Patents

Literature

38results about How to "Improve water pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

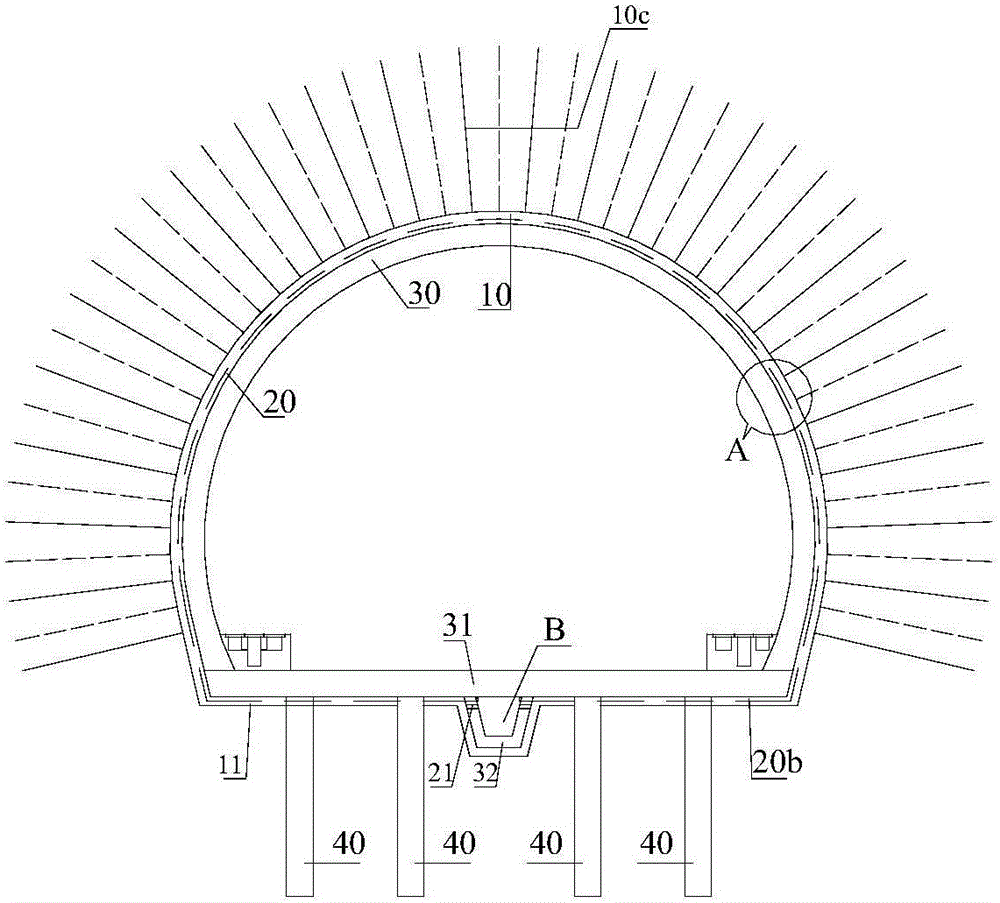

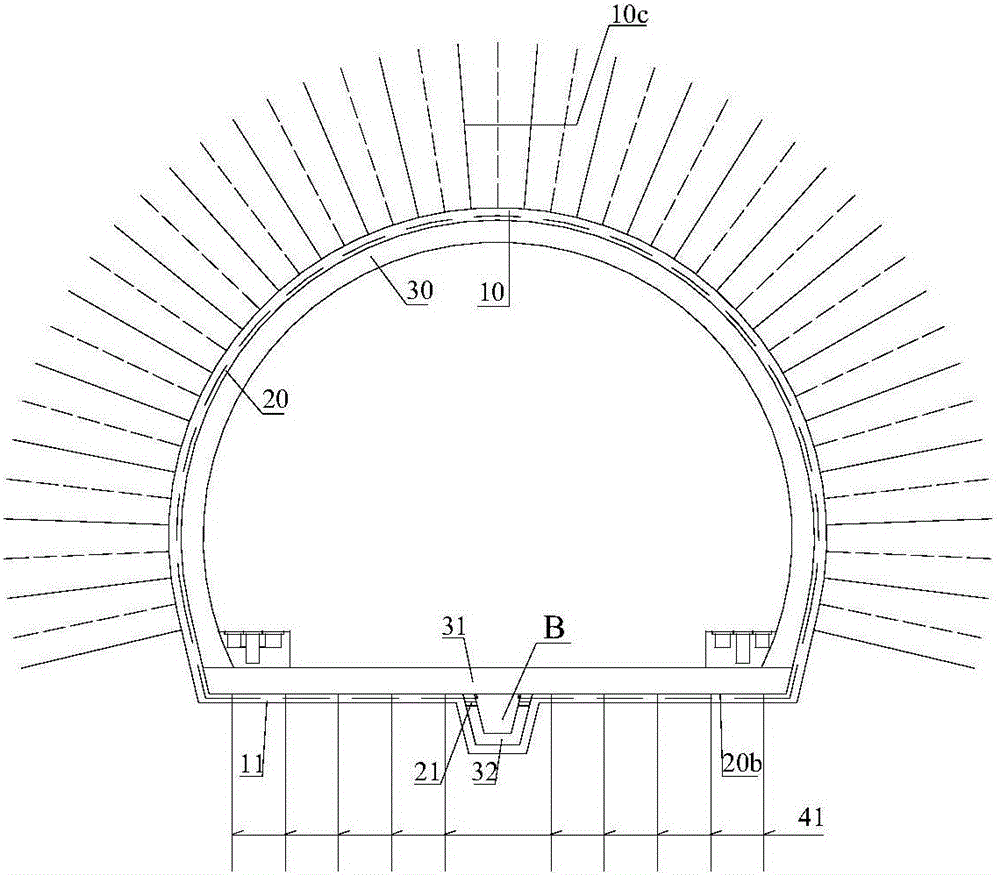

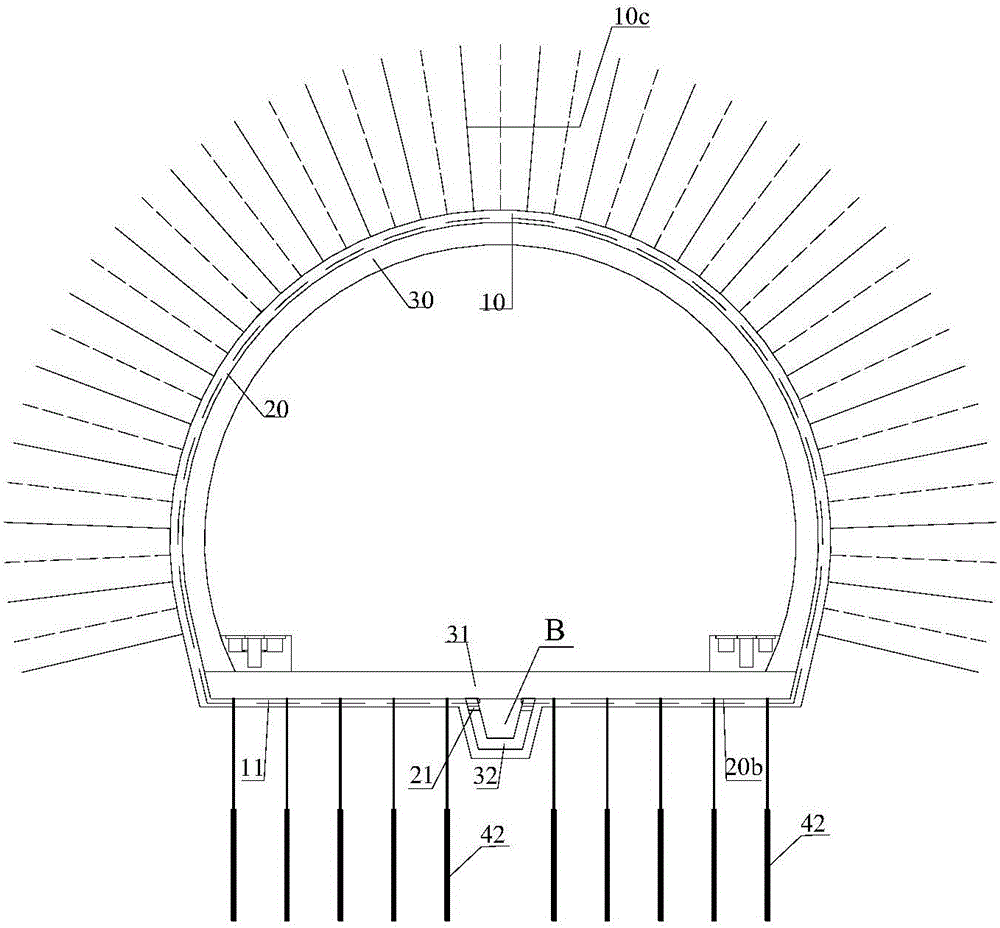

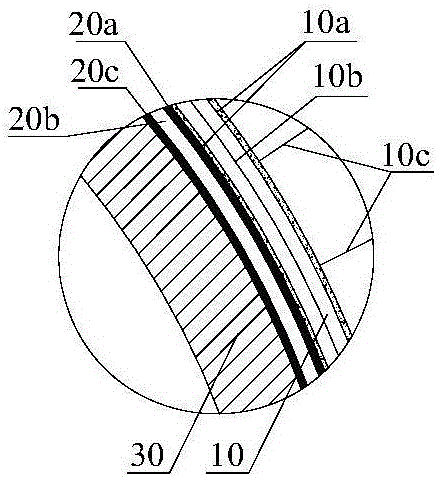

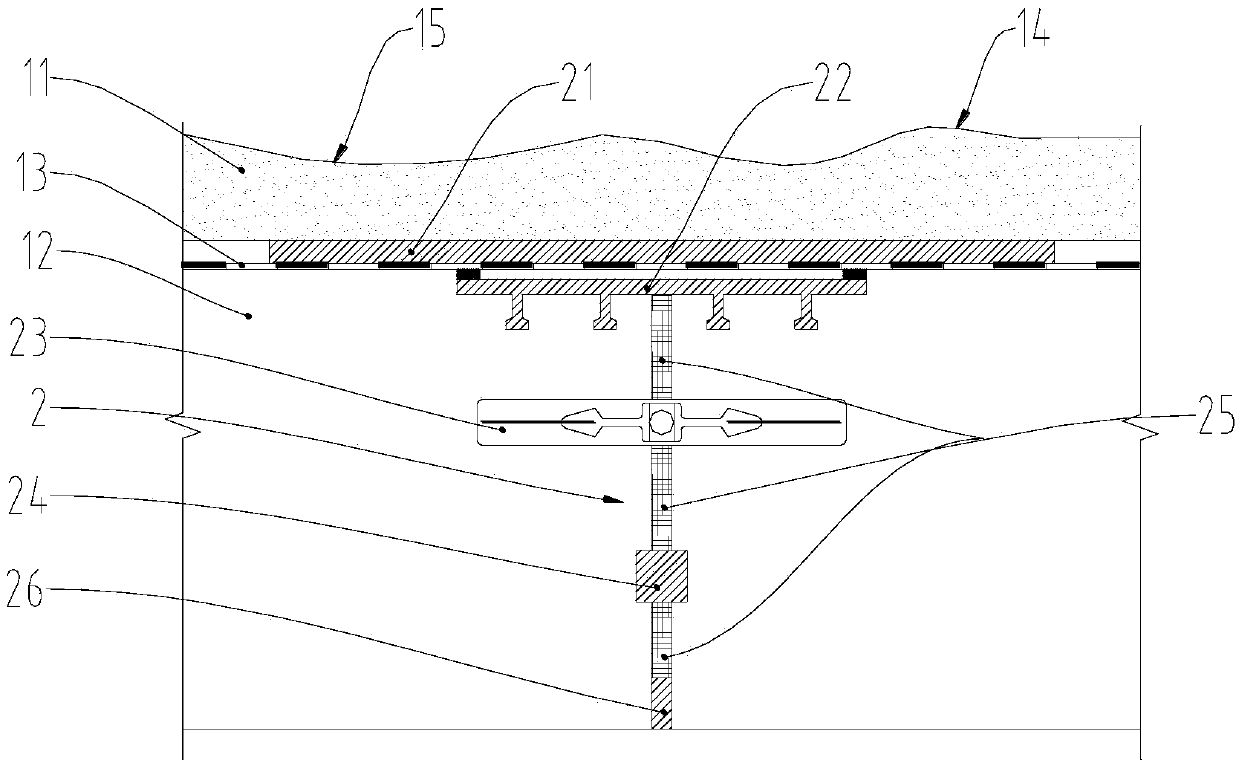

Floor anchoring constraint tunnel lining structure

ActiveCN105927272AImprove carrying capacityAvoid cracking and bulgingUnderground chambersDrainageEngineeringStructural engineering

The invention relates to a floor anchoring constraint tunnel lining structure, so as to effectively reduce vertical deformation of a base and enhance hydraulic pressure resistance and floating resistance of the lining structure. The floor anchoring constraint tunnel lining structure comprises a primary arch wall bracing structure, a secondary lining structure, a waterproof and drainage system and a central drainage channel, and the waterproof and drainage system is arranged between the primary arch wall bracing structure and the secondary lining structure. The secondary lining structure comprises a secondary arch wall lining and a floor, the floor is located on a base leveling course, and two ends of the floor are solidified with two ends of the secondary arch wall lining. Vertical constraint members are arranged in a base rock and soil layer under the floor transversely in a spaced manner as well as in the route extension direction in a spaced manner, the lower end of each vertical constraint member extends into a stable rock and soil layer, and the upper end of each vertical constrain member penetrates the base leveling course to be fixedly connected with the floor.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Special high-temperature resistant waterproof air and moisture permeable resin for coating printing and preparation method thereof

InactiveCN103265682AImprove heat resistanceGood flexibilityFibre treatmentMoisture permeabilitySilsesquioxane

The invention discloses special high-temperature resistant waterproof air and moisture permeable resin for coating printing and a preparation method thereof. The resin is prepared by the following steps of: obtaining a prepolymer through a reaction between polyether polyol and diisocyanate; and modifying the prepolymer by use of polyhedral oligomeric silsesquioxane to obtain the resin, wherein the average molecular weight of the resin is 50000-150000g / mol, the viscosity is 60000-100000cps / 25 DEG C, and the solid content of the resin is 30-55%. In the polyurethane resin prepared by the method disclosed by the invention, the moisture permeability can reach 7500g / m<2>.24H, and the water pressure resistance is greater than 10000mmH2O; moreover, the polyurethane resin has the processing characteristic of tolerating a temperature of 200-230 DEG C for continuous 30S during coating printing; and the resin has highly-permeable coating and soft and smooth handfeel, and is washable and very suitable for the direct coating and coating printing technology of fabric coating processing.

