Heat treatment method capable of improving performance stability of medium/high-tonnage smelted CuNiSiCr alloy

A heat treatment method and technology for stability, applied in the field of heat treatment that can improve the performance stability of CuNiSiCr alloys smelted in medium and high tonnage, can solve the problems of deterioration of mechanical properties such as strength, high output capacity requirements, and small post-processing space, so as to maintain high strength High conductivity, strong operability, reducing the effect of precipitation and coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 (CuNiSiCr alloy)

[0038] 1) For a 25mm thick smelted CuNiSiCr solid solution alloy plate, solid solution at 950°C for 2h, water quenching, the average grain size is 100μm;

[0039] 2) Cold rolling is used to cold deform the CuNiSiCr alloy plate, and the deformation amount is about 50%;

[0040] 3) Recrystallize the cold deformed alloy at 840°C for 1 hour;

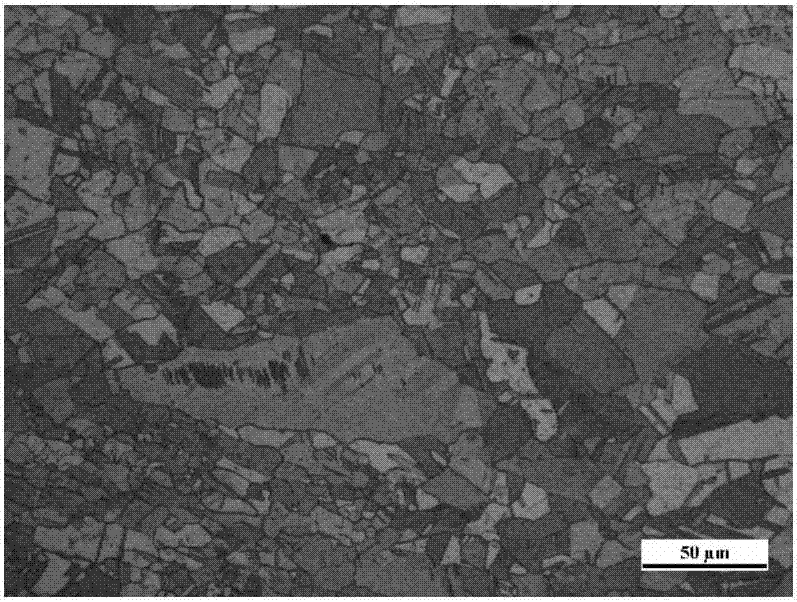

[0041] 4) Observe the recrystallized grains. The average grain size is about 50 μm, which meets the service requirements and does not need repeated recrystallization;

[0042] 5) Aging the recrystallized CuNiSiCr alloy at 450-540°C for 3 hours.

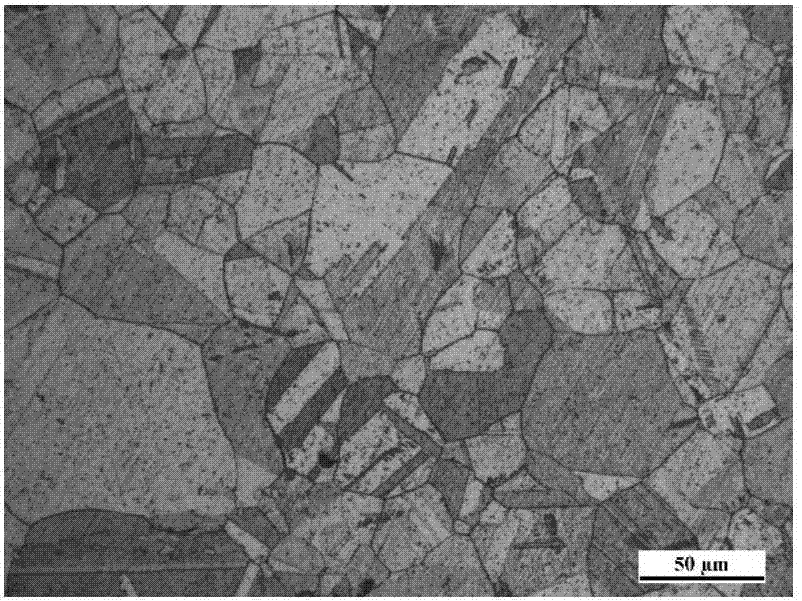

[0043] Such as figure 1 As shown, the average grain size of the ex-factory state is about 75 μm, and it can be seen that the precipitated phase particles are obvious, and the solid solution state is not good;

