Log cut-off sorting machine based on diameter

A kind of sorting machine and log technology, which is applied in the direction of sorting, sawing components, sawing equipment, etc., can solve the problem of not having the classification and storage of cut sections, and achieve the effect of improving cutting and sorting efficiency and facilitating subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

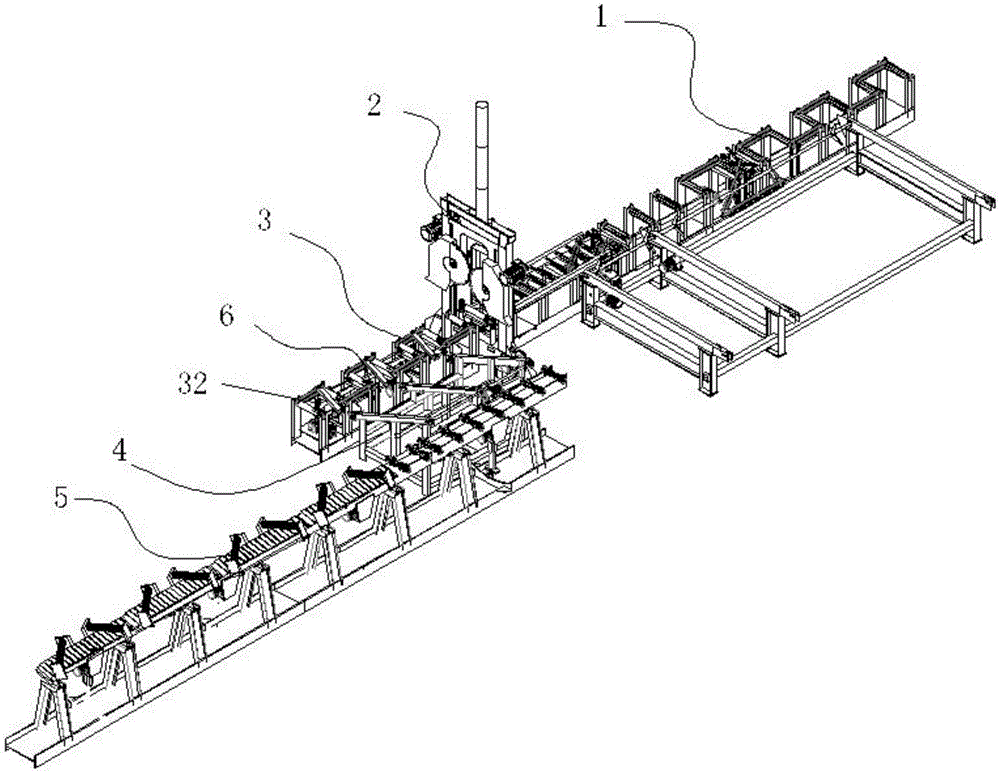

[0024] as attached Figure 1-7 As shown in one, the present invention sequentially includes a feeding rack 1 along the log conveying direction, a first cutting device 2, a conveying device 3, a second cutting device 4, and a sorting device 5; the conveying device 3 includes a base and is arranged on the base There are a number of transmission conveyor rollers 31 on the base, and one end of the base is provided with a log position sensing device 32 corresponding to the second cutting device;

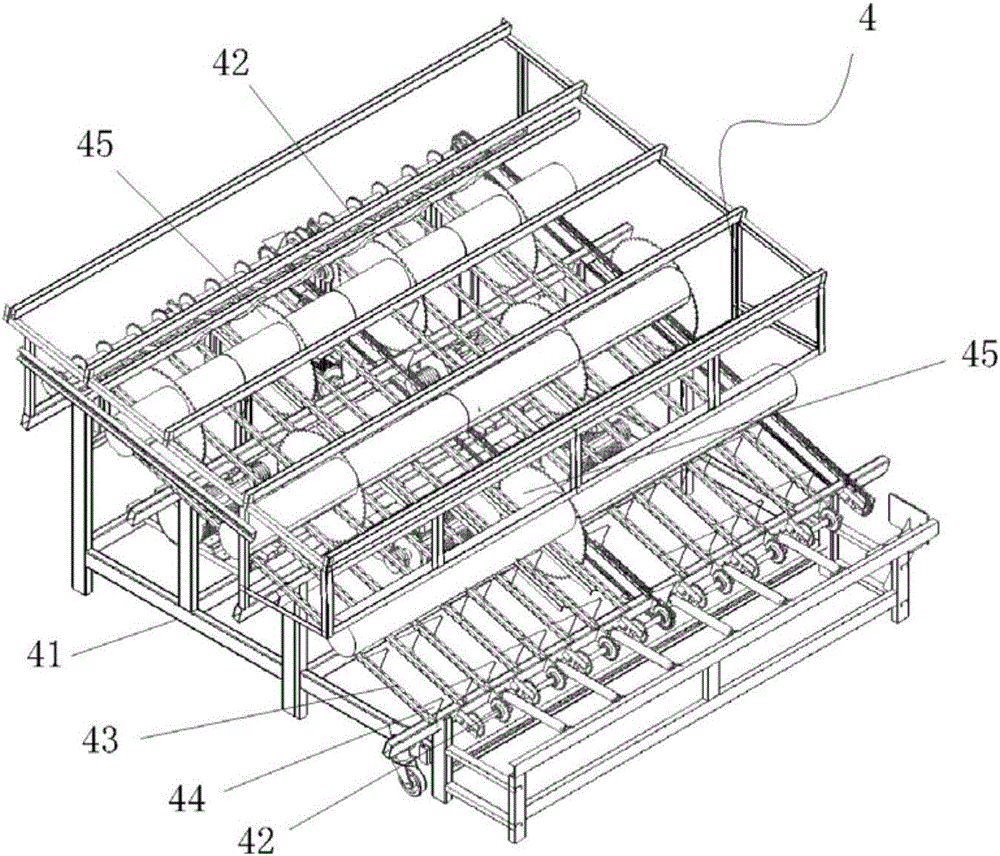

[0025] The second cutting device 4 comprises a frame 41 that is slope-shaped, the higher end of the frame shown and the lower end are all provided with drive shafts 42, and the drive shafts at the two ends are evenly provided with some sprockets at intervals. The sprocket is surrounded by a conveying chain 43, and the chain is provided with a plurality of log conveying rods 44 at intervals towards the outside. The conveying rods 44 at the same position on each chain form a horizontal row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com