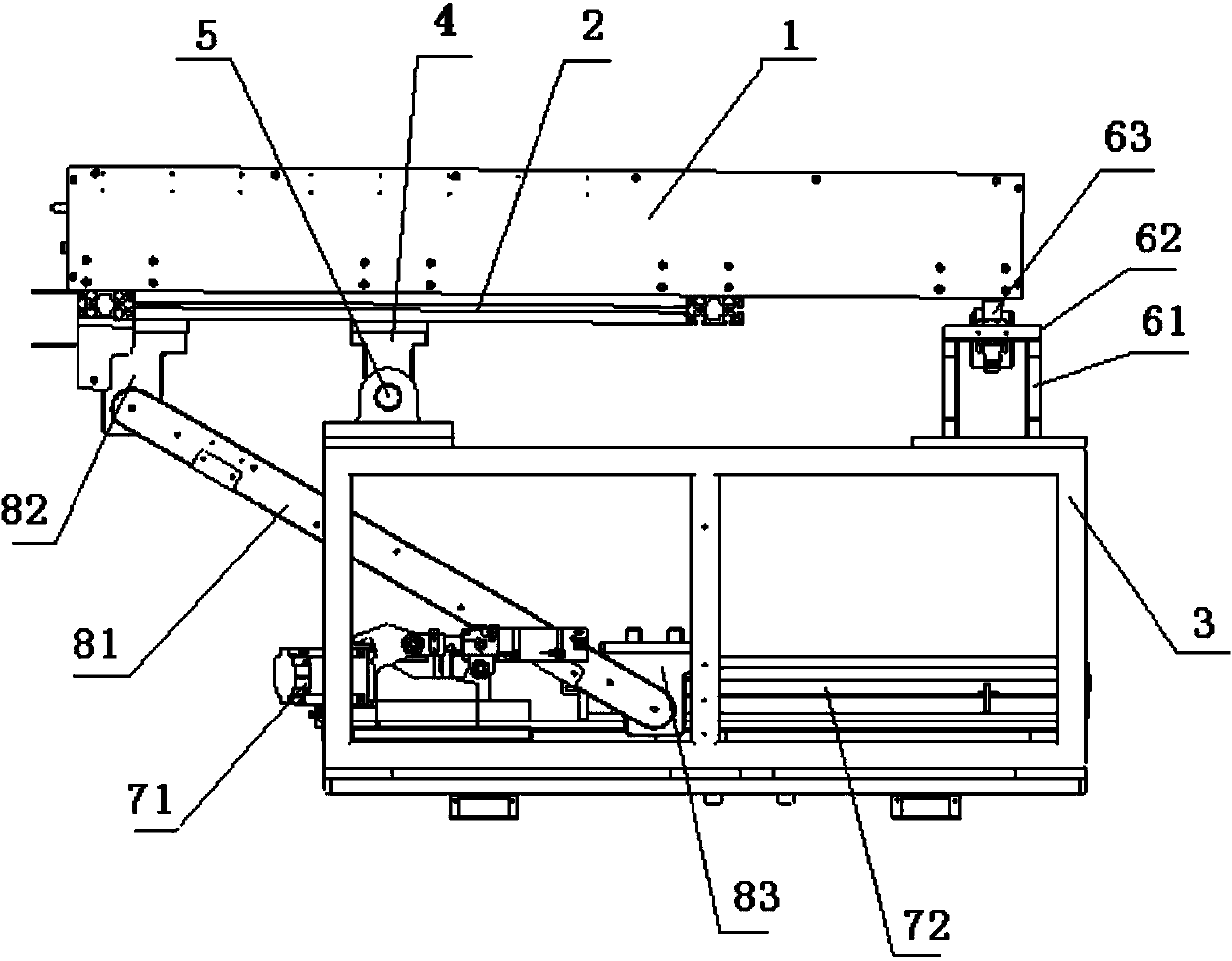

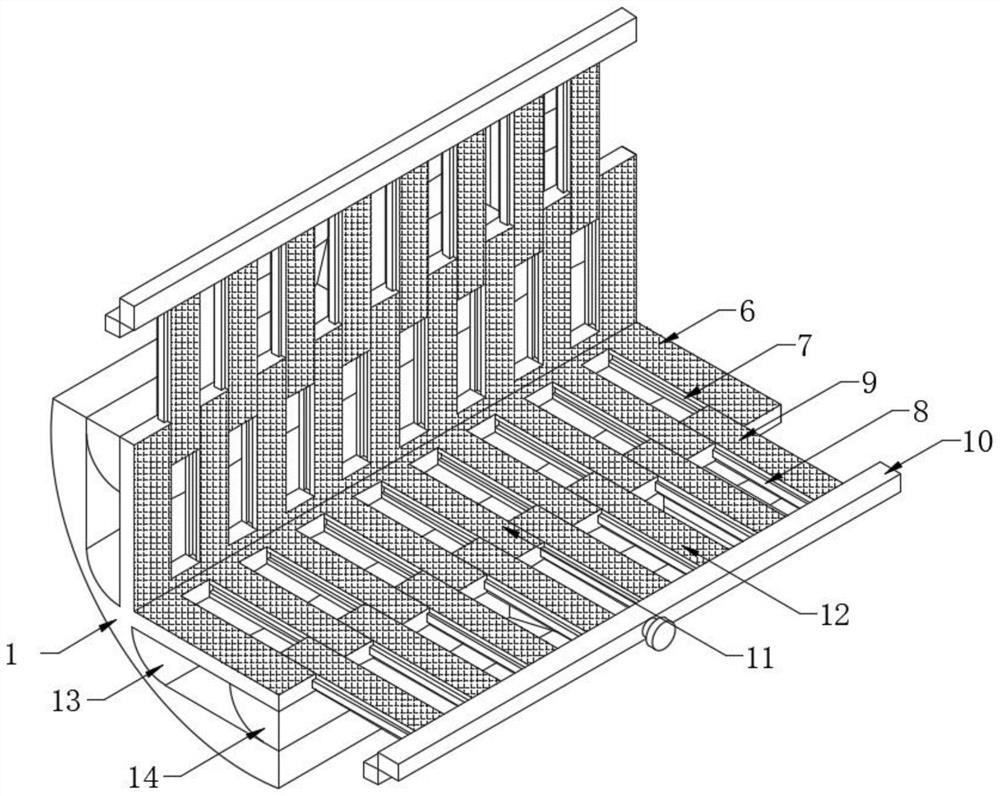

Automatic stacking machine for C-shaped steel and Z-shaped steel

PendingCN113148672AIncrease the scope of applicationImprove work efficiencyStacking articlesDe-stacking articlesPhysicsElectric machinery

The invention discloses an automatic stacking machine for C-shaped steel, Z-shaped steel and steel bar truss plates, and relates to the technical field of C-shaped steel stacks, Z-shaped steel stacks and steel bar truss plate stacks. The automatic stacking machine specifically comprises a main frame and a conveying frame. The main frame is formed by welding rectangular pipes. The conveying frame is fixedly installed at the bottom of the main frame, and conveying carrier rollers are arranged on the surface of the conveying frame. The conveying frame further comprises a first turnover arm, a second turnover shaft and a second turnover arm, wherein the first turnover arm is mounted on the surface of a first turnover shaft in a sleeving connection manner; the second turnover shaft is connected to the side face of a second turnover motor; and the second turnover arm is connected to the outer wall of the first turnover shaft in a sleeving manner. According to the automatic stacking machine for the C-shaped steel and the Z-shaped steel, the C-shaped steel, the Z-shaped steel, columnar profiles and steel bar truss plates can be clamped and turned over, the application range of the automatic stacking machine is widened, meanwhile, the profiles can be stacked in order, and therefore the manual turnover and stacking mode is replaced, the working efficiency is improved easily, the stacking uniformity is improved, and the automatic stacking machine solves the problems about industrial automation and recruitment difficulty for production enterprises, and achieves the aim of people substitution with machines.

Owner:辽宁鑫硕智能机械有限公司

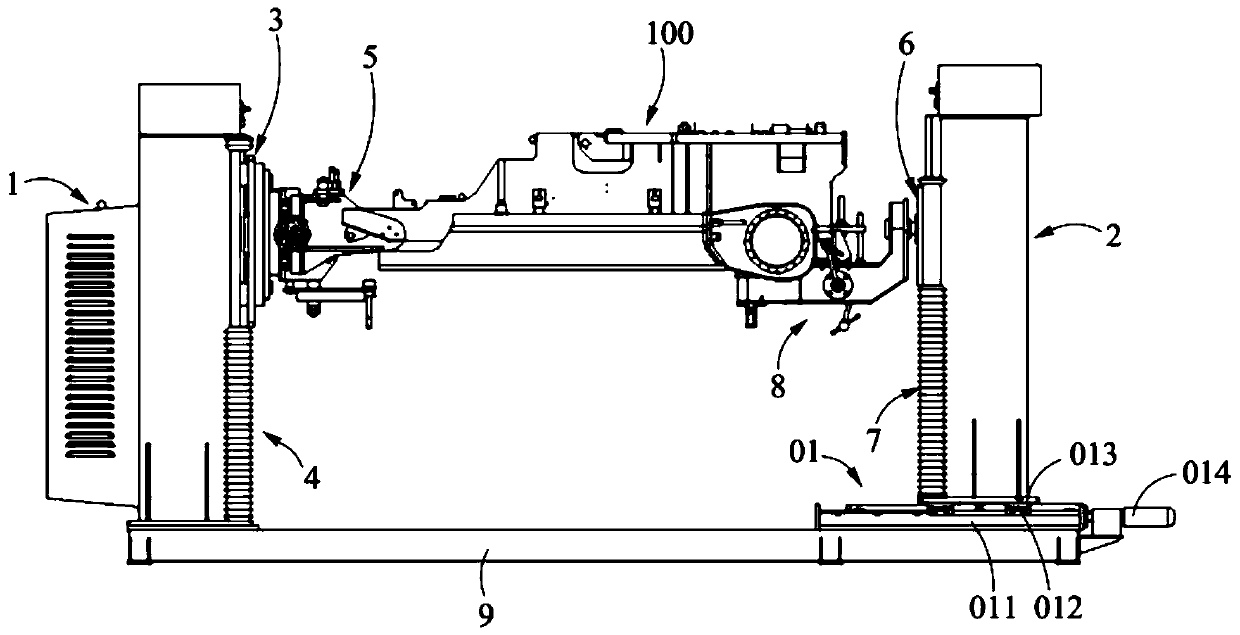

Continuous foaming aluminum automatic production line

InactiveCN107096910AIncrease productivityReduce demandMolten metal conveying equipmentsEngineeringProduction line

The invention relates to a continuous foaming aluminum automatic production line comprising a rotating part, a pretreatment part, a pouring part and a discharging part. The rotating part comprises a rotating mechanism used for driving a material receiving mould to conduct rotating motion, and a clamping block is arranged on the outer side edge of the material receiving mould; the pretreatment part is arranged on the rotating track of the material receiving mould and comprises a spraying mechanism and a turnover preheating mechanism; the pouring part is arranged on the rotating track of the material receiving mould and comprises a pouring device used for pouring foaming aluminum into the material receiving mould; and the discharging part is arranged on the rotating track of the material receiving mould and at the rear end of the pouring device and comprises a turnover device a. The problems that the discharging efficiency of the foaming aluminum is low, continuous automatic discharging and conducting of release agent automatic spraying on the material receiving mould in the operation process are not achieved are overcome.

Owner:CHANGXING CAZENOVE FUNANCE IND CO LTD

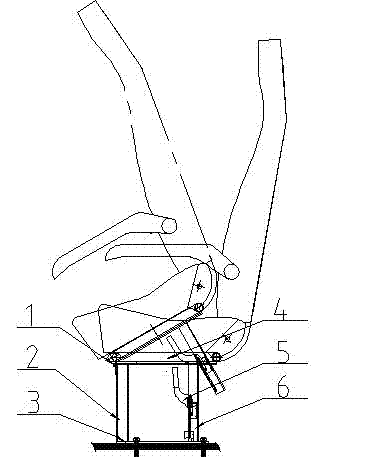

Automobile turnover seat

InactiveCN102529755AImprove connection strengthReduce passenger casualtiesMovable seatsSTI OutpatientCushion

The invention provides an automobile turnover seat, belongs to the technical field of automobile seats, and is mainly used for solving the problems that the common passenger seats cannot turn over or do not have enough space after the seats are turned over, which cause serious injuries to the passengers (elementary school students) in the automobile in case of an emergency. The automobile turnover seat is mainly characterized by comprising a seat cushion, a seat framework, a front seat leg, a back seat leg and a mounting bottom plate, wherein the seat framework is permanently connected with the back seat leg; the front seat leg is permanently connected with the mounting bottom plate; the seat framework and the front seat leg are permanently connected through a turnover hinge on the top of the seat legs; the back seat leg and the mounting bottom plate are connected through a rapid clamp arranged on the back seat leg and a barb arranged on the bottom plate, thus the strength of the connection between the seat and the automobile body floor is enhanced; meanwhile, the back rest and the seat framework are in bolted connection and are of a non-turnover structure, thus the shock resistance capability of the seat in the front and back directions can be improved. The automobile turnover seat provided by the invention has the characteristics of simple structure, convenience for use and low cost and is mainly used for the turnover seats of automobiles (passenger cars).

