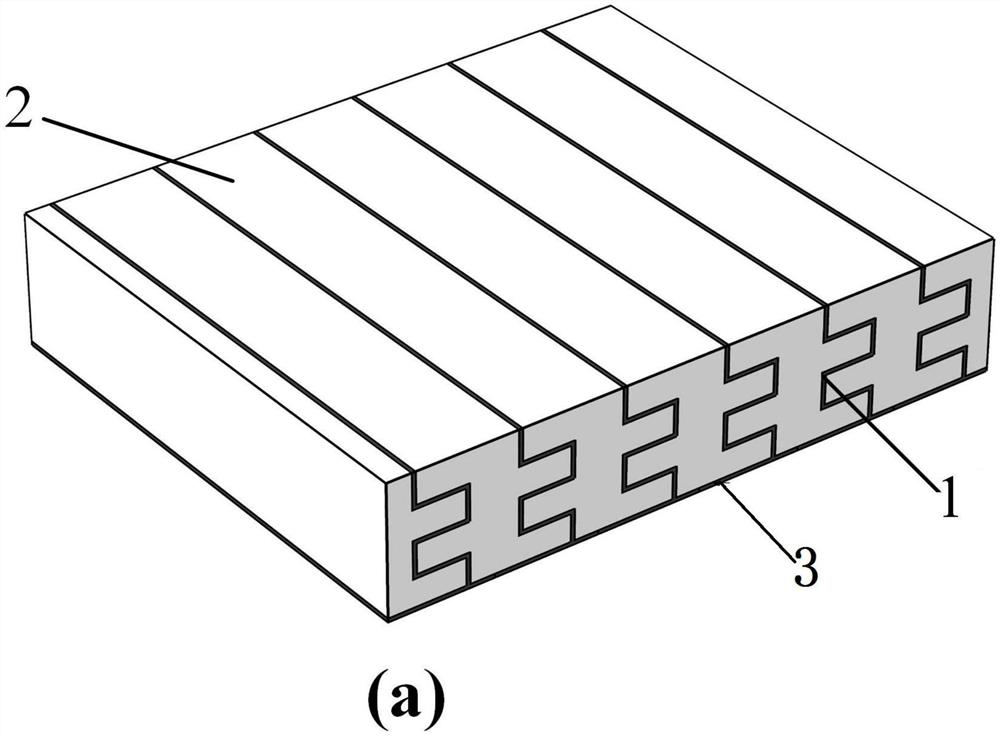

Underwater sound absorption structure with zigzag partition plates filled with viscous-elastic materials

A technology of viscoelasticity and baffles, which is applied in the direction of sound-generating devices and instruments to achieve the effects of easy manufacture, simple structure and improved sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Examples of materials:

[0042] Metal steel: it is treated as rigid in the simulation calculation.

[0043] Viscoelastic material 1: characterized by a density of 800kg / m 3 , the longitudinal wave velocity is 800m / s, the longitudinal wave loss factor is 0.09, the shear wave velocity is 80m / s, and the shear wave loss factor is 0.9.

[0044] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0045] The structural dimensions of embodiment and comparative example:

