Flow channel type marine organism adhesion testing device

A technology of marine organisms and testing devices, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of difficulty in meeting the needs of antifouling material research, low degree of automation, and low test accuracy, and achieve reliable design principles and automation High-level, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

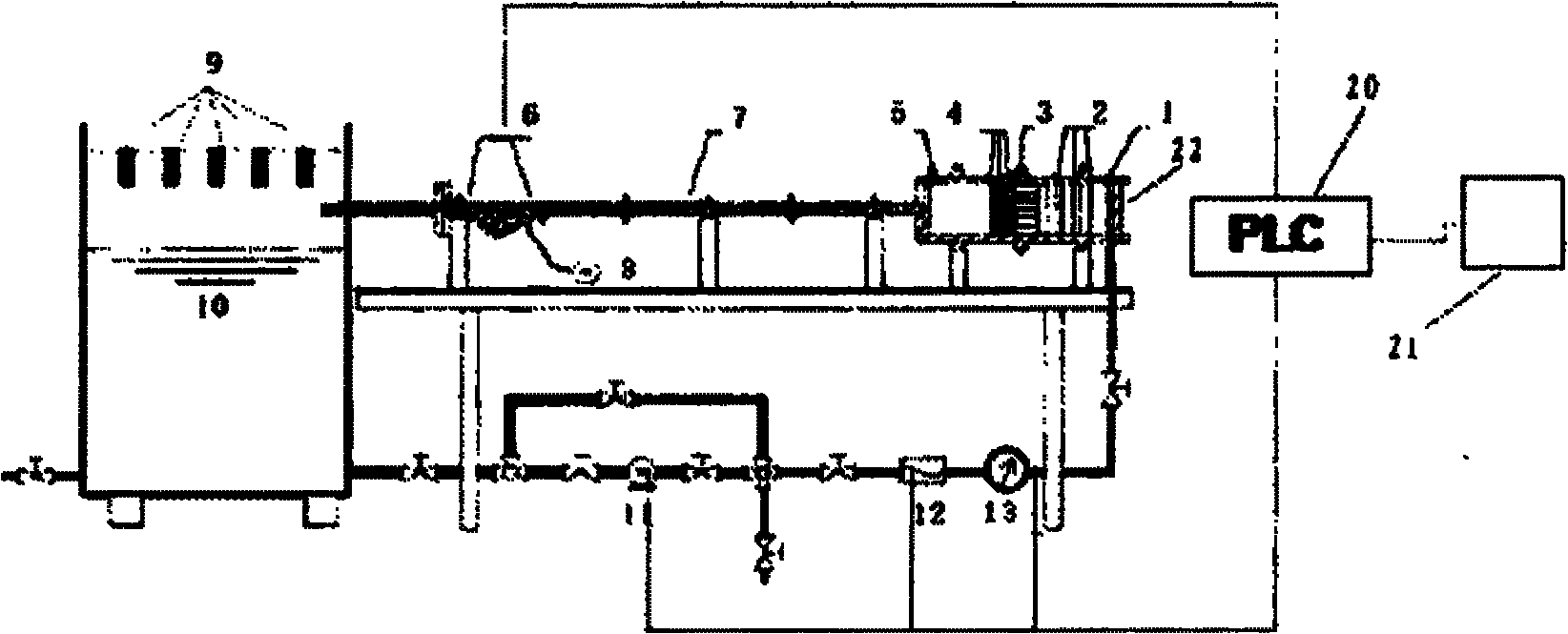

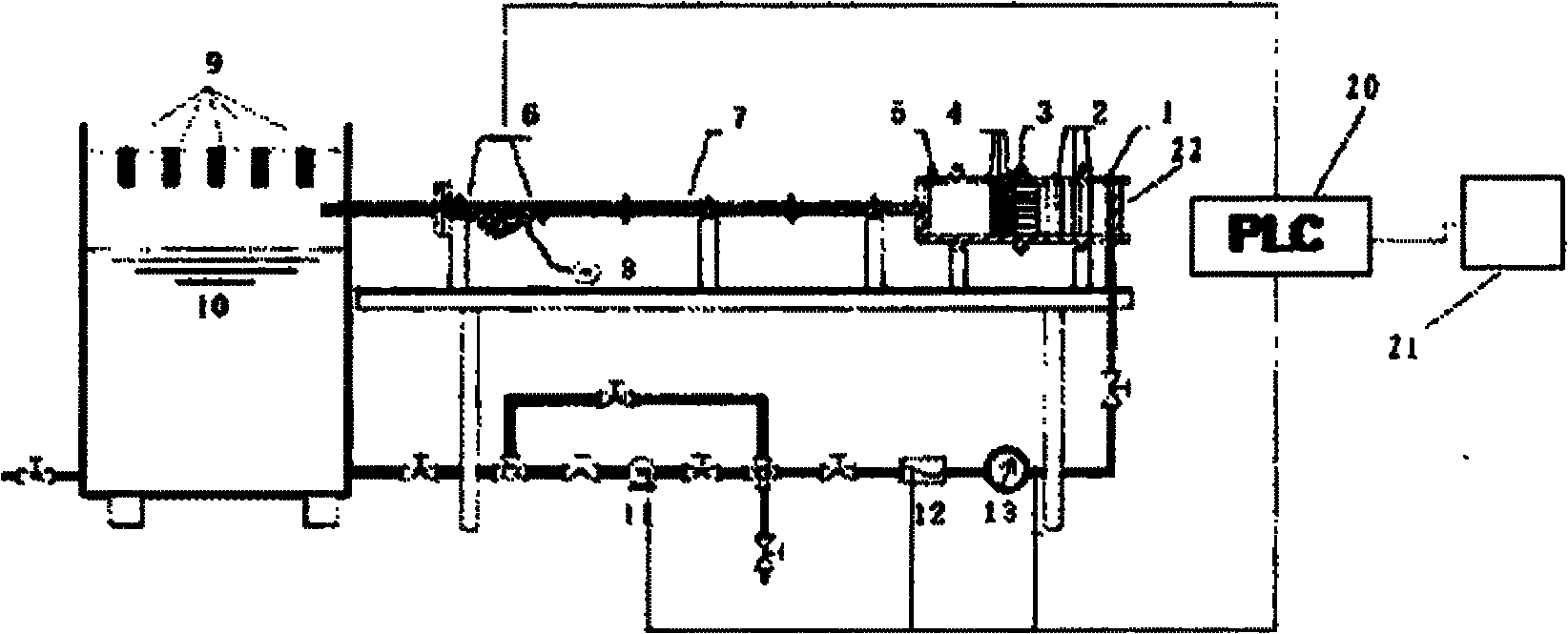

[0011] In the present embodiment, the settling chamber 22 of the box structure is provided with water inlet 1, perforated stainless steel plate 2, honeycomb polycarbonate plate 3, stainless steel sieve plate 4, and exhaust valve 5 in order from right to left. The left end of the sedimentation chamber 22 is provided with a test chamber 7 transversely, a differential pressure transmitter 6 is provided on the left side of the test chamber 7, a vacuum pump 8 is installed in the test chamber 7, and a water tank 10 and a water tank 10 are provided at the left end of the test chamber 7 A light source 9 is made at the top of the tank 10, and the pipeline from the bottom of the water tank 10 is connected to the water inlet 1 through a multi-end valve control. The connected pipelines are respectively made with a variable frequency pump 11, a flow meter 12 and a pressure transmitter 13; a programmable controller 20 , The computer 21 communicates with the differential pressure transmitter 6...