Owner:宜兴市华夏化工材料有限公司

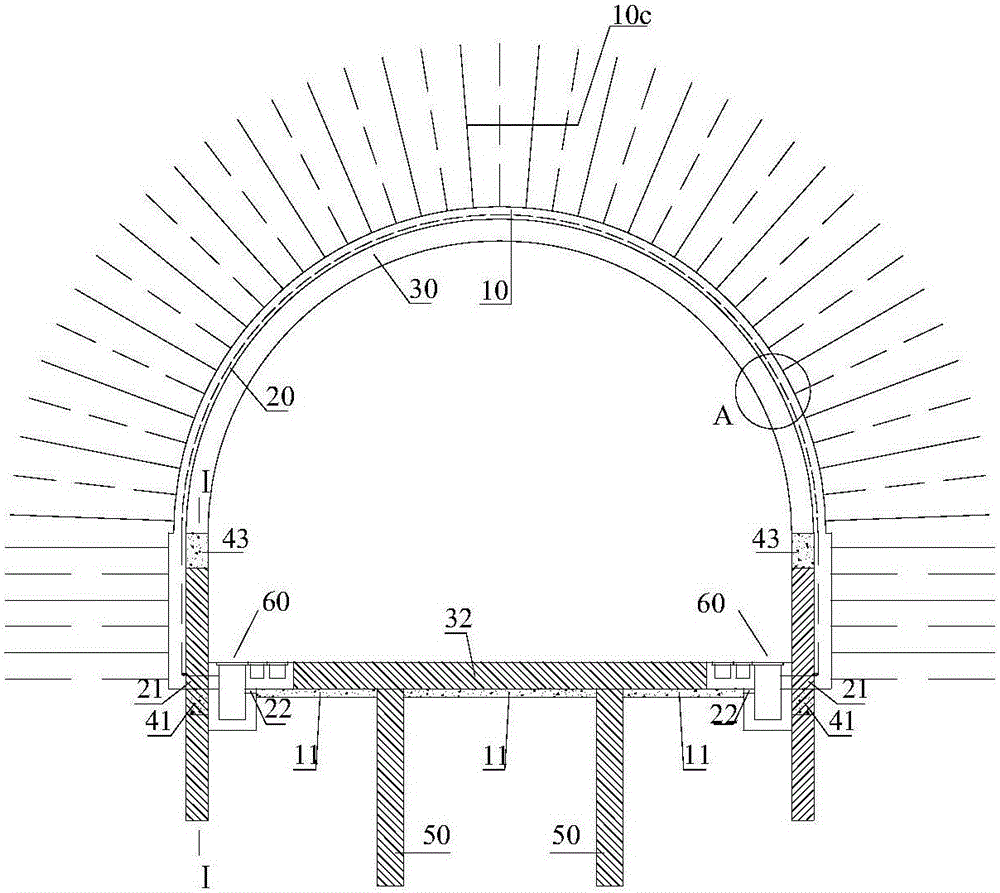

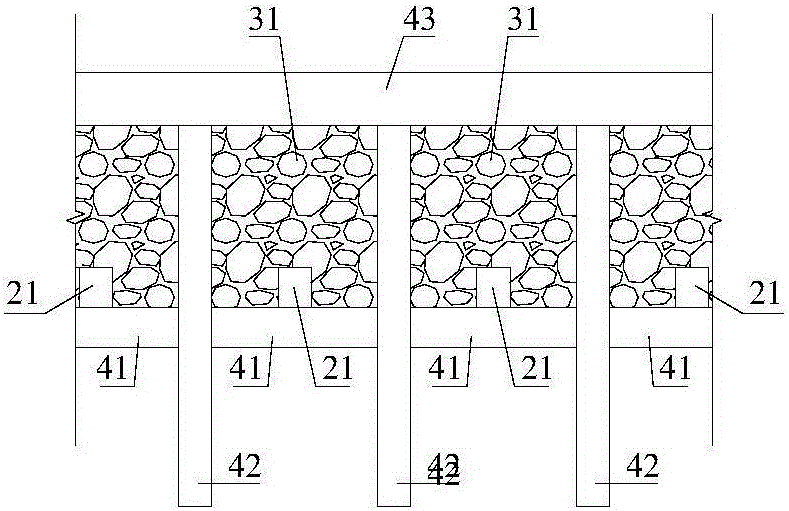

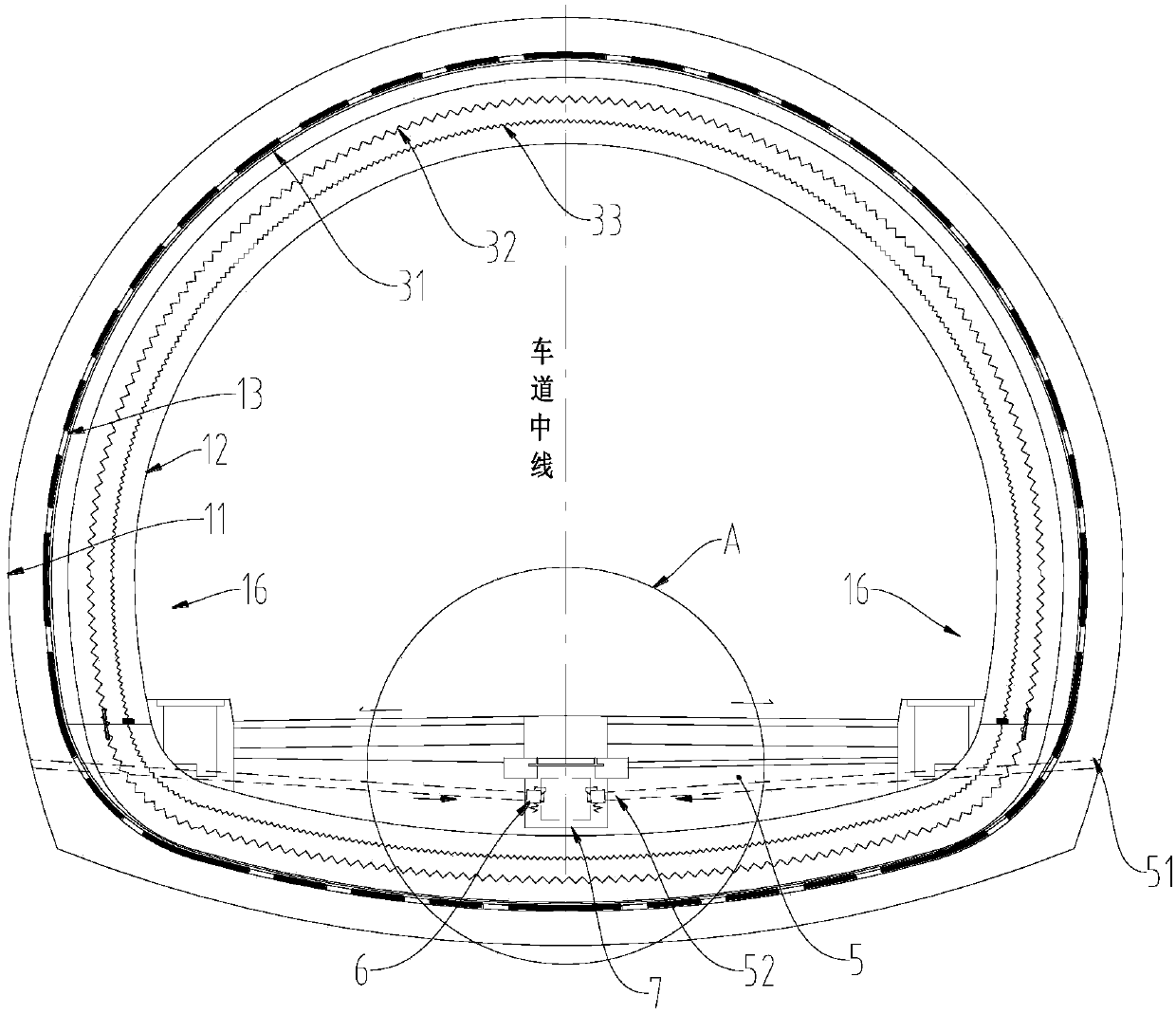

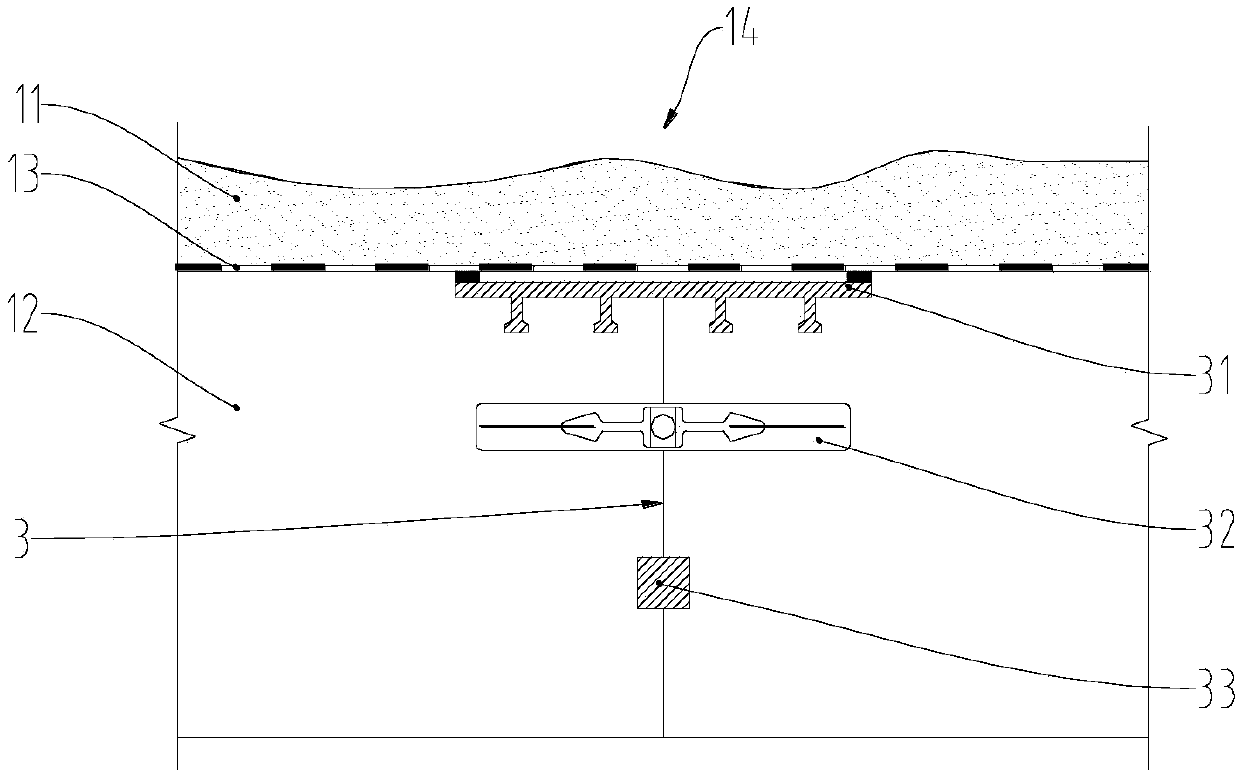

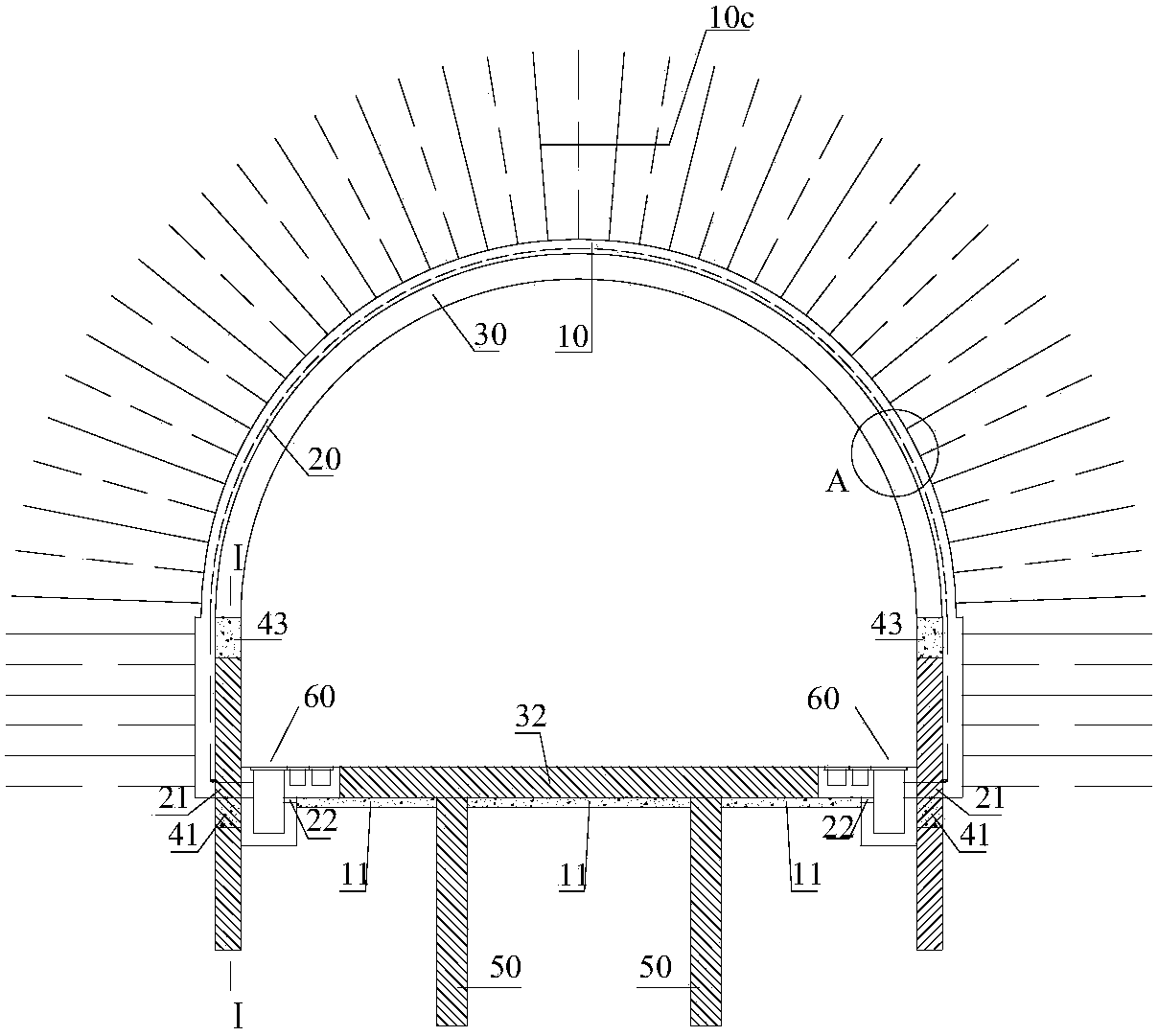

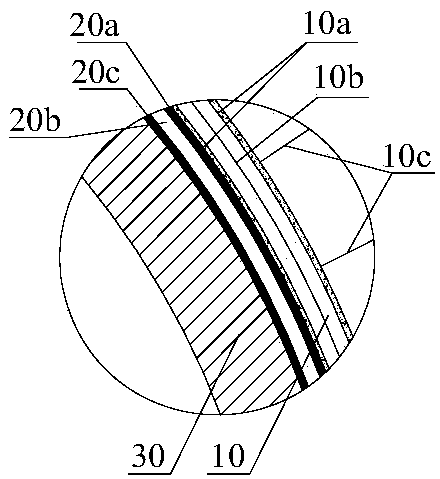

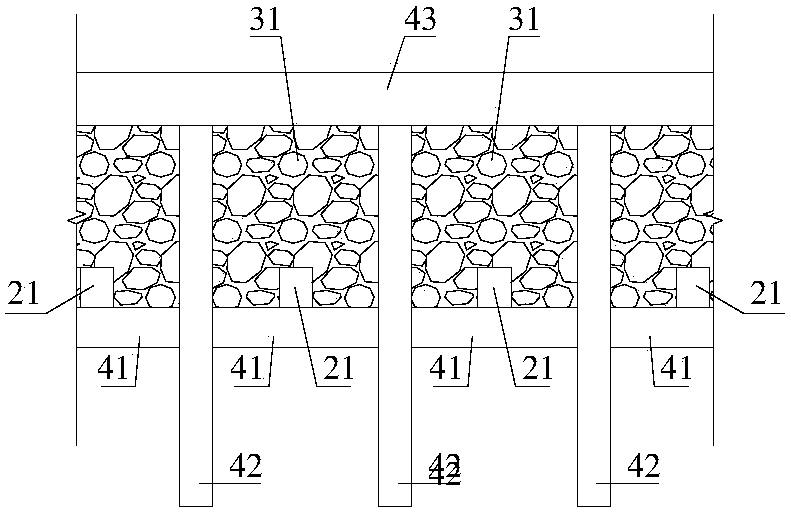

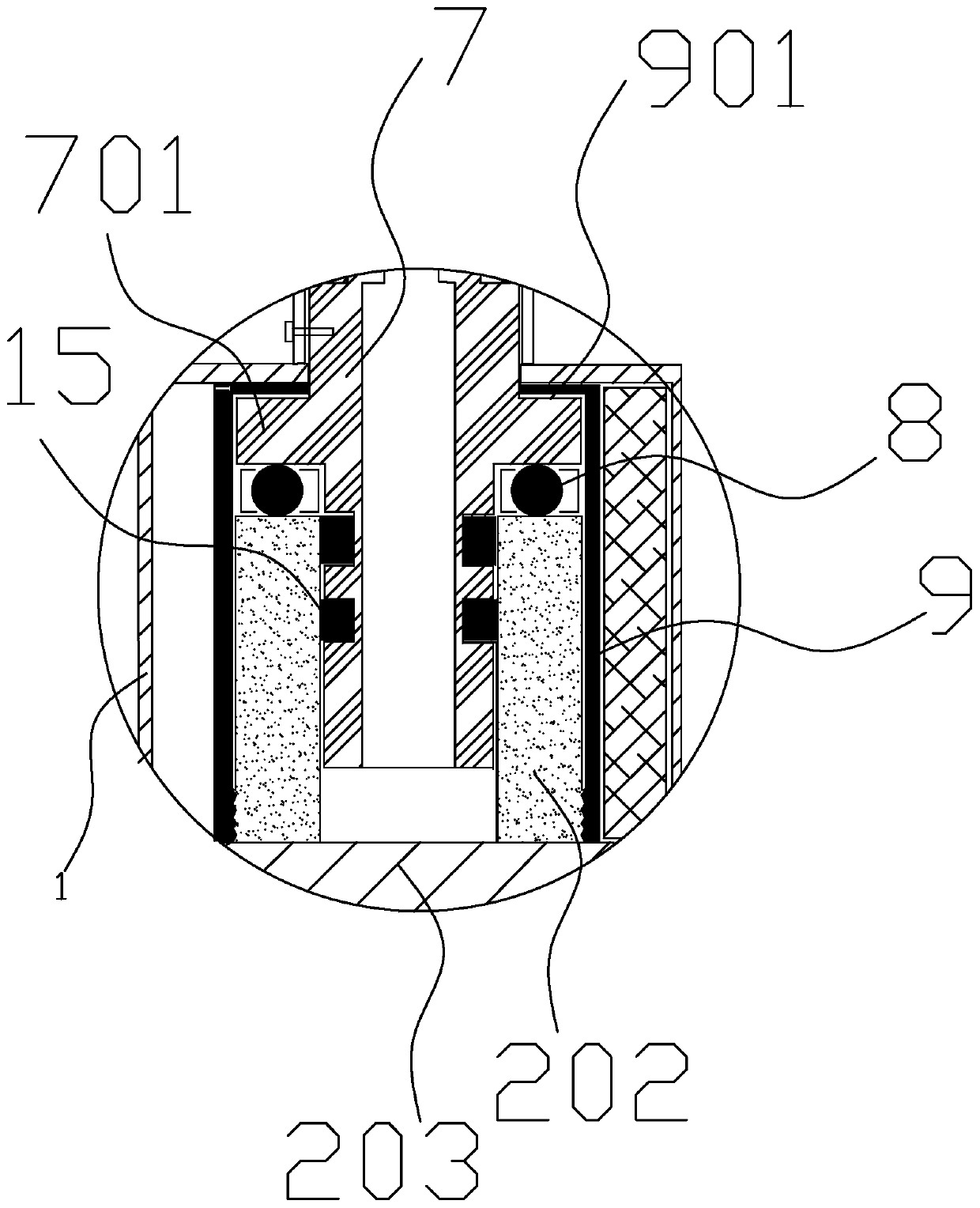

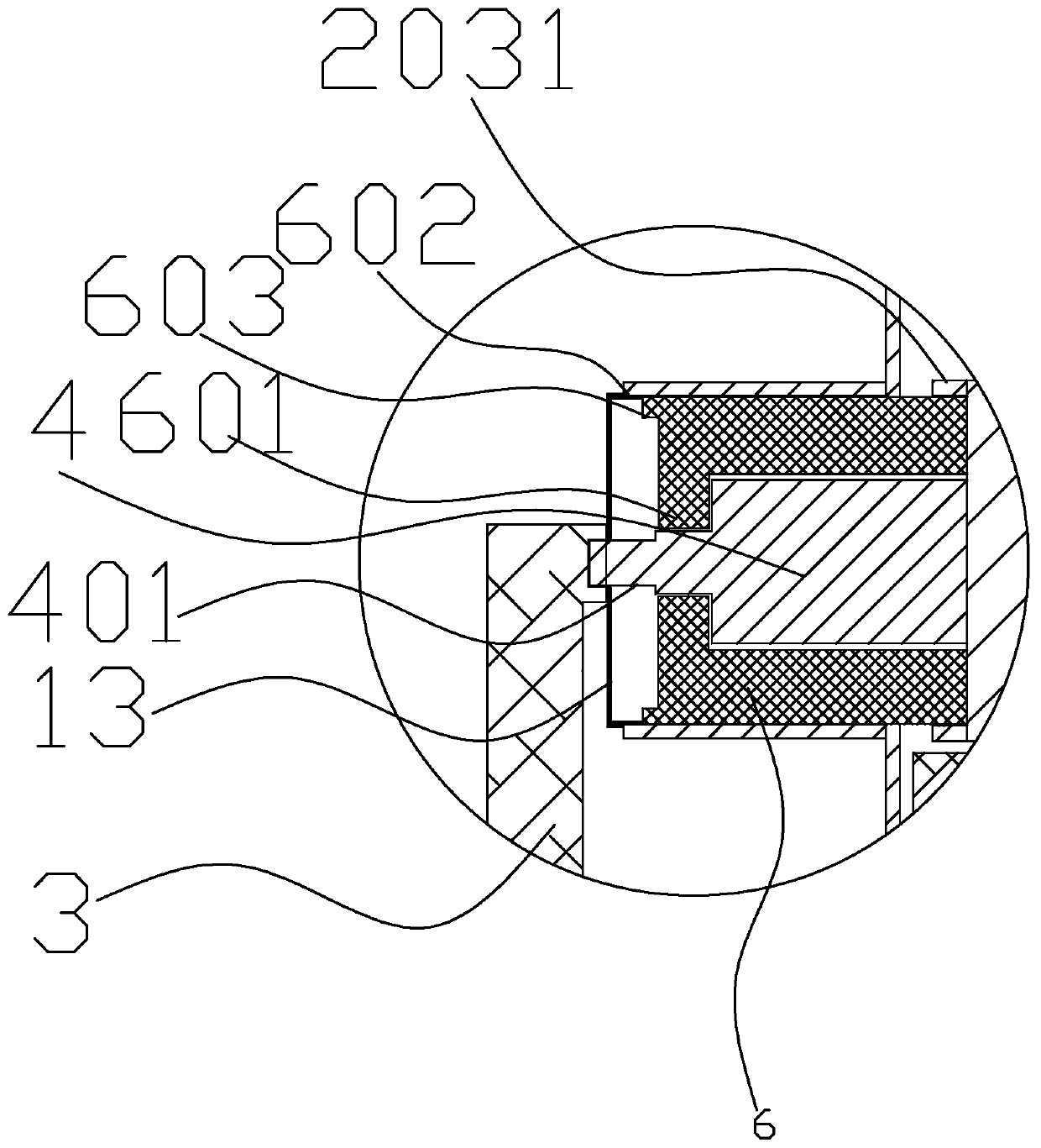

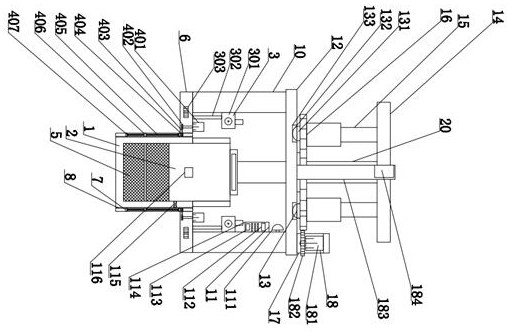

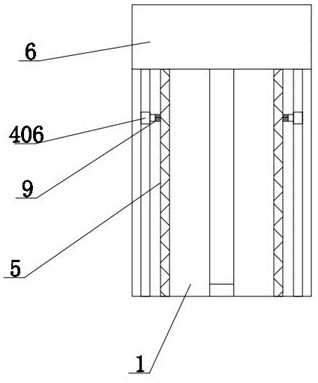

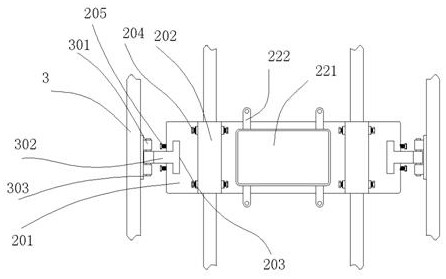

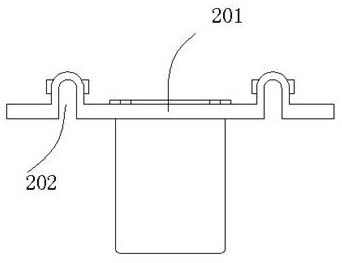

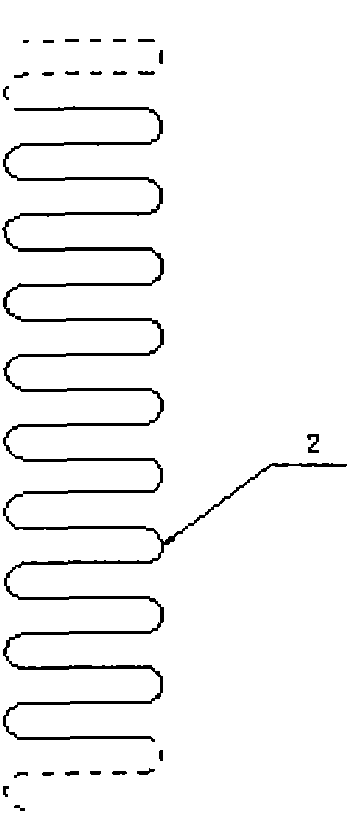

Separated maintainable tunnel lining structure

ActiveCN106437748APromote excretionEasy to excludeUnderground chambersDrainageStructural engineeringFlood season

The invention provides a separated maintainable tunnel lining structure to effectively avoid the phenomenon that a side wall structure is fractured and damaged due to the fact that underground water soars in rain-flood seasons but the discharge capacity is insufficient, improve the hydraulic pressure and floating resistant capacity of the lining structure and reduce the damage risks of underground water in rain-flood seasons to the lining structure, especially a tunnel bottom structure. The separated maintainable tunnel lining structure comprises an arch wall primary supporting structure, a water prevention and discharge system and a lining structure body which are arranged from outside to inside. The lining structure body comprises a secondary arch lining, a side wall frame supporting structure, a filling wall and a tunnel bottom pile-plate structure. The tunnel bottom pile-plate structure comprises a base plate laid on a base confining bed and anchorage piles longitudinally and transversely arranged along a tunnel at intervals. The upper ends of the anchorage piles are fixedly connected with the base plate. The two circumferential ends of the water prevention and discharge system lead to longitudinal drainage ditches formed in the two transverse sides of the base plate.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

