Cofferdam construction method combining film bag sand filling with steel sheet pile

A technology of steel sheet pile cofferdam and construction method, which is applied in sheet pile wall, foundation structure engineering, excavation and other directions to achieve the effects of strong foundation adaptability, fast construction progress and lower construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

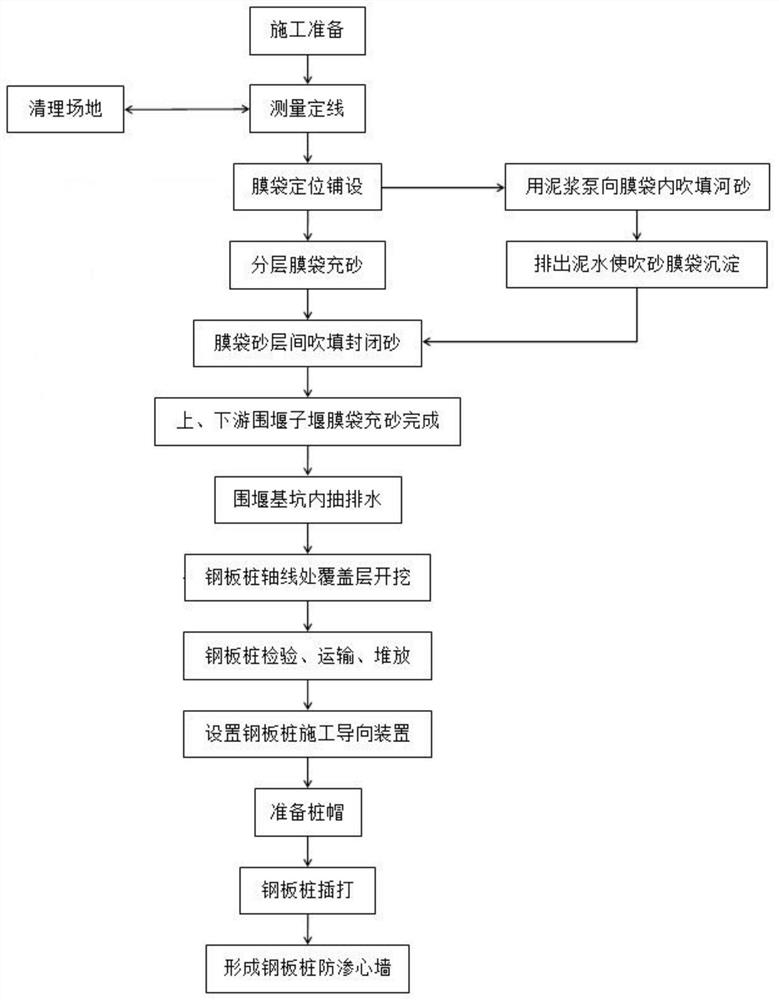

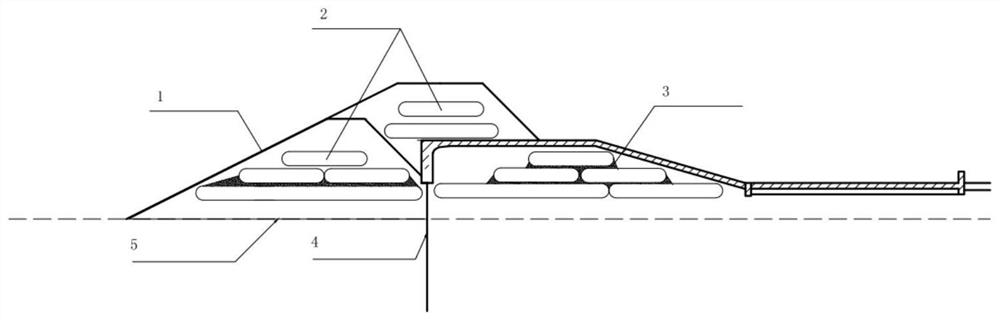

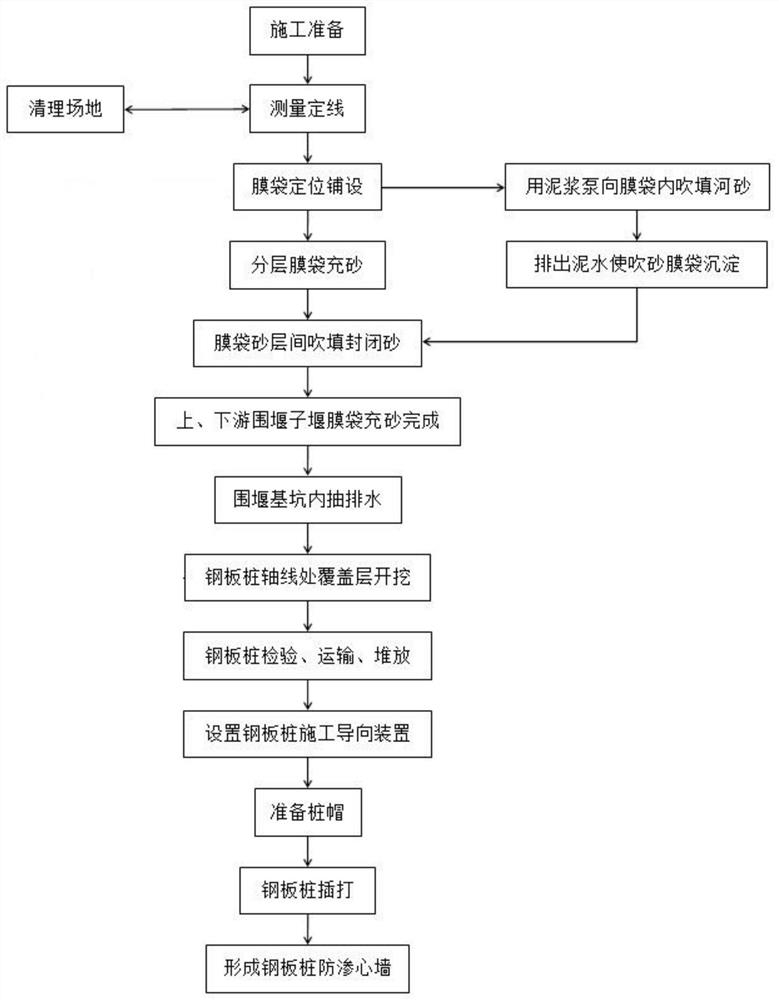

[0033] In this embodiment, the construction method of the present invention is applied to the upper reaches of the river gate of Hepu County, Guangxi Beiwu County, 250 m, downstream of the shaft length of 260 m. Append figure 1 Attachment figure 2 As shown, the present embodiment utilizes a membrane bag sand sand binding steel sheet pile cofferdam construction method: including the following steps:

[0034] S1: Measuring the line, determine the position of the steel plate pile to prevent the centerline of the steel sheet, the position of the film bag and the slope line of the film bag sandwich.

[0035] S2: Membrane bag positioning, film bag starting from the bottom of the riverbed, laying and construction from the left bank to the right bank, should choose the low tide to start construction to facilitate operation. The membrane bag should be laid in the direction of the smooth flow, and the film bag is placed in the position of the measured position, and the four-angle of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com