Embodiment 2

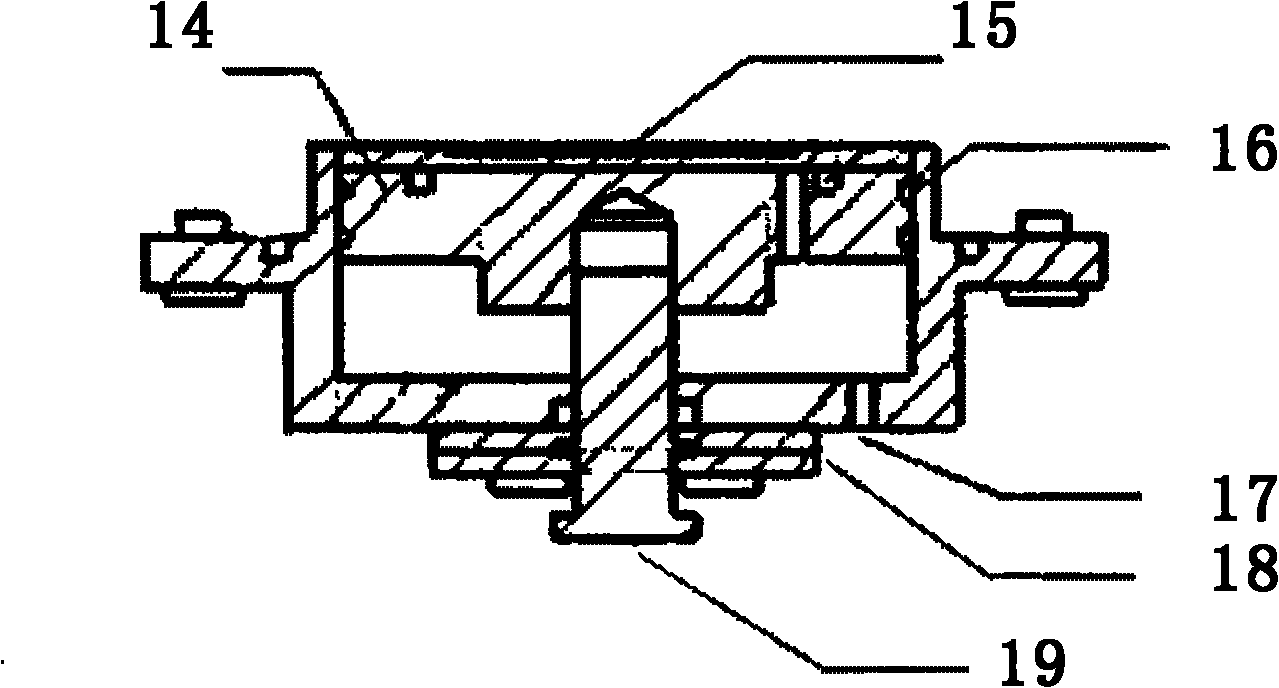

[0013] In this embodiment, the sample to be tested is fixed on the sample mounting table 15, the vacuum pump 8 is turned on, and the vacuum is drawn to fix the sample to be tested on the stage 14, and then the sample mounting table 15 is mounted on the test chamber 7 and passed the height The regulator 19 adjusts the height of the sample so that the surface of the sample to be tested is level with the lower surface of the test chamber 7; when the exhaust valve 5 is opened, seawater enters the sedimentation chamber 22 from the water inlet 1, and then passes through the perforated stainless steel plate 2 in a honeycomb shape. Carbonate plate 3, 24 mesh stainless steel sieve plate 4, after sea water is filled with the whole device, and after observing that there are no bubbles in the test chamber 7, close the exhaust valve 5; increase the sea water flow rate and test the adhesion of the fouling organisms on the surface of the material.

Embodiment 3

[0015] In this example, Ulva pertusa Kjellm (Ulva pertusa Kjellm) was collected from the sea area, washed repeatedly with seawater, brought back to the laboratory at low temperature, and rinsed with filtered and disinfected seawater for 4-5 times to remove protozoa and epiphytes; The algae body was stored under constant conditions of temperature 4℃ and photoperiod 12L:12D for later use. Several strains were selected and placed in a Erlenmeyer flask containing sterilized seawater for aerated culture at a water temperature of 15℃ and continuous light for 15 hours. Collect the spores of Ulva vulgare; dilute the collected spores of Ulva vulgaris with f / 2 nutrient solution to a concentration of 1×10 5 Each / L, shake well for use; place the self-made experimental samples A, B, C, D, E obliquely into a 250ml beaker containing 200ml experimental spore solution, at 20℃, light intensity about 7000Lx, light to dark ratio 12 :Incubate for 24 hours under the condition of 12; after 24 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com