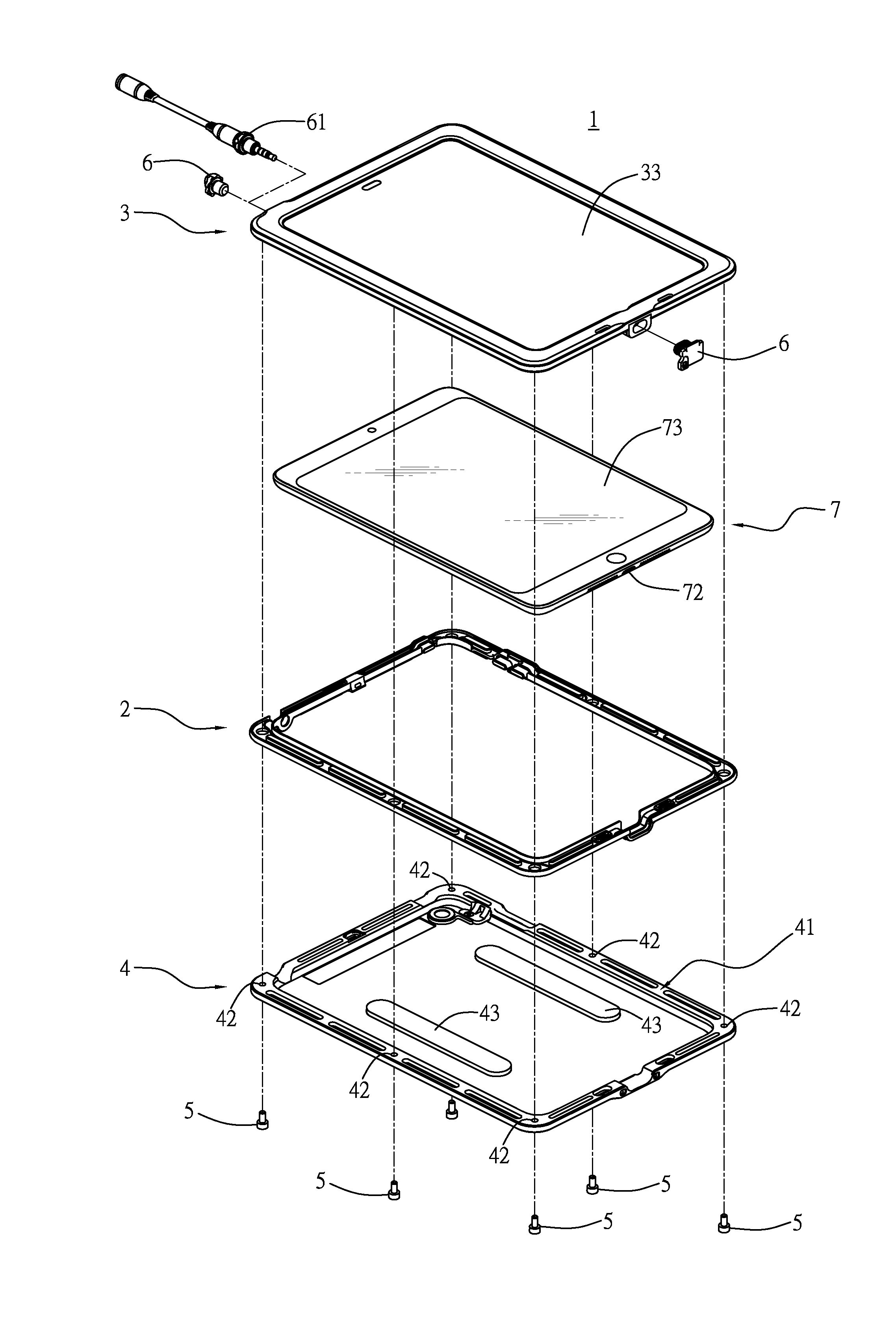

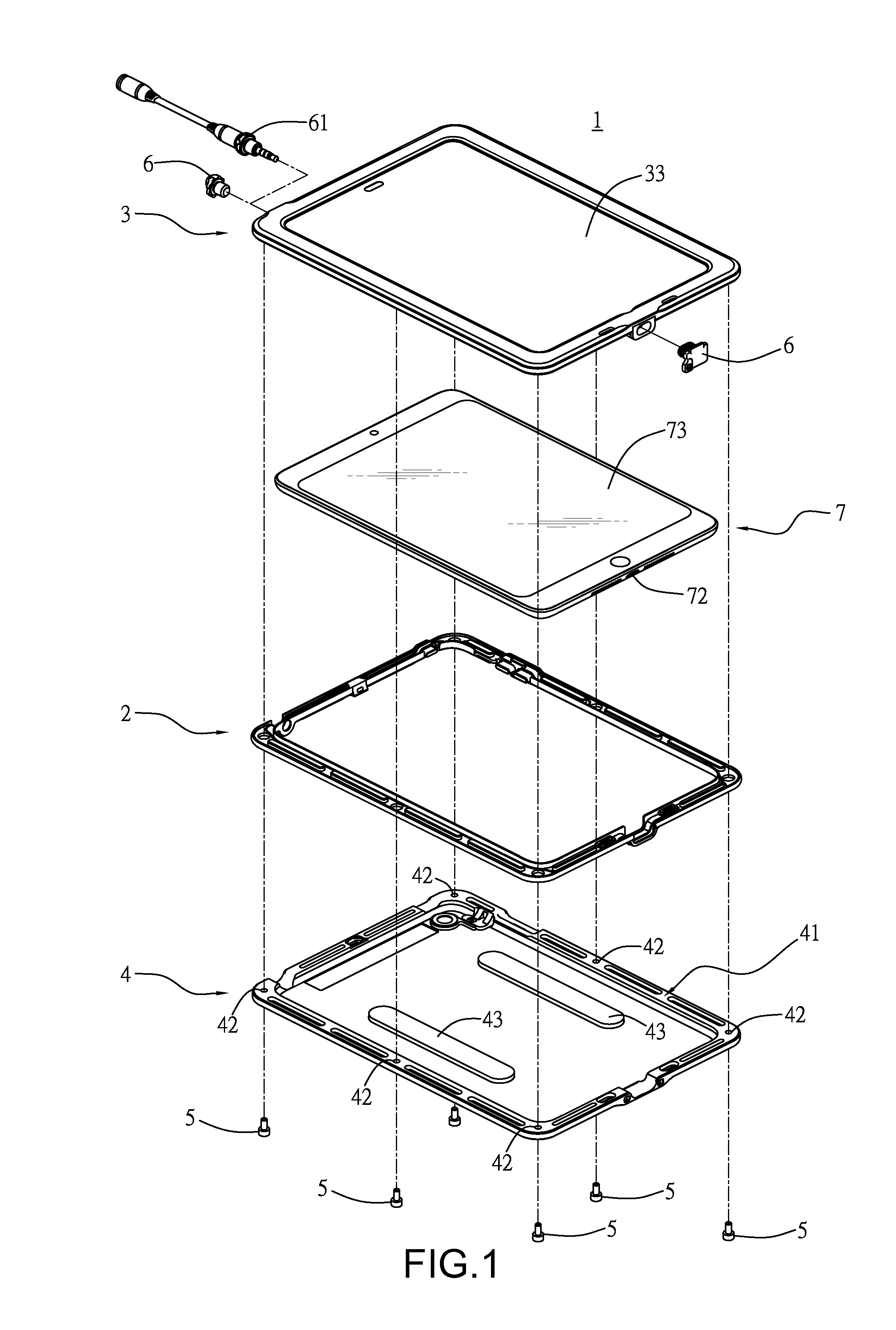

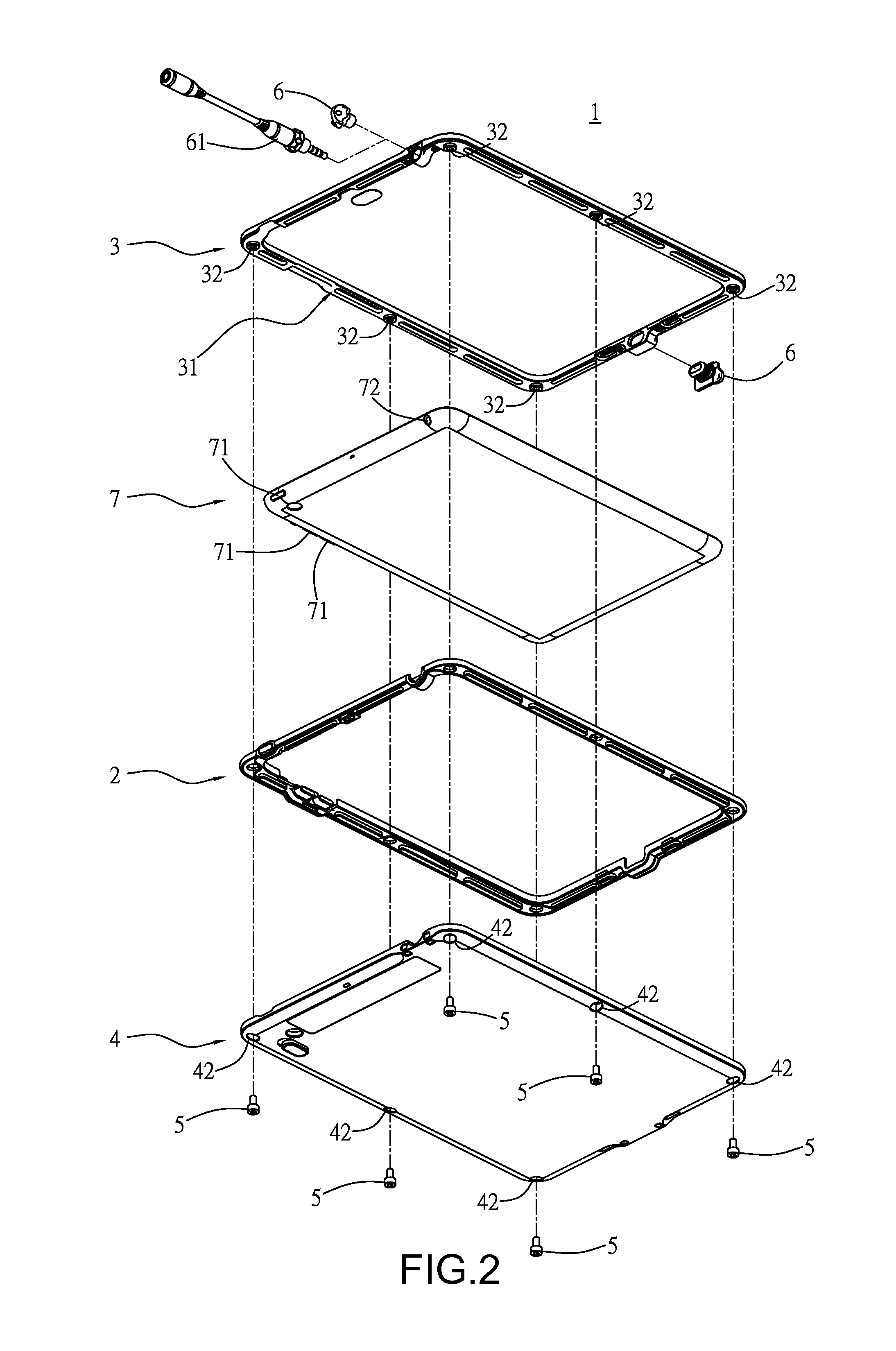

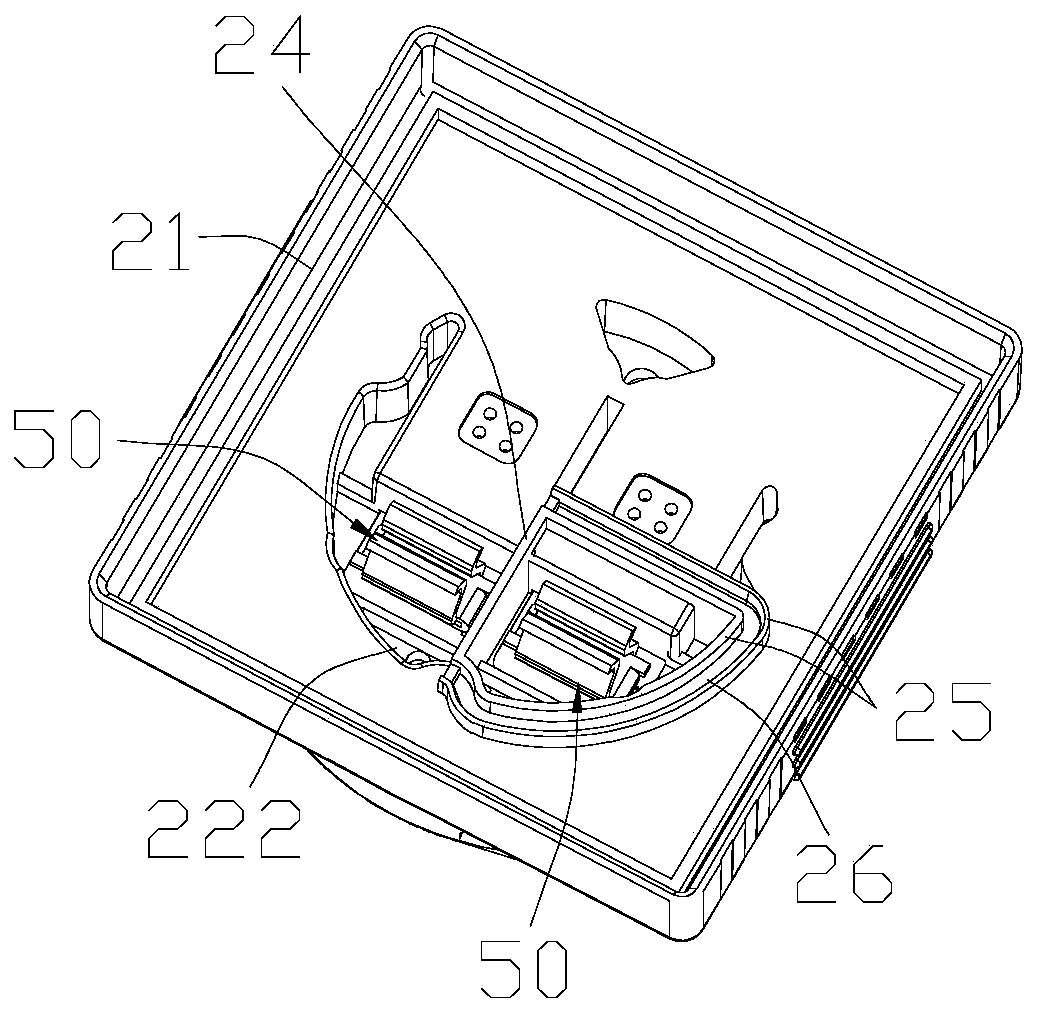

Waterproof container

InactiveUS20150208535A1Convenience in operationConvenience in useDigital data processing detailsCasings/cabinets/drawers detailsEngineeringMechanical engineering

