Overturning mechanism used for conducting picture inspection on liquid crystal panel

A liquid crystal panel and flipping mechanism technology, which is applied in the direction of flipping objects, pile separation, thin material processing, etc., can solve the problems of high energy consumption of the flipping mechanism and complex work efficiency of the mechanism, and achieve low energy, improved work efficiency, and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

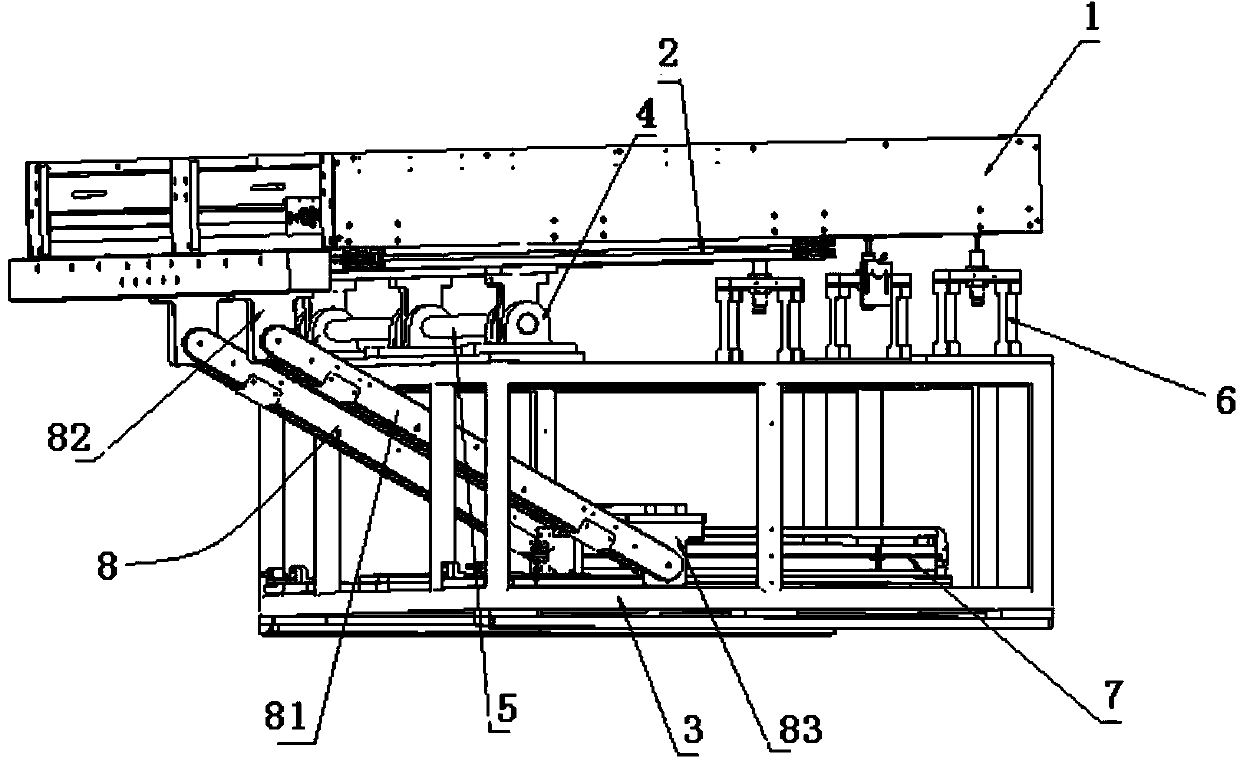

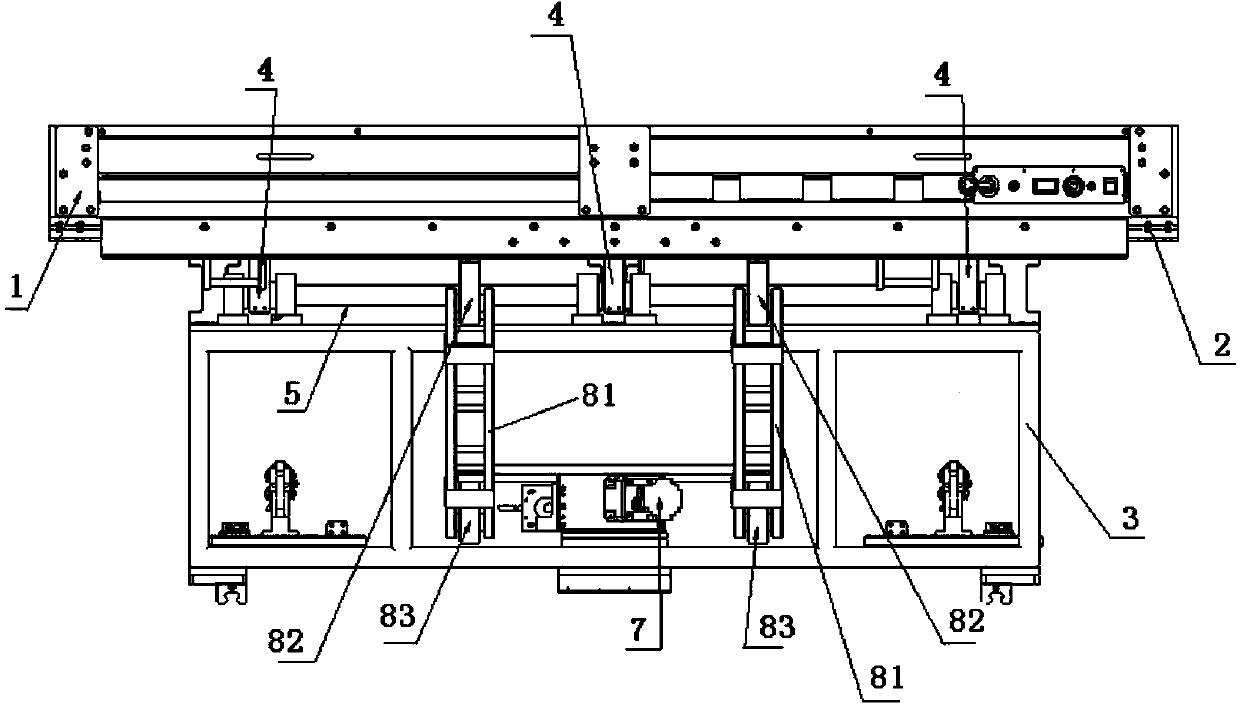

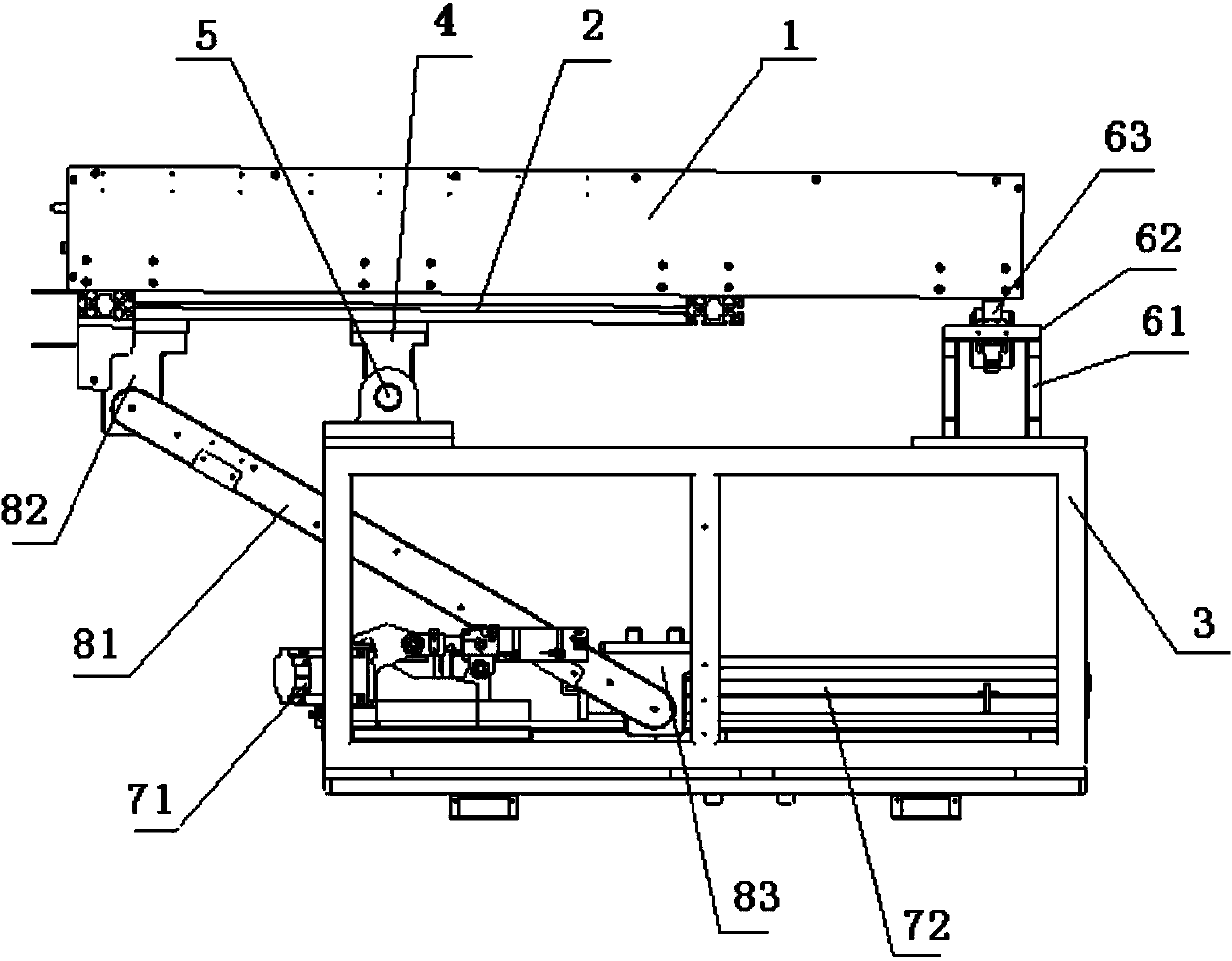

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a flipping mechanism for checking the screen of a liquid crystal panel includes a light box 1 for fixing the liquid crystal panel to be tested, a light box seat 2 fixed at the bottom of the light box, and a support set under the light box seat Frame 3, one side of the top of the support frame is fixedly connected with a support shaft 5 through a bearing 4, and the middle part of the bottom of the light box base is fixedly connected with the support shaft through a bearing; the other side of the top of the support frame is fixedly provided with a buffer device 6 , a power unit 7 is fixed in the support frame; a connecting rod device 8 connecting the power device and one side of the light box seat is also provided, and the connecting rod device, the supporting shaft and the buffer device are in common The light box is supported, and the power device can drive the connecting rod device and driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com