Frame turnover tool

A technology for frame turning and tooling, which is applied to workbenches, auxiliary devices, manufacturing tools, etc., can solve the problems of low frame turning operation efficiency, large frame weight and volume, and high labor intensity, so as to reduce the occupation of the frame. The effect of reducing land area, reducing labor intensity and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

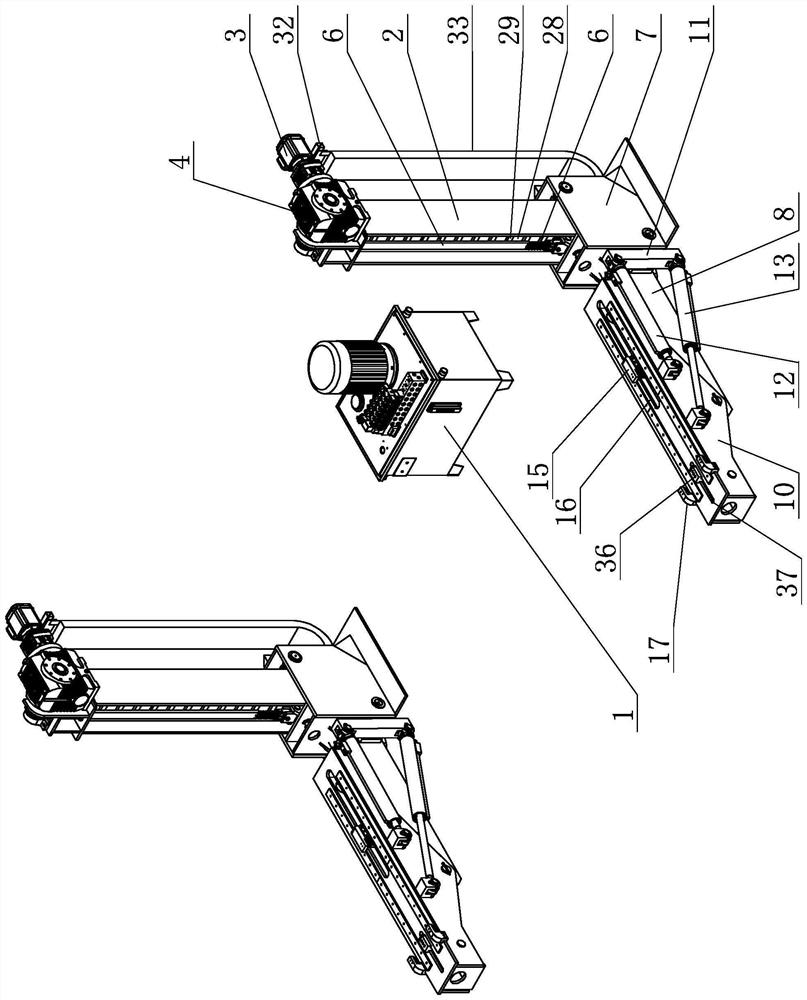

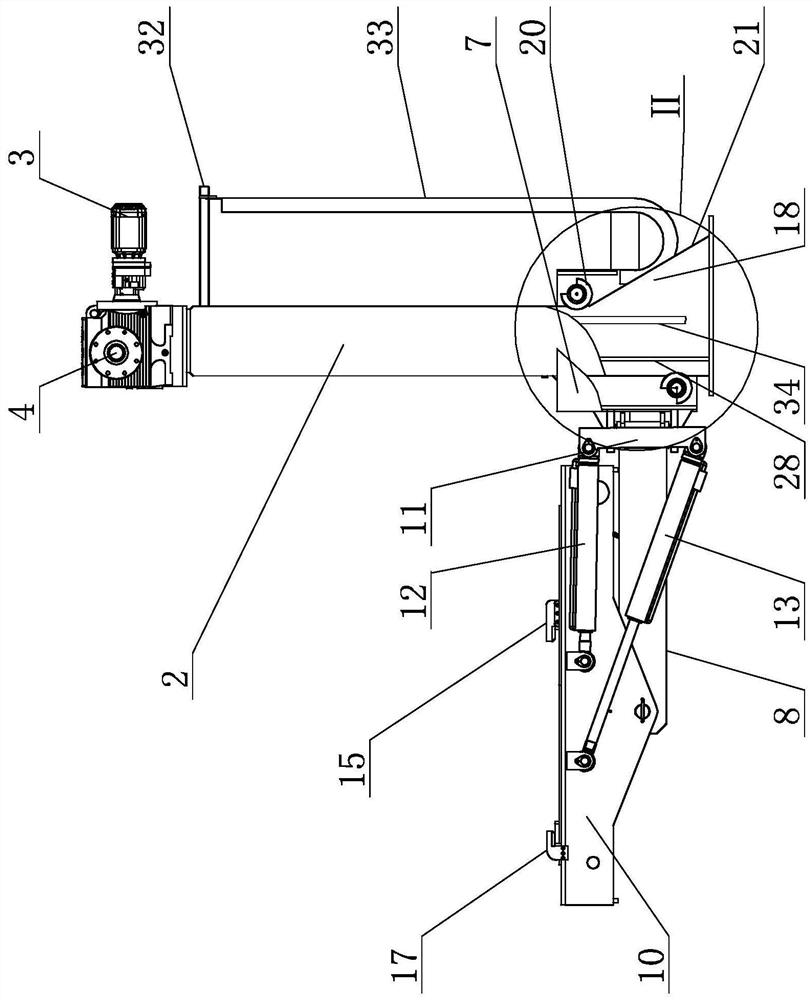

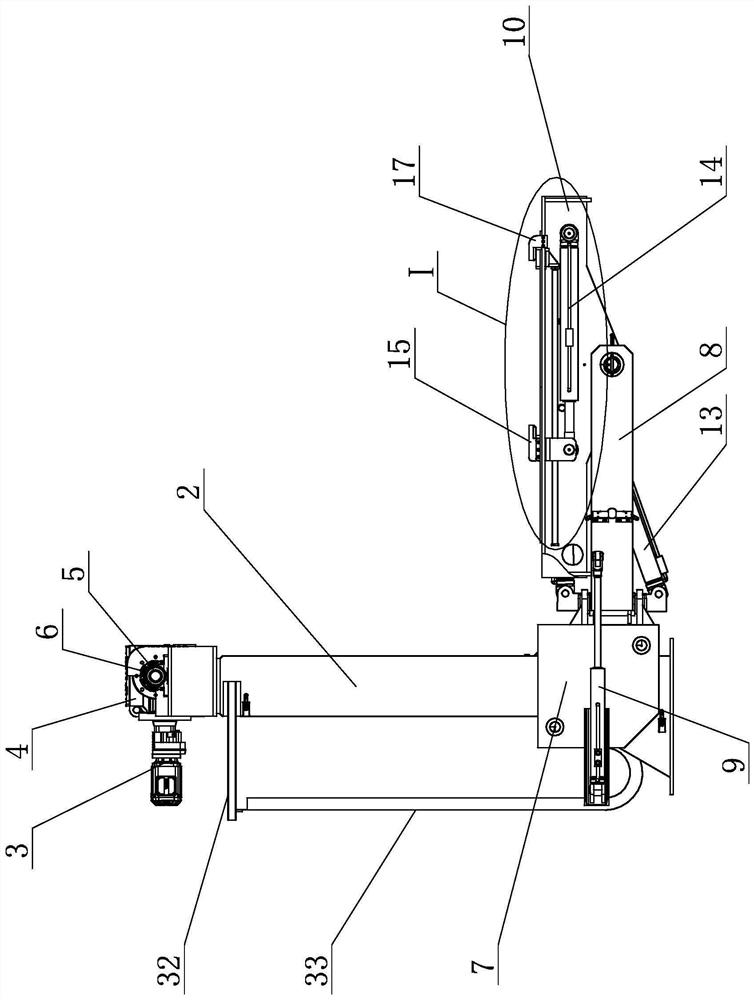

[0015] A kind of vehicle frame overturning tool described in the present invention, such as figure 1 As shown, it includes a hydraulic station 1 and two sets of frame overturning mechanisms arranged side by side. The frame overturning mechanism can undertake the frame, and the hydraulic actuator on the frame overturning mechanism is controlled by the operation of the hydraulic station 1 to complete the frame overturning mechanism. flip operation.

[0016] like figure 2 and image 3 As shown, each group of vehicle frame overturning mechanisms includes a vertical column 2, the top of the column 2 is equipped with a lifting motor 3 and a reducer 4, the output shaft of the reducer 4 is provided with a lifting sprocket 5, and the lifting sprocket 5 is equipped with a chain 6, and the outer circumference of the column 2 is equipped with a lifting sleeve 7. The chain 6 is connected to the lifting sleeve 7 through the anti-fall device. When the lifting motor 3 is started, it can dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com