Equipment capable of spraying biogas slurry and turning over and burying straws and stratified straw returning method

A biogas slurry and straw technology, which is applied in the field of agricultural machinery research, can solve the problems of reducing soil fertility, not adjusting the depth of straw burial, and incomplete decomposition, so as to improve soil organic matter content, increase soil organic carbon storage capacity, maintain and The effect of maintaining soil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

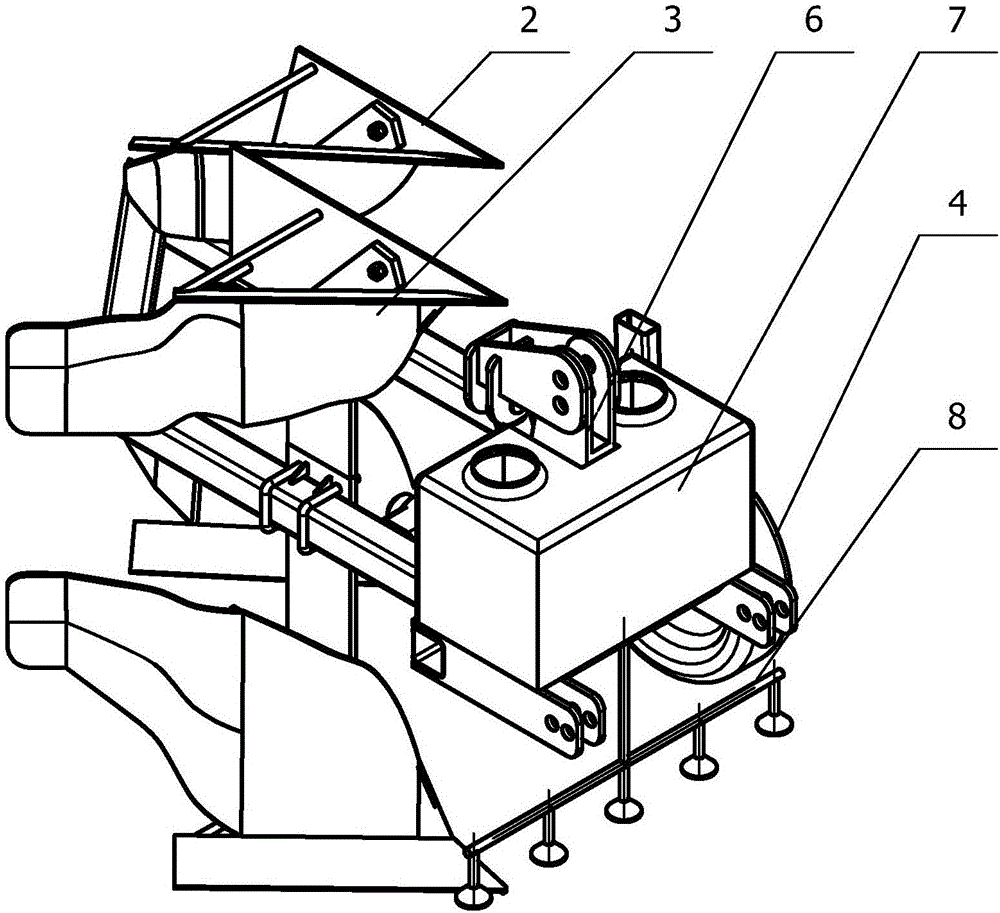

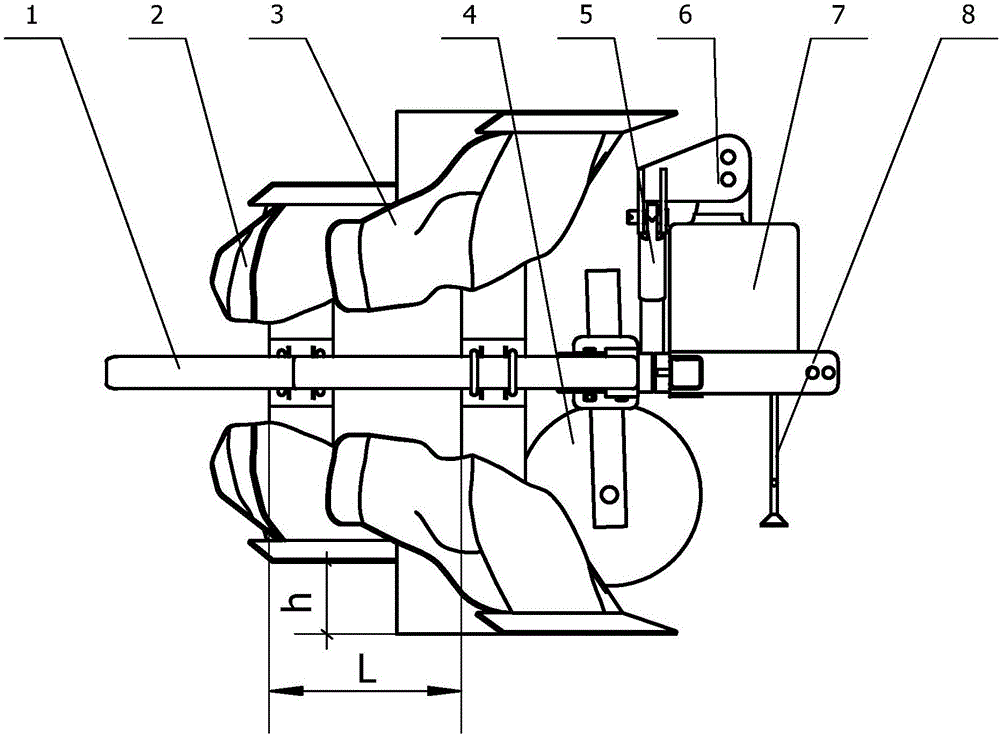

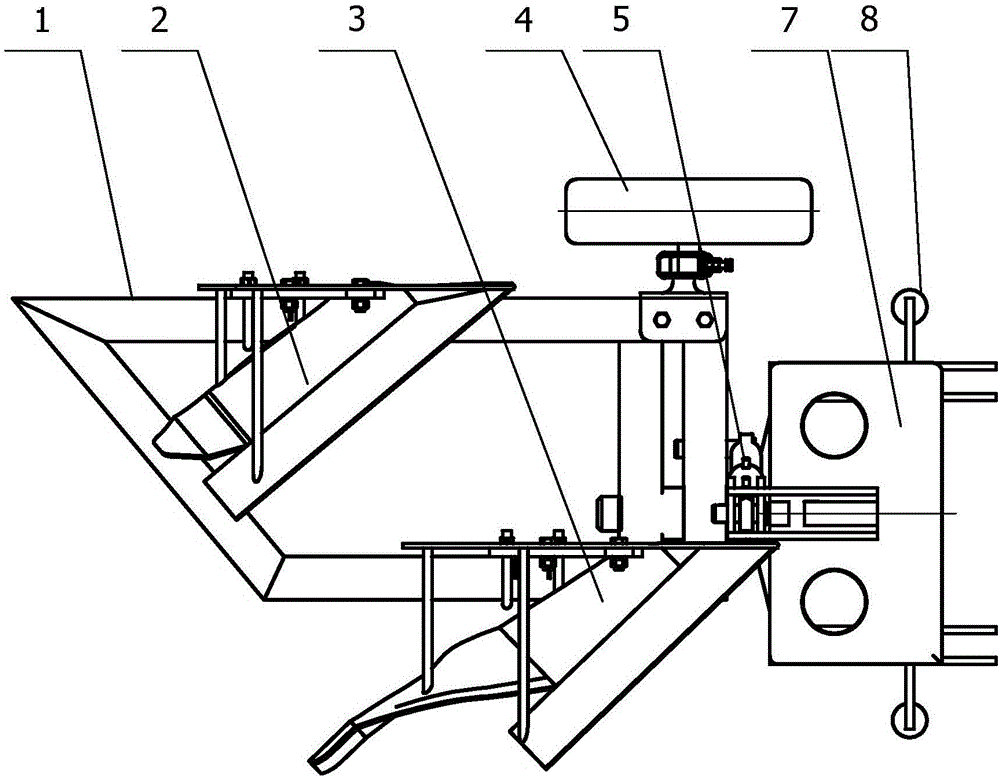

Image

Examples

Embodiment 1

[0034] Example 1: Implementation in the corn plot of Cainiu Town, Tieling.

[0035] The specific operation steps of this embodiment are as follows:

[0036] (1) Harvest and pulverize straw by using a self-propelled corn harvester (model 4YZ-5-Y215), so that the crop straw is pulverized into small fragments of 4 cm, which are evenly spread on the surface of the plot;

[0037] (2) When the soil moisture content is below 18%, use the machine tool of the present invention to carry out biogas slurry spraying and straw burying operations;

[0038] (3) The depth of burial of straw in the first year is 20cm, the depth of burial of straw in the second year is 25cm, and the depth of burial of straw in the third year is 30cm, and three years is a cycle;

[0039] (4) After working with this machine, use the combined soil preparation machine (model 1SZL-180) to carry out rotary tillage and ridge suppression, and sowing can be done in the following year.

[0040] Comparative Experiment of...

Embodiment 2

[0043] Example 2: Implemented in a paddy field in Baqiangzi Town, Panjin.

[0044] The specific operation steps of this embodiment are as follows:

[0045] (1) Harvesting and pulverizing straw with a crawler-type combine harvester (model DR85-4LZ-2.5), so that the crop straw is pulverized into small fragments of 3 cm, which are evenly spread on the surface of the plot;

[0046] (2) When the soil moisture content is below 18%, use the machine tool of the present invention to carry out biogas slurry spraying and straw burying operations;

[0047] (3) The depth of burial of straw in the first year is 19cm, the depth of burial of straw in the second year is 24cm, and the depth of burial of straw in the third year is 29cm, and three years is a cycle;

[0048] (4) After working with this machine, fertilize the next year and then use the rotary tiller (model 1GZ-190) to perform rotary tillage, and the rice can be transplanted after soaking in the field.

[0049] Comparative Experim...

Embodiment 3

[0051] Example 3: Implemented in a corn plot in Gaojiadian Town, Tieling.

[0052] The specific operation steps of this embodiment are as follows:

[0053] (1) Harvest and pulverize stalks with a self-propelled corn harvester (model 4YZ-5-Y215), so that the crop stalks are pulverized into small fragments of 5 cm, which are evenly spread on the surface of the plot;

[0054] (2) When the soil moisture content is below 18%, use the machine tool of the present invention to carry out biogas slurry spraying and straw burying operations;

[0055] (3) The depth of burial of straw in the first year is 21cm, the depth of burial of straw in the second year is 26cm, and the depth of burial of straw in the third year is 31cm, and three years is a cycle;

[0056] (4) After working with this machine, use the combined soil preparation machine (model 1SZL-180) to carry out rotary tillage and ridge suppression, and sowing can be done in the following year.

[0057] Comparative Experiment of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com