A kind of environment-friendly shield tail sealing grease and preparation method thereof

A shield tail seal and environment-friendly technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of shield tail seal grease underground environmental pollution, etc., achieve good pumpability, good sealing performance, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

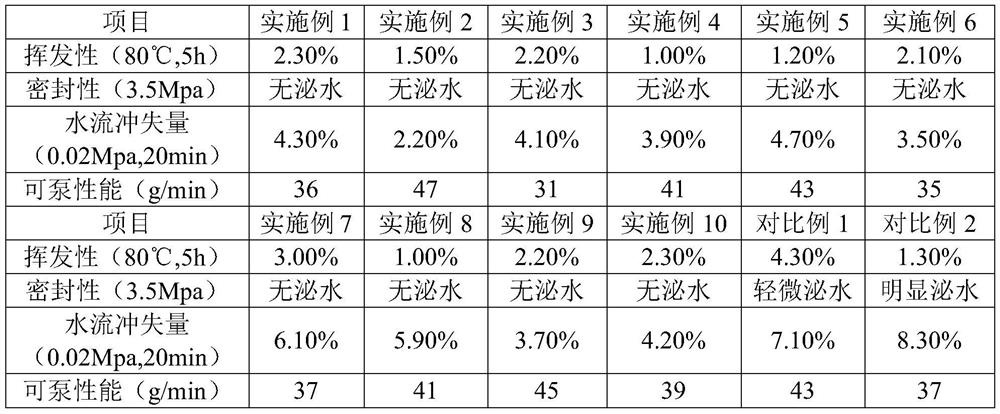

Examples

Embodiment 1

[0020] Weigh 35 parts of base oil composition, 23 parts of light calcium carbonate and 19 parts of bentonite and add them to the mixer for mixing. After stirring for 2 hours, add 8 parts of PMA, 2 parts of HSD and 2 parts of ordinary lithium-based grease, and then mix and stir for 0.5 hours. During the stirring process, the temperature in the mixer was kept at 50°C. Finally, 9 parts of glass fiber and 2 parts of bamboo fiber were added to it and stirred for 1 hour. 1 part isooctyl alcohol modified rapeseed oil mixed with 10 parts soybean oil.

Embodiment 2

[0022] Weigh 25 parts of base oil composition, 20 parts of light calcium carbonate, 20 parts of bentonite, 10 parts of graphite and 5 parts of talc powder and add them to the mixer for mixing. After stirring for 1 hour, add 8 parts of PMA, 3 parts of HSD and 4 parts of ordinary lithium Grease, mix and stir for 1 hour. During the stirring process, the temperature in the mixer is kept at 45°C. Finally, 3 parts of glass fiber, 1 part of bamboo fiber and 1 part of cotton fiber are added to it and stirred for 0.5 hours. After the stirring is completed, it is cooled at room temperature to obtain Environmentally friendly shield tail seal grease; the base oil composition is a mixture of 20 parts of isooctyl alcohol modified rapeseed oil and 5 parts of biodiesel.

Embodiment 3

[0024] Weigh 35 parts of base oil composition, 15 parts of light calcium carbonate, 5 parts of silicon dioxide, 5 parts of calcium hydroxide and 5 parts of talc powder and add them to the mixer for mixing. After stirring for 1 hour, add 5 parts of OCP, 1 part of HSD, 3 parts of 1 part of ordinary lithium-based grease and 2 parts of extreme-pressure lithium-based grease, and then mixed and stirred for 0.5 hours. Stir for 1 hour, and cool at room temperature after stirring to obtain an environmentally friendly shield tail seal grease; the base oil composition is prepared by mixing 17.5 parts of isooctyl alcohol-modified rapeseed oil and 17.5 parts of soybean oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com