Owner:DONGFENG XIANGYANG TOURING CAR

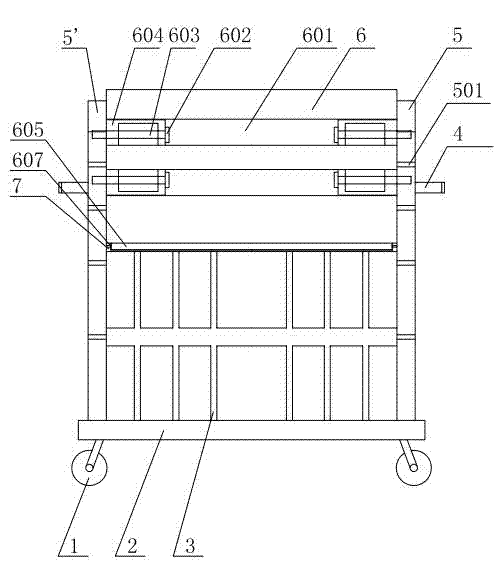

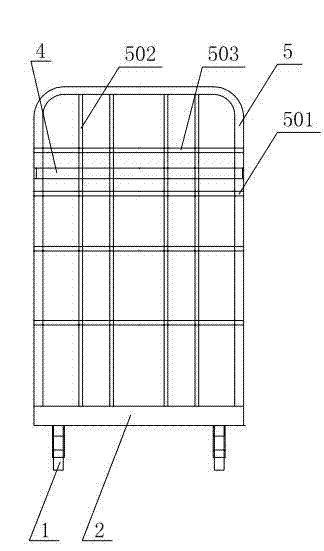

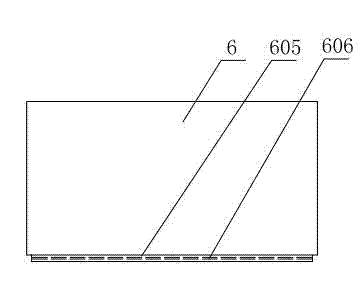

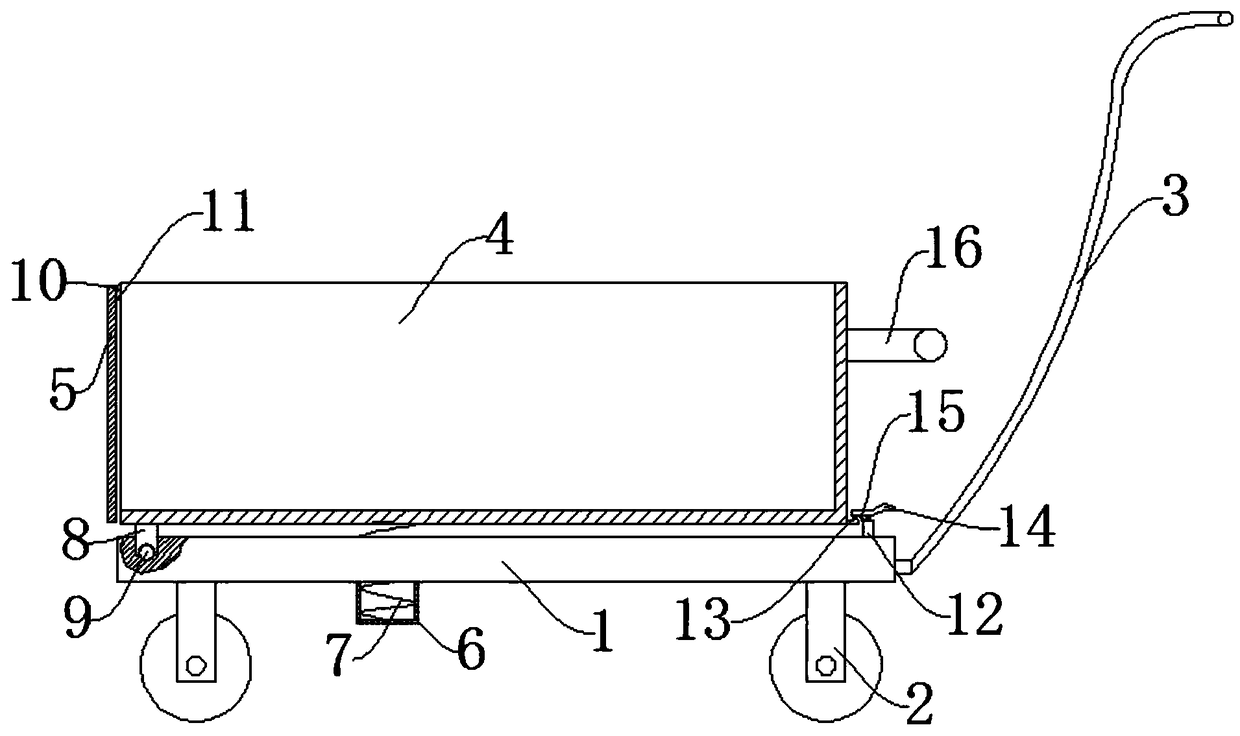

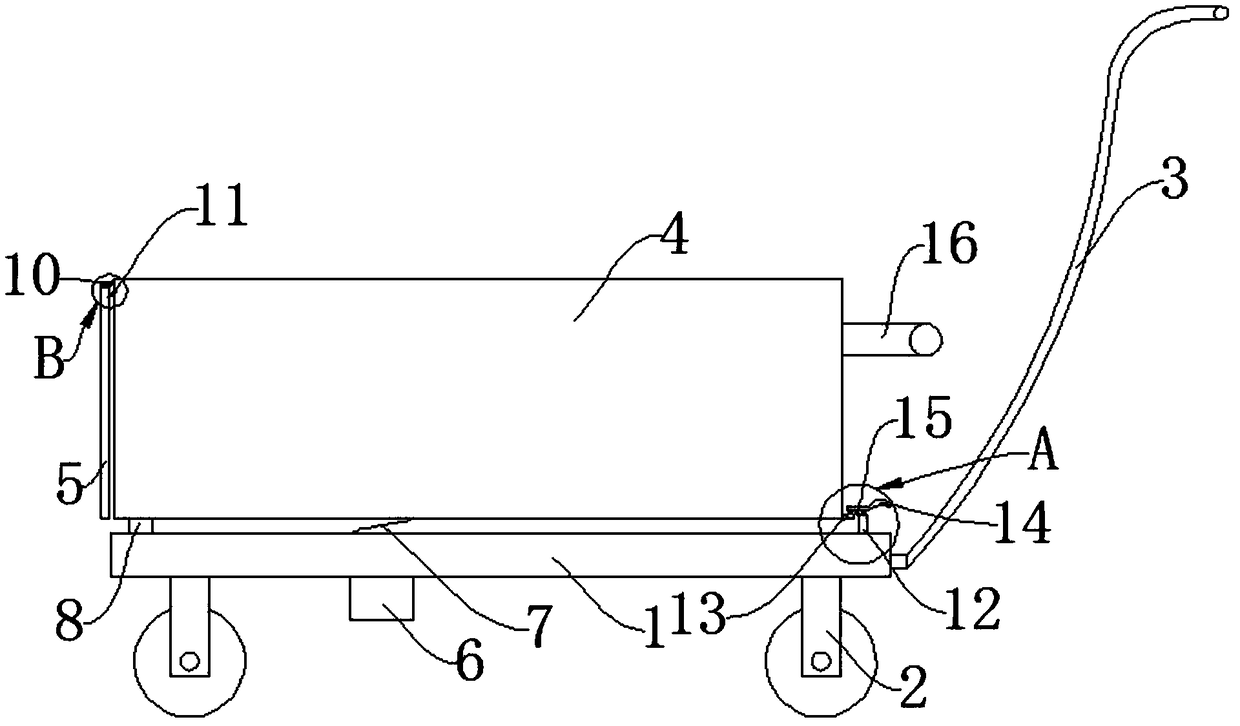

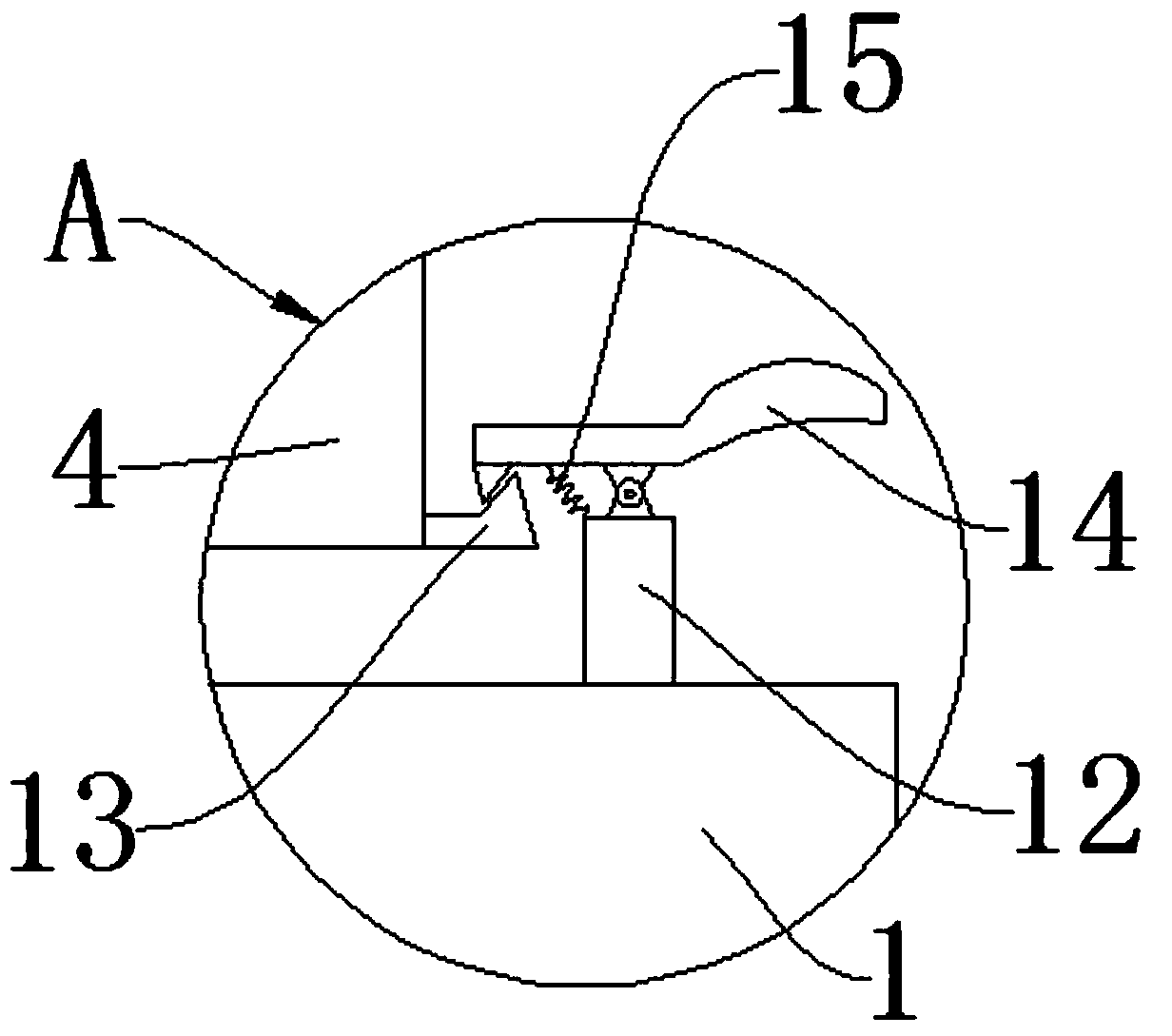

Folding type table trolley

InactiveCN102963404AImplement the flip functionExtend your lifeHand carts with multiple axesAgricultural engineering

Owner:WUXI JIESI LOGISTICS EQUIP

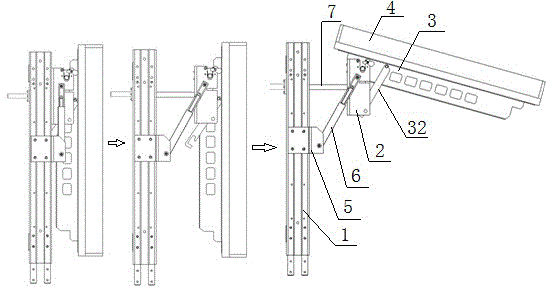

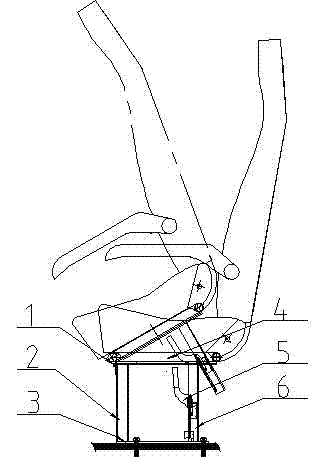

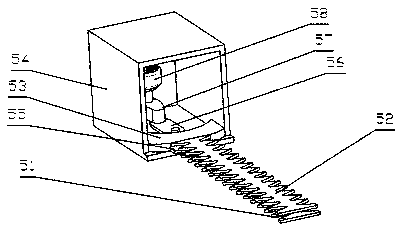

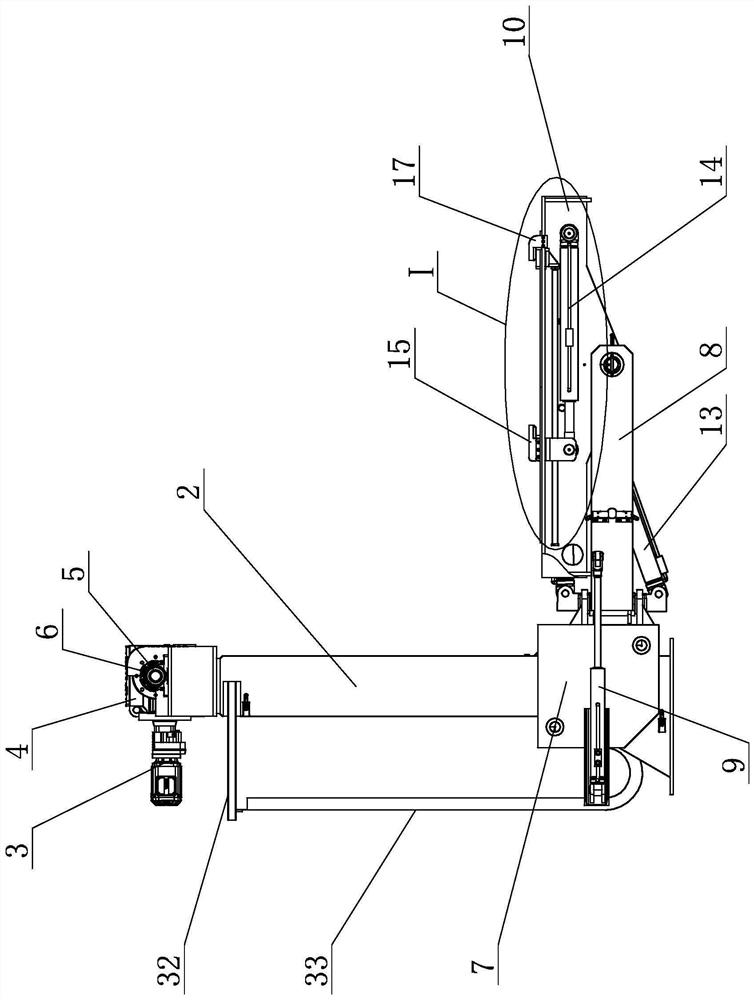

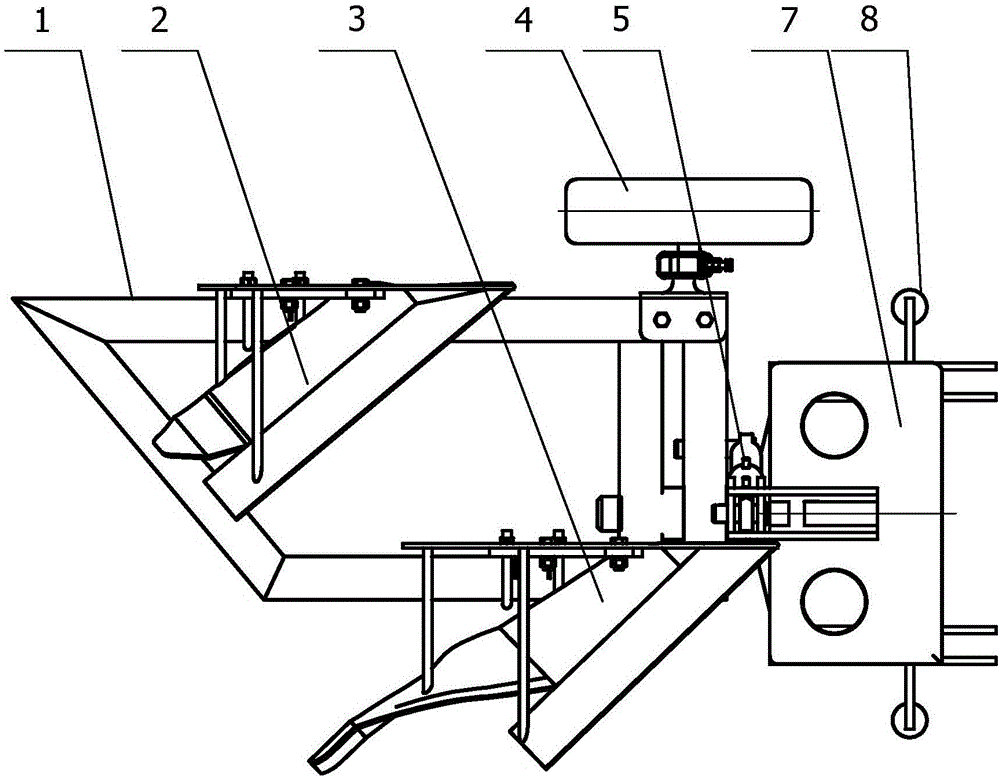

Electric pruning machine for green hedges in garden

InactiveCN109362383AEasy to trimPruning saves effortHedge trimming apparatusCuttersEngineeringMoving frame

The invention discloses an electric pruning machine for green hedges in a garden, and belongs to the technical field of garden equipment. The electric pruning machine for green hedges in the garden comprises a moving frame and rolling wheels arranged at the bottom of the moving frame, a lifting device is arranged on the moving frame and moves up and down along the moving frame, a turnover device is arranged in the lifting device, and a pruning device is arranged on the turnover device. The electric pruning machine has the advantages that the machine is reasonable in structure design, can conveniently prune hedge plants in the garden in a labor-saving mode, is higher in working efficiency, and can conveniently move, prune the hedge plants of different heights according to the need, and respectively prune the tops or the side surfaces of the green hedges.

