High-water-pressure washing-resistant polyurethane primer resin for textile coating and preparation method of high-water-pressure washing-resistant polyurethane primer resin

A textile coating, water-resistant technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low water pressure, poor water resistance, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

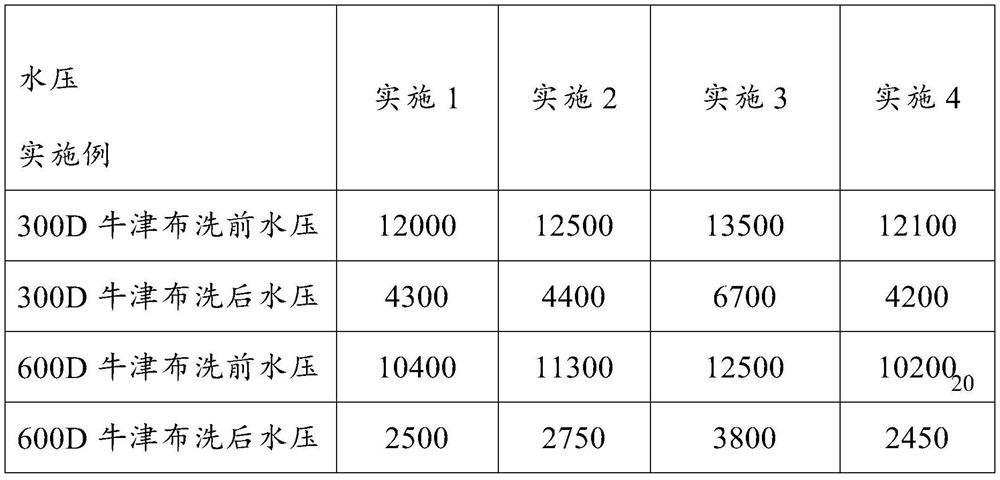

Examples

Embodiment 1

[0033] Polyurethane primer resin for high water pressure washable textile coating, the polyurethane primer resin for high water pressure washable textile coating consists of the following components by weight percentage:

[0034] JPP-100: 0.01%, adipic acid and neopentyl glycol copolymerized diol: 44%, polycarbonate diol: 5%, 1,4-butanediol: 1.5%, trimethylolpropane: 0.05%, toluene diisocyanate: 2%, 4,4-diphenylmethane diisocyanate: 2%, ethylene glycol: 0.05%, malic acid: 0.05%, dimethylformamide: 20%, toluene: 25.34% .

[0035] The preparation method of the polyurethane primer resin for the textile coating of the above-mentioned high water pressure washable comprises the following steps:

[0036] The first step: 45% dimethylformamide, JPP-100, adipic acid and neopentyl glycol copolymerized diol, polycarbonate diol, 1,4-butanediol, trimethylol Put all the propane into the reactor and stir for 15 minutes and keep it warm at 65°C;

[0037] The second step: add all the toluene...

Embodiment 2

[0043] Polyurethane primer resin for high water pressure washable textile coating, the polyurethane primer resin for high water pressure washable textile coating consists of the following components by weight percentage:

[0044] JPP-100: 0.3%, adipic acid and neopentyl glycol copolymerized diol: 24%, polycarbonate diol: 10%, 1,4-butanediol: 3%, trimethylolpropane: 1%, toluene diisocyanate: 8%, 4,4-diphenylmethane diisocyanate: 8%, ethylene glycol: 0.5%, malic acid: 0.5%, dimethylformamide: 24.7%, toluene: 20% .

[0045]The preparation method of the polyurethane primer resin for the textile coating of the above-mentioned high water pressure washable comprises the following steps:

[0046] Step 1: Copolymerize 55% dimethylformamide, JPP-100, adipic acid and neopentyl glycol, polycarbonate diol, 1,4-butanediol, trimethylol Put all the propane into the reactor and stir for 25 minutes and keep it warm at 75°C;

[0047] The second step: add all the toluene diisocyanate and keep ...

Embodiment 3

[0053] Polyurethane primer resin for high water pressure washable textile coating, the polyurethane primer resin for high water pressure washable textile coating consists of the following components by weight percentage:

[0054] JPP-100: 0.01%, adipic acid and neopentyl glycol copolymerized diol: 30.19%, polycarbonate diol: 7.5%, 1,4-butanediol: 2.4%, trimethylolpropane: 0.1%, toluene diisocyanate: 4.9%, 4,4-diphenylmethane diisocyanate: 4.7%, ethylene glycol: 0.1%, malic acid: 0.1%, dimethylformamide: 25%, toluene: 25% .

[0055] The preparation method of the polyurethane primer resin for the textile coating of the above-mentioned high water pressure washable comprises the following steps:

[0056] The first step: 50% dimethylformamide, JPP-100, adipic acid and neopentyl glycol copolymerized diol, polycarbonate diol, 1,4-butanediol, trimethylol Put all the propane into the reactor and stir for 20 minutes and keep it warm at 70°C;

[0057] The second step: add all the tolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com