Exposure device and rectification device of baseal plate

An exposure device and substrate technology, which is applied in the direction of photolithography exposure device, overflow exposure, microlithography exposure equipment, etc., can solve the problems of incomplete adsorption, suction leakage, deformed substrate, etc., and achieve high-efficiency exposure and realization The effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

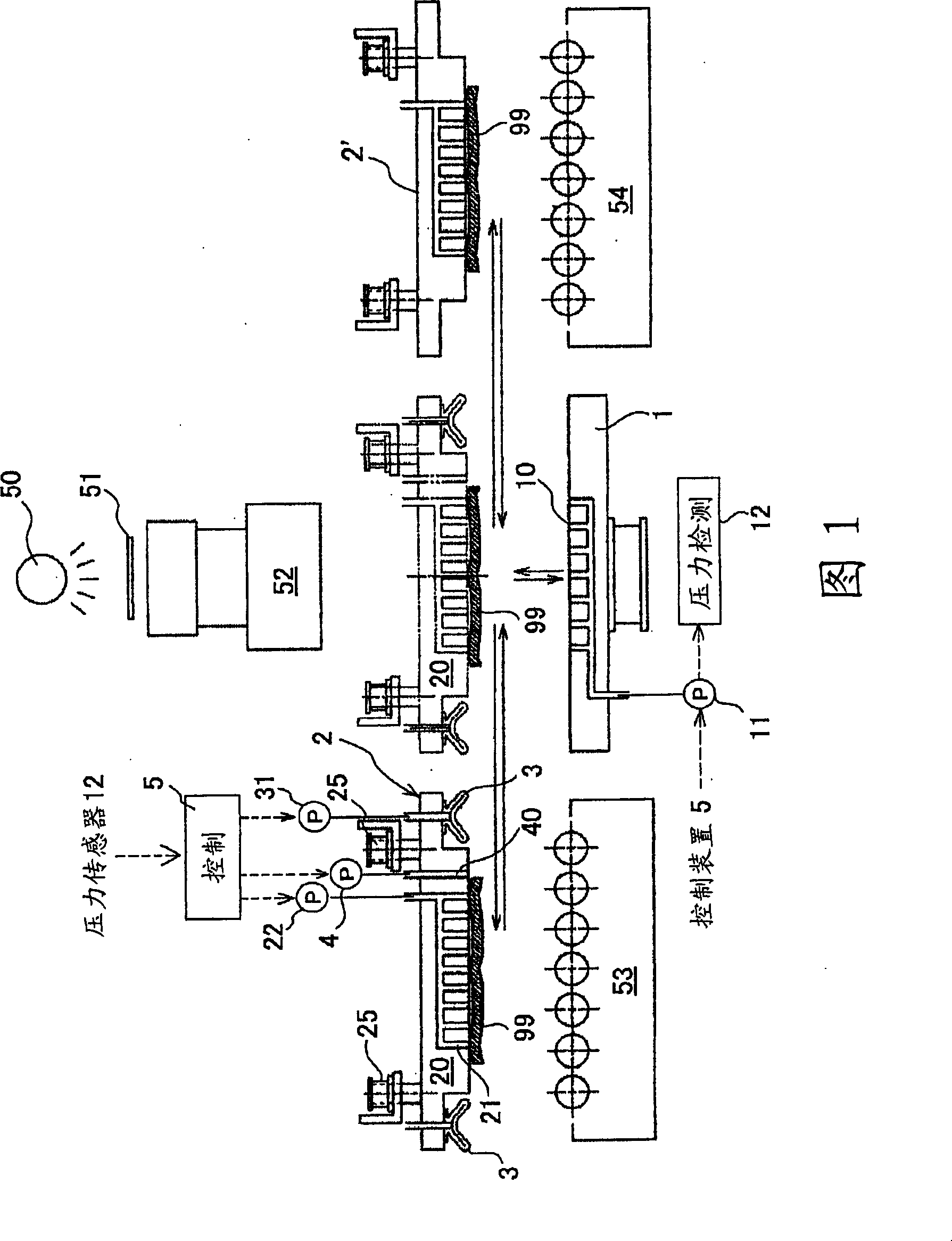

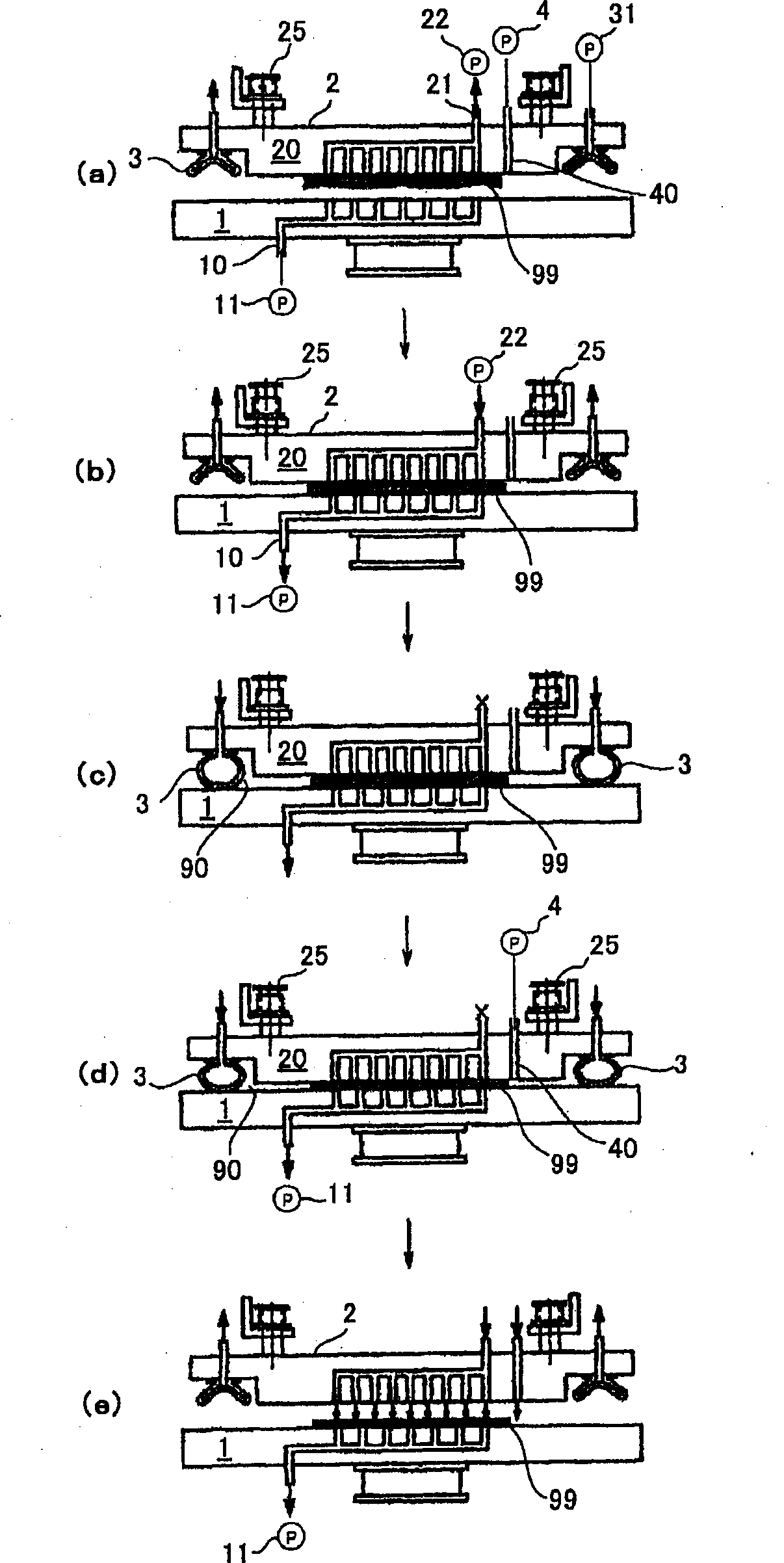

