A kind of preparation method of ultra-thin and ultra-transparent microporous membrane

A microporous film, ultra-thin technology, applied in textiles and papermaking, etc., can solve the problems of low air permeability and difficulty in taking into account the anti-drilling effect, and achieve excellent waterproof performance, excellent anti-drilling performance, and excellent air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

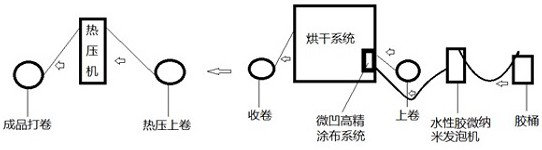

[0044] A preparation method of an ultra-thin and ultra-transparent microporous membrane, such as figure 1 shown, the specific steps are as follows:

[0045] (1) Preparation of raw materials;

[0046] Water-based glue: PU;

[0047] Functional additives: Shanghai Huzheng colorless and transparent nano-silver solution, the grade is AGS-WM1000A / B / C;

[0048] Water-based foam stabilizer: Shenzhen Guangsiyuan polyurethane soft foam stabilizer GSYPU G-595 silicone oil;

[0049] Silicone resin polyether emulsion water-based foam stabilizer: Shandong Yousu Chemical modified silicone resin polyether microemulsion FM-550;

[0050] water;

[0051] Base fabric: superfine denier filament fabric;

[0052] Hydrophobic finishing agent: Shanghai Huzheng colorless transparent hydrophobic coating additive SSJ-FG3 / SSJ-F181;

[0053] (2) Adjusting glue;

[0054] In parts by weight, 100 parts of water-based glue, 2 parts of functional additives and water were mixed in a glue bucket to obtain ...

Embodiment 2

[0073] A method for preparing an ultra-thin and ultra-transparent microporous membrane is basically the same as that in Example 1, except that step (6) is omitted.

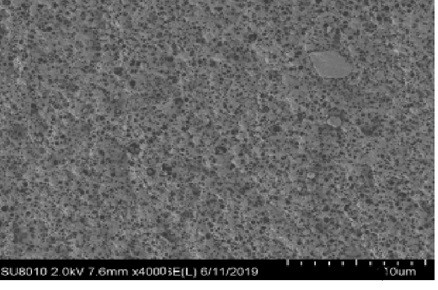

[0074] The final ultra-thin and ultra-transparent microporous membrane is a membrane containing micropores, the thickness of the membrane is 5 μm, the pore diameter of the micropores is 1-5 μm, and the average pore diameter is 3 μm; the air permeability of the membrane is in accordance with GB / T 5453 "Textiles. The standard test of "Testing of the Air Permeability of Fabrics" conforms to the national standard, and the anti-drilling property of the film conforms to the national standard according to the GB / T14272-2011 "Down Clothing" standard. KPa.

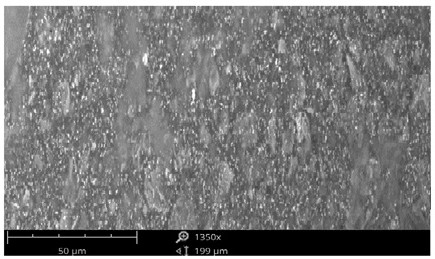

[0075] Comparing Example 1 with Example 2, it can be seen that the thickness of the ultra-thin and ultra-transparent microporous film without hot pressing of Example 2 is slightly higher than that of the ultra-thin and ultra-transparent microporous film of Example 1 th...

Embodiment 3

[0077] A preparation method of an ultra-thin and ultra-transparent microporous membrane, the specific steps are as follows:

[0078] (1) Preparation of raw materials;

[0079] Water-based glue: PU;

[0080]Functional additives: Shanghai Huzheng colorless and transparent nano-silver solution, the grade is AGS-WM1000A / B / C;

[0081] Water-based foam stabilizer: Shenzhen Guangsiyuan polyurethane soft foam stabilizer GSYPU G-595 silicone oil;

[0082] Silicone resin polyether emulsion water-based foam stabilizer: Shandong Yousu Chemical modified silicone resin polyether microemulsion FM-550;

[0083] water;

[0084] Basement membrane: opp membrane;

[0085] Hydrophobic finishing agent: Shanghai Huzheng colorless transparent hydrophobic coating additive SSJ-FG3 / SSJ-F181;

[0086] (2) Adjusting glue;

[0087] In parts by weight, 100 parts of water-based glue, 2 parts of functional additives and water were mixed in a glue bucket to obtain a mixture with a viscosity of 500 CPS, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com