Transmission electron microscope in-situ nano indentation method for micron alloy containing isometric single nano-twin crystal

A technology of nano-twinning and transmission electron microscopy, which is applied in the use of radiation for material analysis, etc., can solve the problems that the in-situ nano-indentation method of transmission electron microscopy is difficult to implement, difficult to operate, and difficult to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

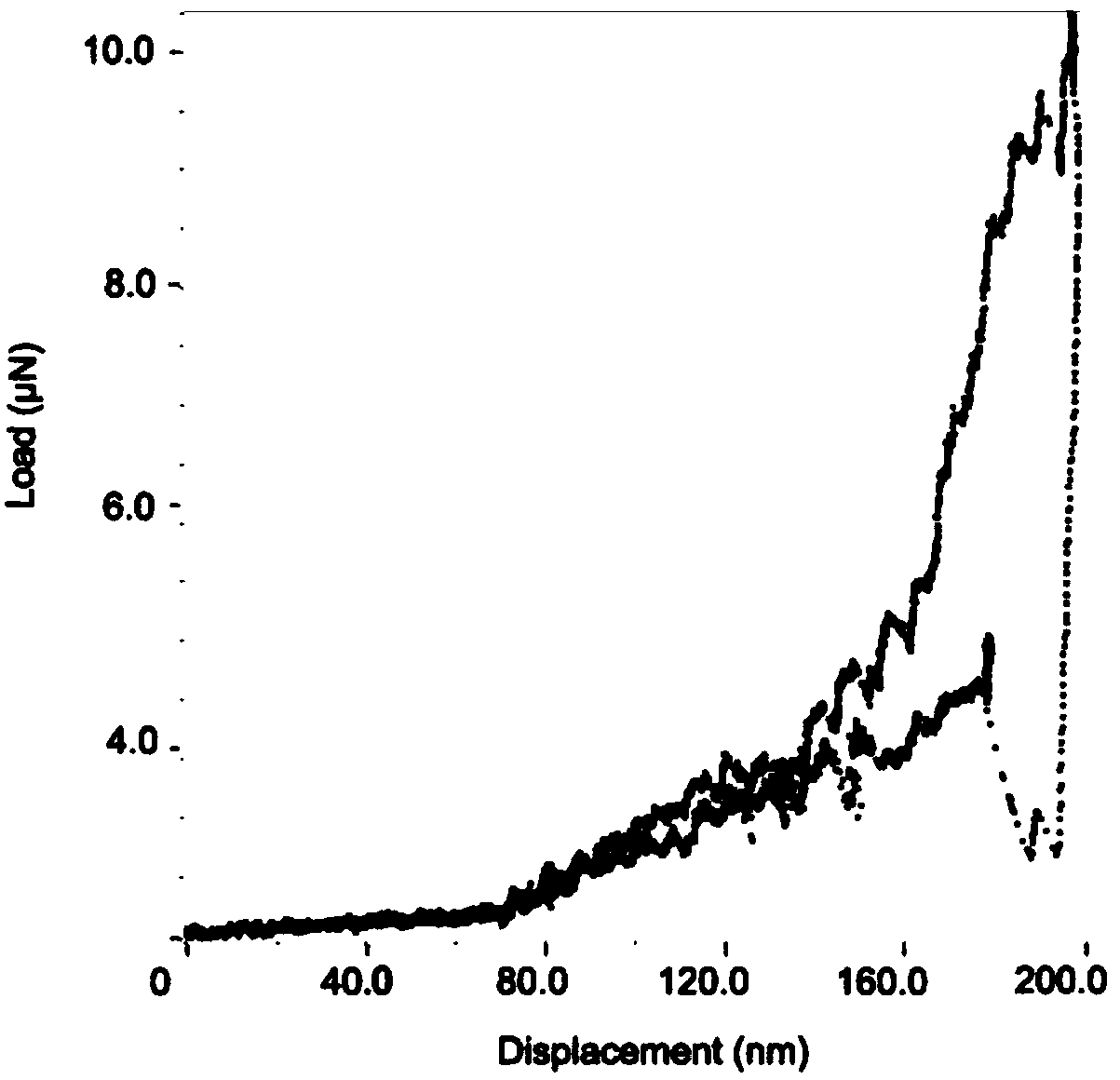

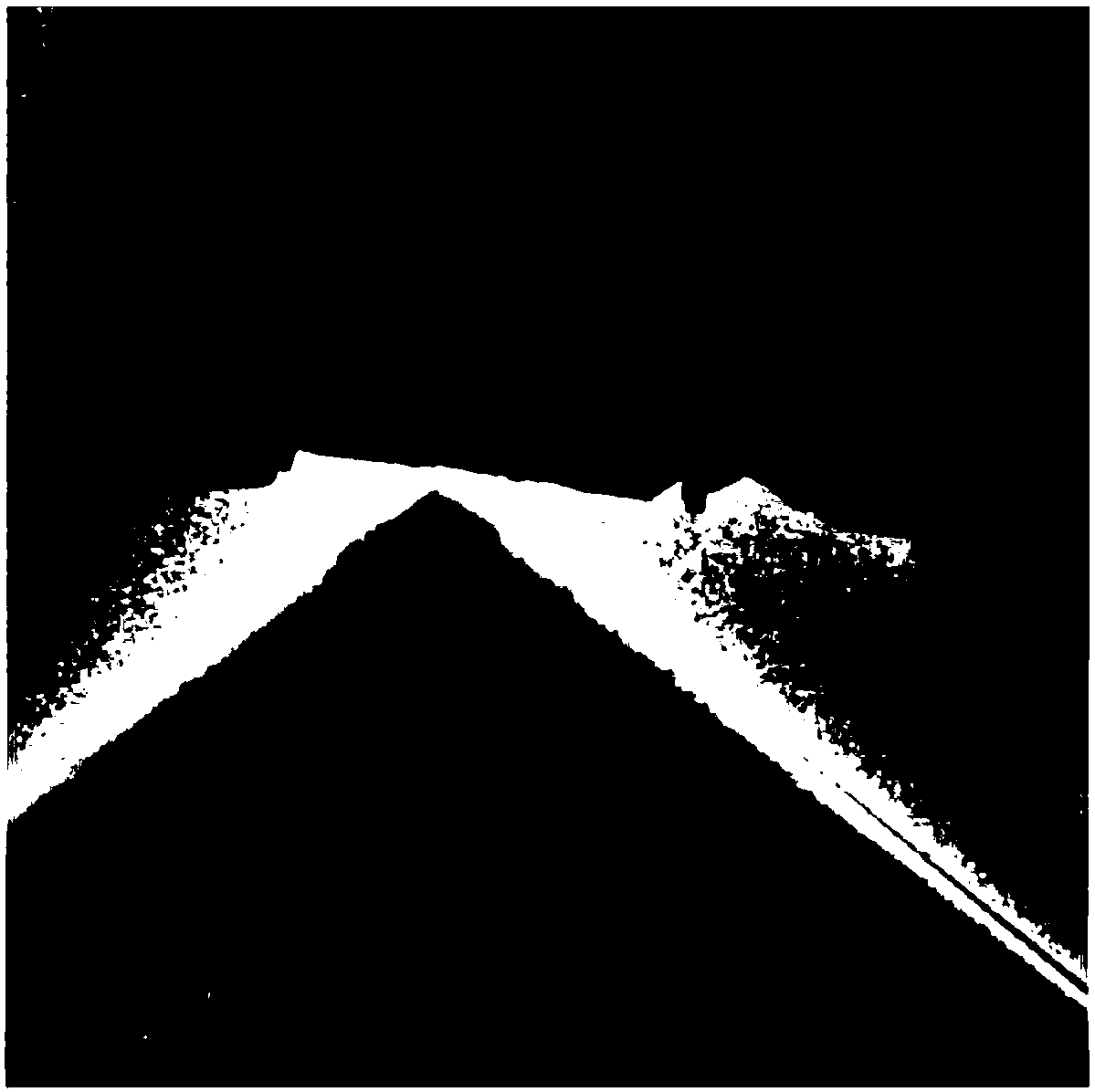

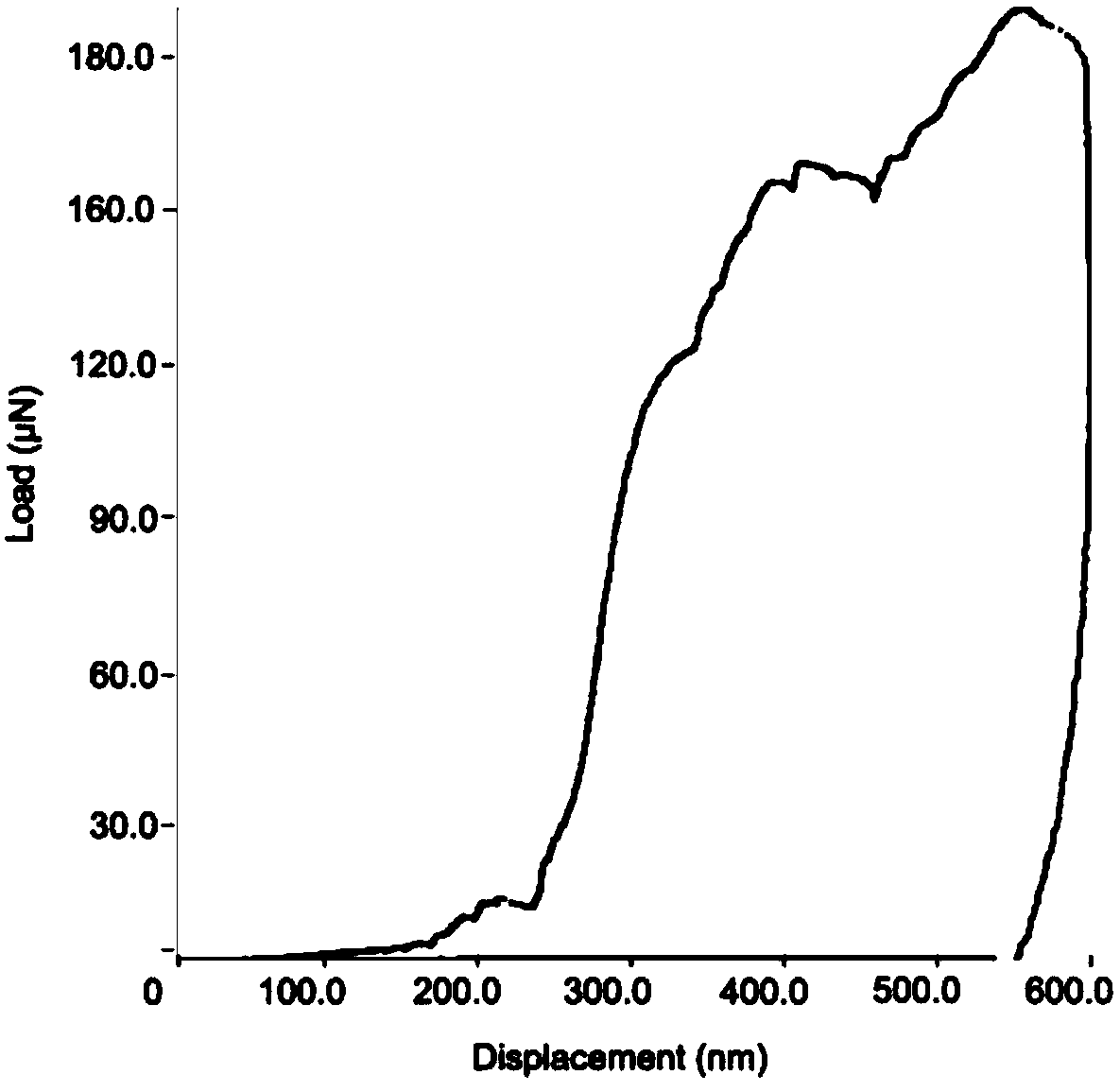

[0034] A commercial 4-inch Si(111) silicon wafer that has been chemically mechanically polished uses the Ar ion beam etching method in the IC manufacturing process to etch a quadrangular pyramid pit on the silicon wafer. The pit depth is 100-200 μm, two four The distance between the pyramids is 300-400 μm, and an array of such micro-pits is formed covering the surface of the silicon wafer. After the etching is completed, use a diamond pen to cut small pieces with a length and width of 8-9 mm. Put 4 small pieces into the chemical vapor deposition equipment to grow the macro-micro-nano integrated diamond tool. After the growth is completed, the radius of curvature of each tip is 60-90nm, and the height of the tip is 100-200μm , the distance between the tool tips is 300-400μm, the tool tips form an array, coveri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com