Owner:徐颖

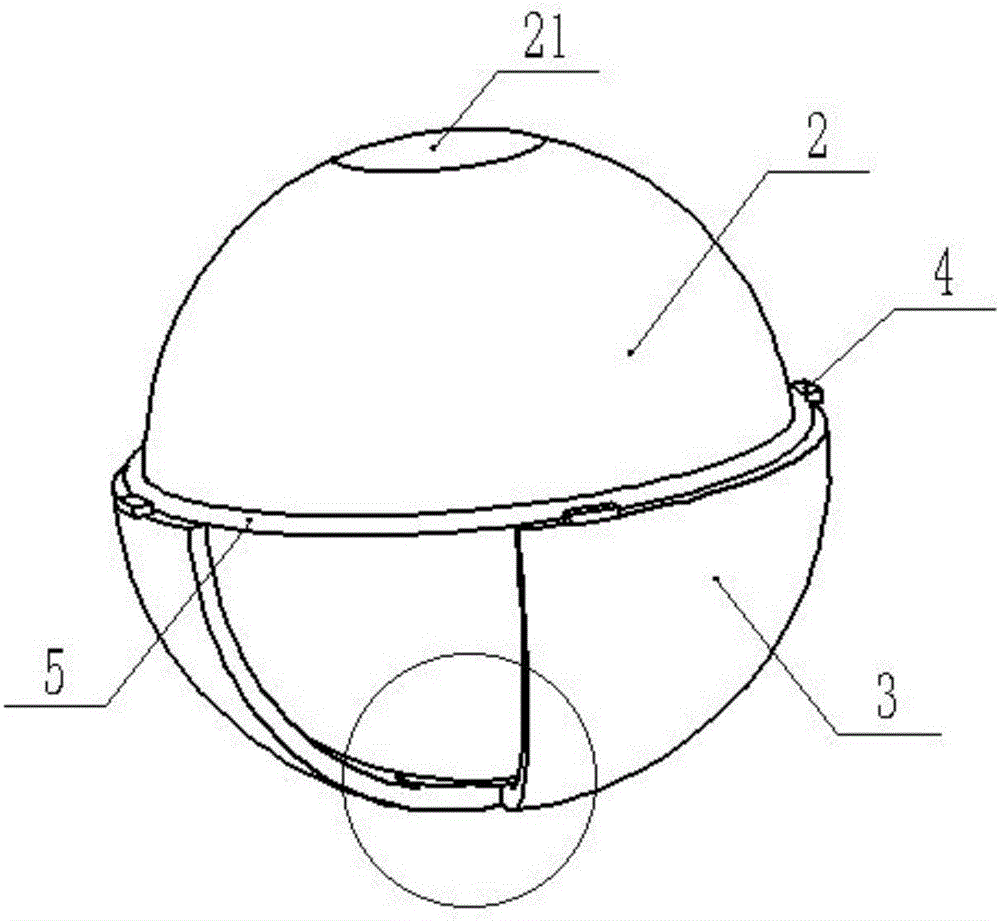

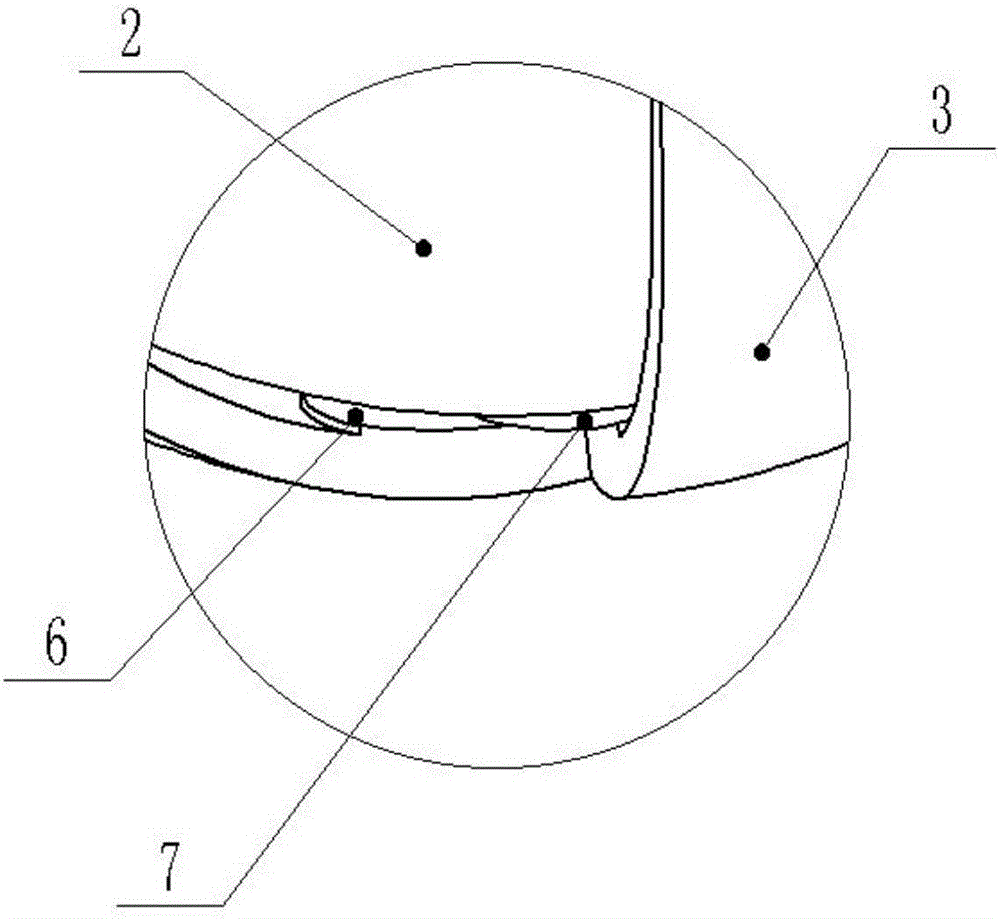

Ball type multifunctional mouse

ActiveCN106843547AImplement the flip functionImprove accuracyCharacter and pattern recognitionEnergy efficient computingBall typeComputer science

The invention provides a ball type multifunctional mouse. The ball type multifunctional mouse comprises a mouse body, a ball and a support, wherein the ball is located in the support, the support is located between a left button and a right button on the mouse body to form the mouse, and relative movement of the ball in the support corresponds to trajectory movement of a cursor to achieve page turning and cursor positioning; the mouse body comprises a scanning device, an infrared induction device and a timekeeping vibration device, and the part, corresponding to the hand operation position, of the back of the mouse body is made of a flexible sweat absorption material. According to the ball type multifunctional mouse, a roller is replaced with the ball to achieve page turning, precise positioning can be achieved in automatic page turning, the accuracy of cursor movement positioning is improved, the positioning time is shortened, and the working efficiency is improved.

Owner:SHANDONG JIANZHU UNIV

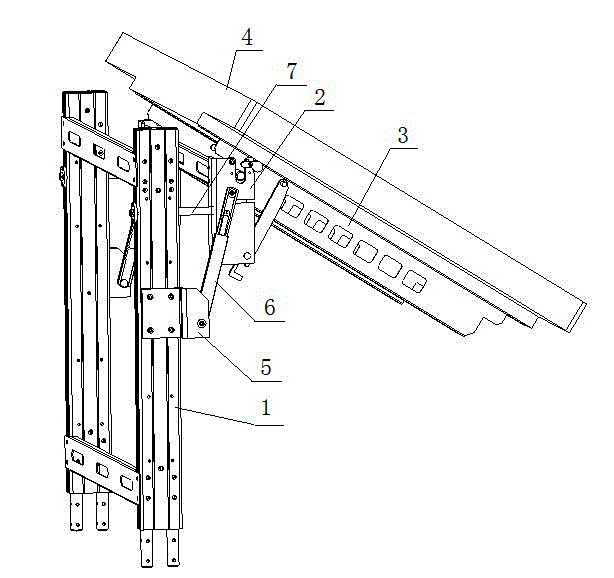

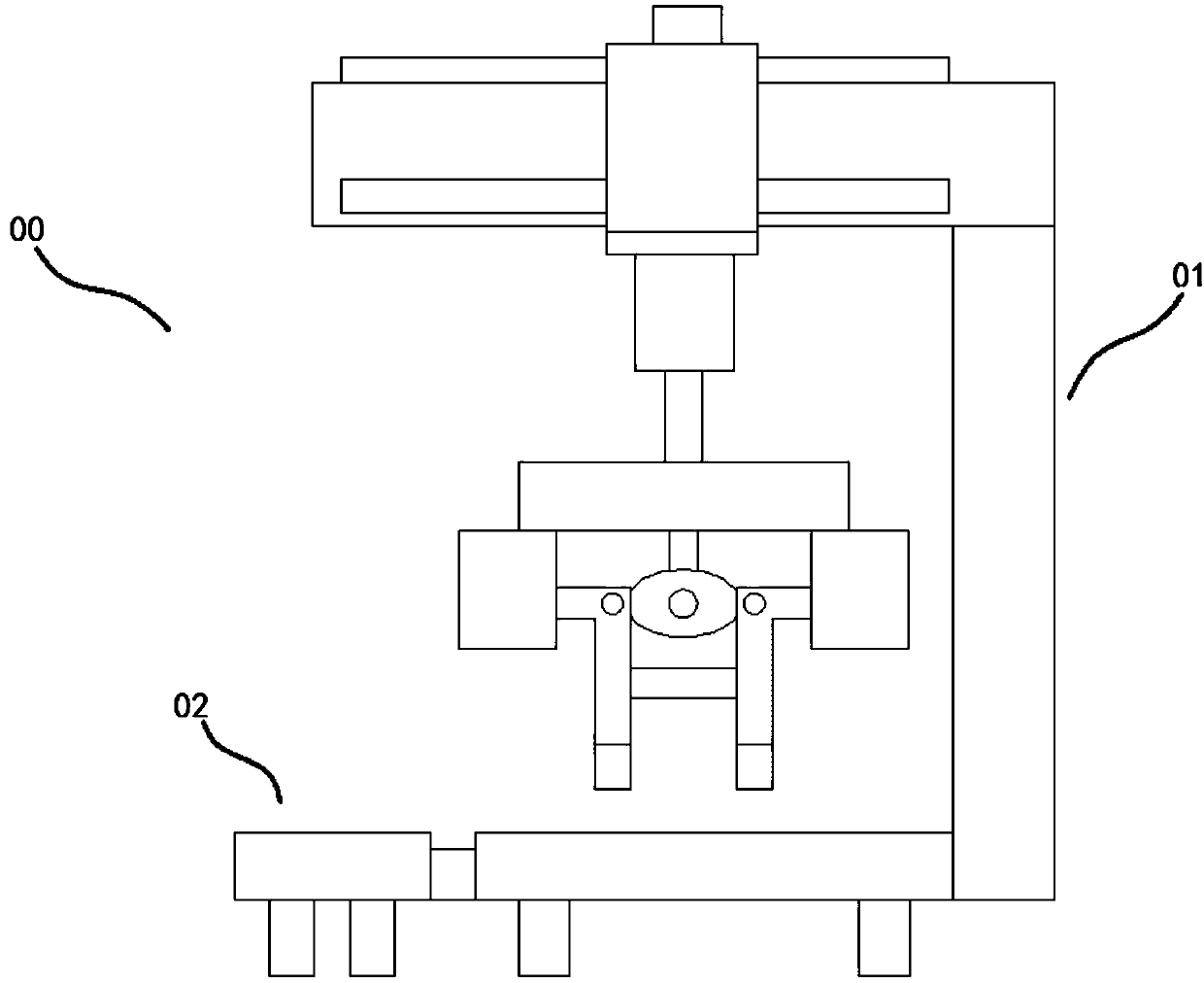

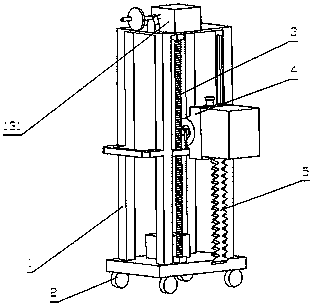

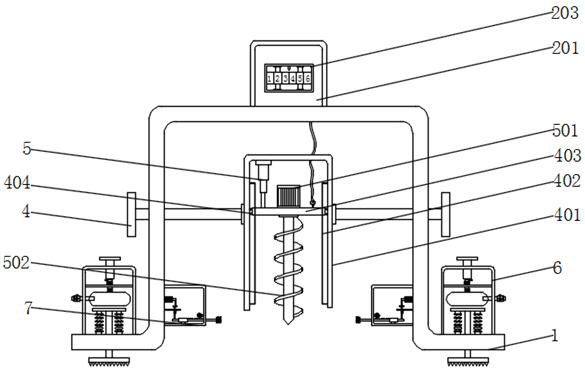

Frame turnover tool

InactiveCN113695828AExpand the scope of useReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryVehicle frame

The invention provides a frame turnover tool. The frame turnover tool comprises a hydraulic station and two sets of frame turnover mechanisms arranged side by side, wherein each set of the frame turnover mechanism comprises a vertically-arranged stand column, a lifting motor and a speed reducer are installed at the top end of each stand column, a lifting chain wheel is arranged on an output shaft of each speed reducer, a chain is installed on each lifting chain wheel in a matched mode, and a lifting sleeve is installed on the periphery of each stand column in a matched mode. Turnover bases can rotate by 360 degrees in situ, compared with a traditional turnover method, the occupied area of a frame turnover station is effectively reduced, interference with other procedures or stations is avoided, the turnover bases achieve the turnover function through the combined action of two turnover oil cylinders, the stability of frame turnover operation is improved, swing bases can rotate to the position on one side before a frame is placed, so that a trolley for conveying the frame can be smoothly moved to the front side of the frame turnover tool, and after the frame is in place, the swing bases rotate to the original position to achieve bearing of the frame.

