Waterproof wax-leakage environment-friendly wood floor and production method thereof

A production method and wood flooring technology, applied in wood processing equipment, construction, manufacturing tools, etc., can solve problems such as adverse effects on human health, affecting the normal use of floors, and coarse paraffin molecular structure, so as to achieve superior water repellency and improve wood quality. Utilization rate and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

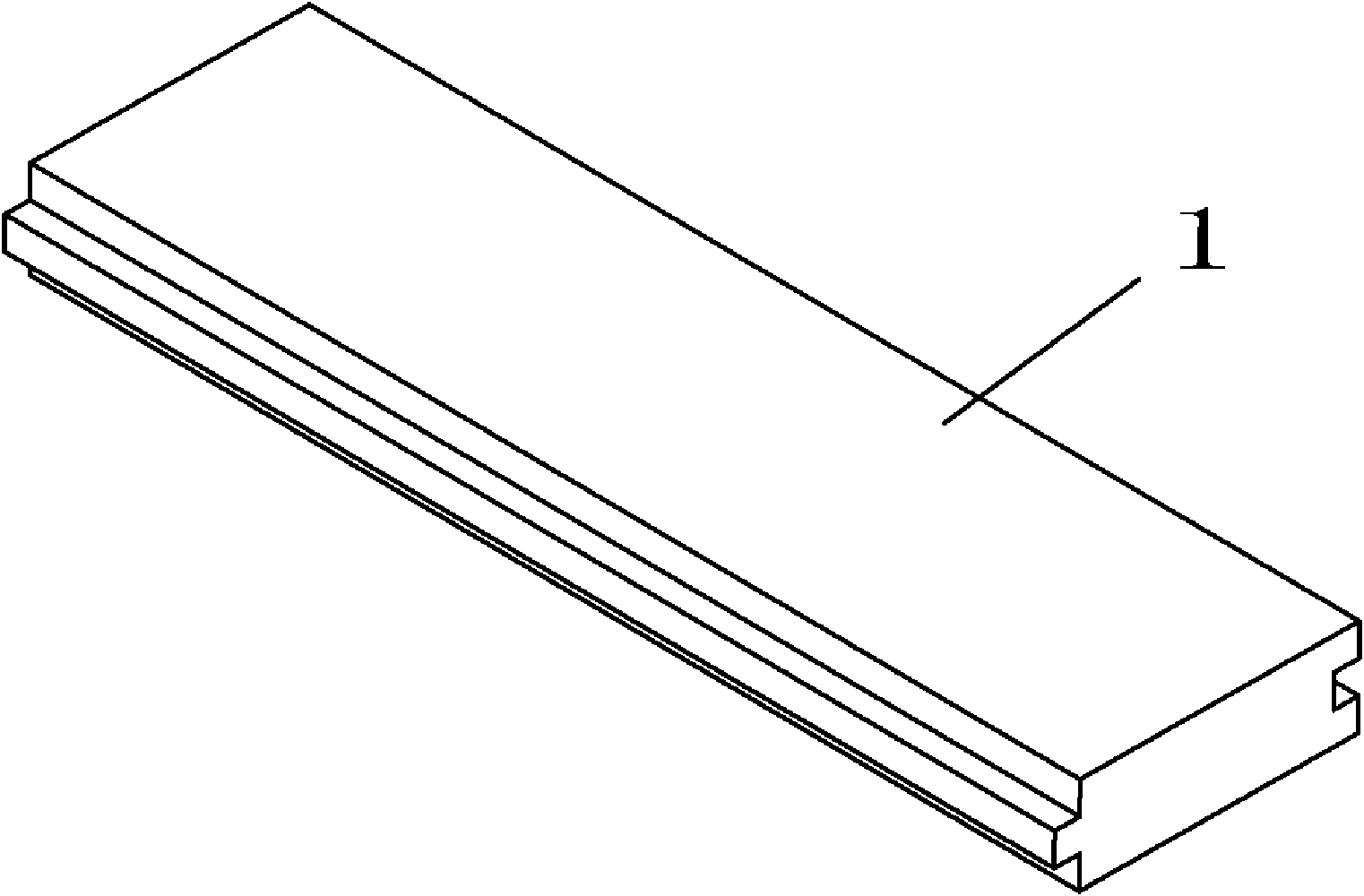

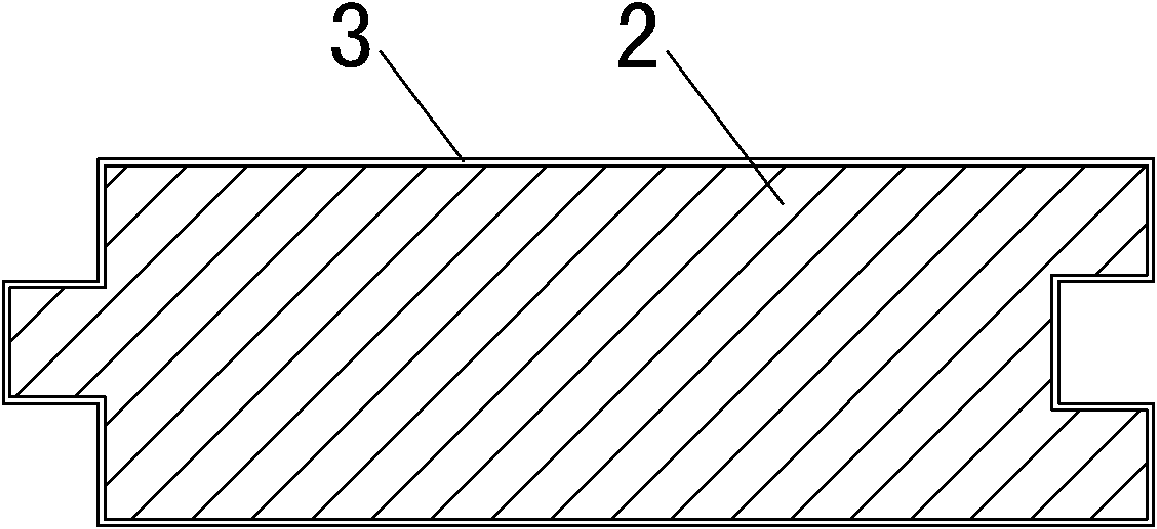

[0045] Example. Such as figure 1 , 2 As shown, the wooden floor 1 is divided into two layers from the inside to the outside. The first layer is the substrate 2, and the second layer is the waxy waterproof layer 3. The waxy waterproof layer 3 is an EM nano-emulsified wax layer. The inside of the substrate 2 and the fiber ducts of the wood are filled with EM nano-emulsified wax produced by Shanghai Joule Wax Industry Co., Ltd.

[0046] During production, the floor is first cut to the required specifications such as (920*130*20), and then coded into a rectangle of (185*1200*1600), each layer in the middle is separated by 2mm steel wire mesh, and 8 #The fixed frame made of channel steel is fastened with 8 20mm screws to fix the plate; then the plate is put into a heat treatment furnace for drying treatment, the drying time is 12 hours, and the screws need to be tightened during the process . Put EM nano-emulsified wax in the heat treatment furnace in advance, heat the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com