Viscous-elastic material transverse partition plate partition underwater sound absorption structure

A transverse baffle, viscoelastic technology, applied in the direction of sound-producing equipment, instruments, etc., to achieve good underwater sound absorption performance, improve water pressure resistance, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Examples of materials:

[0049] Metal steel: characterized by a density of 7850kg / m 3 , Young's modulus 205GPa, Poisson's ratio 0.28.

[0050] Viscoelastic material: It is characterized by a density of 900kg / m3, a longitudinal wave velocity of 900m / s, a longitudinal wave loss factor of 0.09, a shear wave velocity of 100m / s, and a shear wave loss factor of 0.9.

[0051] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0052] The structural dimensions of embodiment and comparative example:

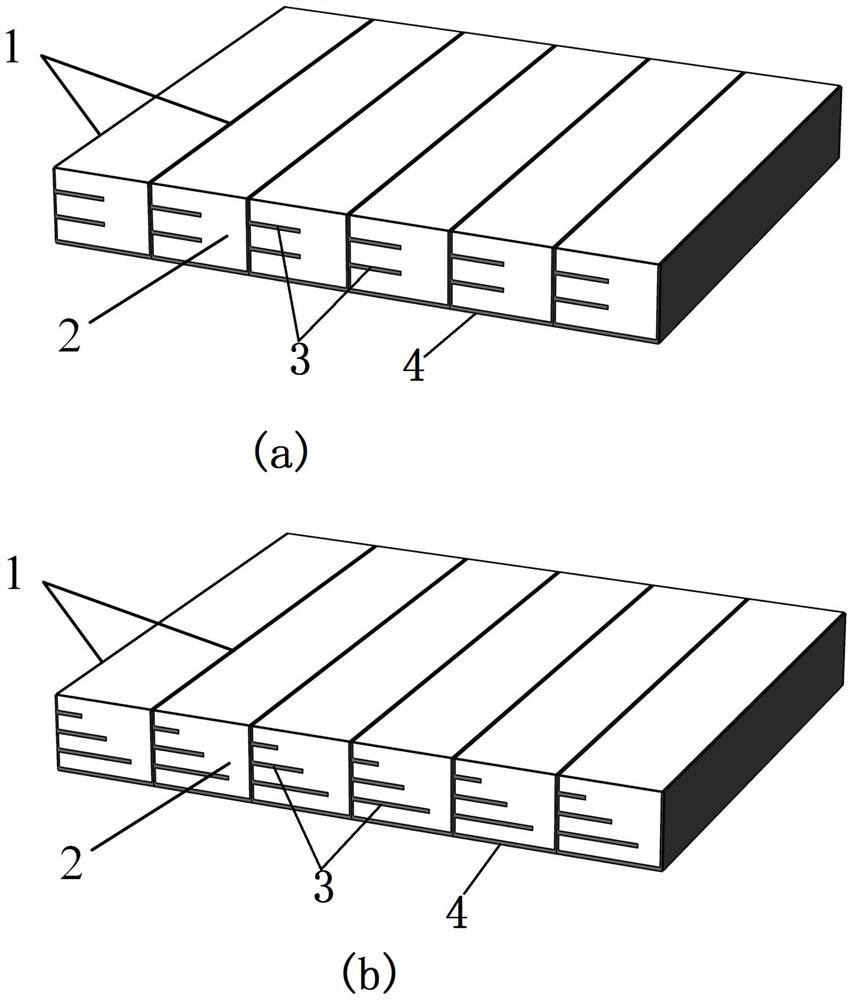

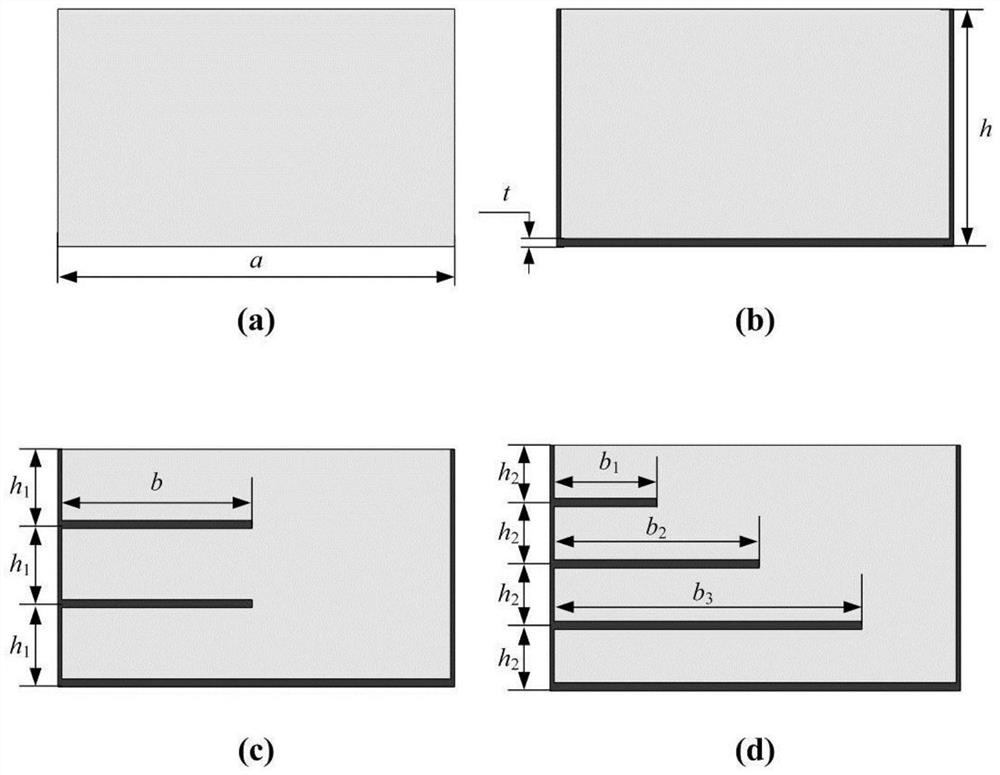

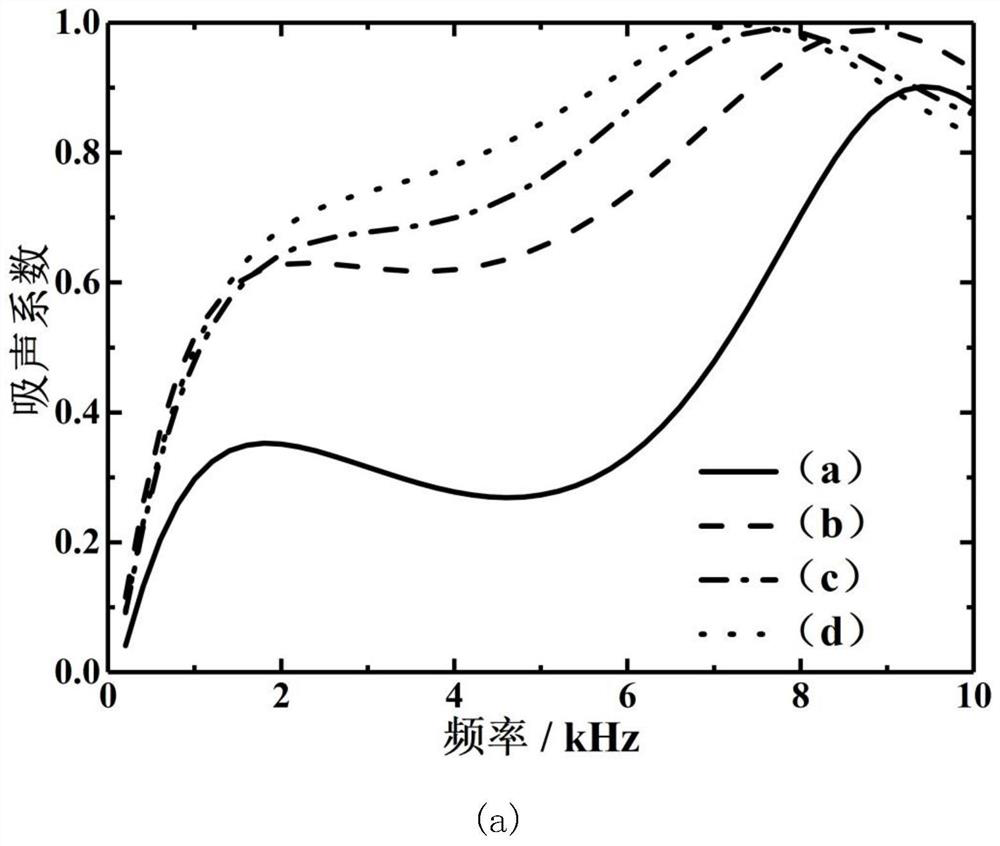

[0053] see figure 2 , (a) is a uniform viscoelastic material with equal thickness, (b) is a viscoelastic material with fixed cell walls, (c) is a viscoelastic material with a transverse partition, and the length of the transverse partition is the same, (d ) is provided with three transverse partitions of different lengths, and the distance between the three partitions is equal from top to bottom. In order to ensure the objectivity of the compar...

Embodiment 2

[0055] Examples of materials:

[0056] Metal steel: characterized by a density of 7850kg / m 3 , Young's modulus 205GPa, Poisson's ratio 0.28.

