Fabricated building wall body

A building wall, prefabricated technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of inability to splicing size adjustment, poor accuracy, and high bolt tightening strength, so that the width of the wall can be quickly adjusted. , Quick and easy adjustment, easy splicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

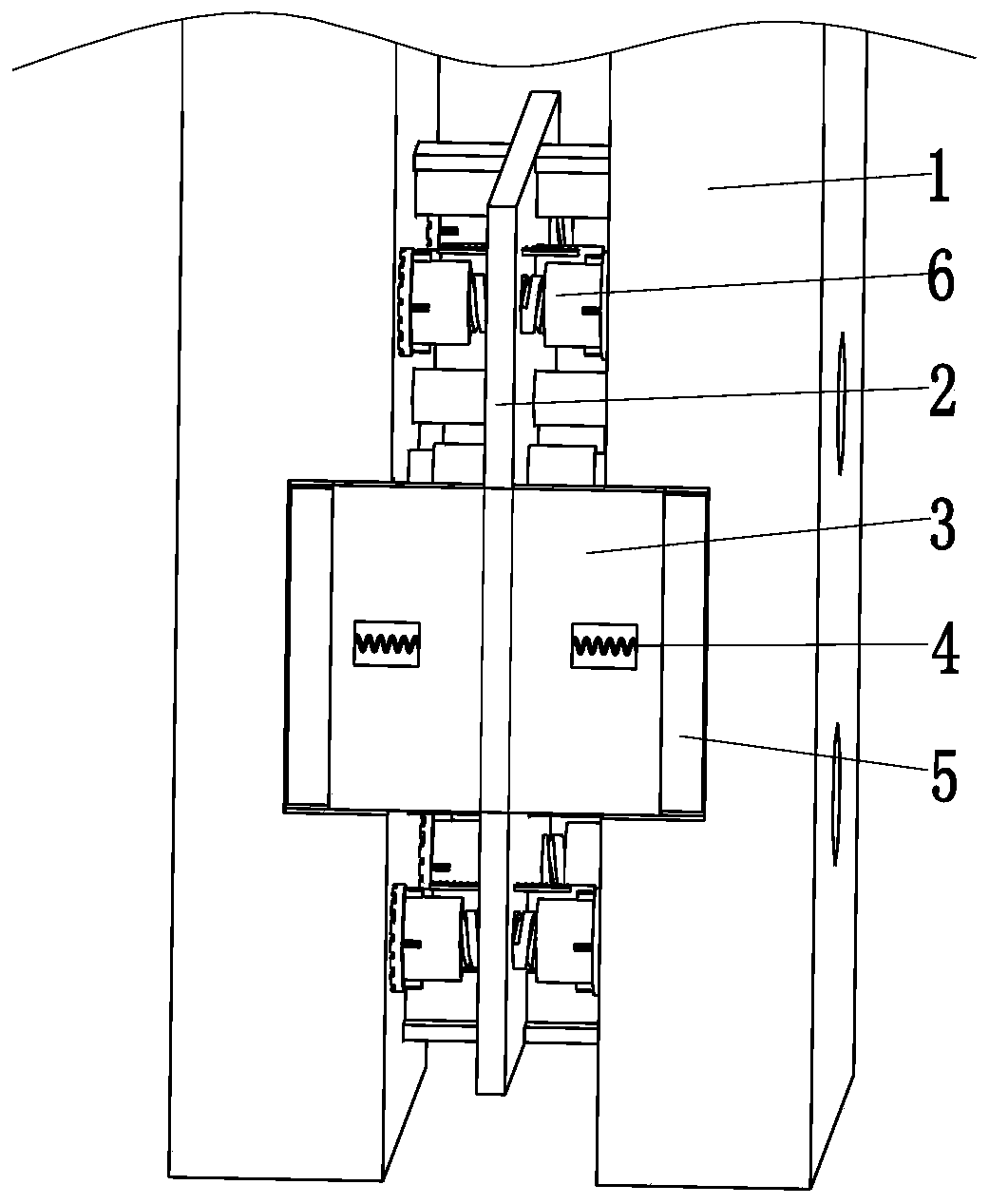

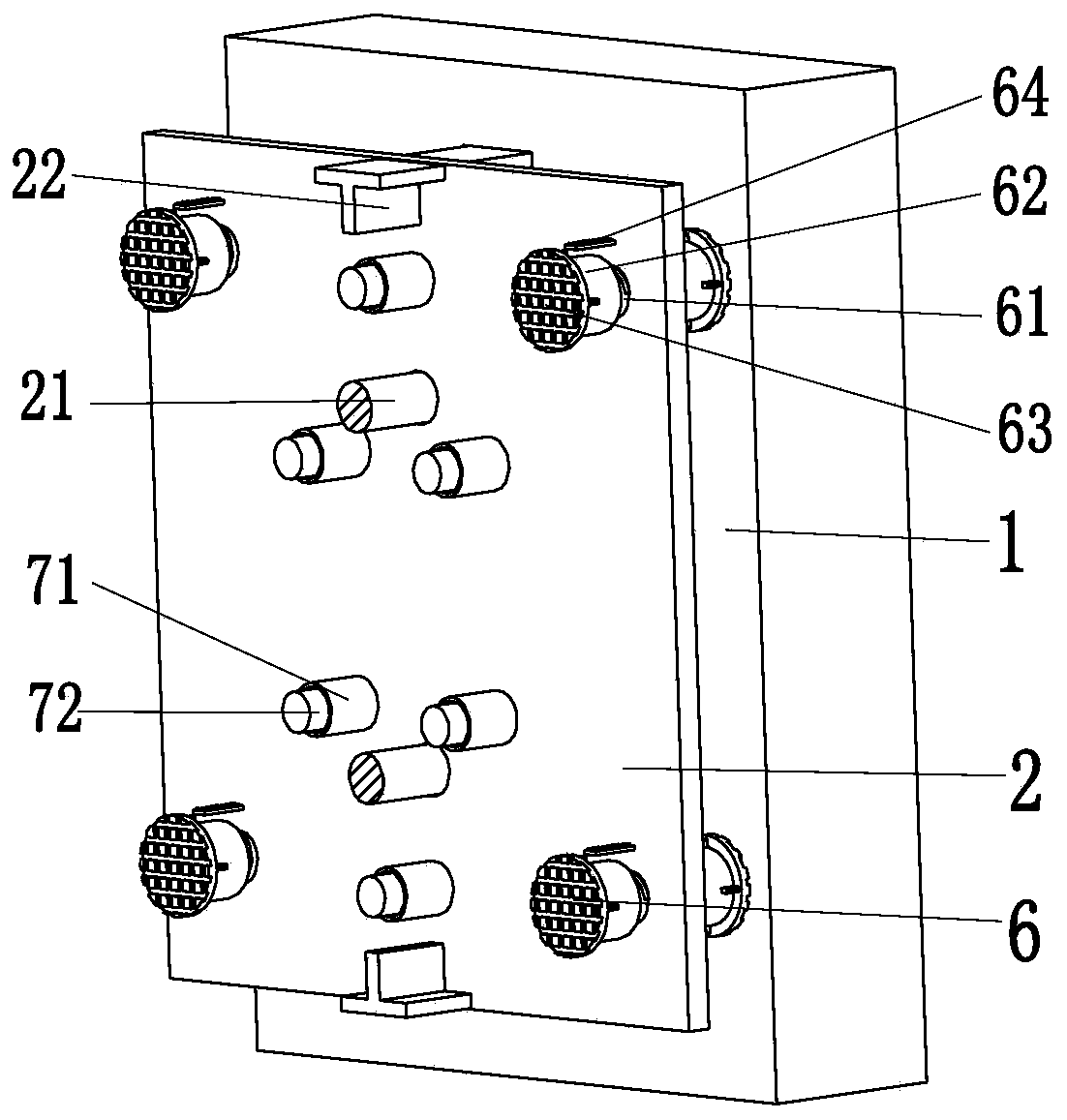

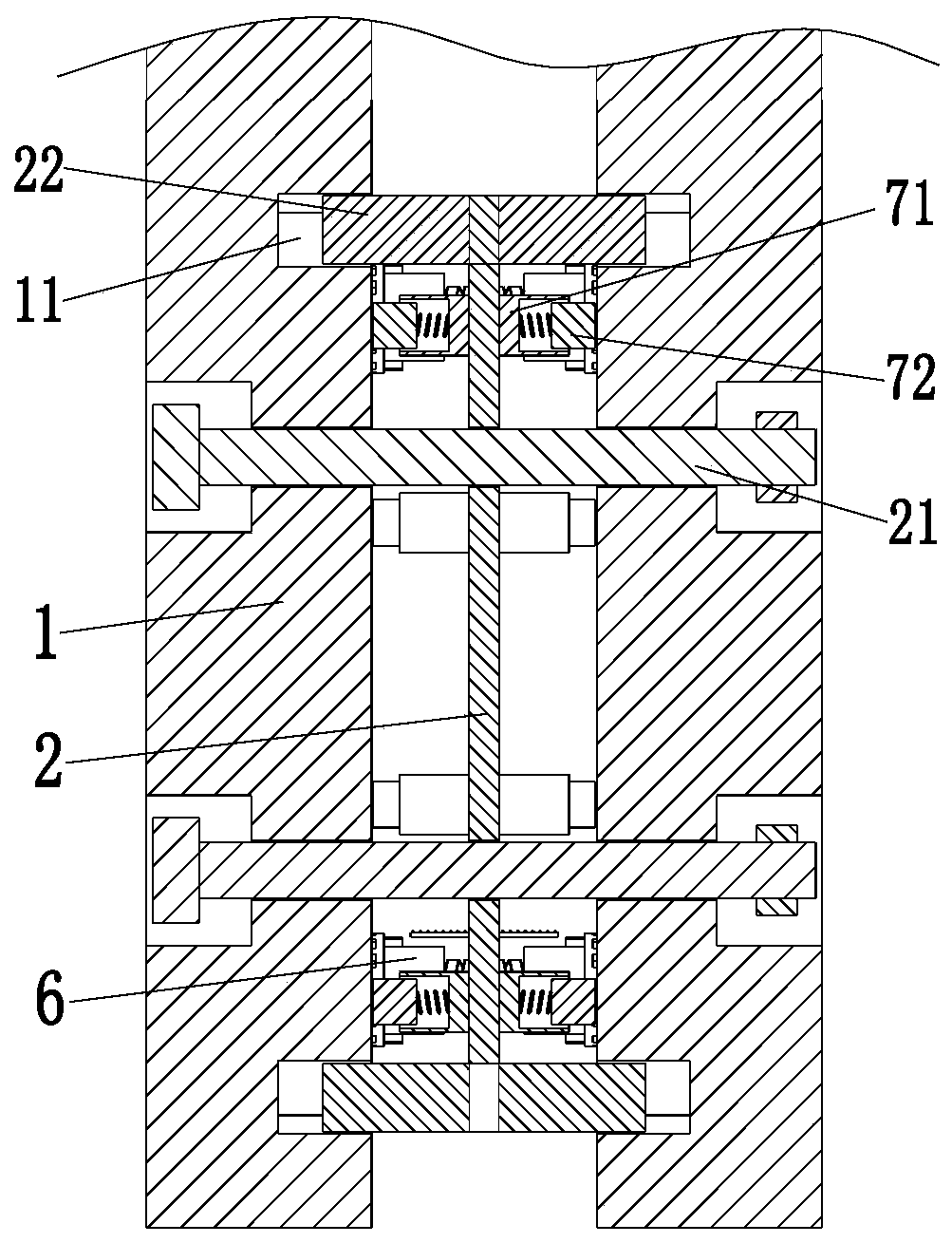

[0033] Such as Figure 1 to Figure 3 As shown, a prefabricated building wall includes a wall panel 1, a connecting frame 2, a side support plate 3, a side support spring 4, a fitting plate 5 and a limit mechanism 6, and the number of the wall panels 1 is two, The square column structure of the wall panel 1, the front and rear inner sides of the wall panel 1 are provided with card slots, the connecting frame 2 is located