Container bag

a technology for containers and bags, applied in the field of containers, can solve the problems of large damage risk of said reinforcement wall, which is made as an accessory, and large space between the bags remaining unused, and achieves the effect of relatively small risk of load contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

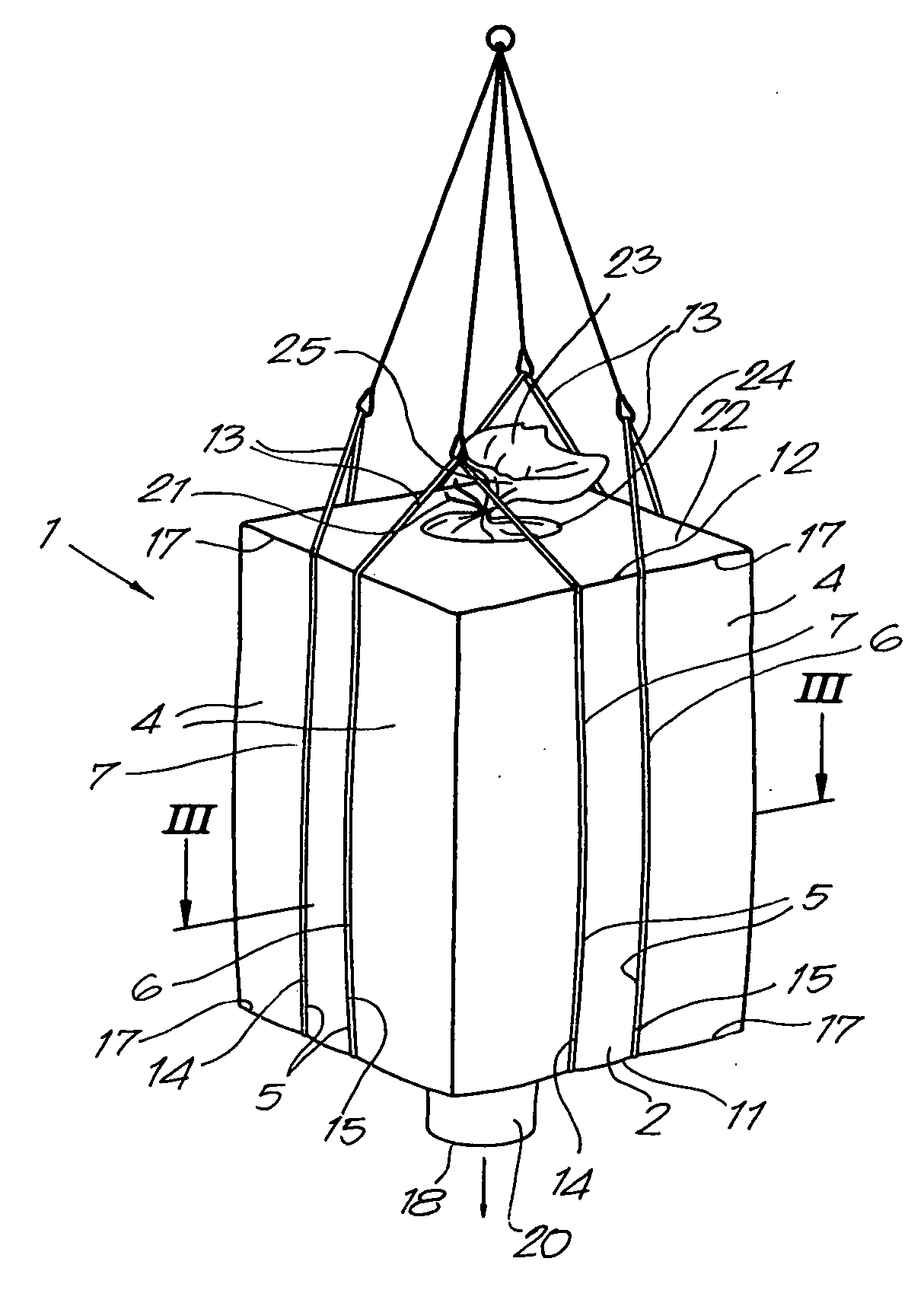

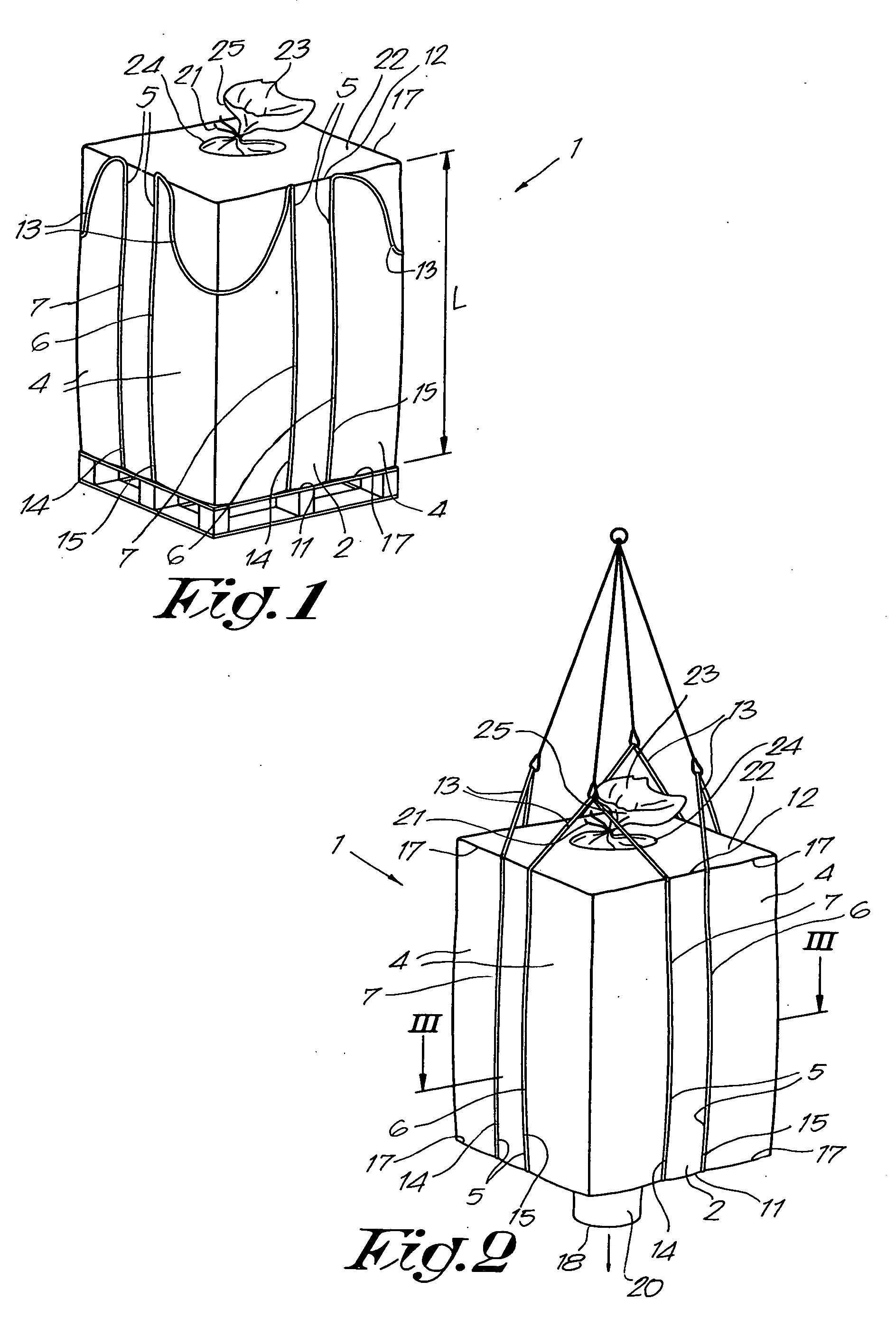

[0037] FIGS. 1 to 3 represent a container bag 1 according to the invention which mainly consists, when filled, of a cylindrical wall part 2 forming a filling space 3 and onto which are provided, on the outside, different accessories 4.

[0038] The wall part 2 as well as the accessories 4 are usually made of a fabric, whereby the accessories 4 are in this case rectangular or practically rectangular bands which are fixed to the wall part 2 with their longitudinal sides 5 in the longitudinal direction X-X′ of the cylindrical wall part 2, for example by means of stitching, stapling, gluing or the like.