Owner:刘帅

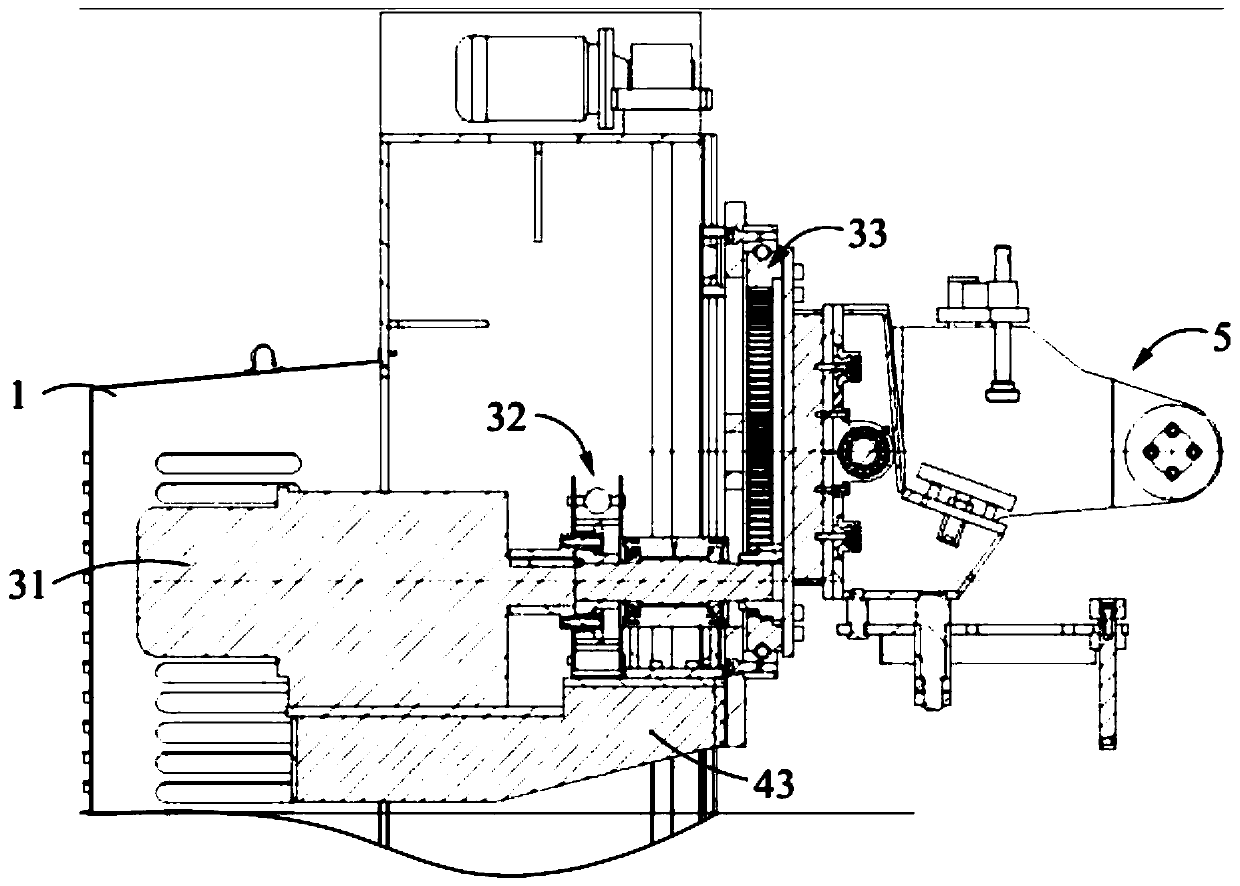

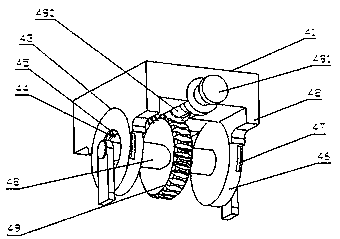

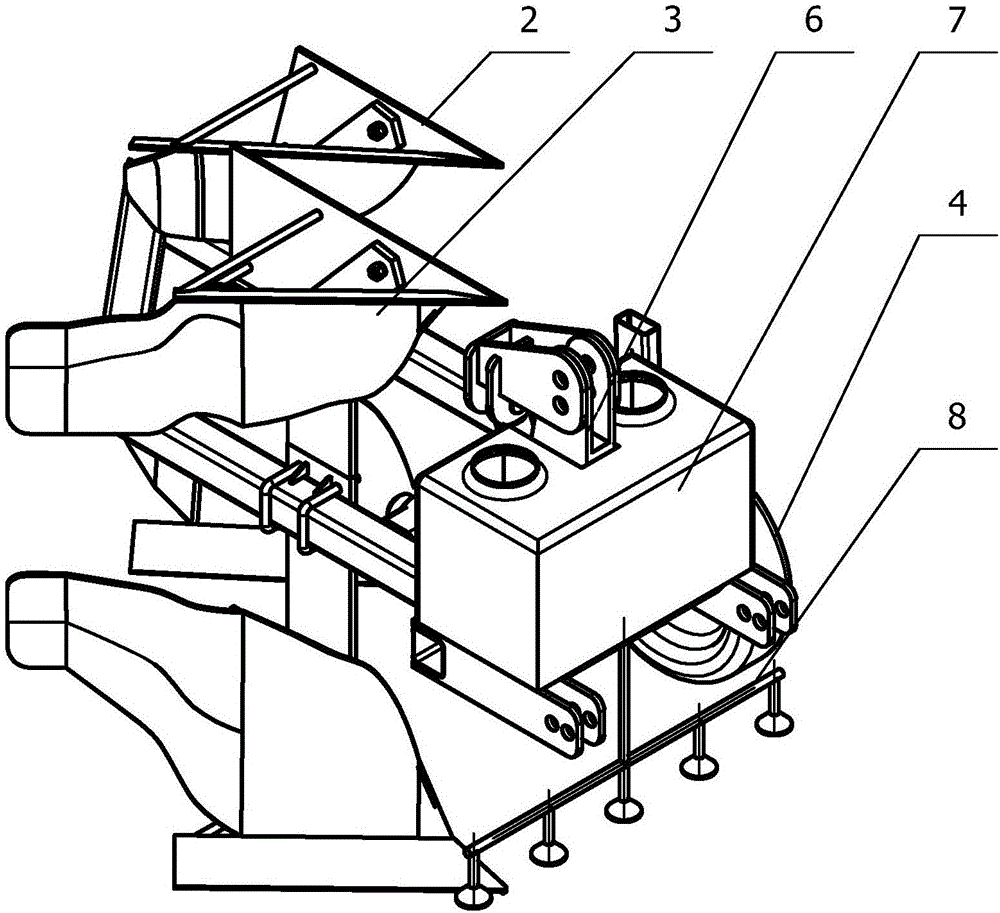

Turning device for catapult power device

The invention discloses a turning device for a catapult power device, and relates to the turning device which is used for conducting vertical lifting and horizontal filling on the catapult power device. The invention aims at providing the turning device which is simple in structure, safe and convenient, and simple and convenient in operation. The turning device for the catapult power device comprises a spiral elevator which is arranged on one side of a sliding support through a first support, a rack which is fixedly connected with the output end of a screw of the spiral elevator, and a gear wheel which is meshed with the rack; the rack is fixed at one side of the sliding support through a supporting seat, the gear wheel is connected with a gear wheel shaft which rotates synchronously with the gear wheel in a sleeving mode, and one end of the gear wheel shaft penetrates through the sliding support and is in rigid connection with a mounting flange. By means of the turning device for the catapult power device, the requirements of the vertical lifting and the horizontal filling for the catapult power device are met, 90 degrees turnover of the catapult power device can be achieved conveniently, and the catapult power device can be fastened at any position in the turnover process.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

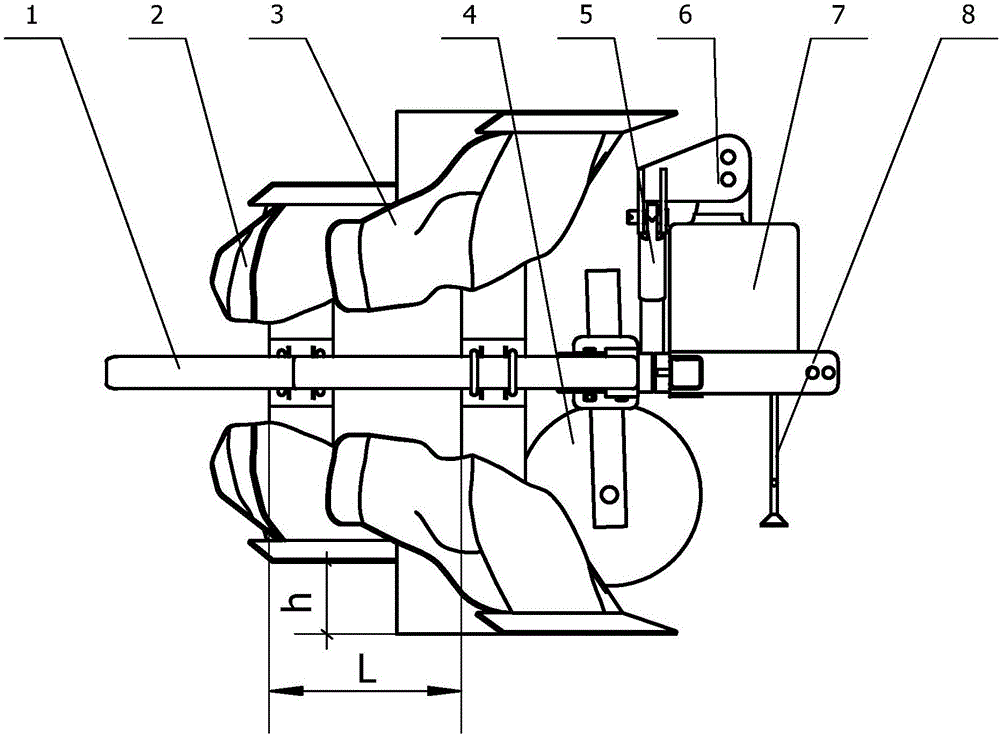

Equipment capable of spraying biogas slurry and turning over and burying straws and stratified straw returning method

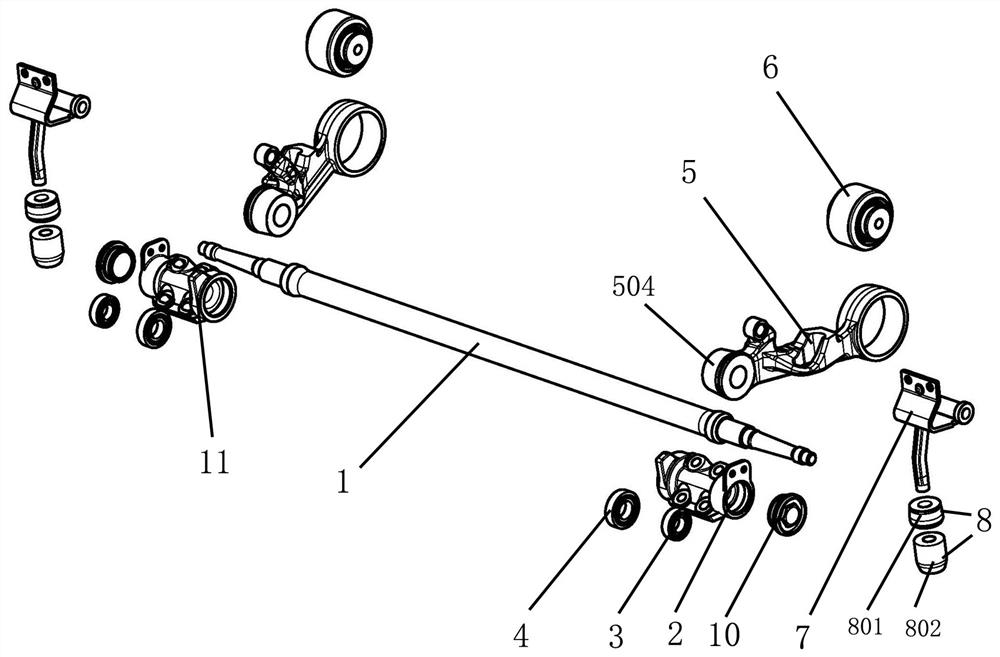

PendingCN107517609AImplement the flip functionAccelerate the rate of decaySpadesPloughsTransmitted powerAutomotive engineering

The invention relates to equipment capable of spraying biogas slurry and turning over and burying straws and a stratified straw returning method. The equipment capable of spraying biogas slurry and turning over and burying straws includes a rack, a pushing plow, a ditching plow, a ground wheel component, a hydraulic cylinder, a hanger, a connecting shaft, a biogas slurry spraying system and a power system. The hanger is connected with the front end of the rack in the advancing direction through the connecting shaft, and the rack can rotate around the connecting shaft. Biogas slurry spraying components are arranged at the upper portion of the hanger. The hydraulic cylinder is obliquely arranged on one side of the connecting shaft. One end of the hydraulic cylinder is connected with the hanger, while the other end is connected with the rack. The power system is connected with the hydraulic cylinder to transmit power and drive the hydraulic cylinder to stretch out and draw back and drive the rack to turn over 180 degrees around the connecting shaft. The ground wheel component is arranged at the left side of the rack in the advancing direction, the pushing plow and the ground wheel component are arranged at the same side of the rack, and the ditching plow is arranged at the right side of the rack in the advancing direction. The equipment achieves a turn-over function of operating plows as an upper plough share and a lower plough share work alternately. Therefore, the work efficiency is improved, the labor intensity is reduced, and the stratified straw returning purpose is achieved.

