High voltage vibrating wire strain gauge

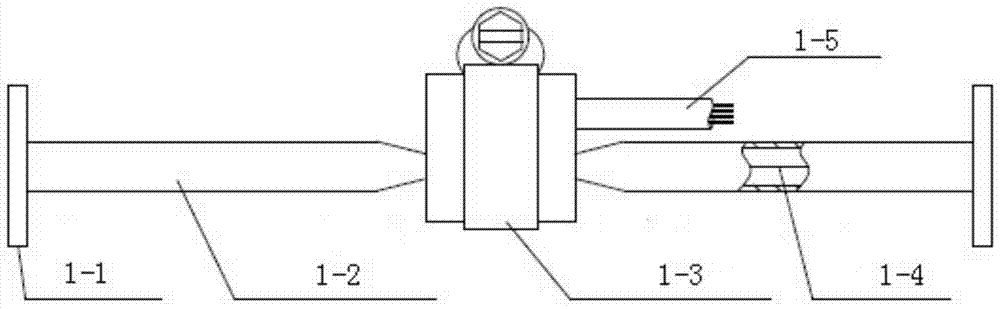

A vibrating wire and strain gauge technology, which is applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve the problem of low measurement stability and low measurement accuracy of vibrating wire strain gauges. Insufficient resistance to water pressure and other problems, to achieve the effect of maintaining the stability of the measured value and long-term adaptability, the stability of the measured value and the long-term reliability guarantee, and ensuring the long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

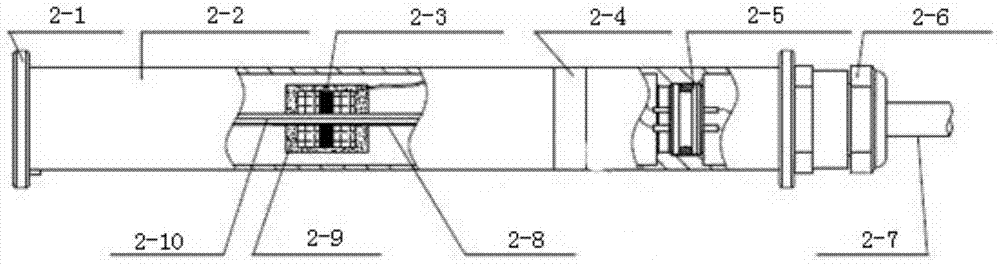

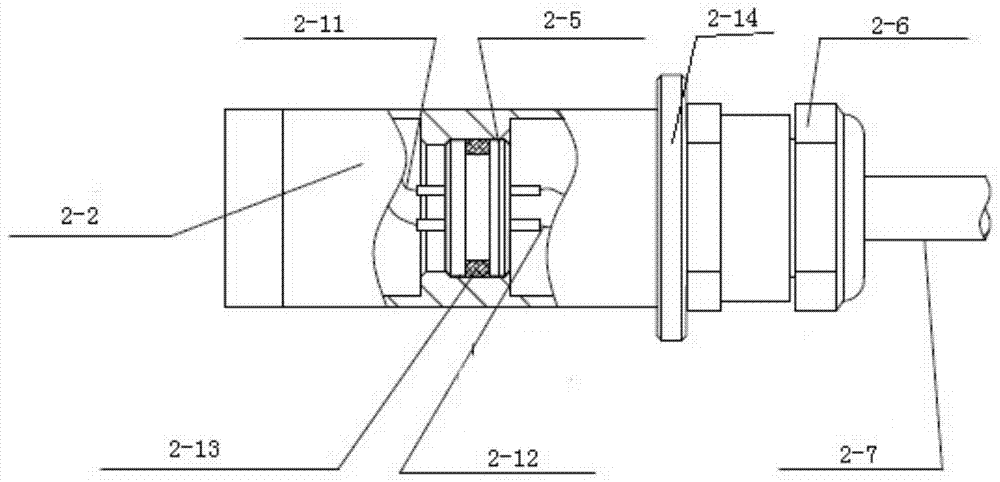

[0017] Such as figure 2 As shown, the high-voltage vibrating wire strain gauge of the present invention includes a cable joint 2-6, a cable 2-7, a left flange 2-1, a right flange 2-14, and is placed between the left and right flanges. Protective shell 2-2, measuring device 2-3 placed inside the protective shell 2-2, right end fixed end 2-4, partition joint 2-5, steel string 2-10 and steel string protective pipe 2-8 .

[0018] Among them, the steel string 2-10 is stretched inside the steel string protection tube 2-8, and fixed on the left flange 2-1 and the right fixed end 2-4, and the right fixed end 2-4 is mainly used for fixing The other end of the steel string 2-10, its main function is to cooperate with the left flange 2-1 to jointly fix and tension the steel string 2-10, between the right fixed end 2-4 and the protective shell 2-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com