[0057] Viscoelastic material: characterized by a density of 900kg / m 3 , The longitudinal wave velocity is 1200m / s, the longitudinal wave loss factor is 0.2, the shear wave velocity is 120m / s, and the shear wave loss factor is 0.9.

[0058] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0059] The structural dimensions of embodiment and comparative example:

[0060] see figure 2 , (a) is a comparative example of a viscoelastic material with uniform thickness, (b) is a viscoelastic material with a fixed cell wall, (c) is a viscoelastic material with a transverse partition, and the length of the transverse partition is the same, (d) Three horizontal partitions of different lengths are installed, and the distance between the three partitions is equal from top to bottom and longer and longer. In or...

Embodiment 3

[0062] Examples of materials:

[0063] Metal steel: characterized by a density of 7850kg / m 3 , Young's modulus 205GPa, Poisson's ratio 0.28.

[0064] Viscoelastic material: characterized by a density of 800kg / m 3 , the longitudinal wave velocity is 800m / s, the longitudinal wave loss factor is 0.2, the shear wave velocity is 100m / s, and the shear wave loss factor is 0.9.

[0065] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0066] The structural dimensions of embodiment and comparative example:

[0067] see figure 2 , (a) is a comparative example of a viscoelastic material with uniform thickness, (b) is a viscoelastic material with a fixed cell wall, (c) is a viscoelastic material with a transverse partition, and the length of the transverse partition is the same, (d) Three horizontal partitions of different lengths are installed, and the distance between the three partitions is equal from top to bottom and longer and longer. In ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com