Owner:LIAONING ACAD OF AGRI SCI

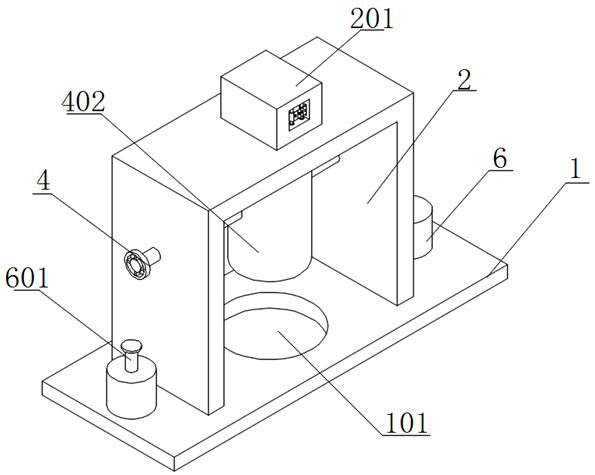

Fixed-depth soil turning treatment equipment for soil pollution control

PendingCN114323743AEasy to observeEasy to measureWithdrawing sample devicesCleaning using toolsElectrically conductiveEngineering

The invention discloses soil pollution abatement fixed-depth soil turning treatment equipment which comprises a bottom plate, a fixing frame, a hand wheel, a fixer and a cleaner, the fixing frame is installed at the top of the bottom plate, a control panel is installed on the inner wall of a meter, and a control shaft is installed on the outer walls of the two sides of the fixing frame in a penetrating mode; a first electric telescopic rod is installed on the top wall of the interior of the protector, and a cleaner is installed on the inner wall of the fixing frame. The depth can be conveniently measured by installing a meter and a metering strip, when an installation plate moves downwards, a circular ring is driven to move downwards, the circular ring drives the metering strip to move, meanwhile, a second electric telescopic rod extends, a conductive rod makes contact with a conductive block, and along with movement of the metering strip, numbers displayed by the metering strip pass through a display groove, and the depth can be conveniently measured. And through the action of the fixed shaft and the guide wheel, the metering strip can be exposed out of the display groove, so that a worker can conveniently check the entering depth of the auger, and observation is facilitated.

Owner:河南省环境修复研究院有限公司

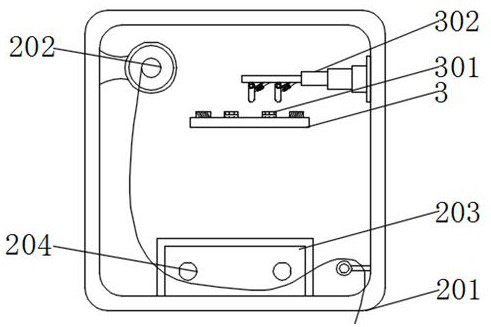

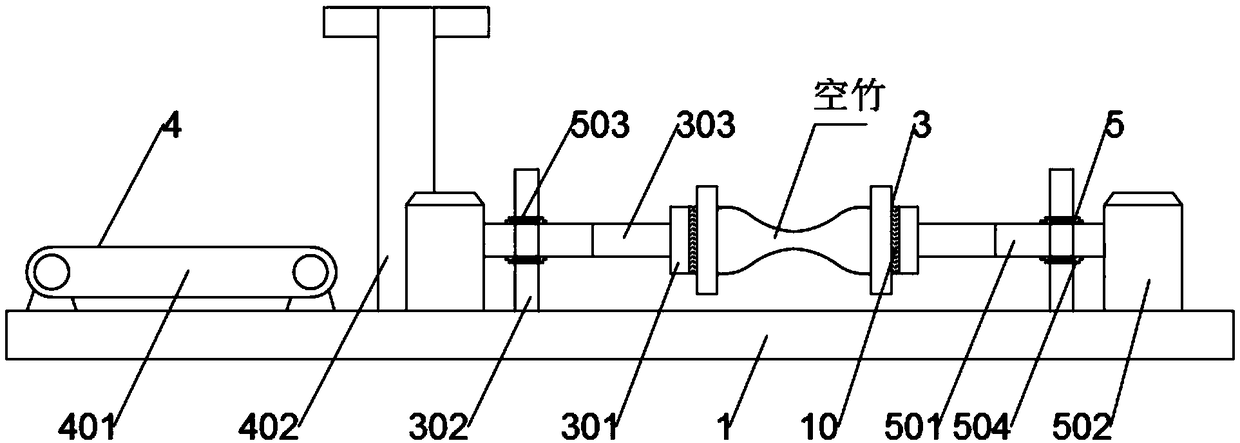

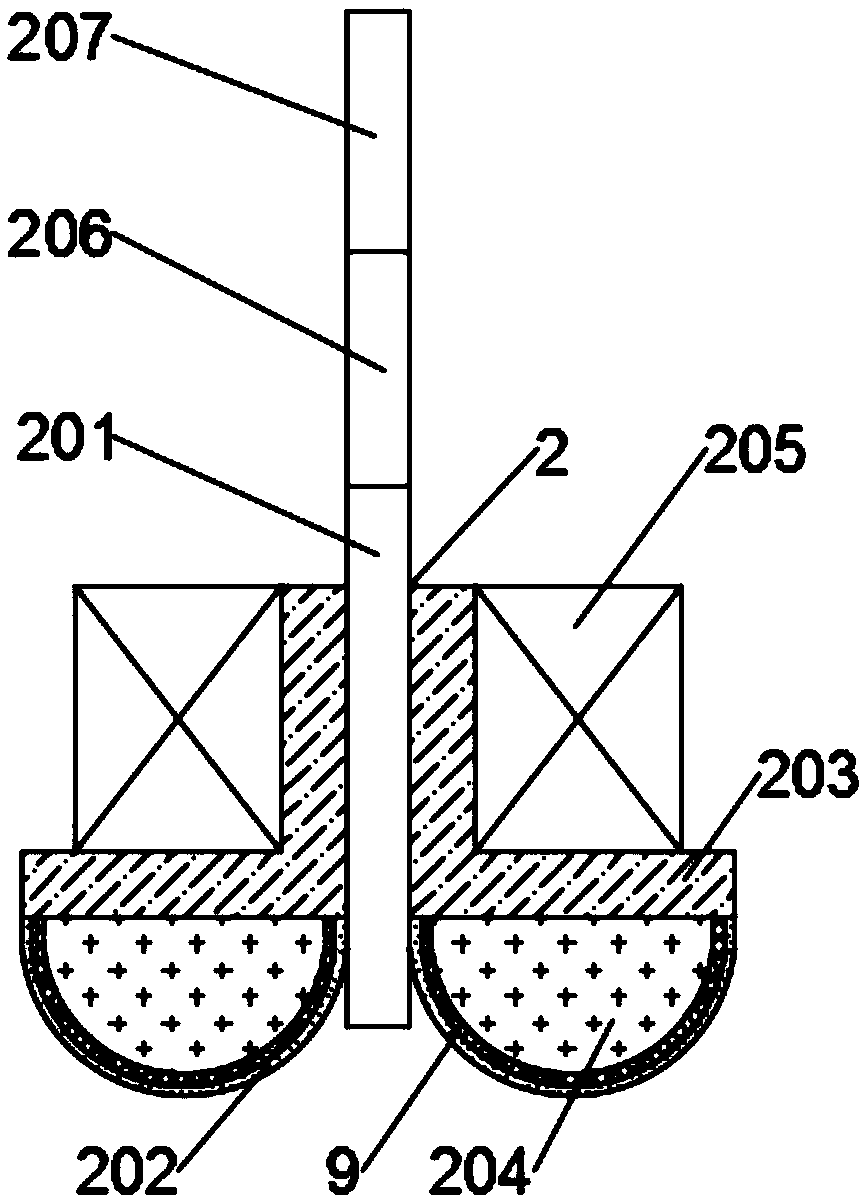

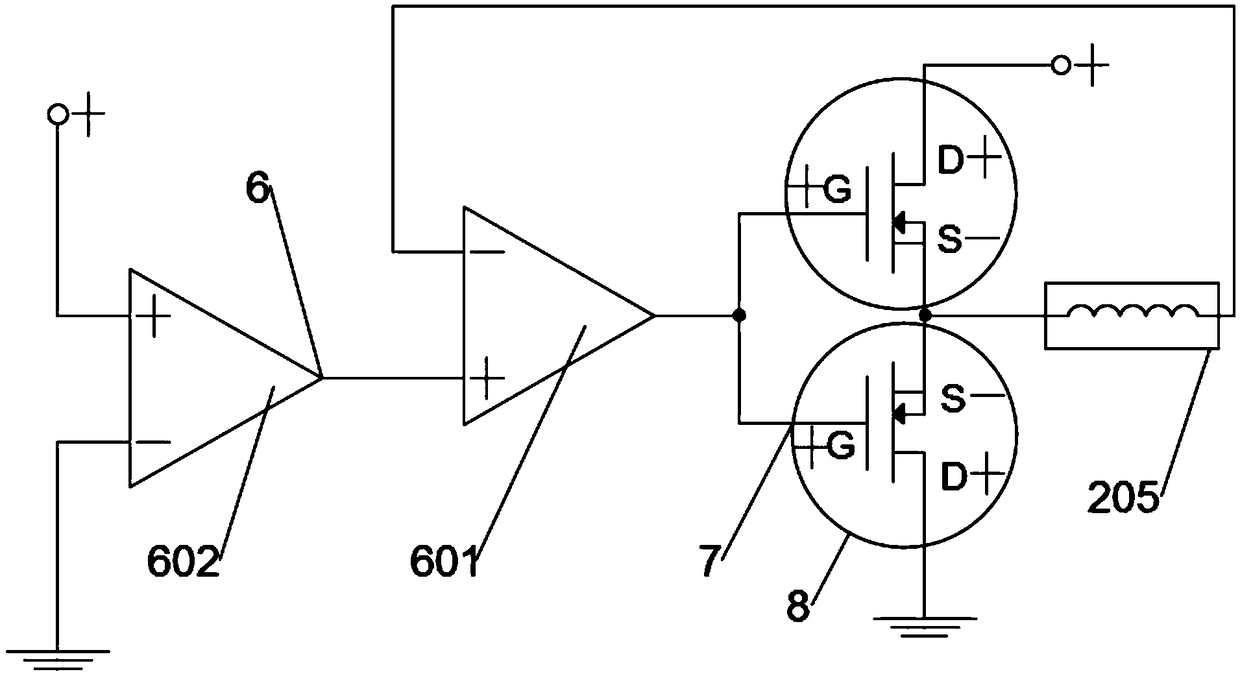

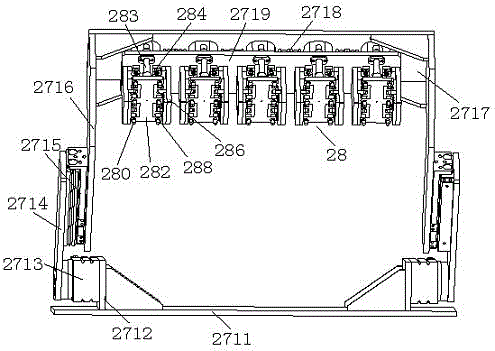

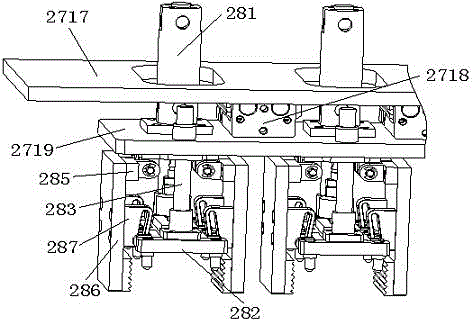

Lossless polishing device for diabolo processing

InactiveCN108687647AGuaranteed polishing effectReduce lossesPolishing machinesGrinding feedersEngineeringRejection rate

The invention discloses a lossless polishing device for diabolo processing. The lossless polishing device comprises a diabolo processing table, a magnetic polishing mechanism, a diabolo clamping mechanism for installing diabolo, and a feeding conveying mechanism used for conveying to-be-polished diabolo to the diabolo clamping mechanism are arranged above the diabolo processing table. The magneticpolishing mechanism is arranged above the diabolo clamping mechanism. The feeding conveying mechanism is arranged on one side of the diabolo clamping mechanism. The diabolo clamping mechanism is provided with two rotation drive mechanisms used for driving the diabolo clamping mechanism to drive the diabolo for rotary polishing. The structure is simple, operation is simple and convenient, and thefunction of comprehensive polishing treatment on the surface of the to-be-polished diabolo can be achieved; the polishing quality is guaranteed, and the diabolo polishing processing rejection rate isgreatly reduced; and the full-automatic feeding function of the to-be-polished diabolo can be achieved, the time consumed for the whole diabolo processing process is shortened, and accordingly the diabolo processing and producing efficiency is improved.

Owner:CHENGDU UNIV OF INFORMATION TECH

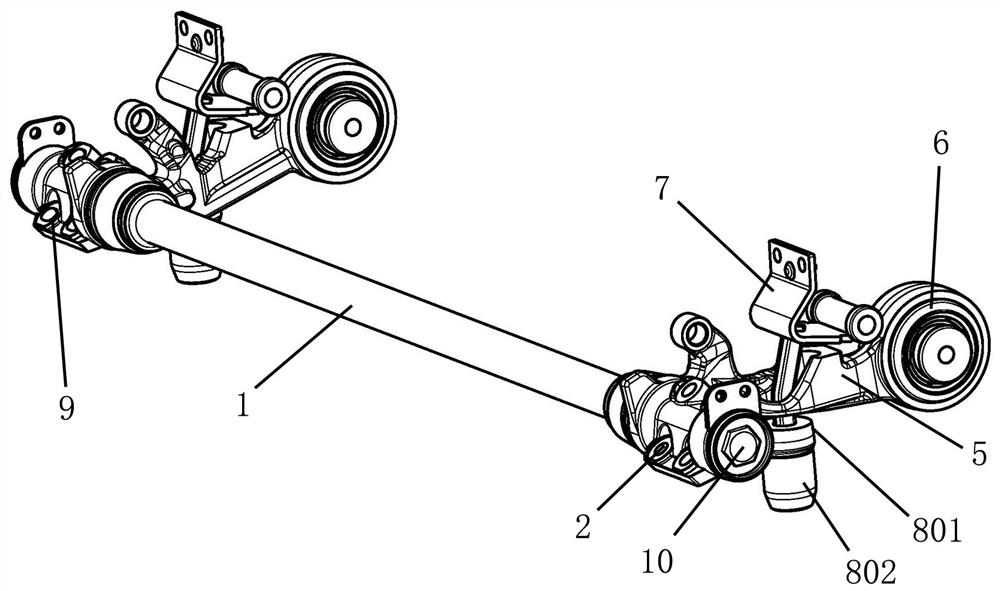

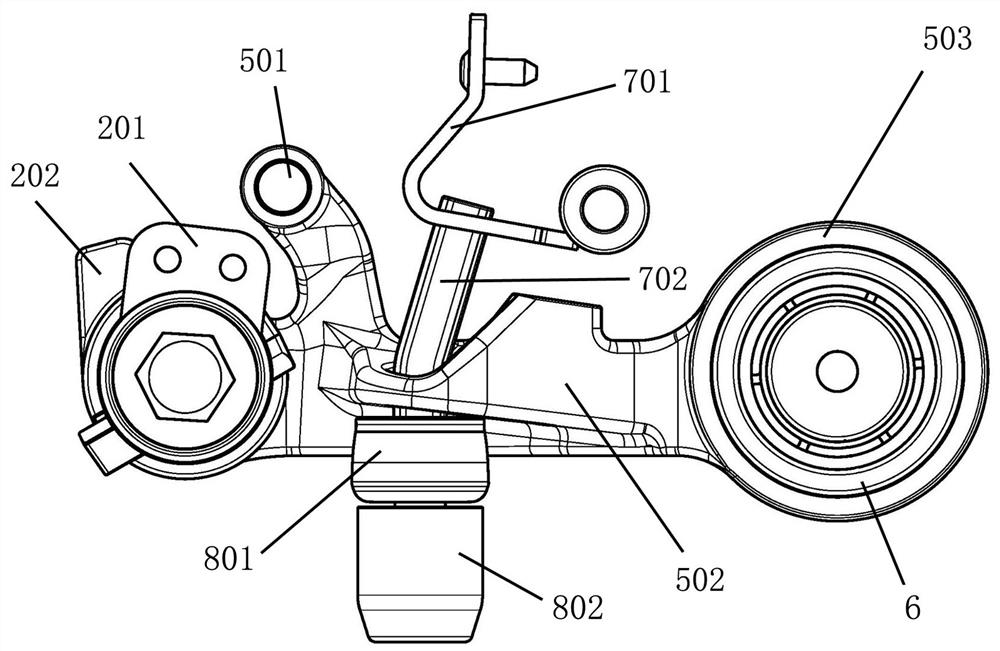

Maintenance-free heavy truck body stabilizing device integrating multiple limiting functions

