Method for producing coated kraft card board by home-made paper machine

A technology of coated kraftboard and paper machine, applied in the direction of paper coating, paper machine, paper machine wet end, etc., can solve the unseen technical report of coated kraftboard production, the production of unseen coated kraftboard Reports, unseen patents and related information and other issues, to achieve significant environmental benefits, high strength and printing adaptability, to meet the needs of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

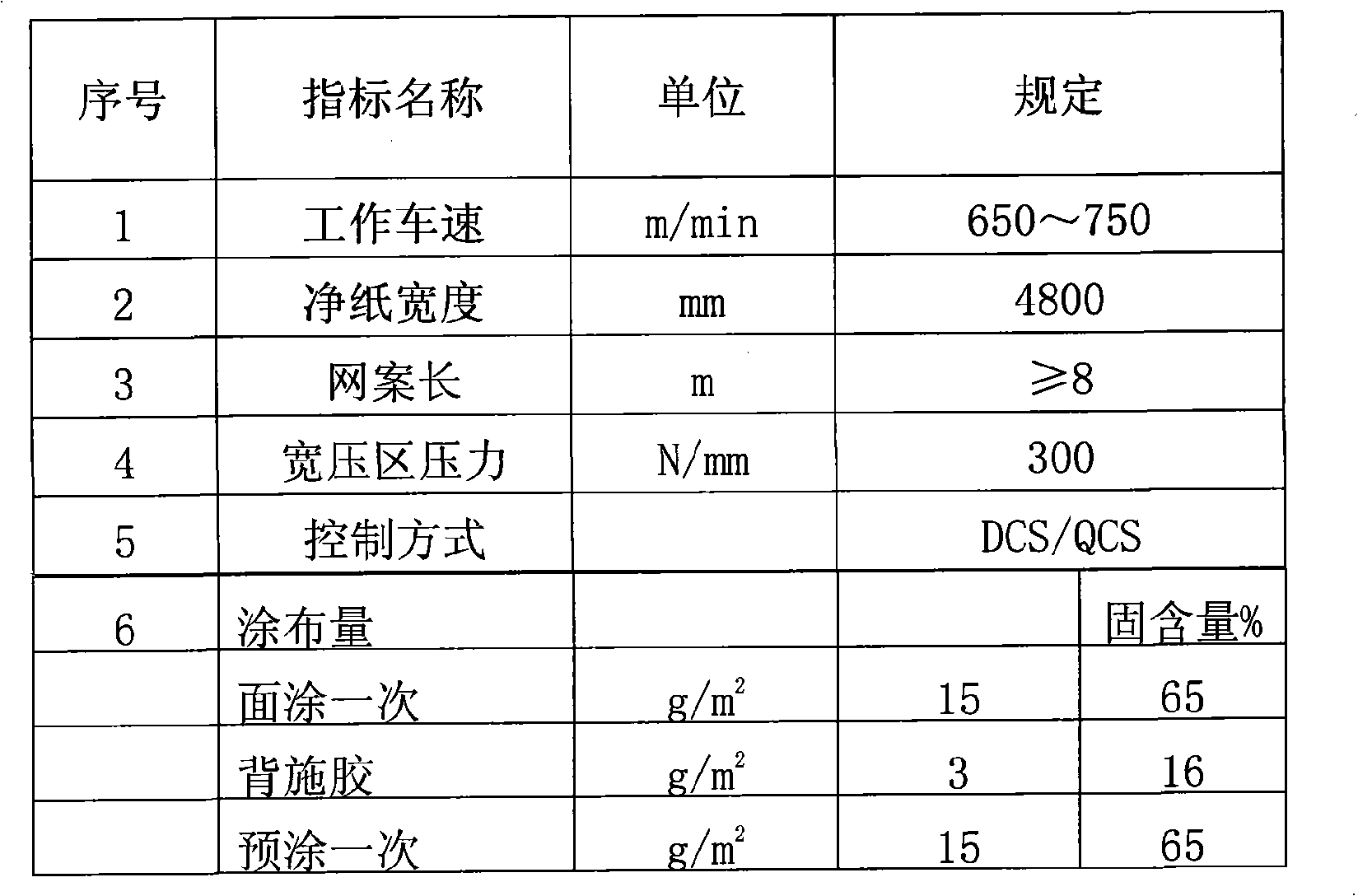

[0028] 1. Production technology plan

[0029] 1. Product plan

[0030] Product name: coated kraft cardboard

[0031] Quantitative range: 150~350g / m 2 .

[0032] Product specifications: flat paper 787X1092, 889X1194 and other specifications required by users.

[0033] Web 787, 889, 1092, 1194 and other user-required specifications.

[0034] 2. Selection of fiber raw materials

[0035] Commercial wood pulp board, mixed waste paper (including AOCC) and waste newsprint are used as main raw materials, and they are treated reasonably to meet product quality requirements, rationally utilize resources, and improve economic benefits.

[0036] 3. Pulping process

[0037] It is mainly composed of bleached commercial softwood pulp processing production line, bleached commercial hardwood pulp processing production line, deinking waste newsprint processing production line, mixed waste paper processing production line, waste newsprint processing production line, auxiliary material prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com