Owner:WU DA CHUNG

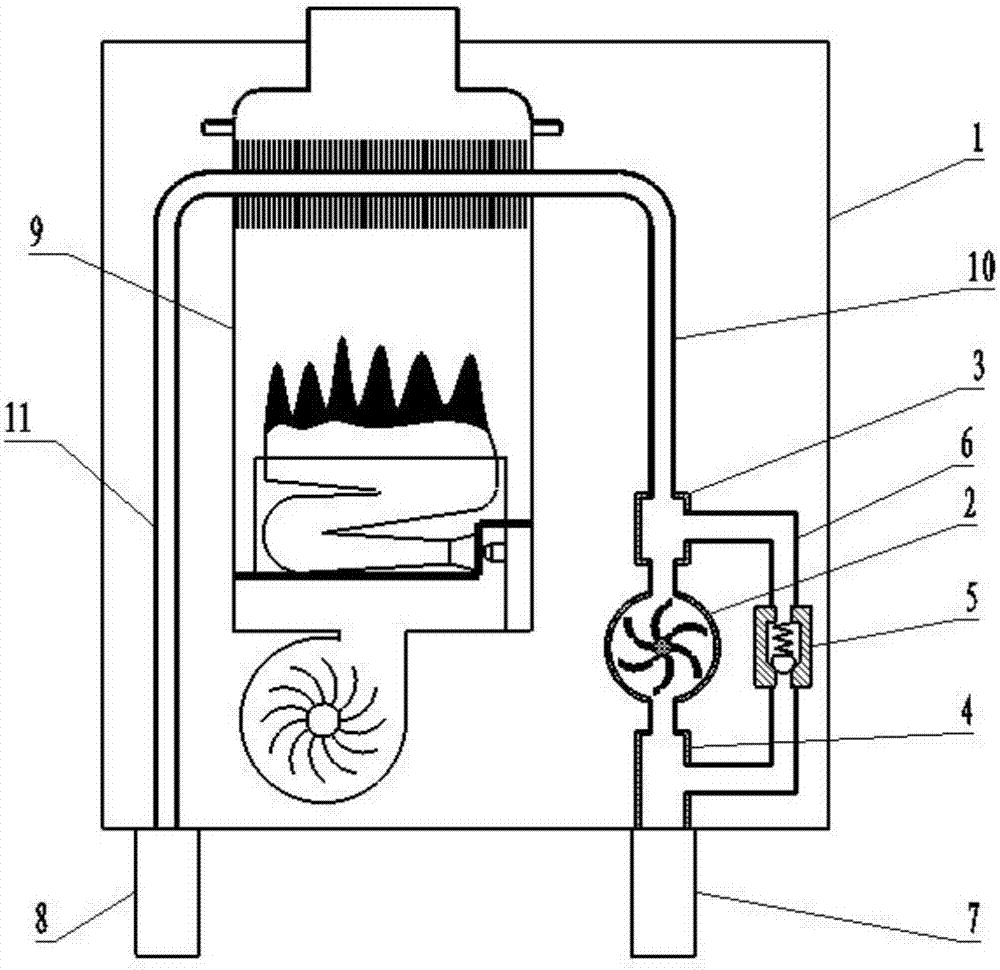

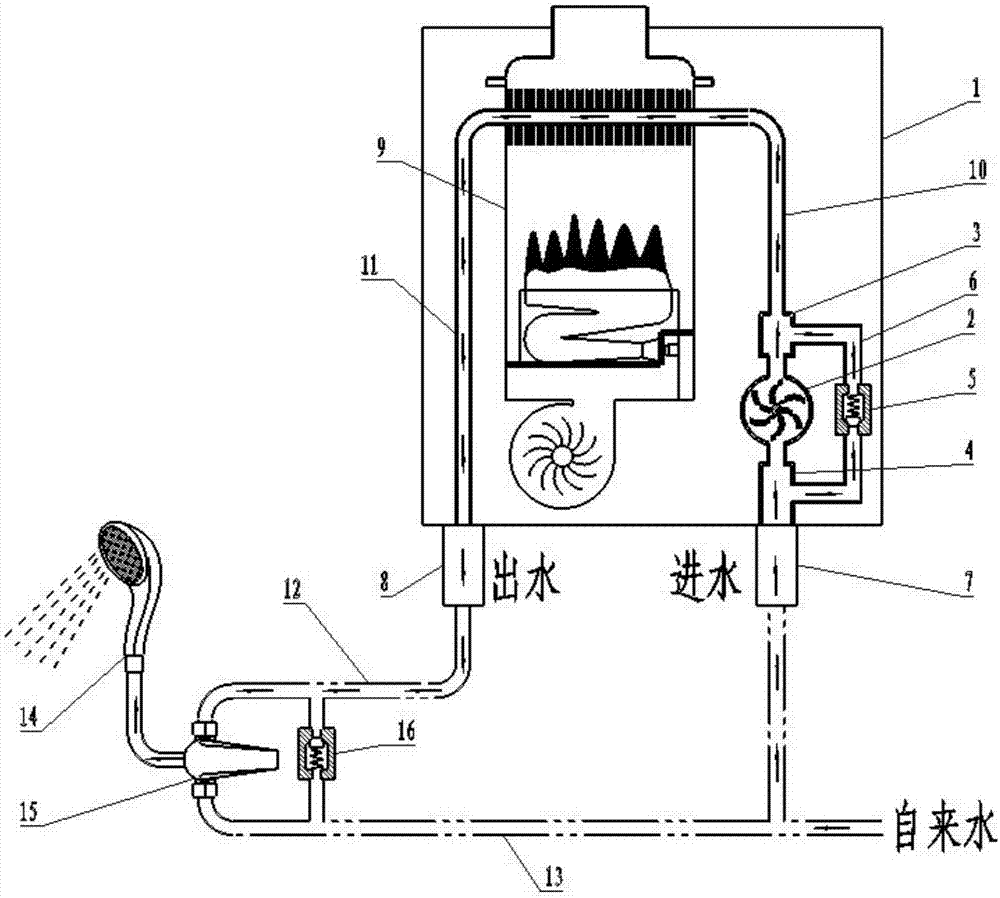

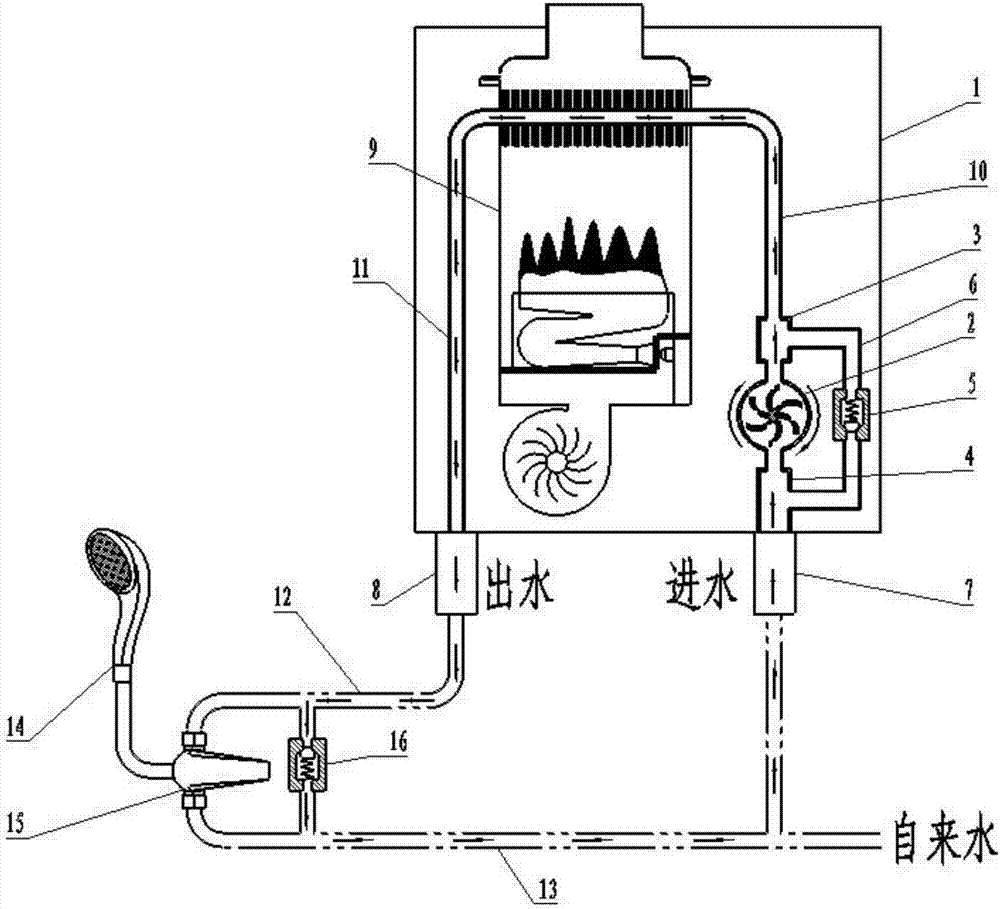

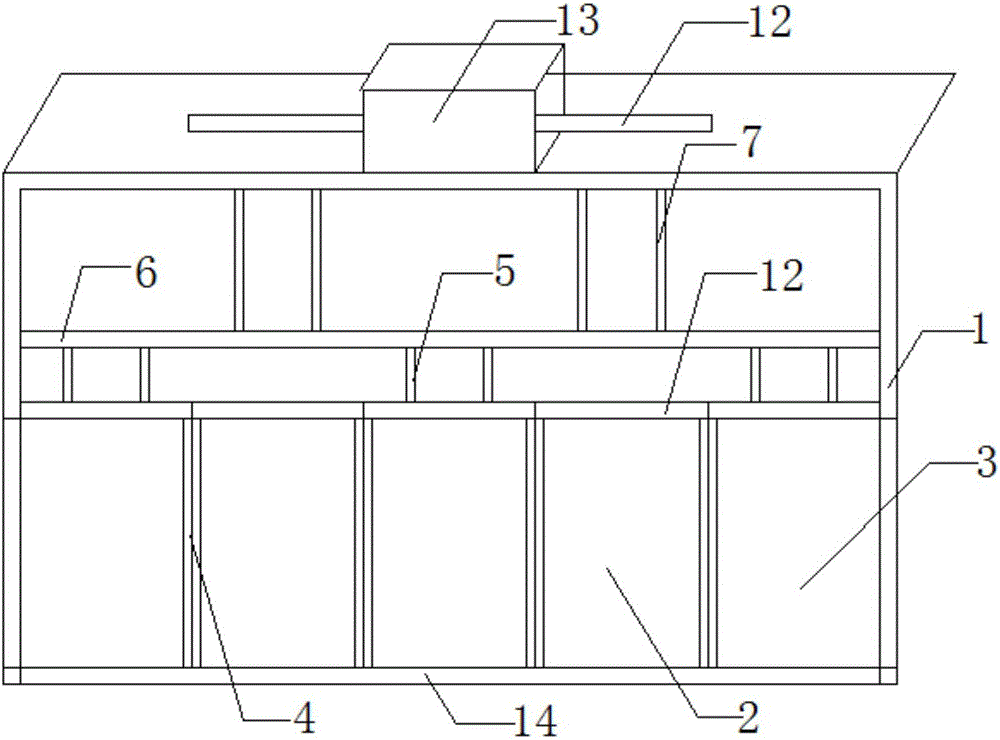

Zero-cold-water water heater

The invention relates to the technical field of water heaters, in particular to a zero-cold-water water heater. The zero-cold-water water heater comprises a main body, a heat exchange device mounted in the main body, an internal water inlet pipeline with a water inlet joint, and an internal water outlet pipeline with a water outlet joint; a circulating pump is arranged on the internal water inletpipeline; a water outlet direction of the circulating pump in an operating state is consistent with a water flowing direction of the internal water inlet pipeline; a parallel pipeline is connected toa water inlet end and a water outlet end of the circulating pump; a first one-way valve is arranged on the parallel pipeline; and the first one-way valve enables water currents to flow from the waterinlet end of the circulating pump to the water outlet end of the circulating pump. The water heater can overcome the problem of insufficient water passing flow in an open-circuit state of a water heater with a zero cold water function in the prior art.

Owner:VATTI CORP LTD

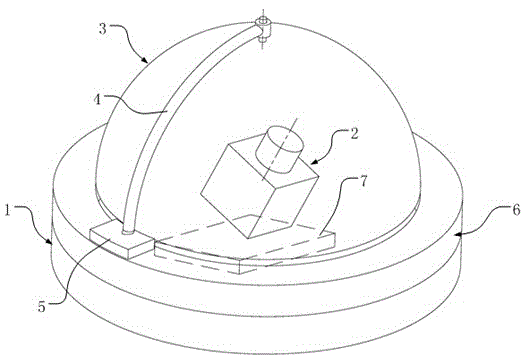

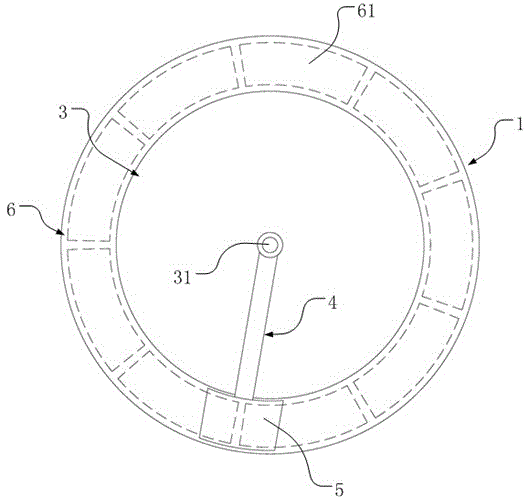

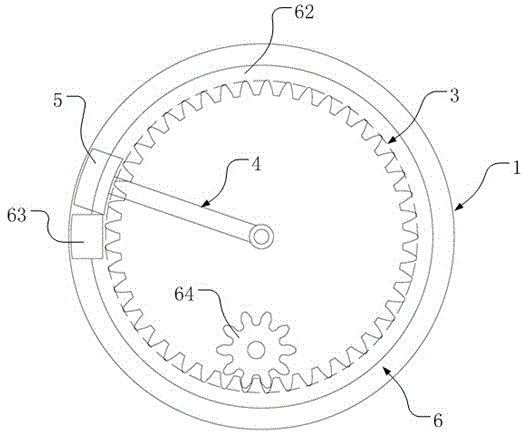

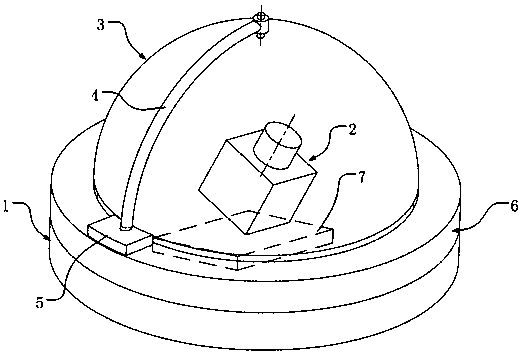

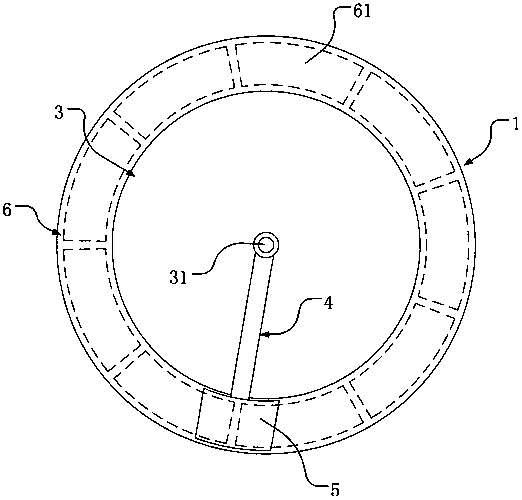

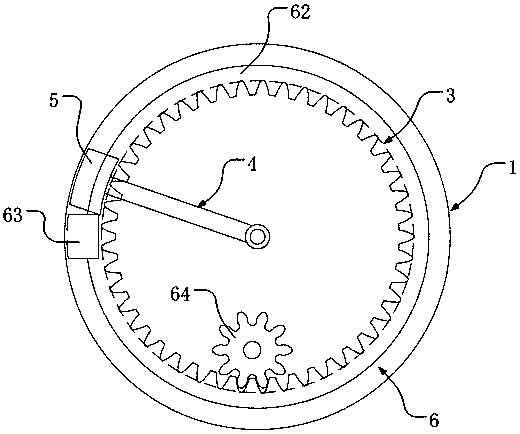

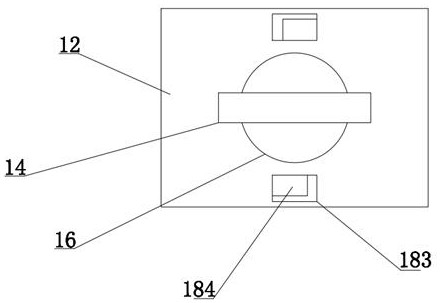

Automatic cleaning system for video capture window of underwater monitoring device

ActiveCN105478397AGuaranteed long-term useHigh water pressure resistanceCleaning using toolsHinge angleBusbar

The invention discloses an automatic cleaning system for a video capture window of an underwater monitoring device. The automatic cleaning system comprises a disc-shaped base, a video capture module and a transparent window cover. The outer surface of the window cover is a rotation curved surface which is formed in the manner that a busbar with one end on the center axis rotates around the center axis by a circle. The center axis of the window cover is coaxial with the center axis of the base. A cleaning scraper is arranged on the outer wall of the window cover in a striding manner. The inner edge of the cleaning scraper is attached to the outer surface of the window cover in a matched manner. The cleaning scraper is hinged to the window cover and can rotate around a hinge shaft. The part, between the cleaning scraper and the window cover, of the hinge shaft is coaxial with the center axis of the window cover. The cleaning scraper is driven by external force to rotate around the hinge shaft.

Owner:GUANGZHOU SEA DOG PHOTOELECTRIC SCI & TECH CO LTD

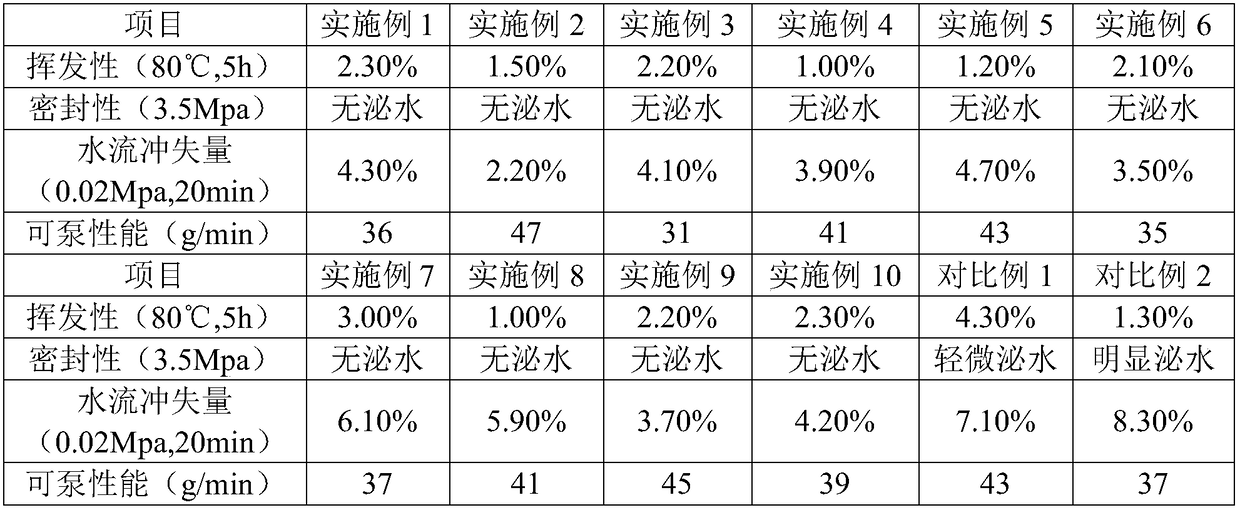

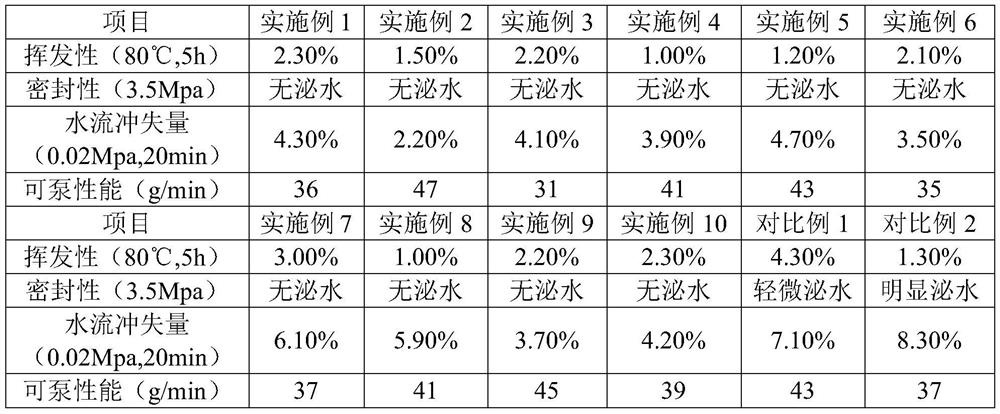

Environmental-friendly shield tail seal grease and preparation method thereof

The invention provides an environmental-friendly shield tail seal grease and a preparation method thereof. The environmental-friendly shield tail seal grease is prepared from combining the following raw materials in parts by weight: 20 to 35 parts of base oil composition, 6 to 15 parts of viscosity index modifier, 30 to 55 parts of waterproof sealing material, 2 to 5 parts of lubricating agent, and 5 to 25 parts of complex fiber, wherein the base oil composition is prepared from mixing isooctyl alcohol modified colleseed oil and soybean oil or biodiesel according to the mass ratio being 1 to 4:1; the complex fiber is prepared from mixing a mineral fiber and a plant fiber according to the mass ratio being 1 to 4.5:1. The base oil composition is prepared from mixing the isooctyl alcohol modified colleseed oil and the soybean oil or the biodiesel, has excellent abrasion resistance and oxidation resistance, and no harm on soil and underground water, can be degraded within a short term in the underground environment, and solves the problem that a shield tail seal grease has severe pollution on the underground environment during the shield process on the basis of ensuring a better sealing performance.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

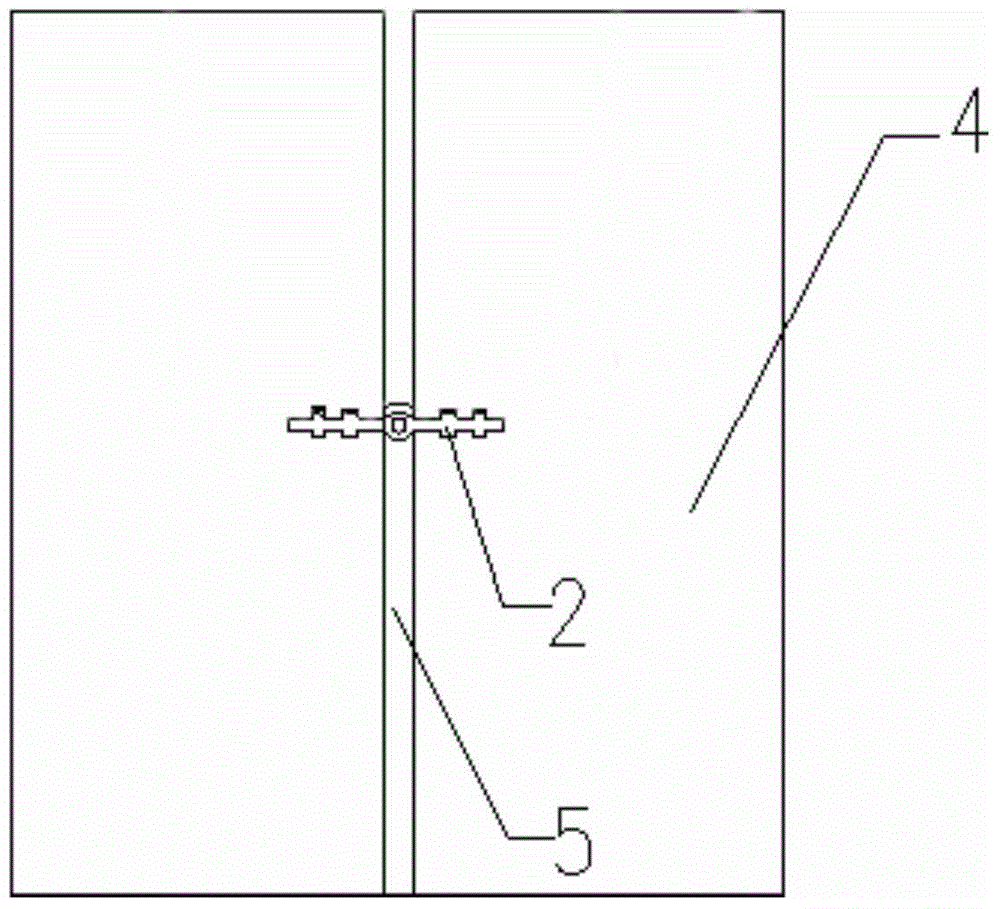

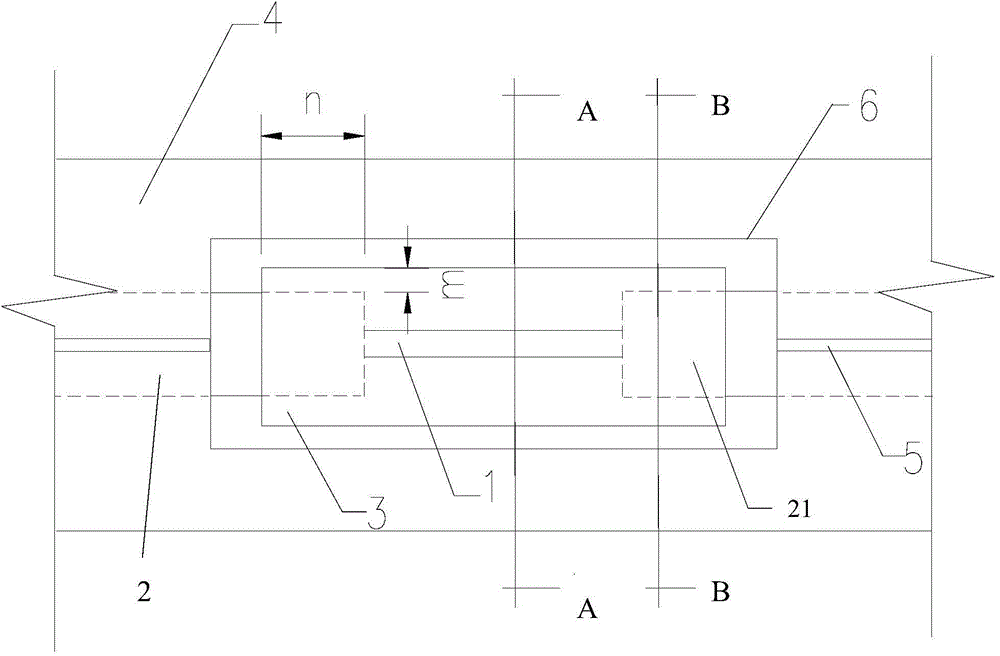

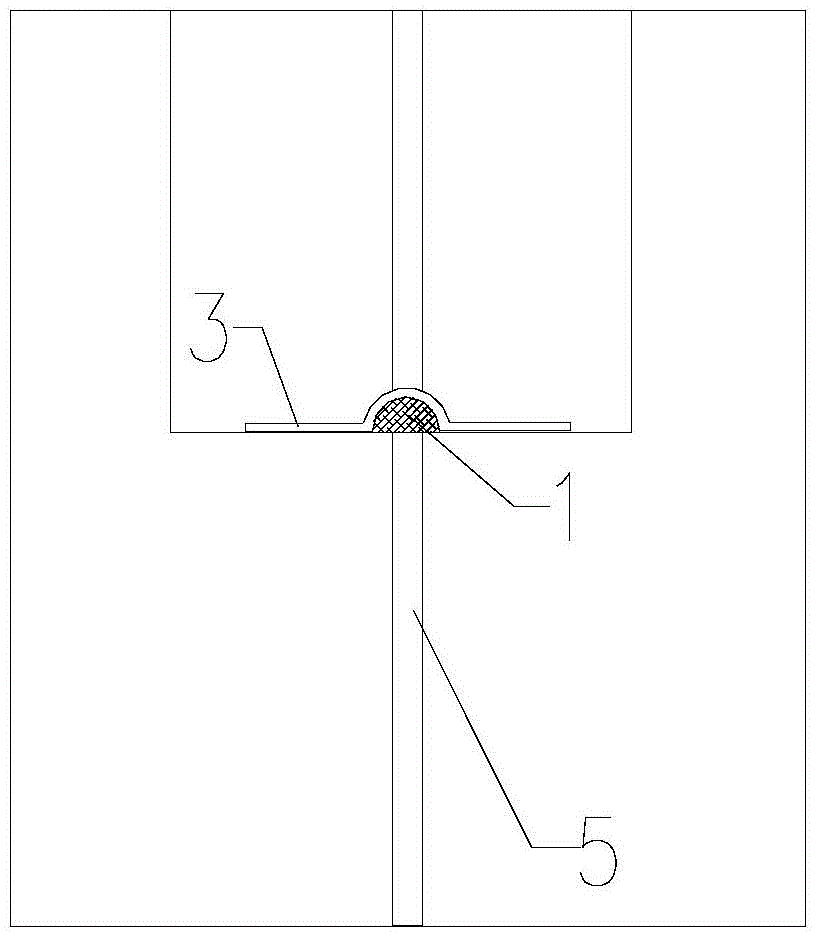

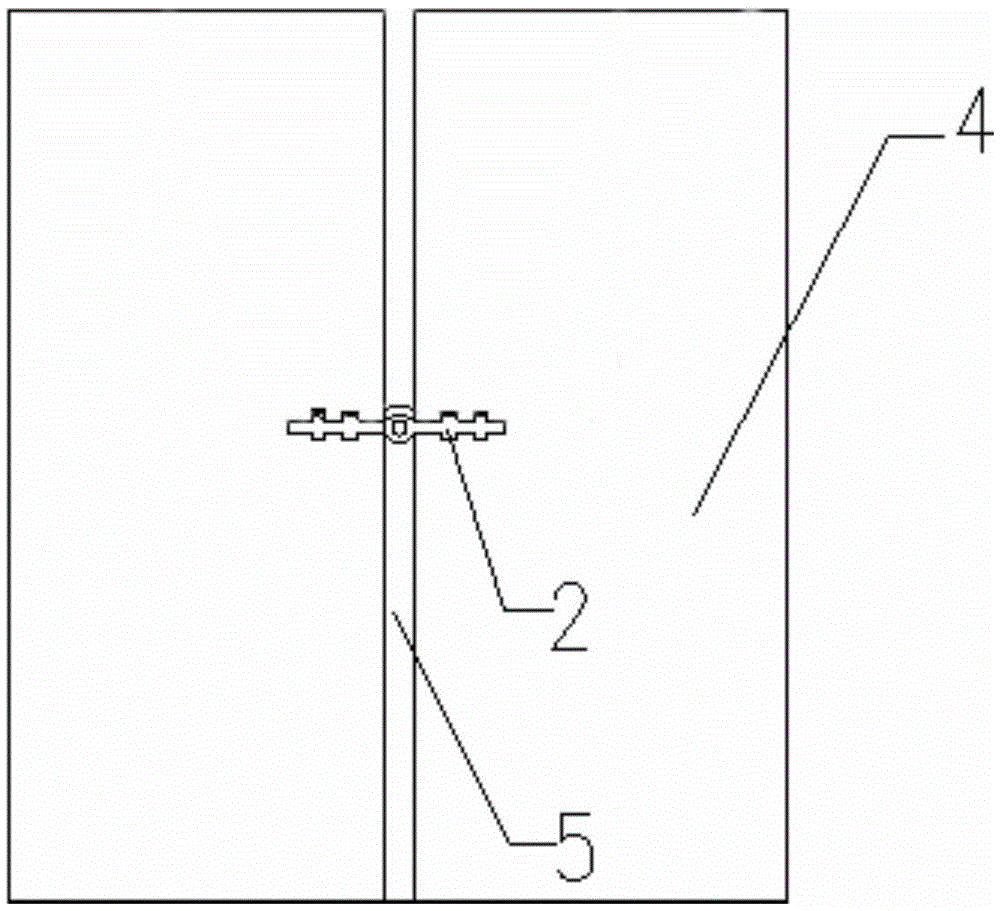

Partitioned waterproof system for water-enriching section of tunnel

PendingCN107816361AImprove waterproof performanceReduce water pressureUnderground chambersDrainageEngineeringMiddle line