ActiveCN111645765AImplement the flip functionIncreased flip safetyInterconnection systemsLoading-carrying vehicle superstructuresTruckHydraulic ram

The invention discloses a maintenance-free heavy truck body stabilizing device integrating multiple limiting functions, and relates to the field of heavy truck body stabilization. The device comprisesa stabilizer bar and stability maintaining structures arranged on the two sides of the stabilizer bar in a mirror symmetry mode, each stability maintaining structure comprises a bearing pedestal, aninner bearing, an outer bearing, a limiting bracket, a limiting block and a swing arm, the bearing pedestals, the inner bearings, the outer bearings and the swing arms sleeve the stabilizer bar, and the limiting brackets are installed in through holes formed in connecting rod parts of the swing arms and penetrate through the through holes to be connected with the limiting blocks; the bearing realizes a maintenance-free structure, the device is matched with a hydraulic oil cylinder to realize a cab overturning function, and the functions of cab up-and-down movement limiting, overturning track limiting and overturning angle limiting are also integrated; a clamping block end of the swing arm is a mounting interface of the suspension shock absorber before assembly; and a connecting lug on thebearing seat is also integrated with a front altitude valve mounting bracket interface. The device is highly integrated, and the number and types of parts are reduced; the bearing type maintenance-free structure can greatly prolong the service life of the product; and cab rollover safety is improved.

Owner:DAYUN AUTOMOBILE CO LTD

Bar optical coating overturning clamp

PendingCN114032522AImplement the flip functionEasy to processVacuum evaporation coatingSputtering coatingRotary stageOptical coating

The invention belongs to the technical field of bar processing and relates to a bar optical coating overturning clamp. Supporting plates are supported through a supporting assembly, the number of the supporting plates is two; the two supporting plates are oppositely arranged on the supporting assembly; two rotating tables are provided and are correspondingly installed on the supporting plates in a sliding mode respectively; two installing seats are provided and are correspondingly installed on the rotating tables respectively; two power pieces are provided and are correspondingly fixed to the supporting plates respectively; the output ends of the power pieces are fixedly connected with the rotating tables, so that the the power pieces drive the rotating tables to rotate and drive the installing seats to rotate; and clamping assemblies are mounted on the installing seats and used for clamping a bar and rotating along with the installing seats, so that the overturning of the bar can be realized, machining is convenient, and the machining efficiency is improved.

Owner:桂林芯隆科技有限公司

All-water-blown spraying mechanism for high heat-resistance sound absorbing sponge used for automobiles

The invention discloses an all-water-blown spraying mechanism for a high heat-resistance sound absorbing sponge used for automobiles. The all-water-blown spraying mechanism comprises a base body, a shell, atomizing nozzles, a recovery cavity and a control panel; the recovery cavity is arranged in the base body; a liquid outlet is formed in the outer wall of one side of the base body; an overturning mechanism is arranged at the central position of the top end of the base body; the shell is arranged above the overturning mechanism; the bottom end of the interior of the shell is provided with a power cavity; a storage cavity is arranged in the shell above the power cavity; a liquid inlet is formed in the central position of the top end of the shell; a limiting cover is arranged at the centralposition of the bottom end of the shell; a flow chute is formed in the bottom end of the shell in the limiting cover; and the bottom end of the flow chute is provided with the atomizing nozzles at anequal distance. Pollution to the environment when the spraying mechanism is used is avoided, so that a spraying effect when the spraying mechanism is used is improved, and moreover, the phenomenon that spraying liquid precipitates and coagulates when the spraying mechanism is used is avoided.

