Lifting type back row seat handrail and vehicle provided with same

A rear seat, lift-type technology, applied in the direction of armrests, vehicle seats, vehicle parts, etc., can solve the problems of complex structure, cumbersome process, and inability to adjust height, and achieve the effect of meeting height requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

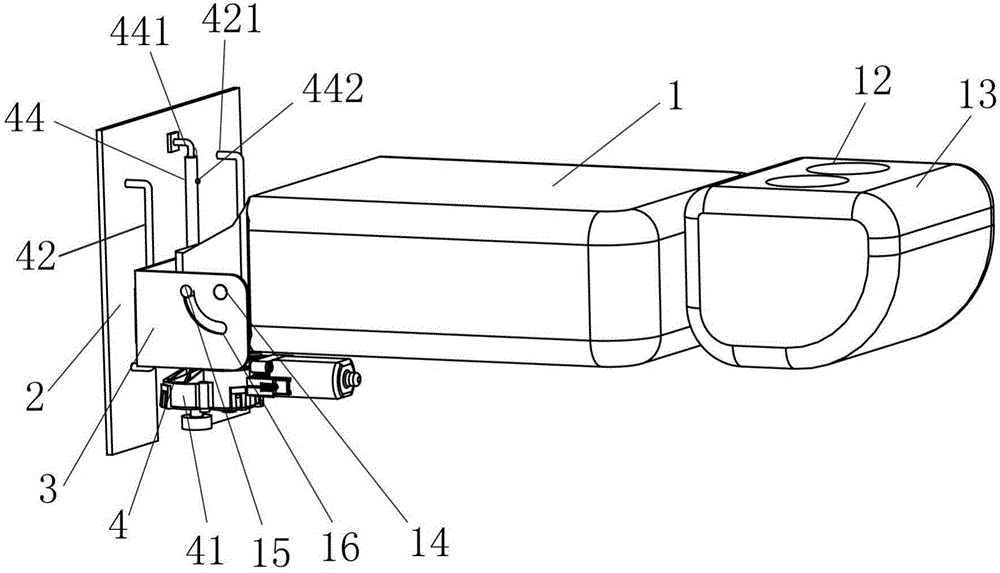

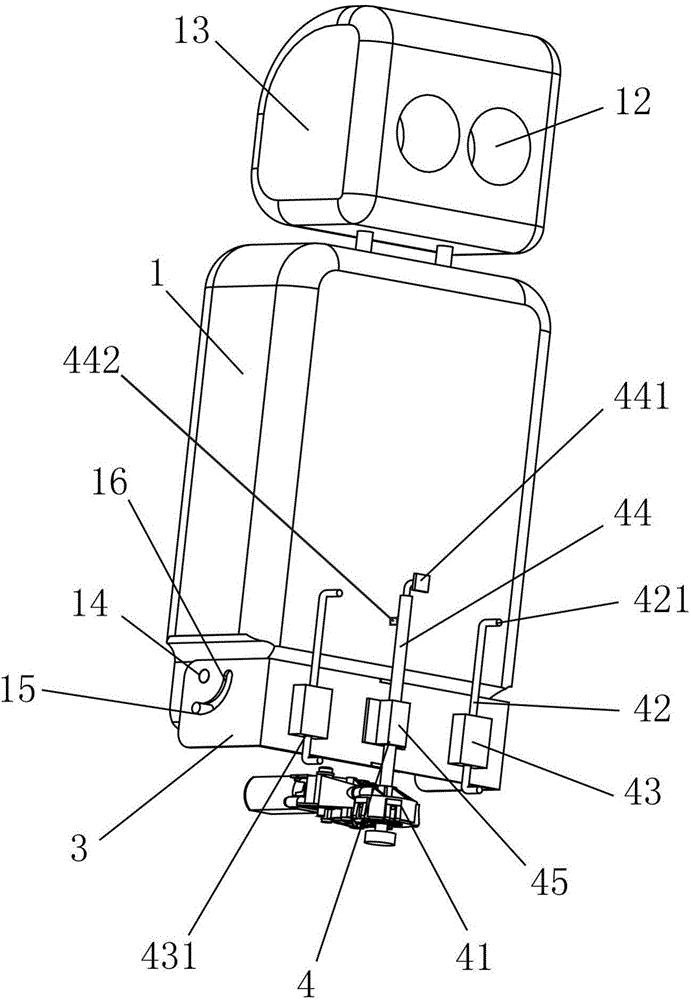

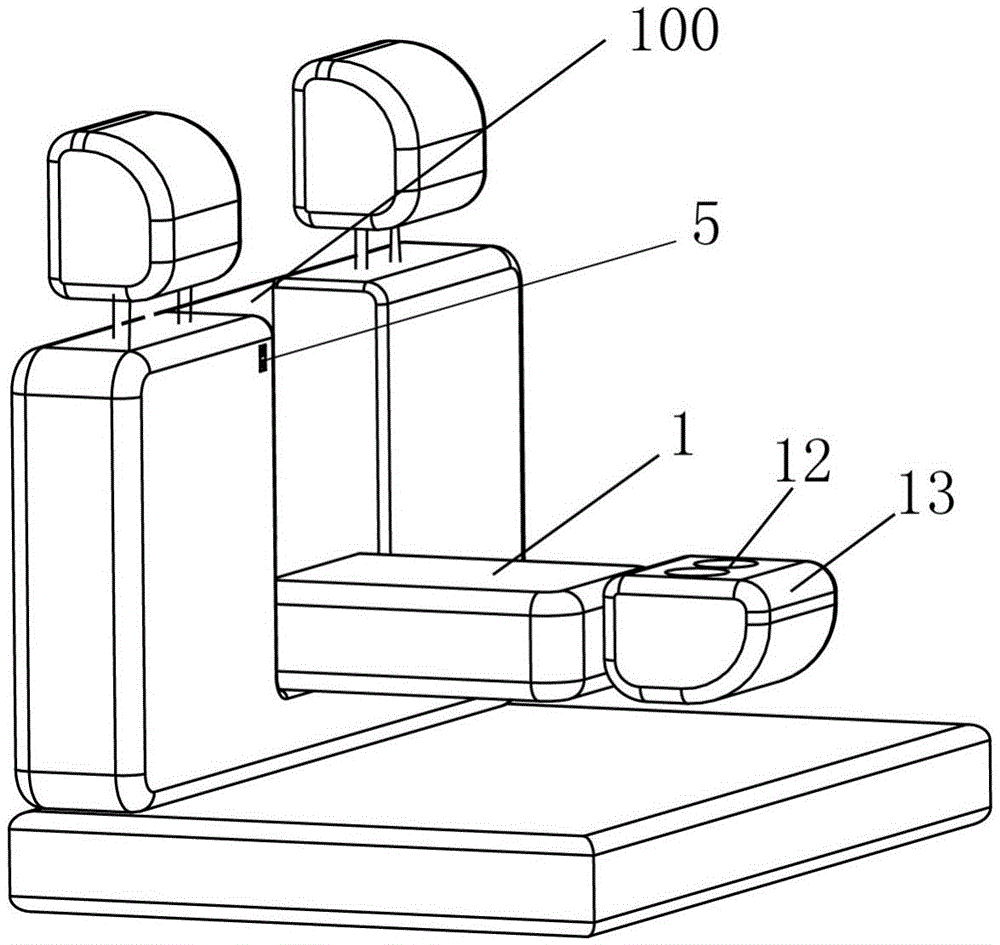

[0032] figure 2 An embodiment of the headrest part is shown: the top end of the armrest body 1 is plugged with a headrest 13, and the inner side of the headrest 13 is provided with a cup holder 12 that can hold a water cup; or another Figure 4In the embodiment shown in: the top end 11 of the armrest body 1 is arranged in the shape of a headrest, and the inside of the headrest-shaped top end 11 is provided with a cup holder 12 . According to the height requirements of passengers, the most comfortable position can be found by adjusting the height of the headrest-shaped top part 11 or the plug-in headrest 13 by lifting the armrest body 1, and the armrest body 1 can be lowered to the lowest position when there are no passengers , its headrest-shaped top portion 11 or headrest 13 will be in a low position to avoid affecting the driver's rear view.

[0033] image 3 and Figure 4 Shown is a schematic diagram of the use state of the present invention. When rear passengers need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com