The invention relates to a partitioned waterproof system for a water-enriching section of a tunnel, which belongs to the waterproof field of tunnels and aims to improve the waterproof performance of the water-enriching section and avoid the seepage of the water-enriching section. The system comprises a water stopping rubber mat which is circumferentially sealed along the tunnel and is arranged ata settlement joint, and the water stopping rubber mat is located between an initial support and a waterproof layer; one side of the water stopping rubber mat along the middle line is longitudinally overlapped to a conventional lining section along the tunnel while the other side of the water stopping rubber mat is longitudinally overlapped to the water enriching section along the tunnel. Accordingto the system provided by the invention, a seepage gap between the waterproof layer and the initial support is partitioned at the settlement joint by arranging the water stopping rubber mat to blockwater seeping into the seepage gap between the waterproof layer and the initial support in the water-enriching section, so that water seeping into the seepage gap is prevented from flowing into the conventional lining section along the seepage gap.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

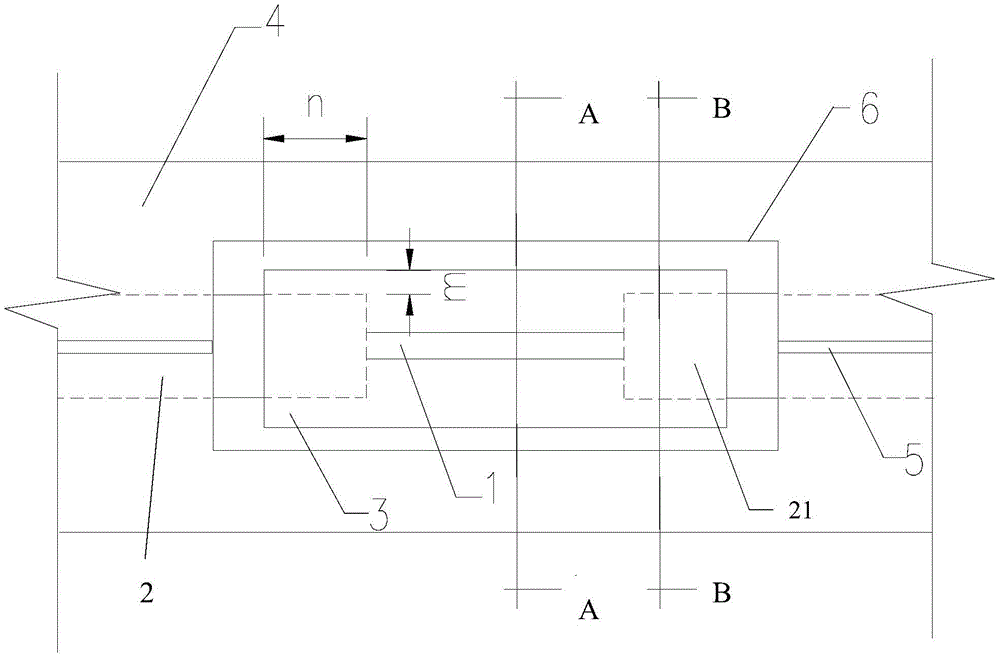

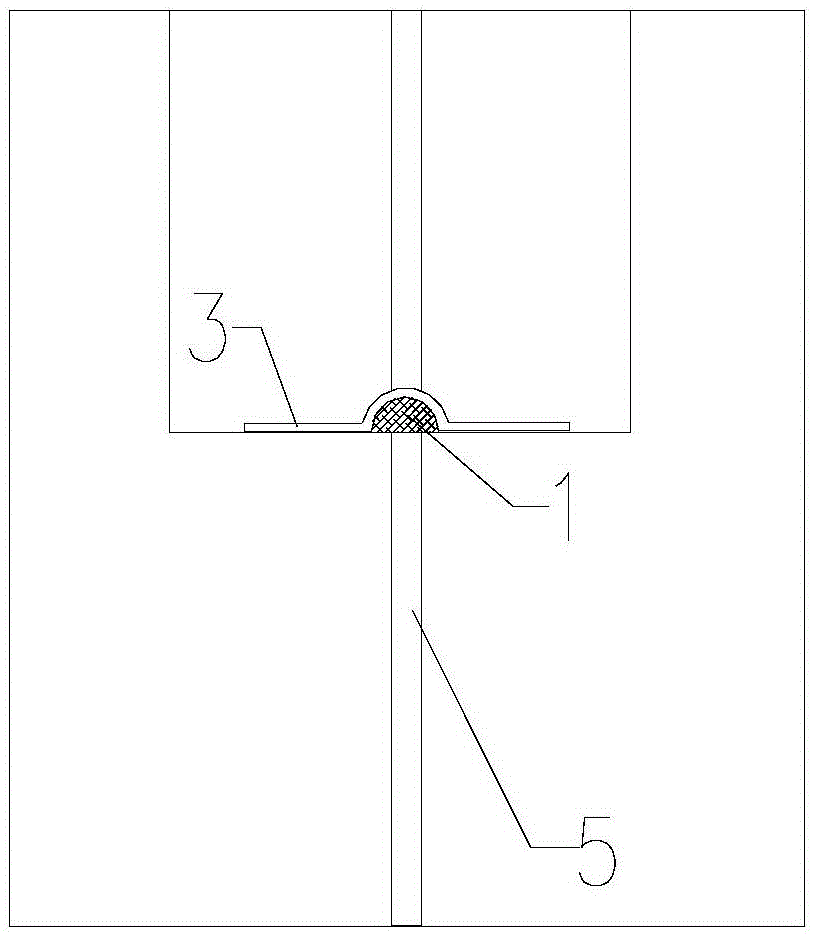

Connecting structure and connecting method for expansion joint water-stop belt of hydraulic concrete member

InactiveCN104060576AWill not affect normal scalingImprove water pressure resistanceMarine site engineeringEngineeringExpansion joint

The invention provides a connecting structure and a connecting method for an expansion joint water-stop belt of a hydraulic concrete member. The connecting structure comprises a protection layer and a sealing filling layer, wherein an expansion joint at the broken part of the water-stop belt is filled with the sealing filling layer; the protection layer coats the sealing filling layer and the outer side of the end of the broken part of the water-stop belt, and is combined with the end. A seam on the broken part is preferably enclosed by the sealing filling layer, so that the protection layer can be supported as required. The protection layer can be molded directly by coating a flexible film material on site in order to be tightly combined with the end of the water-stop belt. An activating agent and a bonding agent are preferably coated between the protection layer and the water-stop belt. The connection problem at the broken part of the expansion joint water-stop belt of the hydraulic concrete member can be solved. Compared with the process of replacing the water-stop belt by chiseling in the conventional way, the connecting method is simple and feasible; moreover, the water-stop belt has perfect performance after being connected.

Owner:BEIJING IWHR KHL +1

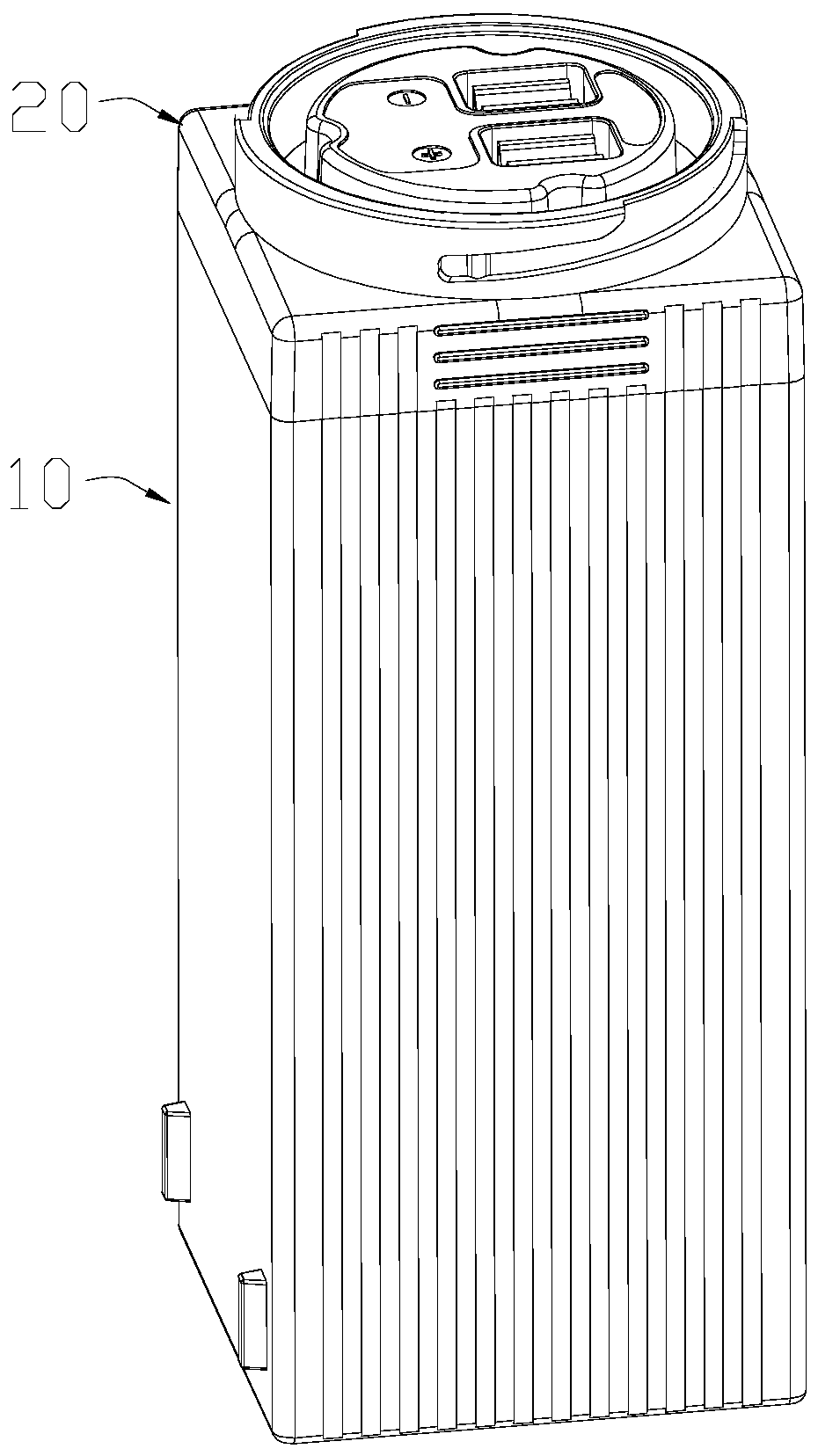

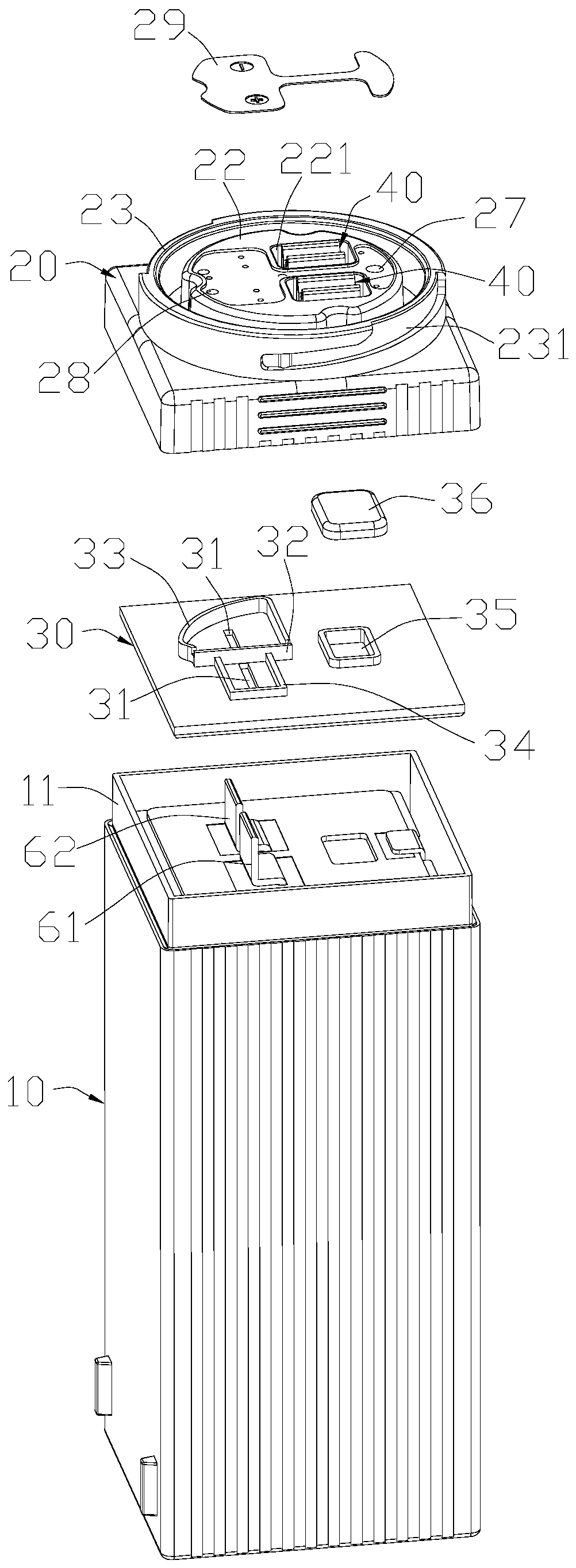

Waterproof shell of waterproof power supply, waterproof power supply and manufacturing method of waterproof power supply

PendingCN110213923AAchieve isolationAvoid the problem of galvanic corrosionHermetically-sealed casingsBattery packElectrical and Electronics engineering

The invention discloses a waterproof shell of a waterproof power supply, the waterproof power supply and a manufacturing method of the waterproof power supply. The waterproof shell comprises a shell,a cover, a sealing plate, two connection terminals and two output terminals, wherein the cover is matched onto an opening end of the shell, the sealing plate is arranged in the opening end of the shell, the two connection terminals are arranged on an inner surface of the cover and are isolated with each other, the two output terminals are arranged on an outer surface of the cover and are isolatedwith each other, the two output terminals are respectively connected with the two connection terminals, two output holes are formed in the sealing plate, a protruding first isolation wall and a firstprotruding wall are arranged on an inner surface of the cover, a protruding second isolation wall and a second protruding wall are arranged on the sealing plate, the second isolation wall is matched with the first isolation wall, the second protruding wall is matched with the first protruding wall, and the two connection terminals are insulated and isolated. By arranging the sealing plate in the waterproof shell, secondary sealing of a battery pack is achieved; and by arranging the isolation walls and the protruding walls on the sealing plate and the cover, isolation between a positive terminal and a negative terminal of the waterproof power supply is achieved.

Owner:深圳市依卓尔能源有限公司

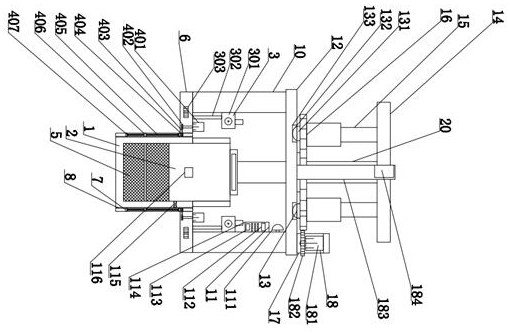

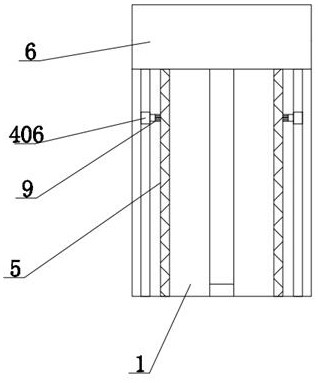

Hydropower station water inlet water flow control device

InactiveCN106284242AImprove sealingImprove stabilityWater-power plantsHydro energy generationWater flowEngineering

The invention discloses a hydropower station water inlet water flow control device. The hydropower station water inlet water flow control device comprises a water inlet device body. An electromechanical room is arranged in the middle of the upper portion of the water inlet device body. Rotating shafts are installed on the two sides of the electromechanical room. A steel frame is arranged in the middle of the water inlet device body. A thin steel wire rope is arranged on the lower portion of the steel frame. The steel frame is fixedly connected with a hook through the thin steel wire rope. The lower portion of the hook is in welded connection with a connecting rod. A movable water fender is fixed to the lower portion of the connecting rod in a welded mode. A water insulation pier is connected to the left side of the movable water fender through a clearance. Sliding rails are arranged on the two sides of the water insulation pier. The upper portion of the steel frame is in telescopic connection with a thick steel wire rope. The rotating shafts are rotationally connected with the steel frame through the thick steel wire rope. The hydropower station water inlet water flow control device has the advantages of being reasonable in structural design, easy to operate and capable of effectively controlling the hydropower station water inlet water flow situation.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