Owner:ZHEJIANG CHUANYANG SPONGE

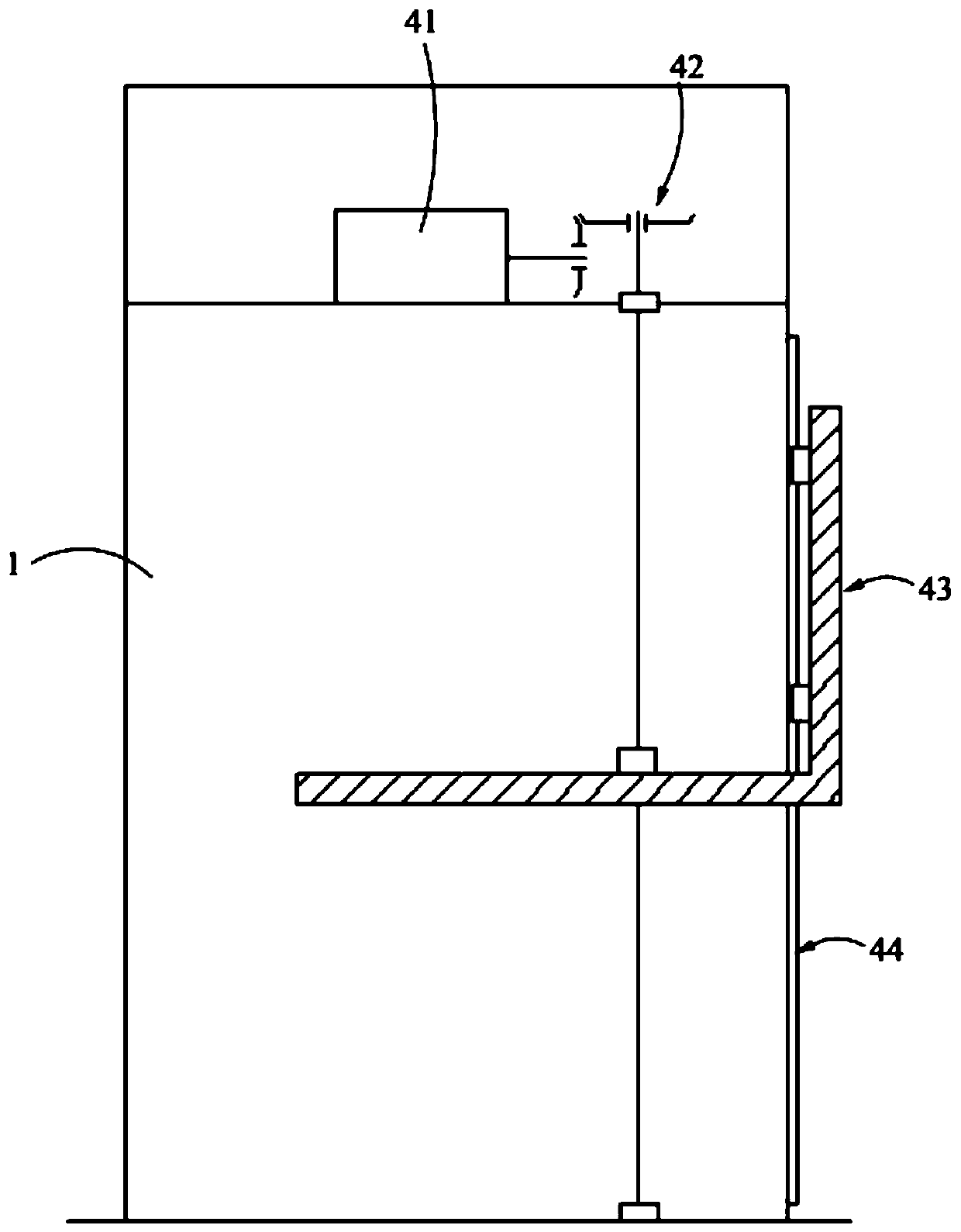

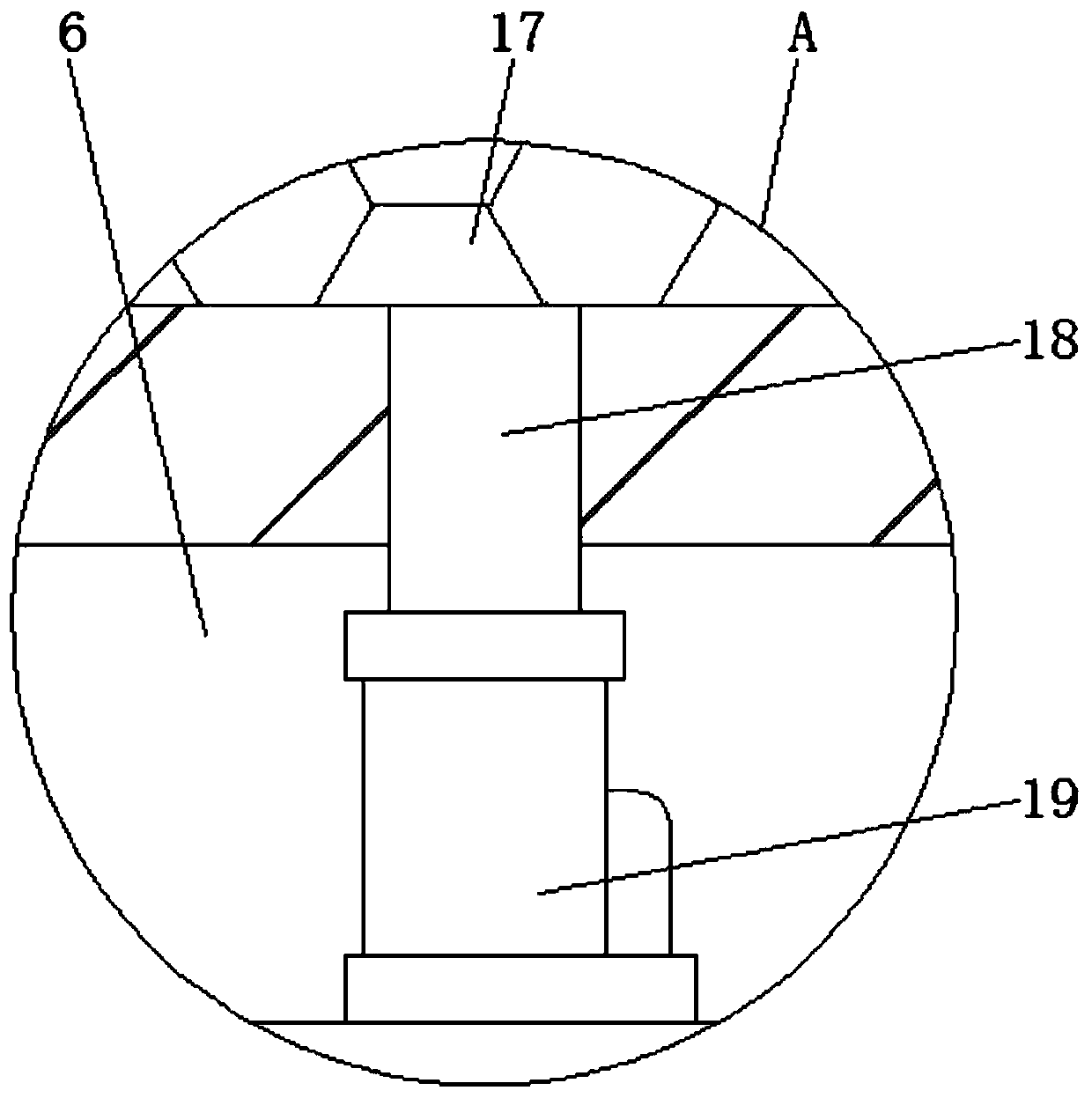

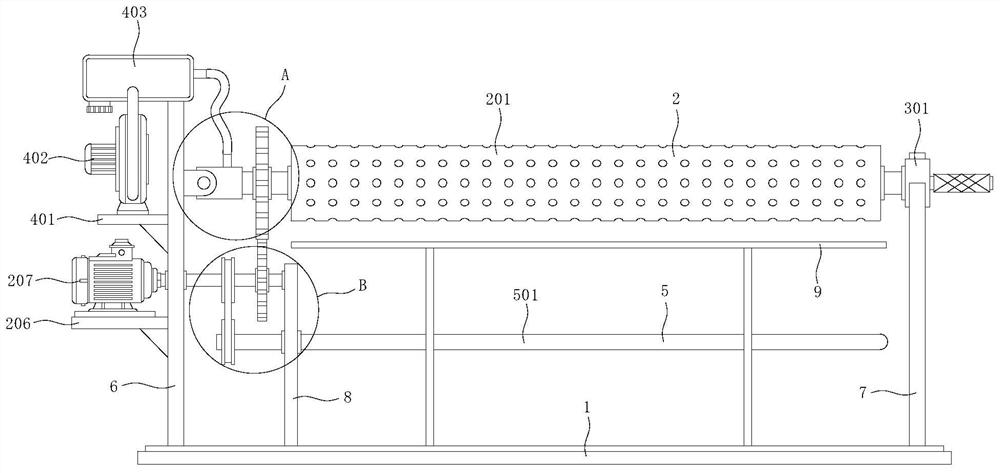

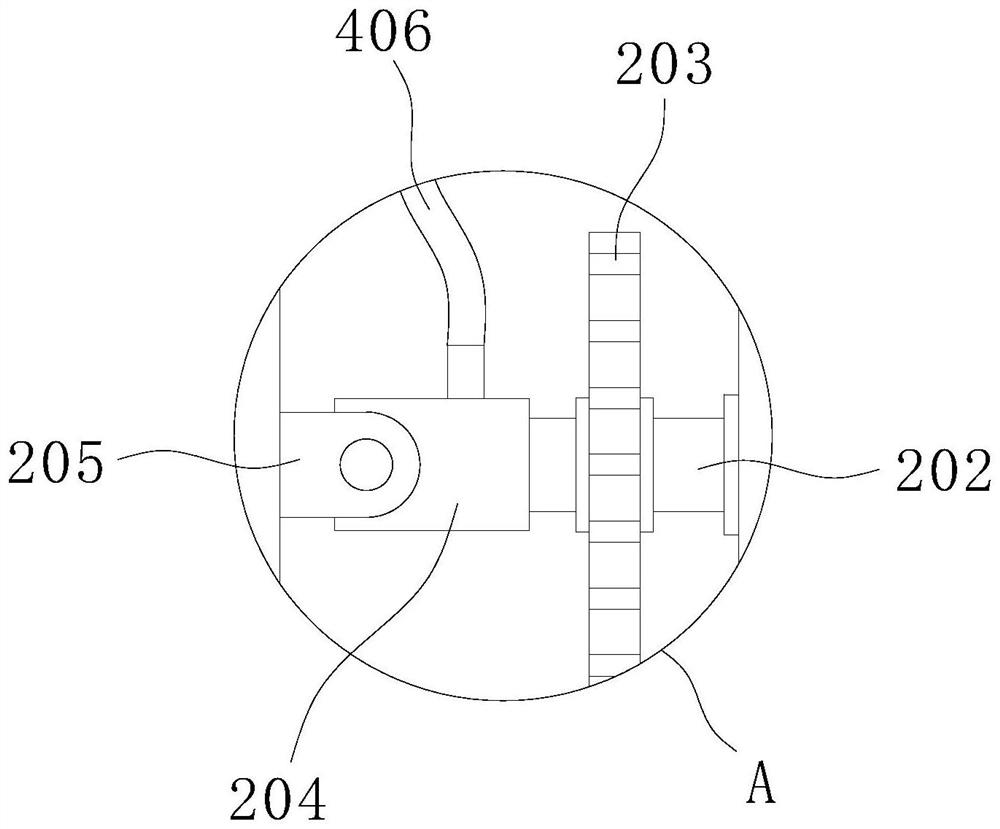

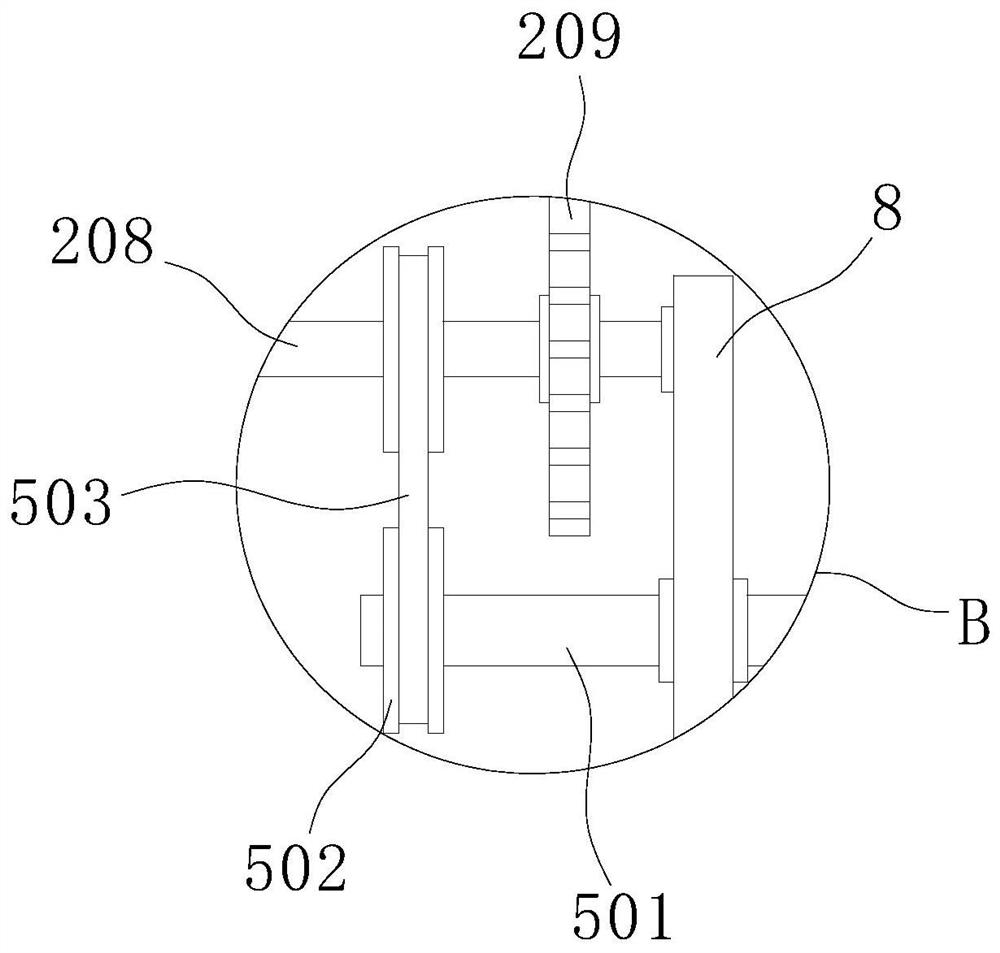

Drum-type receiving lapper for melt-blown non-woven fabric production

ActiveCN113430718AImprove production and processing efficiencyReduce labor burdenTextile disintegration and recoveryNon-woven fabricsNonwoven fabricMechanical engineering

The invention discloses a drum-type receiving lapper for melt-blown non-woven fabric production, and relates to the technical field of non-woven fabric production. The drum-type receiving lapper for melt-blown non-woven fabric production comprises a base; a left supporting plate, a right supporting plate and a mounting plate are fixedly mounted at the top of the base; the mounting plate is located between the left supporting plate and the right supporting plate; a receiving mechanism is arranged above the base; a limiting mechanism is arranged at the top of the right supporting plate; a negative pressure mechanism is arranged on one side of the left supporting plate; and a collecting mechanism is arranged on the mounting plate. According to the drum-type receiving lapper for melt-blown non-woven fabric production, a receiving drum adopts a hinged structural design, so that an overturning function is realized on the premise of not influencing transmission, an operator can conveniently sleeve a non-woven fabric winding drum on the receiving drum before web forming, the non-woven fabric does not need to be manually wound on the receiving drum, the labor burden of the operator is relieved, the overall production and processing time is shortened, and the production and processing efficiency of the melt-blown non-woven fabric is improved.

Owner:湖州创塑新材科技有限公司

Overturning positioning device and working method thereof

ActiveCN109955153AReasonable structural designImplement the flip functionAbrasive blasting machinesEngineeringManipulator

The invention discloses an overturning positioning device and a working method thereof. The overturning positioning device comprise a conveying belt A, a conveying belt B, a temporary storage belt mechanism, a manipulator and a clamping rotation mechanism, the conveying belt A and the conveying belt B are arranged in parallel, and positioning columns are fixedly arranged on the conveying belt A and the conveying belt B correspondingly; the temporary storage belt mechanism abuts against one end of the conveying belt A; the manipulator is mounted between the temporary storage belt mechanism andthe conveying belt B; and the clamping rotation mechanism is mounted on the manipulator. The manipulator and the clamping rotation mechanism are adopted to replace an original overturning air cylinderand an original slide way, after parts conveyed on the conveying belt A slide into the temporary storage belt structure and are taken down from the temporary storage belt by the manipulator, the partoverturning function is achieved in the process of putting the parts on the conveying belt B, double-sided surface treatment of the parts can be realized without the need of stopping operation of theconveying belt A and the conveying belt B, and the working efficiency is obviously improved.

Owner:MIBA PRECISION COMPONENTS CHINA

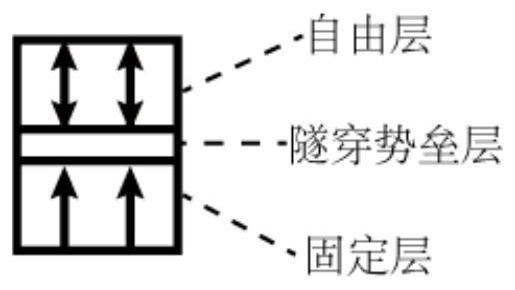

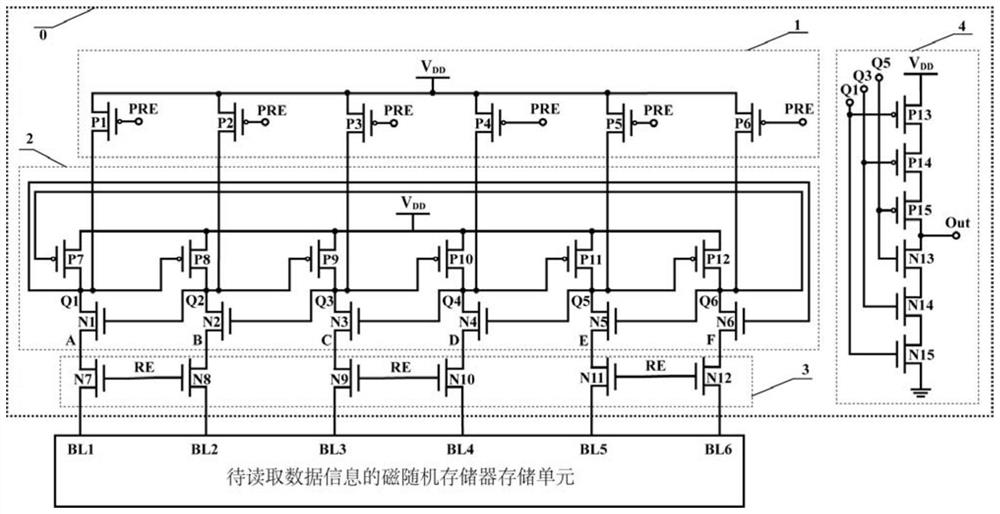

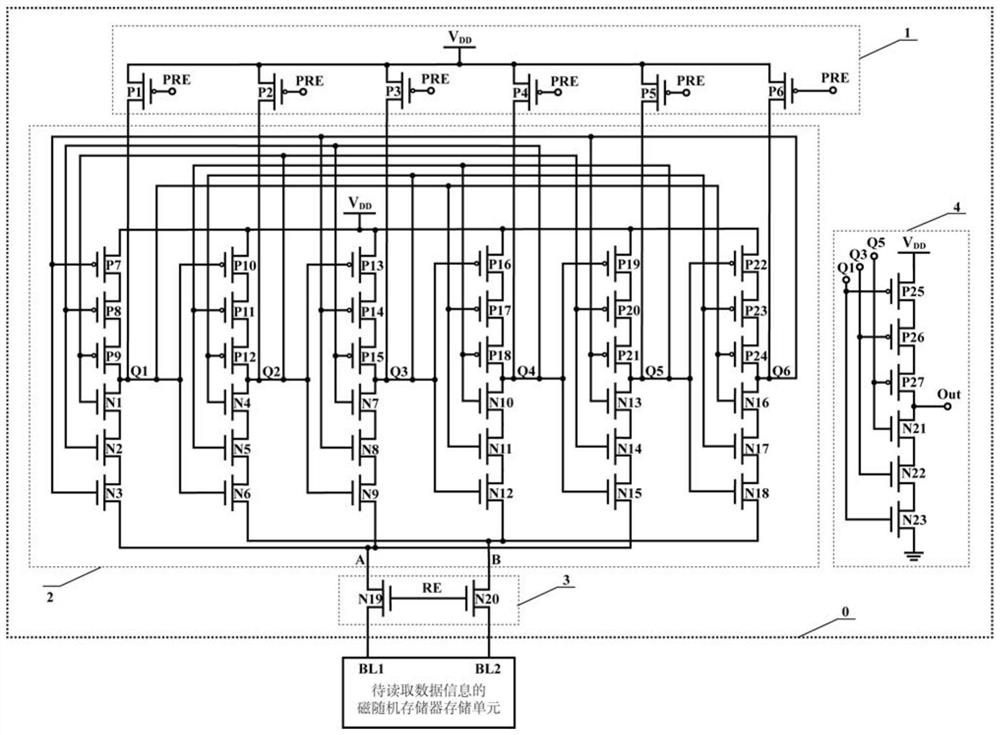

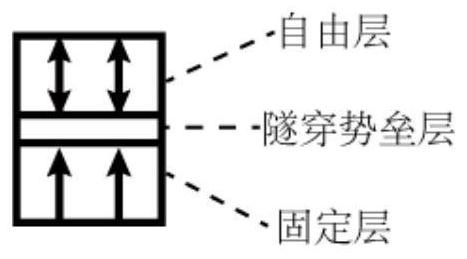

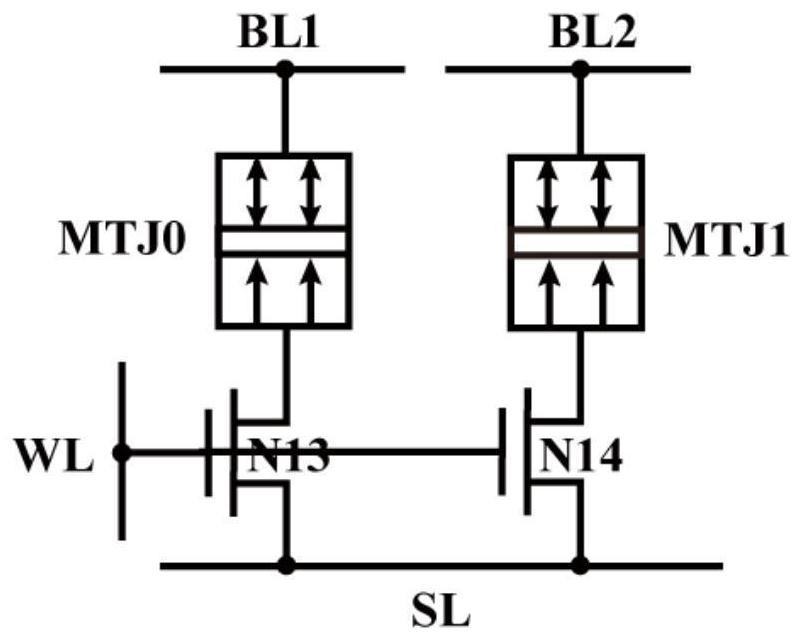

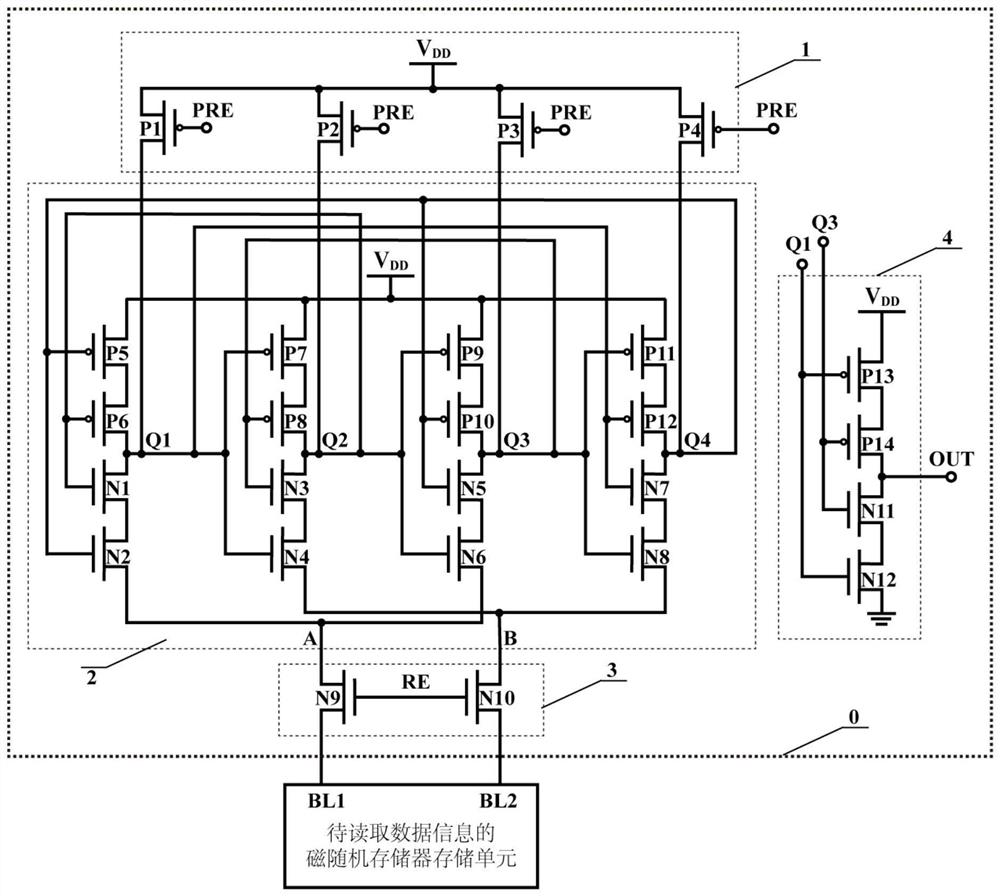

Magnetic memory reading circuit capable of resisting single-event double-node upset based on DICE