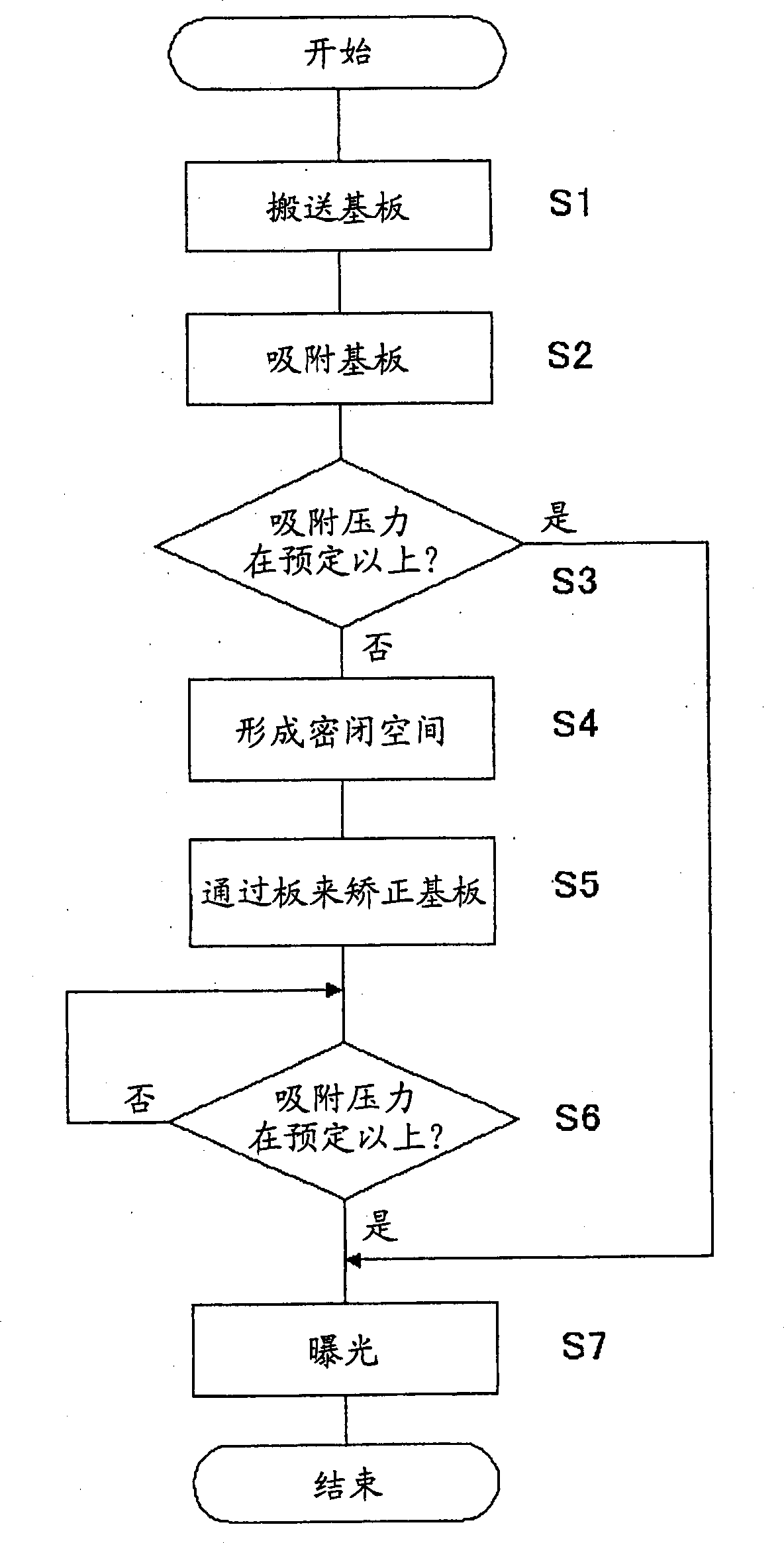

[0016] Embodiments of the exposure apparatus for printed wiring boards of the present invention will be described below with reference to the drawings.

[0017] In FIG. 1 , an exposure stage 1 places a substrate 99 for printed wiring as an exposure target to be exposed, and exposes the substrate 99 through a light source 50 , a mask 51 , and a projection lens 52 . The exposure stage 1 is movable in the XYZ directions and rotatable in the θ direction by a driving device (not shown).

[0018] The exposure stage 1 is provided with a suction hole 10 , and the substrate 99 is suctioned and fixed by a suction pump 11 . A pressure sensor 12 is provided on the suction pump 11 to detect the suction pressure and detect whether the suction is performed normally.

[0019] On the entry side of the exposure stage 1 is provided a transfer device 2 configured to place the substrate 99 transferred from the previous process by the carry-in conveyor 53 on the exposure stage 1 .

[0020] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com