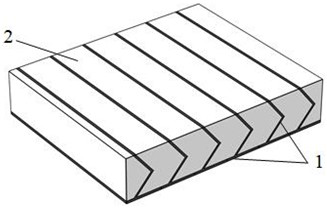

Underwater sound absorption structure with fish scale-shaped partition plates filled with viscouselastic material

A viscoelastic and scale-like technology, which is applied in the field of underwater sound-absorbing composite structure design, can solve the problems of poor broadband sound-absorbing performance of viscoelastic materials, and achieve the effect of improving sound-absorbing performance, simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Examples of materials:

[0024] Metal steel: it is treated as rigid in the simulation calculation.

[0025] Viscoelastic material 1: characterized by a density of 900kg / m 3 , the longitudinal wave velocity is 1000m / s, the longitudinal wave loss factor is 0.09, the shear wave velocity is 100m / s, and the shear wave loss factor is 0.5.

[0026] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0027] The structural dimensions of embodiment and comparative example:

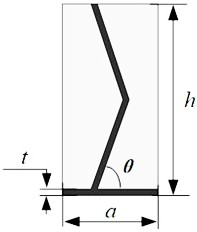

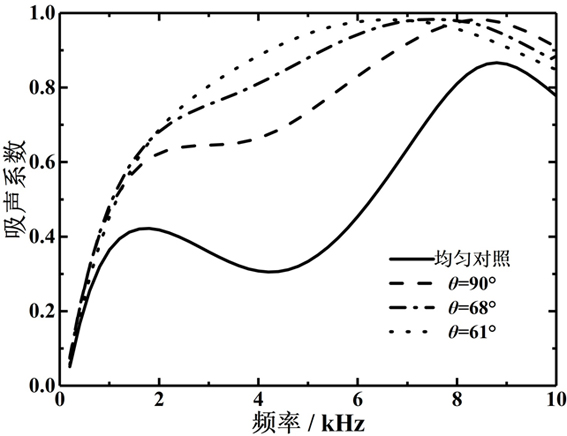

[0028] With reference to Fig. 1 (b), in order to guarantee the objectivity of contrast, the thickness of embodiment and comparative example h keep consistent as h =50mm, the viscoelastic material on both sides of the partition forms a cell, and the width of the cell is a =25mm. Partition thickness t =1mm, the inclination angles of the bottom of the fish scale partition are respectively θ =90°, θ =68° and θ =61° for analysis, where θ =90° indicates a vertical cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com