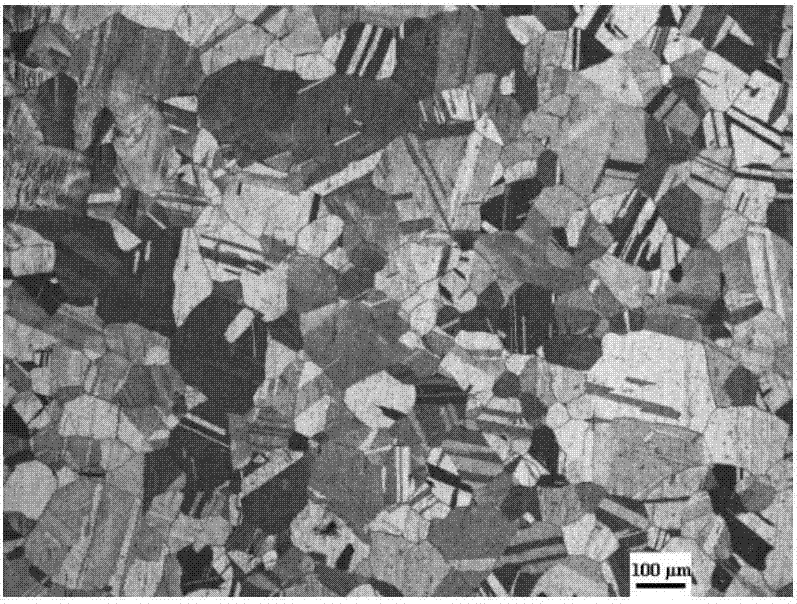

[0044] Such as figure 2 As shown, after solid solution at 950°C for 2 hours, the precipitated phase particles have been greatly reduced, indicatin...

Embodiment 2

[0046] Embodiment 2 (CuNiSiCr alloy)

[0047] 1) For a 25mm thick smelted CuNiSiCr solid solution alloy plate, solid solution at 950°C for 2h, water quenching, the average grain size is 100μm;

[0048] 2) Cold rolling is used to cold deform the CuNiSiCr alloy plate, and the deformation amount is about 50%;

[0049] 3) Recrystallize the cold deformed alloy at 870°C for 1 hour;

[0050] 4) Observe the recrystallized grains. The average grain size is about 50 μm, which meets the service requirements and does not need repeated recrystallization;

[0051] 5) Aging the recrystallized CuNiSiCr alloy at 450-540°C for 3 hours.

[0052] Such as figure 1 As shown, the average grain size of the ex-factory state is about 75 μm, and it can be seen that the precipitated phase particles are obvious, and the solid solution state is not good;

[0053] Such as figure 2 As shown, after solid solution at 950°C for 2 hours, the precipitated phase particles have been greatly reduced, indicatin...

Embodiment 3

[0055] Embodiment 3 (CuNiSiCr alloy)

[0056] 1) For a 25mm thick smelted CuNiSiCr solid solution alloy plate, solid solution at 950°C for 2h, water quenching, the average grain size is 100μm;

[0057] 2) Cold rolling is used to cold deform the CuNiSiCr alloy plate, and the deformation amount is about 50%;

[0058] 3) Recrystallize the cold deformed alloy at 900°C for 1 hour;

[0059] 4) Observe the recrystallized grains. The average grain size is about 50 μm, which meets the service requirements and does not need repeated recrystallization;

[0060] 5) Aging the recrystallized CuNiSiCr alloy at 450-540°C for 3 hours.

[0061] Such as figure 1 As shown, the average grain size of the ex-factory state is about 75 μm, and it can be seen that the precipitated phase particles are obvious, and the solid solution state is not good;

[0062] Such as figure 2 As shown, after solid solution at 950°C for 2 hours, the precipitated phase particles have been greatly reduced, indicatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com