Automatic stacking machine for C-shaped steel and Z-shaped steel

A palletizer and automatic technology, applied in the field of C, Z-section steel automatic palletizer, can solve the problems of heavy workload and low work efficiency, and achieve the effect of improving uniformity, improving work efficiency and stacking neatly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

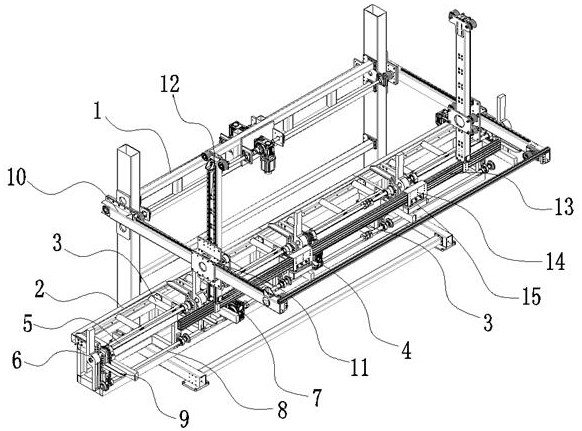

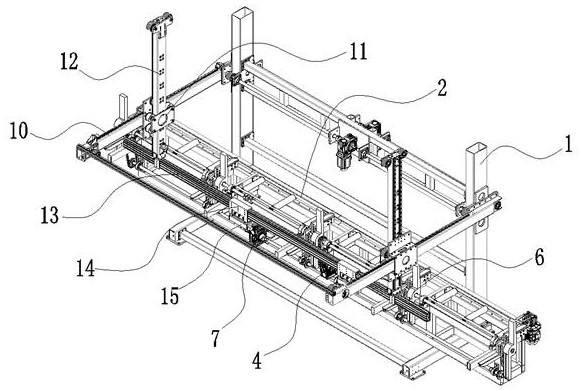

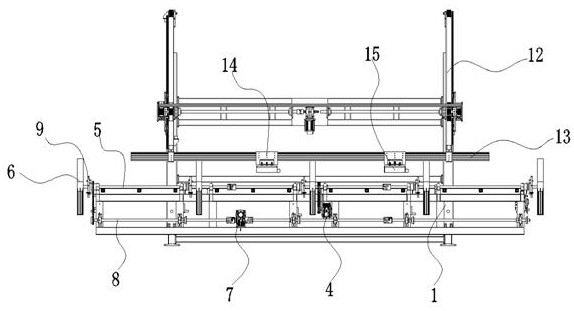

[0046] see Figure 1 to Figure 5 , the present invention provides a technical solution: C, Z-shaped steel automatic palletizer, comprising:

[0047] The main frame 1 is formed by welding rectangular tubes;

[0048] The transmission frame 2 is fixedly installed on the bottom of the main frame 1, and the surface of the transmission frame 2 is provided with a transmission idler 3;

[0049] Carrier 2 also includes:

[0050] The first overturning motor 4 is fixed on the middle part of the side of the transmission frame 2;

[0051] The first turning shaft 5, which is connected to the side top of the transmission frame 2;

[0052] The first turning arm 6 is sleeved and installed on the surface of the first turning shaft 5;

[0053] The second turning motor 7 is fixed on the side bottom of the transmission frame 2;

[0054] The second turning shaft 8 is connected to the side of the second turning motor 7;

[0055] The second turning arm 9 is sleeved on the outer wall of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com