Display screen detecting mechanism

A technology of detection mechanism and display screen, applied in measurement devices, testing optical performance, instruments, etc., can solve the problems of low detection efficiency, poor detection effect, waste of cost, etc., and achieve the effects of convenient operation, simple structure and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

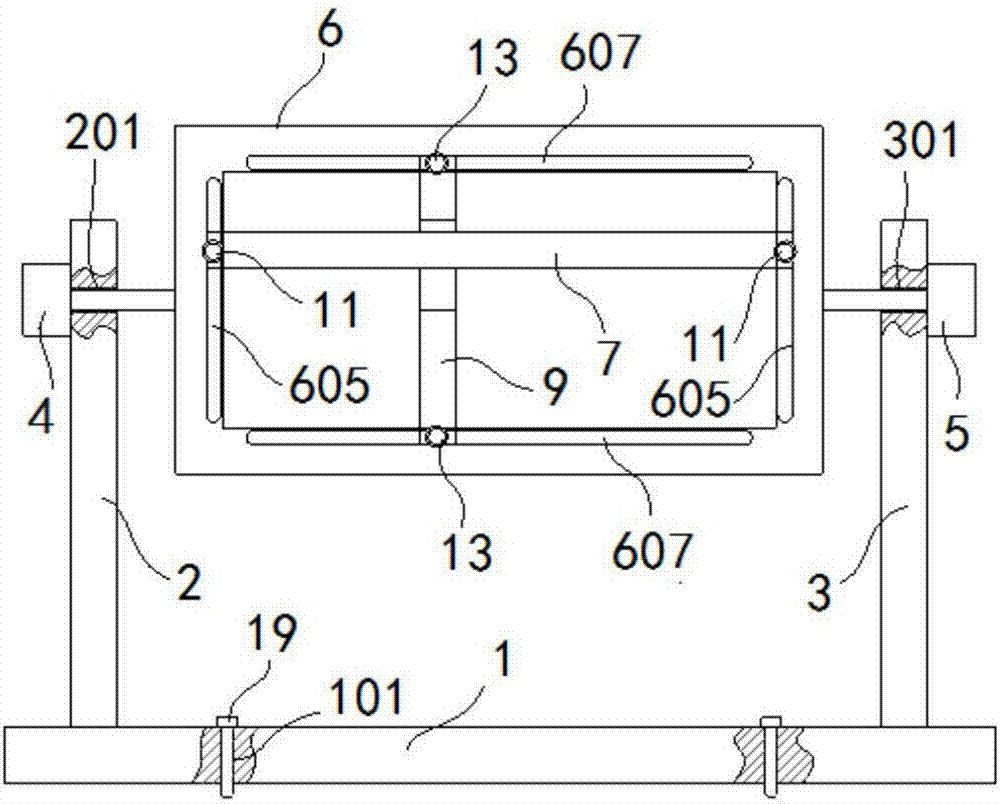

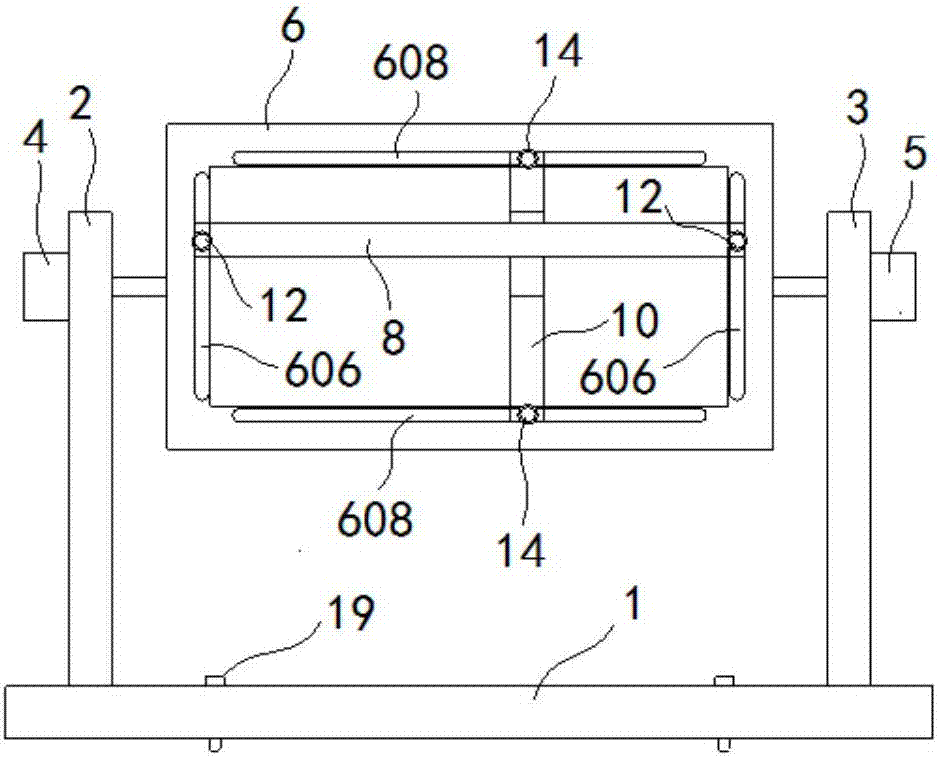

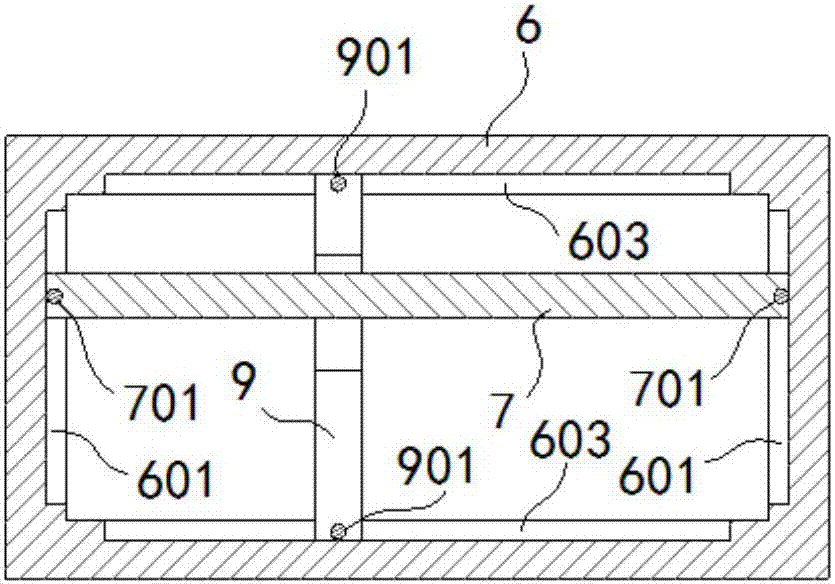

[0028] Such as figure 1 , figure 2 As shown, the display screen detection mechanism of the present invention includes:

[0029] A bottom plate 1, a first support 2 and a second support 3 are respectively arranged on both sides of the upper end of the bottom plate 1 . A plurality of installation holes 101 are formed on the bottom plate 1 , and fixing bolts 19 are arranged on the installation holes 101 .

[0030] A first rotating electrical machine 4 and a second rotating electrical machine 5 , the first rotating electrical machine 4 is fixed on the first bracket 2 , and the second rotating electrical machine 5 is fixed on the second bracket 3 . The first bracket 2 is provided with a first through hole 201, the second bracket 3 is provided with a second through hole 301, and the first rotating motor 4 passes through the first through hole 201 and is connected to the The first end of the installation frame 6 is connected to the second end of the installation frame 6 after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com