between the two wall panels 1, and the front and rear sides of the connecting frame 2 are distributed with two side supports 3. The side support plate 3 is symmetrically installed on the left and right sides of the connecting frame 2, the outer surface of the side support plate 3 and the outer surface of the wall panel 1 are in the same plane, and the side support plate 3 is located in the slot provided by the wall panel 1 , The side of the side support plate 3 is provided with a square groove, and in the square groove of each side support plate 3, a fitting pl...

Embodiment 2

[0039] Such as Figure 4 to Figure 7 As shown, in this embodiment, a prefabricated building wall includes a wall panel 1, a connecting frame 2, a side support plate 3, a side support spring 4, a fitting plate 5 and an installation mechanism 8. The wallboard 1 on the left side adopts a non-porous structure, and a bolt hole is distributed at the upper and lower ends of each mounting hole of the connecting frame 2; the side support plate 3 is installed on the front side, and the left end of the side support plate 3 is Solid structure, the right end of the side support plate 3 is provided with a square groove, and a fitting plate 5 is installed in the square groove of each side support plate 3 through a side support spring 4 .

[0040] The installation mechanism 8 includes an installation connecting column 81, a raised plate 82, a limit plate 83 and a fixing bolt 84. The installation connecting column 81 is installed on the right side of the wall panel 1 on the left side of the co...

Embodiment 3

[0047] Such as Figure 8 As shown, two wall panels 1 can be quickly spliced to form a wall through the connecting device in the first embodiment or the connecting device in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com