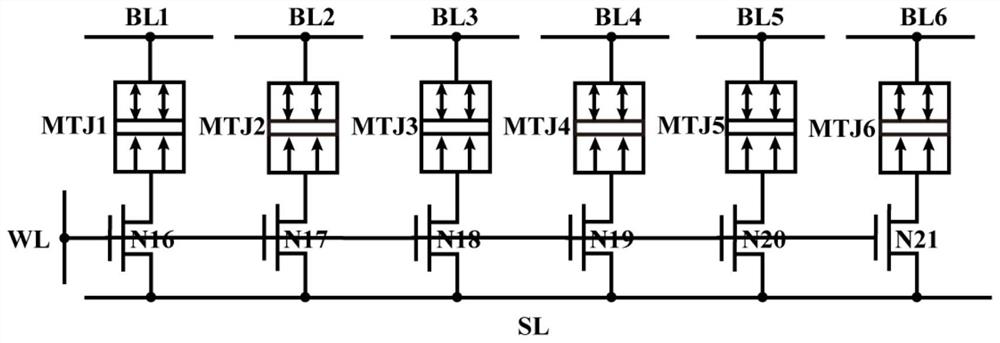

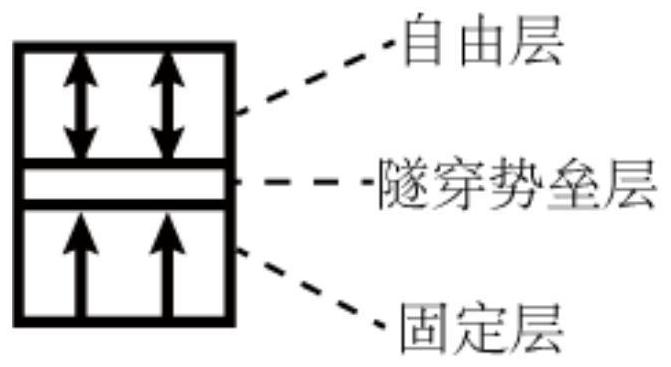

ActiveCN112053716ARealize double-node rollover functionImplement the flip functionDigital storageBit lineRandom access memory

The invention discloses a magnetic memory read circuit capable of resisting single-event double-node upset based on DICE. The input end of a pre-charging circuit module is connected with a pre-charging signal PRE; The output end of the pre-charging circuit is connected with an internal node Q1, an internal node Q2, an internal node Q3, an internal node Q4, an internal node Q5 and an internal nodeQ6 of a latch circuit module. The output end of the latch circuit is connected with the input end of a read circuit separation module. The output end of the read circuit separation module is connectedwith a bit line BL1, a bit line BL2, a bit line BL3, a bit line BL4, a bit line BL5 and a bit line BL6 of a magnetic random access memory storage unit having data information is to be read. The inputend of an output circuit module is connected with the internal node Q1, the internal node Q3 and the internal node Q5 of the latch circuit module. The output end OUT of an output circuit module is the output end of the magnetic memory read circuit. According to the magnetic memory read circuit, not only can a data information reading function be realized at a high speed and low power consumption, but also the single-event double-node upset resistance is realized in the data information reading process.

Owner:HEFEI INNOVATION RES INST BEIHANG UNIV

Magnetic memory reading circuit capable of resisting single-event double-node upset based on C unit

ActiveCN112053715ADoes not affect logic levelsRealize double-node rollover functionDigital storageBit lineRandom access memory

The invention relates to a magnetic memory reading circuit capable of resisting a single-event double-node upset based on a C unit. The magnetic memory reading circuit is characterized in that the input end of a pre-charging circuit is connected with a pre-charging signal PRE; the output end of the pre-charging circuit is connected with an internal node Q1, an internal node Q2, an internal node Q3, an internal node Q4, an internal node Q5 and an internal node Q6 of a latch circuit; the output end of the latch circuit is connected with the input end of a read circuit separation module. the output end of the read circuit separation module is connected with a bit line BL1 and a bit line BL2 of a magnetic random access memory storage unit having data information to be read; the input end of anoutput circuit is connected with the internal node Q1, the internal node Q3 and the internal node Q5 of a latch circuit module; and the output end OUT of an output circuit module is the output end ofthe magnetic memory reading circuit . According to the magnetic memory reading circuit, not only can a data information reading function be realized at high speed and low power consumption, but alsothe single-event double-node upset resistance is realized in the data information reading process.

Owner:HEFEI INNOVATION RES INST BEIHANG UNIV

Waste cart capable of facilitating dumping special for laser cutting machine tool

InactiveCN109014612AEasy to cleanEasy to collectLaser beam welding apparatusEngineeringPulp and paper industry

The invention discloses a waste cart capable of facilitating dumping special for a laser cutting machine tool. The waste cart comprises a cart body. A push handle is arranged on the end face of one side of the cart body. Wheels are arranged at the bottom end of the cart body, and the four wheels are evenly arranged at the bottom end of the cart body. A carriage is arranged at the upper end of thecart body. The waste cart capable of facilitating dumping special for the laser cutting machine tool is characterized in that the design of a dumper is simulated, and waste of the laser cutting machine tool can be cleared up conveniently; the cart body serves as a device body, and the waste produced by the machine tool can be collected, transferred and cleaned conveniently through the wheels, thepush handle and the carriage arranged on the cart body; the top end and one side face of the carriage are both of an open structure, and the waste can fall in and be dumped conveniently; the carriageis matched with a rotating support through a rotating shaft and thus can be tipped over relative to the cart body, and meanwhile the handle can assist in dumping when the amount of the waste is too large; and the device is compact and reasonable on the whole, and using can be made more convenient.

Owner:安徽鹏展电子科技有限公司

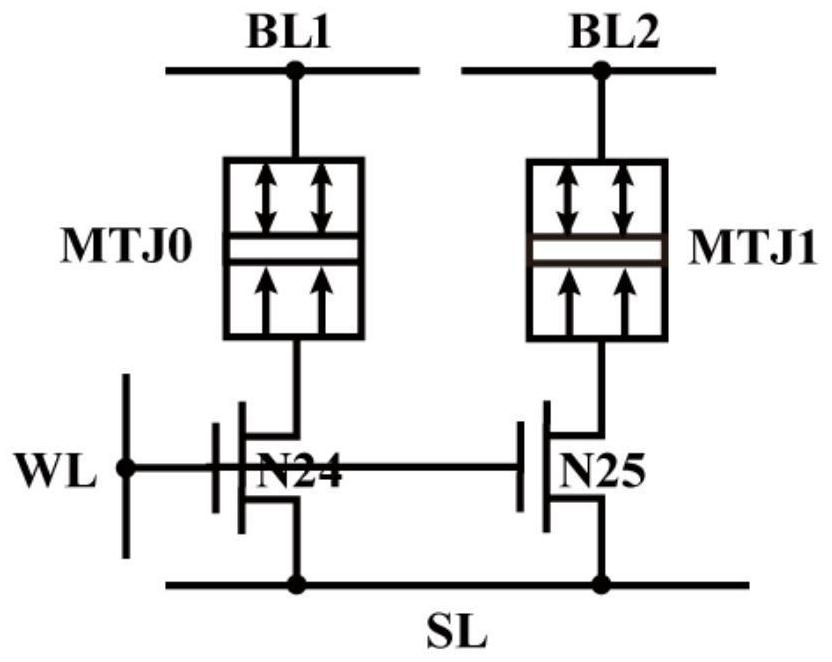

Magnetic memory reading circuit capable of resisting single-event upset based on C unit

PendingCN112053718ADoes not affect logic levelsImplement the flip functionDigital storageMagnetic storageData information

The invention discloses a magnetic memory reading circuit capable of resisting a single-event upset based on C unit. The magnetic memory reading circuit is characterized in that the input end of a pre-charging circuit module is connected with a pre-charging signal PRE; the output end of the pre-charging circuit module is connected with an internal node Q1, an internal node Q2, an internal node Q3and an internal node Q4 of a latch circuit module; the output end of the latch circuit module is connected with the input end of a read circuit separation module; the output end of the read circuit separation module is connected with a bit line BL1 and a bit line BL2 of a magnetic random access memory storage unit having data information to be read; the input end of an output circuit module is connected with the internal node Q1 and the internal node Q3 of the latch circuit module; and the output end OUT of the output circuit module is the output end of the magnetic memory reading circuit provided by the invention. According to the magnetic memory reading circuit, not only can a data information reading function be realized at high speed and low power consumption, but also the single eventupset resistance is realized in the data information reading process.

Owner:HEFEI INNOVATION RES INST BEIHANG UNIV

Simple auxiliary turning-over device for medical nursing

InactiveCN114344006AReduce the chance of secondary injuryAvoid close contactNursing bedsGear wheelNursing care

The simple auxiliary turning-over device comprises a positioning frame, gear ring bases, first positioning tables, second positioning tables, fixing rods and gears, gear rings are fixedly arranged at the two ends of the outer wall of the positioning frame, and the first positioning tables are fixedly arranged on the two sides of the positioning frame at equal intervals; sliding grooves are formed in the middle positions of the two sides of the multiple first positioning tables. According to the simple auxiliary turning-over device for medical nursing, a motor fixed to one side of one positioning seat drives one gear to rotate, when the positioning frame is turned over by more than 45 degrees, one side of the face of a patient can be turned over to the top ends of the first positioning table and the second positioning table on the other side, and therefore the turning-over function is achieved; the simple auxiliary turning-over device for internal medicine nursing is simple in structure, convenient to use, capable of avoiding short-distance contact between medical staff and a patient and protecting the medical staff, the probability of secondary injury of the patient is reduced due to the fact that the simple auxiliary turning-over device for internal medicine nursing is convenient and practical, and the use efficiency of the simple auxiliary turning-over device for internal medicine nursing is improved.

Owner:镇平县人民医院

Feeding unit of brake pump shell feeding machine

InactiveCN106743587ANovel structureImplement the flip functionMetal working apparatusConveyor partsRotary stage

The invention discloses a feeding unit of a brake pump shell feeding machine. The feeding unit comprises a feeding mounting plate, wherein two ends of the upper plane of the feeding mounting plate are fixed with feeding rotary air cylinder mounting plates perpendicular to the two ends through reinforcing ribs; the two feeding rotary air cylinder mounting plates are positioned on the same horizontal line; transverse feeding rotary air cylinders are fixed on outer side faces of the two feeding rotary air cylinder mounting plates; rotary tables of the two feeding rotary air cylinders are outwards; a feeding sliding table air cylinder mounting plate is fixed on a rotary table of each of the two feeding rotary air cylinders; and feeding sliding table air cylinders are fixed on opposite inner lateral faces of the two feeding sliding table air cylinder mounting plates. Through the manner, the feeding unit is simple and novel in structure, can realize the overturning function, realizes full-automatic operation during the feeding process, can continuously realize automatic feeding, and replaces manual feeding of a workpiece.

Owner:苏州迈邻物业管理有限公司

Bilateral transferring and overturning device

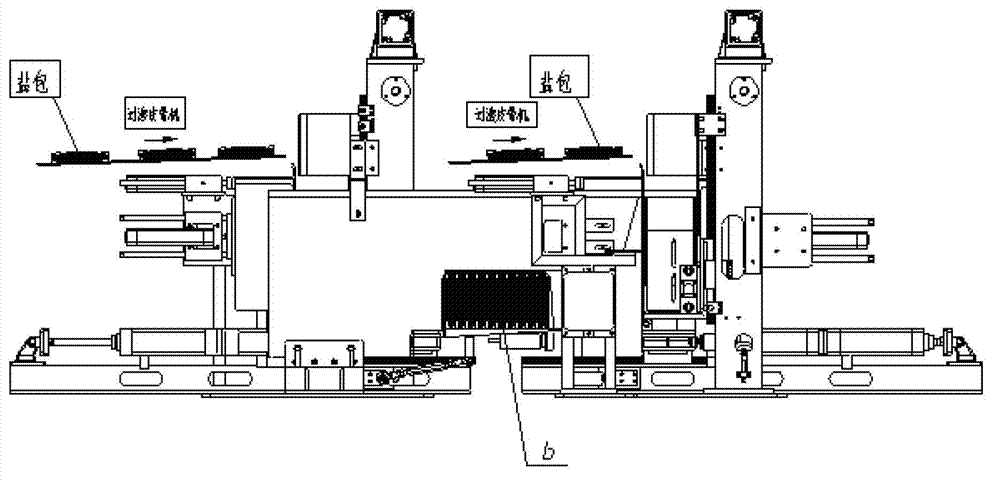

The invention relates to a bilateral transferring and overturning device. A left stacking device and a right stacking device are located on the left and right side respectively, arranged at the same direction of an inlet port, and connected with two parallel transitional belt conveyors in a butt manner respectively to convey salt bags. A left transferring and overturning device and a right transferring and overturning device are arranged on the upper sides of the left stacking device and the right stacking device respectively and are located at a same straight line. When the left transferring and overturning device and the right transferring and overturning device are turned to horizontal positions, two stacking clamp positions are completely overlapped; and when transferring and overturning are performed alternately, the left transferring and overturning device and the right transferring and overturning device can share one set of corollary equipment on the front side and the back side. A left channel plate and a right channel plate are mounted on the front side and the back side and form a fixed-space channel while the transferring clamps are overturned. The two side channel plates are fixed with the channel plate bases through connecting supports fixedly and reliably, disassembling is easy and facilitated when the equipment is repaired. When the equipment runs, the two stacking devices run independently, the two transferring and overturning devices are overturned alternately, each device has an automatic waiting station, so that the entire line can be guaranteed to run continuously without shutting down simultaneously.

Owner:WUHAN RENTIAN PACKAGING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com