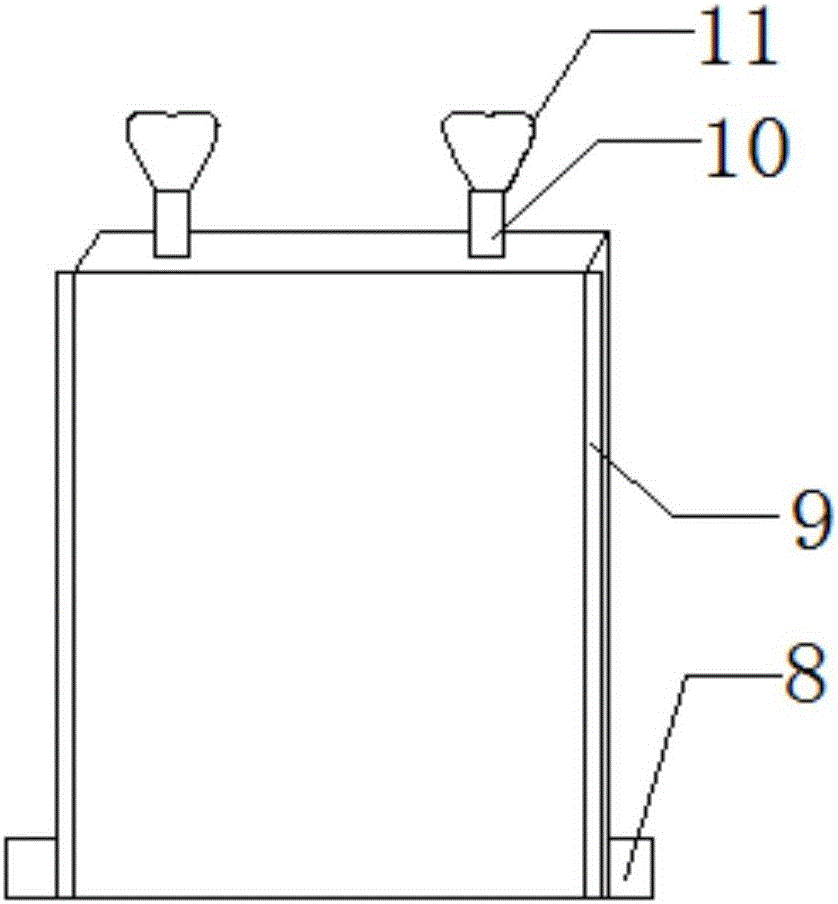

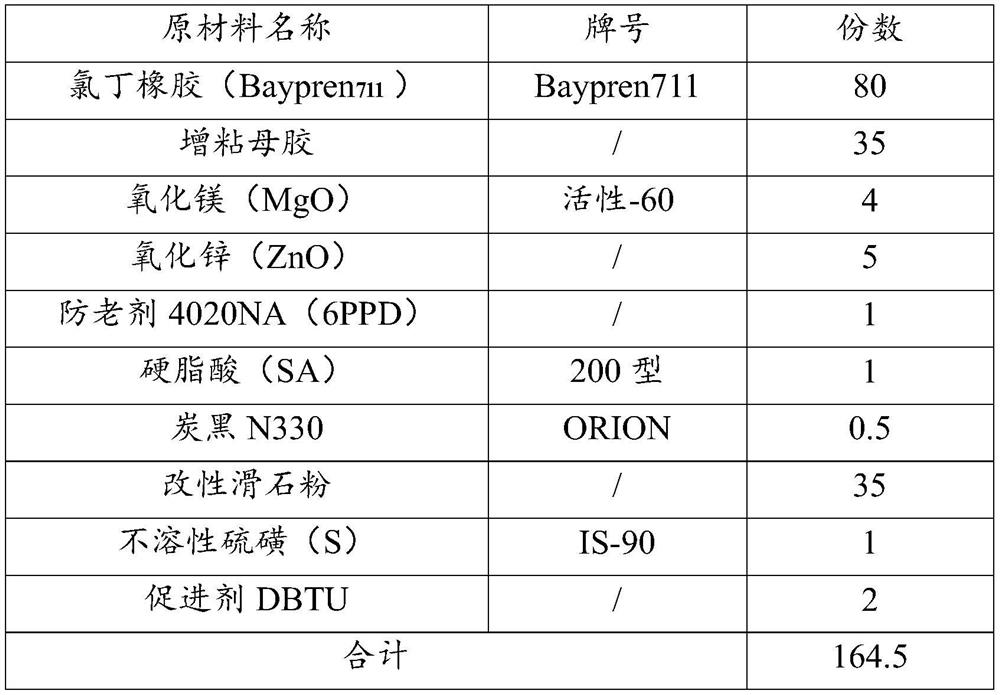

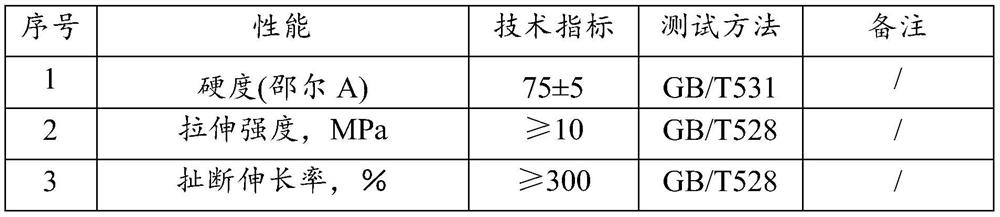

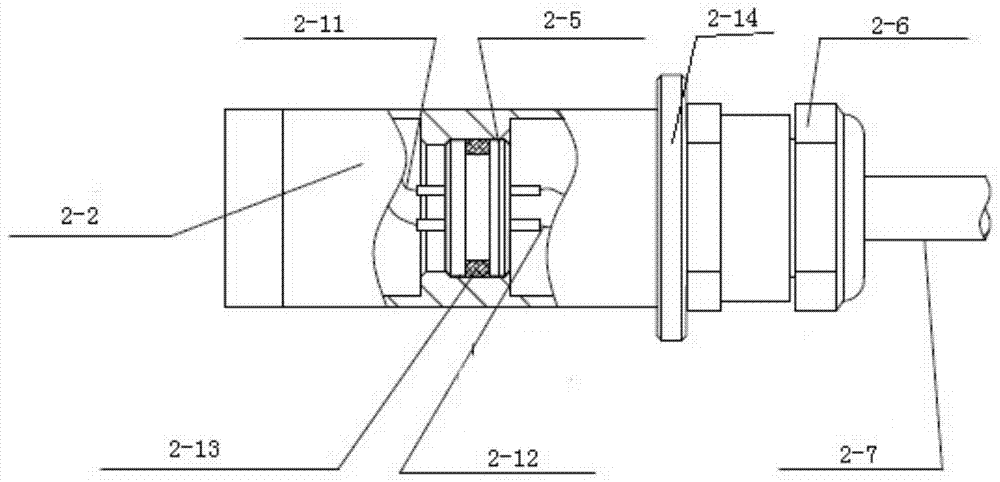

Preparation method of watertight connector, product thereof and composite rubber material for preparing watertight connector

ActiveCN112694652AImprove water tightnessImprove insulation performanceContact member cases/bases manufactureCouplings bases/casesRubber materialPolymer science

The invention relates to the field of watertight devices, and particularly relates to a preparation method of a watertight connector, a product thereof and a composite rubber material for preparing the watertight connector. The preparation method of the watertight connector comprises the steps of preparing a composite rubber material and forming the watertight connector. The watertight connector has good watertightness, insulativity and pressure resistance, current deep sea coverage is met, and stable electric transmission use requirements are met.

Owner:北京海迪创科技有限公司 +1

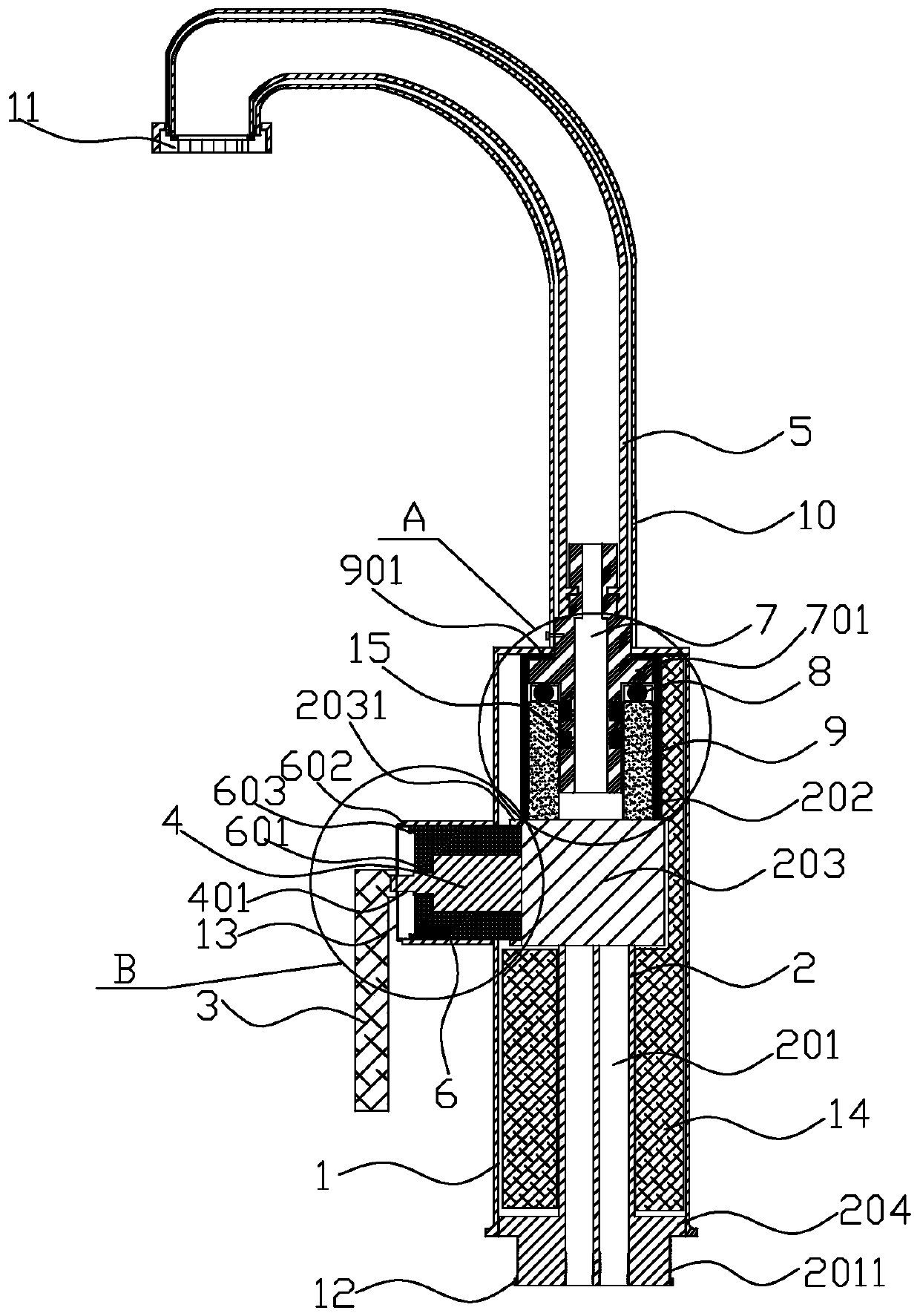

Faucet filled with anti-impact high-dense elastomer material and preparation method of faucet

ActiveCN102155577AReinforces and improves impact resistanceExcellent water pressure resistanceOperating means/releasing devices for valvesValve housingsFilling materialsSurface finishing

The invention relates to a faucet, in particular to the faucet filled with an anti-impact high-dense elastomer material and a preparation method of the faucet. The faucet comprises an acrylonitrile butadiene styrene (ABS) plastic shell and mating parts, wherein the mating parts comprise a valve core, a handle, a water outlet net, a seal ring, a fastening screw and the like. The method comprises the following steps of: combining and connecting water channels of the faucet according to a waterway requirement of the faucet; putting the water channels into a mould of a shell of the faucet and fixing the water channels; fusing a high-dense elastomer which is mixed with an inorganic filling material by an extruder, an injection moulding machine, a kneading machine and an open mill, and filling the high-dense elastomer into the mould of the shell of the faucet; cooling the high-dense elastomer in the mould until the high-dense elastomer is formed, taking the high-dense elastomer out of the mould, and carrying out injection moulding on the high-dense elastomer to form a plastic shell of the faucet; and carrying out surface treatment on the shell, installing the filled faucet into the plastic shell of the faucet, and assembling the prepared faucet mating parts which are produced by the conventional process and comprise the valve core, the handle, the water outlet net, the seal ring, the fastening screw and the like into the faucet filled with the anti-impact high-dense elastomer material according to the conventional assembling mode.

Owner:XIAMEN RUNNER IND CORP

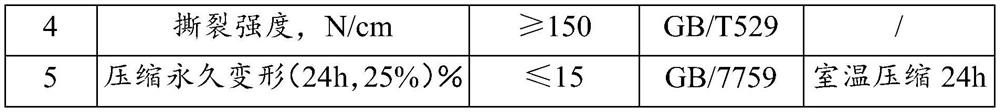

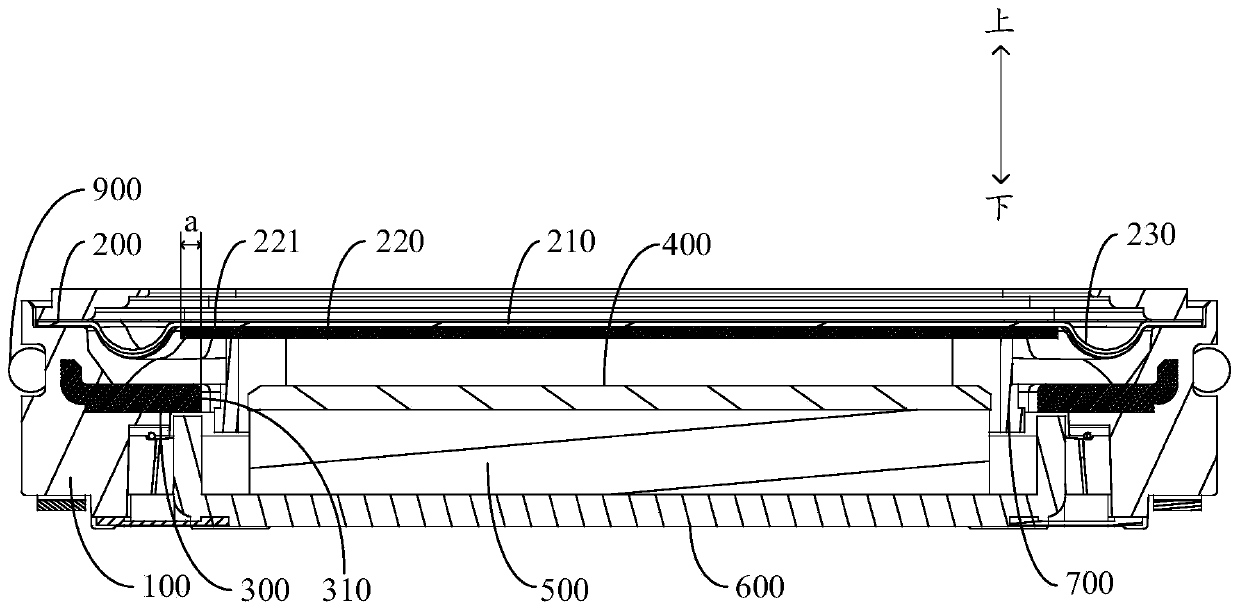

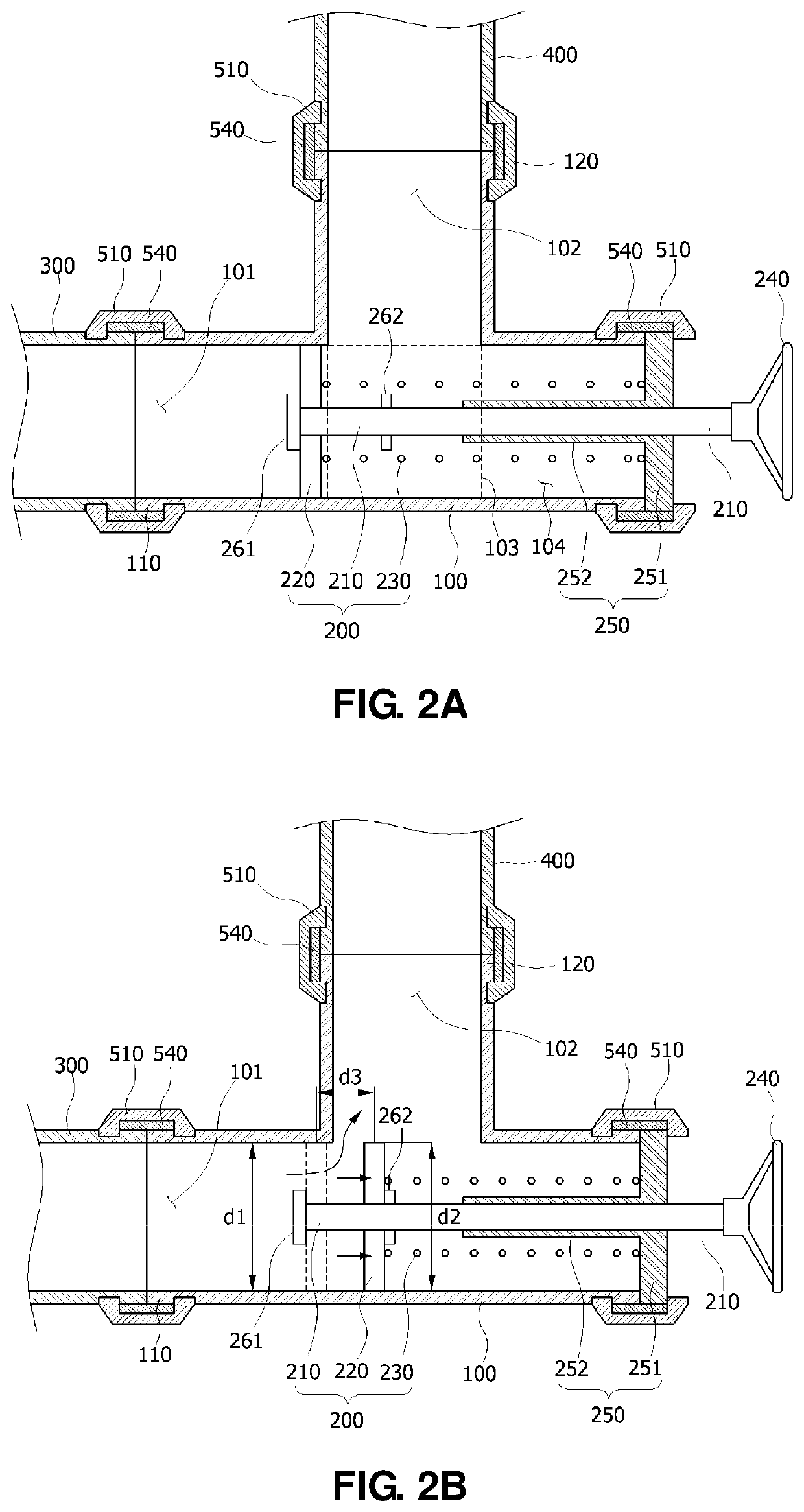

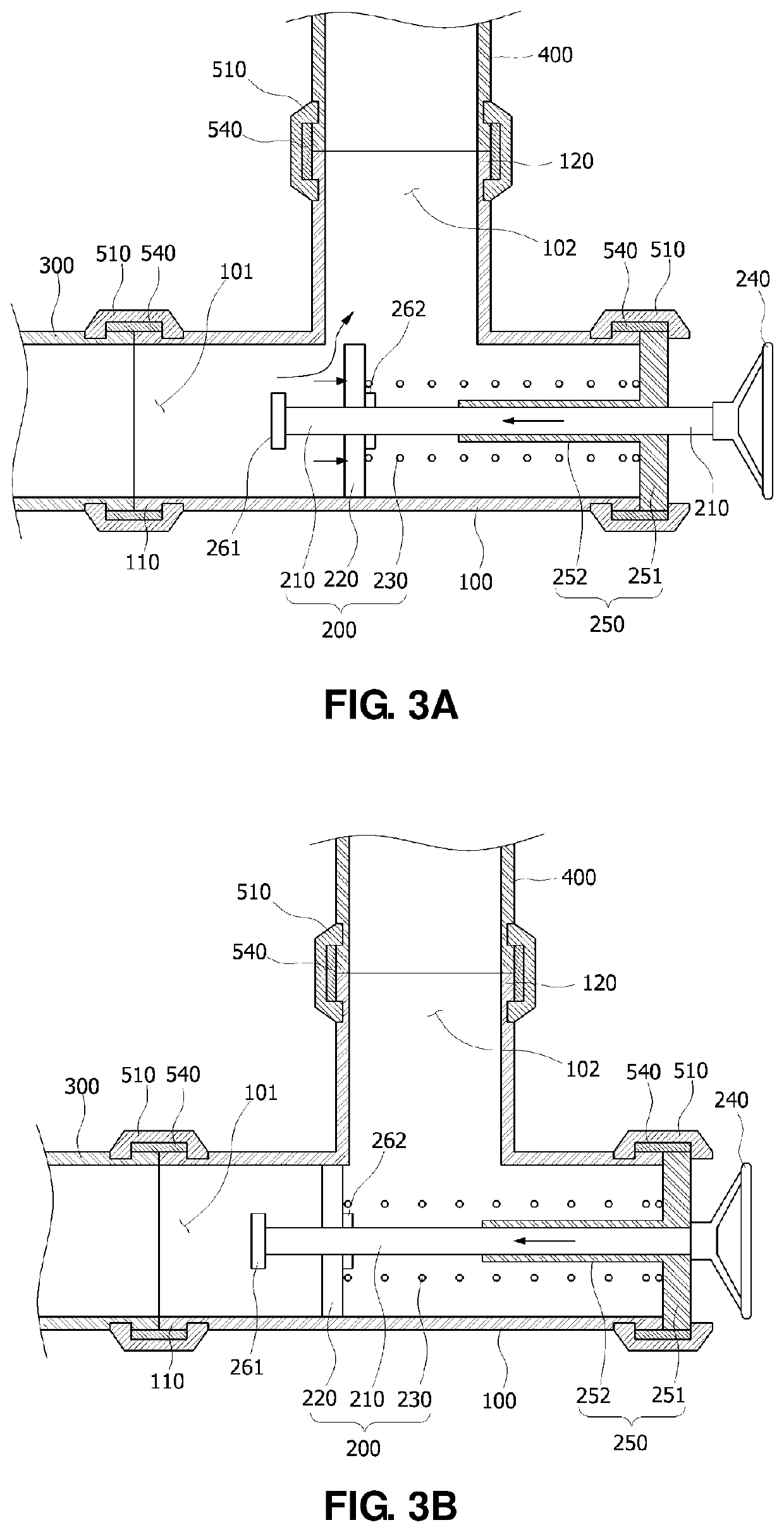

Sound production device

ActiveCN109874093AImprove water pressure resistanceImprove waterproof reliabilityElectrical transducersEngineeringSound production

The invention discloses a sound production device which comprises a vibration system and a magnetic circuit system. The vibration system comprises a vibrating diaphragm and a voice coil which are connected together. The magnetic circuit system comprises a central magnet and side magnets arranged on the outer side of the central magnet. A central magnetic conductive plate is arranged on the centralmagnet, and side magnetic conductive plates are correspondingly arranged on the side magnets, wherein the vibrating diaphragm comprises a middle part, an edge part arranged around the middle part anda reinforcing part arranged in the middle part; in the height direction of the sounding device, the side magnetic conductive plate is correspondingly located below the vibrating diaphragm, the reinforcing part is provided with an extending part extending towards the side part, and the extending part crosses the inner side edge of the side magnetic conductive plate. The technical scheme has the advantage of high water pressure resistance, and the waterproof reliability of the acoustic device is improved.

