Preparation method of watertight connector, product thereof and composite rubber material for preparing watertight connector

A watertight connector and compound rubber technology, which is applied to the parts of the connecting device, the manufacture and connection of the contact box/base, etc., can solve the problem of difficult maintenance of the connector.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The embodiment of the present invention relates to a method for preparing a watertight connector, which includes two parts, one is the preparation of a composite rubber material, and the other is forming the watertight connector. Mixed neoprene can be obtained by banburying and kneading the raw materials, and then the pretreatment of wires and cables is put into the mold for vulcanization. Therefore, it has the characteristics of simple preparation process and is convenient for practical popularization.

[0046] Specifically, the raw materials of the composite rubber material in the embodiment of the present invention include: chloroprene rubber, tackifier masterbatch 3, modified talcum powder, insoluble sulfur, zinc oxide, magnesium oxide, anti-aging agent, processing aid and accelerator; The composition of the masterbatch is neoprene rubber, terpene resin, and talcum powder.

[0047]Neoprene has good physical and mechanical properties, oil resistance, heat resistance...

Embodiment 1

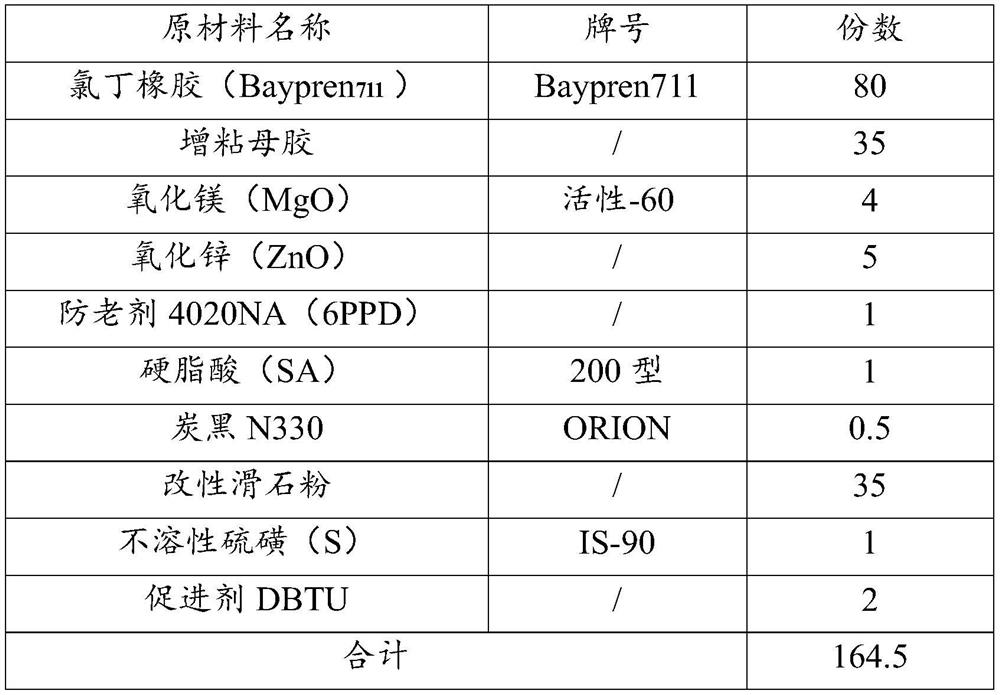

[0079] The mixing process of neoprene, wherein the formula of neoprene in Table 1.

[0080] Table 1 Formulation of Neoprene

[0081]

[0082] According to the above ratio, add neoprene Baypren711 into the internal mixer, add tackifier masterbatch, stearic acid, anti-aging agent and other processing aids in turn, then add magnesium oxide, add carbon black and modified talcum powder in batches , adding zinc oxide, sulfur and accelerator DBTU. After the mixing of rubber materials is completed, the material is discharged with an open mixer. Adjust the roller distance of the open mill to the minimum, thin it 5 times, gradually increase the roller distance, discharge and unload the sheet, stop the machine, cool to room temperature, and prepare the mixed neoprene rubber.

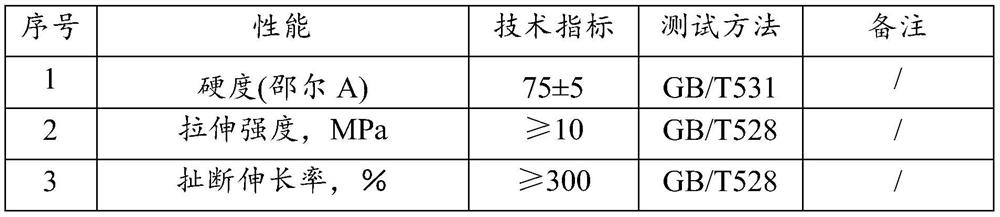

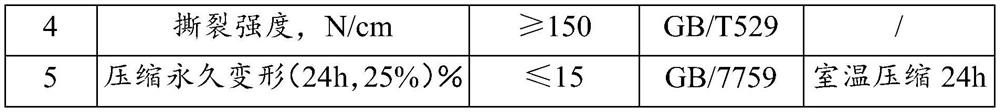

[0083] Part of the mixed neoprene was vulcanized on a flat vulcanizer, and samples were taken out to test its mechanical properties. The test results are shown in Table 2.

[0084] Table 2 Main performance indi...

Embodiment 2

[0088] Connector male head forming process:

[0089] Table 3 Connector male equipment and tools

[0090] serial number name Specification use 01 Several single-core wires Φ1.5mm Components 02 Butt terminal—male / Components 03 Brass Shoulders / Components 04 positioning needle Φ2.0*25mm Components 05 Inlay Φ8.0*2.8mm Components 06 CHEMLOK glue 205 and CH220 binder 07 Rubber for Homemade Connectors JTCR-4 Molded sample 08 Forming mold 1 set / Molded sample 09 A set of pressure sensors 0-2000Kg Monitor injection pressure 10 Scissors, wire strippers, etc. / strip the wire 11 Set of welding torch and welding wire / Soldering wires and terminals 12 jack 2T Rubber injection 13 Plate vulcanizing agent 50T Sample forming 14 Blast drying oven DHG-9035A Mold and rubber preheating

[0091] 1. Wire and needle core pretreatment

[0092] 1.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com