Turning device for catapult power device

A technology of a power device and a flip device, which is applied to the launch device and other directions, can solve the problems that the ejection power device cannot be used and stopped at any time, and the vertical lifting requirements of the ejection power device cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

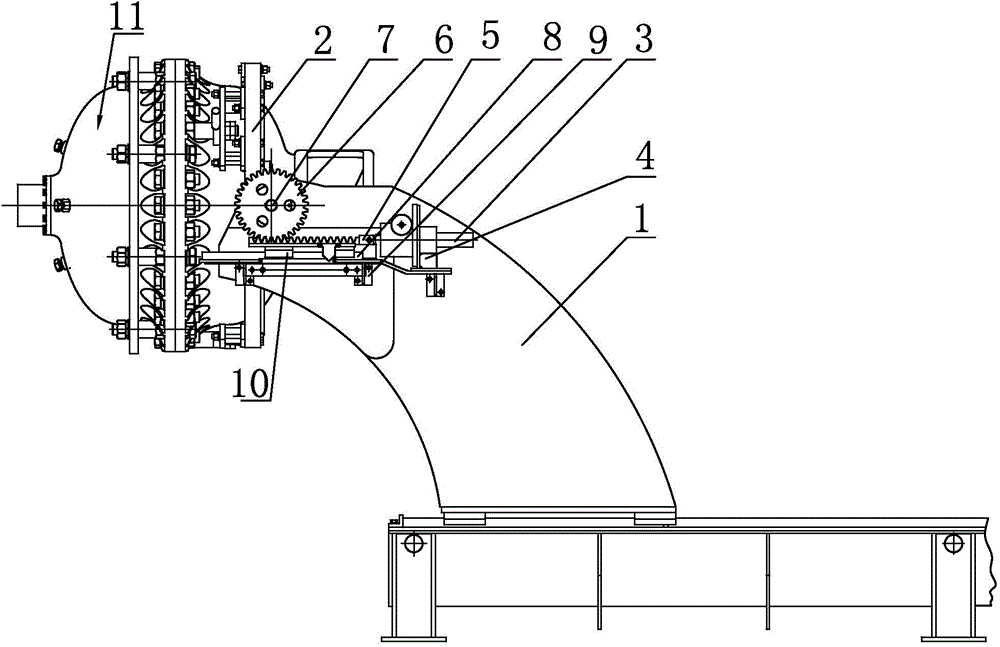

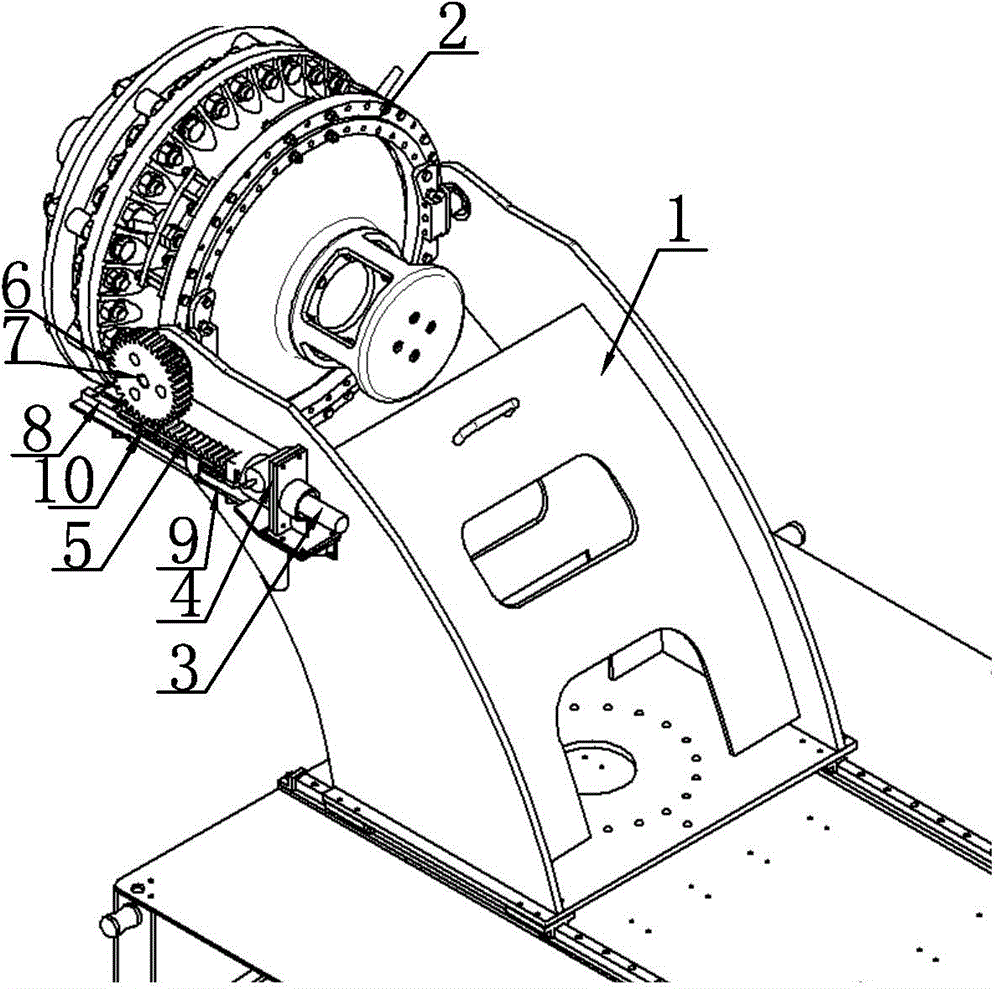

[0015] Such as figure 1 , figure 2 As shown, the flipping device for the ejection power device of the present invention includes a screw jack 3 installed on one side of the sliding bracket 1 through a first bracket 4, a rack 5 welded to the output end of the screw of the screw jack 3, and meshed with the rack 5. The gear 6 and the rack 5 are arranged on one side of the sliding bracket 1 through the support seat, the bottom of the rack 5 is equipped with a guide rail 8 parallel to the rack 5, and the guide rail 8 is fixed on one side of the sliding bracket 1 through the second bracket 9 On the contact surface of the rack 5 and the guide rail 8, a slider 10 is welded, the rack 5 can drive the slider 10 to move back and forth along the guide rail 8, the gear shaft 7 is sleeved on the gear 6, and the gear 6 drives the gear through a flat key The shaft 7 rotates synchronously. One end of the gear shaft 7 passes through the sliding bracket 1 and is screwed to the mounting flange 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com