Owner:GOERTEK INC

A Separate Repairable Tunnel Lining Construction

ActiveCN106437748BPromote excretionEasy to excludeUnderground chambersDrainageStructural engineeringFlood season

The invention provides a separated maintainable tunnel lining structure to effectively avoid the phenomenon that a side wall structure is fractured and damaged due to the fact that underground water soars in rain-flood seasons but the discharge capacity is insufficient, improve the hydraulic pressure and floating resistant capacity of the lining structure and reduce the damage risks of underground water in rain-flood seasons to the lining structure, especially a tunnel bottom structure. The separated maintainable tunnel lining structure comprises an arch wall primary supporting structure, a water prevention and discharge system and a lining structure body which are arranged from outside to inside. The lining structure body comprises a secondary arch lining, a side wall frame supporting structure, a filling wall and a tunnel bottom pile-plate structure. The tunnel bottom pile-plate structure comprises a base plate laid on a base confining bed and anchorage piles longitudinally and transversely arranged along a tunnel at intervals. The upper ends of the anchorage piles are fixedly connected with the base plate. The two circumferential ends of the water prevention and discharge system lead to longitudinal drainage ditches formed in the two transverse sides of the base plate.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Repair connection structure and repair connection method of hydraulic concrete member expansion joint waterstop

InactiveCN104060576BWill not affect normal scalingImprove water pressure resistanceMarine site engineeringEngineeringExpansion joint

The invention proposes a connection structure and connection method of hydraulic concrete member expansion joint waterstop, which includes a protective layer and a sealing filling layer, and the sealing filling layer is filled in the expansion joint where the waterstop is damaged. A layer is coated on the outer side of the sealing filling layer and the damaged end of the waterstop, and is combined with the end. The sealing filling layer preferably closes the seam of the damaged part, and can provide the required supporting function for the protective layer. The protective layer can be directly formed by coating a flexible membrane material on site, so as to be closely combined with the end of the waterstop. It is better to apply activator and adhesive between the protective layer and the waterstop. The invention can solve the connection problem of the damaged part of the waterstop in the expansion joint of the hydraulic concrete member, and is simple and easy compared with the conventional process of chiseling and replacing the waterstop, and the performance of the waterstop is intact after the connection.

Owner:BEIJING IWHR KHL +1

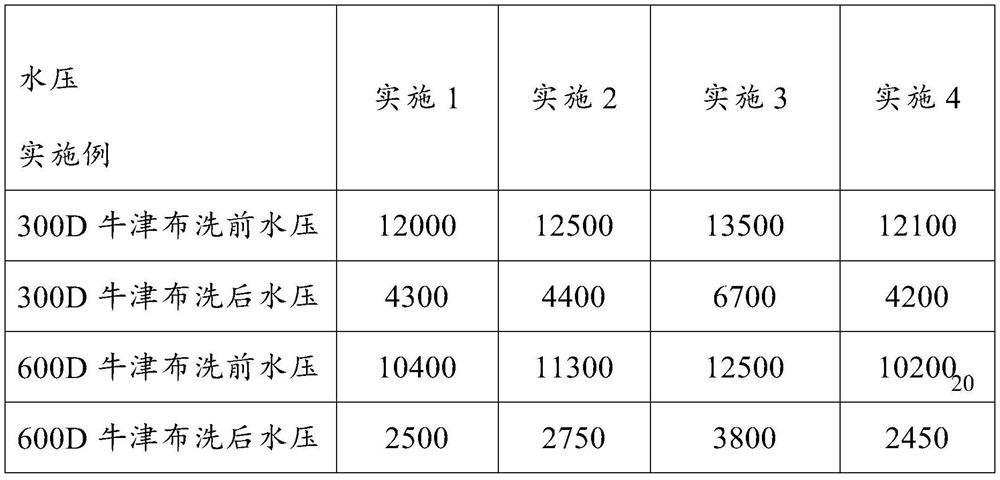

High-water-pressure washing-resistant polyurethane primer resin for textile coating and preparation method of high-water-pressure washing-resistant polyurethane primer resin

InactiveCN112745473AExcellent water repellencyGood water pressurePolyurea/polyurethane coatingsPolymer scienceSide chain

The invention provides high-water-pressure washable polyurethane primer resin for a textile coating and a preparation method of the primer resin, and the primer resin is prepared from the following components: adipic acid and neopentyl glycol copolymerized dihydric alcohol, polycarbonate dihydric alcohol, 1, 4-butanediol, trimethylolpropane, toluene diisocyanate, 4, 4-diphenylmethane diisocyanate and ethylene glycol. The side chain methyl of the neopentyl glycol has good water repellency, so that the water pressure resistance of the product can be greatly improved, the hydrolysis resistance of the product is improved by combining the polycarbonate polyol, the water pressure before washing and the water pressure after washing of the product can be improved, and the product is also suitable for cloth with high denier (such as 600D oxford cloth and the like). The high-water-pressure washable polyurethane primer resin can be used for meeting the use requirements of the product under outdoor environment conditions, the adhesive force of the primer resin to the base material can be improved, the problem that the product prepared by coating the high-water-pressure washable polyurethane primer resin is easy to absorb water and swell is relieved, and the adhesive force of the polyester polyol is good, so that the water pressure after washing is greatly helped and improved.

Owner:禾瑞(漳州)助剂有限公司

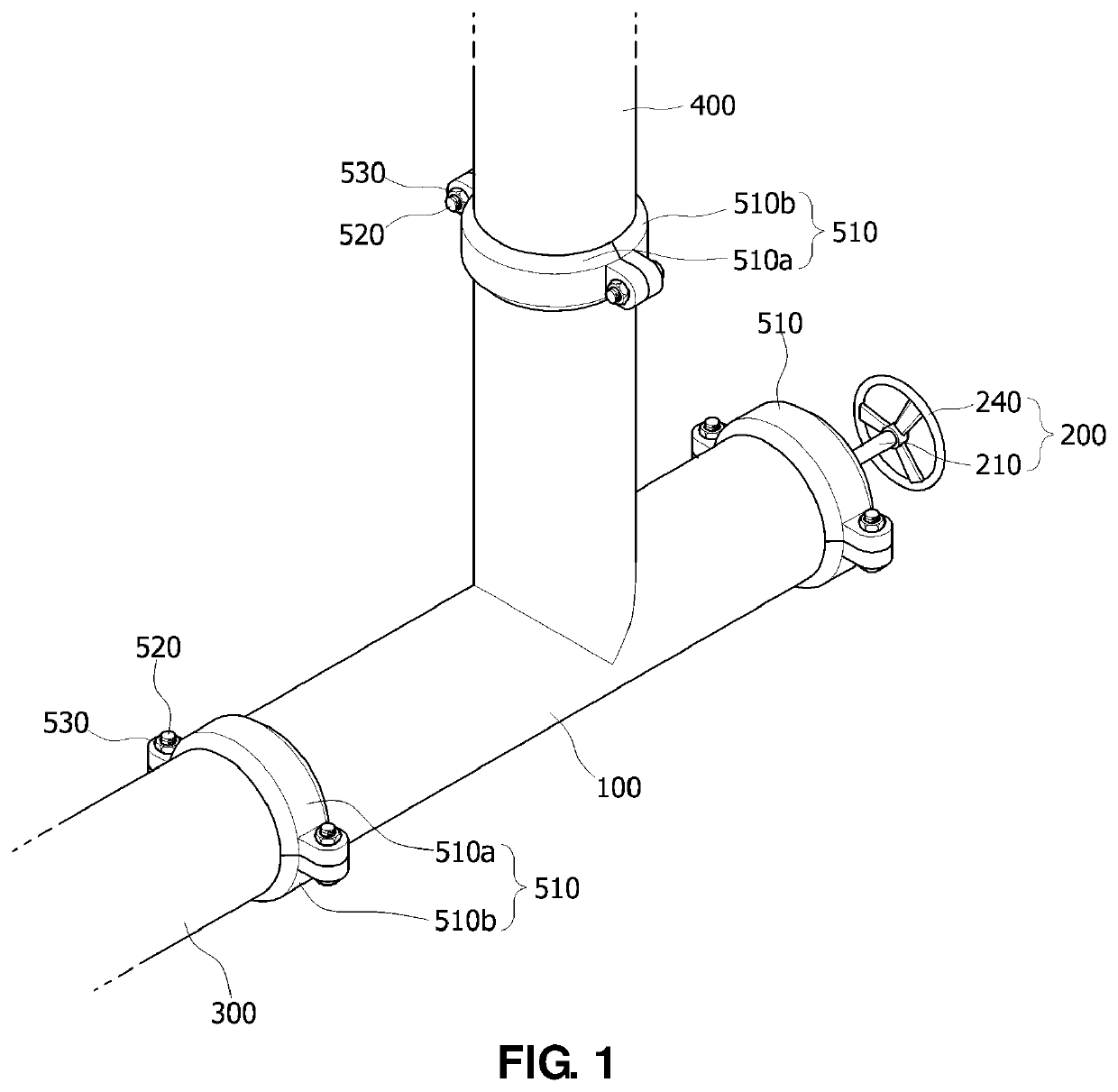

Valve assembly

ActiveUS20200149651A1Reduce volumeReduce weightSleeve/socket jointsFlanged jointsSS - Stainless steelVALVE PORT

A valve assembly is disclosed. The valve assembly is installed between an inlet pipe and an outlet pipe through which a fluid is transferred, the valve assembly including: a valve body in which an inlet portion which is connected to the inlet pipe and through which the fluid is introduced, a space portion in which the fluid supplied to an inside of the valve body through the inlet portion stays, and an outlet portion which is connected to the outlet pipe and through which the fluid of the space portion is discharged to the outside are formed; and an opening and closing unit configured to open or close a path of the fluid by moving in a state of being in close contact with an inner surface of the valve body, wherein the valve body is formed of a pipe of a steel or stainless-steel material.

Owner:DO QOOM CORP LTD

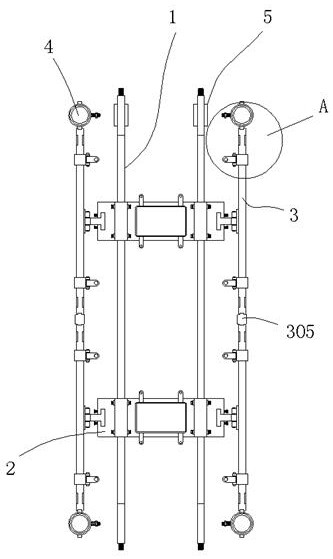

High voltage vibrating wire strain gauge

ActiveCN105091806BImprove water pressure resistanceReliable guarantee of cable stabilityUsing subsonic/sonic/ultrasonic vibration meansVibrating wireEngineering

The invention discloses a high pressure-resistant vibrating wire strain gauge comprising a cable joint, a cable, left and right flanges, a protection shell arranged between the left and right flanges, and a measuring device, a right fixed end, a partition joint, a steel wire and a steel wire protection tube which are arranged inside the protection shell. The steel wire is stretched and drawn in the steel wire protection tube, and is fixed to the left flange and the right fixed end. The measuring device is fixed to the steel wire protection tube by an injection mold. The measuring device, the steel wire, the steel wire protection tube, the left flange and the right fixed end form an integrated string core sensitive component. The integrated string core sensitive component is disposed inside the protection shell and completely isolated from the outside to ensure reliable resistance to water pressure. The partition joint is disposed in a cavity between the right fixed end and the right flange to play an isolation role. The water pressure resistance of the high pressure-resistant vibrating wire strain gauge of the invention is improved greatly, and the value measurement stability is improved significantly.

Owner:NANJING NARI GROUP CORP +1

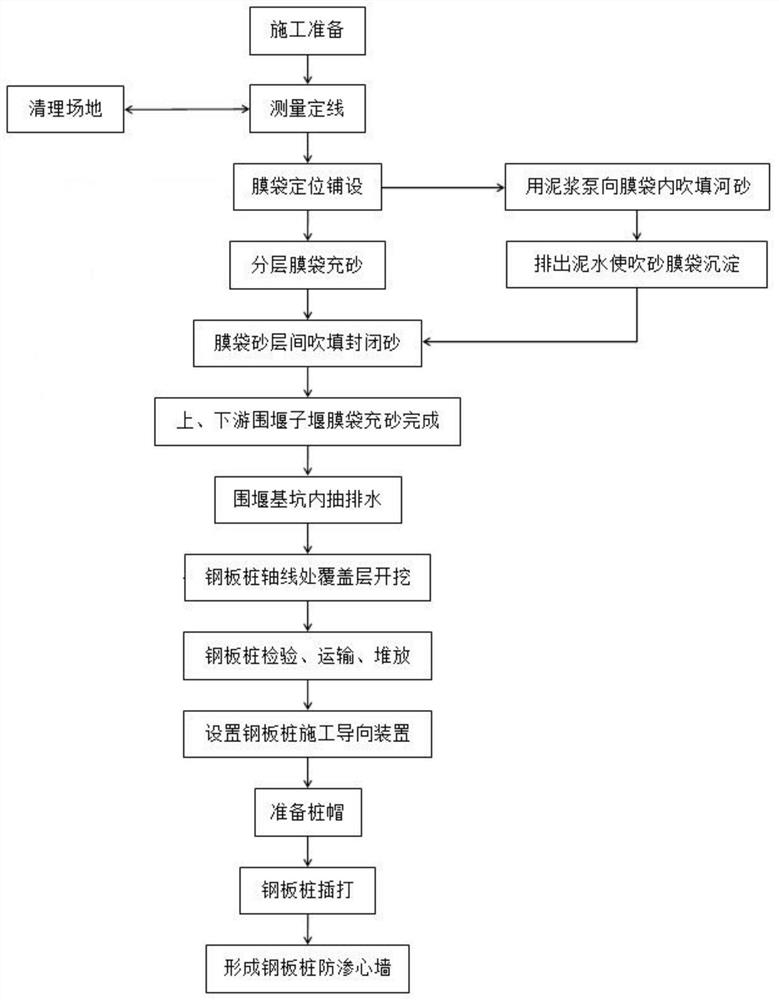

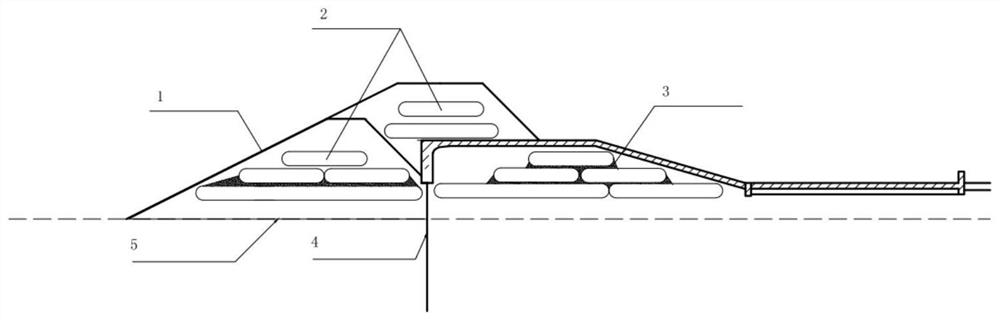

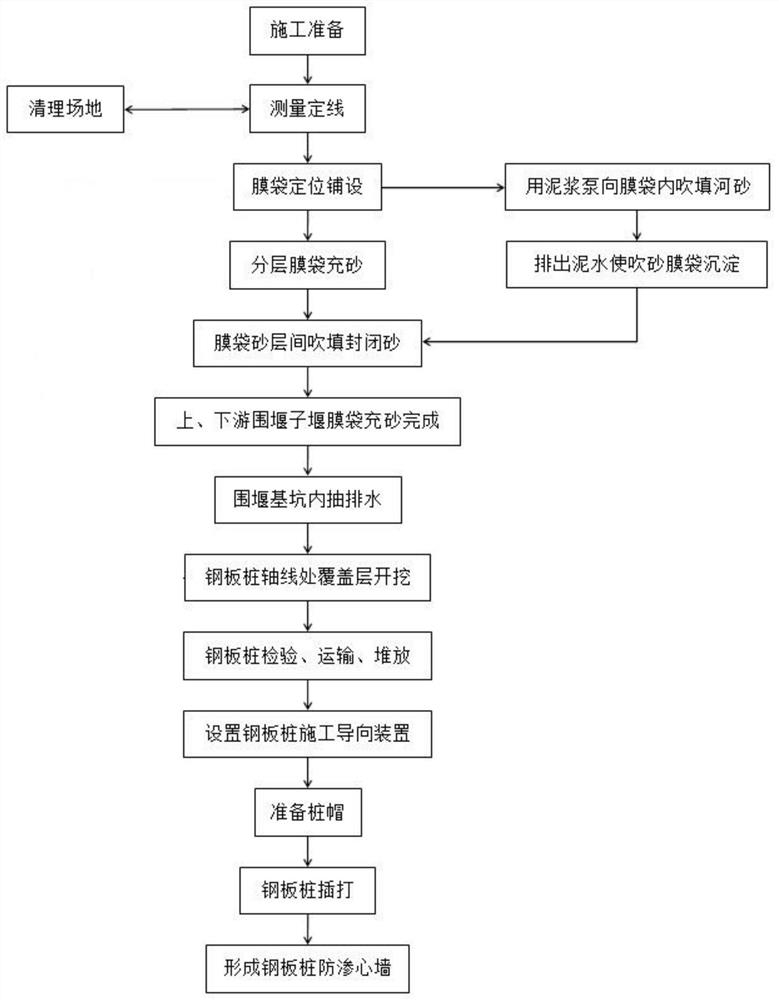

Cofferdam construction method combining film bag sand filling with steel sheet pile

PendingCN113957913AImprove integrityImprove stabilityProtective foundationExcavationsWater dischargeCofferdam

The invention discloses a cofferdam construction method combining film bag sand filling with a steel sheet pile. The cofferdam construction method comprises the steps of measurement and alignment, film bag positioning and laying, layer-by-layer film bag sand filling, muddy water discharging to enable a film bag sand cofferdam to precipitate, blow filling of closed sand between two layers of film bag sand, water pumping and drainage in a cofferdam foundation pit, steel sheet pile anti-seepage core wall construction and the like. According to the construction method, the film bag sand filling is combined with the steel sheet pile anti-seepage full-section cofferdam, the upper portion of the cofferdam is piled up with the film bag wrapped with sand soil, the lower portion of the cofferdam is anti-seepage through the steel sheet piles, the whole cofferdam becomes a whole, so that the cofferdam is high in integrity, good in self stability, high in adaptability to foundation, high in water pressure resistance and good in anti-seepage effect. The problem that the construction cofferdam is constructed under complex underwater geological conditions can be basically and effectively solved, the overall stability of a cofferdam structure is improved, and the cofferdam construction method has the advantages of being simple in process, fast in construction progress, low in cost and the like and has wide application prospects in the field of cofferdam construction of water conservancy projects.

Owner:广西建工集团海河水利建设有限责任公司

Automatic Cleaning System for Video Capture Window of Underwater Surveillance Equipment

ActiveCN105478397BGuaranteed cleanlinessGuaranteed long-term useCleaning using toolsBusbarEngineering

The invention discloses an automatic cleaning system for video collection windows of underwater monitoring equipment, which includes a disk-shaped base, a video collection module and a transparent window cover. The outer surface of the window cover is a busbar with one end on the central axis. A rotating curved surface is formed by rotating around the central axis. The central axis of the window cover is coaxial with the central axis of the base. A cleaning scraper is provided across the outer wall of the window cover. The inner edge of the cleaning scraper matches and fits the outer surface of the window cover. The cleaning scraper is hinged on the window cover and can rotate around the hinge axis. The hinge axis between the cleaning scraper and the window cover is coaxial with the central axis of the window cover; the cleaning scraper is driven by an external force to rotate around the hinge axis.

