Zero-cold-water water heater

A water heater and zero-cold water technology, which is applied in the direction of water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large water flow of water heaters, insufficient flow of water, and insufficient diameter of circulating pumps, etc., to save floor space Management costs, saving the cost of the whole machine, and high water pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

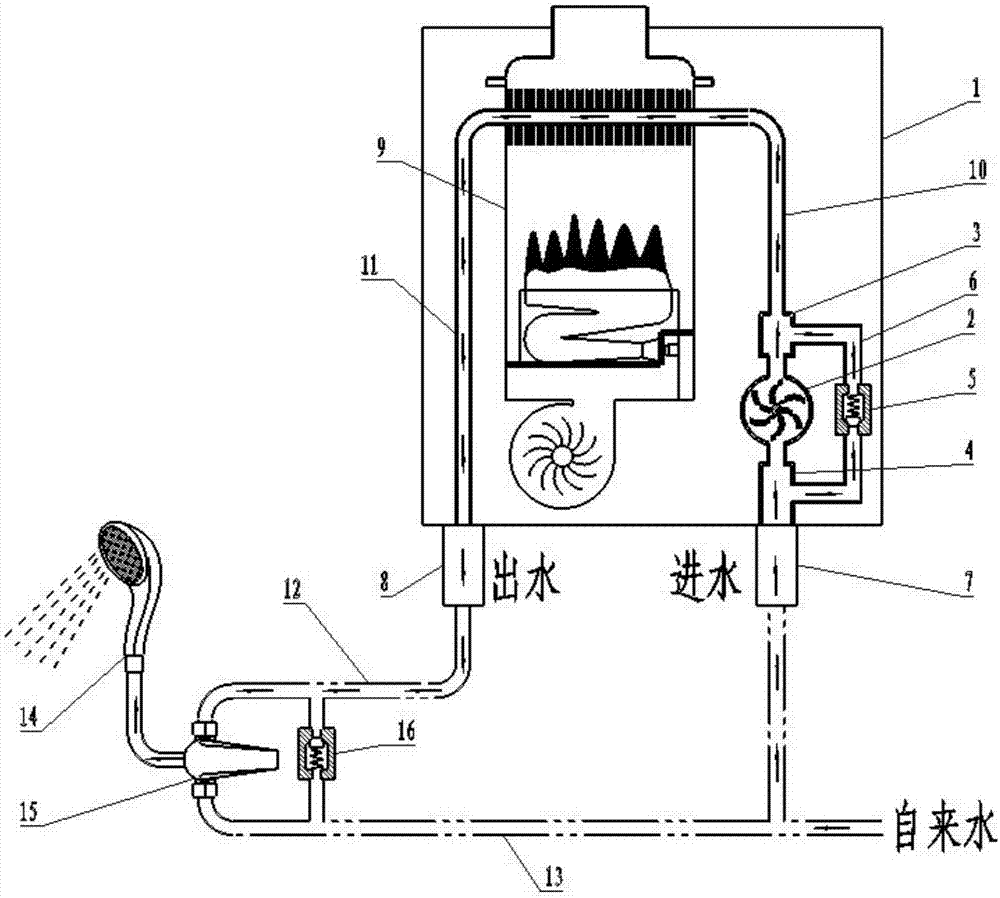

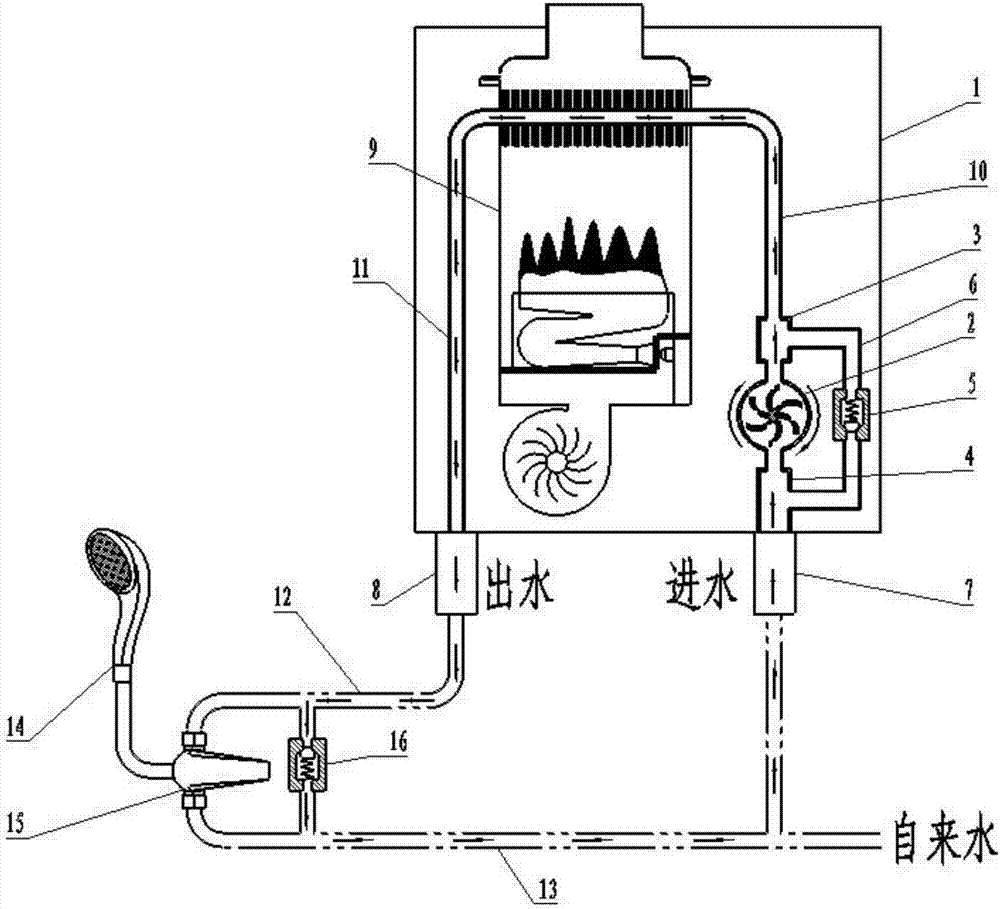

[0030] In this embodiment, the water heater is a gas water heater. Those skilled in the art can predict that the pipeline structure of the present invention is also suitable for other types of water heaters, such as electric water heaters. The arrows in the figures indicate the direction of water flow.

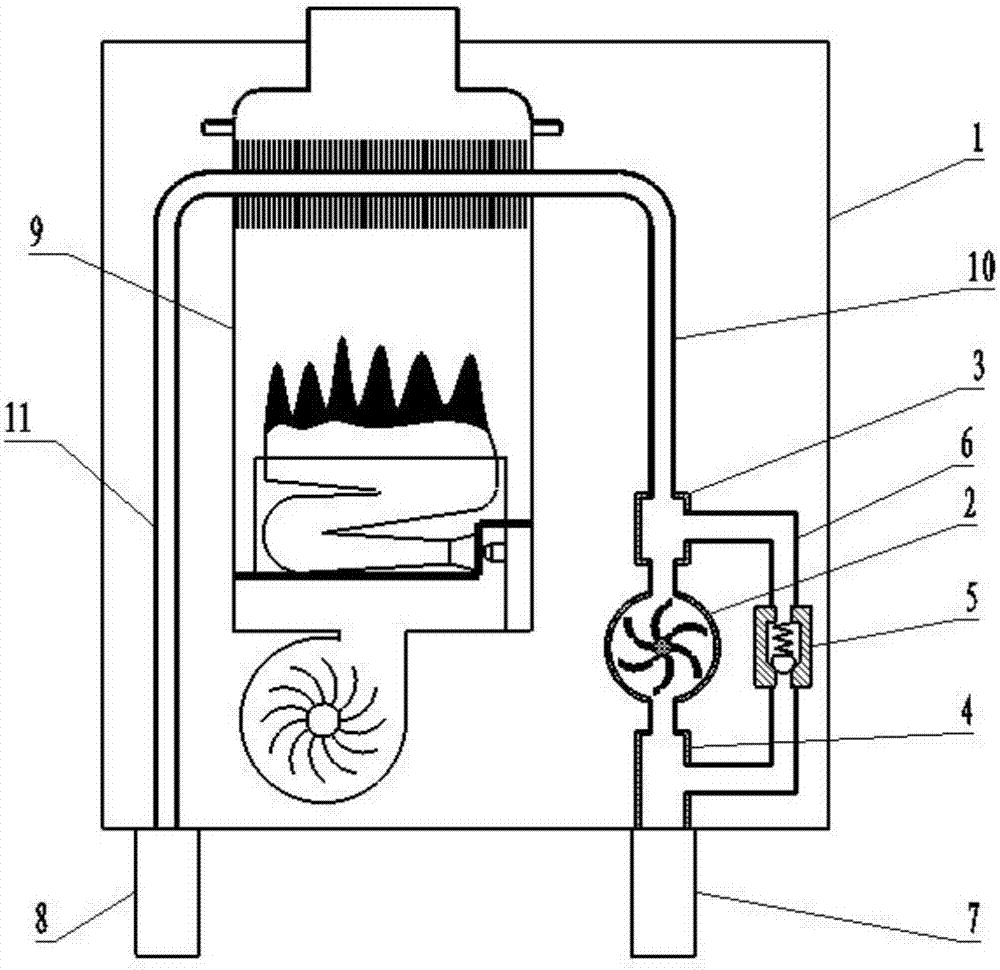

[0031] like figure 1 As shown in the figure, a zero-cold water water heater of the present invention includes a water heater body 1, a circulating pump 2, a split three-way valve 3, a confluence three-way valve 4, a first one-way valve 5, a water inlet connector 7, a water outlet connector 8, a heat exchange 9, internal water inlet pipeline 10 and internal water outlet pipeline 11. The inner water inlet pipeline 10 is communicated with the water inlet joint 7 , and the inner water outlet pipeline 11 is communicated with the water outlet joint 8 . The circulating pump 2 is installed on the internal water inlet pipe 10 of the water heater body 1 , and the water outlet directi...

Embodiment 2

[0036] The basic structure of the water heater in Embodiment 2 is the same as that in Embodiment 1, except that the water inlet pipeline is changed.

[0037] like Figure 4 As shown, a water return joint 18 is provided outside the water heater body 1, a bypass branch 17 is provided on the water inlet pipeline of the circulating pump 2 to communicate with the return water joint 18, and the bypass branch 17 is provided with The third one-way valve 19, the conduction direction of the third one-way valve 19 is consistent with the direction of the water flow from the return water joint 18 to the water inlet end of the circulating pump 2.

[0038] like Figure 5 As shown, during installation, a backwater three-way valve 20 is provided at the hot water pipeline 12 near the water equipment 14 , and the backwater three-way valve 20 is communicated with the backwater joint 18 through the backwater pipeline 21 . Therefore, the water stored in the hot water pipeline 12 can flow back to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com