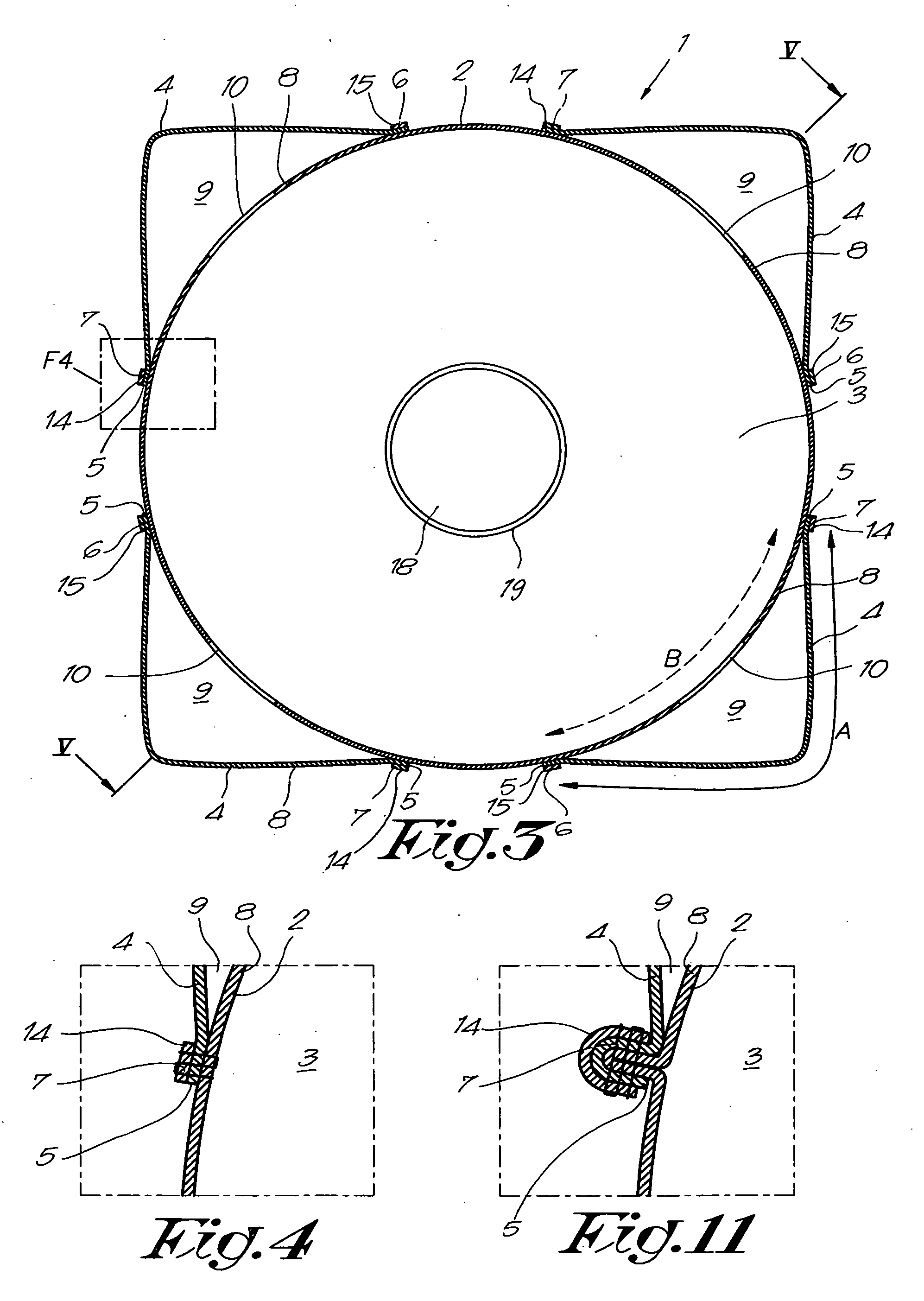

[0039] As is represented more in detail in FIG. 4, the accessories 4 are in this case fixed to the wall part 2 by means of stitching, whereby we can distinguish two fastening seams 6-7 per accessory 4.

[0040] According to the invention, the width A of the accessories is larger than the peripheral distance B between both fastening seams 6-7, measured along the edge of a part 8 of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com