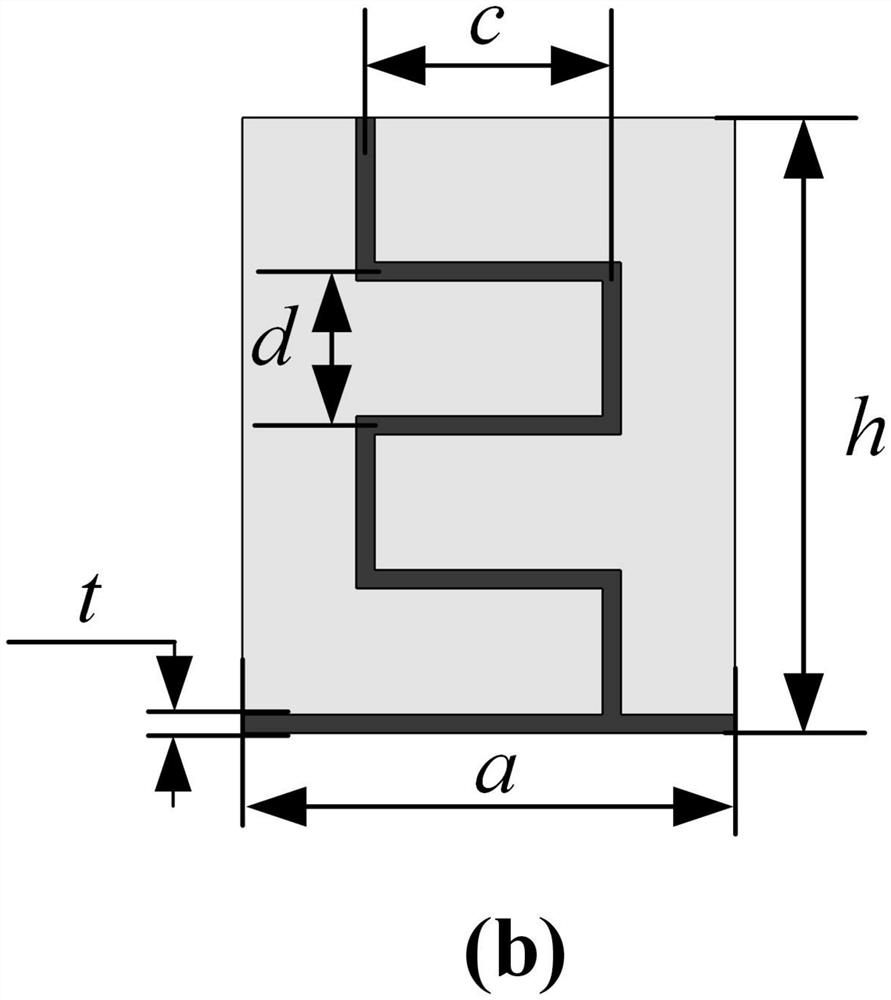

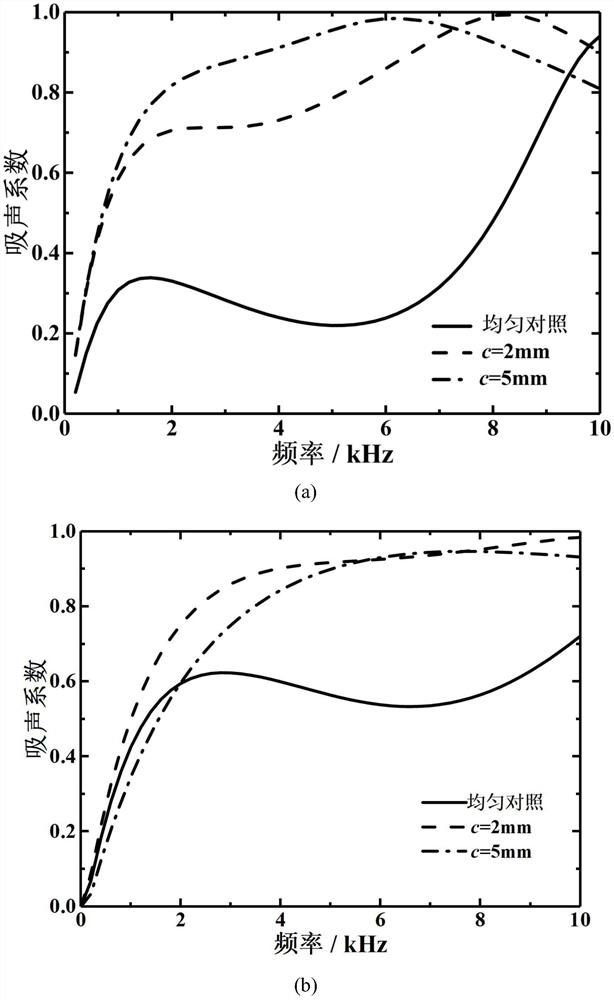

[0046] The control example is a uniform rubber material of equal thickness, see figure 1 In (b), in order to ensure the objectivity of the comparison, the thickness h of the embodiment and the comparative example remains consistent as h=40mm, and the width of the cell is a=25mm; the thickness t=1mm of the zigzag partition, the thickness of the zigzag partition The parameters are d = 10mm for the longitudinal height of the bend, and c for the transverse length. In the discussi...

Embodiment 2

[0048] Examples of materials:

[0049] Metal steel: it is treated as rigid in the simulation calculation.

[0050] Viscoelastic material 1: characterized by a density of 900kg / m 3 , the longitudinal wave velocity is 1000m / s, the longitudinal wave loss factor is 0.2, the shear wave velocity is 100m / s, and the shear wave loss factor is 0.9.

[0051] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0052] The structural dimensions of embodiment and comparative example:

[0053] The comparative example is a uniform rubber material of equal thickness. In order to ensure the objectivity of the comparison, the thickness h of the embodiment and the comparative example remains consistent as h=40mm, and the width of the cell is a=20mm; the thickness t=1mm of the zigzag partition, The parameters of the zigzag partition are d = 10mm in the longitudinal height of the bend, and c in the transverse direction. In the discussion, c = 2mm and c = 5mm are re...

Embodiment 3

[0055] Examples of materials:

[0056] Metal steel: it is treated as rigid in the simulation calculation.

[0057] Viscoelastic material 1: characterized by a density of 900kg / m 3 , The longitudinal wave velocity is 1200m / s, the longitudinal wave loss factor is 0.2, the shear wave velocity is 150m / s, and the shear wave loss factor is 0.8.

[0058] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0059] The structural dimensions of embodiment and comparative example:

[0060] The comparative example is a uniform rubber material of equal thickness. In order to ensure the objectivity of the comparison, the thickness h of the embodiment and the comparative example remains consistent as h=50mm, and the width of the cell is a=3mm; the thickness t=1mm of the zigzag partition, The parameters of the zigzag partition are d = 10mm in the longitudinal height of the bend, and c in the transverse direction. In the discussion, c = 2mm and c = 5mm are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com