Owner:GUANGZHOU SEA DOG PHOTOELECTRIC SCI & TECH CO LTD

A kind of environment-friendly shield tail sealing grease and preparation method thereof

ActiveCN108865372BNo harmSolve the more harmful problemsLubricant compositionBiodieselPhysical chemistry

The invention provides an environment-friendly shield tail sealing grease and a preparation method thereof. The environment-friendly shield tail sealing grease is composed of the following raw materials in parts by weight: 20-35 parts of base oil composition, viscosity index modifier 6-15 parts, 30-55 parts of waterproof sealing material, 2-5 parts of lubricant, 5-25 parts of composite fiber, the base oil composition is isooctyl alcohol modified rapeseed oil and soybean oil or biodiesel by mass The composite fiber is formed by mixing mineral fiber and plant fiber at a mass ratio of 1-4.5:1. The base oil composition used in the present invention is a mixture of isooctyl alcohol modified rapeseed oil and soybean oil or biodiesel, which has excellent anti-wear performance and oxidation resistance, and is not harmful to soil and groundwater. It can be degraded in a short to medium term. On the basis of ensuring good sealing performance, it solves the problem of serious pollution of the shield tail sealing grease to the underground environment during the shield tunneling process.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

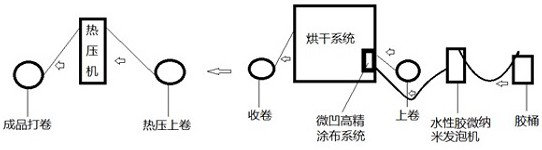

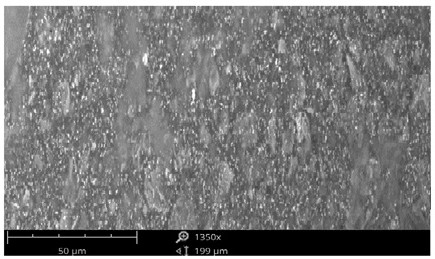

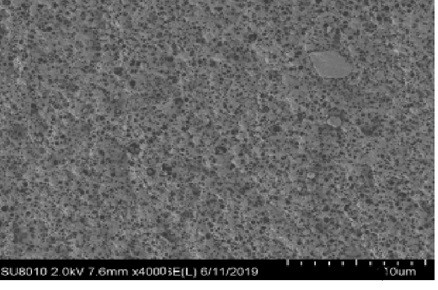

A kind of preparation method of ultra-thin and ultra-transparent microporous membrane

ActiveCN114703673BWith slow rebound propertiesImprove water pressure resistanceTextiles and paperMicro nanoPolymer science

The invention relates to a preparation method of an ultra-thin and ultra-transparent microporous membrane. The ultra-thin and ultra-transparent microporous membrane is a membrane containing micropores, the thickness of the membrane is below 5 μm, and the pore size of the micropores is below 5 μm; the preparation method is as follows: : Use a micro-nano foaming machine to foam the water-based foam to obtain bubbles, and then carry out micro-concave high-precision coating to obtain an ultra-thin and ultra-transparent microporous film; the water-based foam is mainly composed of water-based glue, water-based foam stabilizer, It is composed of silicone resin polyether emulsion water-based foam stabilizer and water; the foaming control parameters of the micro-nano foaming machine include: the specific gravity of the bubbles is 350~700 g / L, the working speed of the stirring head is 250~400 rpm, and the output of the pump 100~500L / hour; the diameter of the bubbles is less than 5μm; the thickness of the coating is less than 5μm during micro-concave high-precision coating, and at the same time greater than or equal to the diameter of the bubbles. The method of the invention is simple, the thickness of the prepared product is small, and the air permeability and anti-drilling down property are good, which effectively fills the blank of the prior art.

Owner:WUJIANG HANTA TEXTILE FINISHING

Environment-friendly split type faucet

PendingCN109972698AAvoid pollutionLow costDomestic plumbingValve housingsEngineeringMechanical engineering

The invention relates to the technical field of plumbing equipment, and provides an environment-friendly split type faucet. The environment-friendly split type faucet comprises a three-way shell, a plastic inner valve core pipe, a handheld switch, a valve and a water outlet pipe, and further comprises a first connecting part, a second connecting part, a ball ring and a sleeve. The first connectingpart sleeves the valve, and the lower end of the first connecting part is detachably connected with a mounting seat of a plastic inner valve core pipe valve core. One end of the second connecting parts partially penetrates through a water outlet of the plastic inner valve core pipe and rotatably connected with the water outlet of the plastic inner valve core pipe in a sealed mode, and a notchingaccommodating the ball ring is formed between a second ring boss of the second connecting part and the end port of the water outlet of the plastic inner valve core pipe, and the ball ring sleeves thenotching located between the second ring boss of the second connecting part and the end port of the water outlet of the plastic inner valve core pipe. The environment-friendly split type faucet solvesthe problems of high cost, complex structure and inconvenient assembly of an existing environment-friendly faucet.

Owner:黄小龙

Faucet filled with anti-impact high-dense elastomer material and preparation method of faucet

ActiveCN102155577BLow costImprove water pressure resistanceOperating means/releasing devices for valvesValve housingsElastomerFilling materials

The invention relates to a faucet, in particular to the faucet filled with an anti-impact high-dense elastomer material and a preparation method of the faucet. The faucet comprises an acrylonitrile butadiene styrene (ABS) plastic shell and mating parts, wherein the mating parts comprise a valve core, a handle, a water outlet net, a seal ring, a fastening screw and the like. The method comprises the following steps of: combining and connecting water channels of the faucet according to a waterway requirement of the faucet; putting the water channels into a mould of a shell of the faucet and fixing the water channels; fusing a high-dense elastomer which is mixed with an inorganic filling material by an extruder, an injection moulding machine, a kneading machine and an open mill, and filling the high-dense elastomer into the mould of the shell of the faucet; cooling the high-dense elastomer in the mould until the high-dense elastomer is formed, taking the high-dense elastomer out of the mould, and carrying out injection moulding on the high-dense elastomer to form a plastic shell of the faucet; and carrying out surface treatment on the shell, installing the filled faucet into the plastic shell of the faucet, and assembling the prepared faucet mating parts which are produced by the conventional process and comprise the valve core, the handle, the water outlet net, the seal ring, the fastening screw and the like into the faucet filled with the anti-impact high-dense elastomer material according to the conventional assembling mode.

Owner:XIAMEN RUNNER IND CORP

Hydraulic gate for dam flood prevention

ActiveCN112627124AStable opening and closingAvoid damageBarrages/weirsClimate change adaptationHydraulic cylinderGear wheel

The invention discloses a hydraulic gate for dam flood prevention. The hydraulic gate comprises a gate body and a door frame, the gate body is slidably connected into the door frame, hollow plates are fixedly connected to the left side and the right side of the door frame, and vertical plates are fixedly connected to the upper ends of the hollow plates. A hydraulic cylinder on a fluted disc stretches out and draws back to drive the gate body to slide up and down in the door frame, so that stable gate opening and closing are achieved; a transmission mechanism is arranged, a third gear is driven to rotate through a second motor arranged on a transverse plate, the fluted disc is rotatably connected with the transverse plate, rotation of the third gear is in linkage with rotation of the fluted disc, the upper end of the gate body is rotationally connected with a hanging rod, when the gate body is pushed upwards by the hydraulic cylinder, the fluted disc rotates by 90 degrees, and the top plate at the upper end of the hydraulic cylinder connected with the hanging rod can enter a containing groove in a pressing column; and the containing groove serves as a second protection project of the top plate, so that the situation that equipment is damaged greatly after the hydraulic cylinder is out of control can be avoided.

Owner:佛山市力众机械有限公司

Viscous-elastic material transverse partition plate partition underwater sound absorption structure

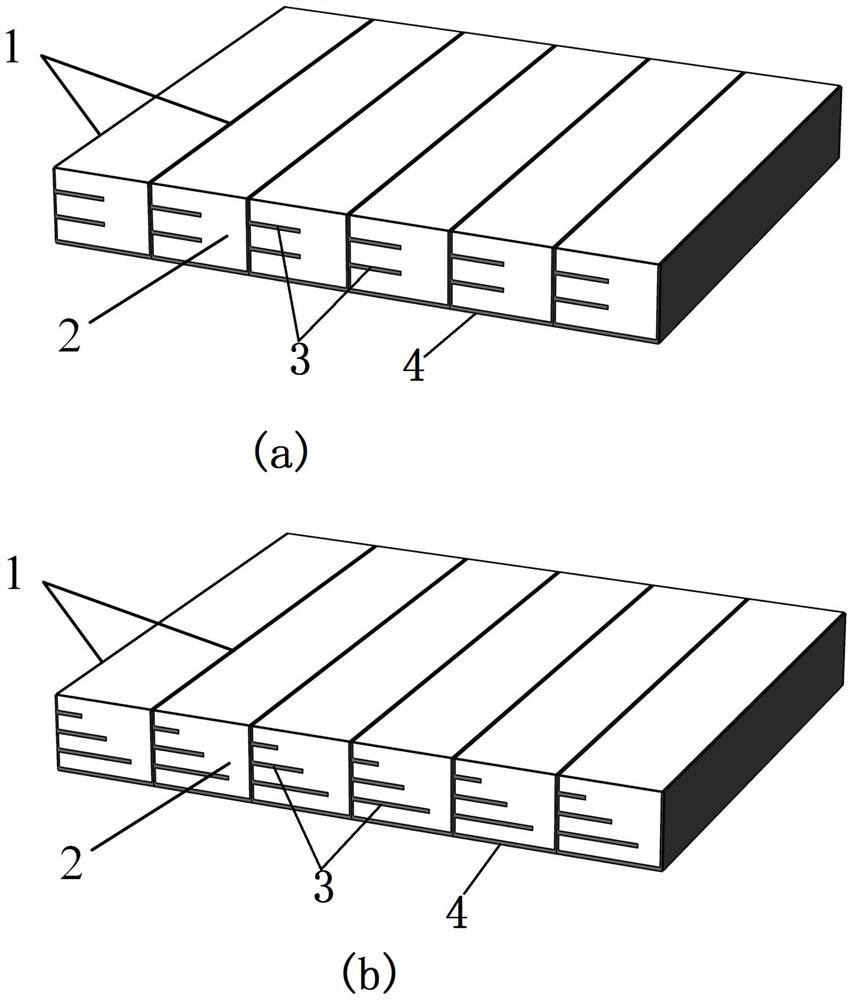

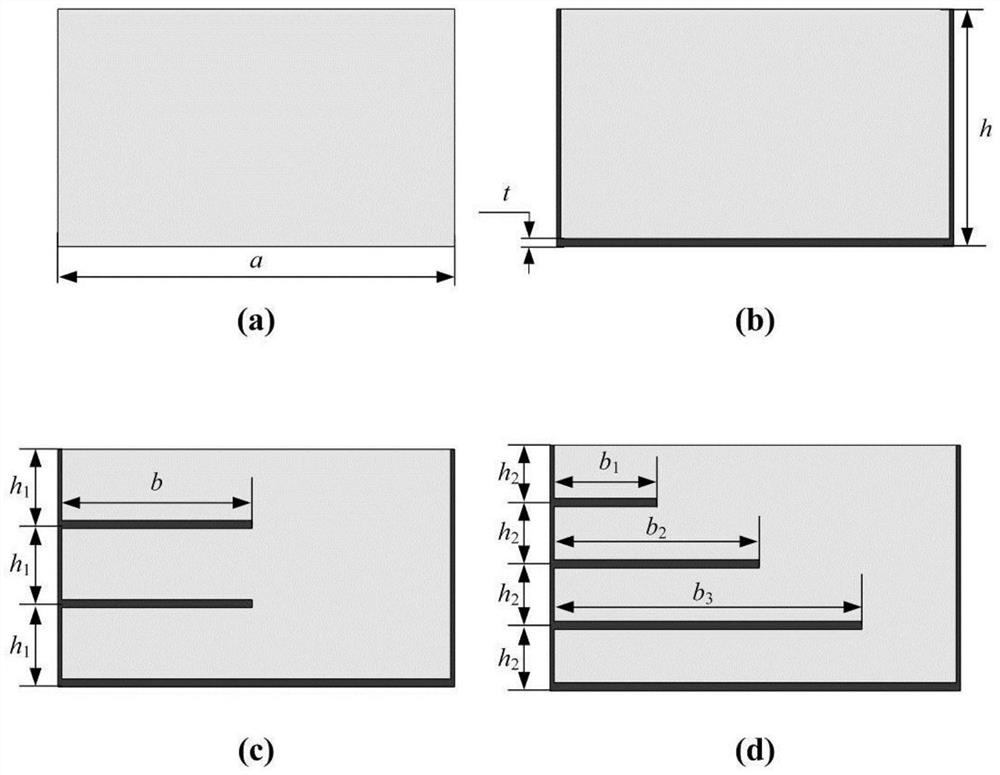

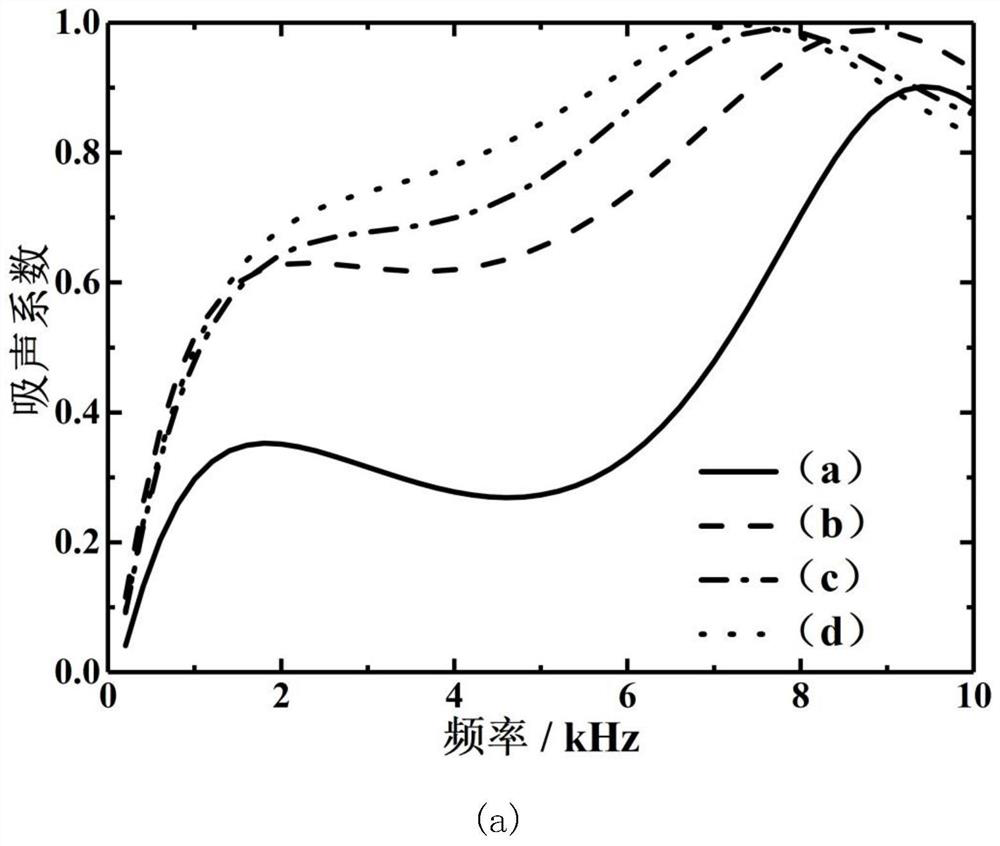

PendingCN112053671AImprove sound wave loss capabilityImprove water pressure resistanceSound producing devicesWall plateEngineering

The invention discloses a viscous-elastic material transverse partition plate partition underwater sound absorption structure. A plurality of wall plates are vertically arranged on a bottom plate at intervals, a plurality of transverse partition plates are horizontally arranged on one side of each wall plate, a cell is formed between every two adjacent wall plates, and a viscous-elastic material is arranged in each cell. According to the structure, more adjustable parameters including structural parameters and material parameters are provided in the design aspect, corresponding adjustment canbe conducted according to the actual working condition requirements, the structure is simple, and manufacturing is easy.

Owner:XI AN JIAOTONG UNIV +1

A hydraulic gate for flood control of a dam

ActiveCN112627124BStable opening and closingAvoid damageBarrages/weirsClimate change adaptationHydraulic cylinderGear wheel

The invention discloses a hydraulic gate for flood control of a dam, comprising a gate body and a door frame, the gate body is slidably connected in the door frame, the left and right sides of the door frame are fixedly connected with a hollow plate, and the upper end of the hollow plate is fixed Connected with risers. Through the expansion and contraction of the hydraulic cylinder on the toothed plate, the gate body is driven to slide up and down in the door frame, so as to realize stable opening and closing of the gate. With the setting of the transmission mechanism, the third gear is driven to rotate by the second motor arranged on the horizontal plate. The disk and the horizontal plate are connected in rotation, the rotation of the third gear is linked to the rotation of the toothed plate, and the upper end of the gate body is connected with the boom for rotation. When the hydraulic cylinder pushes the gate body upward, the toothed plate rotates 90 degrees, The top plate on the upper end of the hydraulic cylinder connected with the boom can enter the placement groove on the pressure column, and the placement groove is used as the second protection project of the top plate, so as to avoid a lot of equipment damage after the hydraulic cylinder is out of control.

Owner:佛山市力众机械有限公司

Water conservancy project dam

InactiveCN113250140AMeet the interception needsEasy to operateDamsFoundation engineeringArchitectural engineeringSlide plate

The invention discloses a water conservancy project dam. The water conservancy project dam comprises a left sliding rod structure, a right sliding rod structure, a sliding base structure and side plates, wherein the left sliding rod structure and the right sliding rod structure are parallel, the sliding base structure is assembled on the sliding rod structures, and the side plates are assembled on the two sides of the sliding base structure; and the two ends of each sliding rod structure are poured on river banks on the two sides. The sliding base structure comprises a sliding plate; two U-shaped parts are arranged on the upper portion of the sliding plate; an opening is formed in the bottom of each U-shaped part; inserting grooves are formed in the left side and the right side of the sliding plate; the sliding rod structures are arranged in the U-shaped parts in a matched manner; and after the outer portions of the U-shaped parts are screwed in, fixing pieces for the sliding rod structures are connected. The device is set up in an assembling manner, and therefore after the sliding rod structures are set up, assembling is sequentially conducted from the bank on one side to the bank on the other side, equipment such as ships is not needed during assembling, operation is simple and convenient, and the construction cost is lower.

Owner:王佩琴

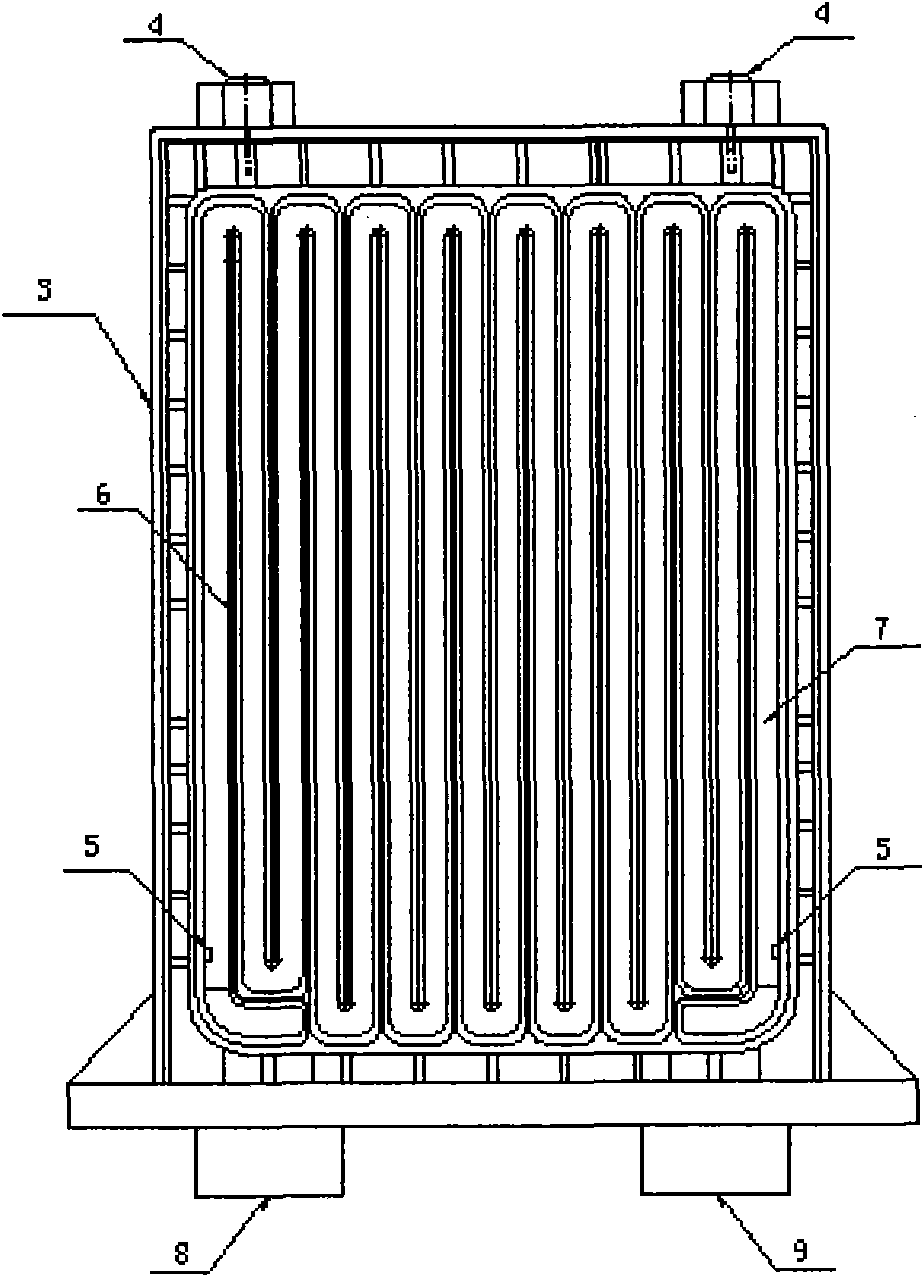

Uniform-section upright main water passage alloy belt water-cooled resistor

ActiveCN102290171BHigh strengthImprove stabilityResistor detailsNon-adjustable resistorsOpen waterWater channel

The invention relates to a uniform-section upright main water passage alloy belt water-cooled resistor, which mainly comprises a corrugated alloy belt resistor core, a uniform-section upright main water passage main board, two uniform-section upright main water passage side boards and two metal electrodes, wherein the uniform-section upright main water passage main board and the two uniform-section upright main water passage side boards are made of PVDF (polyvinylidene fluoride) fluoroplastic. Both sides of the uniform-section upright main water passage main board are provided with symmetrical open water channels, which consist of upright main water channels and curved water channels connected with the upright main water channels, the water channels on both sides are connected to form a serial water passage or parallel water passages according to need, and the bottom is provided with a water inlet and a water outlet; one side of each uniform-section upright main water passage side board is provided with an open water channel which corresponds to the open water channel on the uniform-section upright main water passage main board; the two electrodes are enchased on the uniform-section upright main water passage main board, one end of each electrode is extended out of the open water channel to serve as an internal electrode, and the other end of each electrode is extended out of the side or top of the main board to serve as an external electrode; and the corrugated alloy belt is wound in the open water channels according to the trend of the water passage, both ends of the corrugated alloy belt are respectively soldered on the two internal electrodes, and thereby the corrugated alloy belt resistor core is formed.

Owner:BEIJING 718 YOUSHENG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com